Prediction of Mechanical Properties of Injection-Molded Weld Lines of Glass Fiber-Reinforced Composites

Abstract

1. Introduction

2. Methodology

2.1. Materials

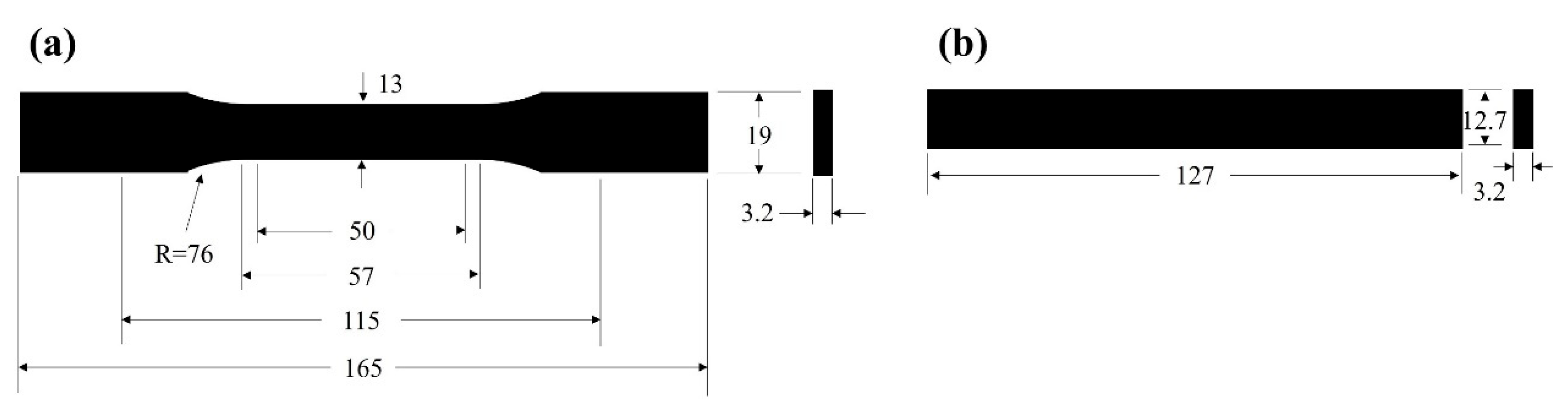

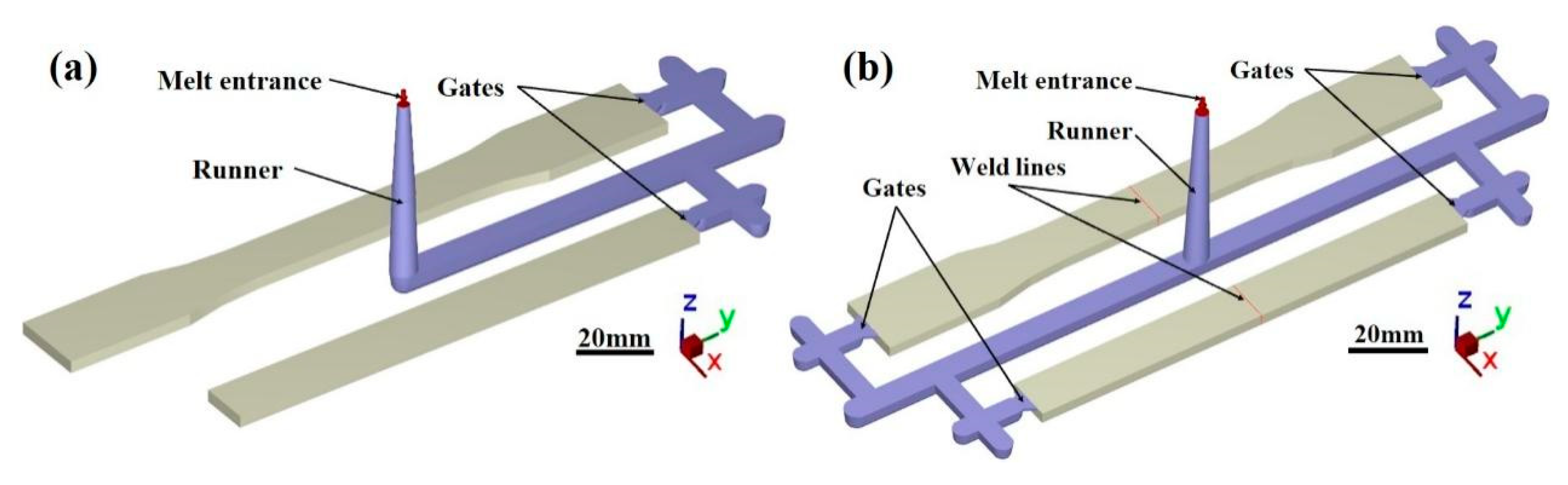

2.2. Specimen Preparation and Characterizations

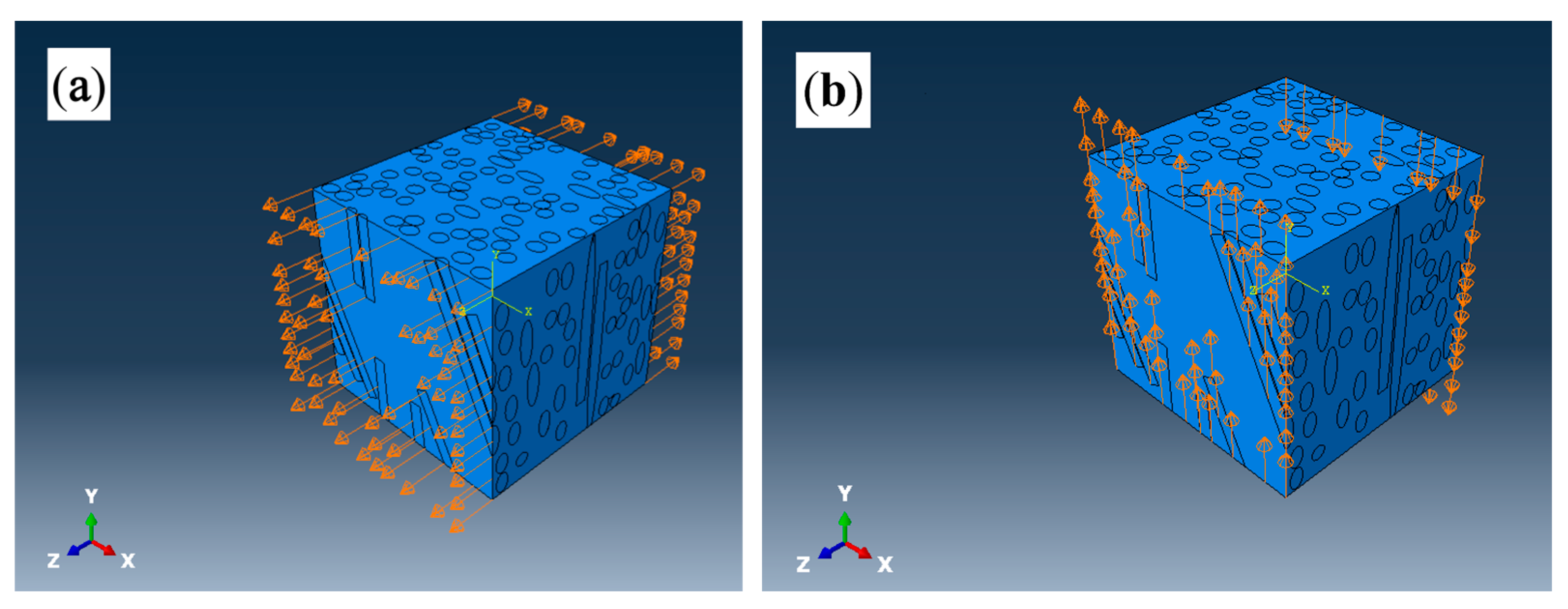

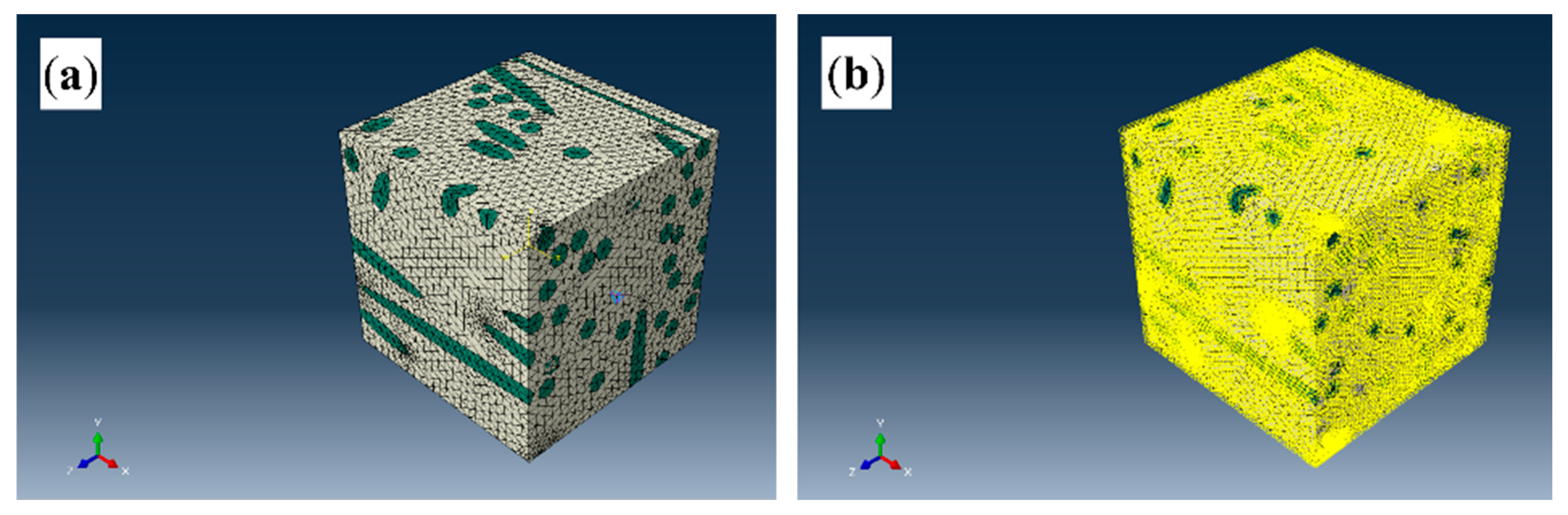

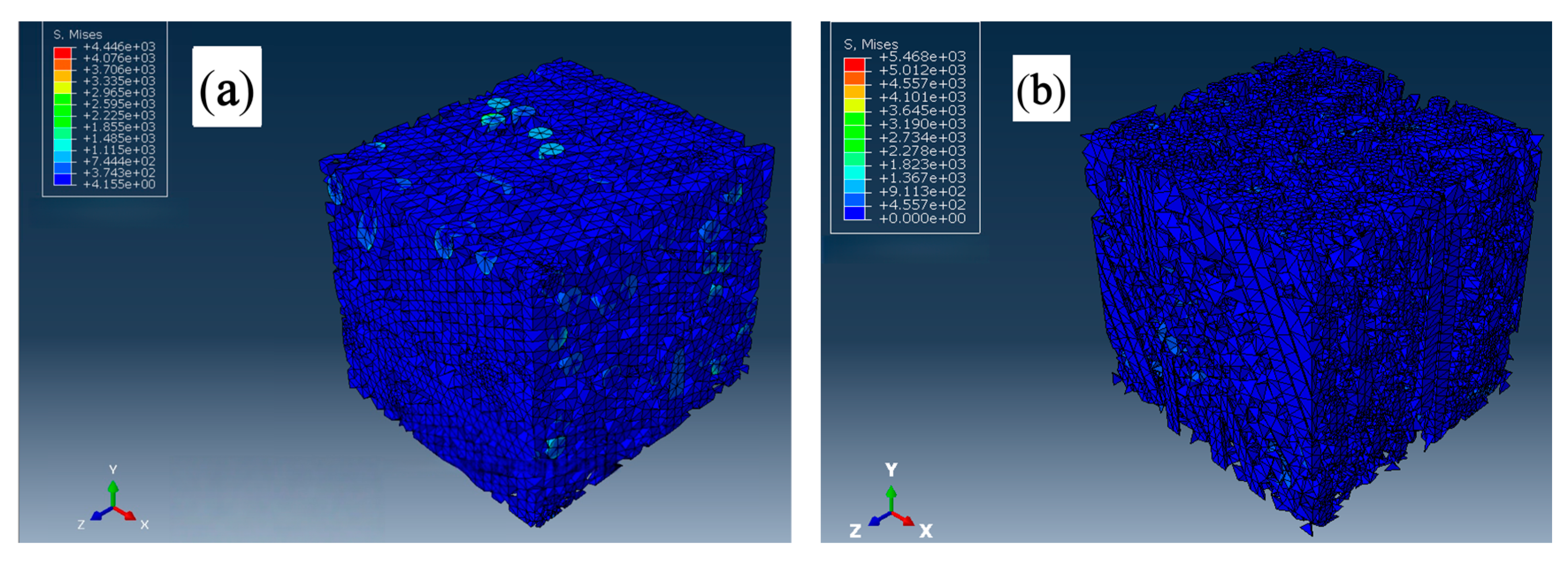

2.3. Simulation Framework

- 1.

- Polymer chain diffusion was based on the Flory–Huggins free energy theory [37], which governs molecular chain interdiffusion at weld lines as follows:

- 2.

2.4. Modeling

3. Experimental Results and Discussion

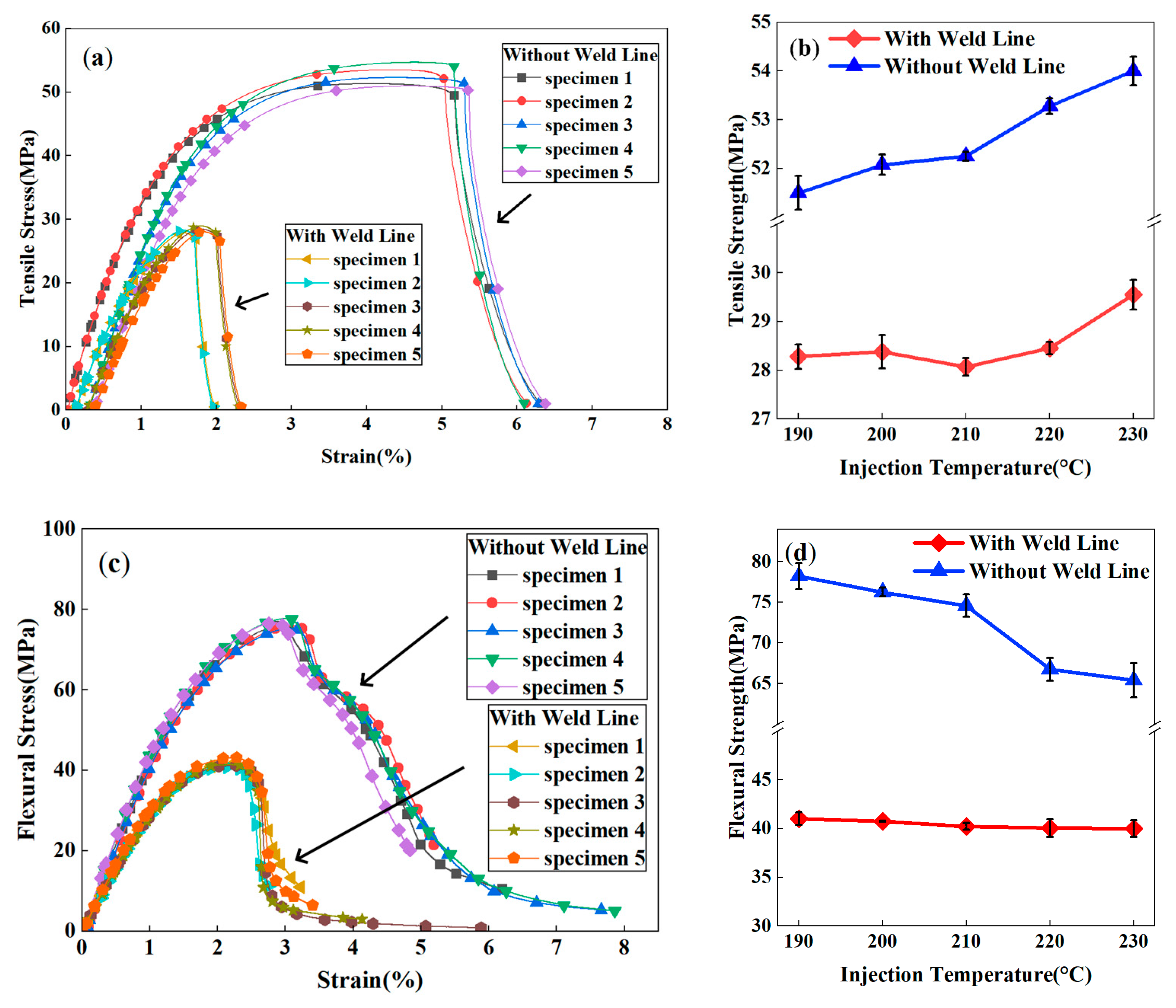

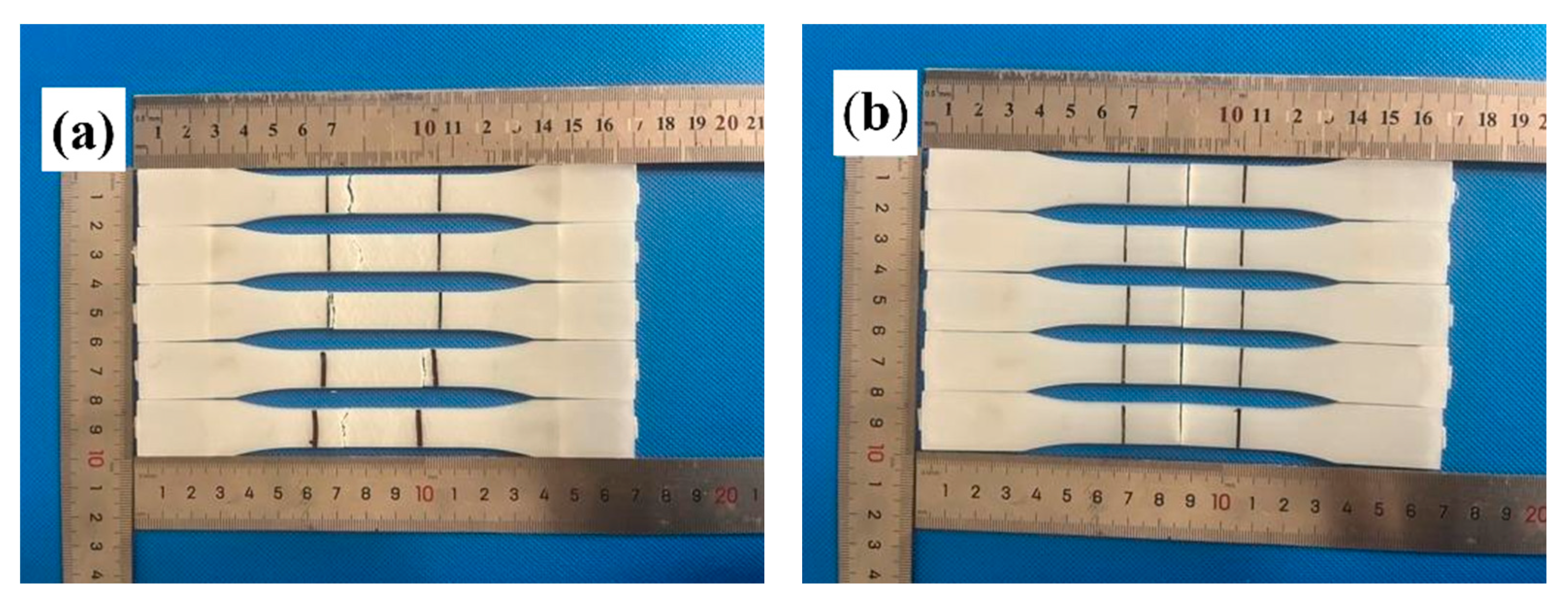

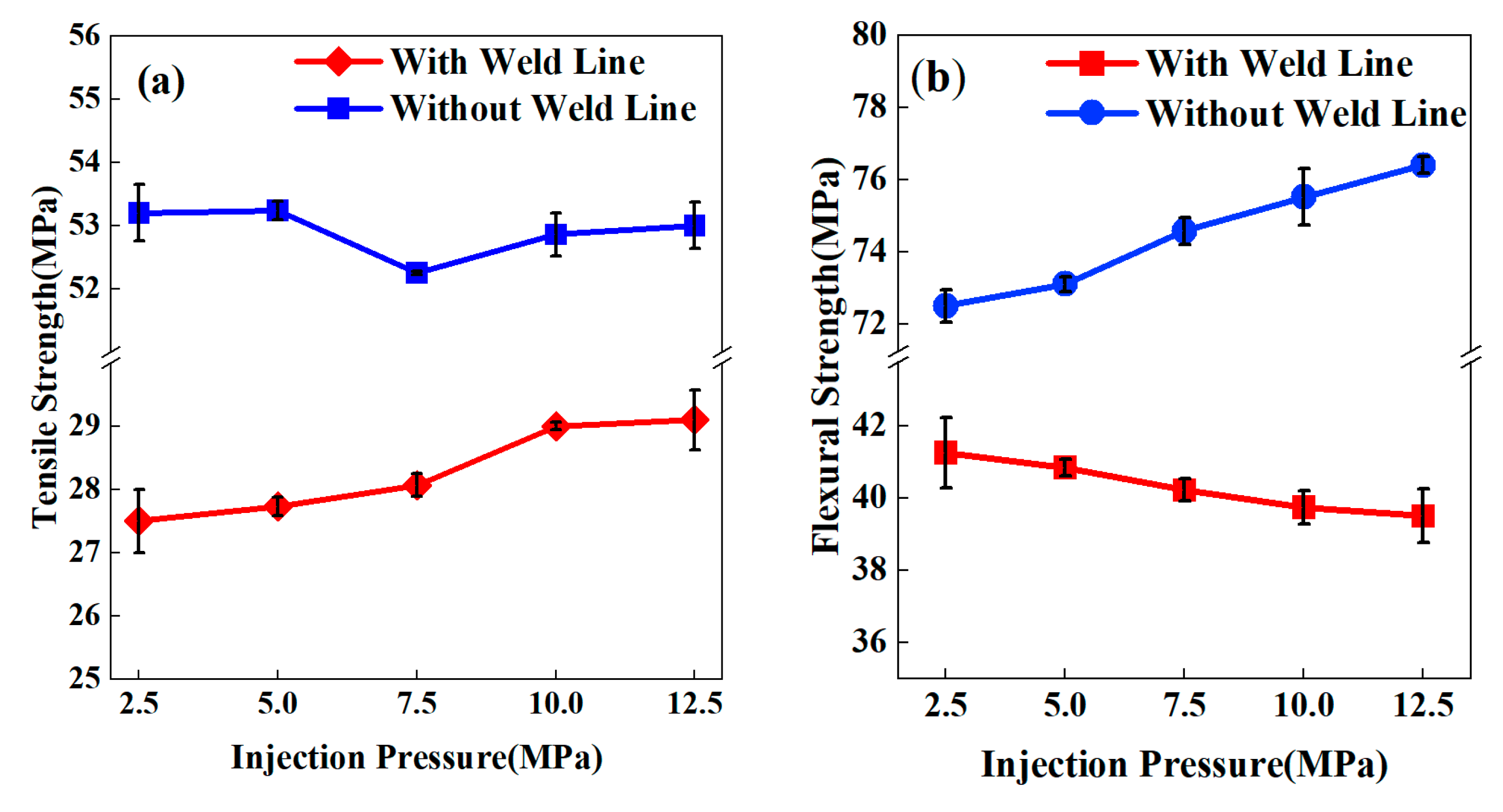

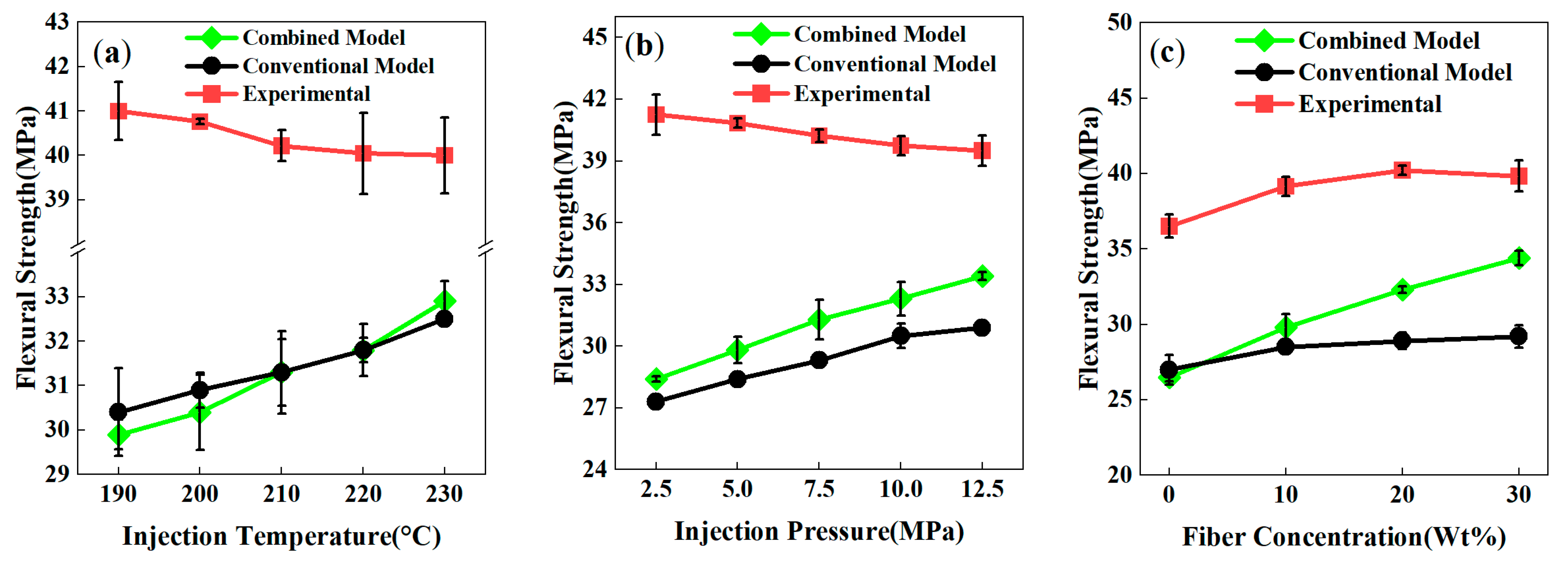

3.1. Influence of Injection Temperature on Mechanical Properties of Weld Lines

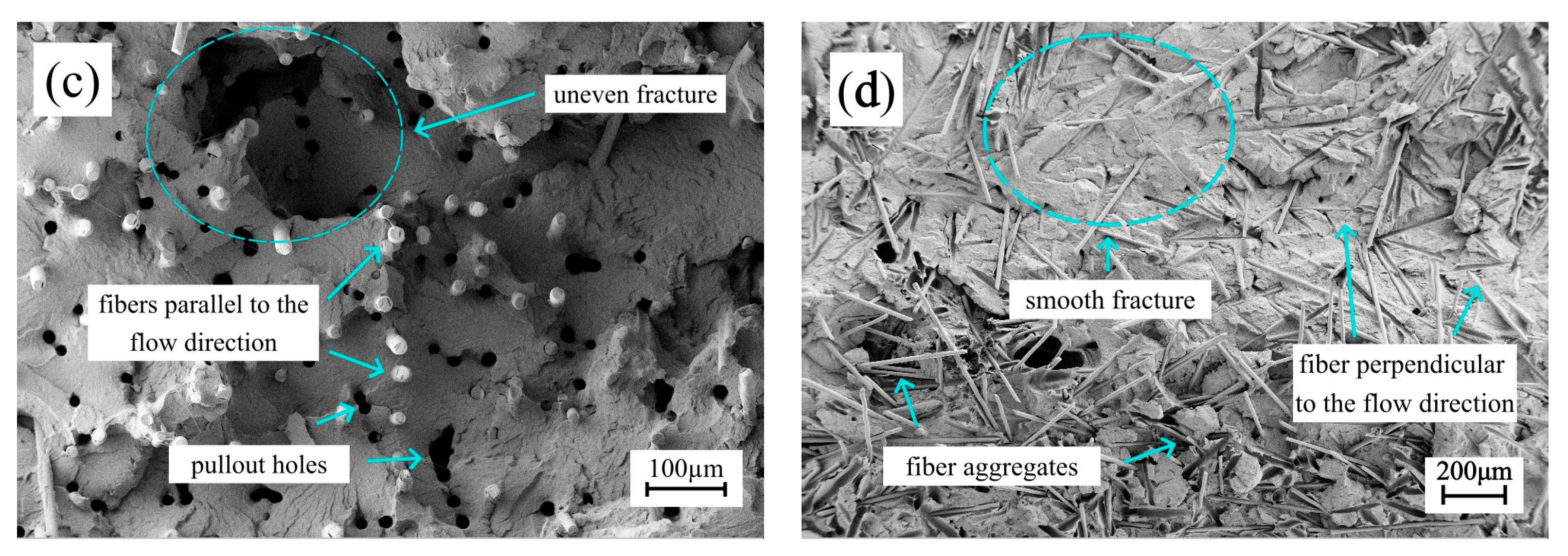

3.2. Influence of Injection Pressure on the Mechanical Properties of Weld Lines

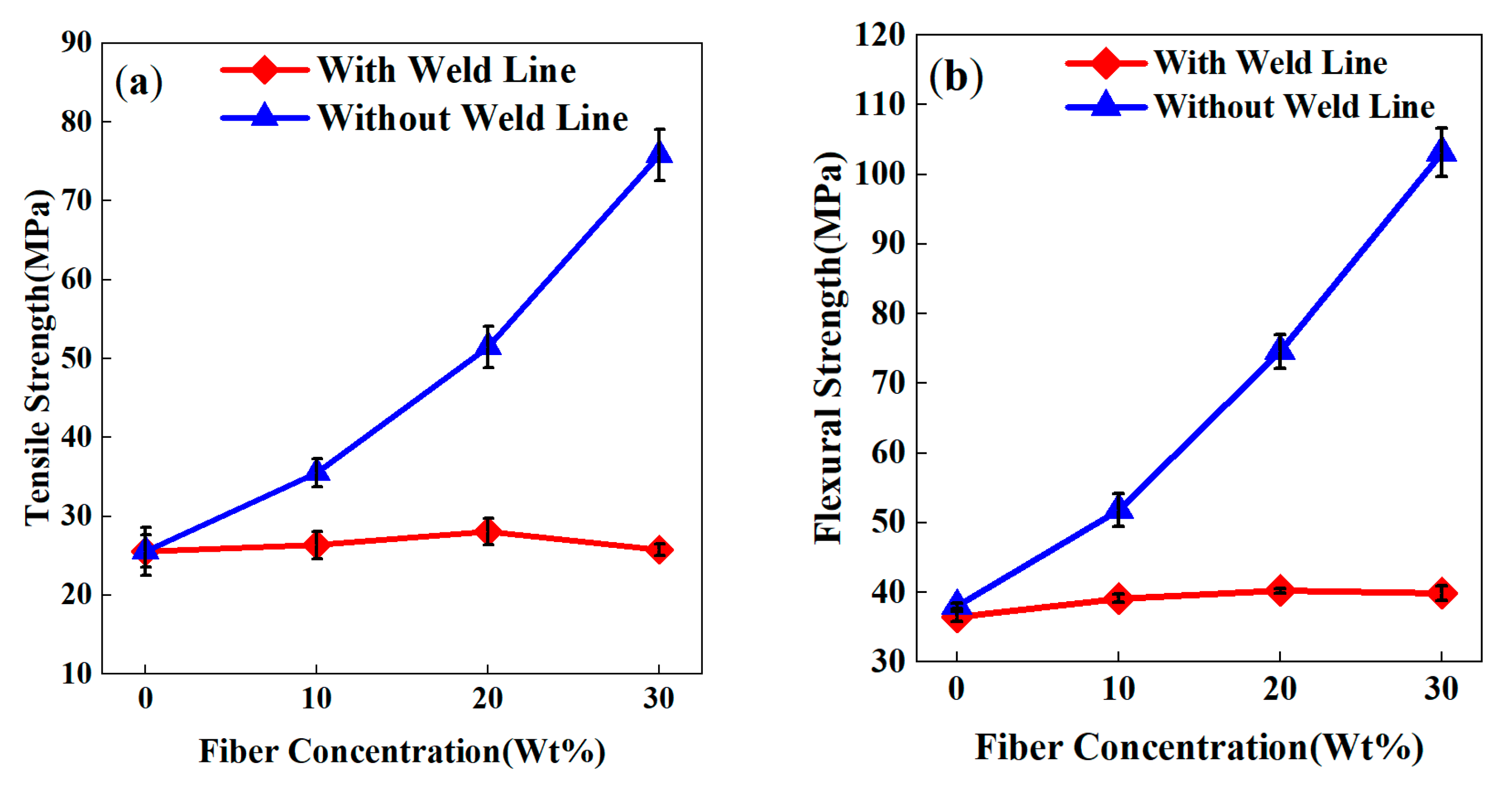

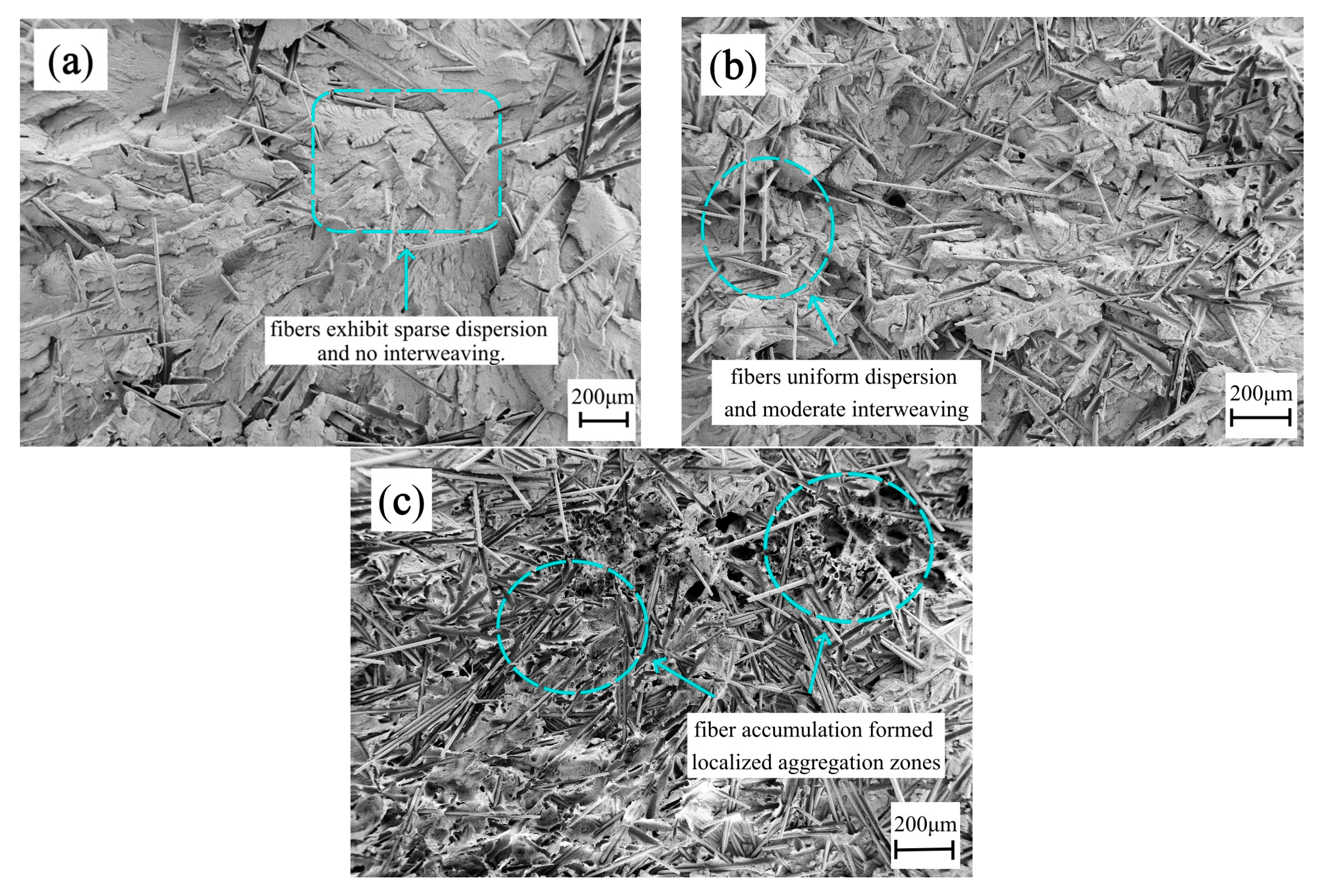

3.3. Effect of Fiber Content on Mechanical Properties of Weld Lines

4. Simulation Results Analysis

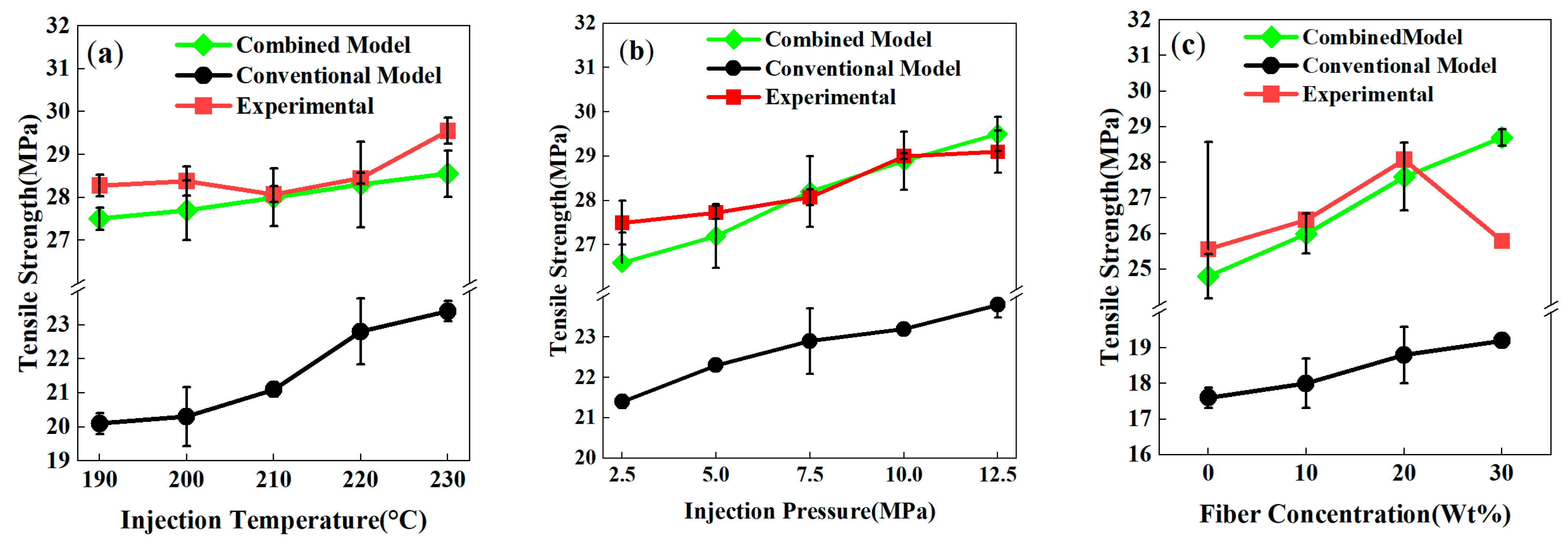

4.1. Tensile Strength Prediction

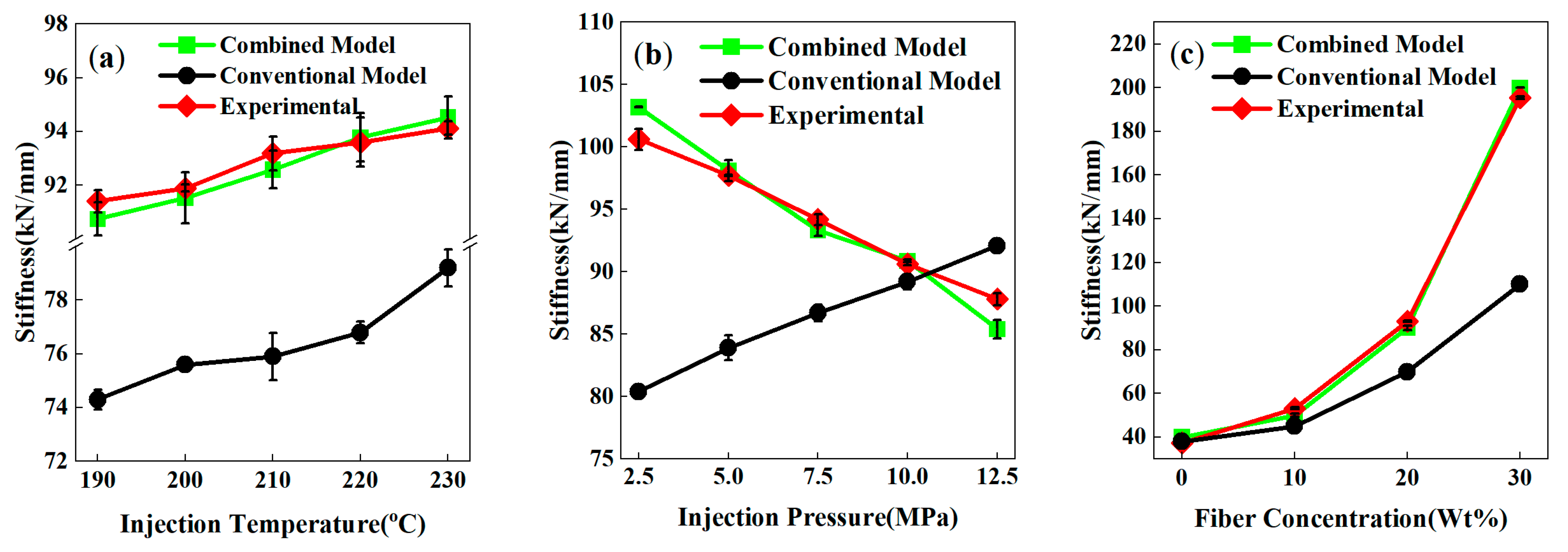

4.2. Stiffness Prediction

4.3. Flexural Strength Prediction

5. Conclusions

- (1)

- Injection temperature, injection pressure, and fiber content all affect the mechanical properties of weld lines, with fiber content exerting the most significant influence. When the fiber content exceeds 20wt%, the tensile and flexural strengths of weld lines decrease sharply compared with specimens without weld lines. In the weld line region, the fibers align parallel to the fracture surface and form aggregates, providing a very weak reinforcing effect to the matrix.

- (2)

- A novel multiscale simulation framework was developed by integrating polymer chain diffusion dynamics (Flory–Huggins free energy theory) and orientation-dependent fiber–matrix interfacial debonding mechanics, which, for the first time, realizes the coupling of semi-crystalline polymer dynamics and long-fiber anisotropy and solves the defects of traditional models that ignore intermolecular chain interactions and crystallization kinetics–fiber orientation coupling. The framework integrates Moldex3D-derived fiber orientation data, Digimat microstructure reconstruction, and Abaqus multiscale analysis and clarifies the influence of the laws of injection temperature, pressure, and fiber content on the mechanical properties of weld lines.

- (3)

- Experimental validation shows that the model has high prediction accuracy for the tensile strength and stiffness of weld lines in PP-GF composites with an error of less than 10% and 3.5%, respectively. The industrial optimization directions derived from the research include increasing the melt temperature to enhance chain diffusion, moderating the injection pressure to suppress excessive fiber alignment, and controlling the fiber content within 20wt% to balance the reinforcement effect and weld line defects. This study provides effective simulation tools for the weld line control and performance optimization of fiber-reinforced composites.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Patri, M.; Samui, A. Chapter 29—Glass Fibre Composites for Aerospace and Other Applications. In Technical Organic and Inorganic Fibres from Natural Resources; Woodhead Publishing: Sawston, UK, 2025; pp. 795–834. [Google Scholar]

- Yan, L.; Xu, H. Lightweight Composite Materials in Automotive Engineering: State-of-the-Art and Future Trends. Alex. Eng. J. 2025, 118, 1–10. [Google Scholar] [CrossRef]

- Papathanasiou, T.; Kuehnert, I.; Polychronopoulos, N. Chapter 5—Flow-Induced Alignment in Injection Molding of Fiber-Reinforced Polymer Composites. In Flow-Induced Alignment in Composite Materials, 2nd ed.; Woodhead Publishing: Sawston, UK, 2022; pp. 123–185. [Google Scholar]

- Li, X.; Zuo, Z.; Mi, H.; Dong, B.; Antwi-Afari, M.; Liu, C.; Shen, C. A Review of Research Progress on the Minimization of Weld Lines in Injection Molding. Int. J. Adv. Manuf. Technol. 2024, 132, 5179–5210. [Google Scholar] [CrossRef]

- Tran, N.T.; Seefried, A.; Gehde, M.; Hirz, J.; Klaas, D. Flow Disturbance Characterization of Highly Filled Thermoset Injection Molding Compounds behind an Obstacle and in a Spiral Flow Part. Polymers 2023, 15, 2984. [Google Scholar] [CrossRef]

- Jadhav, G.; Gaval, V. Weld-Lines and Its Strength Evaluation in Injection Moulded Parts: A Review. Polym. Eng. Sci. 2023, 63, 3523–3536. [Google Scholar] [CrossRef]

- Nguyen, V.; Uyen, T.; Minh, P.; Do, T.; Huynh, T.; Nguyen, T.; Nguyen, V. Weld Line Strength of Polyamide Fiberglass Composite at Different Processing Parameters in Injection Molding Technique. Polymers 2023, 15, 4102. [Google Scholar] [CrossRef]

- Daiyan, H.; Andreassen, E.; Grytten, F.; Lyngstad, O.; Luksepp, T.; Osnes, H. Low-Velocity Impact Response of Injection-Moulded Polypropylene Plates-Part 2: Effects of Moulding Conditions, Striker Geometry, Clamping, Surface Texture, Weld Lines and Paint. Polym. Test. 2010, 29, 894–901. [Google Scholar] [CrossRef]

- Dzulkipli, A.; Azuddin, M. Study of the Effects of Injection Molding Parameters on Weld Lines Formation. Procedia Eng. 2017, 184, 663–672. [Google Scholar] [CrossRef]

- Raz, K.; Sedlacek, F. Effect of Melt Temperature on Weld Line Strength. Key Eng. Mater. 2024, 801, 264–269. [Google Scholar] [CrossRef]

- Kagitci, Y.; Tarakcioglu, N. The Effect of Weld Lines on Tensile Strength in a Polymer Composite Part. Int. J. Adv. Manuf. Technol. 2016, 85, 1125–1135. [Google Scholar] [CrossRef]

- Malguarnera, S.; Manisali, A. The Effects of Processing Parameters on the Tensile Properties of Weld Lines in Injection Molded Thermoplastics. Polym. Eng. Sci. 1981, 21, 586–593. [Google Scholar] [CrossRef]

- Chrysostomou, A.; Hashemi, S. Mechanical Properties of Injection Moulded Styrene Maleic Anhydride (SMA). Part II: Influence of Short Glass Fibres and Weld Lines. J. Mater. Sci. 1998, 33, 4491–4501. [Google Scholar] [CrossRef]

- Vaxman, A.; Narkis, M.; Siegmann, A.; Kenig, S. Weld-Line Characteristics in Short Fiber Reinforced Thermoplastics. Polym. Compos. 1991, 12, 161–168. [Google Scholar] [CrossRef]

- Hashemi, S. Thermal Effects on Weld and Unweld Tensile Properties of Injection Moulded Short Glass Fibre Reinforced ABS Composites. Express Polym. Lett. 2007, 1, 688–697. [Google Scholar] [CrossRef]

- Mofakhami, E.; Gervat, L.; Fayolle, B.; Miquelard Garnier, G.; Ovalle, C. Effect of Fibre Concentration on the Mechanical Properties of Welded Reinforced Polypropylene. Compos. Part B Eng. 2024, 269, 111111. [Google Scholar] [CrossRef]

- Wang, X.; Bao, Z.; Gao, D.; Huang, S.; Huang, L.; Chen, Q.; Zhao, H.; Han, W.; Xu, Y. Mechanical Properties of Weld Lines in Injection-Molded Carbon Fiber-Reinforced Nylon (PA-CF) Composites. Polymers 2023, 15, 2476. [Google Scholar] [CrossRef] [PubMed]

- Tian, Z.; Xie, Y. CAE Analysis and Solutions to Common Defects in Injection Molding. Eng. Plast. Appl. 2007, 6, 24–27. [Google Scholar] [CrossRef]

- Livingston, R. In Situ Characterization of Fiber-Matrix Interface Debonding Via Full-Field Measurements. Master’s Thesis, Rowan University, Glassboro, NJ, USA, 2021. [Google Scholar]

- Fisa, B.; Rahmani, M. Weldline Strength in Injection Molded Glass Fiber-Reinforced Polypropylene. Polym. Eng. Sci. 1991, 31, 1330–1335. [Google Scholar] [CrossRef]

- Tran, M.; Nguyen, H.; Nguyen, V.; Pham, S.; Do, T.; Nguyen, V. Optimizing the Tensile Strength of Weld Lines in Glass Fiber Composite Injection Molding. Materials 2024, 17, 3428. [Google Scholar] [CrossRef] [PubMed]

- Paturi, U.; Kolluru, S.; Kalvakolanu, S. Prediction of weld-line width and sink-mark depth of plastic injection moulded parts using neural networks. Mater. Today Proc. 2023, 2, 295. [Google Scholar] [CrossRef]

- Polat, A.; Deliktas, B.; Yazici, M.; Voyiadjis, G. Computational modeling of weld-line impacts on mechanical behavior of fiber-reinforced thermoplastics. Eur. J. Mech.-A/Solids 2025, 109, 105485. [Google Scholar] [CrossRef]

- Guo, S.; Bousmina, M.; Ait-Kadi, A. A Modified Model Predictions and Experimental Results of Weld-Lines Strength in Injection Molded PS/PMMA Blends. Polymer 2004, 45, 2911–2920. [Google Scholar] [CrossRef]

- Harnnarongchai, W.; Patcharaphun, S. Prediction of Weld Lines Strength for Injection Molded Short Glass-Fiber Composites. Mater. Today Proc. 2024, 77, 1122–1126. [Google Scholar] [CrossRef]

- Ruan, C.; Ouyang, J.; Liu, S. Multi-Scale Modeling and Simulation of Crystallization During Cooling in Short Fiber Reinforced Composites. Int. J. Heat Mass Transf. 2012, 55, 1911–1921. [Google Scholar] [CrossRef]

- Pieressa, A.; Baruffa, G.; Sorgato, M.; Lucchetta, G. Enhancing Weld Line Visibility Prediction in Injection Molding Using Physics-Informed Neural Networks. J. Intell. Manuf. 2025, 36, 4305–4318. [Google Scholar] [CrossRef]

- Matsuoka, T. Fiber Orientation Prediction in Injection Molding. In Polypropylene Structure, Blends and Composites; Karger-Kocsis, J., Ed.; Springer: Berlin/Heidelberg, Germany, 1995; pp. 113–141. [Google Scholar]

- Ullah, M.; Wencai, L.; Siebenbuerger, M.; Savella, F.; Palardy, G. Tailoring the Crystallinity of Ultrasonically Welded Interfaces in Glass Fiber-Reinforced Thermoplastic Composites. ACS Appl. Eng. Mater. 2025, 3, 1455–1467. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Zheng, D.; Sun, B.; Zhong, H. Injection Molding Optimization for Minimizing the Defects of Weld Lines. Polym.-Plast. Technol. Eng. 2008, 47, 943–952. [Google Scholar] [CrossRef]

- Ou, X.; Wang, D.; Ning, K. Analysis of Typical Defects in Automobile Injection Parts and Solving Measures. Eng. Plast. Appl. 2014, 1, 51–55. [Google Scholar] [CrossRef]

- Zhang, Y. Common Defects and Solutions of Injection Molding. Die Mould. Technol. 2012, 6, 28–30. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average Stress in Matrix and Average Elastic Energy of Materials with Misfitting Inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Cross, M. Rheology of Non-Newtonian Fluids: A New Flow Equation for Pseudoplastic Systems. J. Colloid Sci. 1965, 20, 417–437. [Google Scholar] [CrossRef]

- Flory, P.J. Thermodynamics of high polymer solutions. J. Chem. Phys. 1942, 10, 51–61. [Google Scholar] [CrossRef]

- Hashemi, S. Strength of single- and double-gated injection moulded short glass fibre reinforced polycarbonate. J. Thermoplast. Compos. Mater. 2011, 26, 276–295. [Google Scholar] [CrossRef]

- Babur, O.; Erdal, S. Optimization of injection parameters for mechanical properties of specimens with weld line. Mater. Des. 2007, 28, 706–716. [Google Scholar]

- Zhu, Z.; Yang, Z.; Jiang, H. Review of interfacial debonding behavior of adhesive structures with soft materials. Chin. J. Theor. Appl. Mech. 2021, 53, 1807–1828. [Google Scholar]

- Tan, H.; Liu, C.; Huang, Y.; Geubelle, P. Effect of Nonlinear Interface Debonding on the Constitutive Model of Composite Materials. Int. J. Multiscale Comput. Eng. 2006, 4, 147–167. [Google Scholar] [CrossRef]

| Properties | Test Standards | Value | Unit | |

|---|---|---|---|---|

| PP | PP-30GF | |||

| Density | ASTM D792 | 0.91 | 1.125 | g/cm3 |

| Tensile strength | ASTM D638 | 32 | 61.4 | MPa |

| Flexural strength | ASTM D790 | 36 | 120 | MPa |

| Young’s modulus | ASTM D638 | 1500 | 6500 | MPa |

| Injection Temperature | Fkl of Tensile Strength | Fkl of Flexural Strength |

|---|---|---|

| 190 °C | 0.55 ± 0.03 | 0.52 ± 0.05 |

| 200 °C | 0.54 ± 0.01 | 0.53 ± 0.02 |

| 210 °C | 0.54 ± 0.02 | 0.54 ± 0.03 |

| 220 °C | 0.53 ± 0.03 | 0.60 ± 0.01 |

| 230 °C | 0.55 ± 0.04 | 0.61 ± 0.01 |

| Injection Pressure | Fkl of Tensile Strength | Fkl of Flexural Strength |

|---|---|---|

| 2.5 MPa | 0.52 ± 0.02 | 0.57 ± 0.04 |

| 5 MPa | 0.52 ± 0.01 | 0.56 ± 0.02 |

| 7.5 MPa | 0.54 ± 0.01 | 0.54 ± 0.03 |

| 10 MPa | 0.55 ± 0.05 | 0.53 ± 0.02 |

| 12.5 MPa | 0.55 ± 0.02 | 0.52 ± 0.01 |

| Fiber Contents | Fkl of Tensile Strength | Fkl of Flexural Strength |

|---|---|---|

| 0 wt% | 0.99 ± 0.06 | 0.96 ± 0.01 |

| 10 wt% | 0.74 ± 0.03 | 0.75 ± 0.01 |

| 20 wt% | 0.53 ± 0.02 | 0.54 ± 0.03 |

| 30 wt% | 0.34 ± 0.02 | 0.38 ± 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, Z.; Yan, Y.; Zhang, Y.; Dong, R.; Han, W.; Liu, Q. Prediction of Mechanical Properties of Injection-Molded Weld Lines of Glass Fiber-Reinforced Composites. Polymers 2025, 17, 3120. https://doi.org/10.3390/polym17233120

Bao Z, Yan Y, Zhang Y, Dong R, Han W, Liu Q. Prediction of Mechanical Properties of Injection-Molded Weld Lines of Glass Fiber-Reinforced Composites. Polymers. 2025; 17(23):3120. https://doi.org/10.3390/polym17233120

Chicago/Turabian StyleBao, Zuguo, Yunxiang Yan, You Zhang, Ruihan Dong, Weijian Han, and Qing Liu. 2025. "Prediction of Mechanical Properties of Injection-Molded Weld Lines of Glass Fiber-Reinforced Composites" Polymers 17, no. 23: 3120. https://doi.org/10.3390/polym17233120

APA StyleBao, Z., Yan, Y., Zhang, Y., Dong, R., Han, W., & Liu, Q. (2025). Prediction of Mechanical Properties of Injection-Molded Weld Lines of Glass Fiber-Reinforced Composites. Polymers, 17(23), 3120. https://doi.org/10.3390/polym17233120