Valorization of Unused, Expired Surgical Masks in Polymer-Modified Bitumens Using Maleic Anhydride as a Compatibilizer

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Plan

2.2. Materials

2.3. Modified Bitumen Preparation

2.4. Modified Bitumen Characterization

2.4.1. Subsubsection

2.4.2. Differential Scanning Calorimetry (DSC)

2.4.3. Thermogravimetric Analysis (TGA)

2.4.4. Density

2.4.5. Viscosity of Bituminous Mixtures

2.4.6. Penetration Tests

2.4.7. Softening Tests

2.4.8. Determination of MAH Grafting Degree

2.5. PMBs Performance Comparison

3. Results and Discussion

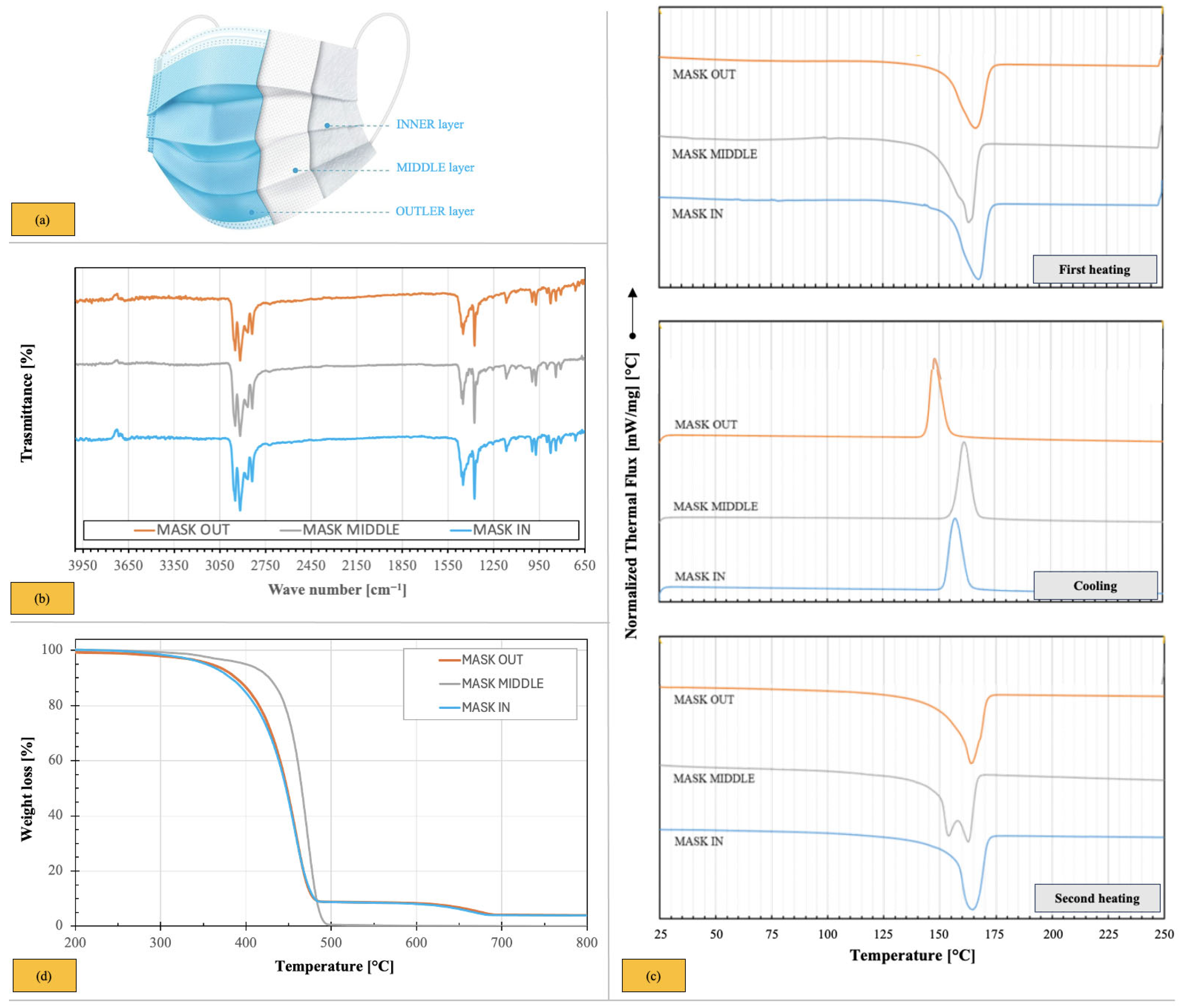

3.1. Disposable Surgical Masks Characterization

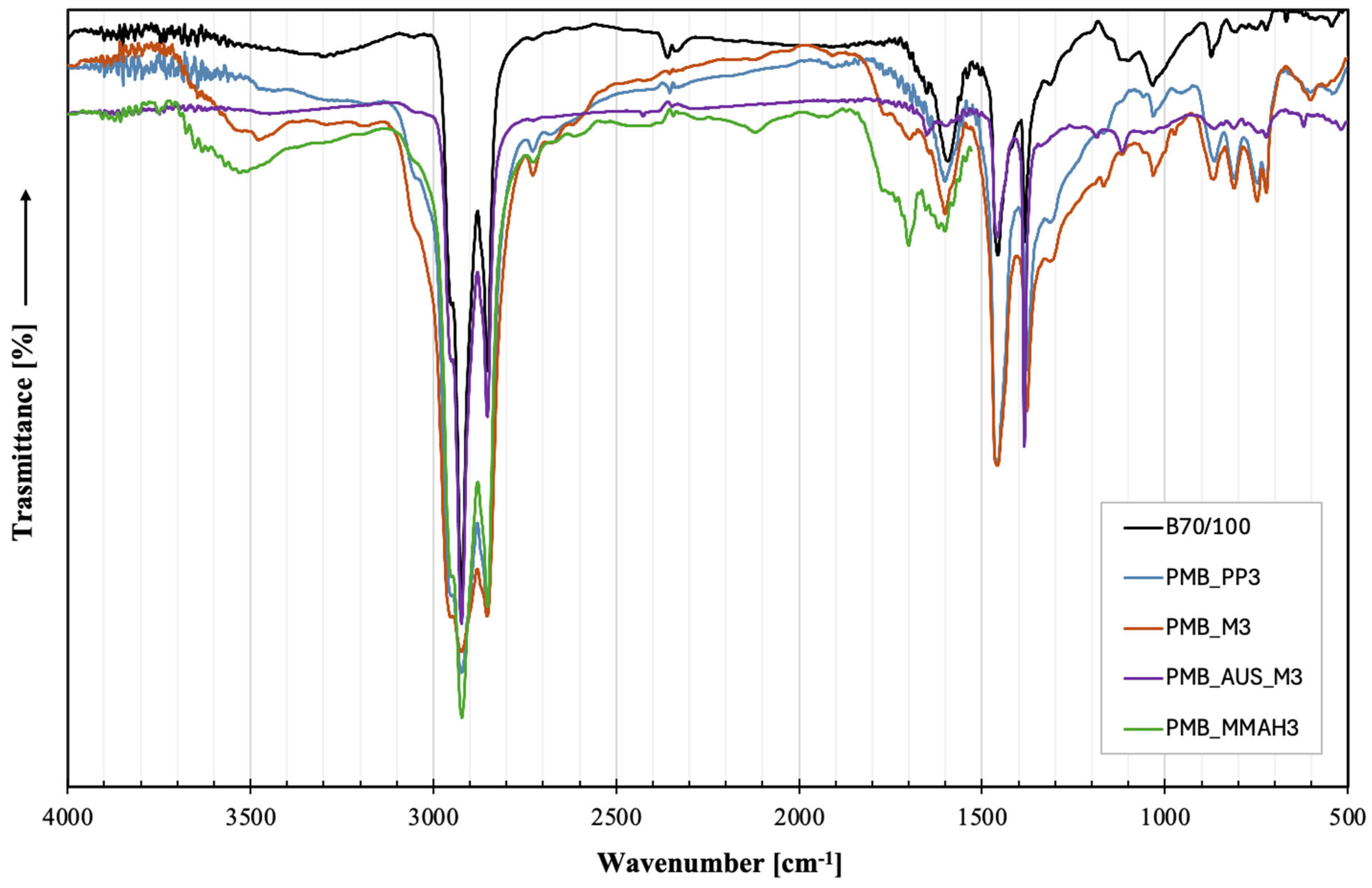

3.2. Infrared Spectroscopic Analysis of PMB Mixtures

3.3. PMBs Mixtures Characterization

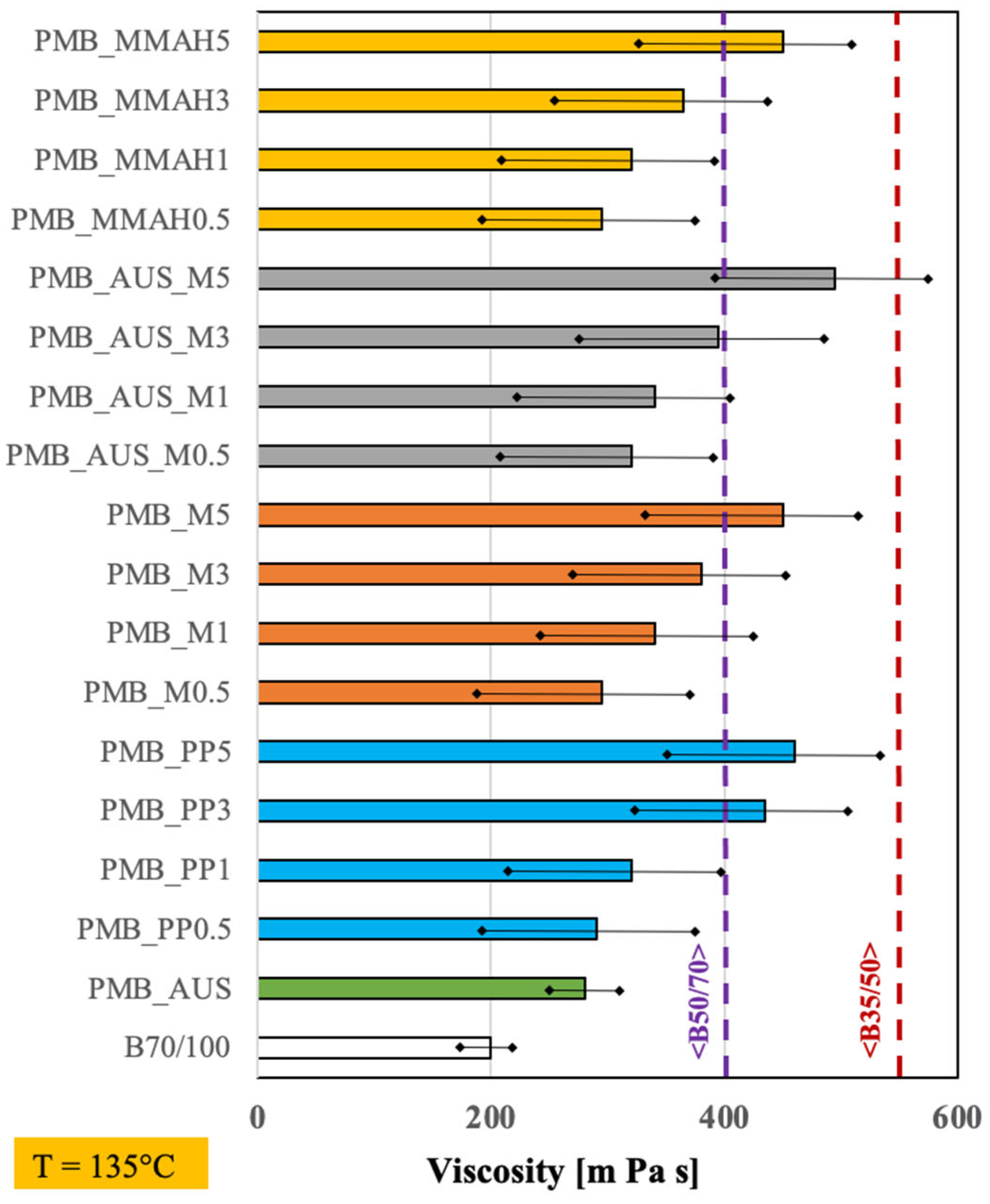

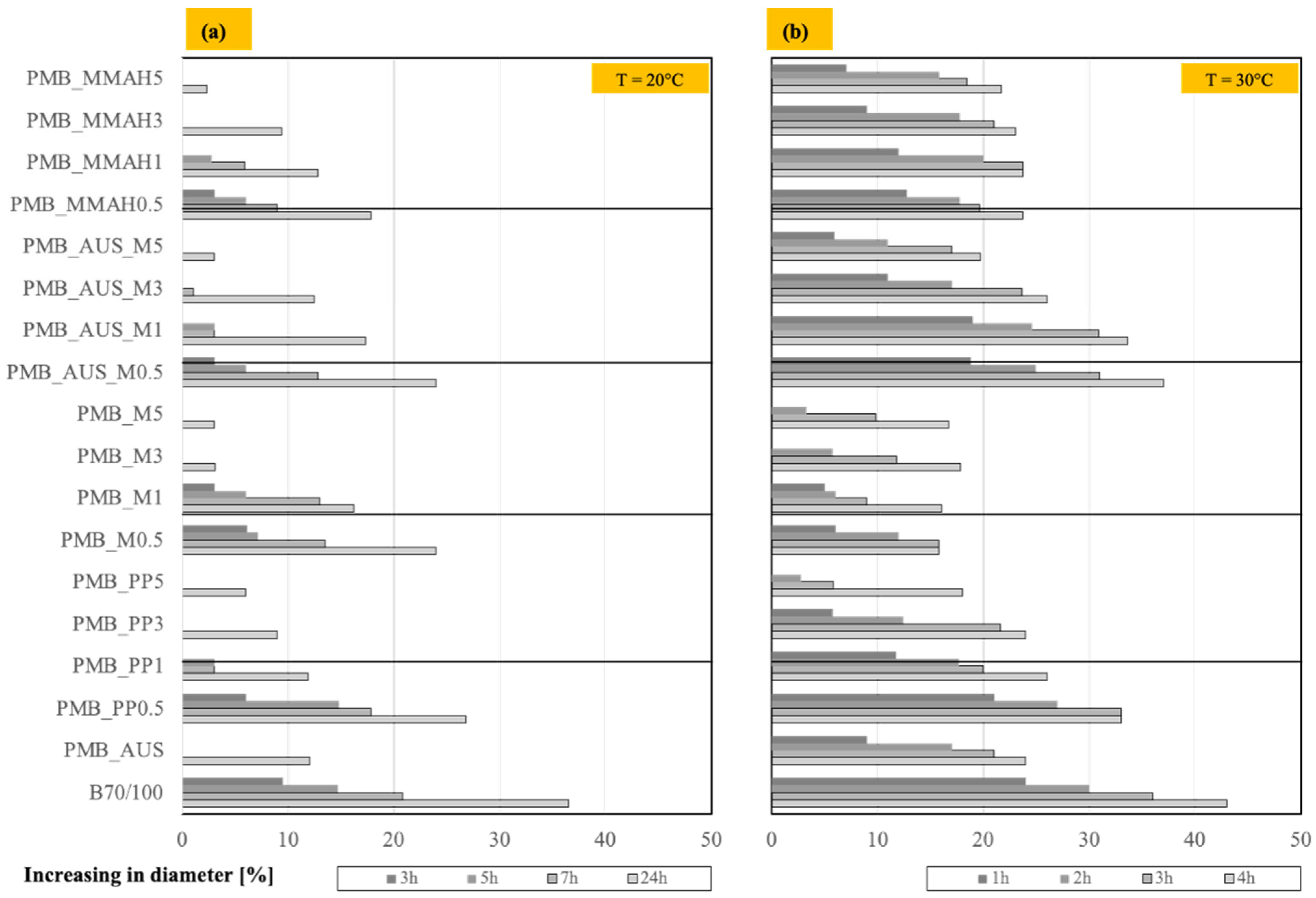

3.3.1. Viscosity

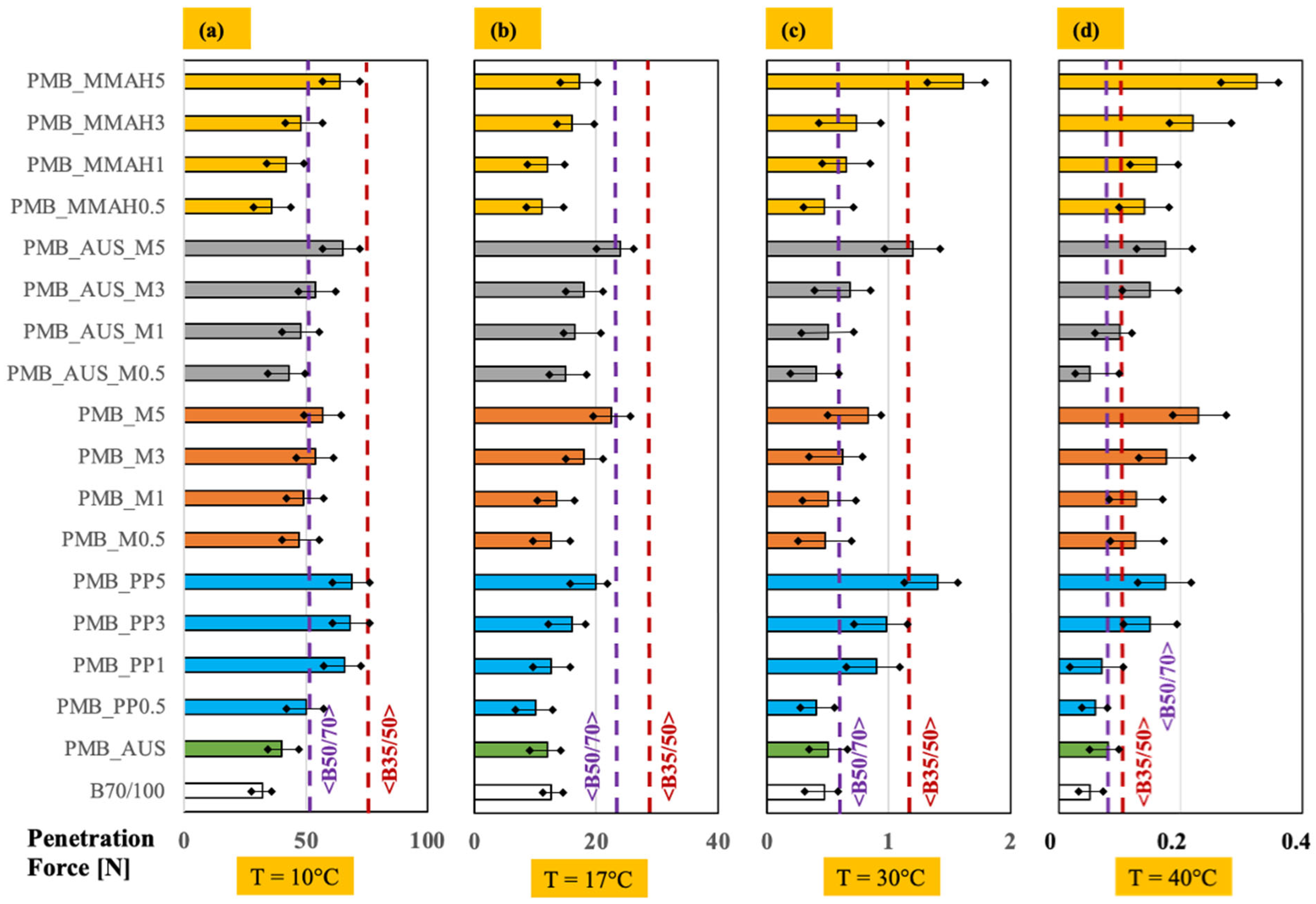

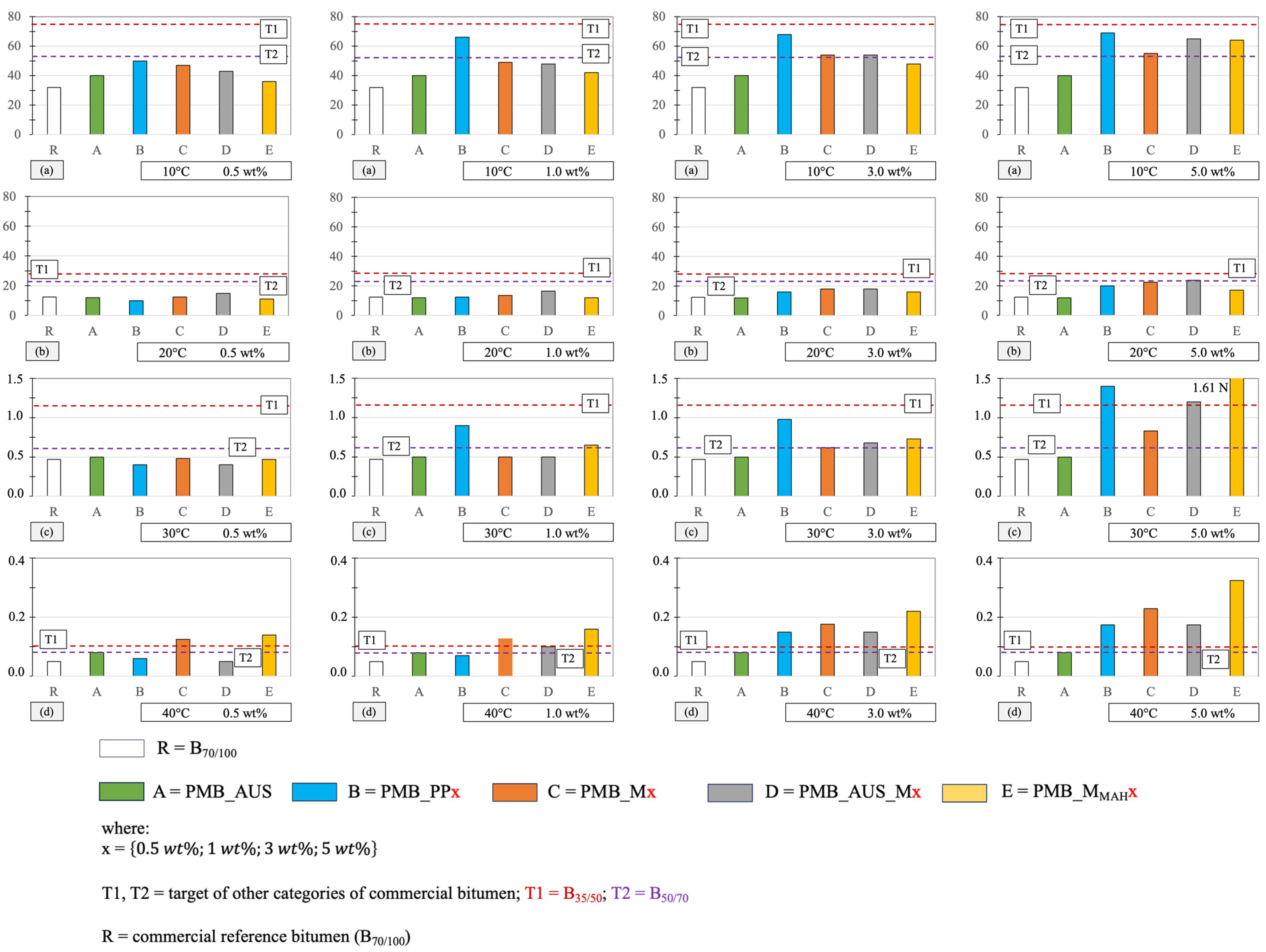

3.3.2. Penetration Force

3.3.3. Softening Measurements

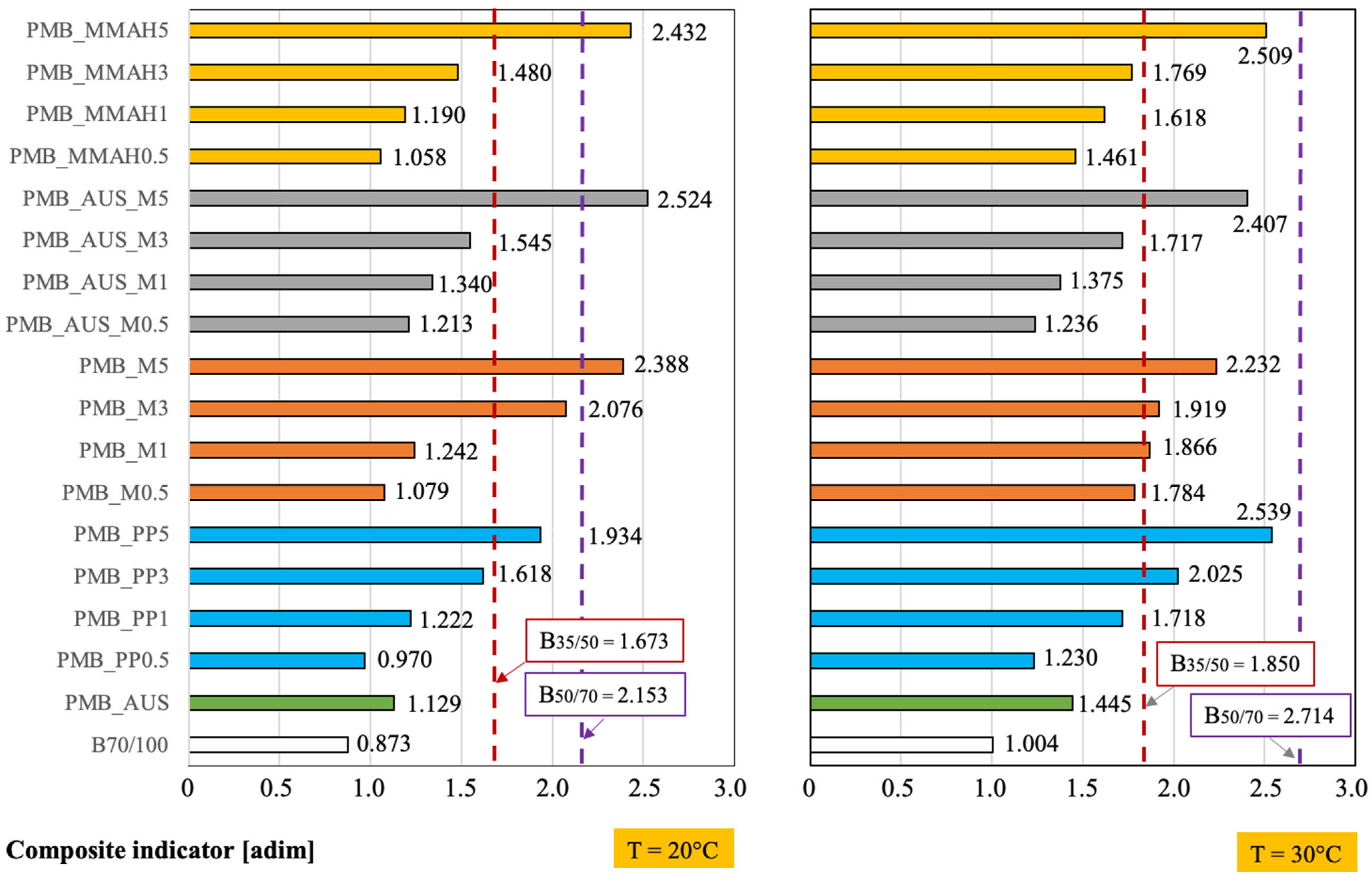

3.4. Overall Performance Evaluation

4. Conclusions

5. Limitations and Future Research Directions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ATR/FT-IR | Attenuated total reflectance infrared spectroscopic analysis |

| CI | Composite indicator |

| DCP | Dicumyl peroxide |

| DSC | Differential scanning calorimetry |

| EBA | Ethylene–butyl acrylate |

| EVA | Ethylene–vinyl acetate |

| AUS | Intune |

| KOH | Potassium hydroxide |

| HCl | Hydrochloric acid |

| MAH | Maleic anhydride |

| PE | Polyethylene |

| PMB | Polymer-modified bitumen |

| PP | Polypropylene |

| RLLDPE | Recycled linear low-density polyethylene |

| SBS | Styrene–butadiene–styrene |

| SEBS | Styrene–ethylene–vinyl acetate |

| SIS | Styrene–isoprene–styrene |

| TGA | Thermogravimetric analysis |

| Tg | Glass transition temperature |

| Tm | Melting temperature |

References

- Ray, S.S.; Lee, H.K.; Huyen, D.T.T.; Chen, S.-S.; Kwon, Y.-N. Microplastics waste in environment: A perspective on recycling issues from PPE kits and face masks during the COVID-19 pandemic. Environ. Technol. Innov. 2022, 26, 102290. [Google Scholar] [CrossRef] [PubMed]

- Idowu, G.A.; Olalemi, A.O.; Aiyesanmi, A.F. Environmental impacts of COVID-19 pandemic: Release of microplastics, organic contaminants and trace metals from face masks under ambient environmental conditions. Environ. Res. 2023, 217, 114956. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Mayorga-Martinez, C.C.; Pumera, M. Magnetically boosted 1D photoactive microswarm for COVID-19 face mask disruption. Nat. Commun. 2023, 14, 935. [Google Scholar] [CrossRef]

- Fadare, O.O.; Okoffo, E.D. COVID-19 face masks: A potential source of microplastic fibers in the environment. Sci. Total Environ. 2020, 737, 140279. [Google Scholar] [CrossRef]

- Majernik, M.; Daneshjo, N.; Malega, P.; Štofková, Z. Environmental Waste Management of Disposable Surgical Coverage. Pol. J. Environ. Stud. 2021, 30, 5163–5174. [Google Scholar] [CrossRef]

- Khojasteh, D.; Davani, E.; Shamsipour, A.; Haghani, M.; Glamore, W. Climate change and COVID-19: Interdisciplinary perspectives from two global crises. Sci. Total Environ. 2022, 844, 157142. [Google Scholar] [CrossRef] [PubMed]

- Türkmen, B.A. Life cycle environmental impacts of disposable medical masks. Environ. Sci. Pollut. Res. 2021, 29, 25496–25506. [Google Scholar] [CrossRef]

- Lyu, L.; Bagchi, M.; Markoglou, N.; An, C.; Peng, H.; Bi, H.; Yang, X.; Sun, H. Towards environmentally sustainable management: A review on the generation, degradation, and recycling of polypropylene face mask waste. J. Hazard. Mater. 2024, 461, 132566. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Acedo-Fuentes, P.; García-Cobos, F.J.; Sánchez-Delgado, F.J.; Mota-López, M.I.; Meneses-Rodríguez, J.M. The recycling of surgical face masks as sound porous absorbers: Preliminary evaluation. Sci. Total Environ. 2023, 786, 147461. [Google Scholar] [CrossRef]

- Win, C.T.T.; Jongvivatsakul, P.; Jirawattanasomkul, T.; Prasittisopin, L.; Likitlersuang, S. Use of polypropylene fibers extracted from recycled surgical face masks in cement mortar. Constr. Build. Mater. 2023, 391, 131845. [Google Scholar] [CrossRef]

- Crespo, C.; Ibarz, G.; Sáenz, C.; Gonzalez, P.; Roche, S. Study of recycling potential of FFP2 face masks and characterization of the plastic mix-material obtained. A way of reducing waste in times of COVID-19. Waste Biomass Valori. 2021, 12, 6423–6432. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.; Shi, L.; Zhao, H.; Wang, J.; Li, W.; Jiang, Z.; Wang, X.; Yao, Y.; Sun, X. A green strategy to recycle the waste PP melt-blown materials: From 2D to 3D construction. Waste Manag. 2023, 157, 159–167. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, J.; Han, J. Effects of thermal oxidative ageing on dynamic viscosity, TG/DTG, DTA and FTIR of SNS- and SBS/sulfur- modified asphalts. Constr. Build. Mater. 2011, 25, 129–137. [Google Scholar] [CrossRef]

- Liu, J.; Fu, H.; Zhou, G.; Guo, Z.; Hu, B.; Li, Y.; Li, Y.; Jiang, X.-Y.; Lu, Q. Preparation of aromatic hydrocarbons from fast pyrolysis of waste medical mask catalyzed by modified HZSM-5. J. Anal. Appl. Pyrolysis 2023, 169, 105797. [Google Scholar] [CrossRef]

- Yuwen, C.; Liu, B.; Rong, Q.; Zhang, L.; Guo, S. Porous carbon materials derived from discarded COVID-19 masks via microwave solvothermal method for lithium--sulfur batteries. Sci. Total Environ. 2022, 817, 152995. [Google Scholar] [CrossRef] [PubMed]

- Parku, G.K.; Collard, F.-X.; Görgens, J.F. Pyrolysis of waste polypropylene plastics for energy recovery: Influence of heating rate and vacuum conditions on composition of fuel product. Fuel Process. Technol. 2020, 209, 106522. [Google Scholar] [CrossRef]

- Yin, K.; Wei, R.; Ruan, J.; Cui, P.; Zhu, Z.; Wang, Y.; Zhao, X. Life cycle assessment and life cycle cost analysis of surgical mask from production to recycling into hydrogen process. Energy 2023, 283, 129225. [Google Scholar] [CrossRef]

- Fabiani, C.; Cavagnoli, S.; Chiatti, C.; Pisello, A.L. Management of disposable surgical masks for tackling pandemic-generated pollution: Thermo-acoustic investigations and life cycle assessment of novel recycled building panels. Resour. Conserv. Recycl. 2022, 186, 106509. [Google Scholar] [CrossRef]

- Wu, W.; Cavalli, M.C.; Jiang, W.; Kringos, N. Differing perspectives on the use of high-content SBS polymer-modified bitumen. Constr. Build. Mat. 2024, 411, 134433. [Google Scholar] [CrossRef]

- Javadi, N.H.S.; Hajimohammadi, A.; Heydari, S.; Ng, J.J.K.C.; Kypreos, J.E.; Khalili, N. Investigating the applicability of storage stability test for waste plastic modified bitumen: Morphological analyses. Constr. Build. Mater. 2024, 441, 13745. [Google Scholar] [CrossRef]

- Al-Abdul Wahhab, H.I.; Dalhat, M.A.; Habib, M.A. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement Des. 2016, 18, 1117–1134. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Biligiri, K.P.; Giustozzi, F. Effect of Various Compatibilizers on the Storage Stability, Thermochemical and Rheological Properties of Recycled Plastic-Modified Bitumen. Int. J. Pavement Res. Technol. 2024, 17, 854–867. [Google Scholar] [CrossRef]

- Rashid, S.; Mudavath, R.; Chandra, H.; Shekhar, I.; Kumar, P.; Srivastava, M.; Kumar, K. A Review on Virgin or Waste Polymers in Bitumen Modification for Ageing and Rejuvenation. Chem. Eng. Technol. 2024, 47, 624–637. [Google Scholar] [CrossRef]

- Wang, T.; Xu, G.; Shi, C.; Xu, X.; Yu, Y.; Gong, M.; Yang, J. Rheological properties of aged bitumen rejuvenated by polymer modified bio-derived rejuvenator. Constr. Build. Mater. 2021, 298, 123249. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Rossi, C.O. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Baranowska, W.; Rzepna, M.; Ostrowski, P.; Lewandowska, H. Radiation and Radical Grafting Compatibilization of Polymers for Improved Bituminous Binders—A Review. Materials 2024, 17, 1642. [Google Scholar] [CrossRef] [PubMed]

- Bettini, S.H.P.; Agnelli, J.A.M. ProduGrafting of maleic anhydride onto polypropylene by reactive extrusion. J. Appl. Polym. Sci. 2002, 85, 2706–2717. [Google Scholar] [CrossRef]

- Garcia-Martinez, J.M.; Laguna, O.; Collar, E.P. Chemical modification of polypropylenes by maleic anhydride: Influence of stereospecificity and process conditions. J. Appl. Polym. Sci. 1998, 68, 483–495. [Google Scholar] [CrossRef]

- Gunka, V.; Prysiazhnyi, Y.; Hrynchuk, Y.; Sidun, I.; Demchuk, Y.; Shyshchak, O.; Bratychak, M. Production of Bitumen Modified with Low-Molecular Organic Compounds from Petroleum Residues. 2. Bitumen Modified with Maleic Anhydride. Chem. Chem. Technol. 2021, 15, 443–449. [Google Scholar] [CrossRef]

- Gadaleta, G.; Notarnicola, M.; De Gisi, S. Impacts of techniques for plastic waste management. In Reuse of Plastic Waste in Eco-Efficient Concrete; Pacheco-Torgal, F., Khatib, J., Colangelo, F., Tuladhar, R., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2024; pp. 37–62. [Google Scholar] [CrossRef]

- Sarkari, N.M.; Ayar, P.; Oskouei, M.H.; Khosrowshahi, F.K.; Mohseni, M. Silane crosslinkable polyethylene waste as bitumen modifier: A new fortunate destiny by in time recycling of thermoplastic waste before conversion to thermoset end-of-life unrecyclable polymer. Constr. Build. Mater. 2021, 287, 122999. [Google Scholar] [CrossRef]

- Tian, Y.; Li, H.; Sun, L.; Zhang, H.; Harvey, J.; Yang, J.Y.; Yang, B.; Zuo, X. Laboratory investigation on rheological, chemical and morphological evolution of high content polymer modified bitumen under long-term thermal oxidative aging. Constr. Build. Mater. 2021, 303, 124565. [Google Scholar] [CrossRef]

- Joohari, I.B.; Giustozzi, F. Chemical and high-temperature rheological properties of recycled plastics-polymer modified hybrid bitumen. J. Clean. Prod. 2020, 276, 123064. [Google Scholar] [CrossRef]

- Yalcin, E.; Ozdemir, A.M.; Kok, B.V.; Yilmaz, M.; Yilmaz, B. Influence of pandemic waste face mask on rheological, physical and chemical properties of bitumen. Constr. Build. Mater. 2022, 337, 127576. [Google Scholar] [CrossRef] [PubMed]

- Garofalo, E.; Di Maio, L.; Scarfato, P.; Apicella, A.; Protopapa, A.; Incarnato, L. Nanosilicates in Compatibilized Mixed Recycled Polyolefins: Rheological Behavior and Film Production in a Circular Approach. Nanomaterials 2021, 11, 2128. [Google Scholar] [CrossRef] [PubMed]

- UNI EN 1426:2024; Bitumen and Bituminous Binders—Determination of Needle Penetration. European Committee for Standardization (CEN): Brussels, Belgium, 2024.

- UNI EN 1427:2015; Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- UNI EN 12591:2021; Bitumen and Bituminous Binders—Specifications for Paving Grade Bitumen. European Committee for Standardization (CEN): Brussels, Belgium, 2021.

- De Roover, B.; Sclavons, M.; Carlier, V.; Devaux, J.; Legras, R.; Momtaz, A. Molecular characterization of maleic anhydride-functionalized polypropylene. J. Polym. Sci. A Polym. Chem. 1995, 33, 829–842. [Google Scholar] [CrossRef]

- Lanyi, F.J.; Wenzke, N.; Kaschta, J.; Schubert, D.W. On the Determination of the Enthalpy of Fusion of α-Crystalline Isotactic Polypropylene Using Differential Scanning Calorimetry, X-Ray Diffraction, and Fourier-Transform Infrared Spectroscopy: An Old Story Revisited. Adv. Eng. Mater. 2020, 22, 1900796. [Google Scholar] [CrossRef]

- UNI EN ISO 2555:2018; Plastics—Resins in the Liquid State or As Emulsions or Dispersions—Determination of Apparent Viscosity Using a Single Cylinder Type Rotational Viscometer Method. European Committee for Standardization (CEN): Brussels, Belgium, 2018.

- Garofalo, E.; Di Maio, L.; Scarfato, P.; Di Gregorio, F.; Incarnato, L. Reactive compatibilization and melt compounding with nanosilicates of post-consumer flexible plastic packagings. Polym. Degrad. Stab. 2018, 152, 52–63. [Google Scholar] [CrossRef]

- UNI EN 14023:2010; Bitumen and Bituminous Binders—Specification Framework for Polymer Modified Bitumens. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- De Feo, G.; Galasso, M.; Landi, R.; Donnarumma, A.; De Gisi, S. A comparison of the efficacy of organic and mixed-organic polymers with polyaluminium chloride in chemically assisted primary sedimentation (CAPS). Environ. Technol. 2013, 34, 1297–1305. [Google Scholar] [CrossRef]

- Chibani, N.; Djidjelli, H.; Dufresne, A.; Boukerrou, A.; Nedjma, S. Study of effect of old corrugated cardboard in properties of polypropylene composites: Study of mechanical properties, thermal behavior, and morphological properties. J. Vinyl. Addit. Technol. 2016, 22, 231–238. [Google Scholar] [CrossRef]

- Shimadzu Corporation, Environmental and Lost Masks FFP2 and Clinical/Surgical Masks Analysis with FTIR and ATR. 2022. Available online: https://www.shimadzu.it/sites/shimadzu.seg/files/pim/pim_document_file/seg_it/applications/application_note/22909/FTIR_mascherine.pdf (accessed on 15 November 2024).

- Nanjing ILUCKU Technologies Ltd. PP for Production of Spunbond and Meltblown Nonwovens. 2021. Available online: https://ilucku.com/pp-for-production-of-spunbond-and-meltblown-nonwovens/ (accessed on 15 November 2024).

- Kara, Y.; Molnár, K. Revealing of process–structure–property relationships of fine polypropylene fiber mats generated via melt blowing. Polym. Adv. Technol. 2021, 32, 2416–2432. [Google Scholar] [CrossRef]

- Yoon, S.; Bhatt, S.D.; Lee, W.; Lee, H.Y.; Jeong, S.Y.; Baeg, J.-O.; Lee, C.W. Separation and characterization of bitumen from Athabasca oil sand. Korean J. Chem. Eng. 2009, 26, 64–71. [Google Scholar] [CrossRef]

- Herrington, P.R.; Wu, Y.; Forbes, M.C. Rheological modification of bitumen with maleic anhydride and dicarboxylic acids. Fuel 1999, 78, 101–110. [Google Scholar] [CrossRef]

- Nivitcha, M.R.; Prasad, E.; Krishnan, J.M. Ageing in modified bitumen using FTIR spectroscopy. Int. J. Pavement Eng. 2015, 17, 565–577. [Google Scholar] [CrossRef]

- Schaur, A.; Unterberger, S.H.; Lackner, R. Impact of molecular structure of PP on thermo-rheological properties of polymer-modified bitumen. Constr. Build. Mater. 2021, 287, 122981. [Google Scholar] [CrossRef]

- Liu, J.; Hao, P.; Sun, B.; Li, Y.; Wang, Y. Rheological Properties and Mechanism of Asphalt Modified with Polypropylene and Graphene and Carbon Black Composites. J. Mater. Civ. Eng. 2022, 34, 04022343. [Google Scholar] [CrossRef]

- Gunka, V.; Hrynchuk, Y.; Sidun, Y.I.; Demchuk, Y.; Prysiazhnyi, Y.; Bratychak, M. Production of Bitumen Modified with Low-Molecular Organic Compounds from Petroleum Residues. 6. Temperature Effect on the Chemical Modification of Bitumen with Maleic Anhydride. Chem. Chem. Technol. 2022, 16, 475–483. [Google Scholar] [CrossRef]

- Ma, D.; Zhao, D.; Zhao, J.; Du, S.; Pang, J.; Wang, W.; Fan, C. Functionalization of reclaimed polyethylene with maleic anhydride and its application in improving the high temperature stability of asphalt mixtures. Constr. Build. Mater. 2016, 113, 596–602. [Google Scholar] [CrossRef]

| Property | Unit | Bitumen | ||

|---|---|---|---|---|

| B35/50 | B50/70 | B70/100 | ||

| Penetration at 25 °C | 1/10 mm | 35–50 | 50–70 | 70–100 |

| Softening Point (Ball and Ring) | °C | 50–58 | 46–54 | 43–51 |

| Penetration Index | - | −1.5–0.7 | −1.5–0.7 | −1.5–0.7 |

| Specific gravity 25 °C/25 °C | - | 1.00–1.10 | 1.00–1.10 | 1.00–1.07 |

| Flash Point COC | °C | 250 | 250 | 250 |

| Dynamic Viscosity at 60 °C | Pa·s | 225 | 145 | 90 |

| Dynamic Viscosity at 135 °C | mPa·s | 370 | 295 | 230 |

| Solubility in organic solvents | wt.% | 99.0 | 99.0 | 99.0 |

| Sample Name | Composition (wt.%) | ||||

|---|---|---|---|---|---|

| B70/100 | Polymer Modifier | ||||

| AUS | PP | M | MMAH (a) | ||

| PMB_AUS | 95.0 | 5.0 | - | - | |

| PMB_PP0.5 | 99.5 | - | 0.5 | - | - |

| PMB_PP1 | 99.0 | - | 1.0 | - | - |

| PMB_PP3 | 97.0 | - | 3.0 | - | - |

| PMB_PP5 | 95.0 | - | 5.0 | - | |

| PMB_M0.5 | 99.5 | - | - | 0.5 | - |

| PMB_M1 | 99.0 | - | - | 1.0 | - |

| PMB_M3 | 97.0 | - | - | 3.0 | - |

| PMB_M5 | 95.0 | - | - | 5.0 | - |

| PMB_AUS_M0.5 | 99.5 | 5 | - | 0.5 | - |

| PMB_AUS_M1 | 99.0 | 5 | - | 1.0 | - |

| PMB_AUS_M3 | 97.0 | 5 | - | 3.0 | - |

| PMB_AUS_M5 | 95.0 | 5 | - | 5.0 | - |

| PMB_MMAH0.5 | 99.5 | - | - | - | 0.5 |

| PMB_MMAH1 | 99.0 | - | - | - | 1.0 |

| PMB_MMAH3 | 97.0 | - | - | - | 3.0 |

| PMB_MMAH5 | 95.0 | - | - | - | 5.0 |

| Parameter | Degree to Which the PMB_MMAH5 Mixture Reaches the Performance Values of Conventional PP-Based Mixtures | |||

|---|---|---|---|---|

| PMB_PP1 | PMB_PP3 | PMB_MMAH5 | ||

| Viscosity | Completely | Completely | Completely | |

| Penetration | 10 °C | Completely | Completely | Completely |

| 20 °C | Completely | Completely | Completely | |

| 30 °C | Completely | Completely | Completely | |

| 40 °C | Completely | Completely | Completely | |

| Softening | 10 °C | Completely | Completely | Completely |

| 30 °C | Completely | Completely | Partly | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scarfato, P.; De Gisi, S.; Apicella, A.; Levi, M.; Dintcheva, N.T.; Incarnato, L. Valorization of Unused, Expired Surgical Masks in Polymer-Modified Bitumens Using Maleic Anhydride as a Compatibilizer. Polymers 2025, 17, 3110. https://doi.org/10.3390/polym17233110

Scarfato P, De Gisi S, Apicella A, Levi M, Dintcheva NT, Incarnato L. Valorization of Unused, Expired Surgical Masks in Polymer-Modified Bitumens Using Maleic Anhydride as a Compatibilizer. Polymers. 2025; 17(23):3110. https://doi.org/10.3390/polym17233110

Chicago/Turabian StyleScarfato, Paola, Sabino De Gisi, Annalisa Apicella, Marinella Levi, Nadka Tz. Dintcheva, and Loredana Incarnato. 2025. "Valorization of Unused, Expired Surgical Masks in Polymer-Modified Bitumens Using Maleic Anhydride as a Compatibilizer" Polymers 17, no. 23: 3110. https://doi.org/10.3390/polym17233110

APA StyleScarfato, P., De Gisi, S., Apicella, A., Levi, M., Dintcheva, N. T., & Incarnato, L. (2025). Valorization of Unused, Expired Surgical Masks in Polymer-Modified Bitumens Using Maleic Anhydride as a Compatibilizer. Polymers, 17(23), 3110. https://doi.org/10.3390/polym17233110