Snail Shell-Reinforced Waste-Based Polymer Composites for Radiation Shielding and Anti-Reflective Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

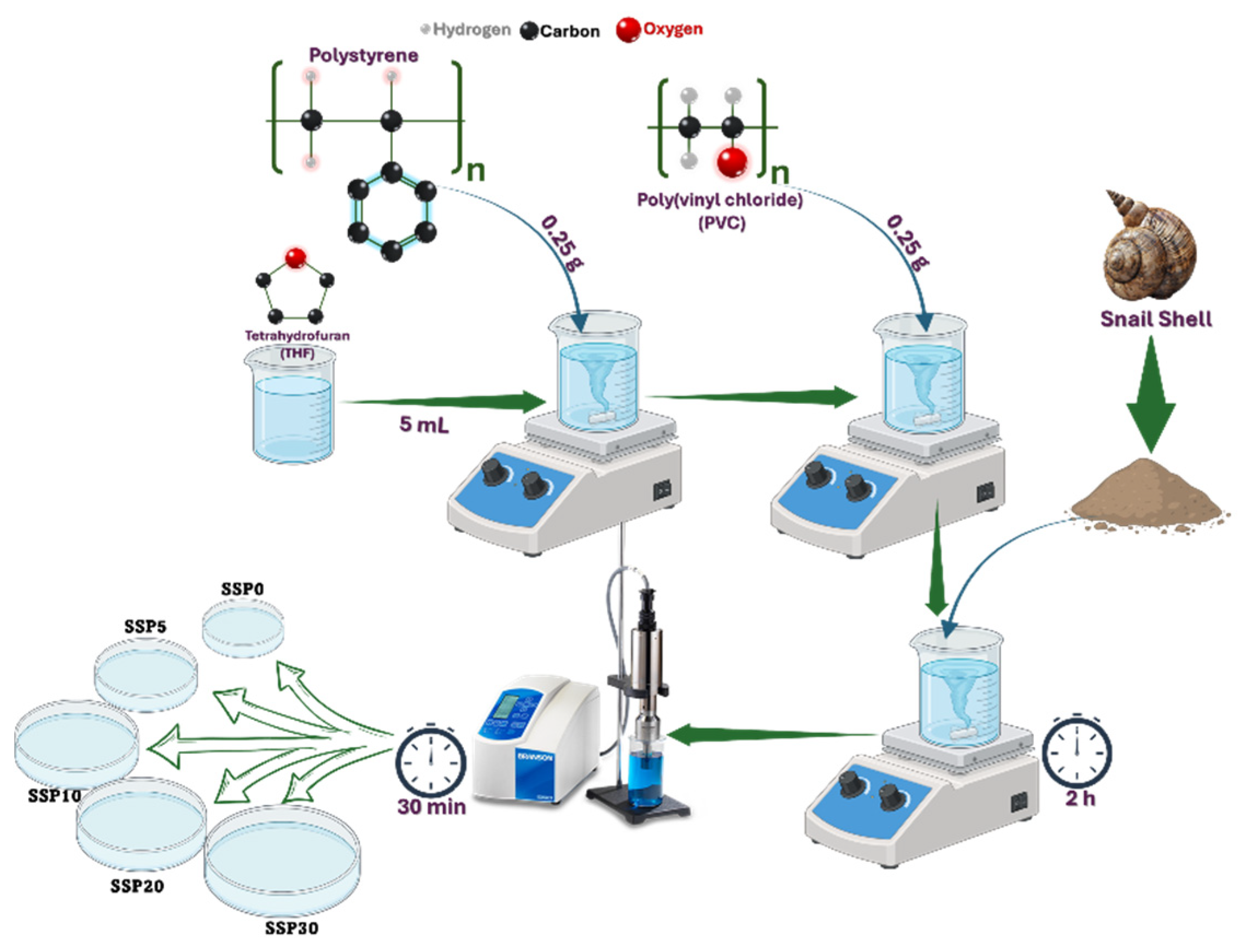

2.2. Preparation of Snail Shell Powder

2.3. Purification of Box Filling Foam

2.4. Preparation of PVC/PSt Blend Films

2.5. Preparation of PVC/PSt/SSP Nanocomposite Films

2.6. High-Energy Experimental Procedure

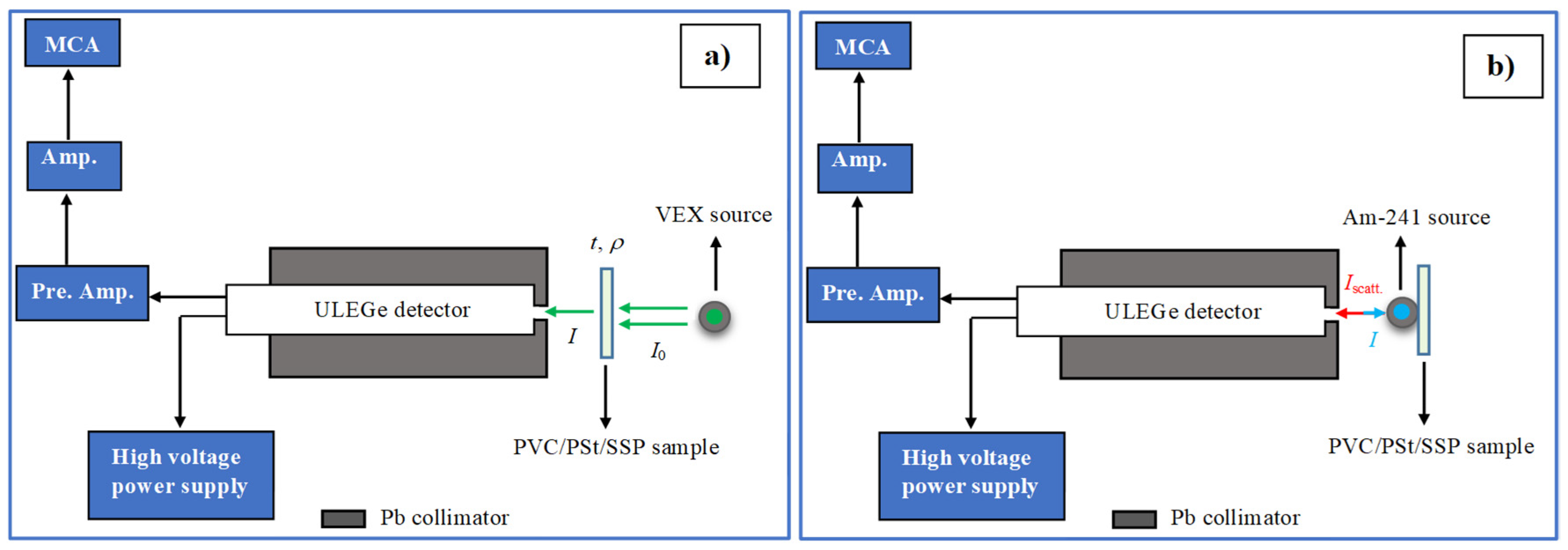

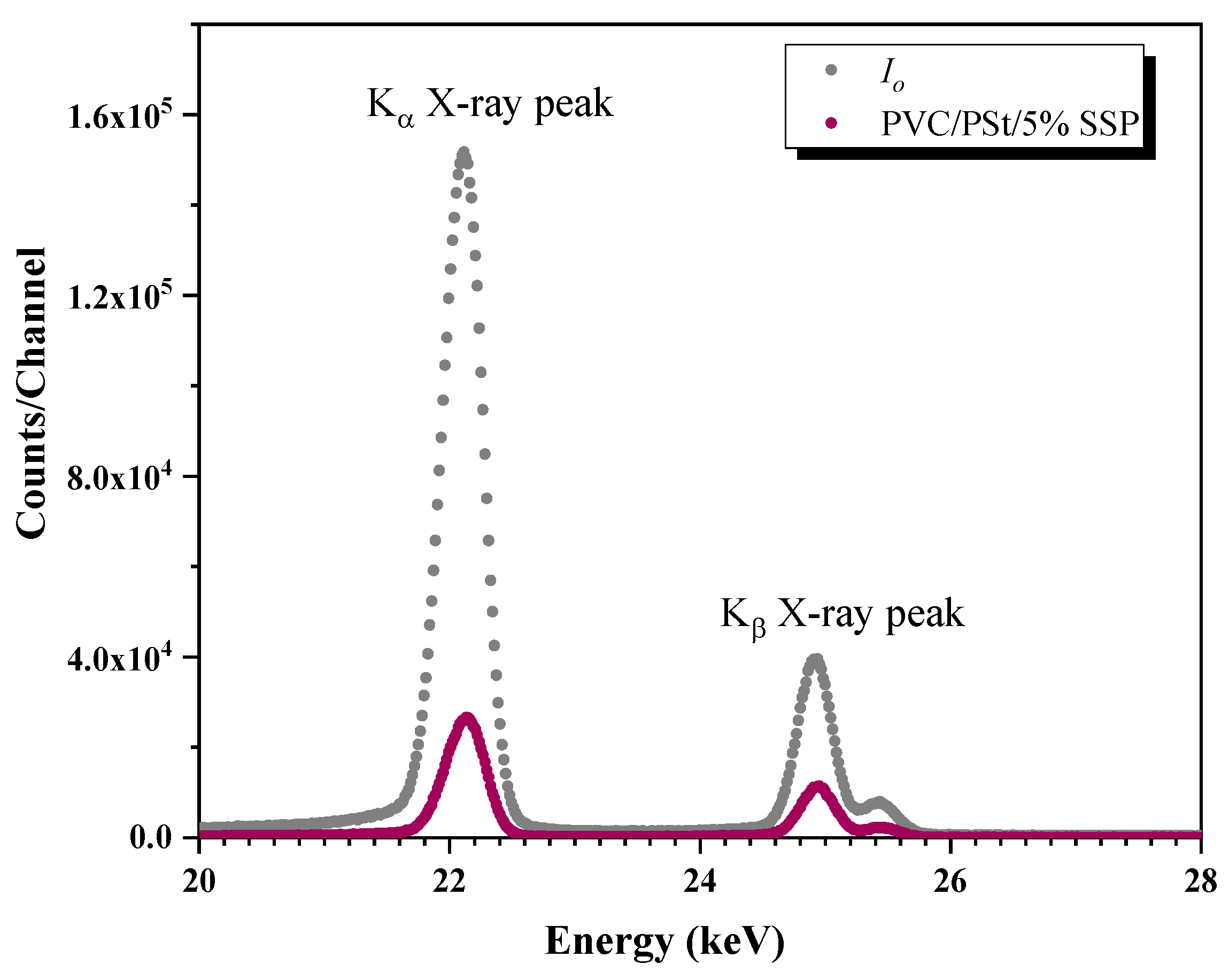

2.6.1. Photon Attenuation Measurement Procedure

2.6.2. Albedo Number Determination

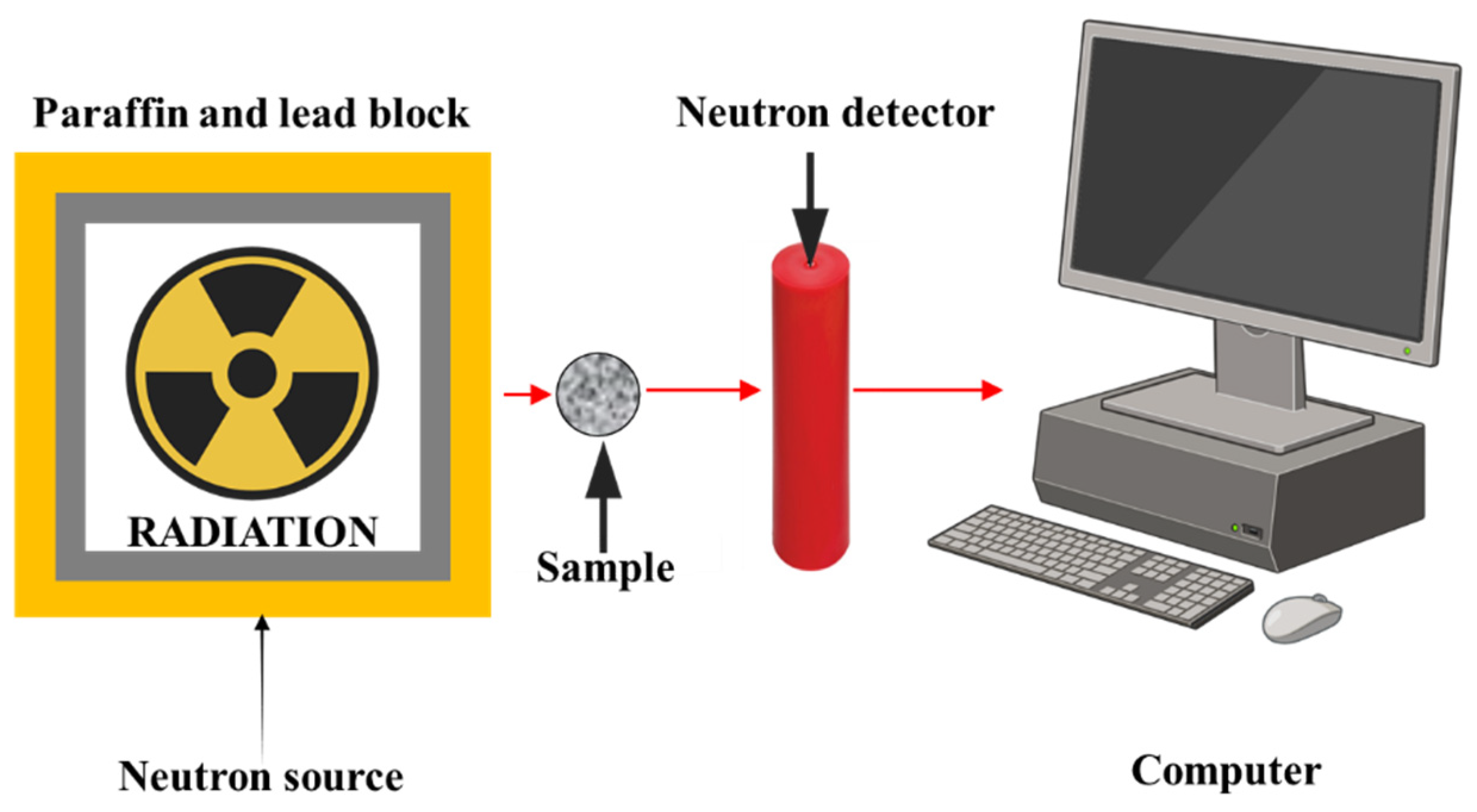

2.6.3. Neutron Attenuation

2.7. Characterization Methods

3. Results and Discussions

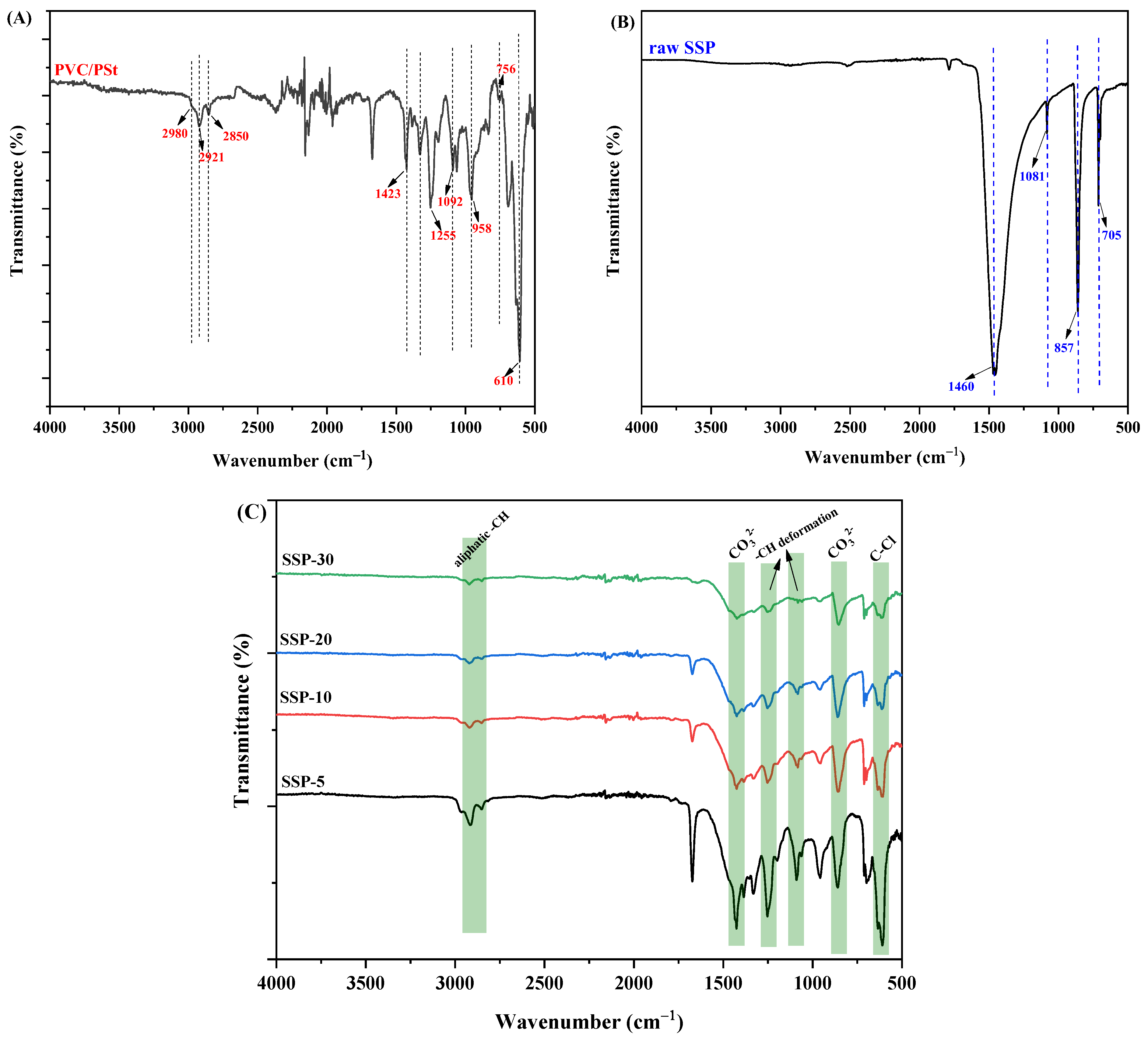

3.1. ATR-IR Analysis

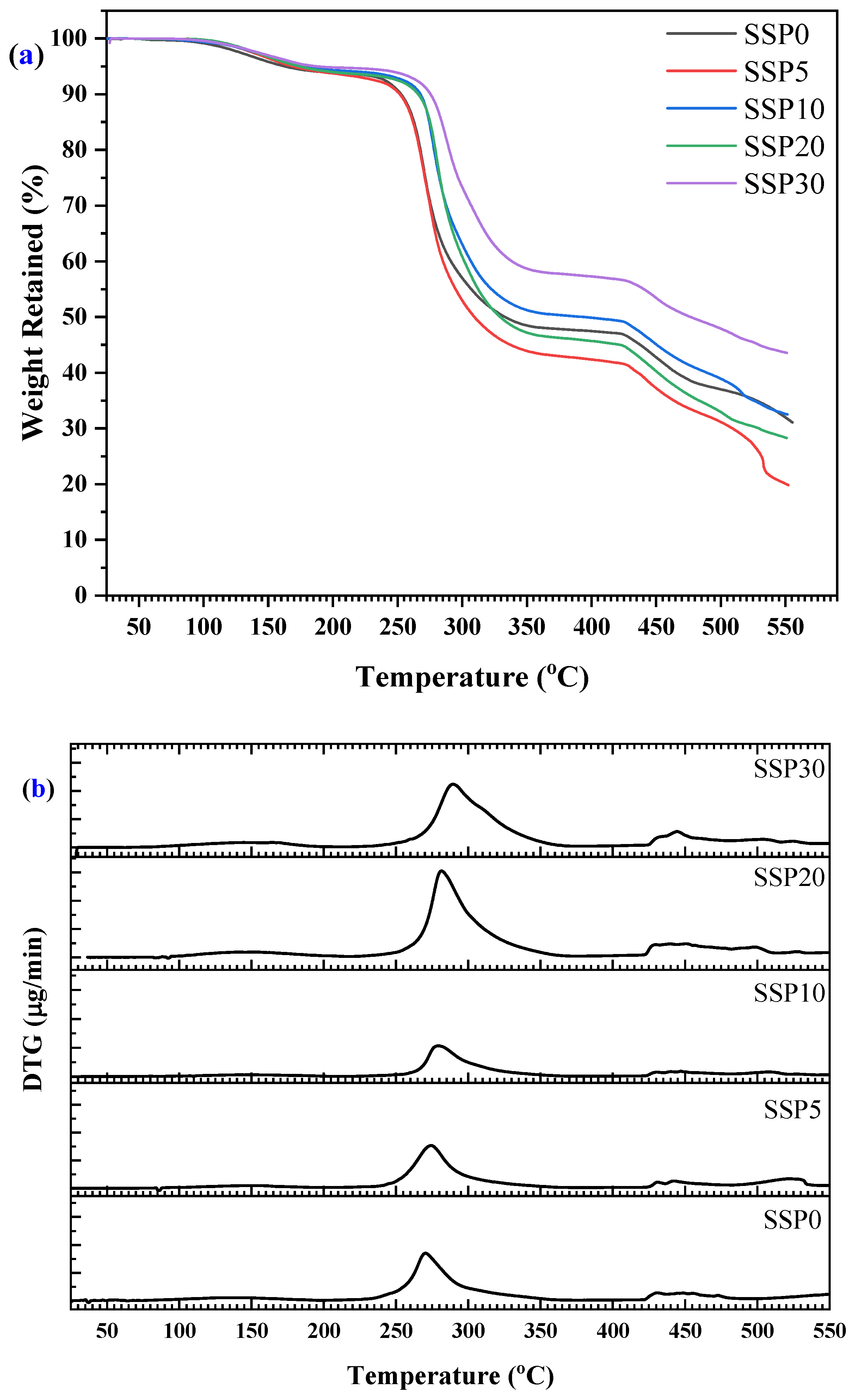

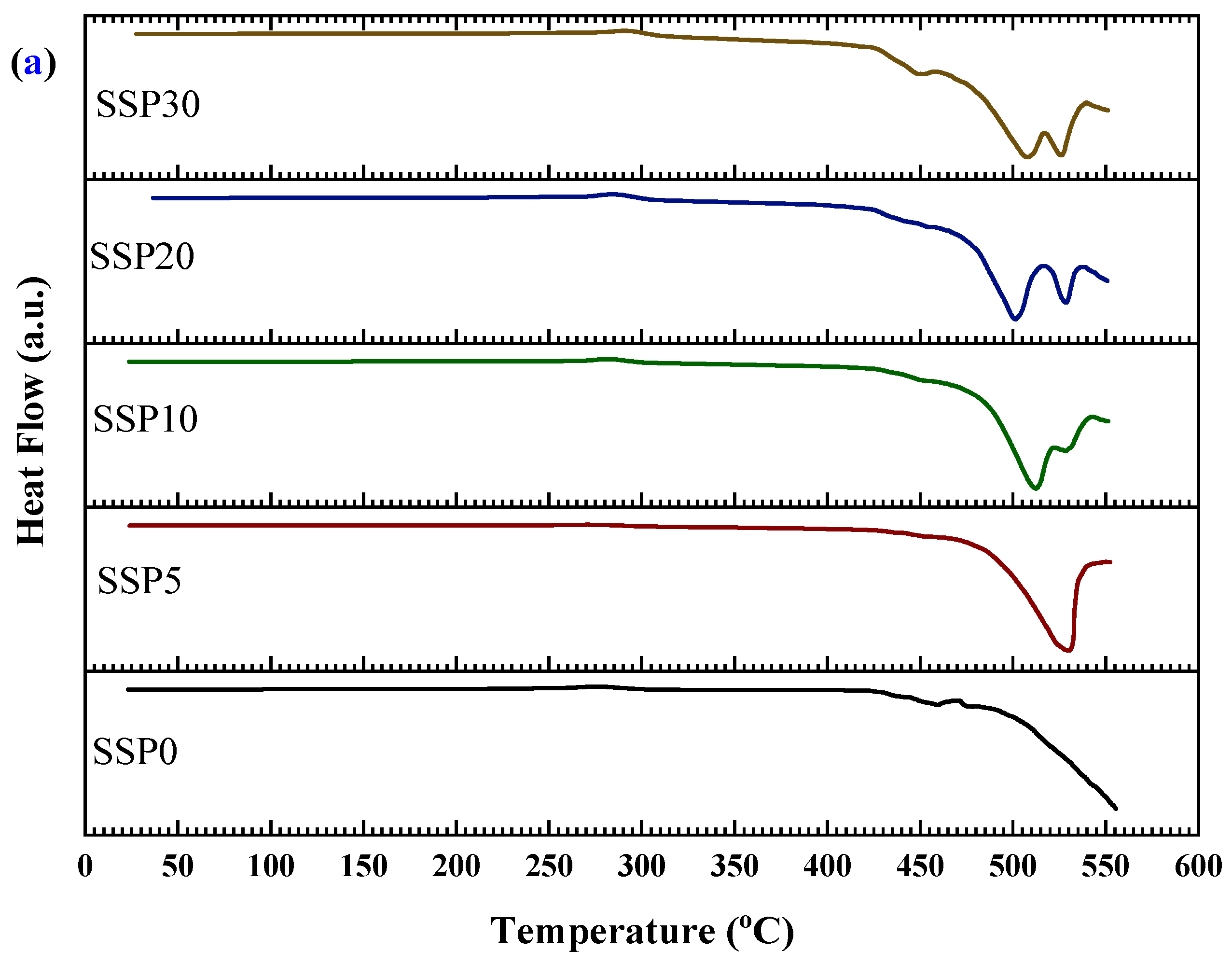

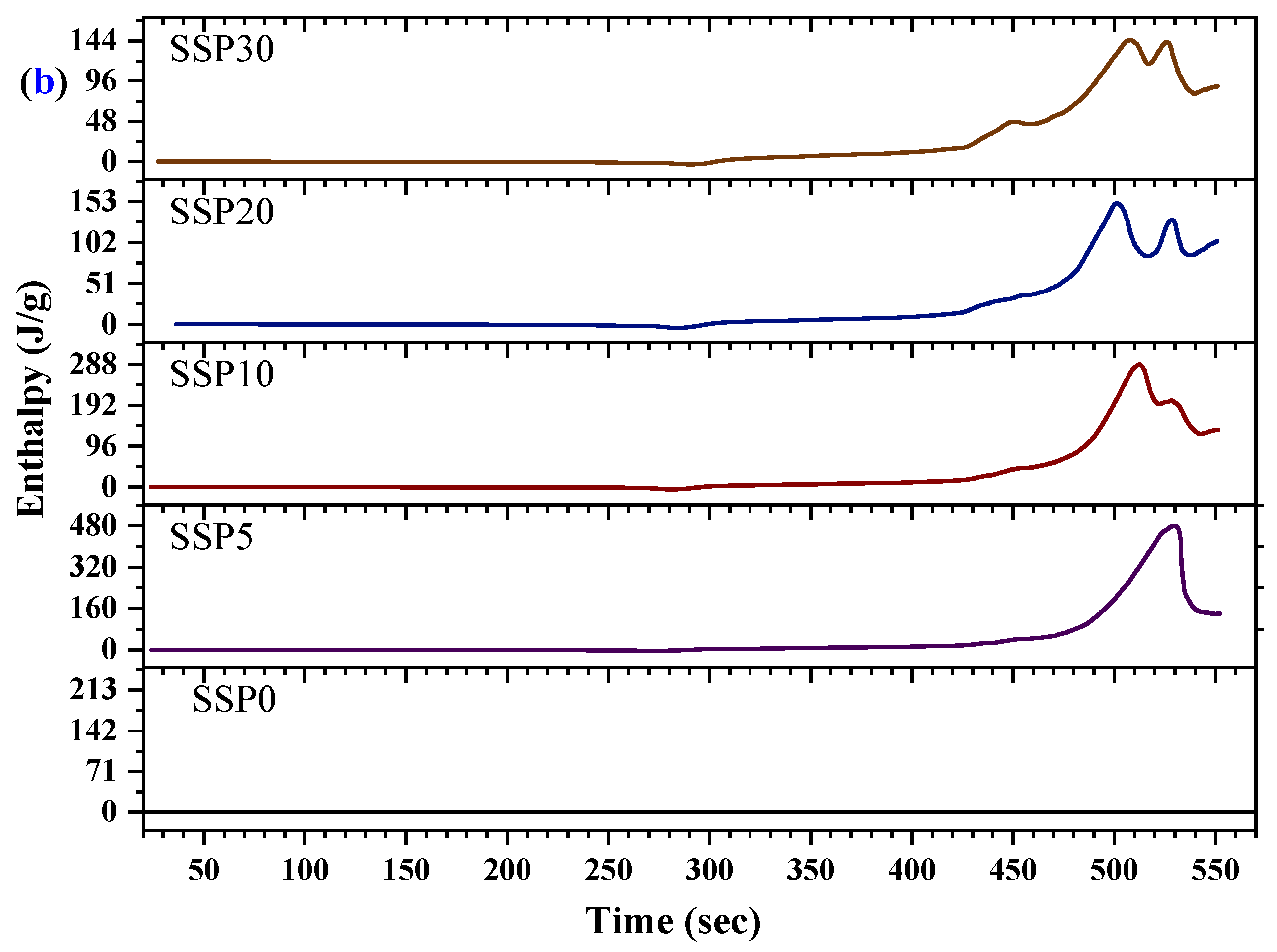

3.2. Thermal Analysis (TGA and DSC)

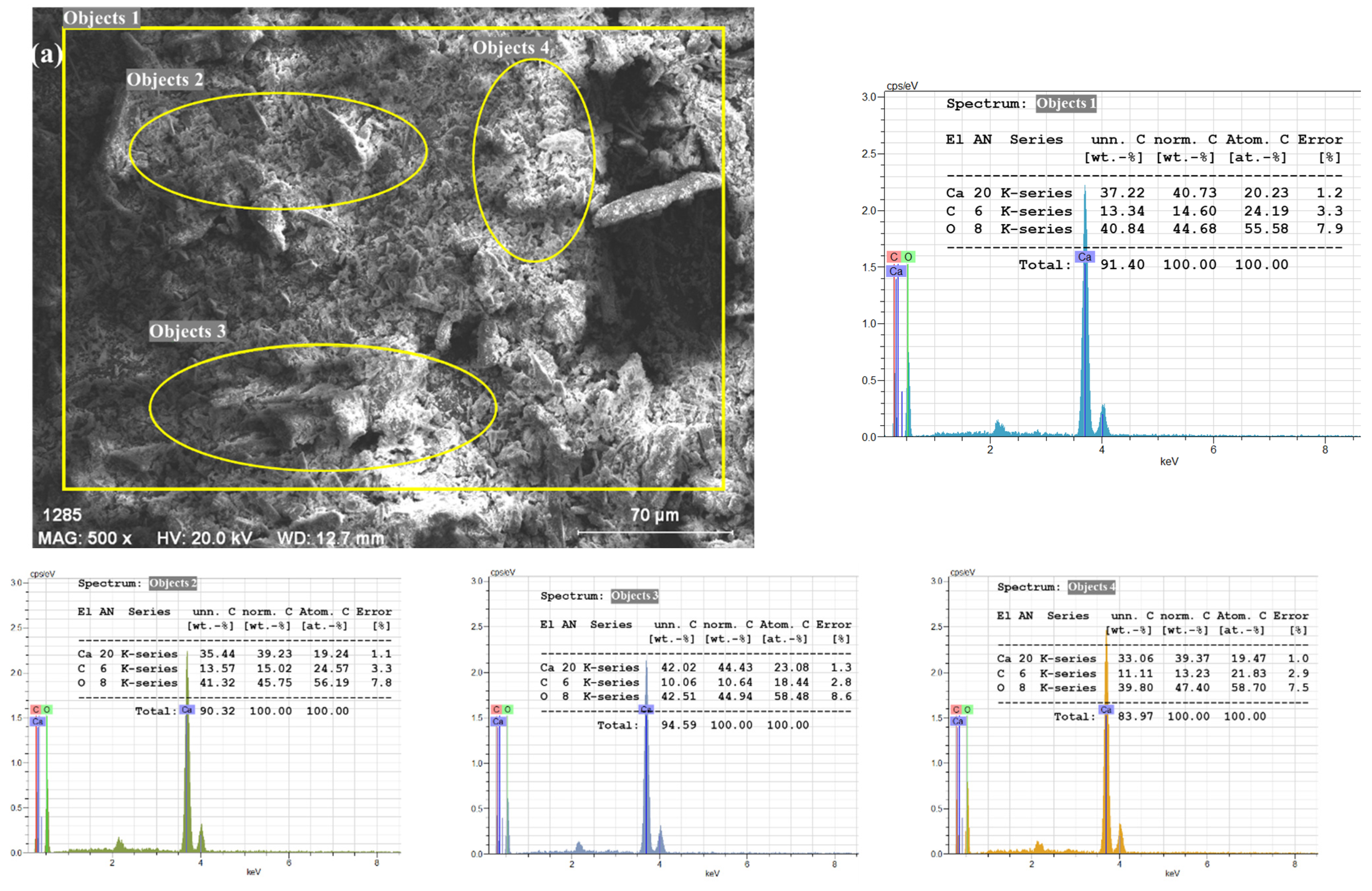

3.3. Surface Morphology

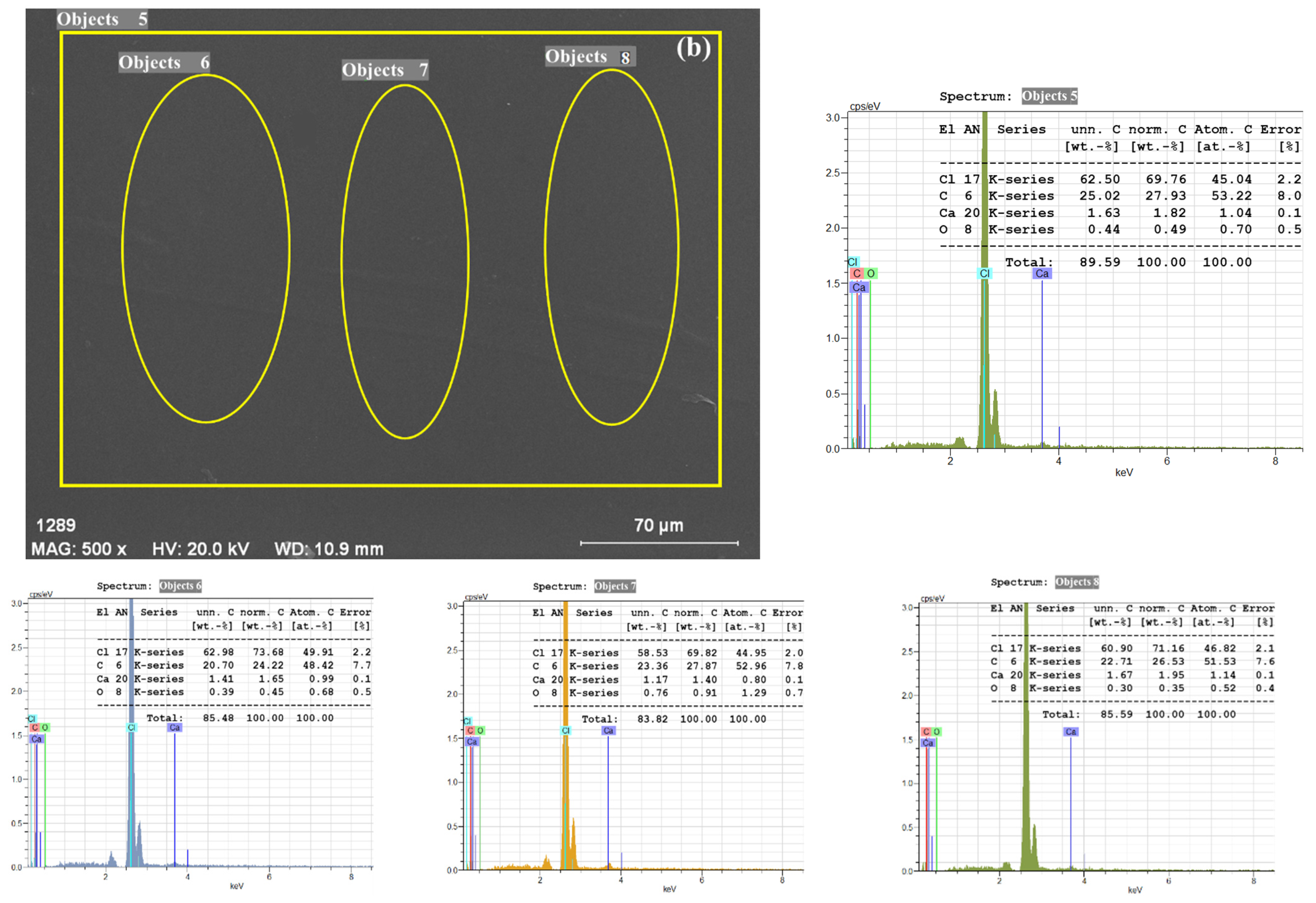

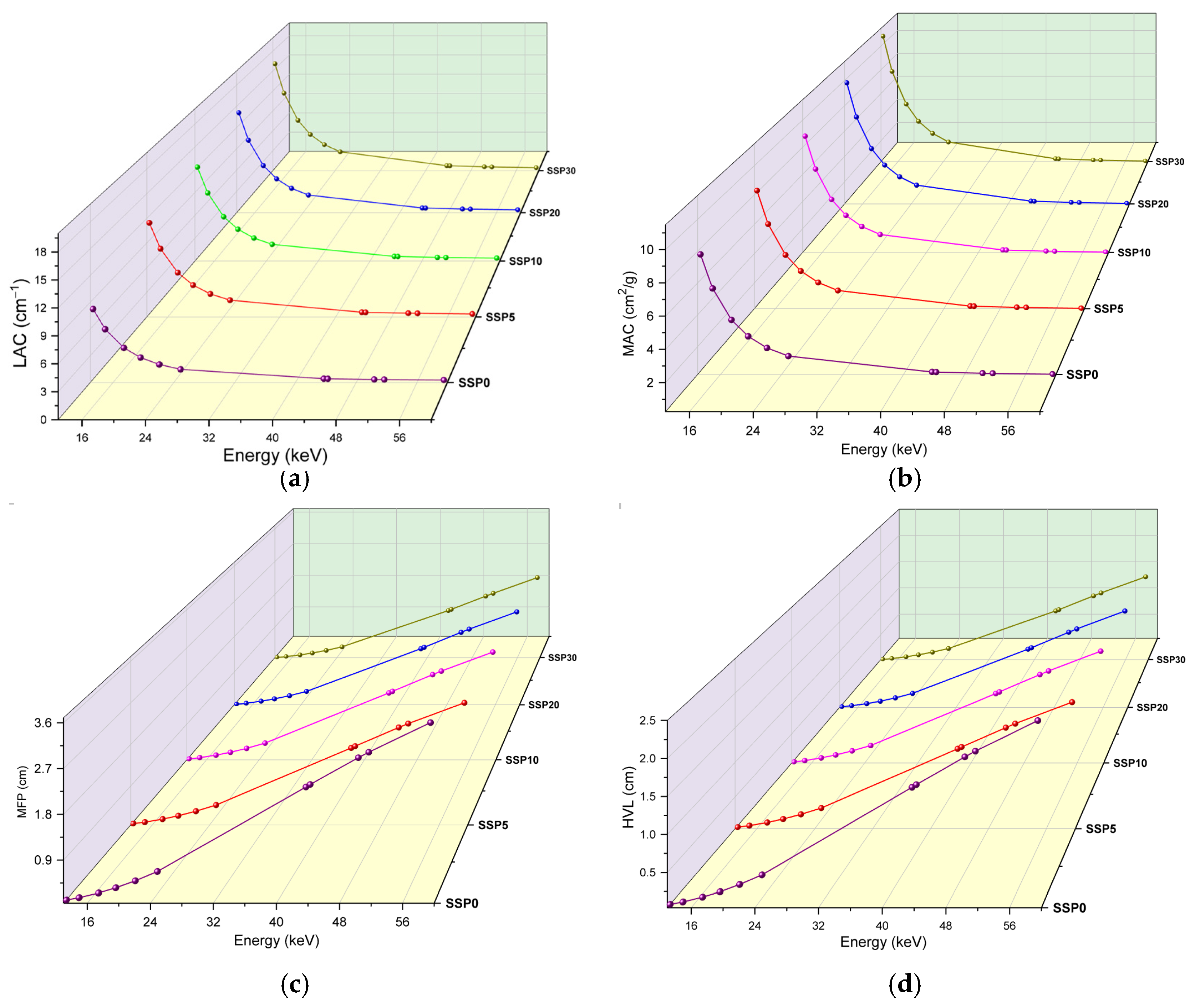

3.4. XRD Analysis

3.5. High Energy Experiments

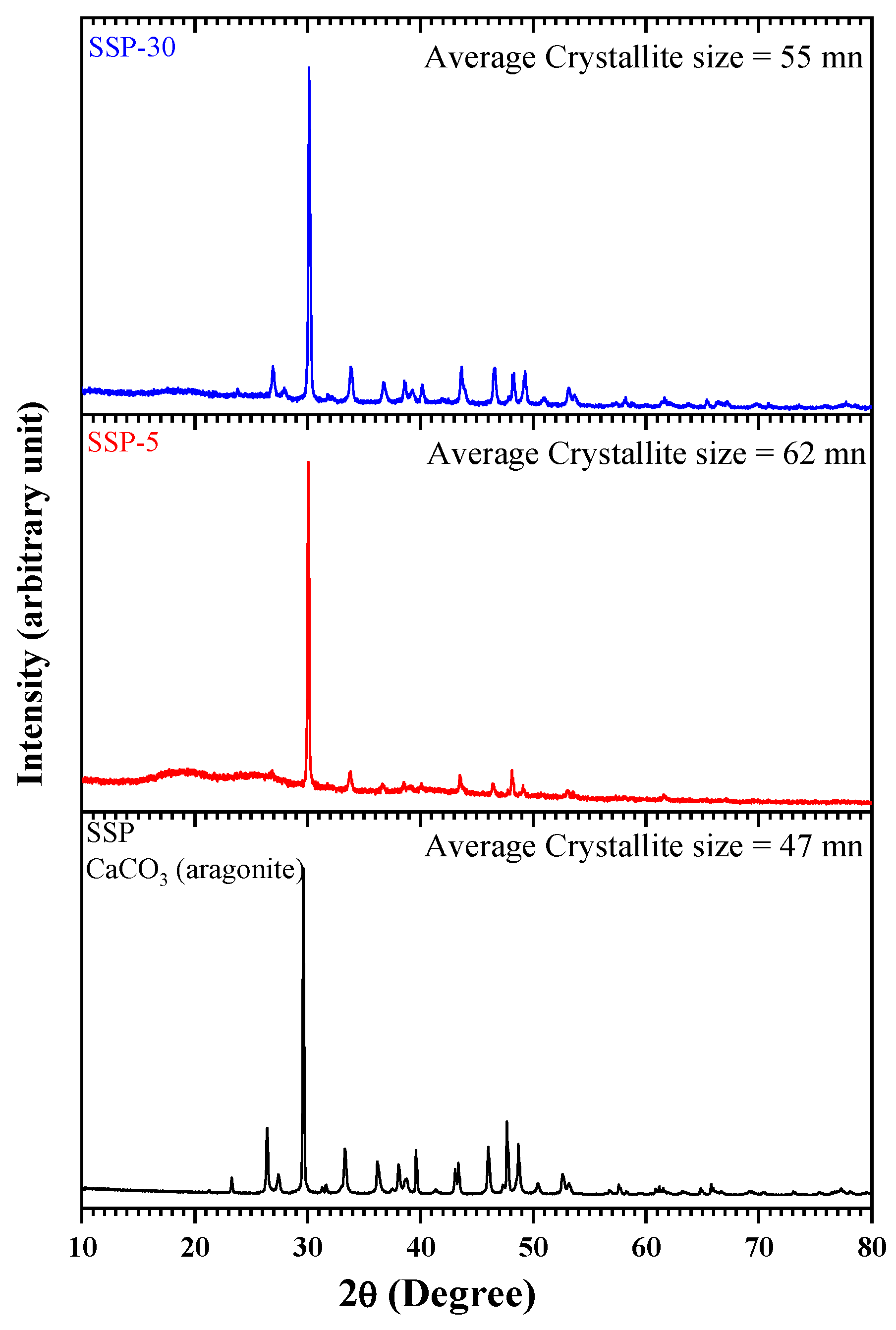

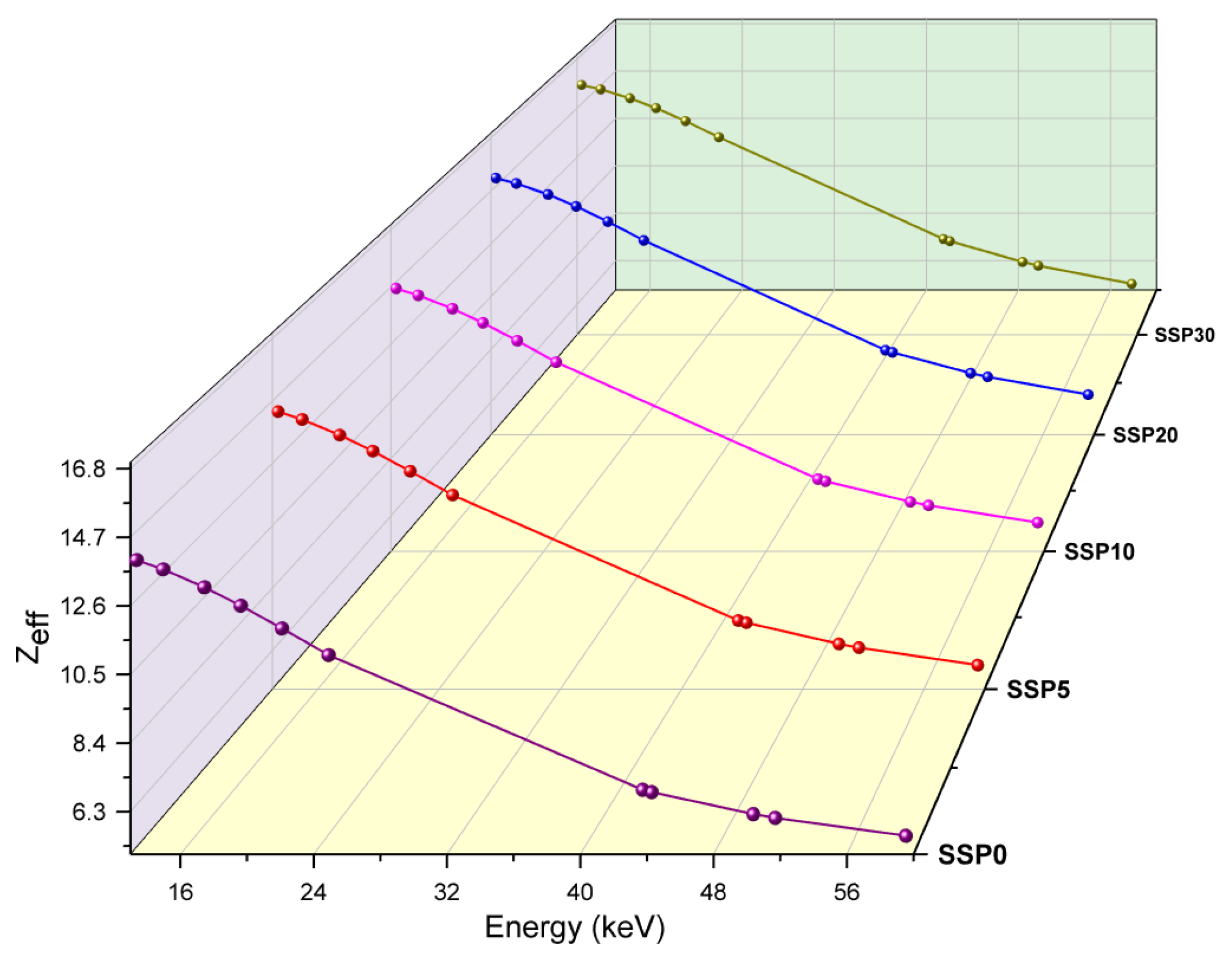

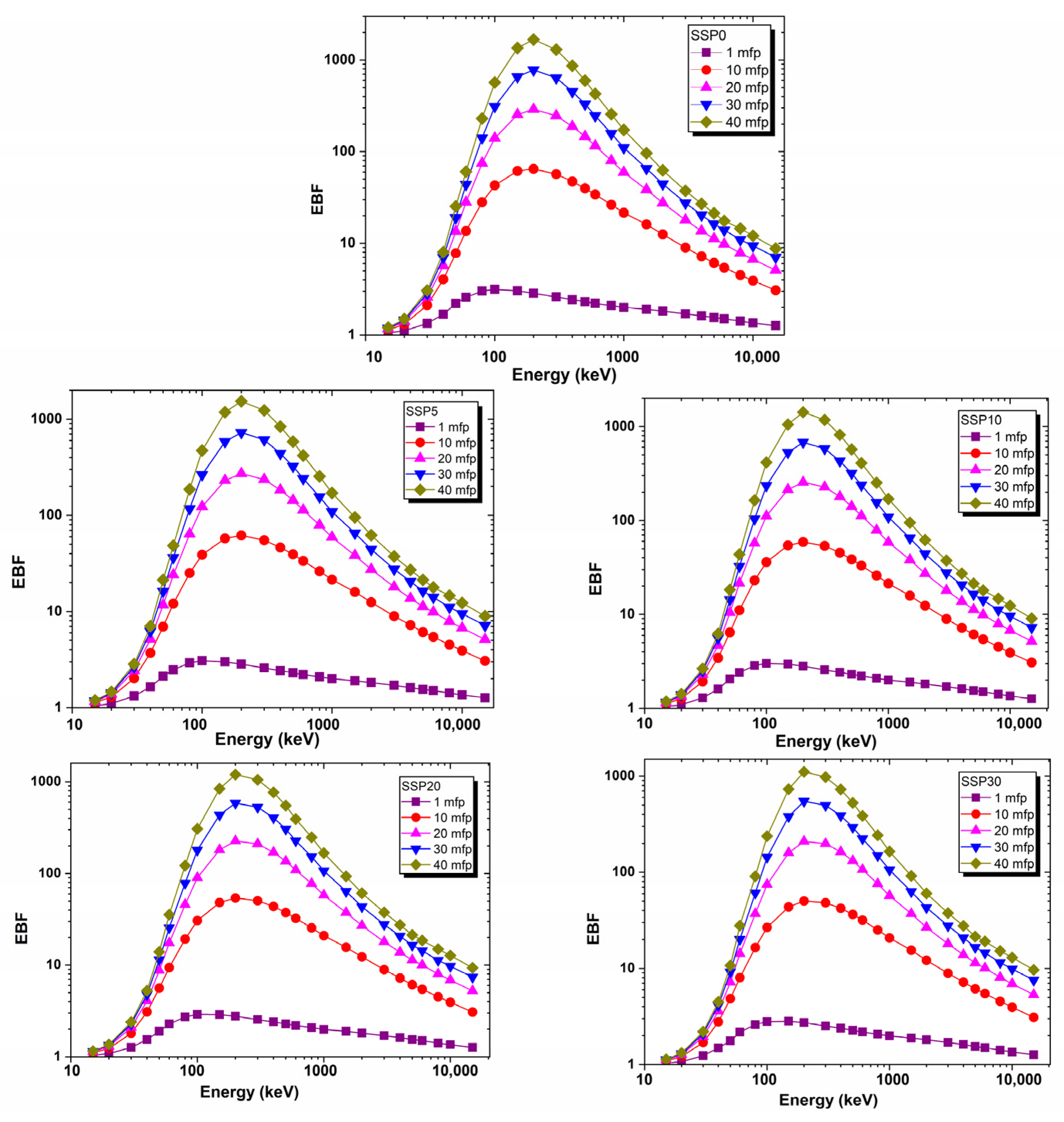

3.5.1. Photon Attenuation

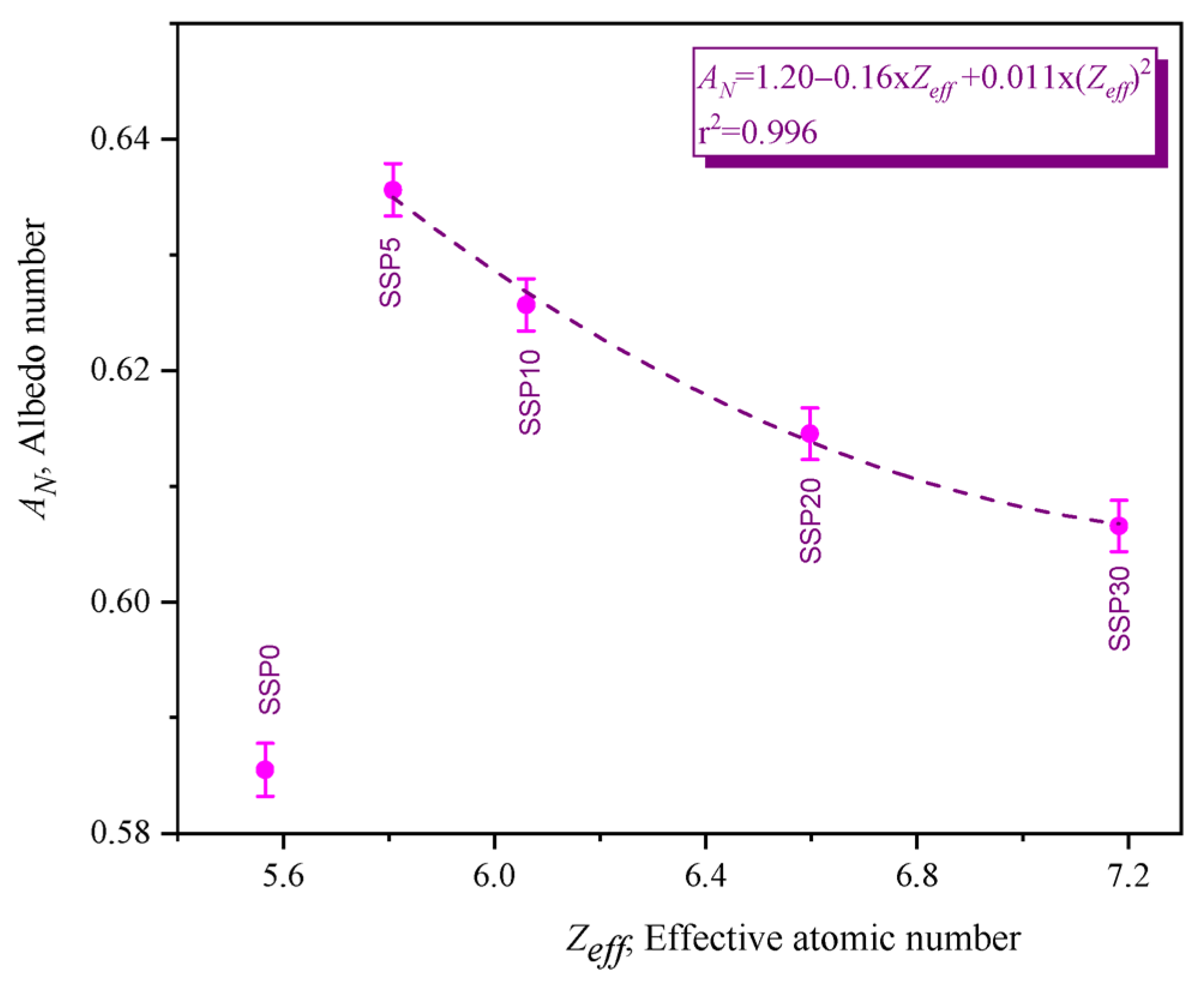

3.5.2. Albedo Number

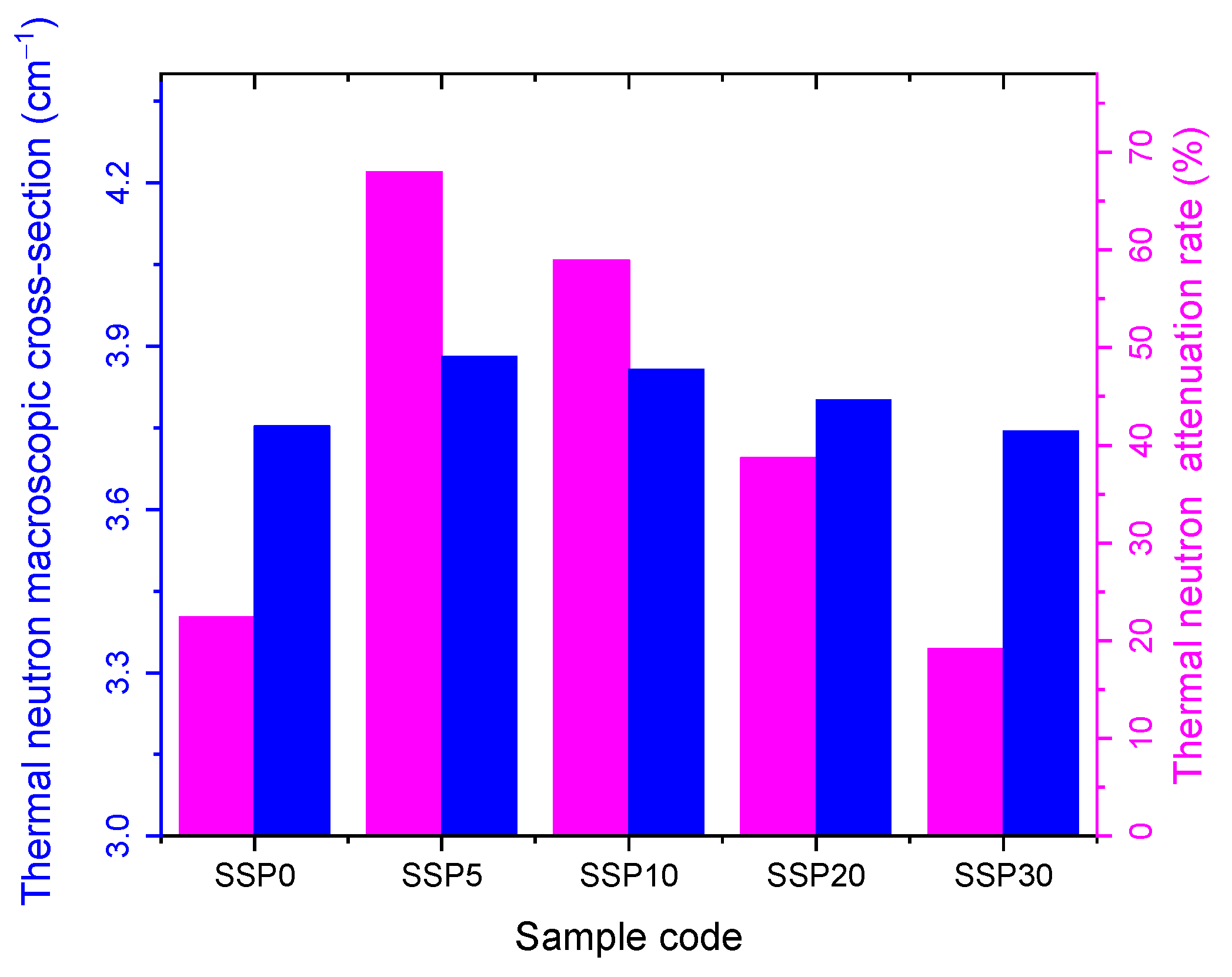

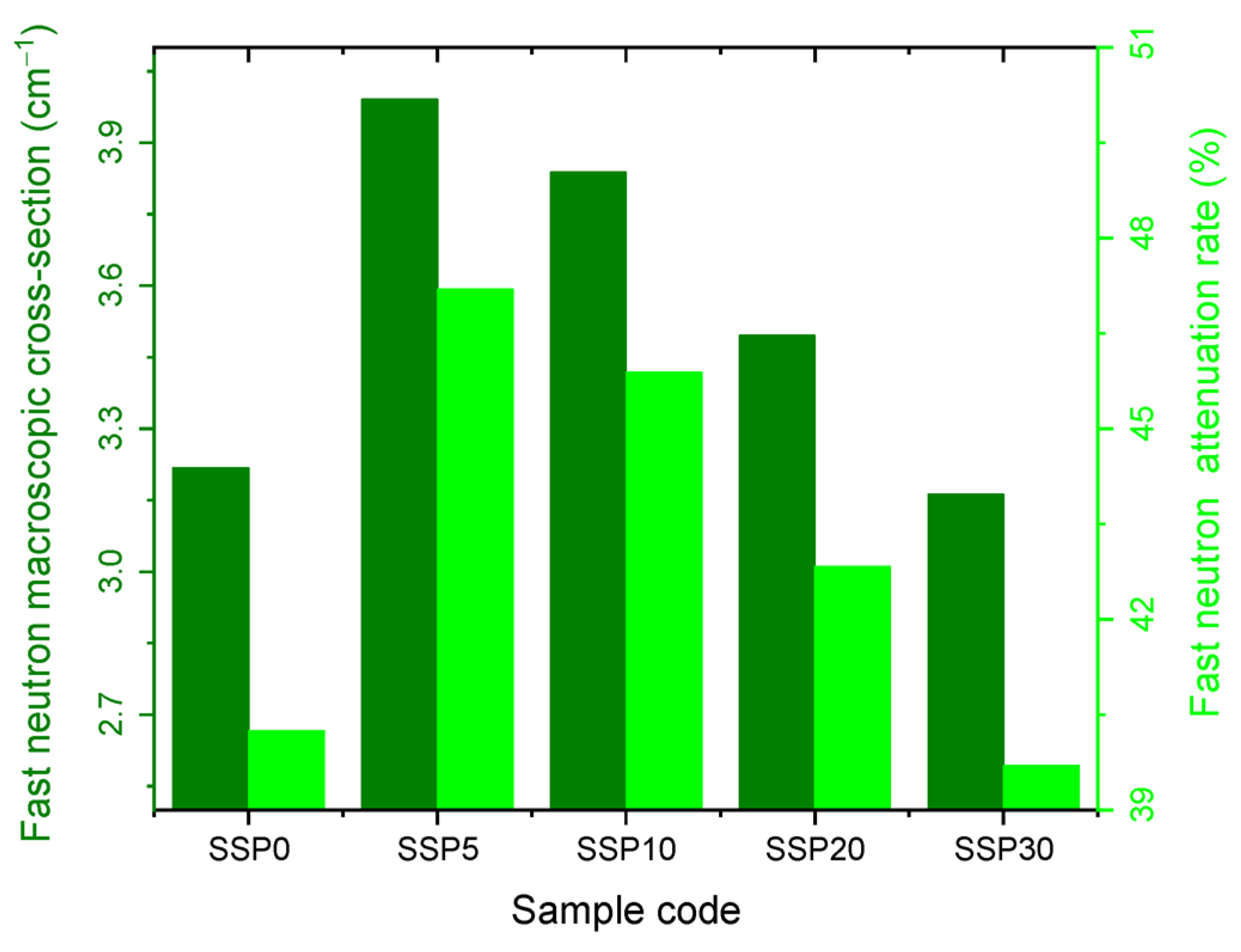

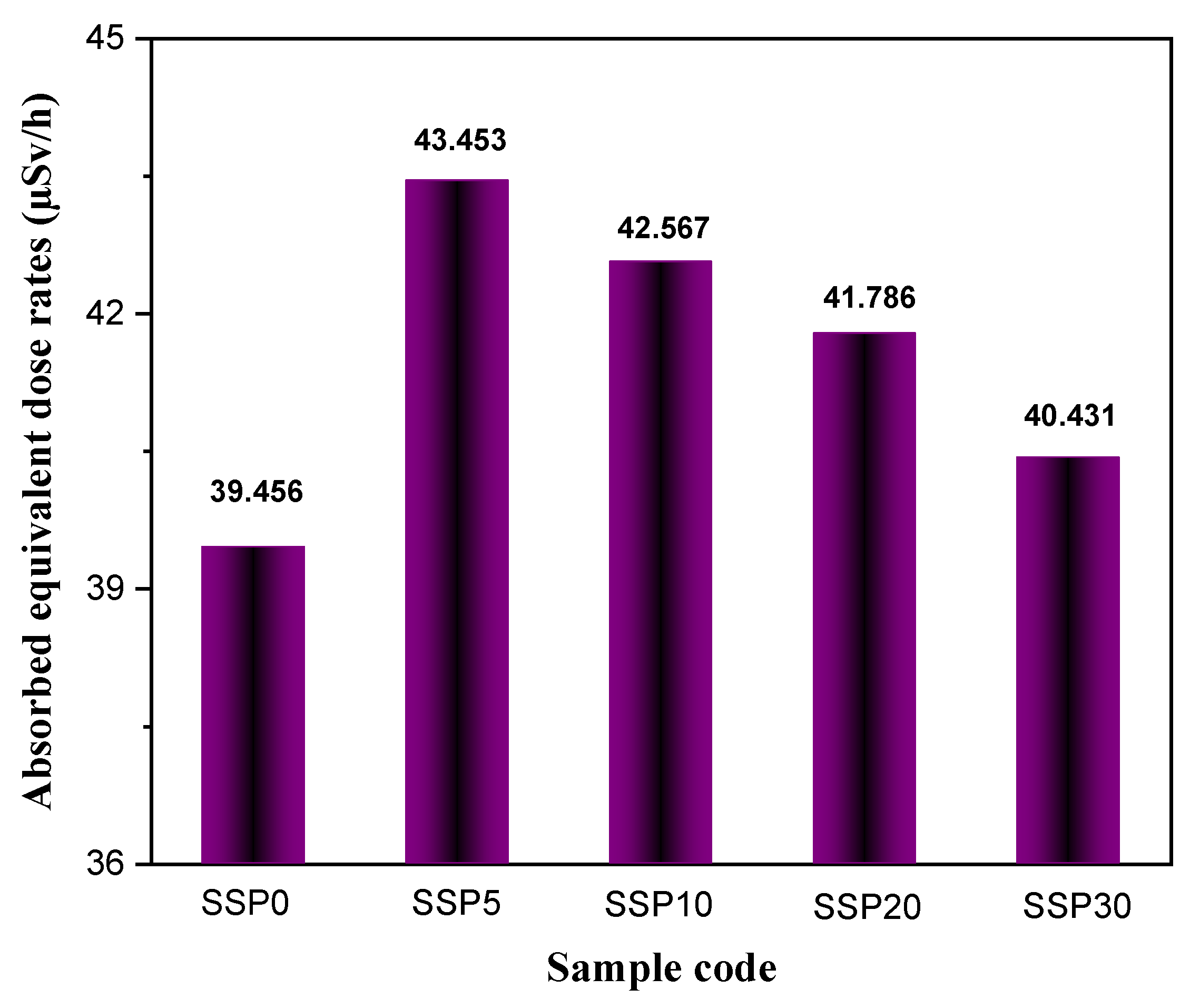

3.5.3. Neutron Attenuation

4. Conclusions

- ❖

- It has been observed that snail shells have higher absorbent than animal bones in the literature.

- ❖

- The radiation shielding and anti-reflective performance of snail shell-based polymer films suggests that powdered snail shells could also be used as additives in concrete-based materials for high-energy photon applications.

- ❖

- C and O elements in the SSP structure affect fast and thermal neutron cross-sections.

- ❖

- It was found that the radiation-shielding behavior followed the following order:

- ❖

- SSP30 > SSP20 > SSP10 > SSP5 for X-rays.

- ❖

- The order of thermal and fast neutron macroscopic cross-section is SSP30 < SSP20 < SSP10 < SSP5.

- ❖

- The neutron absorption equivalent dose rates (μSv/h) of the composite films behavior followed the following order: SSP30 < SSP20 < SSP10 < SSP5.

- ❖

- The film with the highest reflection efficiency is SSP5. The film with the highest anti-reflection is SSP30.

- ❖

- The PVC/PSt/SSP composite films demonstrated significant photon and neutron attenuation capabilities, along with anti-reflective properties, indicating their potential for use in radiation-shielding applications, including those relevant to nuclear or medical environments.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adepitan, O.L.; Alabi, O.O.; Gbadeyan, O.J.; Deenadayalu, N.; Jayeola, A.T. Investigation into the development and utilization of snail shell biomaterials: A systematic review. Discov. Mater. 2025, 5, 47. [Google Scholar] [CrossRef]

- Potortì, A.G.; Messina, L.; Licata, P.; Gugliandolo, E.; Santini, A.; Di Bella, G. Snail Shell Waste Threat to Sustainability and Circular Economy: Novel Application in Food Industries. Sustainability 2024, 16, 706. [Google Scholar] [CrossRef]

- Das, O.; Babu, K.; Shanmugam, V.; Sykam, K.; Tebyetekerwa, M.; Neisiany, R.E.; Försth, M.; Sas, G.; Gonzalez-Libreros, J.; Capezza, A.J. Natural and industrial wastes for sustainable and renewable polymer composites. Renew. Sustain. Energy Rev. 2022, 158, 112054. [Google Scholar] [CrossRef]

- Taşgin, Y.; Pekdemir, M.E.; Yilmaz, M.; Kanca, M.S.; Kök, M. Physical and shielding properties of Er2O3 rare earth oxide compound content on PCL/PEG blend. Polym. Bull. 2024, 81, 2915–2931. [Google Scholar]

- Cyriac, V.; Ismayil; Noor, I.; Mishra, K.; Chavan, C.; Bhajantri, R.F.; Masti, S.P. Ionic conductivity enhancement of PVA: Carboxymethyl cellulose poly-blend electrolyte films through the doping of NaI salt. Cellulose 2022, 29, 3271–3291. [Google Scholar] [CrossRef]

- El Sayed, A.M. Synthesis, optical, thermal, electric properties and impedance spectroscopy studies on P (VC-MMA) of optimized thickness and reinforced with MWCNTs. Results Phys. 2020, 17, 103025. [Google Scholar]

- Abdelrazek, E.M.; Abdelghany, A.M.; Badr, S.I.; Morsi, M.A. Structural, optical, morphological and thermal properties of PEO/PVP blend containing different concentrations of biosynthesized Au nanoparticles. J. Mater. Res. Technol. 2018, 7, 419–431. [Google Scholar] [CrossRef]

- Alshammari, A.H.; Alshammari, M.; Ibrahim, M.; Alshammari, K.; Taha, T.A.M. Processing polymer film nanocomposites of polyvinyl chloride–Polyvinylpyrrolidone and MoO3 for optoelectronic applications. Opt. Laser Technol. 2024, 168, 109833. [Google Scholar] [CrossRef]

- Nasrallah, D.; Morsi, M.; El-Sayed, F.; Metwally, R. Structural, optical and electrical properties of copper chloride filled polyvinyl chloride/polystyrene blend and its antifungal properties against Aspergillus avenaceus and Aspergillus terreus. Compos. Commun. 2020, 22, 100451. [Google Scholar] [CrossRef]

- Hu, S.; Fu, Z.; Chen, Y.; Zhou, C.; Fei, Z. One-Step Fabrication of PVDF/BTMSPA Composite Membranes for Enhanced n-Butanol/Water Separation. J. Environ. Chem. Eng. 2025, 13, 117251. [Google Scholar] [CrossRef]

- Sheng, M.; Wu, L.; Li, X.; Yan, H.; Lu, X.; Xu, Y.; Li, Y.; Tong, Y.; Qu, J. Preparation and characterization of super-toughened poly (lactic acid)/cross-linked polyurethane blends via one-step dynamic vulcanization. Eng. Sci. 2021, 19, 89–99. [Google Scholar]

- Alkallas, F.H.; Al-Ahmadi, A.N.; Salem, A.; Mwafy, E.A.; Elsharkawy, W.B.; Trabelsi, A.B.G.; Motawea, M.M.; Alshammary, A.J.; Nafee, S.S.; Mostafa, A.M. Influence of Al2O3 nanoparticles on the structural, optical, and electrical properties of PVC/PS nanocomposite for use in optoelectronic devices. Surf. Interfaces 2024, 51, 104651. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kuzmin, A.M.; Masri, T.; Yagoub, M.; Sedira, L.; Pantyukhov, P.; Mausam, K.; Palanisamy, S.; Ma, Q.; Al-Farraj, S.A. Effects of Reinforcement by Both Waste Glass and Barley Straw on Water Resistance, Mechanical, and Thermal Properties of Polyethylene Composite. BioResources 2025, 20, 5967–5987. [Google Scholar] [CrossRef]

- Wang, Y.; Niu, Z.; Han, H.; Wang, J.; Lan, D. Observation of structural, mechanical, thermal and microwave dielectric properties of carbon black reinforced PA6/HDPE nanocomposites. J. Mater. Sci. Mater. Electron. 2023, 34, 1948. [Google Scholar] [CrossRef]

- Piras, S.; Salathia, S.; Guzzini, A.; Zovi, A.; Jackson, S.; Smirnov, A.; Fragassa, C.; Santulli, C. Biomimetic Use of Food-Waste Sources of Calcium Carbonate and Phosphate for Sustainable Materials—A Review. Materials 2024, 17, 843. [Google Scholar] [CrossRef]

- Su, L.; Wu, S.; Fu, G.; Zhu, W.; Zhang, X.; Liang, B. Creep characterisation and microstructural analysis of municipal solid waste incineration fly ash geopolymer backfill. Sci. Rep. 2024, 14, 29828. [Google Scholar] [CrossRef]

- Oladele, I.O.; Betiku, O.T.; Akinseye, J.G.; Makinde-Isola, B.A. Effect of sisal fiber-snail shell hybrid reinforcement on some mechanical properties and moisture uptake of unsaturated polyester resin based composites. Nano Hybrids Compos. 2020, 30, 87–99. [Google Scholar] [CrossRef]

- Syamimi, N.F.; Islam, M.R.; Sumdani, M.G.; Rashidi, N.M. Mechanical and thermal properties of snail shell particles-reinforced bisphenol-A bio-composites. Polym. Bull. 2020, 77, 2573–2589. [Google Scholar] [CrossRef]

- Oladele, I.O.; Linus, O.; Samuel, T.A.; Sunday, B.; Itua, A.N.; Lephuthing, S.S. Mechanical, wear and thermal conductivity characteristics of snail shell-derived hydroxyapatite reinforced epoxy bio-composites for adhesive biomaterials applications. Int. J. Sustain. Eng. 2022, 15, 122–135. [Google Scholar] [CrossRef]

- Gbadeyan, O.J.; Adali, S.; Bright, G.; Sithole, B.; Awogbemi, O. Studies on the mechanical and absorption properties of achatina fulica snail and eggshells reinforced composite materials. Compos. Struct. 2020, 239, 112043. [Google Scholar] [CrossRef]

- Udoye, N.E.; Ezike, G.E.; Fayomi, O.S.I.; Dirisu, J.O. The Study on Mechanical and Electrical Properties of AA6061/Snail Shell Composites. Int. J. Chem. Eng. 2022, 2022, 9711761. [Google Scholar] [CrossRef]

- Karaoui, M.; Hsissou, R.; Alami, M.; Assouag, M. Thermal, flow, and mechanical properties of composites based on polystyrene (PS) and snail shell powder (SSP) biofiller (PS/SSP). Iran. Polym. J. 2023, 32, 621–631. [Google Scholar] [CrossRef]

- Kıstak, C.; Yanen, C.; Aydoğmuş, E. Advanced Sustainable Epoxy Composites from Biogenic Fillers: Mechanical and Thermal Characterization of Seashell-Reinforced Composites. Appl. Sci. 2025, 15, 8498. [Google Scholar] [CrossRef]

- Adeyanju, B.; Adewuyi, B.; Oladele, I.; Daramola, O.; Ajayi, M.A. Properties Evaluation of Snail Shell Nanoparticle Reinforced Epoxy Composites. Res. Sq. 2025. [Google Scholar] [CrossRef]

- Rabiei, N.; Gholamzadeh, L.; Aminian, M.K.; Sharghi, H. Flexible and lead-free polymer composites for X-ray shielding: Comparison of polyvinyl chloride matrix filled with nanoparticles of tungsten oxides. Radiat. Environ. Biophys. 2025, 64, 151–161. [Google Scholar] [CrossRef] [PubMed]

- Alanazi, S.F.; Alotaibi, N.M.; Alsuhybani, M.; Alnassar, N.; Almasoud, F.I.; Almurayshid, M. Fabrication, Structural Characterization, and Photon Attenuation Efficiency Investigation of Polymer-Based Composites. Polymers 2024, 16, 1212. [Google Scholar] [CrossRef]

- Yılmaz, D.; Uzunoğlu, Z. Exploration of the Dependence of Scattering Intensity Ratios on Albedo parameters. Radiat. Phys. Chem. 2025, 236, 112945. [Google Scholar] [CrossRef]

- Hila, F.C.; Asuncion-Astronomo, A.; Dingle, C.A.M.; Jecong, J.F.M.; Javier-Hila, A.M.V.; Gili, M.B.Z.; Balderas, C.V.; Lopez, G.E.P.; Guillermo, N.R.D.; Amorsolo, A.V., Jr. EpiXS: A Windows-based program for photon attenuation, dosimetry and shielding based on EPICS2017 (ENDF/B-VIII) and EPDL97 (ENDF/B-VI. 8). Radiat. Phys. Chem. 2021, 182, 109331. [Google Scholar] [CrossRef]

- Şakar, E.; Özpolat, Ö.F.; Alım, B.; Sayyed, M.; Kurudirek, M. Phy-X/PSD: Development of a user friendly online software for calculation of parameters relevant to radiation shielding and dosimetry. Radiat. Phys. Chem. 2020, 166, 108496. [Google Scholar] [CrossRef]

- Gökçe, H.; Güngör, O.; Yılmaz, H. An online software to simulate the shielding properties of materials for neutrons and photons: NGCal. Radiat. Phys. Chem. 2021, 185, 109519. [Google Scholar] [CrossRef]

- Pekdemir, M.E. Synthesis, characterization and thermal behavior of carbon fiber reinforced poly (vinyl chloride) and poly (ε-Caprolactone). Fibers Polym. 2021, 22, 2861–2868. [Google Scholar] [CrossRef]

- Pekdemir, M.E. Thermal properties and shape memory behavior of titanium carbide reinforced poly (vinyl chloride)/poly (ԑ-caprolactone) blend nanocomposites. Polym.-Plast. Technol. Mater. 2022, 61, 242–250. [Google Scholar] [CrossRef]

- Althobiti, R.A.; Morsi, M.; Alzahrani, E.; Al-Muntaser, A. Reinforcement of the optical, electrical and dielectric properties of PVC/PS/PMMA ternary blend by the sol-gel derived nano-sized TiO2 for high-performance optoelectronic and energy storage applications. J. Energy Storage 2024, 92, 112192. [Google Scholar] [CrossRef]

- Aquino, K.A.d.S.; da Silva, F.F.; Araujo, E.S. Investigation of poly (vinyl chloride)/polystyrene mixture miscibility: Comparison of viscometry criteria with fourier transform infrared spectroscopy and refractive index measurements. J. Appl. Polym. Sci. 2011, 119, 2770–2777. [Google Scholar] [CrossRef]

- Zuliantoni, Z.; Suprapto, W.; Setyarini, P.H.; Gapsari, F. Extraction and characterization of snail shell waste hydroxyapatite. Results Eng. 2022, 14, 100390. [Google Scholar] [CrossRef]

- Karaoui, M.; Hsissou, R.; Alami, M.; Assouag, M. Physico-chemical characterization of snail shells powder prepared by mechanochemical processes and thermal treatment. J. Met. Mater. Miner. 2023, 33, 139–147. [Google Scholar] [CrossRef]

- Ouafi, R.; Ibrahim, A.; Mehdaoui, I.; Asri, M.; Taleb, M.; Rais, Z. Spectroscopic analysis of chemical compounds derived from the calcination of snail shells waste at different temperatures. Chem. Afr. 2021, 4, 923–933. [Google Scholar] [CrossRef]

- Nait Larbi, S.; Moudoud, M.; Hedir, A.; Lamrous, O.; Durmus, A.; Clark, D.; Slimani, F. Characterization of PVC/CaCO3 Nanocomposites Aged Under the Combined Effects of Temperature and UV-Radiation. Materials 2025, 18, 4001. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Kang, S.B.; Yang, E.; Won, S.W. Preparation of adsorptive polyethyleneimine/polyvinyl chloride electrospun nanofiber membrane: Characterization and application. J. Environ. Manag. 2022, 316, 115155. [Google Scholar] [CrossRef] [PubMed]

- Sneddon, G.; McGlynn, J.C.; Neumann, M.S.; Aydin, H.M.; Yiu, H.H.P.; Ganin, A.Y. Aminated poly(vinyl chloride) solid state adsorbents with hydrophobic function for post-combustion CO2 capture. J. Mater. Chem. A 2017, 5, 11864–11872. [Google Scholar] [CrossRef]

- Cruz, P.P.R.; da Silva, L.C.; Fiuza, R.A., Jr.; Polli, H. Thermal dehydrochlorination of pure PVC polymer: Part I—Thermal degradation kinetics by thermogravimetric analysis. J. Appl. Polym. Sci. 2021, 138, 50598. [Google Scholar] [CrossRef]

- Sánchez-Jiménez, P.E.; Perejón, A.; Criado, J.M.; Diánez, M.J.; Pérez-Maqueda, L.A. Kinetic model for thermal dehydrochlorination of poly(vinyl chloride). Polymer 2010, 51, 3998–4007. [Google Scholar] [CrossRef]

- Hachani, S.E.; Necira, Z.; Nebbache, N.; Meghezzi, A.; Ozkoc, G. Effects of magnesia incorporation on properties of polystyrene/magnesia composites. Acta Chim. Slov. 2018, 65, 646–651. [Google Scholar] [CrossRef]

- Puspitasari, P.; Fauzi, A.F.; Susanto, H.; Permanasari, A.A.; Gayatri, R.W.; Razak, J.A.; Abdillah Pratama, M.M. Phase identification and morphology of CaCO3/CaO from Achatina Fulica snail shell as the base material for Hydroxyapatite. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1034, 012128. [Google Scholar] [CrossRef]

- Kolawole, M.Y.; Aweda, J.O.; Abdulkareem, S. Archachatina marginata bio-shells as reinforcement material in metal matrix composites. Int. J. Automot. Mech. Eng. 2022, 14, 4068–4079. [Google Scholar] [CrossRef]

- Parveen, S.; Chakraborty, A.; Chanda, D.K.; Pramanik, S.; Barik, A.; Aditya, G. Microstructure Analysis and Chemical and Mechanical Characterization of the Shells of Three Freshwater Snails. ACS Omega 2020, 5, 25757–25771. [Google Scholar] [CrossRef]

- Savrık, S.A.; Balköse, D.; Ulutan, S.; Ülkü, S. Characterization of poly(vinyl chloride) powder produced by emulsion polymerization. J. Therm. Anal. Calorim. 2010, 101, 801–806. [Google Scholar] [CrossRef]

- Milano, S.; Nehrke, G. Microstructures in relation to temperature-induced aragonite-to-calcite transformation in the marine gastropod Phorcus turbinatus. PLoS ONE 2018, 13, e0204577. [Google Scholar] [CrossRef]

- Korach, C.S.; Pai, R.K. Mechanical Properties of a Nanostructured Poly (KAMPS)/aragonite Composite. In Proceedings of the Mechanics of Biological Systems and Materials, Volume 2: Proceedings of the 2011 Annual Conference on Experimental and Applied Mechanics; Springer: Berlin/Heidelberg, Germany, 2011; pp. 131–136. [Google Scholar]

- Köksal, O.K.; Cengiz, E.; Tozar, A.; Karahan, İ.H.; Apaydın, G. A comprehensive research on gamma-ray attenuation characteristics of the metal-doped hap and natural animal bone. Gümüşhane Üniversitesi Fen Bilim. Derg. 2020, 10, 51–59. [Google Scholar] [CrossRef]

| Sample Codes | PVC | PSt | SSP | Density (g/cm3) |

|---|---|---|---|---|

| SSP0 | 0.375 | 0.625 | 0 | 1.058 |

| SSP5 | 0.353 | 0.588 | 0.059 | 1.381 |

| SSP10 | 0.331 | 0.551 | 0.118 | 1.402 |

| SSP20 | 0.288 | 0.481 | 0.231 | 1.436 |

| SSP30 | 0.248 | 0.413 | 0.340 | 1.485 |

| Target Selected | Energy (keV) | |

|---|---|---|

| Kα | Kβ | |

| Rb | 13.37 | 14.97 |

| Mo | 17.44 | 19.63 |

| Ag | 22.10 | 24.99 |

| Tb | 43.74 (Kα2) and 44.48 (Kα1) | 50.38 (Kβ1) and 51.71 (Kβ2) |

| Parameters | Equations | Descriptions |

|---|---|---|

| Linear attenuation coefficients, (LAC, cm2/g) 1 | and are the intensities of the incident photons and those passing through the absorber, respectively. | |

| Mass attenuation coefficients, (MAC, cm2/g) 1 | is the density and is thickness. | |

| Mean free path, (MFP, cm) 1 | is the linear attenuation coefficient (1/cm). | |

| Half value thickness, (HVL, cm) 1 | is the linear attenuation coefficient (1/cm). | |

| Effective atomic number 1 | The total electronic cross-section is and the total atomic cross section is | |

| Albedo number 2 | dΩ is the solid angle, and are the areas of Compton and coherent scattered peaks. The photo-peak efficiencies are and in Compton (48.87 keV) and coherent (59.54 keV) scattered energies. | |

| Build-up factor 1 | is build up factor. | |

| Fast neutron removal cross-section 3 | Fast neutron removal cross-section of the ith element is denoted by , while represents its partial density. | |

| Fast neutron macroscopic cross-section 4 | and are incident and transmitted intensities for fast neutrons, respectively, within the energy range of 0.8–11 MeV and is absorber thickness. | |

| Thermal neutron cross-section 4 | is the probability of thermal neutrons (25.4 meV) being retained in a unit length of matter. | |

| Mean free path (neutron) | MFP is the part traveled by a neutron between two collisions. | |

| Half value thickness (neutron) | HVL is the thickness of the material that reduces incoming neutron radiation by half. | |

| The absorbed equivalent dose percentage/Neutron attenuation rate | and are the intensities of incident neutrons and those passing through the absorber, respectively. |

| Energy (keV) | SSP0 | SSP5 | SSP10 | SSP20 | SSP30 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Theo. | Exp. | Theo. | Exp. | Theo. | Exp. | Theo. | Exp. | Theo. | Exp. | |

| 13.37 | 7.7908 | 8.1850 ± 0.3942 | 8.2974 | 8.1189 ± 0.1785 | 8.8040 | 8.6028 ± 0.2012 | 9.8172 | 10.1733 ± 0.3560 | 10.8305 | 11.3561 ± 0.6064 |

| 14.97 | 5.6489 | 5.8837 ± 0.2347 | 6.0169 | 6.3116 ± 0.2947 | 6.3849 | 6.1636 ± 0.2213 | 7.1209 | 7.3942 ± 0.2733 | 7.8569 | 8.1247 ± 0.4339 |

| 17.44 | 3.6727 | 3.7939 ± 0.1212 | 3.9104 | 4.1309 ± 0.2205 | 4.1480 | 4.3836 ± 0.2356 | 4.6234 | 4.8914 ± 0.2680 | 5.0988 | 5.3678 ± 0.2866 |

| 19.63 | 2.6430 | 2.7619 ± 0.1189 | 2.8120 | 2.8696 ± 0.0576 | 2.9809 | 3.1447 ± 0.1637 | 3.3189 | 3.4469 ± 0.1280 | 3.6569 | 3.8679 ± 0.2065 |

| 22.10 | 1.9137 | 1.8661 ± 0.0477 | 2.0334 | 2.1123 ± 0.0789 | 2.1530 | 2.0516 ± 0.1014 | 2.3923 | 2.3139 ± 0.0784 | 2.6316 | 2.7568 ± 0.1472 |

| 24.90 | 1.3979 | 1.3606 ± 0.0373 | 1.4822 | 1.5371 ± 0.0549 | 1.5665 | 1.5244 ± 0.0421 | 1.7350 | 1.6902 ± 0.0448 | 1.9036 | 1.9979 ± 0.1067 |

| 43.74 | 0.4043 | 0.4242 ± 0.0199 | 0.4199 | 0.3961 ± 0.0238 | 0.4355 | 0.4152 ± 0.0204 | 0.4667 | 0.4432 ± 0.0236 | 0.4980 | 0.5157 ± 0.0275 |

| 44.28 | 0.3959 | 0.4077 ± 0.0118 | 0.4110 | 0.4233 ± 0.0123 | 0.4260 | 0.4115 ± 0.0145 | 0.4560 | 0.4668 ± 0.0107 | 0.4861 | 0.4988 ± 0.0266 |

| 50.38 | 0.3242 | 0.3428 ± 0.0186 | 0.3344 | 0.3473 ± 0.0129 | 0.3444 | 0.3363 ± 0.0081 | 0.3646 | 0.3459 ± 0.0187 | 0.3848 | 0.3957 ± 0.0211 |

| 51.70 | 0.3126 | 0.2945 ± 0.0181 | 0.3219 | 0.3312 ± 0.0093 | 0.33125 | 0.3475 ± 0.0163 | 0.3498 | 0.3679 ± 0.0180 | 0.3685 | 0.3757 ± 0.0201 |

| 59.54 | 0.2622 | 0.2485 ± 0.0138 | 0.2683 | 0.2773 ± 0.0090 | 0.27426 | 0.2843 ± 0.0101 | 0.2862 | 0.2997 ± 0.0135 | 0.2982 | 0.3057 ± 0.0163 |

| The thermal neutron attenuation parameters of PVC/PSt films (25.4 meV) | |||||

| Parameter | SSP0 | SSP5 | SSP10 | SSP20 | SSP30 |

| ∑ (cm−1) | 3.4024 | 4.219 | 4.058 | 3.695 | 3.344 |

| MFP (cm) | 0.2939 | 0.2370 | 0.2464 | 0.2706 | 0.2990 |

| HVL (cm) | 0.2034 | 0.1640 | 0.1705 | 0.1873 | 0.2069 |

| The fast neutron attenuation parameters of PVC/PSt films (4 MeV) | |||||

| Parameter | SSP0 | SSP5 | SSP10 | SSP20 | SSP30 |

| ∑ (cm−1) | 3.218 | 3.991 | 3.838 | 3.495 | 3.162 |

| MFP (cm) | 0.3107 | 0.2506 | 0.2605 | 0.2861 | 0.3162 |

| HVL (cm) | 0.2150 | 0.1734 | 0.1803 | 0.1980 | 0.2188 |

| The fast neutron removal attenuation parameters of PVC/PSt films. | |||||

| Parameter | SSP0 | SSP5 | SSP10 | SSP20 | SSP30 |

| ∑ (cm−1) | 0.0860 | 0.1095 | 0.1064 | 0.1015 | 0.0975 |

| MFP (cm) | 11.6279 | 9.1324 | 9.3985 | 9.8522 | 10.2564 |

| HVL (cm) | 8.0465 | 6.3196 | 6.5038 | 6.8177 | 7.0974 |

| Composite Material | MAC (cm2/g) | MFP (cm) | HVL (cm) | Reference |

|---|---|---|---|---|

| PVC/PSt/SSP30 (This work) | 0.3057 | 2.20 | 1.53 | This work |

| Natural animal bone | 0.2150 | 6.40 | 4.43 | [45] |

| Eggshell-reinforced epoxy | 0.2460 | ~3.80 | ~2.64 | [19] |

| Snail shell HAp in epoxy | 0.2940 | 2.40 | 1.65 | [18] |

| PbO-reinforced PVC | 0.5500 | 1.48 | 1.02 | [22] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pekdemir, M.E.; Pekdemir, S.S.; Yılmaz, D.; Onay, H.; Nazem Qader, I. Snail Shell-Reinforced Waste-Based Polymer Composites for Radiation Shielding and Anti-Reflective Applications. Polymers 2025, 17, 3115. https://doi.org/10.3390/polym17233115

Pekdemir ME, Pekdemir SS, Yılmaz D, Onay H, Nazem Qader I. Snail Shell-Reinforced Waste-Based Polymer Composites for Radiation Shielding and Anti-Reflective Applications. Polymers. 2025; 17(23):3115. https://doi.org/10.3390/polym17233115

Chicago/Turabian StylePekdemir, Mustafa Ersin, Sibel Selçuk Pekdemir, Demet Yılmaz, Hatice Onay, and Ibrahim Nazem Qader. 2025. "Snail Shell-Reinforced Waste-Based Polymer Composites for Radiation Shielding and Anti-Reflective Applications" Polymers 17, no. 23: 3115. https://doi.org/10.3390/polym17233115

APA StylePekdemir, M. E., Pekdemir, S. S., Yılmaz, D., Onay, H., & Nazem Qader, I. (2025). Snail Shell-Reinforced Waste-Based Polymer Composites for Radiation Shielding and Anti-Reflective Applications. Polymers, 17(23), 3115. https://doi.org/10.3390/polym17233115