Additive Manufacturing of a PA11 Prototype Fabricated via Selective Laser Sintering for Advanced Industrial Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization Techniques

3. Results and Discussion

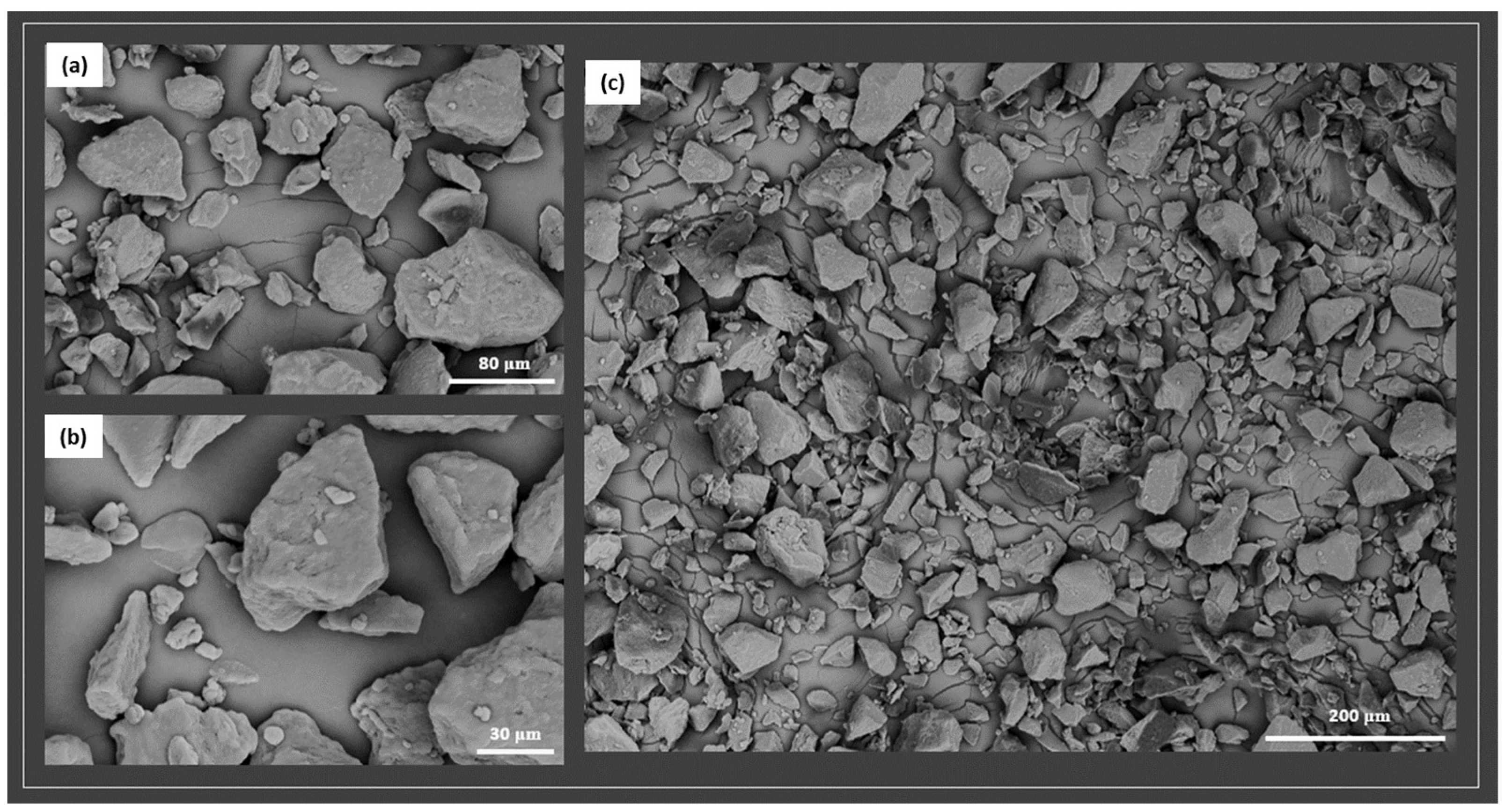

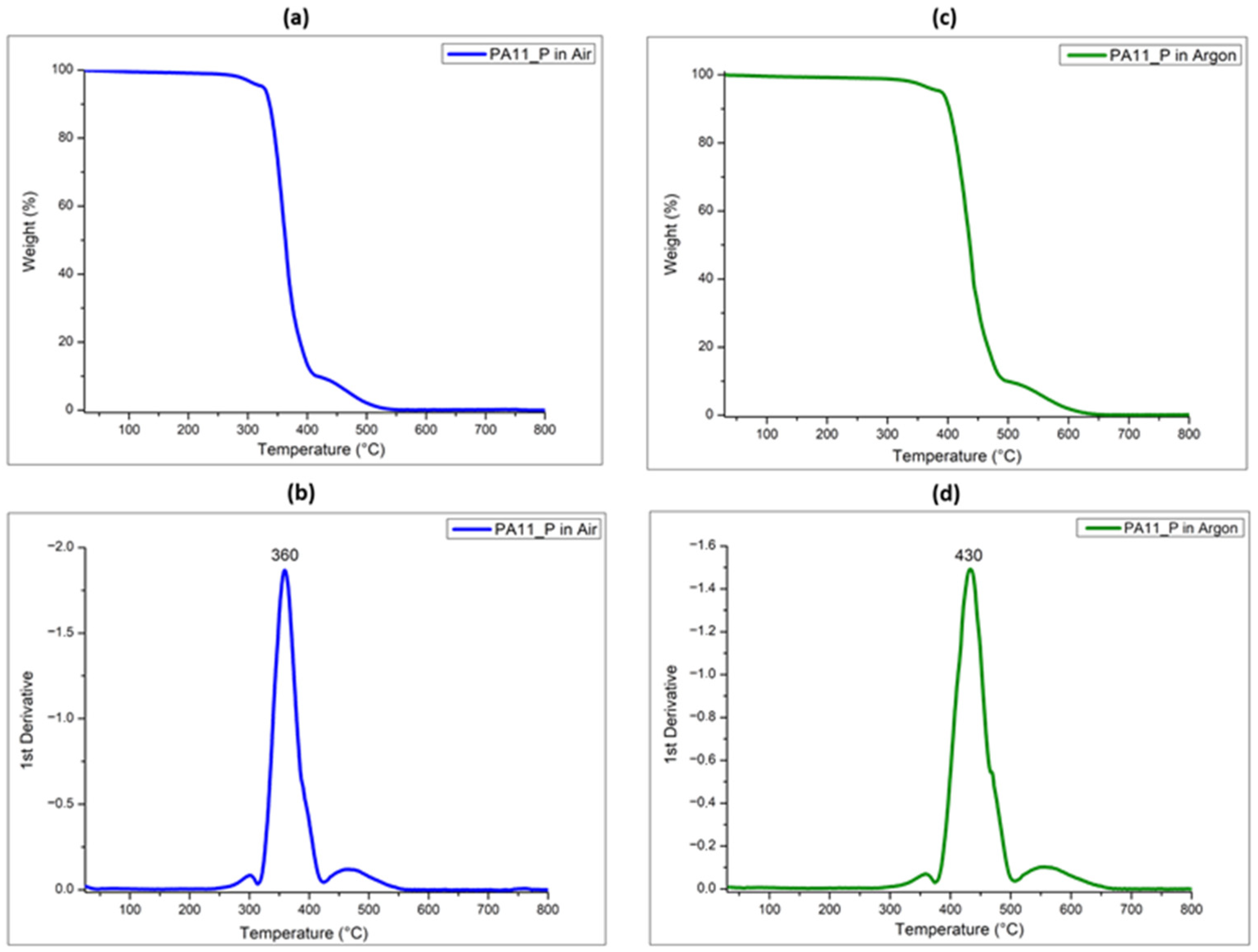

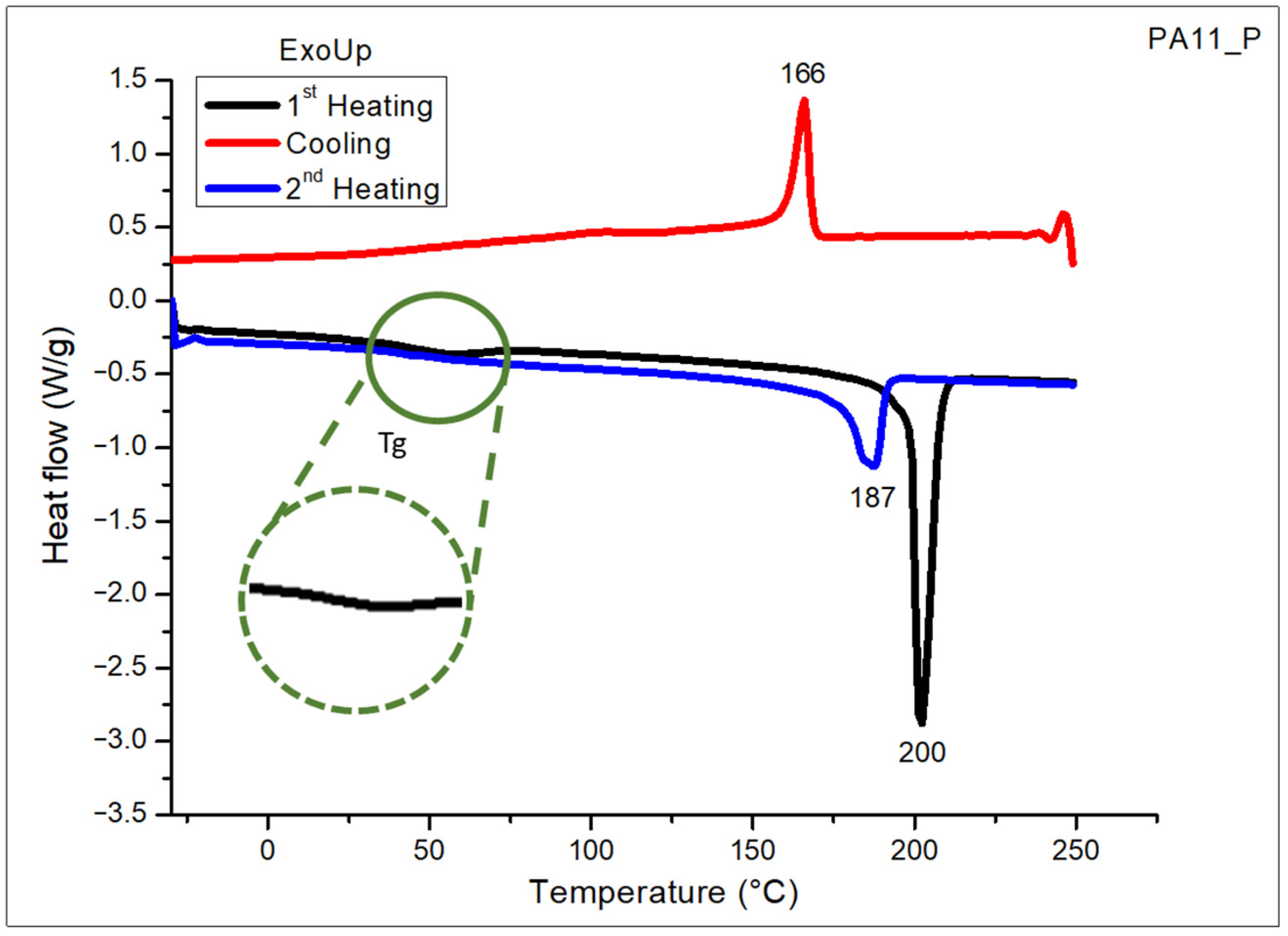

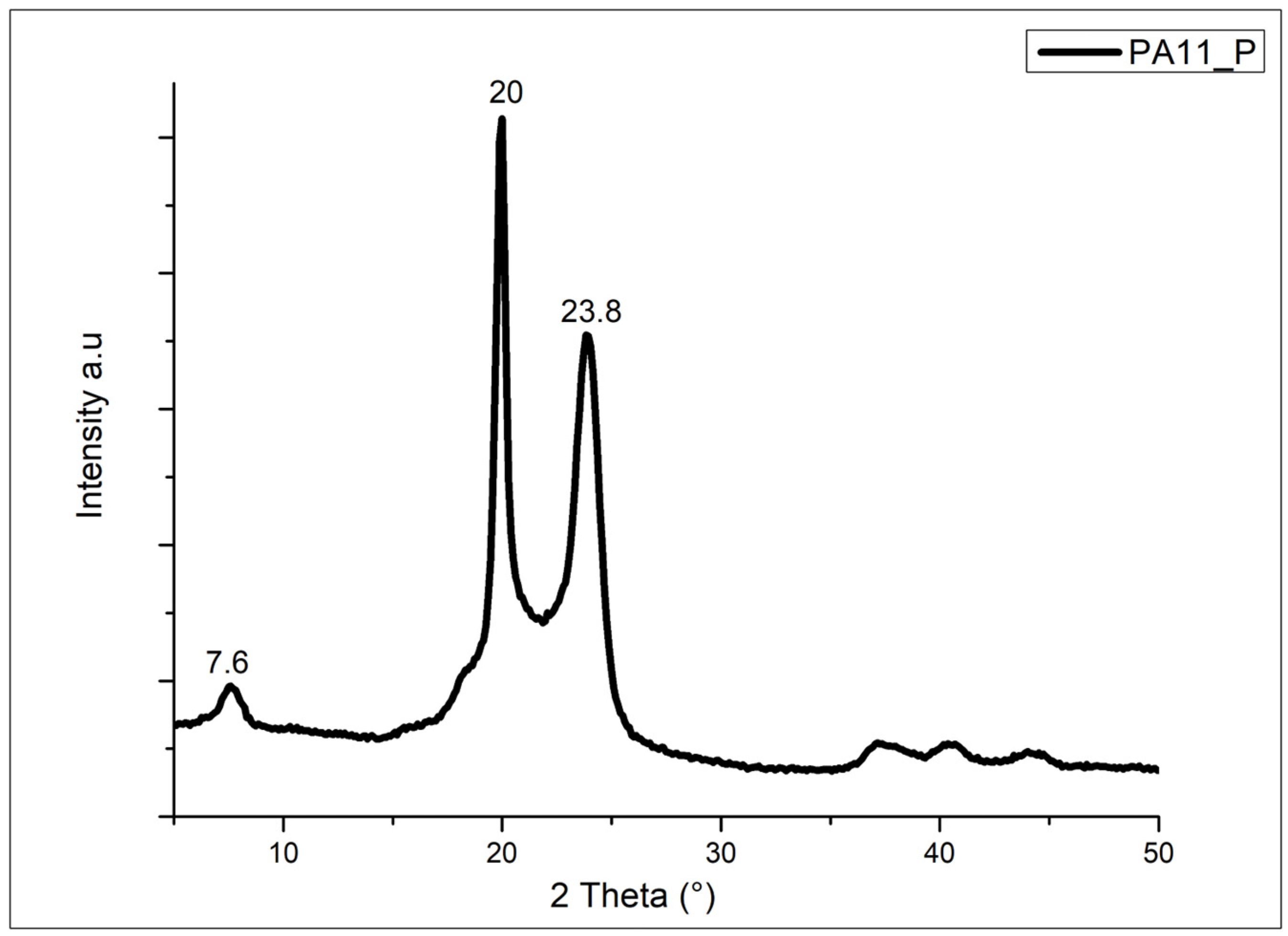

3.1. Characterization of the PA11 Powder

3.2. Density Tests of PA11 Printed Parts

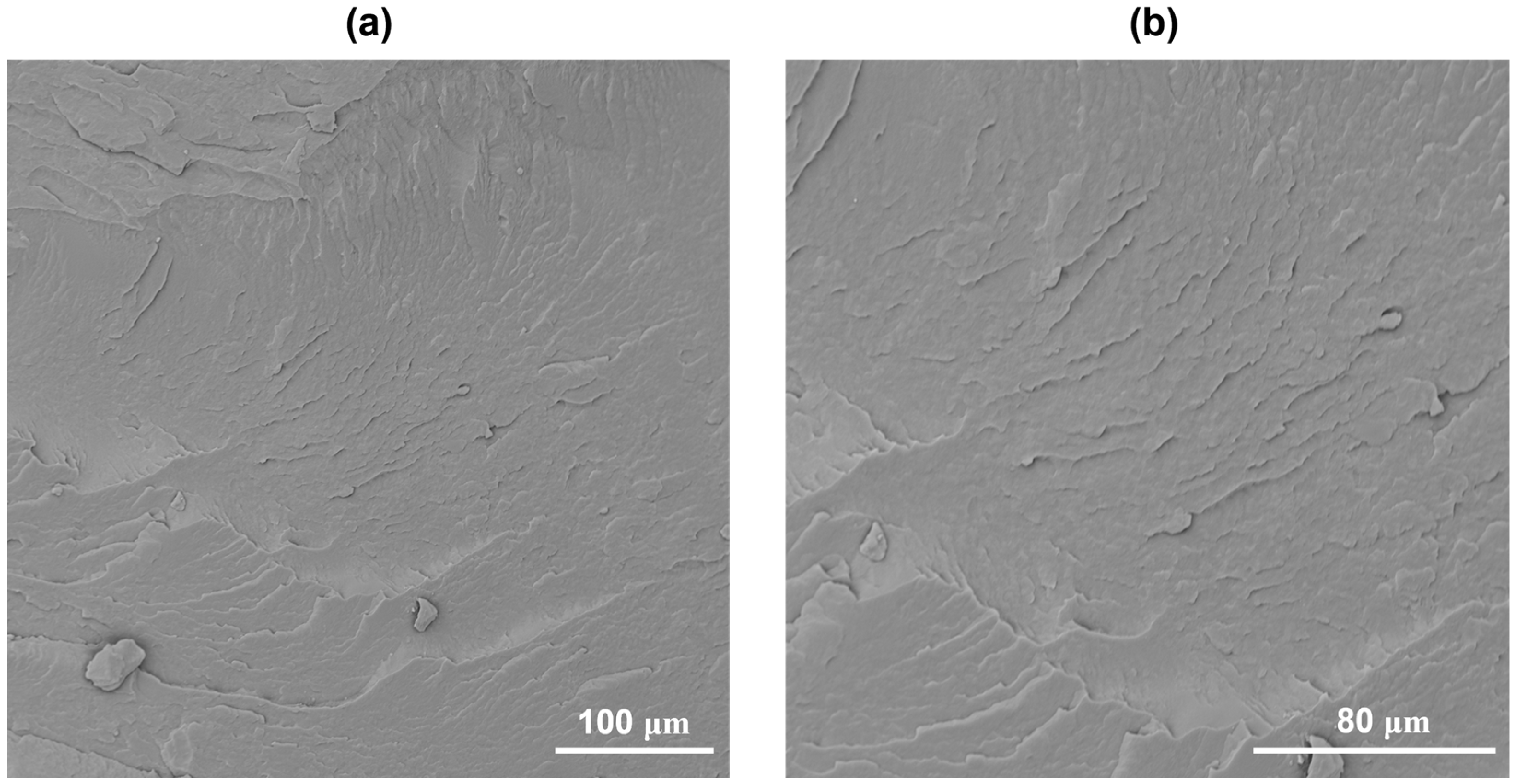

3.3. Microstructure of PA11 Printed Parts

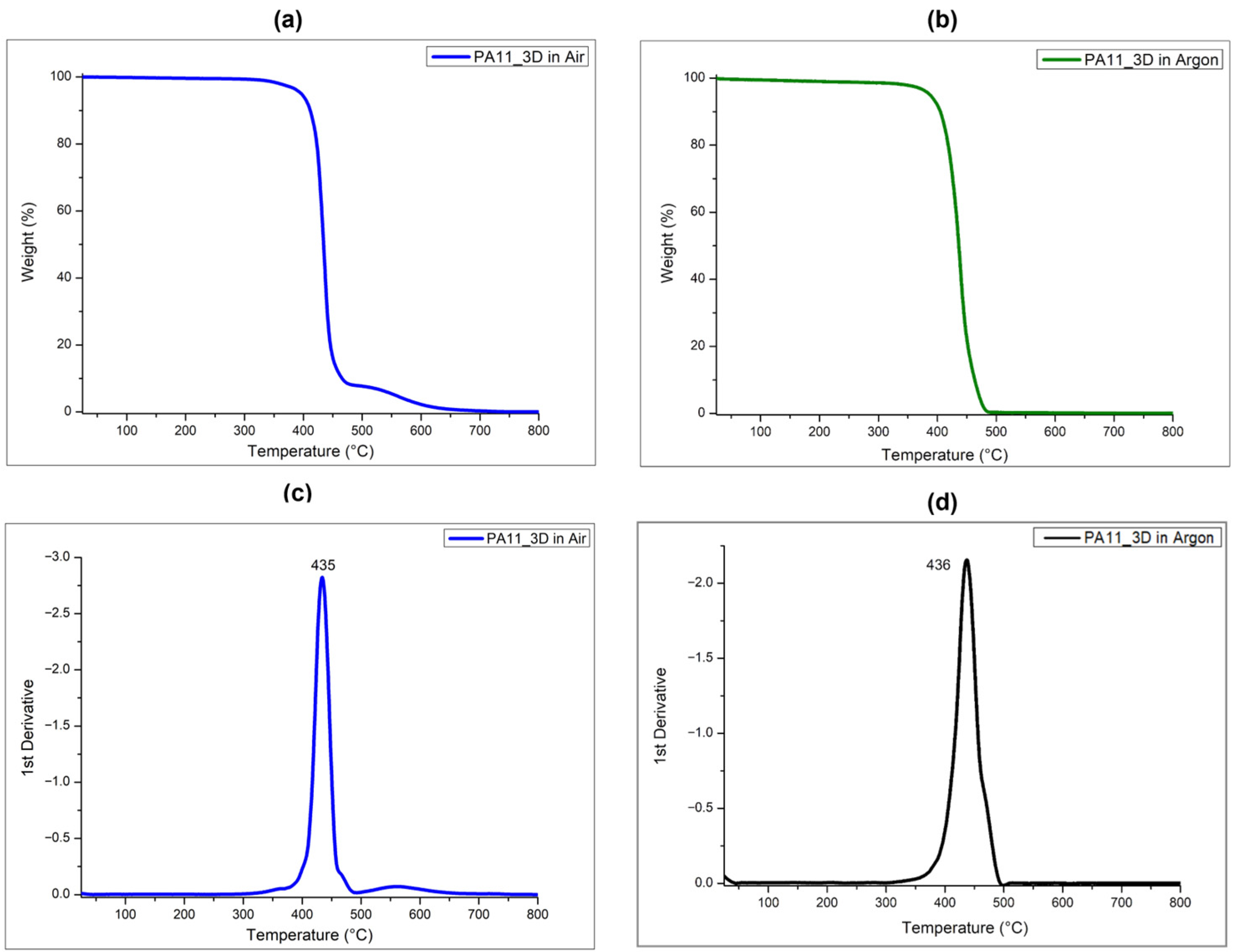

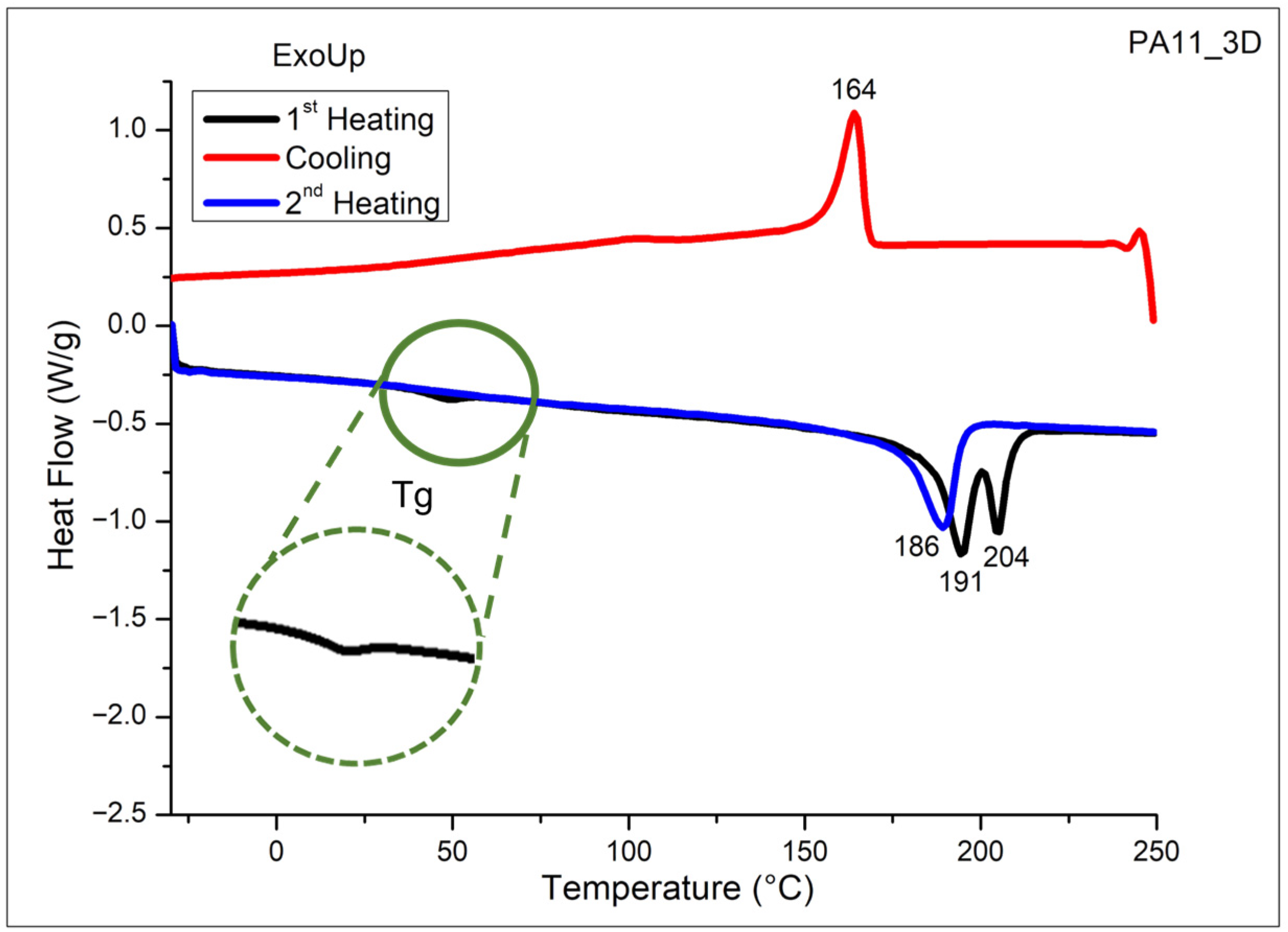

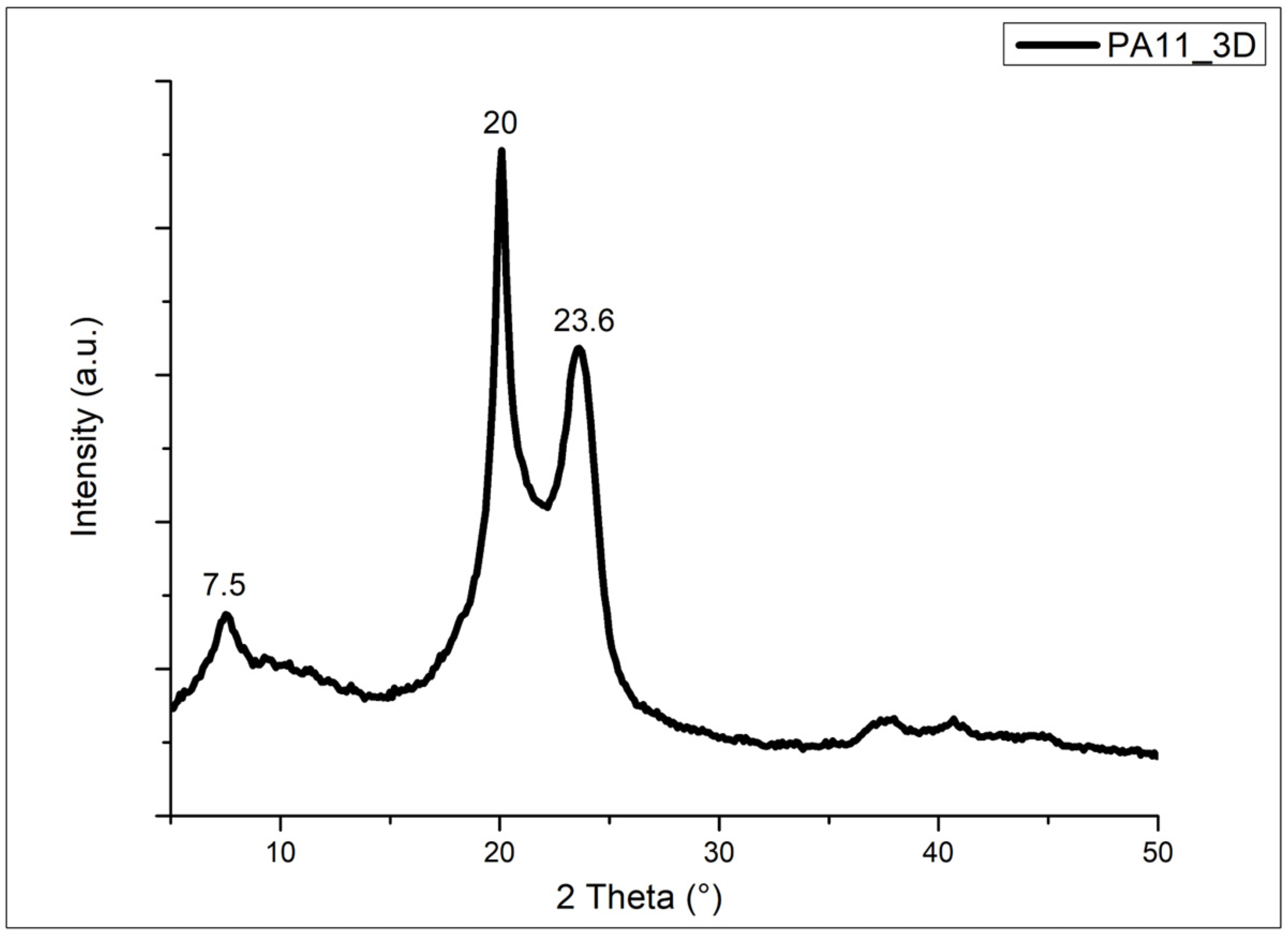

3.4. Thermal Properties of PA11 Printed Parts

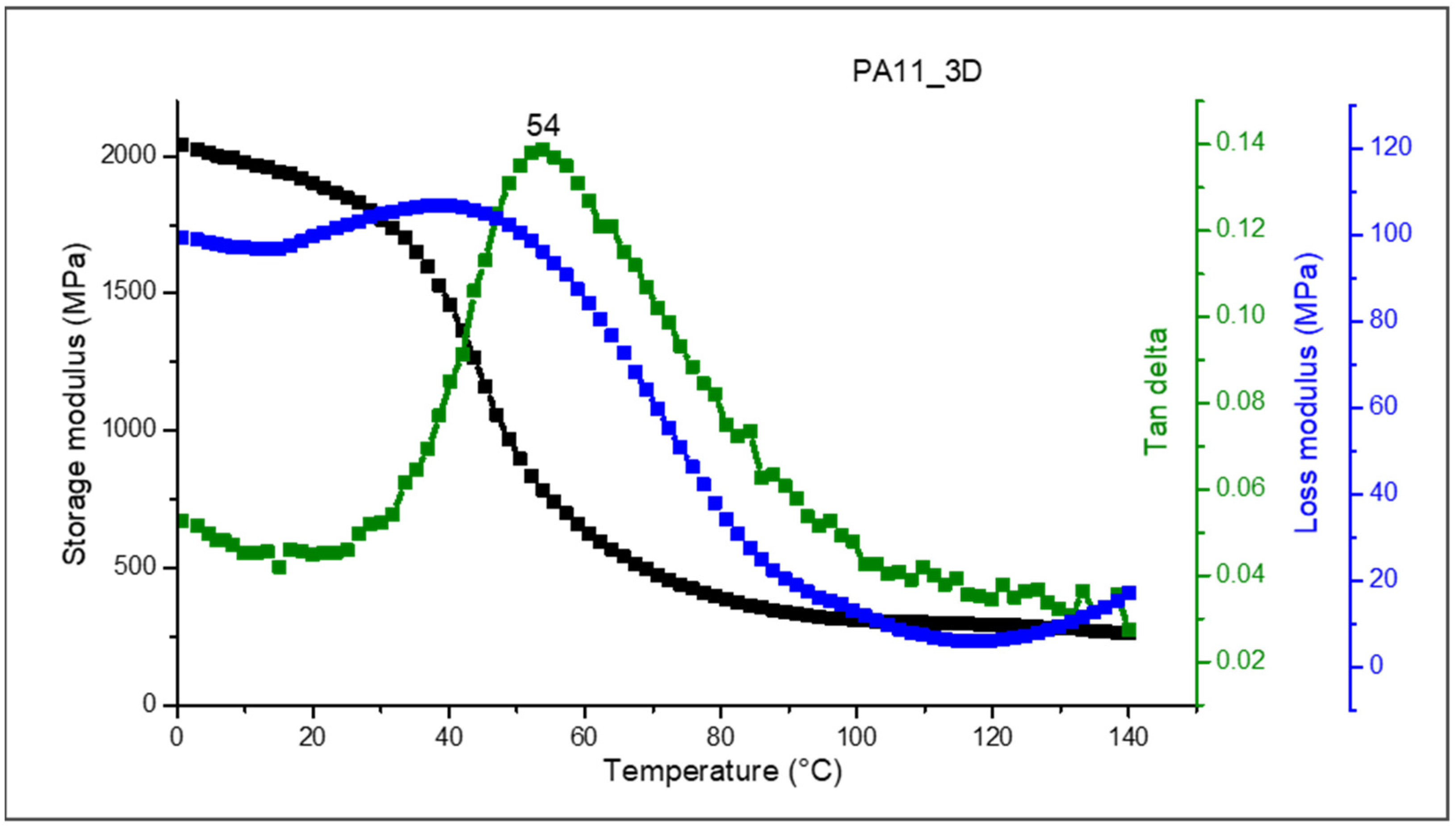

3.5. Dynamic-Mechanical Properties of PA11 Printed Parts

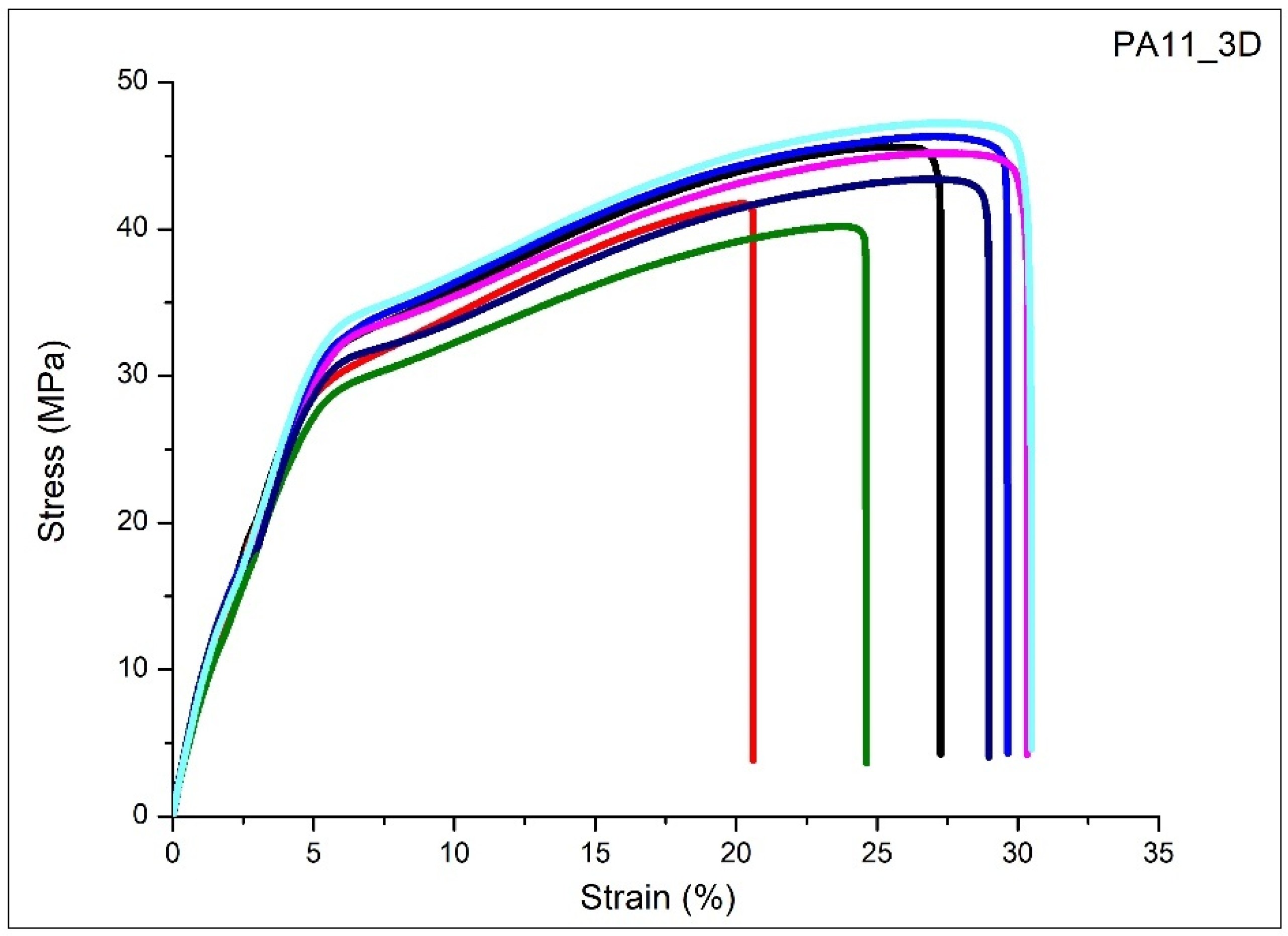

3.6. Tensile Properties of PA11 Printed Parts

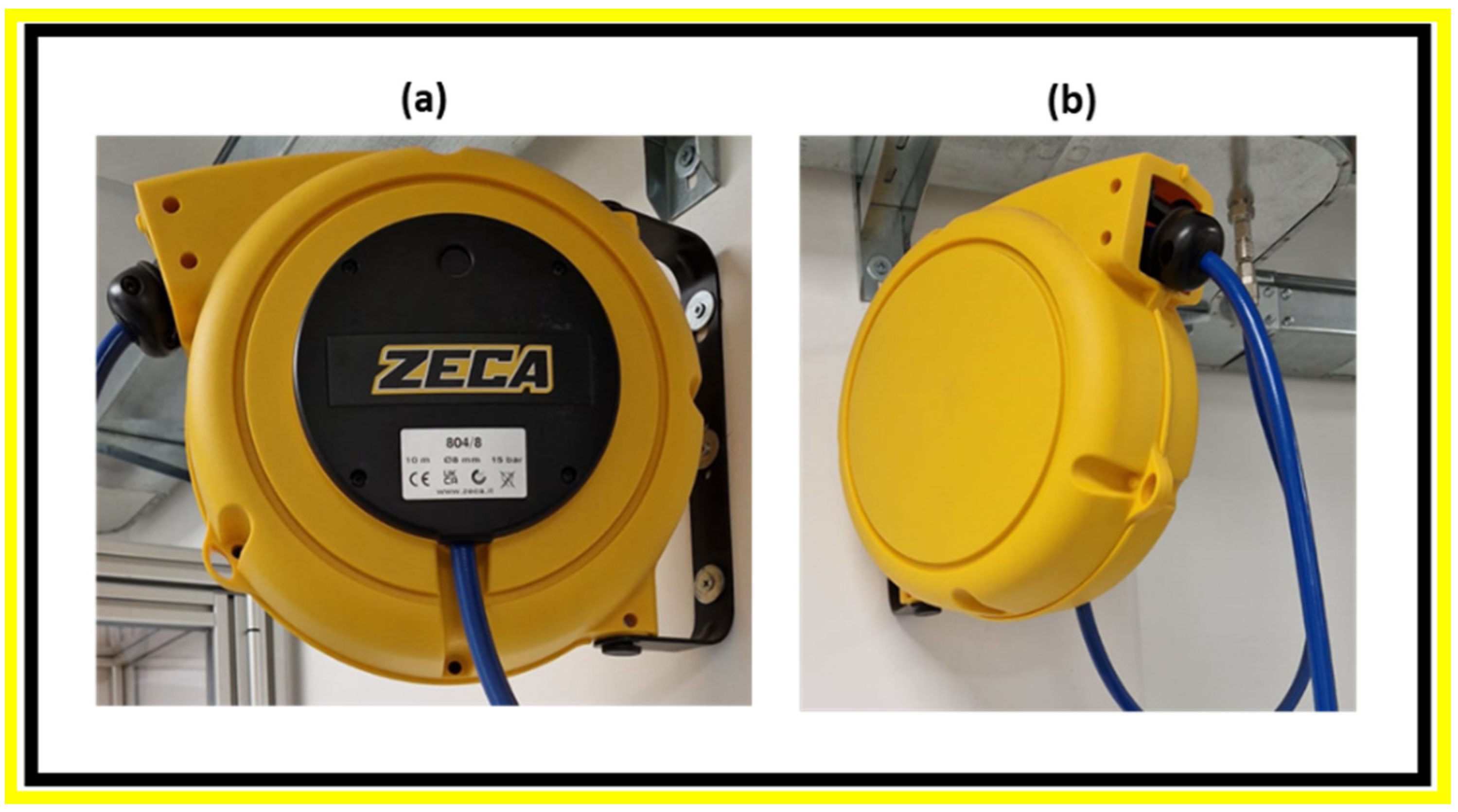

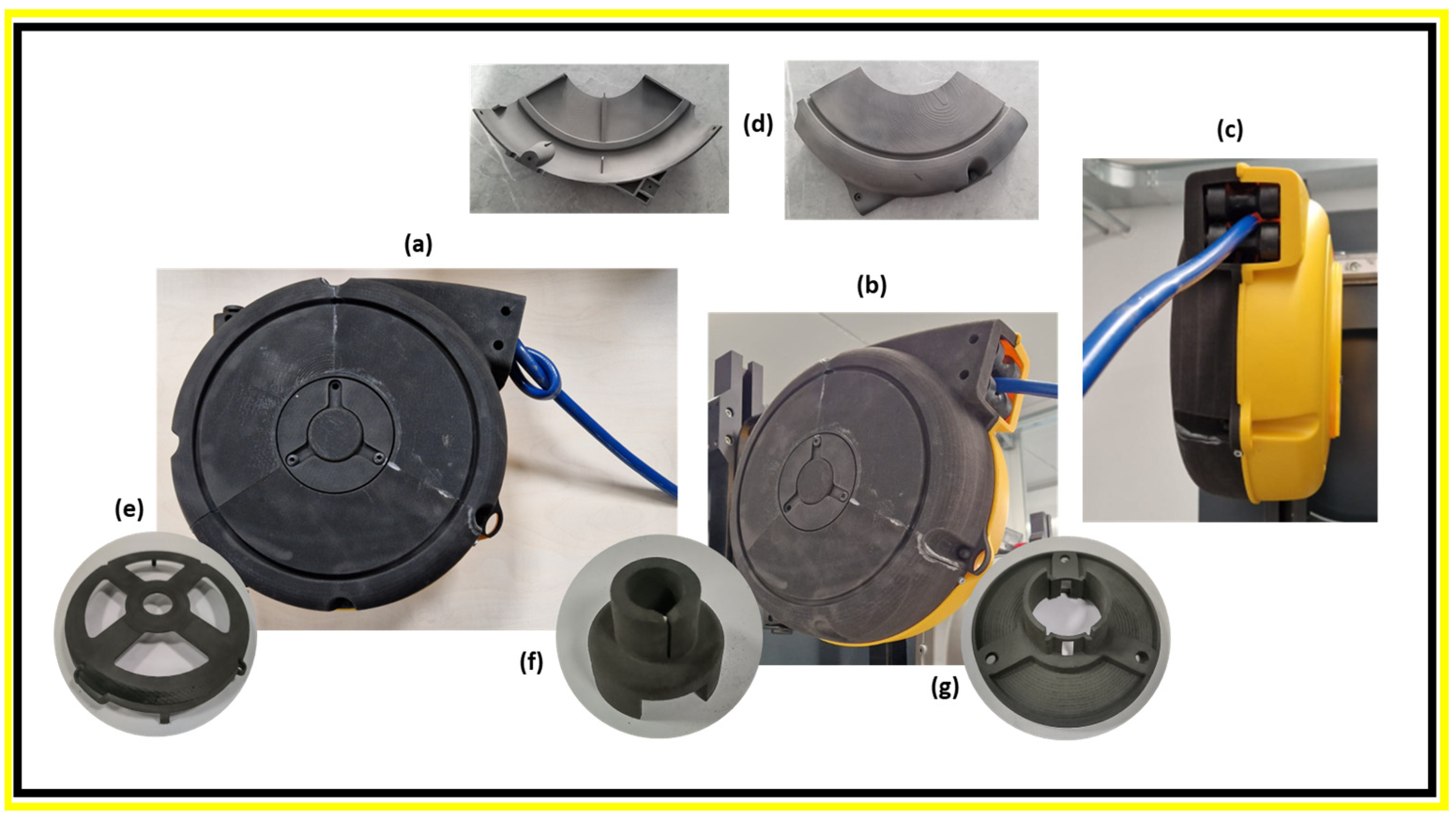

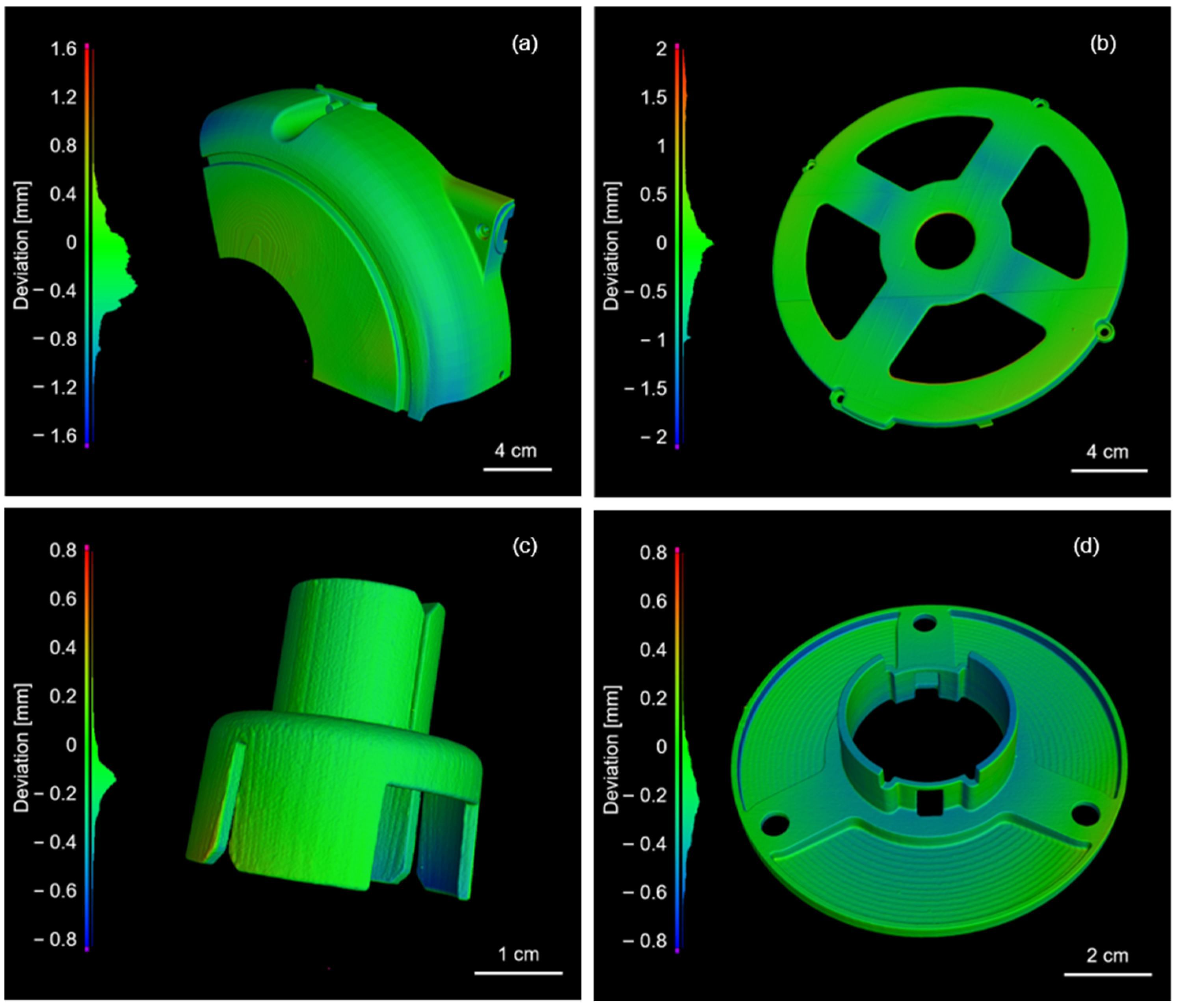

3.7. Fabrication via SLS of Industrial Components for Prototype

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The role of additive manufacturing in the era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Segovia Ramírez, I.; García Marquez, F.P.; Papaelias, M. Review on additive manufacturing and non-destructive testing. J. Manuf. Syst. 2023, 66, 260–286. [Google Scholar] [CrossRef]

- Alghamdi, S.S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Z.; Wu, D.; Bai, J. Current Status and Prospects of Polymer Powder 3D Printing Technologies. Materials 2020, 13, 2406. [Google Scholar] [CrossRef]

- Han, W.; Kong, L.; Xu, M. Advances in selective laser sintering of polymers. Int. J. Extrem. Manuf. 2022, 4, 042002. [Google Scholar] [CrossRef]

- Mulinge, M.F.; Maina, M.; van der Walt, J.G. A review of the techniques used to characterize laser sintering of polymeric powders for use and re-use in additive manufacturing. Manuf. Rev. 2021, 8, 14. [Google Scholar] [CrossRef]

- Mokrane, A.; Boutaous, M.; Xin, S. Process of selective laser sintering of polymer powders: Modeling, simulation, and validation. C. R. Mecanique 2018, 346, 1087–1103. [Google Scholar] [CrossRef]

- Verbelen, L.; Dadbakhsh, S.; van den Eynde, M.; Kruth, J.P.; Goderis, B.; van Puyvelde, P. Characterization of polyamide powders for determination of laser sintering processability. Eur. Polym. J. 2016, 75, 163–174. [Google Scholar] [CrossRef]

- Mahmoud, M.; Huitorel, B.; Fall, A. Rheology and agglomeration behavior of semi-crystalline polyamide powders for selective laser sintering: A comparative study of PA11 and PA12 formulations. Powder Technol. 2024, 433, 119279. [Google Scholar] [CrossRef]

- Colucci, G.; Fontana, F.; Barberi, J.; Vitale Brovarone, C.; Messori, M. Chess-like pieces realized by selective laser sintering of PA12 powder: 3D printing and micro-tomographic assessment. Polymers 2024, 16, 3526. [Google Scholar] [CrossRef]

- Wegner, A.; Harder, R.; Witt, G.; Drummer, D. Determination of Optimal Processing Conditions for the Production of Polyamide 11 Parts using the Laser Sintering Process. Int. J. Recent Contrib. Eng. Sci. 2015, 3, 5–12. [Google Scholar] [CrossRef]

- Winnacker, M.; Rieger, B. Biobased polyamides: Recent advances in basic and applied research. Macromol. Rapid Comm. 2016, 37, 1391–1413. [Google Scholar] [CrossRef]

- Tonello, R.; Conradsen, K.; Bue Pedersen, D.; Revall Frisvad, J. Surface Roughness and Grain Size Variation When 3D Printing Polyamide 11 Parts Using Selective Laser Sintering. Polymers 2023, 15, 2967. [Google Scholar] [CrossRef]

- Androsch, R.; Jariyavidyanont, K.; Schick, C. Enthalpy Relaxation of Polyamide 11 of Different Morphology Far Below the Glass Transition Temperature. Entropy 2019, 21, 984. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Méndez, J.A.; Mutjé, P.; Tarrés, Q.; Espinach, F.X.; Ardanuy, M. Evaluation of Thermal and Thermomechanical Behaviour of Bio-Based Polyamide 11 Based Composites Reinforced with Lignocellulosic Fibres. Polymers 2017, 9, 522. [Google Scholar] [CrossRef] [PubMed]

- Gunputh, U.; Williams, G.; Pawlik, M.; Lu, Y.; Wood, P. Effect of Powder Bed Fusion Laser Sintering on Dimensional Accuracy and Tensile Properties of Reused Polyamide 11. Polymers 2023, 15, 4602. [Google Scholar] [CrossRef]

- Yao, B.; Li, Z.; Zhu, F. Effect of powder recycling on anisotropic tensile properties of selective laser sintered PA2200 polyamide. Eur. Polym. J. 2020, 141, 110093. [Google Scholar] [CrossRef]

- Colucci, G.; Piano, M.; Lupone, F.; Badini, C.; Bondioli, F.; Messori, M. Preparation and 3D printability study of biobased PBAT powder for selective laser sintering additive manufacturing. Mater. Today Chem. 2023, 33, 101687. [Google Scholar] [CrossRef]

- Shian Tey, W.; Cai, C.; Zhou, K. A Comprehensive Investigation on 3D Printing of Polyamide 11 and Thermoplastic Polyurethane via Multi Jet Fusion. Polymers 2021, 13, 2139. [Google Scholar] [CrossRef]

- ASTM B923-20; Standard Test Method for Metal Powder Skeletal Density by Helium or Nitrogen Pycnometry. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D7481; Standard Test Methods for Determining Loose and Tapped Bulk Densities of Powders Using a Graduated Cylinder. ASTM International: West Conshohocken, PA, USA, 2018.

- Giubilini, A.; Colucci, G.; Grasselli, S.; Iuliano Messori, M.; Minetola, P. High-Pressure Homogenization: An Industrially Scalable Method for Producing PHBH Powders for Selective Laser Sintering. Adv. Mater. Technol. 2025, 10, e00049. [Google Scholar] [CrossRef]

- ASTM B962-17; Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle. ASTM International: West Conshohocken, PA, USA, 2017.

- ISO 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- Moradi, A.; Pramanik, S.; Ataollahi, F.; Kamarul, T.; Pingguan-Murphy, B. Archimedes revisited: Computer assisted microvolumetric modification of the liquid displacement method for porosity measurement of highly porous light materials. Anal. Methods 2014, 6, 4396–4401. [Google Scholar] [CrossRef]

- Esposito, G.R.; Dingemans, T.J.; Pearson, R.A. Changes in polyamide 11 microstructure and chemistry during selective laser sintering. Addit. Manuf. 2021, 48, 102445. [Google Scholar] [CrossRef]

- Jariyavidyanont, K.; Jankeb, A.; Androscha, R. Crystal self-nucleation in polyamide 11. Thermochim. Acta 2019, 677, 139–143. [Google Scholar] [CrossRef]

- Benobeidallah, B.; Benhamida, B.; Dorigato, A.; Sola, A.; Messori, M.; Pegoretti, A. Structure and Properties of Polyamide 11 Nanocomposites Filled with Fibrous Palygorskite Clay. J. Renew. Mater. 2019, 7, 89–102. [Google Scholar] [CrossRef]

- Fischer, C.; Seefried, A.; Drummer, D. Crystallization and component properties of PA12 at processing-relevant cooling conditions. Polym. Eng. Sci. 2017, 57, 450–457. [Google Scholar] [CrossRef]

- Su Park, M.; Lee, S.; Kim, A.R.; Choi, I.; Shin, J.; Young-Wun, K. Toughened and hydrophobically modified polyamide 11 copolymers with dimer acids derived from waste vegetable oil. J. Appl. Polym. Sci. 2019, 136, 47174–47185. [Google Scholar] [CrossRef]

- Bahrami, M.; Abenojar, J.; Martínez, M.A. Comparative Characterization of Hot-Pressed Polyamide 11 and 12: Mechanical, Thermal and Durability Properties. Polymers 2021, 13, 3553. [Google Scholar] [CrossRef]

- Zhu, Z.; Majewski, C. Understanding pore formation and the effect on mechanical properties of high-speed sintered polyamide-12 parts: A focus on energy input. Mater. Des. 2020, 194, 108937. [Google Scholar] [CrossRef]

- Payami Golhin, A.; Tonello, R.; Revall Frisvad, J.; Grammatikos, S.; Strandlie, A. Surface roughness of as-printed polymers: A comprehensive review. Int. J. Adv. Manuf. Technol. 2023, 127, 987–1043. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Casamento, F.; Badini, C. Process Phenomena and Material Properties in Selective Laser Sintering of Polymers: A Review. Materials 2022, 15, 183. [Google Scholar] [CrossRef]

- Zeng, Z.; Deng, X.; Cui, J.; Jiang, H.; Yan, S.; Peng, B. Improvement on Selective Laser Sintering and Post-Processing of Polystyrene. Polymers 2019, 11, 956. [Google Scholar] [CrossRef] [PubMed]

| Process Parameters | |

|---|---|

| Laser power [W] | 27 |

| Scan speed [mm/s] | 0.0033 |

| Layer height [mm] | 0.1 |

| Powder bed temperature [°C] | 187 |

| Sintering window [°C] | 170–190 |

| Number of warming layers | 100 |

| Sample | Diameter (µm) | Aspect Ratio | Circularity |

|---|---|---|---|

| PA11 | D[n, 0.1]:9.5 | D[n, 0.1]:0.5 | D[n, 0.1]:0.7 |

| D[n, 0.5]:20.0 | D[n, 0.5]:0.7 | D[n, 0.5]:0.9 | |

| D[n, 0.9]:45.2 | D[n, 0.9]:0.9 | D[n, 0.9]:0.9 |

| Sample | True Density (g/cm3) | Apparent Density (g/cm3) | Tapped Density (g/cm3) | Hausner Ratio (HR) | Packing Factor |

|---|---|---|---|---|---|

| PA11_P | 1.063 ± 0.002 | 0.50 ± 0.01 | 0.58 ± 0.01 | 1.17 ± 0.01 | 0.46 ± 0.01 |

| Sample | Tg a (°C) | Tm1 a (°C) | Tm2 b (°C) | ΔHm a (J/g) | Tc a (°C) | Xc c (%) |

|---|---|---|---|---|---|---|

| PA11_P | 58 | 200 | 187 | 98.4 | 166 | 43 |

| PA11_3D | 50 | 191/204 | 186 | 78.7 | 164 | 35 |

| Sample | Density (Closed Porosity) (g/cm3) | Density (Total Porosity) (g/cm3) | Porosity (%) |

|---|---|---|---|

| PA11_3D | 1.050 ± 0.004 | 1.054 ± 0.004 | 0.8 |

| Sample | Elastic Modulus (MPa) | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|

| PA11_3D | 925 ± 52 | 45 ± 3 | 44 ± 2 | 27 ± 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colucci, G.; Riccardi, D.; Giubilini, A.; Messori, M. Additive Manufacturing of a PA11 Prototype Fabricated via Selective Laser Sintering for Advanced Industrial Applications. Polymers 2025, 17, 3111. https://doi.org/10.3390/polym17233111

Colucci G, Riccardi D, Giubilini A, Messori M. Additive Manufacturing of a PA11 Prototype Fabricated via Selective Laser Sintering for Advanced Industrial Applications. Polymers. 2025; 17(23):3111. https://doi.org/10.3390/polym17233111

Chicago/Turabian StyleColucci, Giovanna, Domenico Riccardi, Alberto Giubilini, and Massimo Messori. 2025. "Additive Manufacturing of a PA11 Prototype Fabricated via Selective Laser Sintering for Advanced Industrial Applications" Polymers 17, no. 23: 3111. https://doi.org/10.3390/polym17233111

APA StyleColucci, G., Riccardi, D., Giubilini, A., & Messori, M. (2025). Additive Manufacturing of a PA11 Prototype Fabricated via Selective Laser Sintering for Advanced Industrial Applications. Polymers, 17(23), 3111. https://doi.org/10.3390/polym17233111