Integrating Polypropylene Fibers and Cement in Clays for Sustainable Clay Bricks

Abstract

1. Introduction

2. Materials and Methods

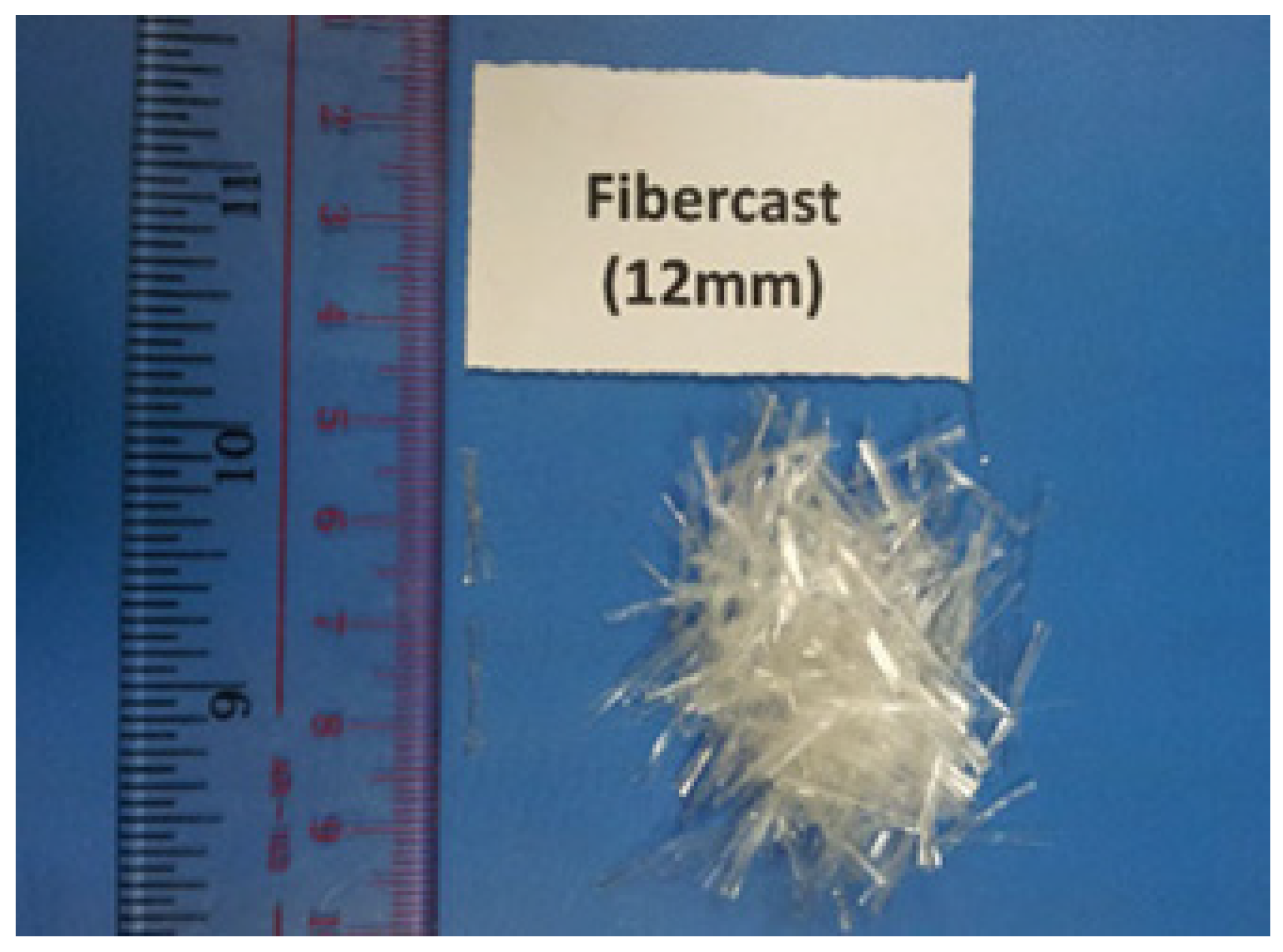

2.1. Materials

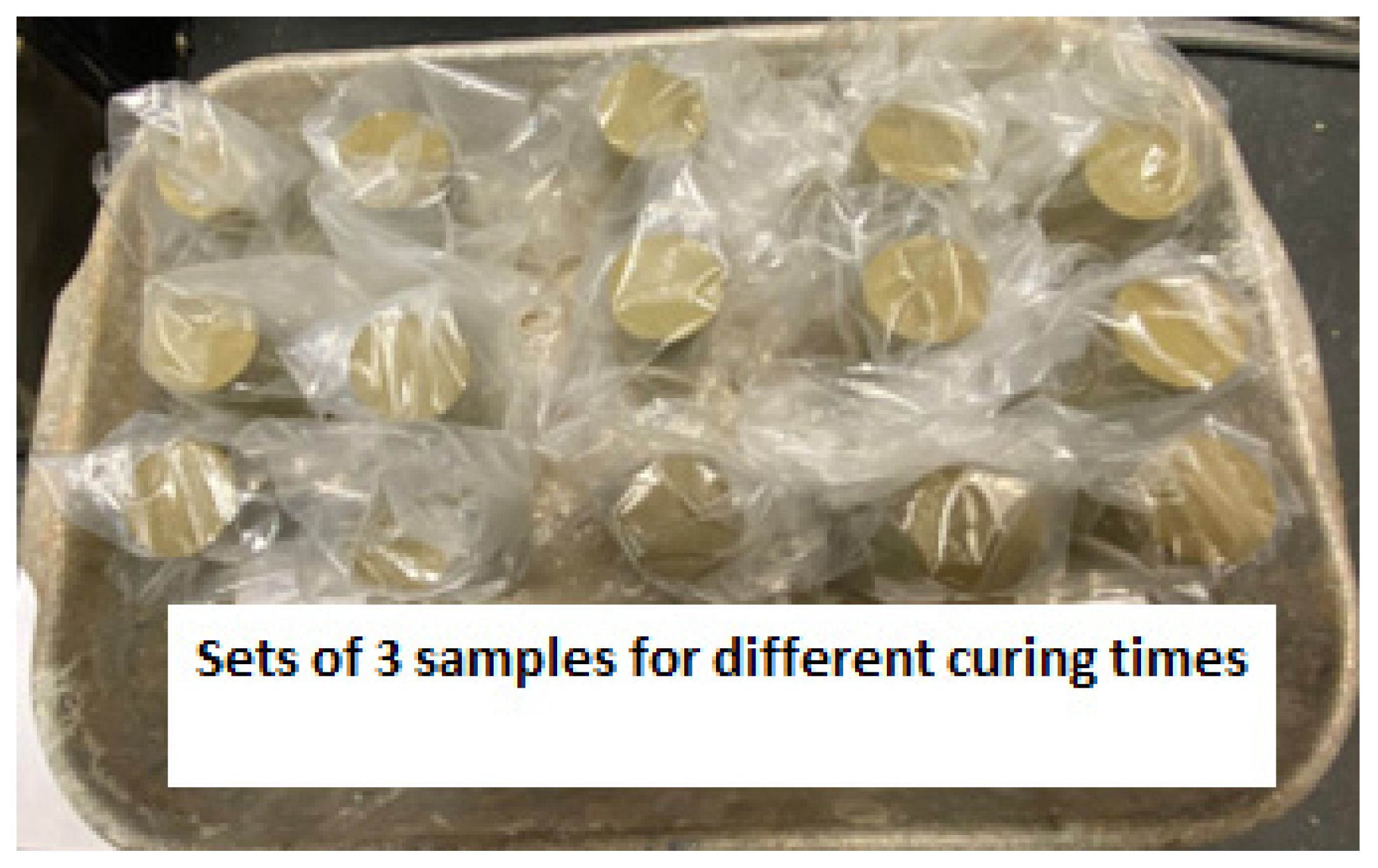

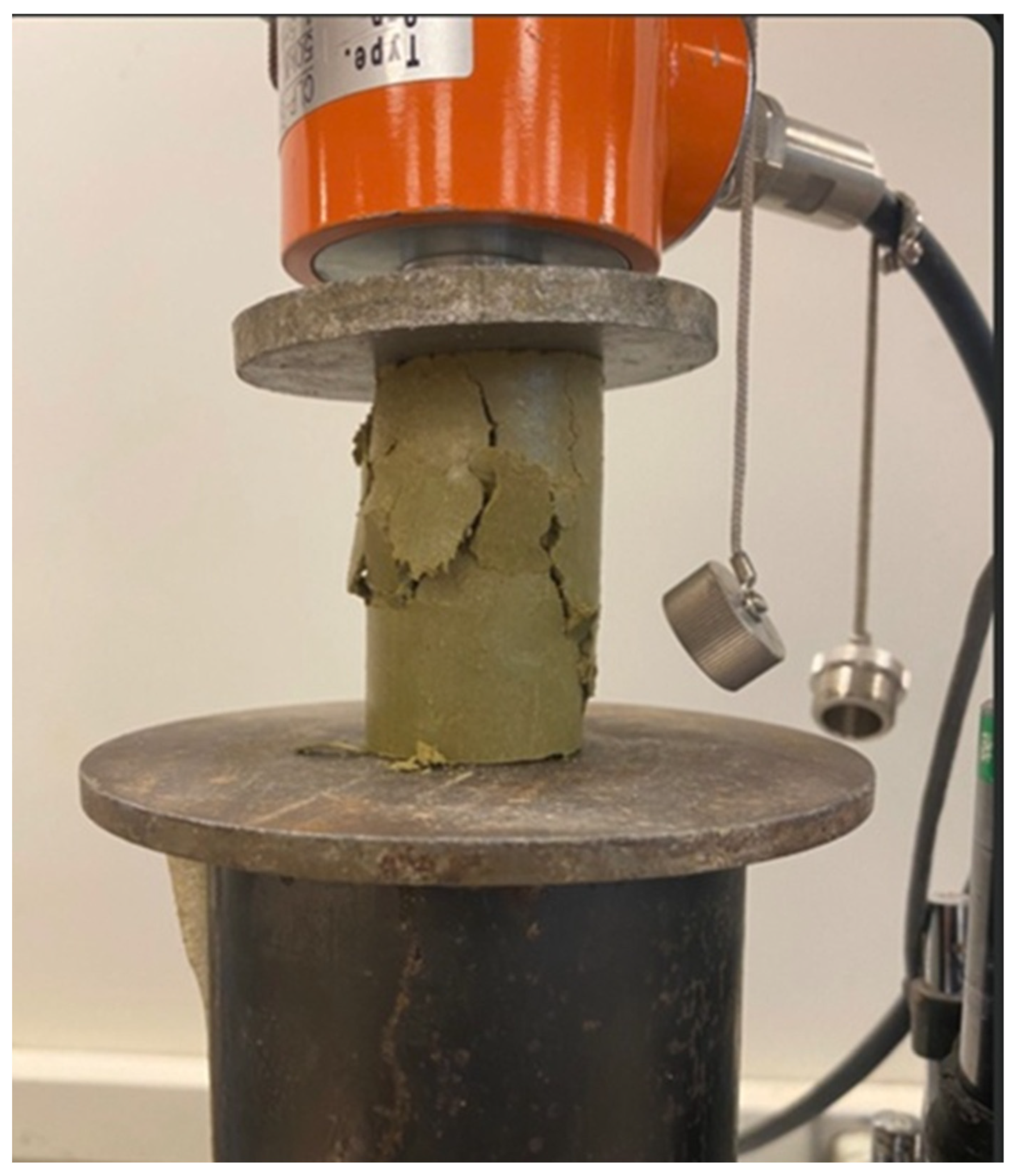

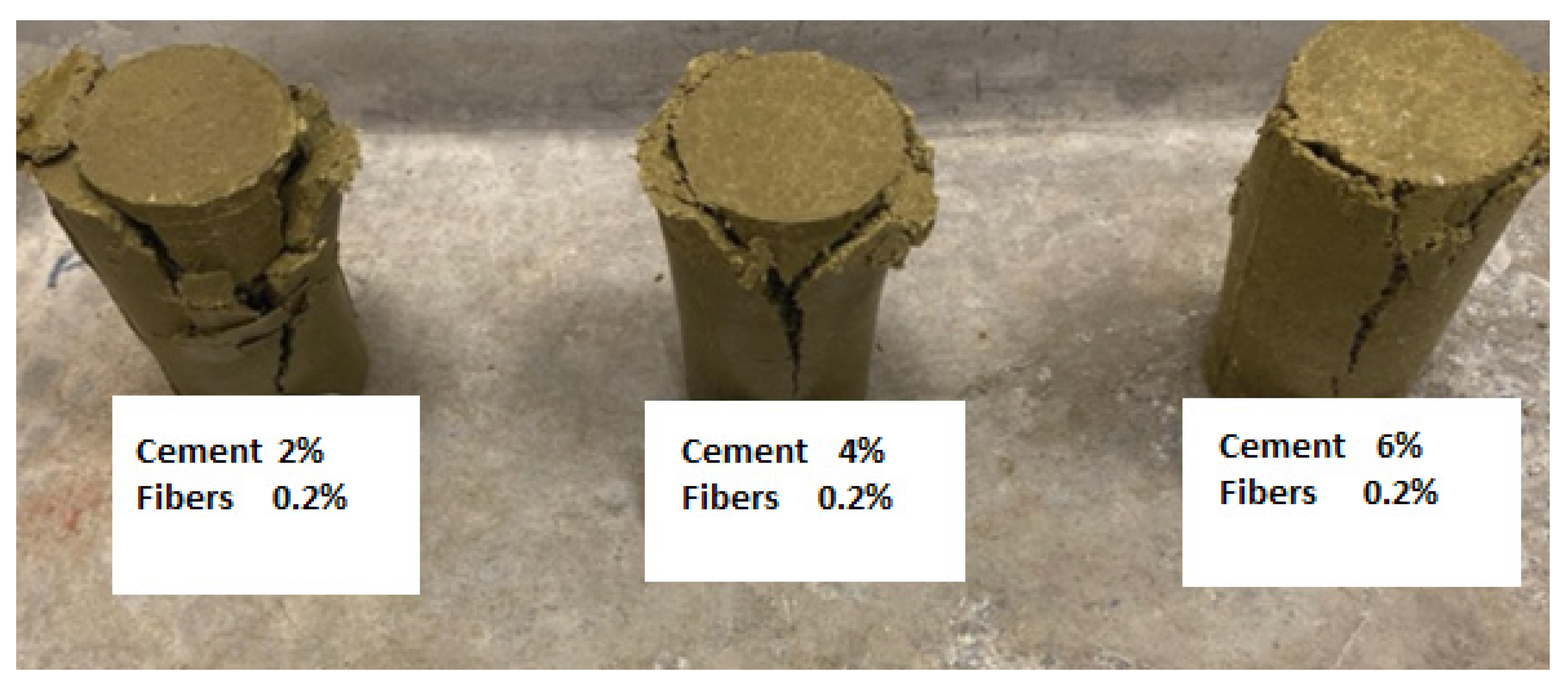

2.2. Testing Procedure

2.3. The Tensile Strength of Fiber-Reinforced Clay

2.4. Shear Tests

2.5. Shrinkage Tests of Polypropylene Clay–Cement Mixtures

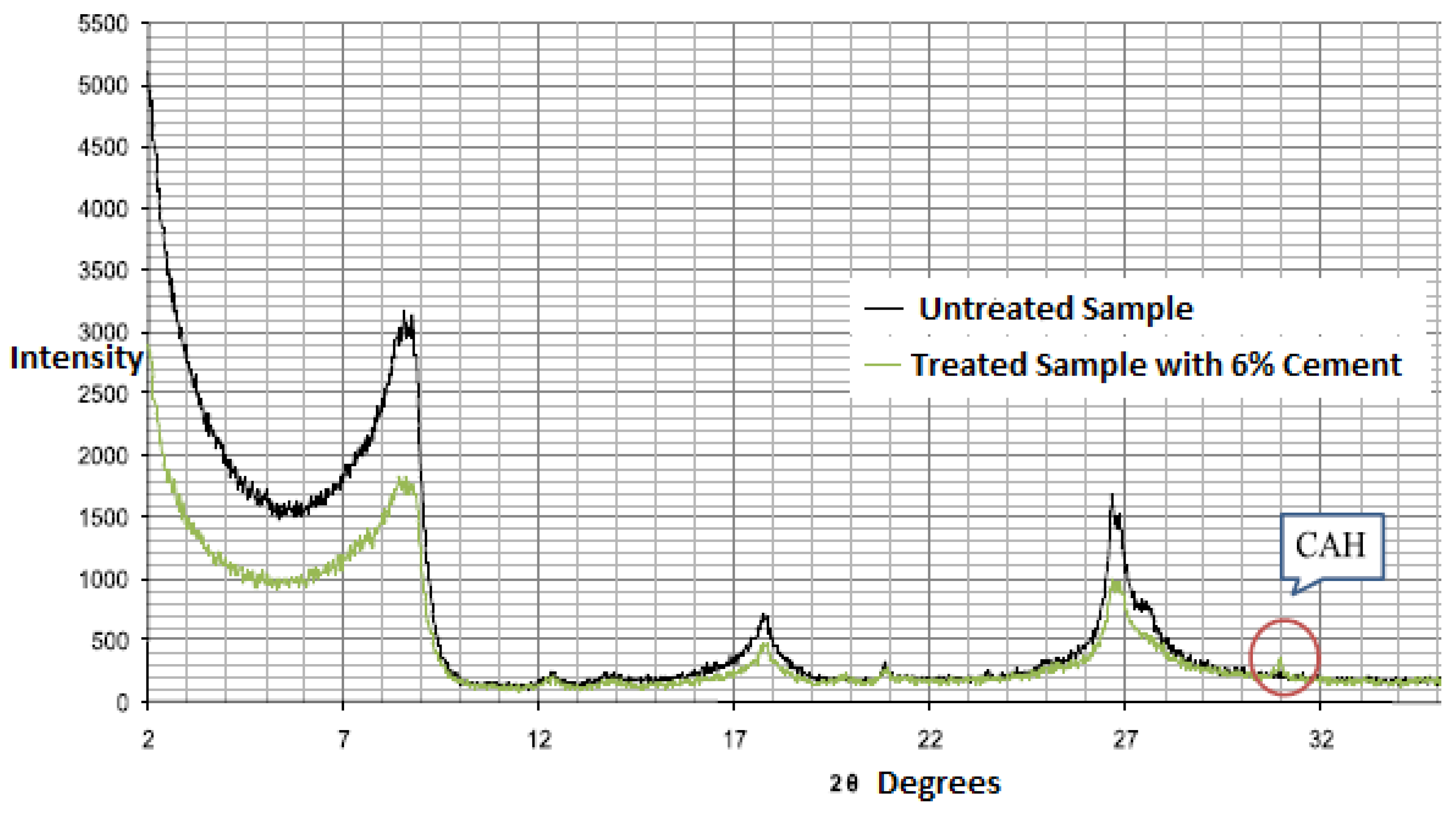

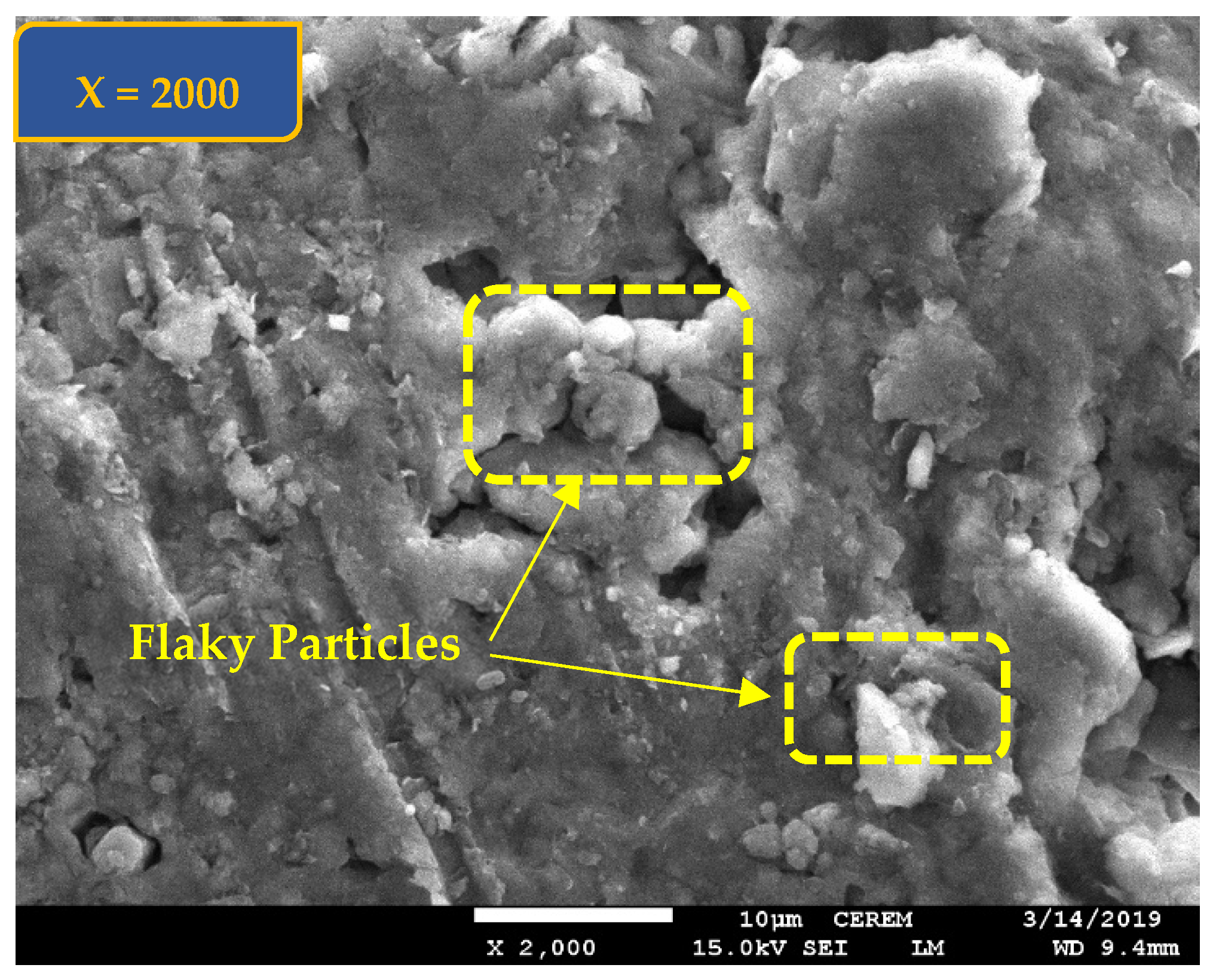

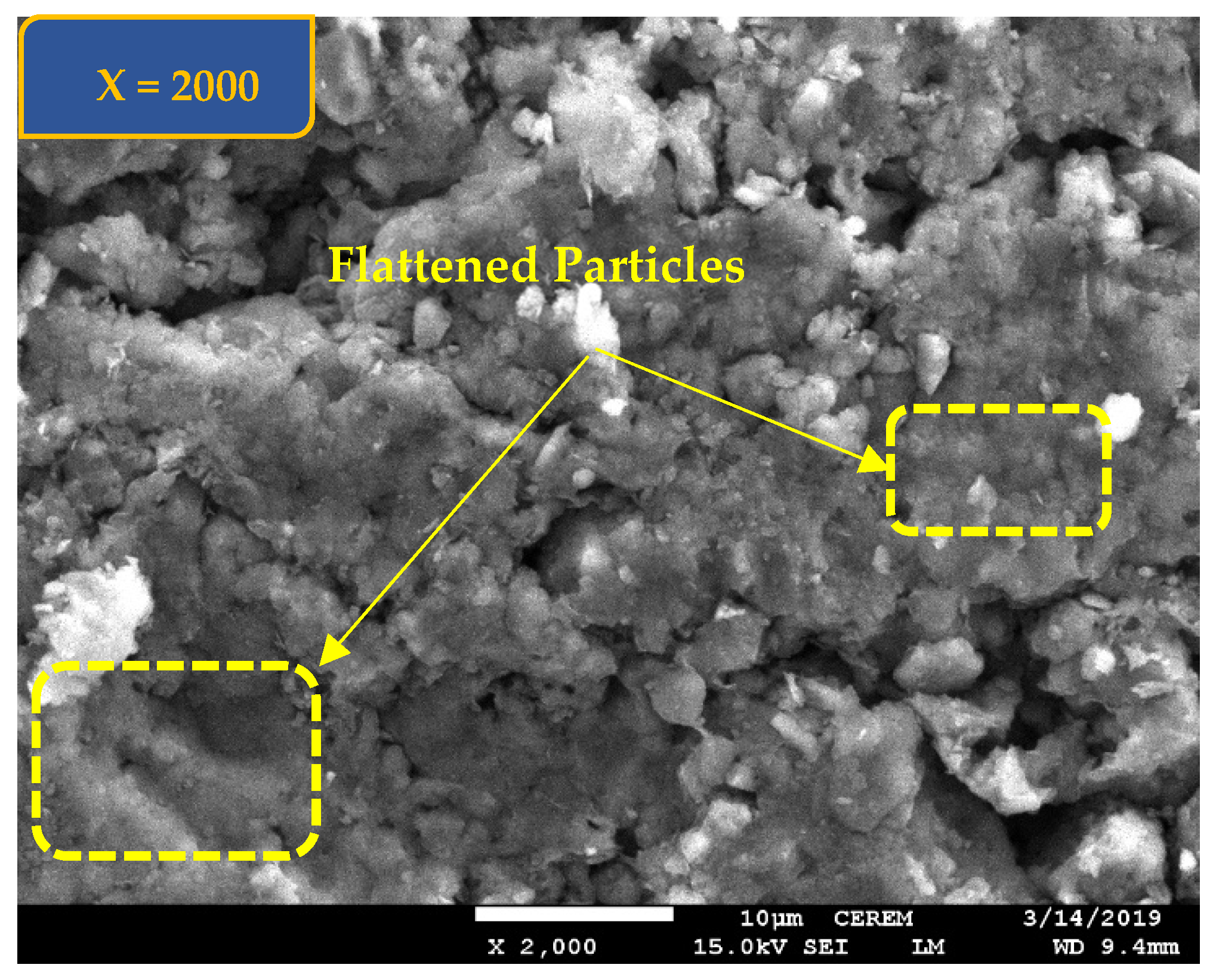

2.6. XRD and SEM Characterization

3. Results and Discussion

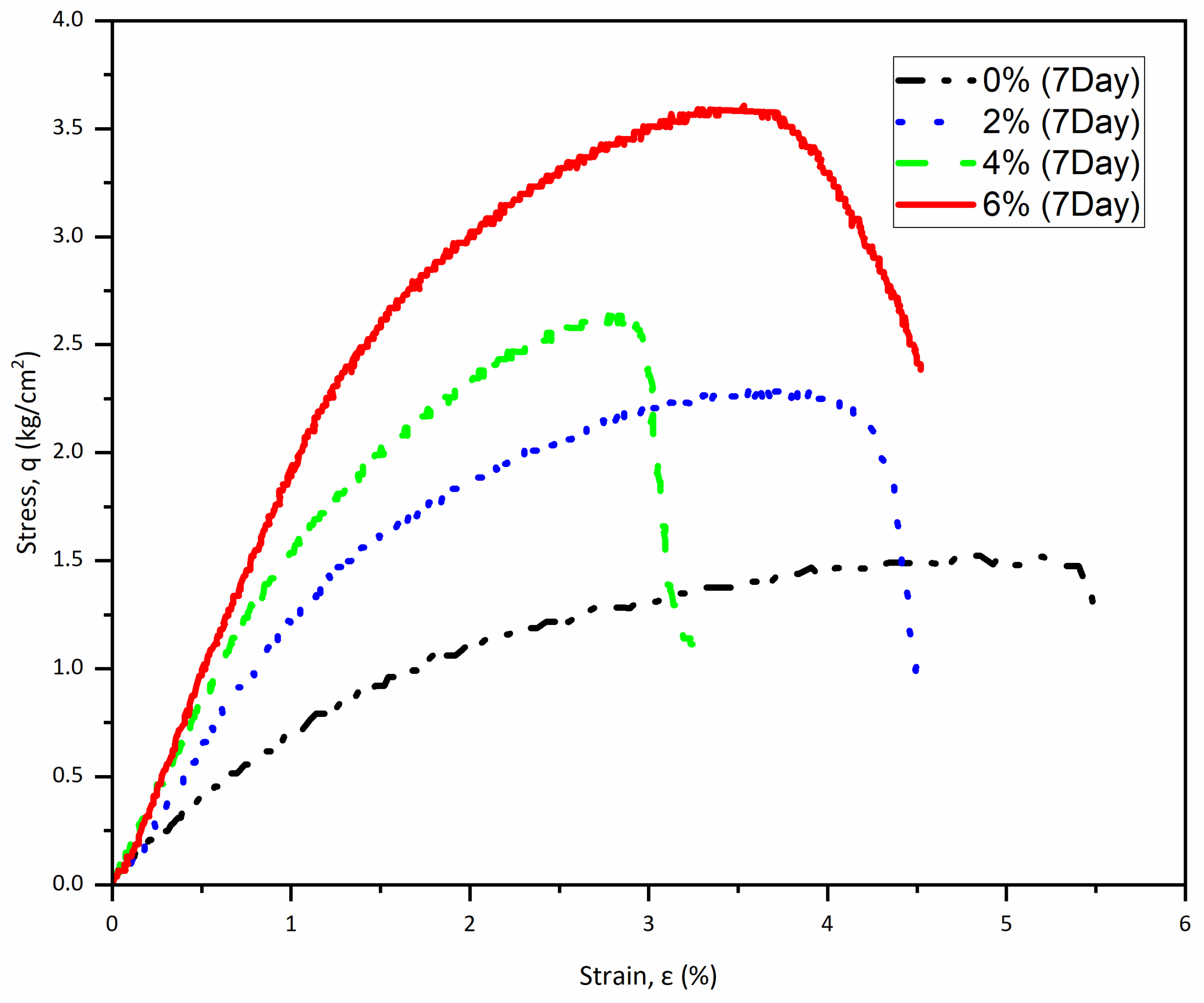

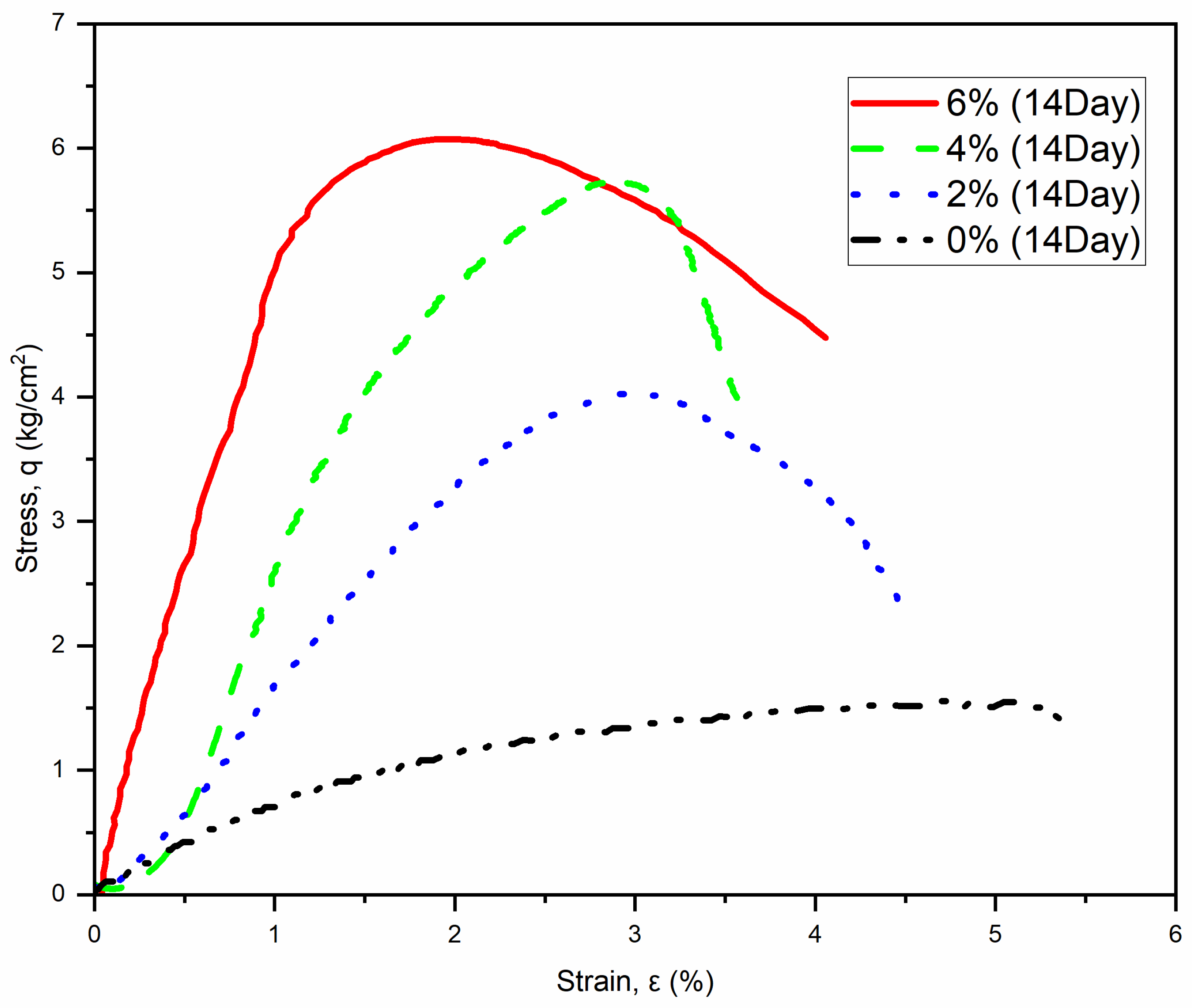

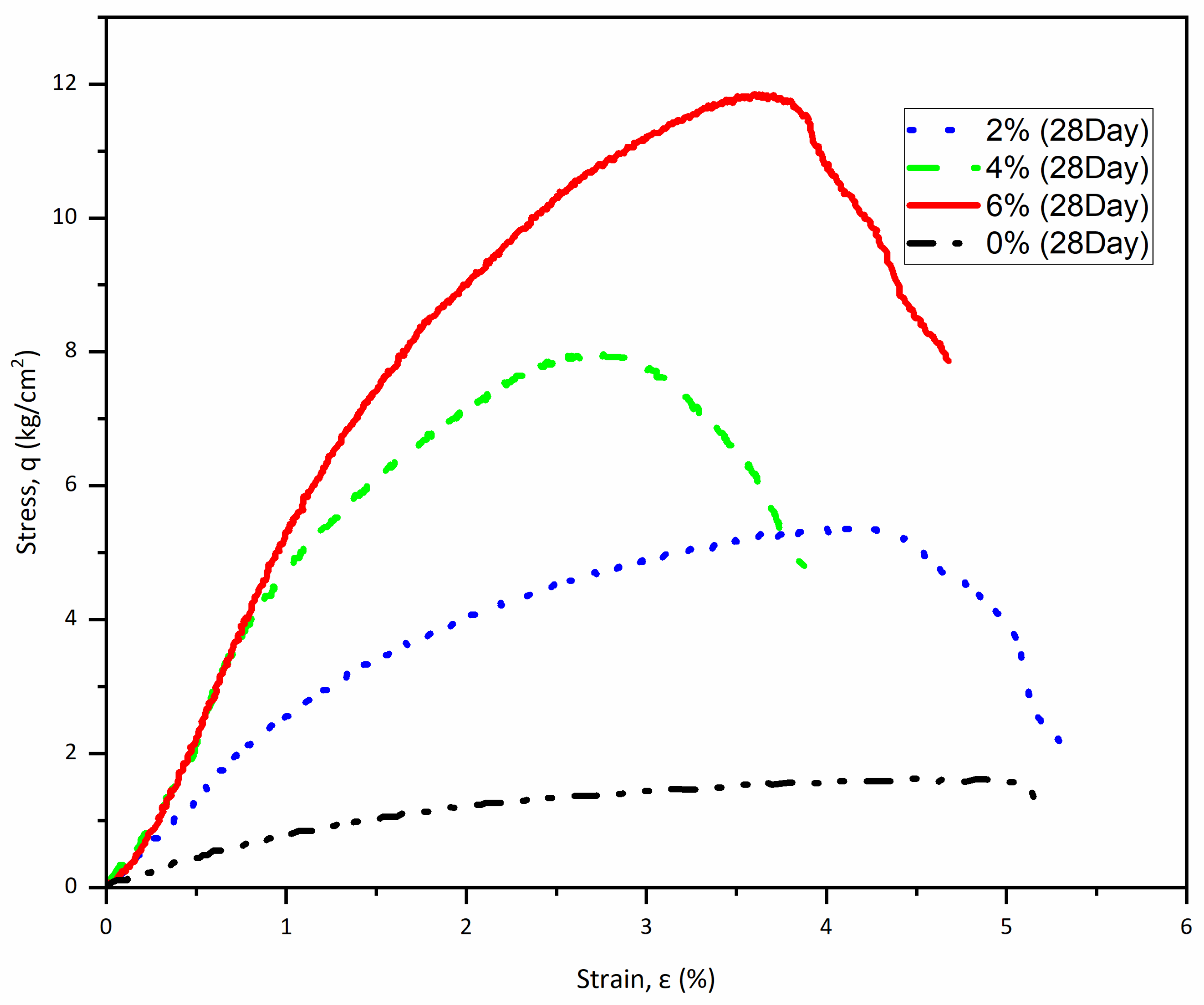

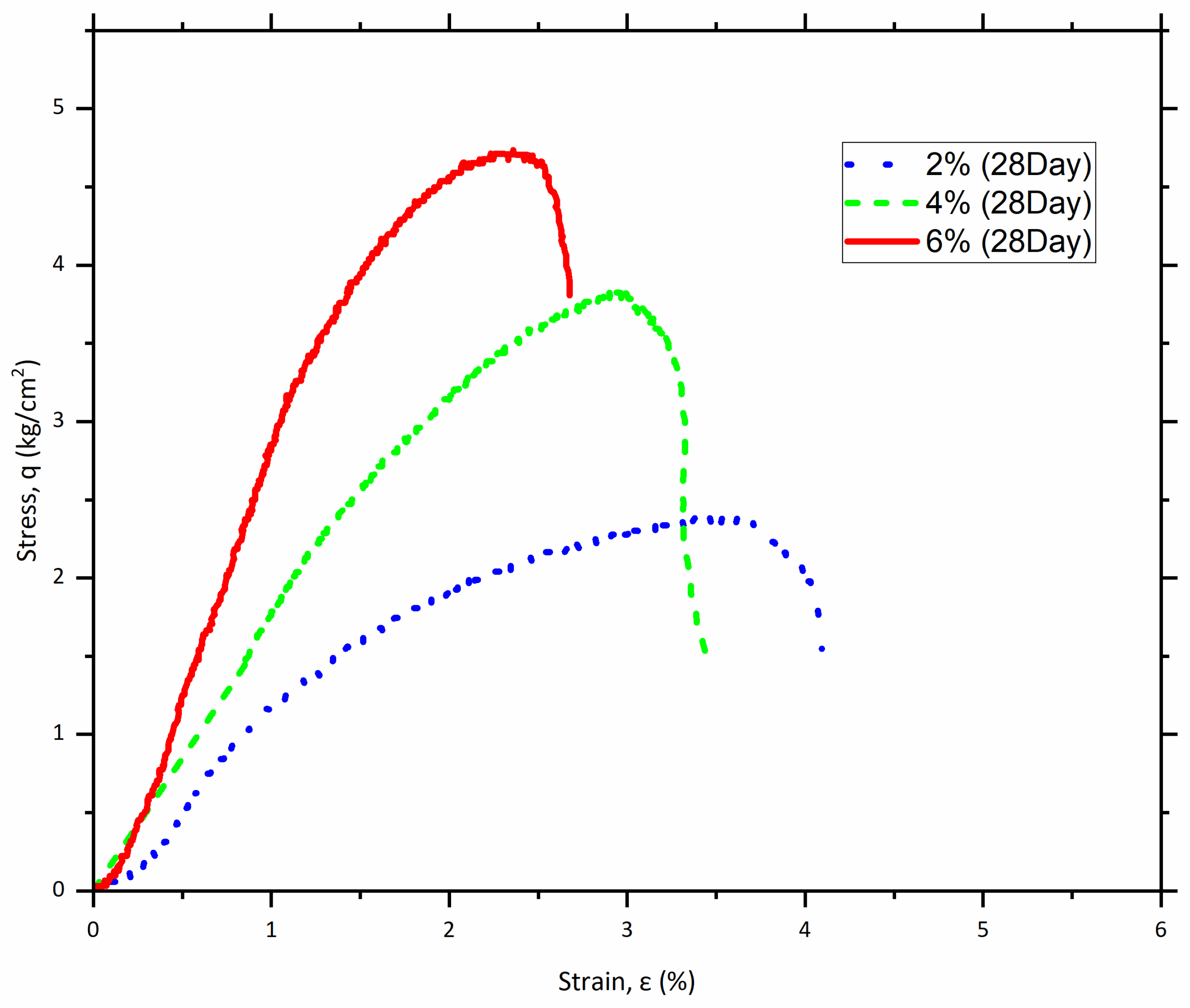

3.1. The Compressive Strength

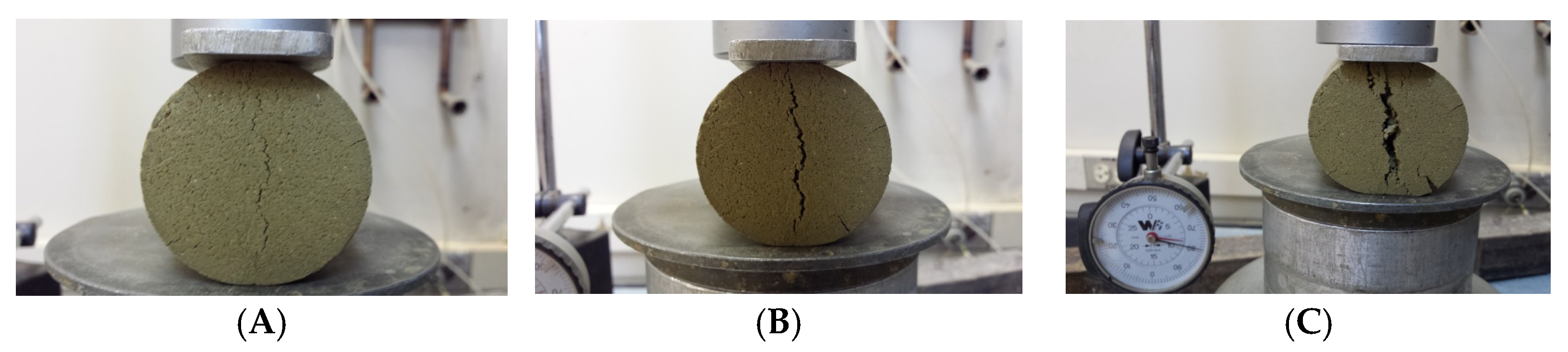

3.2. The Results of Tensile Tests

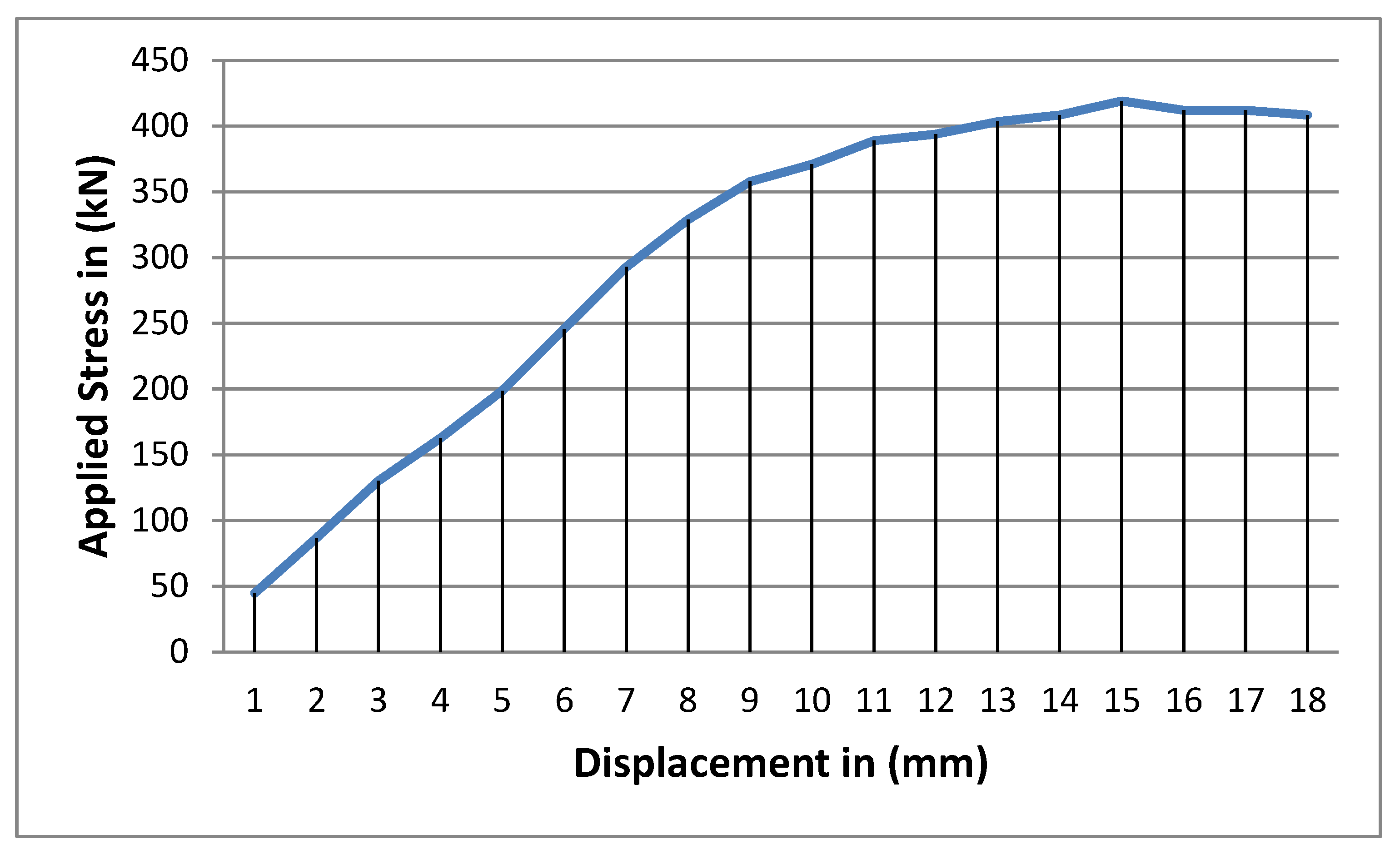

3.3. Effect of Polypropylene Fibers in Shear Strength of Clays

3.4. Effect of Polypropylene Fibers and Cements in Shrinkage of Clays

4. Further Discussion

4.1. Long-Term Evaluation of Polymer–Cement-Enhanced Clay Bricks

4.2. Results Outcome and Leads for Future Works

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- López-Arce, P.; Garcia-Guinea, J.; Gracia, M.; Obis, J. Bricks in historical buildings of Toledo City: Characterisation and restoration. Mater. Charact. 2003, 50, 59–68. [Google Scholar] [CrossRef]

- Cardiano, P.; Ioppolo, S.; DeStefano, C.; Pettignano, A.; Sergi, S.; Piraino, P. Study and characterization of the ancient bricks of monastery of “San Filippo di Fragalà” in Frazzanò (Sicily). Anal. Chim. Acta 2004, 519, 103–111. [Google Scholar] [CrossRef]

- Papayianni, I.; Stefanidou, M. Characteristics of bricks of Byzantine period. In Proceedings of the 12th International Brick/Block Masonry Conference, Madrid, Spain, 25–28 June 2000; International Brick Block Masonry Conference, TIBKAT. Volume 1. [Google Scholar]

- Cheng, Q.; Zhang, J.; Zhou, N.; Guo, Y.; Pan, S. Experimental study on unconfined compression strength of polypropylene fiber reinforced composite cemented clay. Crystals 2020, 10, 247. [Google Scholar] [CrossRef]

- Ndjeumi, C.C.; Djomou, D.P.N.; Nkeng, G.E.; Souaibou, F.A.; Anong, S. Assessment of Cement-Lime as Stabilizer on Mud Bricks. J. Mater. Sci. Chem. Eng. 2024, 12, 1–13. [Google Scholar] [CrossRef]

- Laouidji, Z.; Boutlikht, M.; Douadi, A.; Hebbache, K.; Atiki, E.; Belebchouche, C.; Moretti, L.; Czarnecki, S. Exploring the Effect of Lime and Cement Ratios on the Mechanical Properties of Clay Bricks Made from Different Types of Soils. Buildings 2025, 15, 631. [Google Scholar] [CrossRef]

- Kaniraj, S.R.; Havanagi, V.G. Behavior of cement-stabilized fiber-reinforced fly ash-soil mixtures. J. Geotech. Geoenviron. Eng. 2001, 127, 574–584. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Xiao, H.; Shen, W.; Lee, F.H. Engineering properties of marine clay admixed with Portland cement and blended cement with siliceous fly ash. J. Mater. Civ. Eng. 2017, 29, 04017177. [Google Scholar] [CrossRef]

- ACI. Building Code Requirements for Masonry Structures (ACI 530-05/ASCE 5-05/TMS 402-05); Specification for Masonry Structures (ACI 530.1-05/ASCE 6-05/TMS 602-05); Commentary on Building Code Requirements for Masonry Structures (ACI 530-05/ASCE 5-05/TMS 402-05); Commentary on Specification for Masonry Structures (ACI 530.1-05/ASCE 6-05/TMS 602-05); American Concrete Institute: Farmington Hills, MI, USA, 2005. [Google Scholar]

- BS EN 771-1; Clay Masonry Unit Dimensions & Tolerances. British Standards Institution: London, UK, 2015.

- BS 3921; British Standard Specification for Clay Bricks. British Standards Institution: London, UK, 1985.

- Cultrone, G.; De la Torre, M.J.; Sebastian, E.M.; Cazalla, O.; Rodriguez-Navarro, C. Behavior of Brick Samples in Aggressive Environments. Water Air Soil Pollut. 2000, 119, 191–207. [Google Scholar] [CrossRef]

- Baronio, G.; Binda, L.; Charola, A.E. Deterioration of bricks with and without perforations due to salt cyrstallization. In Proceedings of the 7th International Brick Masonry Conference, Melbourne, Australia, 17–20 February 1985. [Google Scholar]

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purposes. ASTM International: West Conshohocken, PA, USA, 2025.

- Moghal, A.A.B.; Obaid, A.A.K.; Al-Refeai, T.O.; Al-Shamrani, M.A. Compressibility and durability characteristics of lime treated expansive semiarid soils. J. Test. Eval. 2015, 43, 255–263. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Dafalla, M.A.; Elkady, T.Y.; Al-Shamrani, M.A. Lime leachability studies on stabilized expansive semi-arid soil. GEOMATE J. 2015, 9, 1467–1471. [Google Scholar]

- Abduljauwad, S.N. Characteristics and chemical treatment of expansive clay in Al-Qatif, Saudi Arabia. Eng. Geol. 1991, 31, 143–158. [Google Scholar] [CrossRef]

- Almuaythir, S.; Abbas, M.F. Expansive soil remediation using cement kiln dust as stabilizer. Case Stud. Constr. Mater. 2023, 18, e01983. [Google Scholar] [CrossRef]

- Zami, M.S.; Ewebajo, A.O.; Al-Amoudi, O.S.B.; Al-Osta, M.A.; Mustafa, Y.M.H. Strength and durability improvement of cement-stabilized Al-Qatif soil by the addition of sand. Arab. J. Geosci. 2022, 15, 1339. [Google Scholar] [CrossRef]

- Mutaz, M.; Al-Shamrani, M.; Puppala, A.; Dafalla, M. Evaluation of chemical stabilization of a highly expansive clayey soil. Transp. Res. Rec. 2011, 2204, 148–157. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2009.

- Dafalla, M.A.; Moghal, A.A.B. Effect of Fibercast and Fibermesh inclusion on the direct shear and linear shrinkage response of clay. Arab. J. Geosci. 2016, 9, 555. [Google Scholar] [CrossRef]

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D3080M-11; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM: West Conshohocken, PA, USA, 2011.

- Tex-107-E; Test Procedure for Determining the Bar Linear Shrinkage of Soils. Texas Department of Transportation Document, Construction Division: Austin, TX, USA, 1999.

- Mutaz, E.; Dafalla, M.A. Chemical analysis and X-ray diffraction assessment of stabilized expansive soils. Bull. Eng. Geol. Environ. 2014, 73, 1063–1072. [Google Scholar] [CrossRef]

- Shaker, A.A.; Dafalla, M. Introducing Cement-Enhanced Clay-Sand Columns under Footings Placed on Expansive Soils. Appl. Sci. 2024, 14, 8152. [Google Scholar] [CrossRef]

- Dafalla, M.A.; Moghal, A.A.B.; Al-Obaid, A.K. Enhancing tensile strength in clays using polypropylene fibers. GEOMATE J. 2017, 12, 33–37. [Google Scholar] [CrossRef]

- Watauabe, R.; Hagiharn, H.; Sato, H. Structure property relationships of polypropylene-based nanocomposites obtained by dispersing mesoporous silica into hydroxyl-functionalized polypropylene. Part 1: Toughness, stiffness, and transparency. Polym. J. 2018, 50, 1057–1065. [Google Scholar] [CrossRef]

- ASTM D3967; Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. ASTM: West Conshohocken, PA, USA, 2008.

- Phantachang, T.; Kererat, C.; Homwouttiwong, S. Enhancing soil stabilization: The influence of cement and polymer additives on the strength and performance of soil-cement composites for unpaved roads. Rev. Compos. Mater. Av. Compos. Adv. Mater. 2024, 34, 719–727. [Google Scholar] [CrossRef]

- Miturski, M.; Dzięcioł, J.; Szlachetka, O. Effect of Dispersed Polypropylene Fibers on the Strength and Stiffness of Cement-Stabilized Clayey Sand. Sustainability 2025, 17, 5803. [Google Scholar] [CrossRef]

- Bayoumy, M.; El Sawwaf, M.; Nasr, A.; Elsawwaf, A. Strength Characteristics of Clayey Sand Stabilized Using Polypropylene Fiber or Portland Cement. Transp. Infrastruct. Geotech. 2024, 11, 1249–1271. [Google Scholar] [CrossRef]

- Meddah, A.; Goufi, A.E.; Pantelidis, L. Improving Very High Plastic Clays with the Combined Effect of Sand, Lime, and Polypropylene Fibers. Appl. Sci. 2022, 12, 9924. [Google Scholar] [CrossRef]

- Hamza, M.; Aziz, M.; Xiang, W.; Younis, M.W.; Nie, Z.; Ali, M.; Dilawar, M.; Mohammed, A.; Ali, F.; Ullah, R.; et al. Strengthening of high plastic clays by geotextile reinforcement. Arab. J. Geosci. 2022, 15, 805. [Google Scholar] [CrossRef]

- El Majid, A.; Baba, K.; Razzouk, Y. Mitigating Soil Swelling: Exploring the Efficacy of Polypropylene Fiber Reinforcement in Controlling Expansion of Expansive Soils. In Advances in Research in Geosciences, Geotechnical Engineering, and Environmental Science; Baba, K., Ouadif, L., Nounah, A., Bouassida, M., Eds.; Springer Proceedings in Earth and Environmental Sciences (GeoME); Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

| Fibercast 500 | |

|---|---|

| Melt point | 324 °F (162 °C) |

| Ignition point | 1100 °F (593 °C) |

| Thermal conductivity | Low |

| Electrical conductivity | Low |

| Acid and salt resistance | High |

| Tensile strength | 440 N/mm2 |

| Specific gravity | 0.91 |

| Water absorption | Nil |

| Alkali resistance | Alkali proof |

| Sample ID | Cement (%) | Fiber (%) | σ7 (kPa/kg/cm2) | E (MPa) |

|---|---|---|---|---|

| Sample 1 | 0 | 0 | 147.1/1.5 | 3.1 |

| Sample 2 | 2 | 0.2 | 225.5/2.3 | 6.1 |

| Sample 3 | 4 | 0.2 | 255.0/2.6 | 11.0 |

| Sample 4 | 6 | 0.2 | 353/0/3.6 | 10.6 |

| Sample ID | Cement (%) | Fiber (%) | σ14 (kPa/kg/cm2) | E (MPa) |

|---|---|---|---|---|

| Sample 1 | 0 | 0.0 | 153.0/1.56 | 3.36 |

| Sample 2 | 2 | 0.2 | 399.3/4.07 | 14.21 |

| Sample 3 | 4 | 0.2 | 562.6/5.74 | 20.01 |

| Sample 4 | 6 | 0.2 | 599.7/6.11 | 34.65 |

| Sample ID | Cement (%) | Fiber (%) | σ28 (kPa/kg/cm2) | E (MPa) |

|---|---|---|---|---|

| Sample 1 | 0 | 0.0 | 159.8/1.63 | 3.66 |

| Sample 2 | 2 | 0.2 | 519.8/5.30 | 9.83 |

| Sample 3 | 4 | 0.2 | 781.4/7.97 | 20.15 |

| Sample 4 | 6 | 0.2 | 1161.2/11.84 | 24.83 |

| Sample ID | Cement (%) | Fiber (%) | σ28 (kPa/kg/cm2) | E (MPa) |

|---|---|---|---|---|

| Sample 1 | 0 | 0 | 159.8/1.63 | 3.66 |

| Sample 2 | 2 | 0 | 235.4/2.40 | 5.71 |

| Sample 3 | 4 | 0 | 375.7/3.83 | 10.90 |

| Sample 4 | 6 | 0 | 464.7/4.74 | 17.36 |

| Fiber Amount | Tensile Strength (kPa) |

|---|---|

| 0 g/m3 | 54.4 |

| 600 g/m3 | 54.1 |

| 900 g/m3 | 53.4 |

| 1200 g/m3 | 56.6 |

| Cement (%) | Fiber (%) | Shear Strength (kg/cm2) |

|---|---|---|

| 0 | 0 | 0.78 |

| 2 | 0.2 | 2.04 |

| 4 | 0.2 | 2.87 |

| 6 | 0.2 | 3.05 |

| Clay % | 0 gm/m3 Fiber (mm) | 600 gm/m3 Fiber (mm) | 900 gm/m3 Fiber (mm) | 1200 gm/m3 Fiber (mm) |

|---|---|---|---|---|

| 15% | 1.41 | 1.75 | 1.20 | 1.78 |

| 30% | 2.02 | 2.71 | 1.75 | 2.70 |

| 45% | 3.09 | 3.17 | 2.42 | 3.48 |

| 60% | 3.87 | 4.19 | 3.27 | 4.54 |

| 75% | 4.47 | 4.2 | 4.24 | 4.37 |

| 90% | 5.5 | 5.15 | 5.07 | 6.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dafalla, M.; Abden, A. Integrating Polypropylene Fibers and Cement in Clays for Sustainable Clay Bricks. Polymers 2025, 17, 3244. https://doi.org/10.3390/polym17243244

Dafalla M, Abden A. Integrating Polypropylene Fibers and Cement in Clays for Sustainable Clay Bricks. Polymers. 2025; 17(24):3244. https://doi.org/10.3390/polym17243244

Chicago/Turabian StyleDafalla, Muawia, and Awadh Abden. 2025. "Integrating Polypropylene Fibers and Cement in Clays for Sustainable Clay Bricks" Polymers 17, no. 24: 3244. https://doi.org/10.3390/polym17243244

APA StyleDafalla, M., & Abden, A. (2025). Integrating Polypropylene Fibers and Cement in Clays for Sustainable Clay Bricks. Polymers, 17(24), 3244. https://doi.org/10.3390/polym17243244