Numerical Study on Elastic Properties of Natural Fibres in Multi-Hybrid Composites

Abstract

1. Introduction

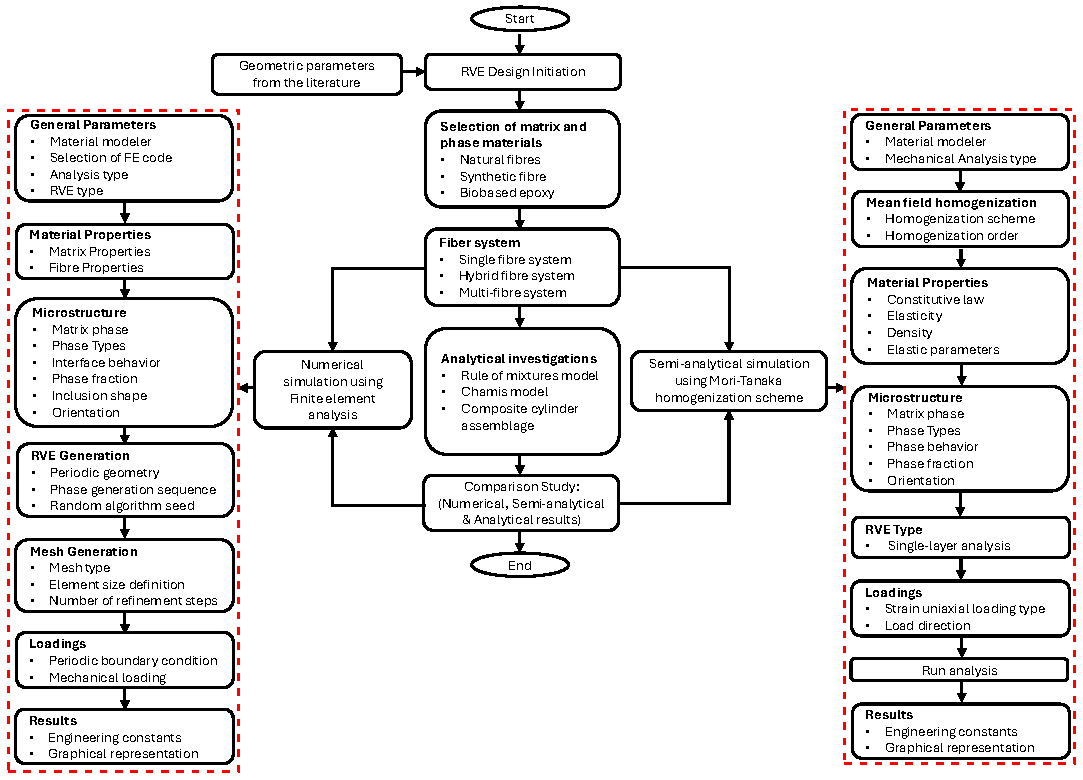

2. Methodology

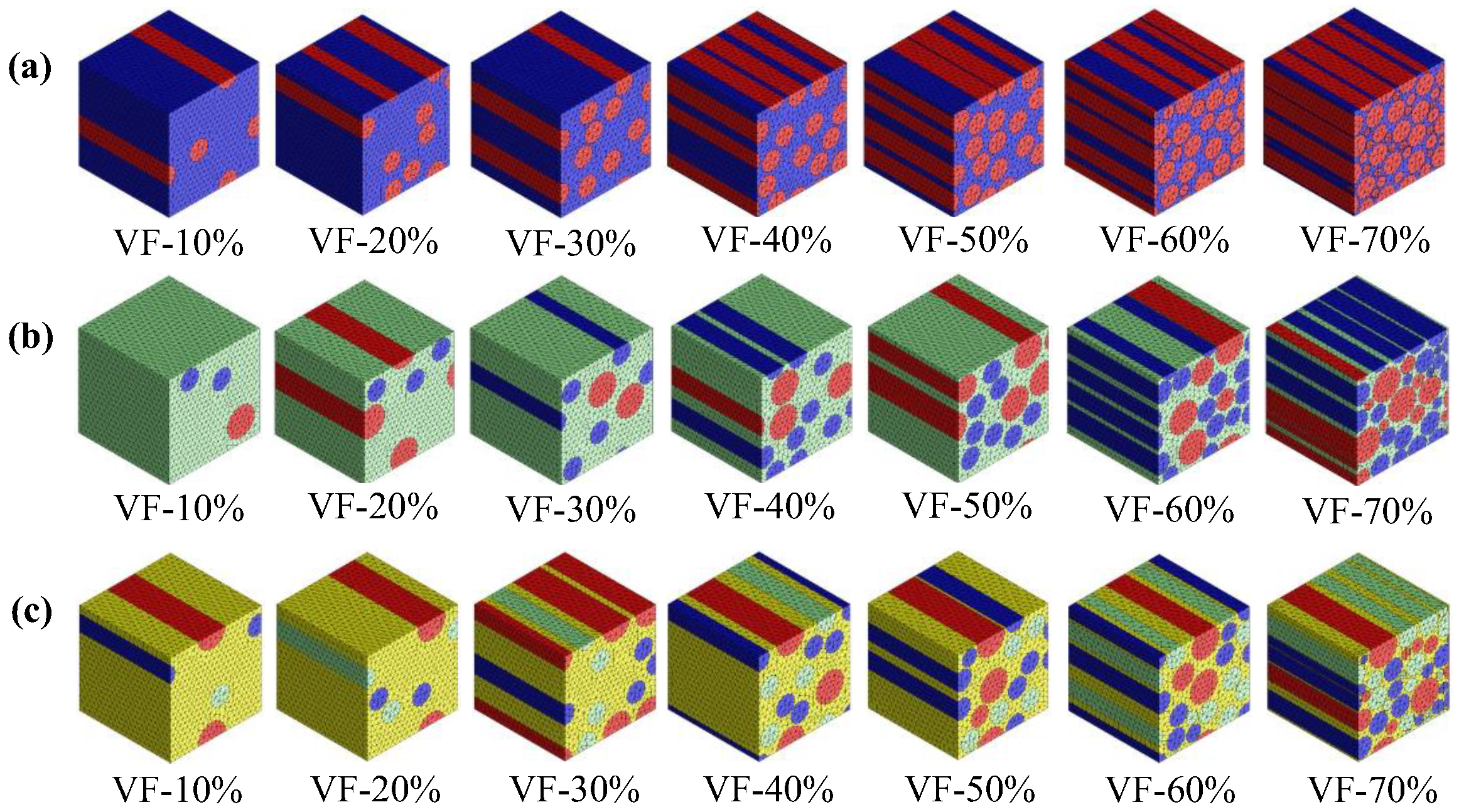

2.1. Finite Element Analysis

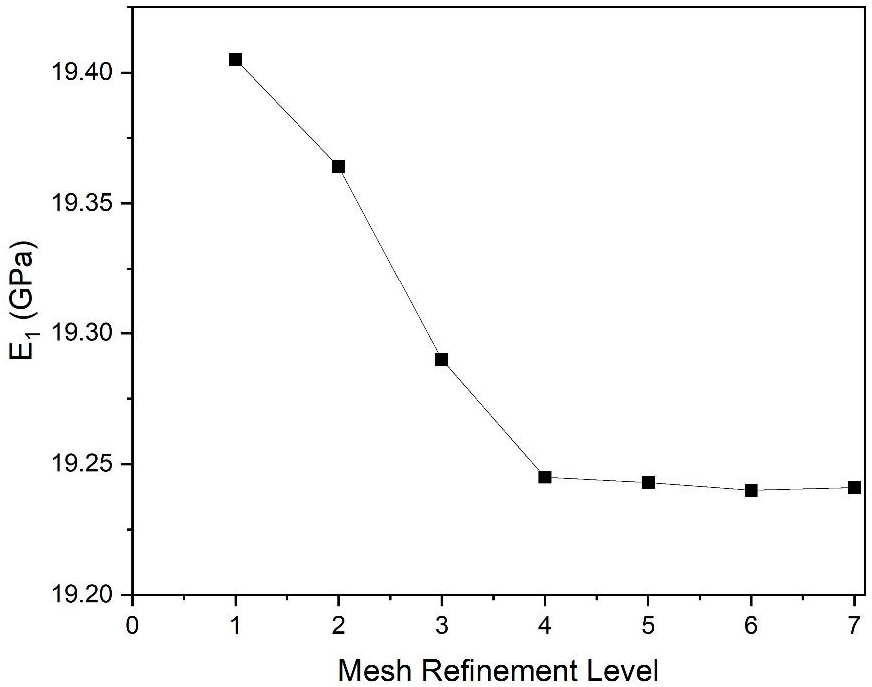

2.2. Mesh Convergence Study

2.3. Mean Field Homogenisation

2.4. Analytical Methods

2.4.1. Rule of Mixture

2.4.2. Chamis Model

2.4.3. Composite Cylinder Assemblage

3. Results and Discussions

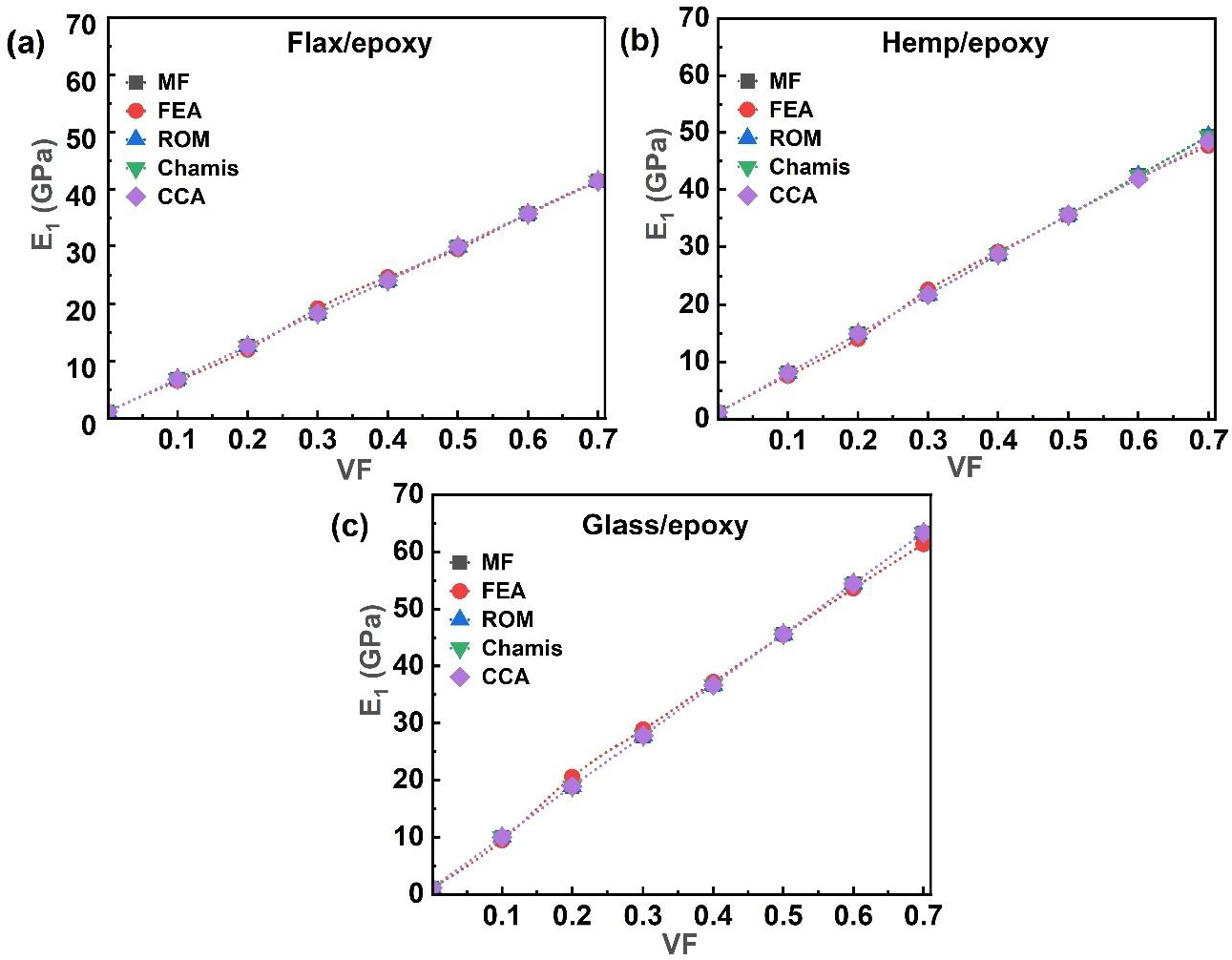

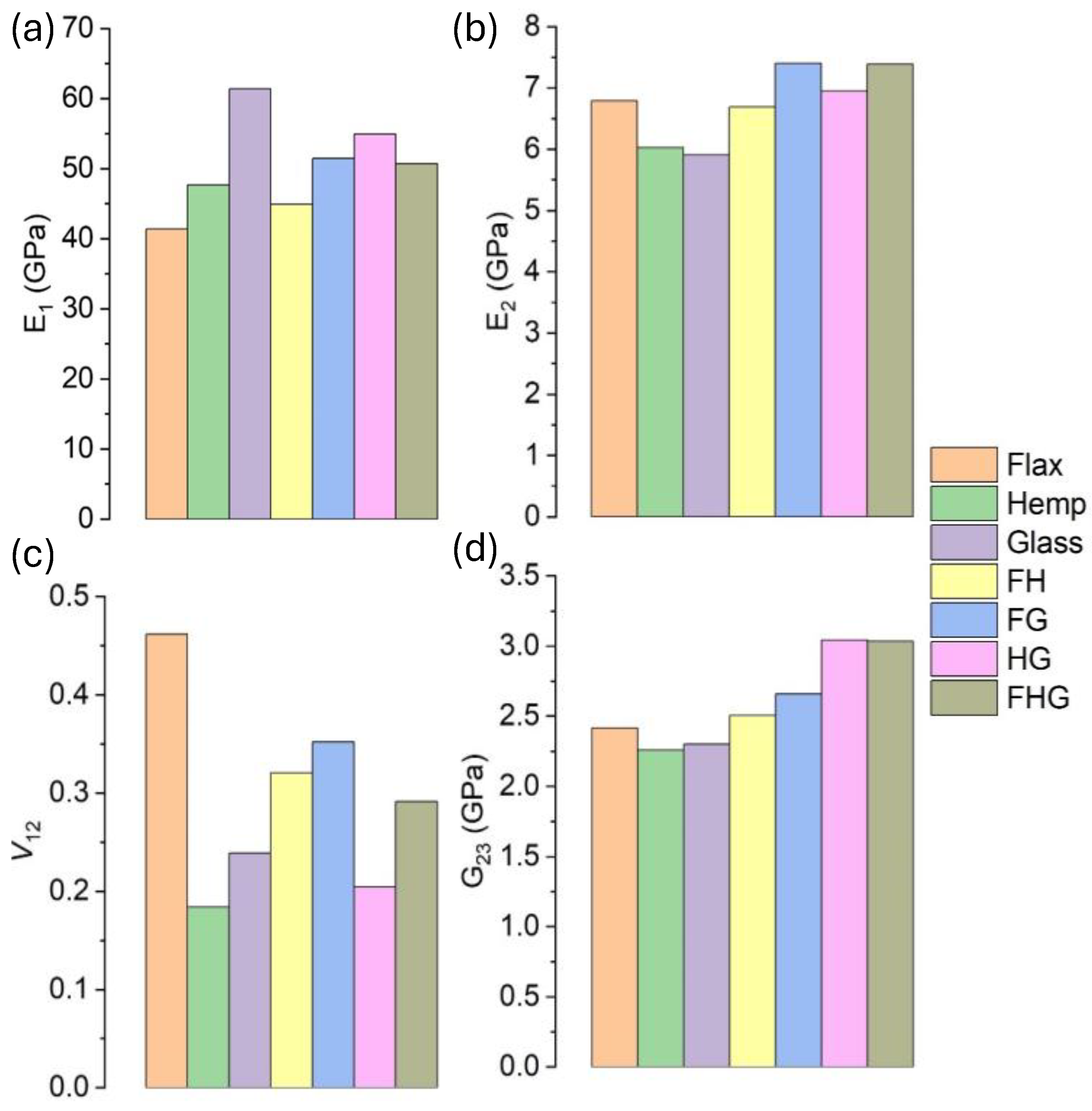

3.1. Longitudinal Modulus

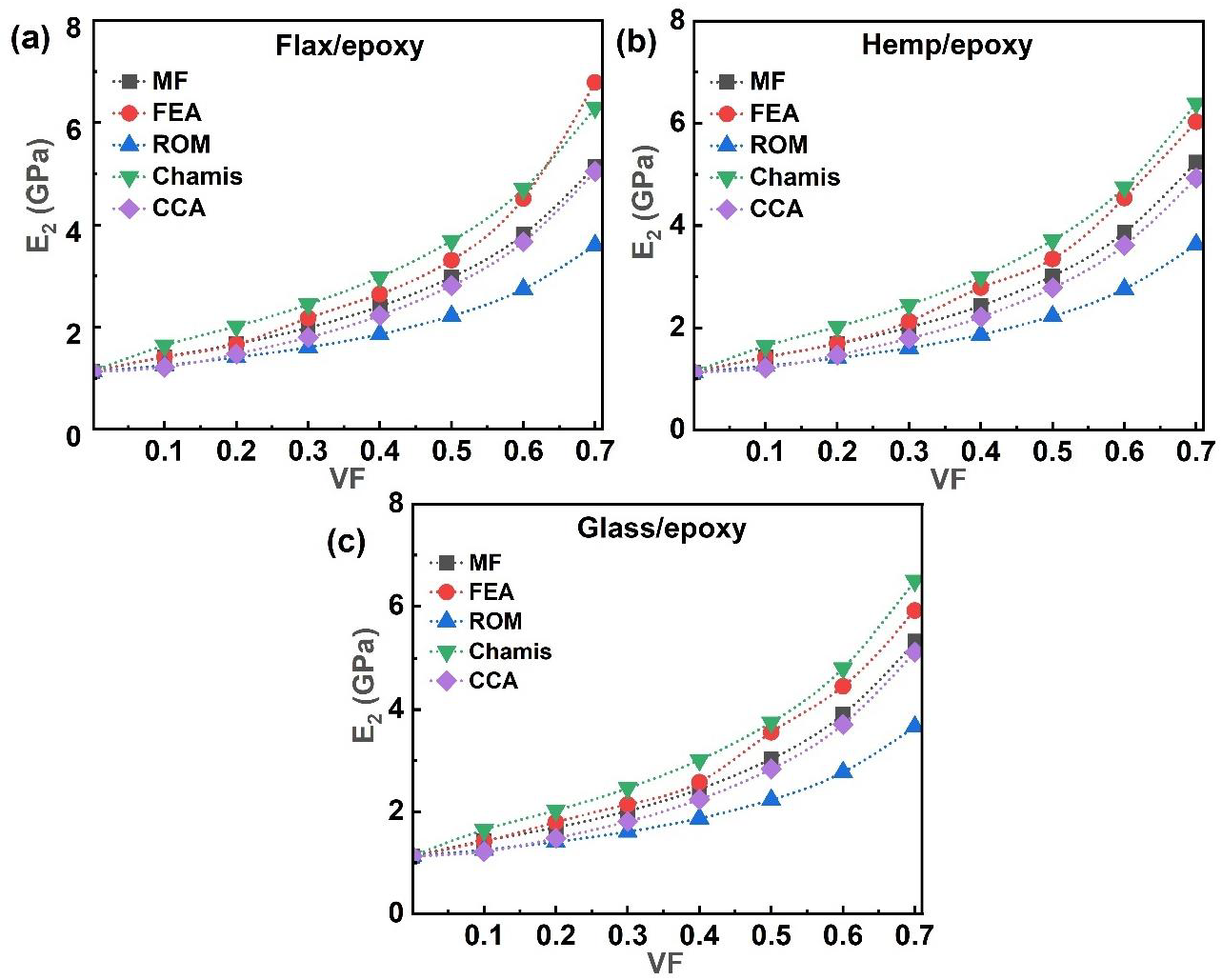

3.2. Transverse Modulus

3.3. Shear Modulus

3.4. Poisson’s Ratio

3.5. Composite Density

3.6. Comparative Study

4. Conclusions

- A consistent increase in the longitudinal modulus (E1) was observed with the increasing VF for all systems. Hybrid and multi-fibre systems generally exhibited higher stiffness than single natural fibre composites. The S-glass/epoxy system achieved the highest E1 value (63.34 GPa at 0.7 VF). In contrast, the multi-fibre flax–hemp–glass (FHG)/epoxy system demonstrated a balanced improvement, providing a 23.17% increase over flax/epoxy.

- Both the transverse modulus (E2) and shear modulus (G23) increased with the VF across all systems. The incorporation of glass fibres, particularly in the flax–glass (FG)/epoxy hybrid system, resulted in the highest transverse and shear stiffness. These results emphasise the matrix–dominated nature of these properties while highlighting the significant reinforcing effect of a higher fibre content.

- The behaviour of Poisson’s ratio (ν12) was highly dependent on fibre type. Composites containing flax fibre showed an increase in the ν12 with the VF, whereas systems with hemp or glass fibres exhibited a decrease. This inverse relationship in flax composites suggests a complex interaction between fibre properties and composite deformability.

- The density of the composites increased with the VF. Hybridising natural fibres (flax–hemp) resulted in a more efficient packing structure and a lower density than the individual fibres. The introduction of glass fibres increased the composite density and enhanced the elastic modulus, while the multi-fibre FHG system provided an optimised balance between weight and performance.

- Good agreement was obtained between the finite element analysis (FEA), mean-field homogenisation (MF), and analytical models, confirming the accuracy of the computational approaches adopted. The mesh convergence study further verified the reliability of the FEA results.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Feng, Y.; Hao, H.; Lu, H.; Chow, C.L.; Lau, D. Exploring the development and applications of sustainable natural fiber composites: A review from a nanoscale perspective. Compos. Part B Eng. 2024, 276, 111369. [Google Scholar] [CrossRef]

- Mylsamy, B.; Shanmugam, S.K.M.; Aruchamy, K.; Palanisamy, S.; Nagarajan, R.; Ayrilmis, N. A review on natural fiber composites: Polymer matrices, fiber surface treatments, fabrication methods, properties, and applications. Polym. Eng. Sci. 2024, 64, 2345–2373. [Google Scholar] [CrossRef]

- Laasri, L. Natural fiber composite features, applications, and markets. Multiscale Text. Preforms Struct. Nat. Fiber Compos. 2023, 31–61. [Google Scholar] [CrossRef]

- Al Mahmud, M.Z.; Rabbi, S.M.F.; Islam, M.D.; Hossain, N. Synthesis and applications of natural fiber-reinforced epoxy composites: A comprehensive review. SPE Polym. 2024, 2024, e10161. [Google Scholar] [CrossRef]

- Soni, A.; Das, P.K.; Gupta, S.K.; Saha, A.; Rajendran, S.; Kamyab, H.; Yusuf, M. An overview of recent trends and future prospects of sustainable natural fiber-reinforced polymeric composites for tribological applications. Ind. Crops Prod. 2024, 222, 119501. [Google Scholar] [CrossRef]

- Ullah, S.; Akhter, Z.; Palevicius, A.; Janusas, G. Review: Natural fiber-based biocomposites for potential advanced automotive applications. J. Eng. Fiber. Fabr. 2025, 20, 15589250241311468. [Google Scholar] [CrossRef]

- Islam, S.; Hasan, B.; Karim, F.; Kodrić, M.; Islam, R.; Khatun, M.M.; Motaleb, K.Z.M.A. Thermoset and thermoplastic polymer composites reinforced with flax fiber: Properties and application—A review. SPE Polym. 2025, 6, e10172. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: A critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Kalia, S.; Dufresne, A.; Cherian, B.M.; Kaith, B.S.; Avérous, L.; Njuguna, J.; Nassiopoulos, E. Cellulose-based bio- and nanocomposites: A review. Int. J. Polym. Sci. 2011, 2011, 837875. [Google Scholar] [CrossRef]

- Oke, W.A.; Adeyemi, O.A.; Bello, K.A.; Adegbenjo, A. Approximate Mode Shape for Damped Structures. Struct. Integr. 2019, 8, 9–14. [Google Scholar] [CrossRef]

- Malik, K.; Ahmad, F.; Gunister, E.; Nakato, T.; Mouri, E.; Muhammad, M.B.; Ali, S. A Review of Flax Fiber Reinforced Thermoset Polymer Composites: Structure and Mechanical Performance. J. Nat. Fibers 2022, 19, 9656–9680. [Google Scholar] [CrossRef]

- Baley, C.; Lan, M.; Bourmaud, A.; Le Duigou, A. Compressive and tensile behaviour of unidirectional composites reinforced by natural fibres: Influence of fibres (flax and jute), matrix and fibre volume fraction. Mater. Today Commun. 2018, 16, 300–306. [Google Scholar] [CrossRef]

- Soatthiyanon, N.; Crosky, A.; Heitzmann, M.T. Comparison of Experimental and Calculated Tensile Properties of Flax Fibres. J. Compos. Sci. 2022, 6, 100. [Google Scholar] [CrossRef]

- Abida, M.; Baklouti, A.; Gehring, F.; Vivet, A.; Bouvet, C. Inverse approach for flax yarns mechanical properties identification from statistical mechanical characterization of the fabric. Mech. Mater. 2020, 151, 103638. [Google Scholar] [CrossRef]

- Verstraete, S.; Buffel, B.; Madhav, D.; Debruyne, S.; Desplentere, F. Short Flax Fibres and Shives as Reinforcements in Bio Composites: A Numerical and Experimental Study on the Mechanical Properties. Polymers 2023, 15, 2239. [Google Scholar] [CrossRef]

- Brunengo, E.; Conzatti, L.; Utzeri, R.; Vicini, S.; Scatto, M.; Falzacappa, E.V.; Castellano, M.; Stagnaro, P. Chemical modification of hemp fibres by plasma treatment for eco-composites based on biodegradable polyester. J. Mater. Sci. 2019, 54, 14367–14377. [Google Scholar] [CrossRef]

- Terzopoulou, Z.N.; Papageorgiou, G.Z.; Papadopoulou, E.; Athanassiadou, E.; Alexopoulou, E.; Bikiaris, D.N. Green composites prepared from aliphatic polyesters and bast fibers. Ind. Crops Prod. 2015, 68, 60–79. [Google Scholar] [CrossRef]

- Tanasă, F.; Zănoagă, M.; Teacă, C.A.; Nechifor, M.; Shahzad, A. Modified hemp fibers intended for fiber-reinforced polymer composites used in structural applications—A review. I. Methods of modification. Polym. Compos. 2020, 41, 5–31. [Google Scholar] [CrossRef]

- Islam, S.; Hasan, M.B.; Kodrić, M.; Motaleb, K.Z.M.A.; Karim, F.E.; Islam, M.R. Mechanical properties of hemp fiber-reinforced thermoset and thermoplastic polymer composites: A comprehensive review. SPE Polym. 2025, 6, e10173. [Google Scholar] [CrossRef]

- Sadeghi, P.; Cao, Q.; Abouzeid, R.; Shayan, M.; Koo, M.; Wu, Q. Experimental and Statistical Investigations for Tensile Properties of Hemp Fibers. Fibers 2024, 12, 94. [Google Scholar] [CrossRef]

- Sala, B.; Surkova, P.; Sanctorum, M.; Guicheret-Retel, V.; Trivaudey, F.; Boubakar, L.; Placet, V. Variability in the elastic and time-delayed properties of structural hemp fibre composites. Compos. Part A Appl. Sci. Manuf. 2022, 161, 107116. [Google Scholar] [CrossRef]

- Antony, S.; Cherouat, A.; Montay, G. Experimental Investigation of the Temperature Effect on the Mechanical Properties of Hemp Woven Fabrics Reinforced Polymer. Appl. Mech. 2021, 2, 239–256. [Google Scholar] [CrossRef]

- Aliotta, L.; Pont, B.D.; Gigante, V.; Russo, P.; Passaro, J.; Lazzeri, A. Investigation of new Poly(lactic acid) (PLA)/Poly(butylene succinate-co-adipate) (PBSA) thermoplastic composites reinforced with different amount of twill hemp fabrics. J. Mater. Sci. 2024, 59, 847–862. [Google Scholar] [CrossRef]

- Premnath, K.; Arunprasath, K.; Sanjeevi, R.; Elilvanan, R.; Ramesh, M. Natural/synthetic fiber reinforced hybrid composites on their mechanical behaviors—A review. Interactions 2024, 245, 111. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Asyraf, M.R.M.; Syamsir, A.; Ma, Q.; Hazrati, K.Z.; Azlin, M.N.M.; Ali, M.M.; Ghani, A.; Hua, L.S.; SaifulAzry, S.; et al. Kenaf/glass fiber-reinforced polymer composites: Pioneering sustainable materials with enhanced mechanical and tribological properties. Polym. Compos. 2024, 45, 14421–14447. [Google Scholar] [CrossRef]

- Raza, A.; Mieloszyk, M.; Rimašauskienė, R.; Jūrėnas, V.; Maqsood, N.; Rimašauskas, M.; Kuncius, T. Dynamic properties and vibration control of additively manufactured carbon and glass fiber reinforced polymer composites using MFC: A numerical study with experimental validation. J. Manuf. Mater. Process. 2025, 9, 235. [Google Scholar] [CrossRef]

- Srinivasan, V.S.; Boopathy, S.R.; Sangeetha, D.; Ramnath, B.V. Evaluation of mechanical and thermal properties of banana–flax based natural fibre composite. Mater. Des. 2014, 60, 620–627. [Google Scholar] [CrossRef]

- Raza, A.; Rimašauskienė, R.; Jūrėnas, V.; Kuncius, T. Enhancing vibration control in kinematically excited addi-tively manufactured continuous fiber composite structures with distinct orientations. Eng. Struct. 2024, 321, 118933. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical review of natural fiber reinforced hybrid composites: Processing, properties, applications and cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef]

- Seydibeyoğlu, M.Ö.; Dogru, A.; Wang, J.; Rencheck, M.; Han, Y.; Wang, L.; Seydibeyoğlu, E.A.; Zhao, X.; Ong, K.; Shatkin, J.A.; et al. Review on Hybrid Reinforced Polymer Matrix Composites with Nanocellulose, Nanomaterials, and Other Fibers. Polymers 2023, 15, 984. [Google Scholar] [CrossRef]

- Saran, C.S.; Satapathy, A. Epoxy-hemp and epoxy-flax composites filled with glass dust for enhanced thermal insulation: An analytical and experimental study. Polym. Compos. 2024, 45, 5244–5255. [Google Scholar] [CrossRef]

- Raza, A.; Rimašauskienė, R.; Jūrėnas, V.; Mahato, S. Experimental investigation of vibration amplitude control in additive manufactured PLA and PLA composite structures with MFC actuator. Eng. Struct. 2023, 294, 116802. [Google Scholar] [CrossRef]

- Gurjar, A.K.; Kulkarni, S.M.; Joladarashi, S.; Doddamani, S. Experimental and numerical investigation on the elastic properties of luffa–cenosphere-reinforced epoxy hybrid composite. Polym. Compos. 2024, 45, 8921–8936. [Google Scholar] [CrossRef]

- Fedotov, A.F. Mori-Tanaka experimental-analytical model for predicting engineering elastic moduli of composite materials. Compos. Part B Eng. 2022, 232, 109635. [Google Scholar] [CrossRef]

- Adekoya, G.J.; Adekoya, O.C.; Sadiku, R.E.; Hamam, Y.; Ray, S.S. Numerical Investigation and Response Surface Optimization of the Effective Modulus and Electrical and Thermal Conductivities of the Borophene Nanoplatelet-Reinforced PEDOT:PSS Nanocomposite for Energy Storage Application. ACS Omega 2022, 7, 48447–48466. [Google Scholar] [CrossRef] [PubMed]

- Starink, M.J.; Syngellakis, S. Shear lag models for discontinuous composites: Fibre end stresses and weak interface layers. Mater. Sci. Eng. A 1999, 270, 270–277. [Google Scholar] [CrossRef]

- Zarubin, V.S.; Sergeeva, E.S.; Magnitsky, I.V. Comparative analysis of averaging methods for obtaining composite material elastic characteristics. IOP Conf. Ser. Mater. Sci. Eng. 2019, 683, 012042. [Google Scholar] [CrossRef]

- Lambri, F.; Bonifacich, F.; Lambri, O.; Weidenfeller, B.; Recarte, V.; Sánchez-Alarcos, V.; Pérez-Landazábal, J. Modified rule of mixtures and Halpin-Tsai models applied to PCL/NiMnInCo 4D printed composites. Internal stresses study during the martensitic transformation. Compos. Sci. Technol. 2025, 265, 111153. [Google Scholar] [CrossRef]

- Firooz, S.; Chatzigeorgiou, G.; Steinmann, P.; Javili, A. Extended general interfaces: Mori–Tanaka homogenization and average fields. Int. J. Solids Struct. 2022, 254–255, 111933. [Google Scholar] [CrossRef]

- Zheng, M.; Yin, Z.; Teng, H.; Liu, J.; Wang, Y. Elastoplastic Behavior of Highly Ductile Materials; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–173. [Google Scholar] [CrossRef]

- Nemeth, N.; Bednarcyk, B.; Pineda, E.; Arnold, S.; Mital, S.; Murthy, P.; Bhatt, R. FEAMAC/CARES Stochastic-Strength-Based Damage Simulation Tool for Ceramic Matrix Composites. In Proceedings of the Annual USACA Conference on Composites, Materials, and Structures, Cocoa Beach, FL, USA, 25–28 January 2016. [Google Scholar]

- Aboudi, J.; Arnold, S.M.; Bednarcyk, B.A. Micromechanics of Composite Materials: A Generalized Multiscale Analysis Approach; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Balasubramani, N.K.; Zhang, B.; Chowdhury, N.T.; Mukkavilli, A.; Suter, M.; Pearce, G.M. Micro-mechanical analysis on random RVE size and shape in multiscale finite element modelling of unidirectional FRP composites. Compos. Struct. 2022, 282, 115081. [Google Scholar] [CrossRef]

- Ogierman, W.; Kokot, G. Particle shape influence on Elastic-Plastic behaviour of Particle-Reinforced composites. Arch. Mater. Sci. Eng. 2014, 67, 70–76. [Google Scholar]

- Chang, H.-S.; Tsai, J.-L. Predict Elastic Properties of Fiber Composites by an Artificial Neural Network. Multiscale Sci. Eng. 2023, 5, 53–61. [Google Scholar] [CrossRef]

- Srivastava, N.; Singh, L.K.; Yadav, M.K.; Kamesh, B. Multiscale modeling and prediction of elastic properties of MWCNT- and RHA-reinforced AlP0507 matrix composite. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 329. [Google Scholar] [CrossRef]

- Alhijazi, M.; Safaei, B.; Zeeshan, Q.; Arman, S.; Asmael, M. Prediction of elastic properties of thermoplastic composites with natural fibers. J. Text. Inst. 2023, 114, 1488–1496. [Google Scholar] [CrossRef]

- Ge, J.; Chao, X.; Hu, H.; Tian, W.; Li, W.; Qi, L. Numerical Assessment of Effective Elastic Properties of Needled Carbon/Carbon Composites Based on a Multiscale Method. C-J. Carbon Res. 2024, 10, 85. [Google Scholar] [CrossRef]

- Sowmya, C.; Ramesh, V.; Karibasavaraja, D. An Experimental Investigation of New Hybrid Composite Material using Hemp and Jute Fibres and Its Mechanical Properties through Finite Element Method. Mater. Today Proc. 2018, 5, 13309–13320. [Google Scholar] [CrossRef]

- Atmakuri, A.; Palevicius, A.; Vilkauskas, A.; Janusas, G. Numerical and Experimental Analysis of Mechanical Properties of Natural-Fiber-Reinforced Hybrid Polymer Composites and the Effect on Matrix Material. Polymers 2022, 14, 2612. [Google Scholar] [CrossRef]

- Barbero, E.J.; Barbero, E.J. Finite Element Analysis of Composite Materials Using Abaqus®, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar] [CrossRef]

- Jithesh, K.; Arivarasu, M.; Rao, M.N. Studies on Oxidation Behaviour of Cobalt-Based Superalloy 605. In Proceedings of the Advances in Materials Processing and Manufacturing Applications, Jaipur, India, 5–6 November 2020. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Shah, D.U.; Bourmaud, A.; Baley, C. Multiscale structure, properties, and characterization approaches of plant fibers to be used in biocomposites. In Biocomposites in Manufacturing; Woodhead Publishing: Cambridge, UK, 2025; pp. 25–53. [Google Scholar]

- Lala, S.D.; Sadikbasha, S.; Deoghare, A.B. Prediction of elastic modulus of polymer composites using Hashin–Shtrikman bound, mean field homogenization and finite element technique. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 1653–1659. [Google Scholar] [CrossRef]

- Magidov, I.; Mikhaylovskiy, K.; Shalnova, S.; Topalov, I.; Gushchina, M.; Zherebtsov, S.; Klimova-Korsmik, O. Prediction and Experimental Evaluation of Mechanical Properties of SiC-Reinforced Ti-4.25Al-2V Matrix Composites Produced by Laser Direct Energy Deposition. Materials 2023, 16, 5233. [Google Scholar] [CrossRef]

- Yıldırım, F.; Demirel, B.; Bulucu, E.D. Investigation of the mechanical properties of calcite reinforced polypropylene by using digimat-mean field homogenization and ansys FEM. Mater. Today Commun. 2022, 33, 105023. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Drapier, S.; Ferreira, M.; Le Duigou, A.; Liotier, P.J.; Ouagne, P.; Soulat, D.; et al. Specific features of flax fibres used to manufacture composite materials. Int. J. Mater. Form. 2019, 12, 1023–1052. [Google Scholar] [CrossRef]

- Sauvageon, T.; Lavoie, J.M.; Segovia, C.; Brosse, N. Toward the cottonization of hemp fibers by steam explosion—Part 1: Defibration and morphological characterization. Text. Res. J. 2018, 88, 1047–1055. [Google Scholar] [CrossRef]

- Aslanova, M.S. Glass Fibers. In Strong Fibres; ASM International: Almere, The Netherlands, 1985; pp. 3–60. [Google Scholar] [CrossRef]

- Liang, S.; Gning, P.B.; Guillaumat, L. Quasi-static behaviour and damage assessment of flax/epoxy composites. Mater. Des. 2015, 67, 344–353. [Google Scholar] [CrossRef]

- Van Vuure, A.W.; Baets, J.; Wouters, K.; Hendrickx, K. Compressive properties of natural fibre composites. Mater. Lett. 2015, 149, 138–140. [Google Scholar] [CrossRef]

- Mahboob, Z.; El Sawi, I.; Zdero, R.; Fawaz, Z.; Bougherara, H. Tensile and compressive damaged response in Flax fibre reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2017, 92, 118–133. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Adeoye, S.A.; Onifade, D.V.; Ighalo, J.O. Multi-scale finite element analysis of effective elastic property of sisal fiber-reinforced polystyrene composites. Mech. Adv. Mater. Struct. 2021, 28, 1245–1253. [Google Scholar] [CrossRef]

- Bhaskara, S.; Devireddy, R.; Biswas, S. Effect of Fiber Geometry and Representative Volume Element on Elastic and Thermal Properties of Unidirectional Fiber-Reinforced Composites. J. Compos. 2014, 2014, 629175. [Google Scholar] [CrossRef]

- Divakarraju, P.V.; Pandurangan, V.; Nithyadharan, M. Atomic force microscopy-based nanoindentation technique for characterizing the transverse and shear moduli of flax fibers. Compos. Sci. Technol. 2024, 258, 110890. [Google Scholar] [CrossRef]

- Le Gall, M.; Davies, P.; Martin, N.; Baley, C. Recommended flax fibre density values for composite property predictions. Ind. Crops Prod. 2018, 114, 52–58. [Google Scholar] [CrossRef]

- Baley, C.; Le Duigou, A.; Bourmaud, A.; Davies, P. Influence of drying on the mechanical behaviour of flax fibres and their unidirectional composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1226–1233. [Google Scholar] [CrossRef]

- Scida, D.; Bourmaud, A.; Baley, C. Influence of the scattering of flax fibres properties on flax/epoxy woven ply stiffness. Mater. Des. 2017, 122, 136–145. [Google Scholar] [CrossRef]

- Tulaphol, S.; Sun, Z.; Sathitsuksanoh, N. Biofuels and Bioproducts from Industrial Hemp, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2021; Volume 6. [Google Scholar] [CrossRef]

- Chowdhury, S.; Wang, X.; Rahman, M.A.; Ulven, C.A. Nanomechanical characterization of hemp fiber with atomic force microscopy. J. Compos. Mater. 2024, 59, 469–478. [Google Scholar] [CrossRef]

- Ribeiro, J.; Bueno, G.; Martín, M.R.; Rocha, J. Experimental Study on Mechanical Properties of Hemp Fibers Influenced by Various Parameters. Sustainability 2023, 15, 9610. [Google Scholar] [CrossRef]

- Soni, S.R.; Schluttenhofer, C.; Sritharan, S.I. Interlaminar Stresses in Hemp Reinforced Composites. In Proceedings of the 6th European Conference on Industrial Engineering and Operations Management, Lisbon, Portugal, 18–20 July 2023; pp. 848–856. [Google Scholar] [CrossRef]

- Muhit, I.B.; Omairey, E.L.; Pashakolaie, V.G. A holistic sustainability overview of hemp as building and highway construction materials. Build. Environ. 2024, 256, 111470. [Google Scholar] [CrossRef]

- Adusumalli, R.B.; Venkateshan, K.C.; Kunchi, C.; Vadlamani, S.R. Tensile testing of single fibres. Procedia Struct. Integr. 2019, 14, 150–157. [Google Scholar] [CrossRef]

- Yeon, J.; Chowdhury, S.C.; Gillespie, J.W. Mechanical properties and damage analysis of S-glass: A reactive molecular dynamics study. Compos. Part B Eng. 2022, 234, 109706. [Google Scholar] [CrossRef]

- Chawla, K.K. Glass fibers (GF). In Encyclopedia of Materials: Science and Technology, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2001; pp. 3541–3545. [Google Scholar]

- Sockalingam, S.; Dey, M.; Gillespie, J.W.; Keefe, M. Finite element analysis of the microdroplet test method using cohesive zone model of the fiber/matrix interface. Compos. Part A Appl. Sci. Manuf. 2014, 56, 239–247. [Google Scholar] [CrossRef]

- Elfakhri, F.; Alkahtani, R.; Li, C.; Khaliq, J. Influence of filler characteristics on the performance of dental composites: A comprehensive review. Ceram. Int. 2022, 48, 27280–27294. [Google Scholar] [CrossRef]

- O’Brien, C.; Zaghi, A.E. Mechanical characteristics of hybrid composites with ±45° glass and 0°/90° stainless steel fibers. Materials 2018, 11, 1355. [Google Scholar] [CrossRef]

- Dalfi, H.K.; Tausif, M.; Yousaf, Z. Effect of twist level on the mechanical performance of S-glass yarns and non-crimp cross-ply composites. J. Ind. Text. 2022, 51, 2921S–2943S. [Google Scholar] [CrossRef]

- Sicomin. SR GreenPoxy 33/SD 477X DNV-GL; Sicomin: Martigues, France, 2023; Volume 33, pp. 1–11. [Google Scholar]

- Don, D.K.; Reiner, J.; Jennings, M.; Subhani, M. Basalt Fibre-Reinforced Polymer Laminates with Eco-Friendly Bio Resin: A Comparative Study of Mechanical and Fracture Properties. Polymers 2024, 16, 2056. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, M.M.; Rasidi, M.; Mohammed, A.M.; Rahman, R.B.; Osman, A.F.; Adam, T.; Betar, B.O.; Dahham, O.S. Interfacial bonding mechanisms of natural fibre-matrix composites: An overview. BioResources 2022, 17, 7031. [Google Scholar] [CrossRef]

- Tandon, G.P.; Weng, G.J. The effect of aspect ratio of inclusions on the elastic properties of unidirectionally aligned composites. Polym. Compos. 1984, 5, 327–333. [Google Scholar] [CrossRef]

- Chamis, C. Mechanics of Composite Materials: Past, Present, and Future. ASTM International. J. Compos. Technol. Res. March 1989, 11, 3–14. [Google Scholar]

- Kaw, A.K. Mechanics of Composite Materials, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Navaneethakrishnan, G.; Karthikeyan, T.; Saravanan, S.; Selvam, V.; Parkunam, N.; Sathishkumar, G.; Jayakrishnan, S. Structural analysis of natural fiber reinforced polymer matrix composite. Mater. Today Proc. 2020, 21, 7–9. [Google Scholar] [CrossRef]

- Takahashi, K.; Chou, T.W. Transverse elastic moduli of unidirectional fiber composites with interfacial debonding. Metall. Mater. Trans. A 1988, 19, 129–135. [Google Scholar] [CrossRef]

- De Kok, J.M.; Peijs, T. Deformation, yield and fracture of unidirectional composites in transverse loading: 2. Influence of fibre–matrix adhesion. Compos. Part A Appl. Sci. Manuf. 1999, 30, 917–932. [Google Scholar] [CrossRef]

- Baley, C.; Perrot, Y.; Busnel, F.; Guezenoc, H.; Davies, P. Transverse tensile behaviour of unidirectional plies reinforced with flax fibres. Mater. Lett. 2006, 60, 2984–2987. [Google Scholar] [CrossRef]

- Le Duigou, A.; Bourmaud, A.; Gourier, C.; Baley, C. Multi-scale shear properties of flax fibre reinforced polyamide 11 biocomposites. Compos. Part A Appl. Sci. Manuf. 2016, 85, 123–129. [Google Scholar] [CrossRef]

- Mittal, V.; Saini, R.; Sinha, S. Natural Fiber-Mediated Epoxy Composites—A Review; Elsevier: Amsterdam, The Netherlands, 2016; Available online: https://www.sciencedirect.com/science/article/pii/S1359836816309660 (accessed on 10 March 2025).

- Sathishkumar, T.P.; Navaneethakrishnan, P.; Shankar, S.; Rajasekar, R.; Rajini, N. Characterization of natural fiber and composites—A review. J. Reinf. Plast. Compos. 2013, 32, 1457–1476. [Google Scholar] [CrossRef]

- Ashby, M.F. Designing Hybrid Materials. In Materials Selection in Mechanical Design, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar] [CrossRef]

- Çuvalci, H.; Erbay, K.; İpek, H. Investigation of the Effect of Glass Fiber Content on the Mechanical Properties of Cast Polyamide. Arab. J. Sci. Eng. 2014, 39, 9049–9056. [Google Scholar] [CrossRef]

| Materials | Density (g/cm3) | Young’s Modulus (GPa) | Poisson’s Ratio | Shear Modulus (GPa) |

|---|---|---|---|---|

| Flax | 1.55 [66,67] | 58.6 [66,67,68] | 0.50 [69] | 19.6 |

| Hemp | 1.393 [70] | 70.0 [71,72] | 0.15 [73,74] | 30.4 |

| S-glass | 2.495 [75,76,77] | 93.0 [78,79,80] | 0.23 [81] | 36.9 |

| Bio-epoxy | 1.159 [82] * | 1.13 ** | 0.30 [82,83] | 0.435 |

| Mesh Refinement Level | Number of Elements | Number of Nodes | E1 (GPa) | Relative Error |

|---|---|---|---|---|

| 1 | 19,407 | 33,967 | 19.405 | 0.845 |

| 2 | 29,704 | 50,736 | 19.364 | 0.635 |

| 3 | 54,062 | 89,328 | 19.290 | 0.254 |

| 4 | 67,312 | 110,262 | 19.245 | 0.021 |

| 5 | 82,321 | 134,031 | 19.243 | 0.010 |

| 6 | 103,669 | 166,234 | 19.240 | 0.005 |

| 7 | 173,873 | 273,837 | 19.241 |

| Fibre System | Anisotropy Ratio (AE) | Reinforcement Efficiency (ηE1, %) | Hybrid Effect Index (HEI) | Specific Stiffness (E1/ρ) (GPa·cm3·g−1) |

|---|---|---|---|---|

| Flax/epoxy | 6.10 | 1.0 | - | 28.91 |

| Hemp/epoxy | 7.91 | 0.97 | - | 36.05 |

| Glass/epoxy | 10.38 | 0.97 | - | 29.31 |

| FH/epoxy | 6.71 | 0.99 | 0.84 | 32.61 |

| FG/epoxy | 6.96 | 0.98 | 0.15 | 29.19 |

| HG/epoxy | 7.91 | 0.98 | 0.76 | 32.16 |

| FHG/epoxy | 6.86 | 0.99 | 1.05 | 31.26 |

| Fibre System | Numerical | Semi-Analytical | Analytical | ||||||

|---|---|---|---|---|---|---|---|---|---|

| E1 | E1 | Error | E1 (ROM, GPa) | Error (ROM, %) | E1 (Chamis, GPa) | Error (Chamis, %) | E1 (CCA, GPa) | Error (CCA, %) | |

| (FEA, GPa) | (MF, GPa) | (MF, %) | |||||||

| Flax/epoxy | 41.42 | 41.4 | 0.05 | 41.39 | 0.07 | 41.39 | 0.07 | 41.4 | 0.05 |

| Hemp/epoxy | 47.69 | 49.35 | 3.46 | 49.34 | 3.45 | 49.34 | 3.45 | 48.41 | 1.5 |

| Glass/epoxy | 61.38 | 63.34 | 3.2 | 63.34 | 3.2 | 63.34 | 3.2 | 63.34 | 3.2 |

| FH/epoxy | 44.93 | 45.69 | 1.69 | 45.36 | 0.97 | 45.36 | 0.97 | 45.39 | 1.03 |

| FG/epoxy | 51.48 | 52.57 | 2.13 | 52.36 | 1.72 | 52.36 | 1.72 | 52.37 | 1.73 |

| HG/epoxy | 54.95 | 56.35 | 2.56 | 56.34 | 2.53 | 56.34 | 2.53 | 56.35 | 2.54 |

| FHG/epoxy | 50.69 | 51.72 | 2.03 | 51.36 | 1.32 | 51.36 | 1.32 | 51.36 | 1.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahid, M.; Monastyreckis, G.; Zeleniakiene, D. Numerical Study on Elastic Properties of Natural Fibres in Multi-Hybrid Composites. Polymers 2025, 17, 3031. https://doi.org/10.3390/polym17223031

Shahid M, Monastyreckis G, Zeleniakiene D. Numerical Study on Elastic Properties of Natural Fibres in Multi-Hybrid Composites. Polymers. 2025; 17(22):3031. https://doi.org/10.3390/polym17223031

Chicago/Turabian StyleShahid, Mughees, Gediminas Monastyreckis, and Daiva Zeleniakiene. 2025. "Numerical Study on Elastic Properties of Natural Fibres in Multi-Hybrid Composites" Polymers 17, no. 22: 3031. https://doi.org/10.3390/polym17223031

APA StyleShahid, M., Monastyreckis, G., & Zeleniakiene, D. (2025). Numerical Study on Elastic Properties of Natural Fibres in Multi-Hybrid Composites. Polymers, 17(22), 3031. https://doi.org/10.3390/polym17223031