3.1. COF Analysis of Reciprocating Wear Tests

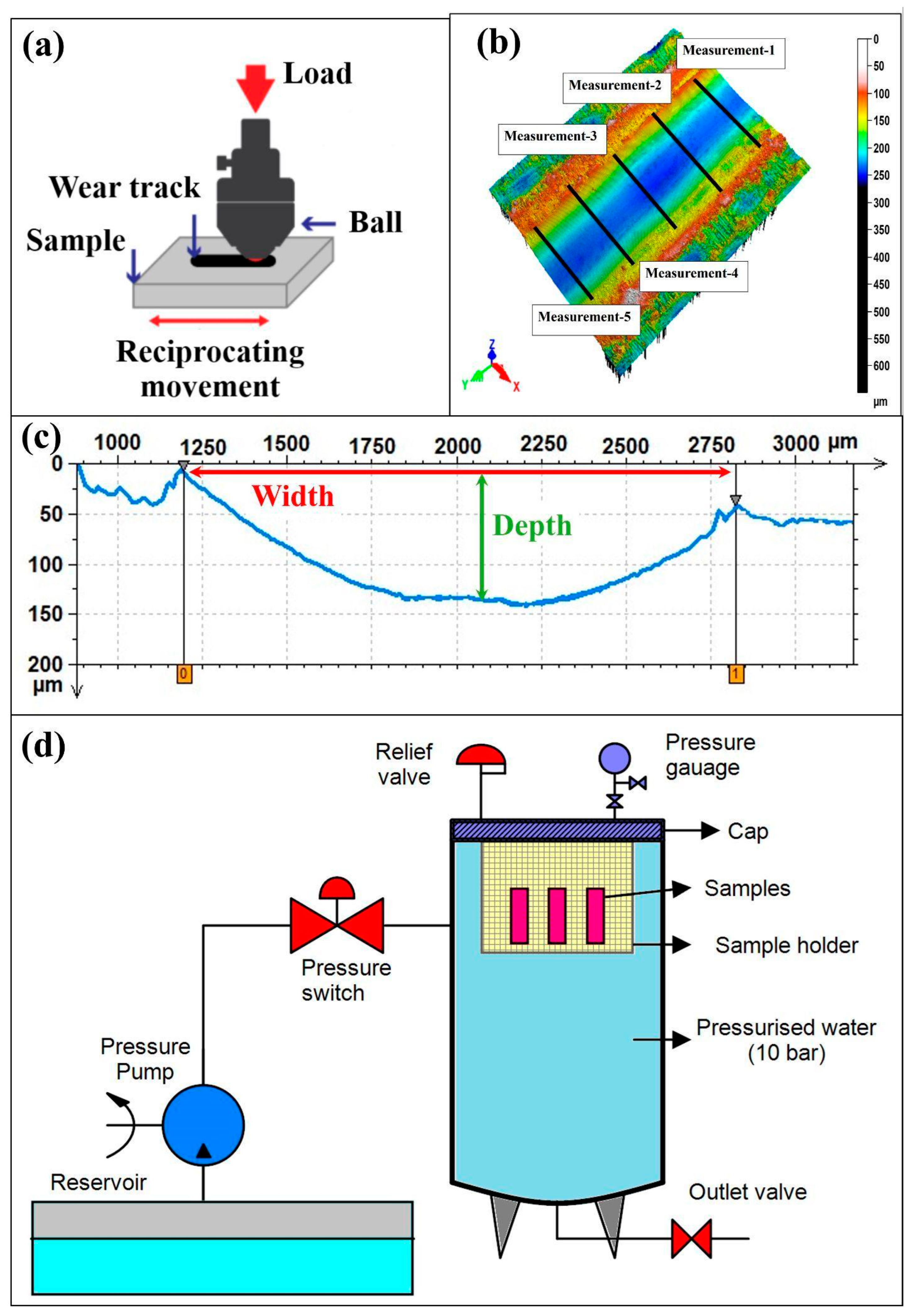

Water uptake of the glass/Kevlar hybrid epoxy laminates were measured at 0, 7, 14, and 21 days and are reported as mean ± SD over three replicates (error bars in the figures; SD ≤ 5% of the mean at all times). The average mass gains were Δm(0) = 0.000 g, Δm(7) = 1.038 ± 0.052 g, Δm(14) = 4.440 ± 0.222 g, and Δm(21) = 5.210 ± 0.261 g, corresponding to normalized uptakes M(t) = Δm/m

0 of 0, 1.70%, 7.28%, and 8.54% for m

0 = 61.003 g. The small dispersions (CV ≤ 5%) indicate good reproducibility and a uniform conditioning state across coupons. A least-squares fit to a short-time Fickian model (Δm ∝ √t) captures the rise and the gradual approach toward a plateau, supporting a diffusion-controlled sorption mechanism. The Kevlar-containing interphases, known to be more hydrophilic than glass/epoxy, plausibly provide additional ingress pathways at intermediate times, whereas the glass fraction and the woven architecture limit swelling and slow the approach to saturation. The decelerating increment from 14 to 21 days suggests the system is nearing, but has not yet reached, equilibrium under the present exposure. Accordingly, tribological performance is strongly governed by swelling duration up to the quasi-equilibrium condition (14 days), at which the COF reaches a minimum; further immersion produces only marginal changes as water uptake and matrix plasticization approach saturation (

Figure 3 and

Figure 4). Quantitative determination of the diffusion coefficient D via Fick’s second law would require the specimen thickness/geometry; nevertheless, the √t scaling together with the low scatter and sub-10% total uptake indicates predominantly Fickian behavior and satisfactory hydrothermal resistance of this hybrid laminate over the tested immersion period.

As shown in

Figure 3, the mass gain exhibits a rapid early uptake that follows a √t (Fickian) trend and progressively approaches quasi-equilibrium by day 21. Statistical reviews and meta-analyses of hygrothermal aging data confirm that the early-time sorption of water in epoxy systems is commonly Fickian (Mt ∝ √t) and that reported diffusion coefficients and initial slopes are highly sensitive to resin chemistry, specimen thickness, and test temperature, which explains why a clean √t fit captures the short-time region so well [

33]. Thickness-dependent modeling work shows that specimens with the thicknesses typical for laminated composite coupons often exhibit an initial Fickian regime followed by slower approach-to-equilibrium or apparent non-Fickian effects as edge saturation, capillary filling of interfacial voids, and fiber–matrix interfacial storage begin to contribute at longer times, behavior that explains an initially precise √t fit that gradually departs as the sample approaches the 21-day quasi-equilibrium [

34]. Finally, topical reviews of moisture uptake in fiber-reinforced composites highlight the role of fiber type (glass vs. aramid/Kevlar), fiber volume fraction, and the integrity of the fiber–matrix interface in setting both the equilibrium uptake and the kinetics: glass/Kevlar hybrid laminates commonly show an early, matrix-dominated Fickian uptake followed by slower, interface-controlled processes (interfacial sorption, microcracking, void filling) that control the long-term plateau observed near three weeks immersion. Together, these studies provide a mechanistic basis for the curve shape observed in

Figure 3 (accurate √t short-time fit plus gradual approach to equilibrium by day 21) [

35].

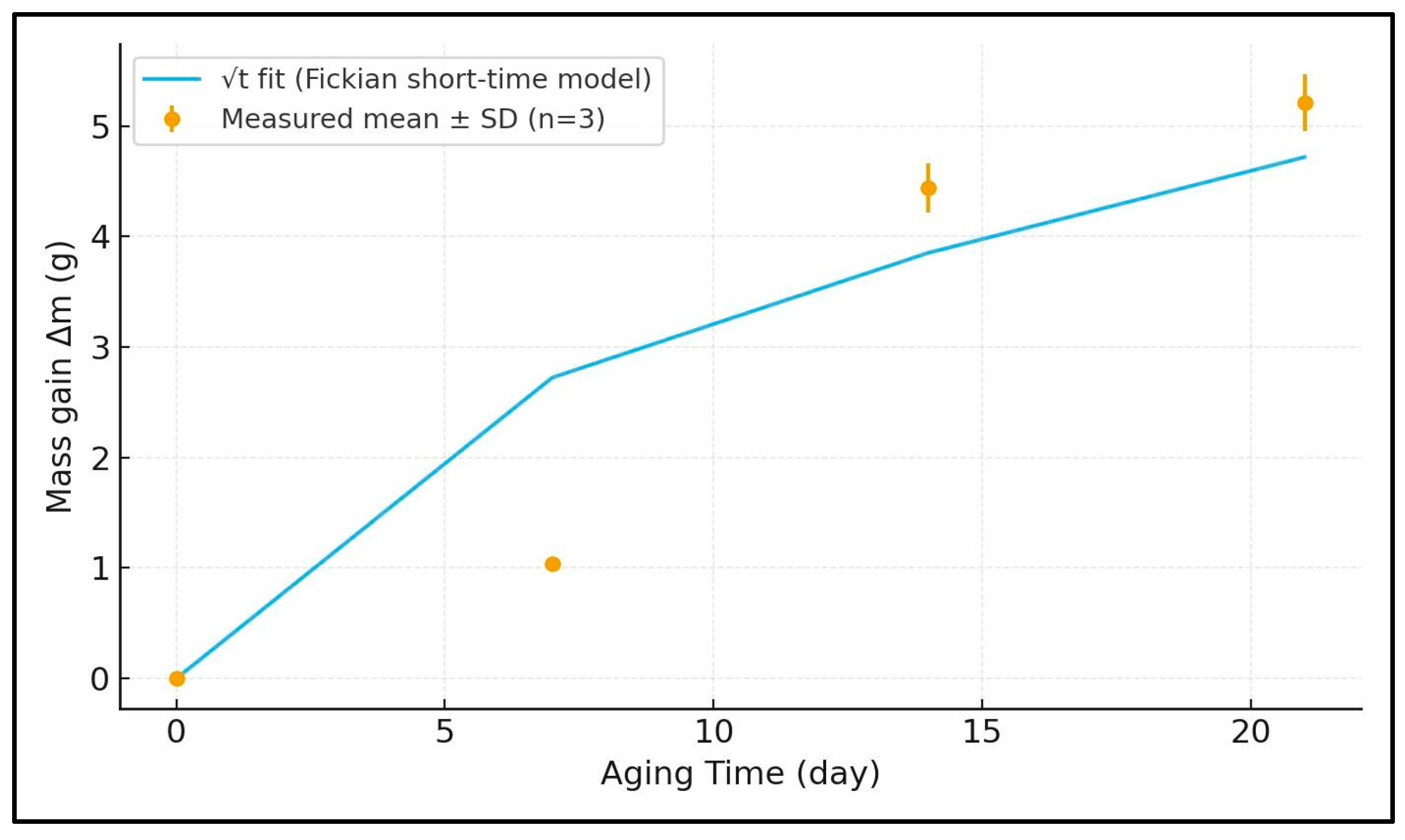

Figure 4a shows that at 1 Hz and 10 m the reference rapidly runs in and stabilizes near μ about 0.7–0.75, while immersion depresses and smooths the response, with 14 days giving the lowest plateau near 0.50–0.55 and 7 and 21 days leveling around 0.58–0.65.

Figure 4b indicates that extending the track to 20 m at 1 Hz magnifies these differences because cumulative sliding consolidates a hydrated third body on the intermediate-aged surface, so the 14-day curve remains near 0.40–0.45 across the entire distance, whereas 7 and 21 days drift toward 0.60 and the reference stays highest.

Figure 4c demonstrates that raising frequency to 2 Hz at 10 m shortens the running-in regime and increases frictional energy input, which slightly elevates the plateaus and narrows the gap between the reference and 21 days, yet the 14-day curve is still the lowest and exhibits reduced noise that is consistent with a coherent water-assisted tribofilm.

Figure 4d confirms that the most demanding combination of 2 Hz and 20 m preserves the advantage of the 14-day condition despite occasional transient drops linked to film renewal, while the 7- and 21-day traces approach the reference and show intermittent spikes that suggest partial tribofilm rupture and debris-driven stick–slip, indicating that intermediate immersion provides an optimal balance of epoxy plasticization, interfacial compliance, and moisture-mediated boundary lubrication.

Water immersion time exerts a nonmonotonic influence on COF, with an intermediate conditioning at 14 days producing the most pronounced and persistent reduction in friction, typically 20–40% lower than the dry reference across both frequencies and track lengths, whereas 7 days yields a partial decrease and 21 days trends back upward, especially at 2 Hz and 20 m. This behavior is consistent with a balance between beneficial water-induced plasticization and interfacial hydration that stabilizes a low-shear tribofilm at intermediate uptake, versus over-plasticization, interfacial swelling, and debris-assisted instabilities that emerge at longer immersion and re-elevate COF, with longer sliding distances amplifying these differences. The non-monotonic COF behavior observed in

Figure 4, where an intermediate immersion (14-day) produces a persistent, 20–40% lower friction plateau, while shorter (7-day) and longer (21-day) exposures show higher and more unstable COF, is consistent with mechanisms reported in the hygrothermal tribology literature. Hygrothermal conditioning can promote the formation of a coherent, moisture-mediated boundary/third-body film that lowers shear strength at the sliding interface and stabilizes friction during moderate exposure, producing a pronounced reduction in steady-state COF (as reported for multi-filler epoxy systems showing transient tribofilm formation and reduced friction after intermediate aging) [

23]. At longer immersion times, however, progressive resin hydrolysis, interfacial debonding and matrix plasticization increase debris production and weaken load-bearing interfaces; these processes both raise effective contact compliance and promote intermittent film rupture and debris-driven stick–slip, which elevates the COF toward or above the dry reference [

24]. Moreover, controlled studies on the role of moisture and oxygen show that small changes in environmental water content can switch tribo-chemical pathways and transfer-film character; so, a system can move from moisture-assisted low-shear sliding (low COF) to moisture-aggravated wear (high COF) as hygrothermal damage accumulates, exactly matching the intermediate-optimal/long-term-deterioration pattern recorded in

Figure 4 [

36].

3.3. Wear Damage Evaluation

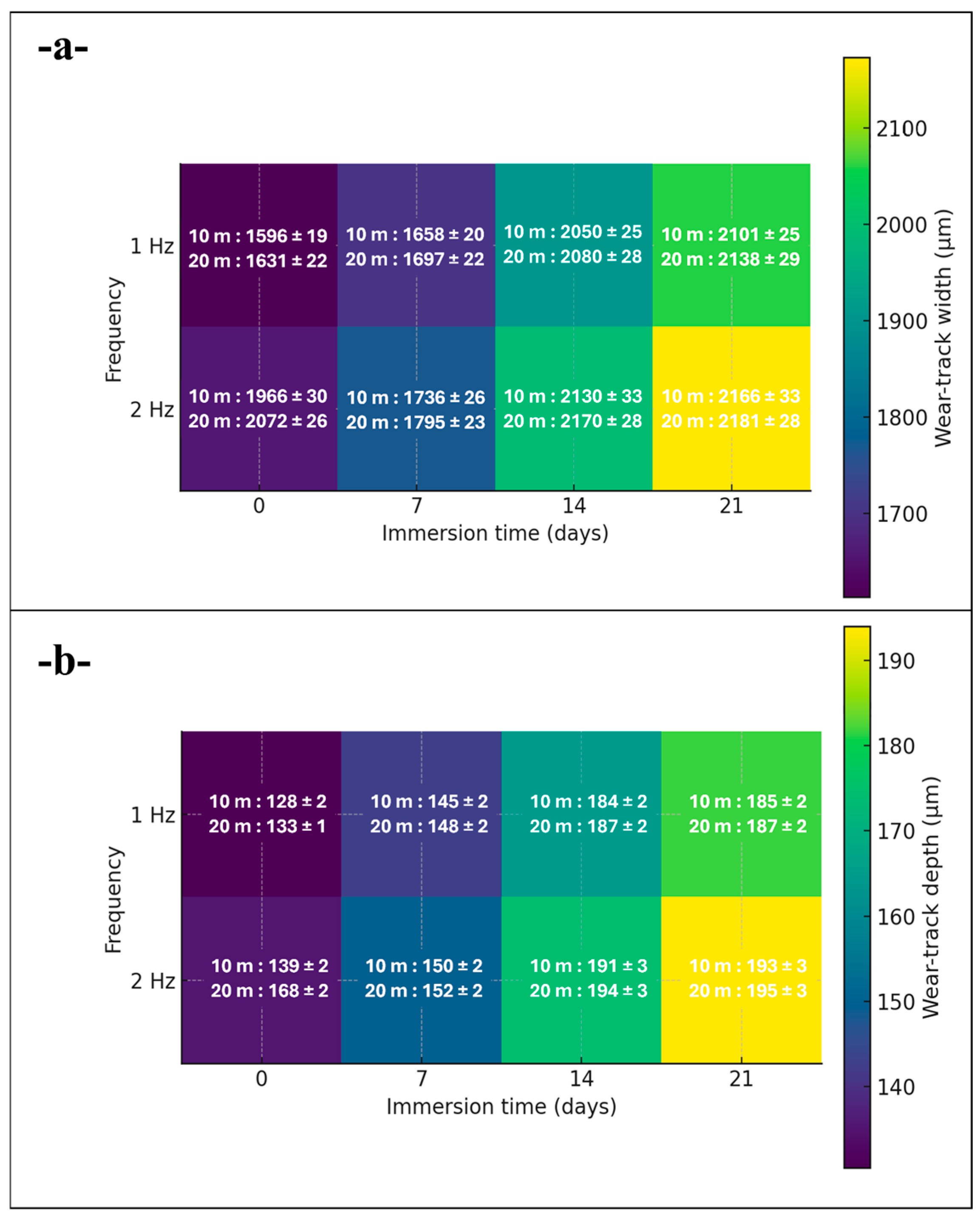

To facilitate an at-a-glance appraisal of global trends, all wear track width (

Figure 5a) and depth (

Figure 5b) data were consolidated into summary heatmaps across immersion time and frequency (

Figure 5). These overviews confirm a monotonic increase with immersion (most pronounced by 14-day) with frequency acting as a secondary amplifier and track length as a minor contributor.

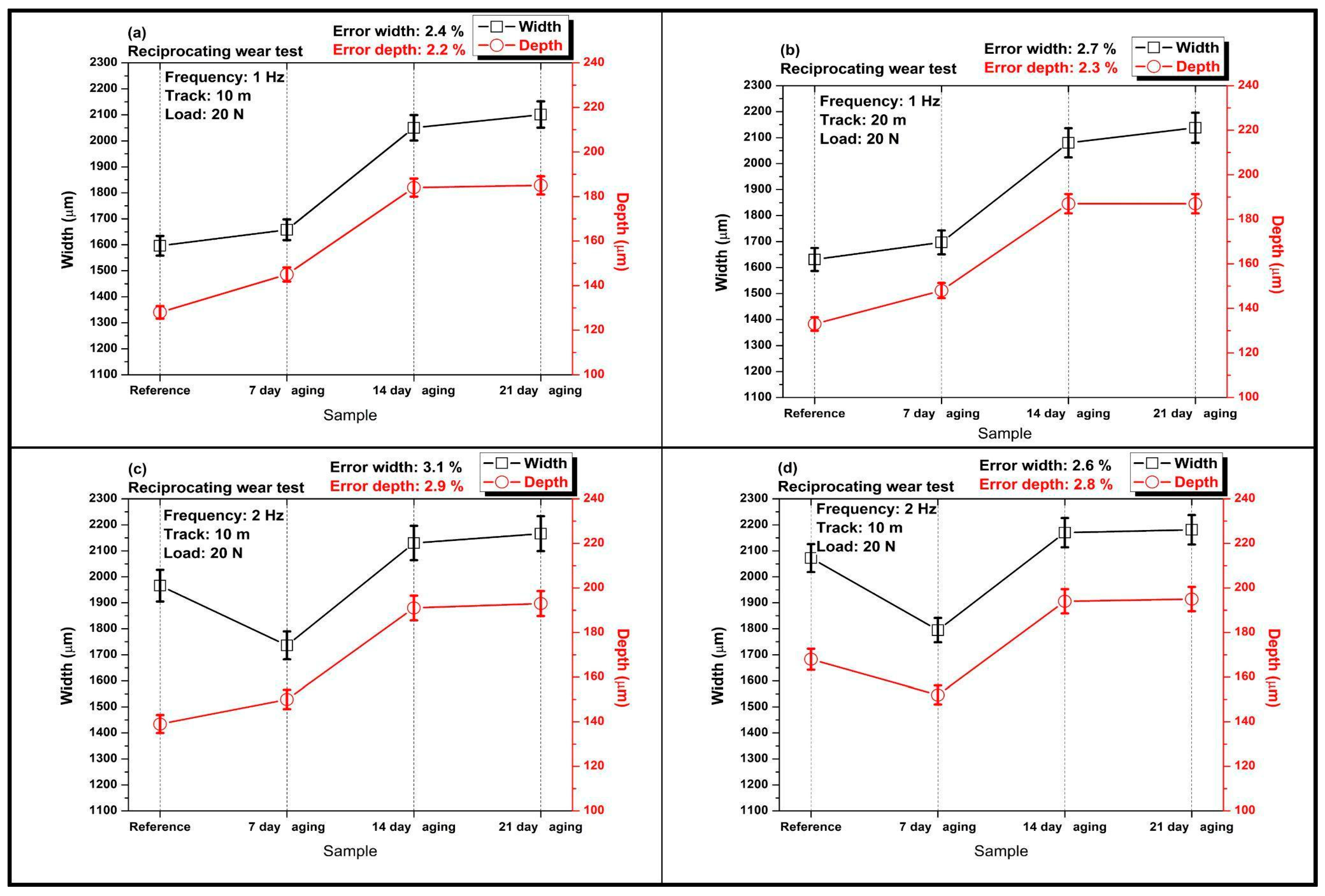

Figure 6 compares the evolution of reciprocating wear track width and depth for the glass/Kevlar epoxy hybrid composites tested at 20 N under four parameter sets: 1 Hz/10 m, 1 Hz/20 m, 2 Hz/10 m, and 2 Hz/20 m, after 0, 7, 14, and 21 days of water immersion.

In

Figure 6a at 20 N, 1 Hz, and 10 m total distance, both wear track width and depth increase with immersion time; a slight rise from reference to 7 days is followed by a pronounced jump by 14 days, after which depth plateaus while width continues to climb. This trend indicates that hydrolytic plasticization and interfacial weakening become dominant beyond a short conditioning period, allowing wider lateral plowing while subsurface penetration saturates.

In

Figure 6b at the same frequency but 20 m distance, the immersion effect is amplified; width and depth grow markedly up to 14 days and then level off or ease slightly at 21 days. The longer sliding distance magnifies matrix softening and fiber/matrix debonding, producing larger scars, whereas the late-stage moderation of depth suggests partial polishing/compaction of debris once the surface is severely damaged.

In

Figure 6c at 2 Hz and 10 m, width exhibits an initial dip at 7 days while depth remains comparatively low, consistent with transient boundary lubrication from absorbed water; by 14 days and 21 days, both metrics recover and exceed the reference, reflecting the transition from lubrication-dominated behavior to moisture-induced degradation (microcracking and interfacial debonding) under higher oscillation rate.

In

Figure 6d the combination of 2 Hz and 20 m yields the strongest immersion dependence: both width and depth decrease at 7 days but rise sharply at 14 days and remain high at 21 days, culminating in the largest scars among all conditions. The synergy of higher reciprocation rate and longer sliding distance with hydrothermal damage accelerates mechanical softening and interfacial failure, broadening the track and deepening penetration after prolonged aging. Overall, immersion induces progressive softening and interfacial degradation that widens and deepens the tracks, amplified by higher frequency and longer distance, with only a transient 7-day reduction at 2 Hz (moisture-assisted lubrication/compaction) before damage dominates at 14 days and 21 days.

The surface topography changes documented in

Figure 6 are underpinned by measurable chemical and mechanical alterations induced by water uptake rather than being purely morphological phenomena. Water molecules absorbed into the epoxy act as a plasticizer, reducing the glassy modulus and yield strength of the matrix and promoting micro-cracking and reduced cohesive energy in the near-surface region; simultaneously, interfacial water accumulation and hydrolysis processes weaken fiber–matrix adhesion. Mechanically this manifests as reduced matrix resistance to shear and indentation, and increased production of fine debris that can be compacted into a third body. The COF behavior (pronounced minimum at 14 days) therefore reflects a competition: at intermediate uptake the matrix is softened enough to allow a coherent, lubricious tribofilm/compacted debris layer that lowers shear strength and COF, whereas at longer immersion progressive hydrolytic degradation and interfacial debonding increase debris production and three-body abrasion, raising effective contact compliance and wear rates.

The width and depth evolutions reported in

Figure 6, namely the progressive widening and deepening with increasing immersion time (pronounced at 14 days and approaching saturation by 21 days) and the stronger effect under higher frequency/longer distance, are consistent with documented hydrothermal aging effects on polymeric composites and polymer–matrix tribological systems. Hygrothermal conditioning can initially promote formation or consolidation of a lubricious transfer/tribofilm (reducing penetration and sometimes narrowing the early wear scar), but with continued uptake the matrix undergoes plasticization and interfacial debonding; these processes increase compliance, facilitate lateral plowing and fiber/matrix pull-out, and produce more and finer debris that promotes three-body abrasive action, all of which enlarge track width and increase maximum depth. Experimental studies across different polymeric systems corroborate this two-stage behavior: hydrothermally aged PTFE-based composites show filler-dependent changes in transfer film and increased wear for fiber-filled systems after aging, consistent with matrix softening and debris-assisted abrasion [

37]. Under seawater/saturated lubrication conditions, polyamide (PA12) composites likewise display locally increased track width and depth where matrix softening and particle detachment occur [

38]. Hydrothermal fatigue studies on glass–ionomer systems further show that thermally/wet aged samples can develop wider and morphologically different friction tracks (with increased nano/microparticle debris and evidence of matrix cracking), linking aging-induced microstructural changes to larger, more irregular scars [

39]. Taken together, these studies support our interpretation of

Figure 6: a transition from short-term/partial lubrication effects (transient narrowing/reduced penetration) to dominant long-term hydrolytically driven softening and interfacial failure that widen and deepen reciprocating wear tracks, with the effect amplified by higher oscillation rate and longer sliding distance.

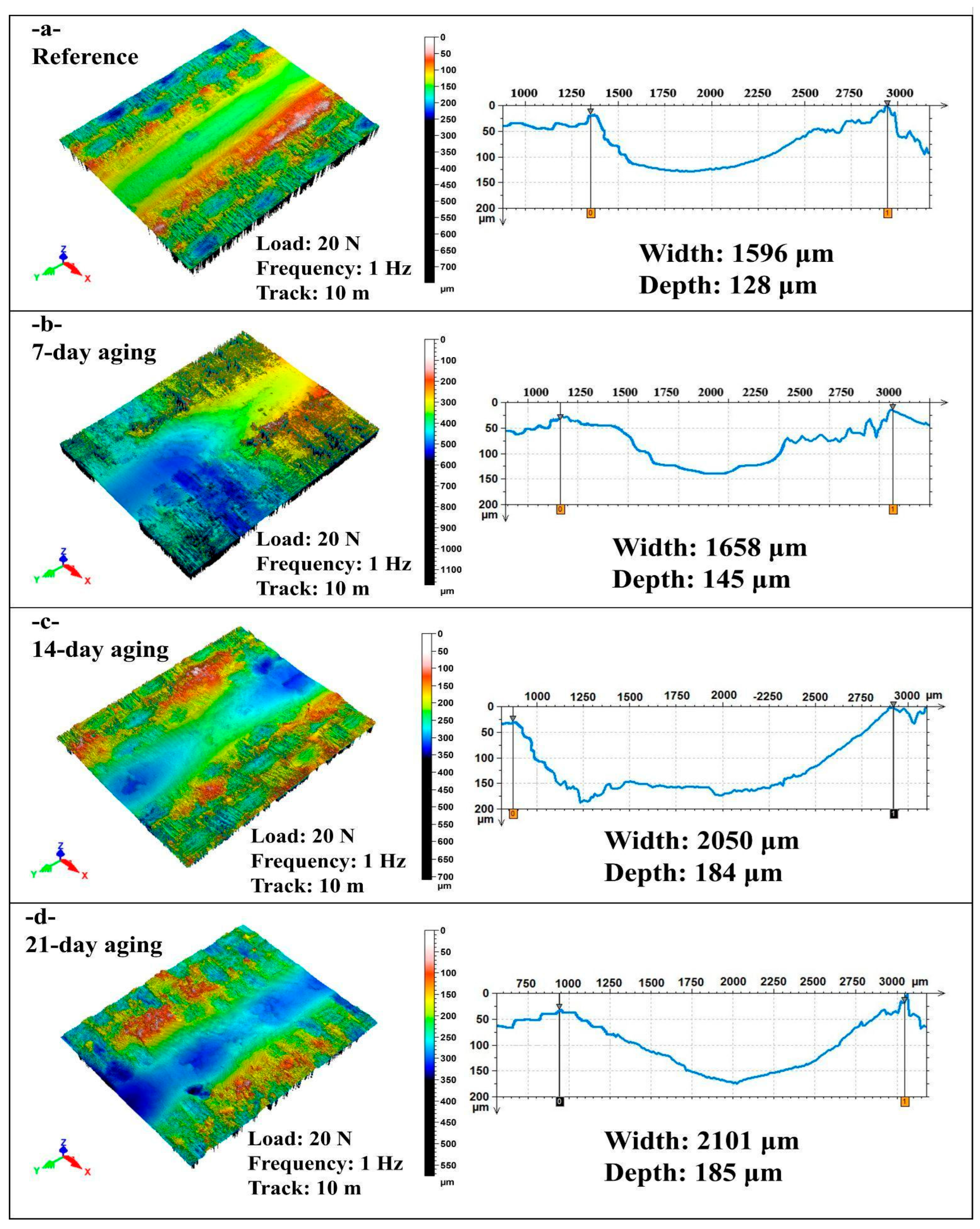

Figure 7 shows non-contact laser profilometry 3D maps and transverse line profiles of reciprocating wear scars for the hybrid epoxy composite tested at 20 N, 1 Hz, and 10 m after 0, 7, 14, and 21 days of water immersion, from which wear track width and maximum depth are quantified.

In

Figure 7a under 20 N, 1 Hz, and 10 m, the 0-day (reference) specimen exhibits a relatively shallow reciprocating groove (depth = 128 µm) with a moderate lateral extent (width = 1596 µm); the 3D map shows a continuous valley flanked by modest, symmetric pile-up ridges and a comparatively smooth floor, indicating limited plastic deformation and minimal interfacial failure at the onset of sliding.

In

Figure 7b after 7 days of immersion, the track widens slightly (1658 µm, +4% vs. reference) and deepens to 145 µm (+13%), while the topography reveals broadened shoulders and more heterogeneous relief with patches consistent with transfer/debris compaction; these changes point to early-stage moisture-induced plasticization that increases lateral plowing without yet producing catastrophic penetration.

In

Figure 7c at 14 days, the wear scar enlarges markedly (width = 2050 µm, +28%; depth = 184 µm, +44%), and the 3D surface shows a deeper, more steep-walled valley with pronounced pile-up and micro-scoring along the reciprocation axis, consistent with matrix softening, fiber/matrix debonding, and easier micro-fracture that together promote both wider material removal and greater subsurface intrusion.

In

Figure 7d following 21 days of immersion, the track width and depth remain high (2101 µm and 185 µm, respectively), with the topology displaying a persistently deep groove but a somewhat smoother, compacted floor—evidence of damage saturation where continued moisture-assisted softening maintains large scars while debris polishing moderates further growth in maximum depth.

Water immersion progressively widens and deepens the wear track modestly at 7 days, markedly by 14 days, and then approaching saturation at 21 days, reflecting moisture-induced matrix plasticization and fiber/matrix interfacial weakening that enhance lateral plowing and penetration, with partial debris compaction/polishing limiting further depth growth at the longest exposure.

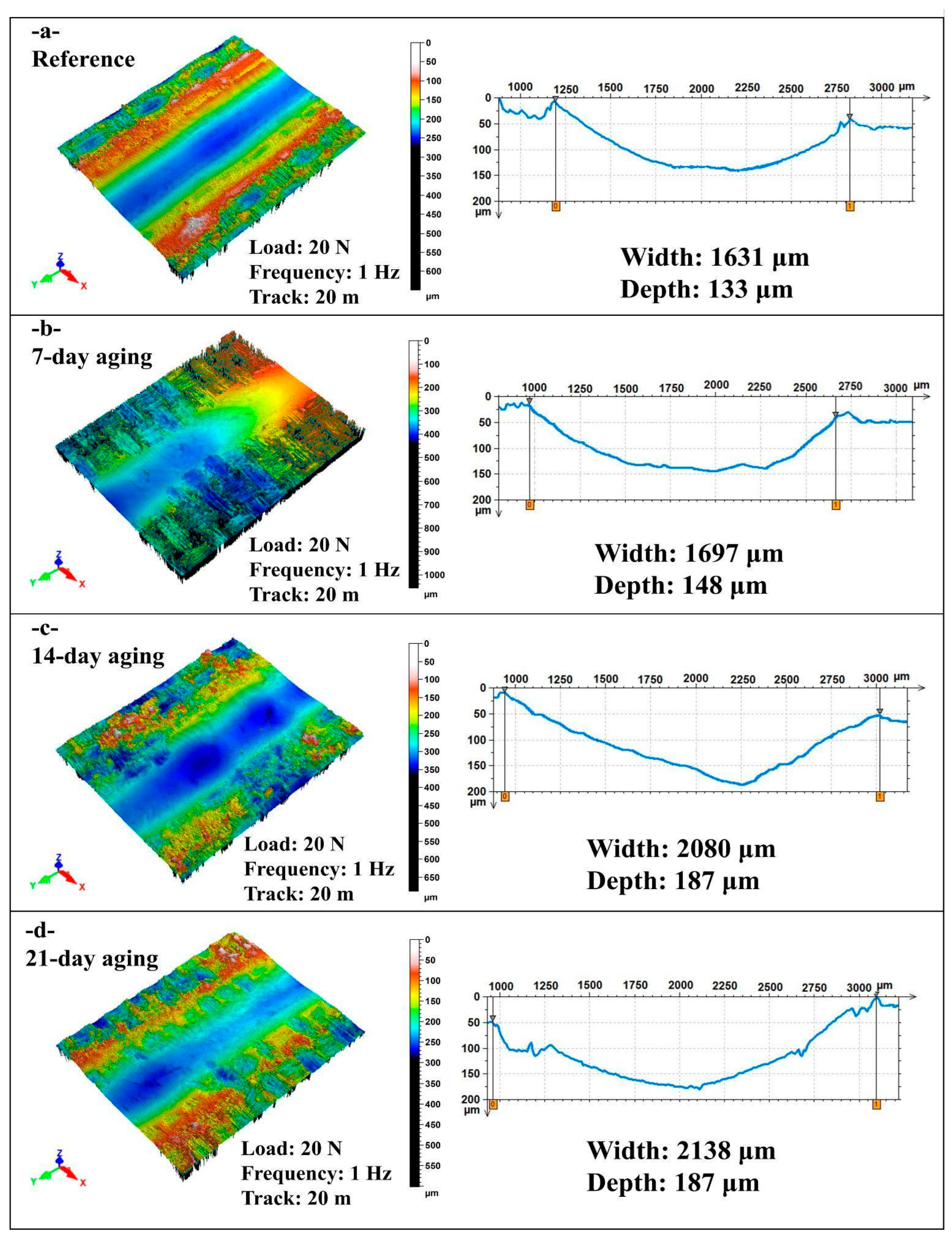

Figure 8 presents non-contact laser profilometry 3D maps and transverse line profiles of reciprocating wear scars for the glass/Kevlar epoxy hybrid composite tested at 20 N, 1 Hz, and 20 m after 0, 7, 14, and 21 days of water immersion; wear track width and maximum depth are extracted from the profiles.

In

Figure 8a at 0-day aging, the track shows a moderately shallow U-shaped valley (width = 1631 µm; depth = 133 µm) with relatively smooth floor and low, symmetric pile-up ridges, indicating limited plastic flow and negligible fiber/matrix disruption at the start of sliding.

In

Figure 8b after 7 days, both metrics rise (width = 1697 µm, +4%; depth = 148 µm, +11%), and the 3D topography displays broadened shoulders and more heterogeneous relief with incipient debris compaction—evidence of early hydrolytic plasticization that facilitates lateral plowing and slightly deeper penetration.

In

Figure 8c by 14 days, the scar enlarges substantially (width = 2080 µm, +28%; depth = 187 µm, +41% vs. reference); the surface map reveals a deeper, steeper-walled groove with pronounced pile-up and micro-scoring along the stroke, consistent with matrix softening and fiber/matrix debonding that accelerate material removal.

In

Figure 8d at 21 days, width increases marginally further (2138 µm), while depth remains at 187 µm, and the groove floor appears somewhat smoother/compacted, suggesting damage saturation where severe moisture-assisted softening maintains a wide track, but continued sliding polishes the valley and limits additional deepening.

Overall, at 20 m sliding distance water immersion progressively widens and deepens the reciprocating wear track, with a pronounced jump by 14 days and a subsequent depth plateau at 21 days; these trends reflect hydrolytic plasticization and interfacial weakening that enhance lateral plowing and penetration, with late-stage debris compaction moderating further depth growth while width remains high.

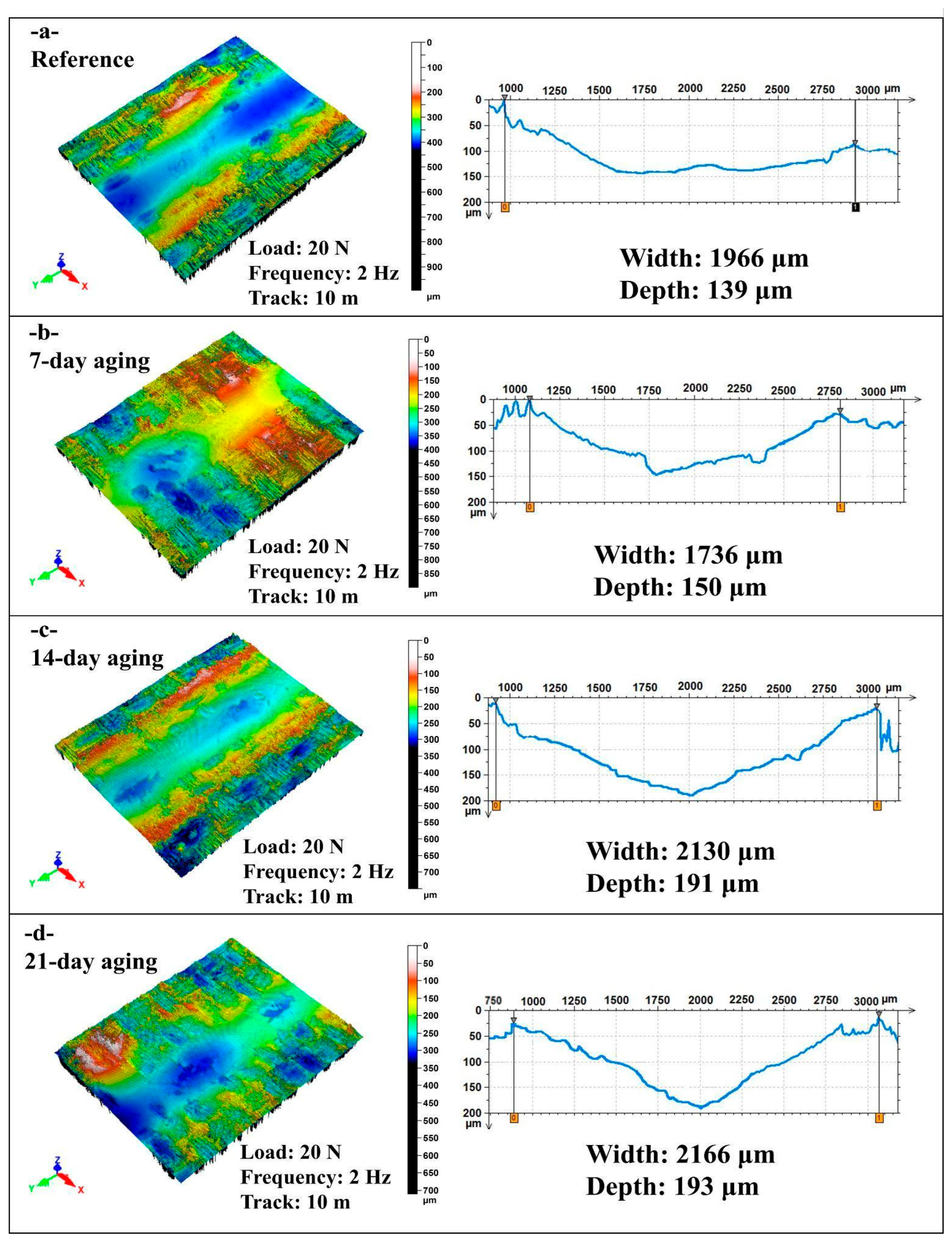

Figure 9 presents non-contact laser profilometry 3D maps and transverse line profiles of reciprocating wear scars for the hybrid epoxy composite tested at 20 N, 2 Hz, and 10 m after 0, 7, 14, and 21 days of water immersion, with wear track width and maximum depth quantified from the profiles.

Figure 9a shows the reference condition with a moderately shallow U-shaped groove, width of 1966 µm and of depth 139 µm, and low symmetric pile-up that indicates limited plastic flow and minimal interfacial failure at test start.

Figure 9b exhibits a narrower but slightly deeper track after 7 days, with a width of 1736 µm, about 12% lower than reference, and a depth of 150 µm, about 8% higher, while the topography reveals a smoother compacted valley consistent with transient moisture-assisted lubrication and debris densification that reduce lateral plowing yet permit modest penetration.

Figure 9c displays a marked enlargement at 14 days, with a width of 2130 µm, about 8% above reference, and a depth of 191 µm, about 37% above reference, with a steeper-walled valley, pronounced pile-up, and micro-scoring that evidence matrix plasticization and fiber–matrix debonding under the higher oscillation rate.

Figure 9d maintains large scars at 21 days, with a width of 2166 µm and depth of 193 µm, while the floor appears smoother and more polished, suggesting damage saturation where continued sliding preserves a broad track and only marginally increases maximum penetration. Water immersion at 2 Hz first produces a short-term narrowing with slight deepening at 7 days due to lubrication and compaction effects, then transitions by 14–21 days to pronounced widening and deepening driven by hydrolytic softening and interfacial degradation, after which depth tends to plateau while the width remains high.

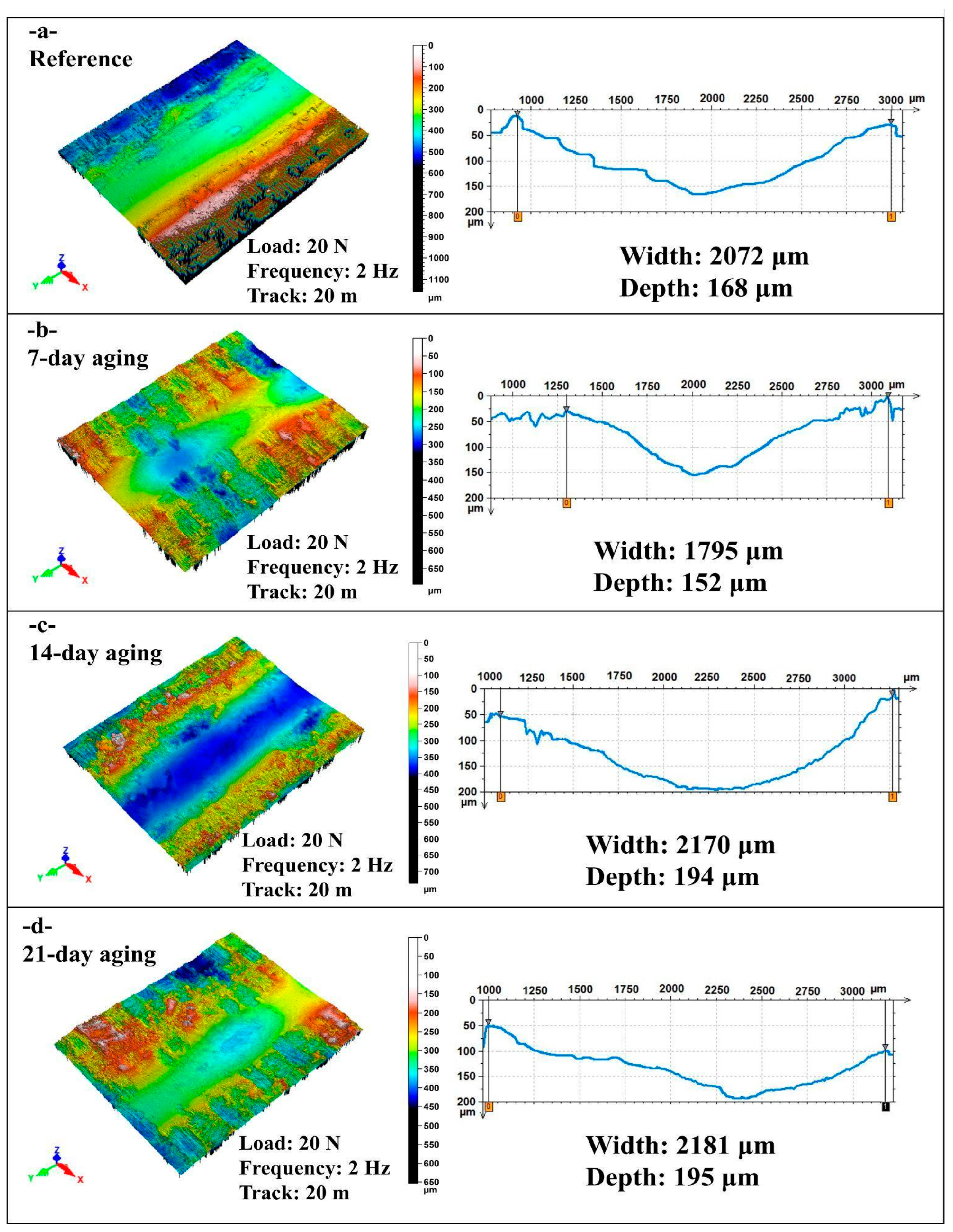

Figure 10 presents non-contact laser profilometry 3D maps and transverse line profiles for reciprocating scars on the hybrid epoxy composite tested at 20 N, 2 Hz, and 20 m after 0, 7, 14, and 21 days of water immersion, from which wear track width and maximum depth were determined.

In

Figure 10a the reference surface shows a broad U-shaped groove with a width of 2072 µm and depth of 168 µm and relatively smooth flanks with limited pile-up, indicating moderate plastic flow and minimal interfacial failure at the start of sliding.

In

Figure 10b after 7 days, the track narrows to 1795 µm and depth decreases to 152 µm, roughly 13% and 10% lower than the reference, while the topography displays a smoother and slightly compacted valley, consistent with transient moisture-assisted lubrication and debris densification that reduce lateral plowing and limit penetration.

In

Figure 10c by 14 days, the scar expands markedly with a width of 2170 µm and depth of 194 µm, about +5% and +16% versus the reference and roughly +21% and +28% versus 7 days, and the 3D map shows a deeper, steeper-walled valley with pronounced pile-up and micro-scoring that signal matrix softening and fiber–matrix debonding under the higher reciprocation rate and long sliding distance.

Figure 10d at 21-day the track remains wide and deep with a width of 2181 µm and depth of 195 µm, essentially sustaining the 14-day damage level, and the groove floor appears slightly polished which points to damage saturation where debris compaction moderates further deepening while the lateral scar extent stays high.

Water immersion under 2 Hz and 20 m first yields a short-term narrowing and slight shallowing at 7 days that can be attributed to lubrication and compaction effects, followed by pronounced widening and deepening at 14 days that persists at 21 days, indicating a transition to hydrolytic softening and interfacial degradation after which penetration plateaus while lateral plowing remains elevated.

3.4. Wear Track SEM Damage Analysis

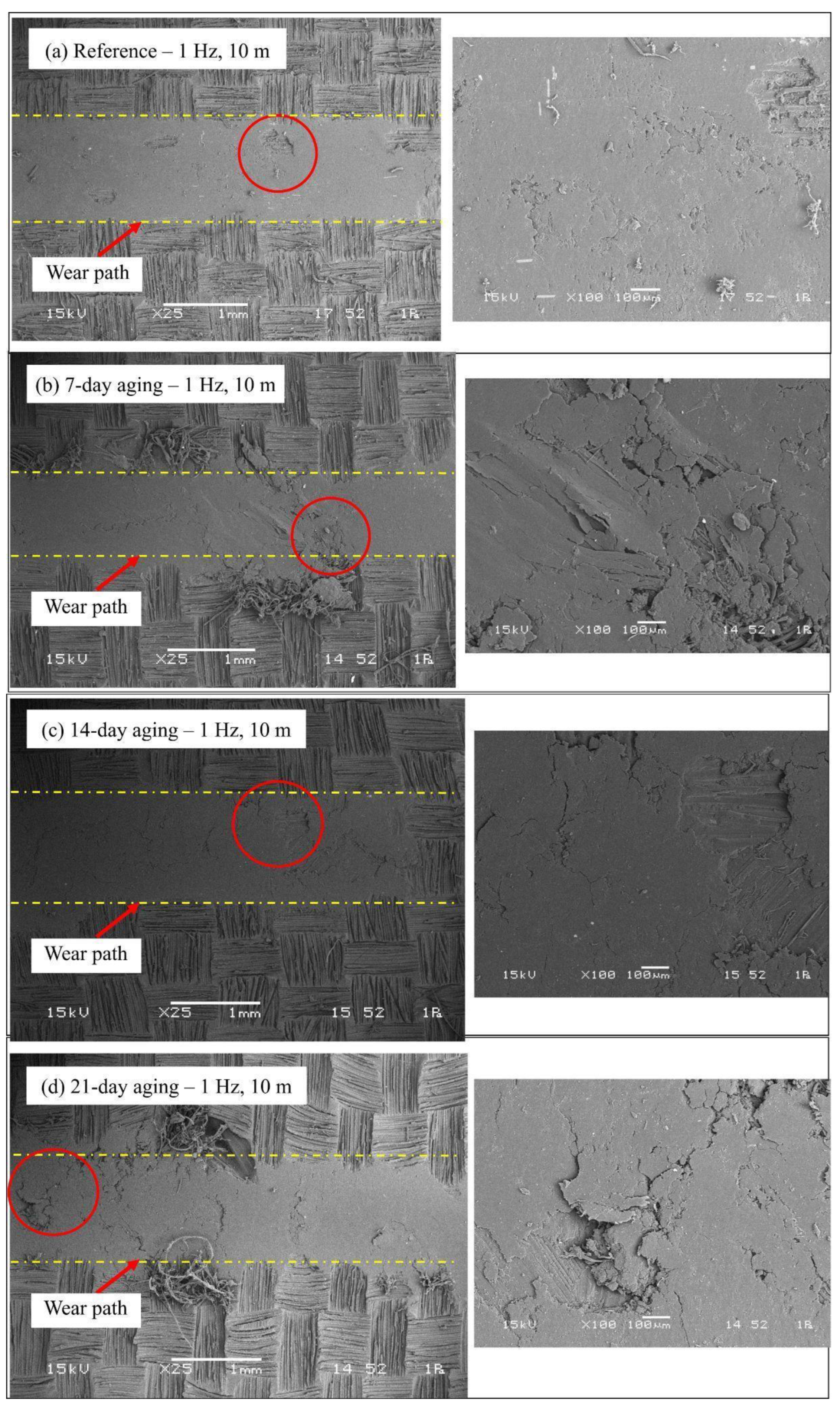

The series of SEM micrographs for the 1 Hz experiments found in

Figure 10 presents the gradual degradation of the glass/Kevlar hybrid epoxy composite with an increase in water immersion time. The unaged control sample (

Figure 11a) displays an attendant wear track under ambient mild abrasive wear conditions, where matrix plowing is restricted while fiber exposure is minimal, suggesting an undamaged fiber–matrix interface from the load-bearing point of view. After 7 days of exposure to an environment that is hydrothermally aged (

Figure 11b), the initiation point for hygrothermal degradation is identified from the enhanced level of matrix micro-cracking coupled with the incipience of fiber-matrix debonding, an intrinsic result emanating from plasticization of the resin allowing enhanced material loss up to the registered increase in wear track width alongside depth. Extensive damage mechanism is initiated after immersing the specimens for 14 days (

Figure 11c), where the prevailing hydrolytic tendering coupled with interfacial attenuation has led to widespread fragmentation of the subsequently weakened matrix, substantial debonding, and excessive fiber pull-out, yielding a rough, fractured surface topography consistent with the maximum loss in tribological performance. After 21 days (

Figure 11d), the mechanism of damage moves toward a saturation regime portrayed by the formation of an impenetrable packed layer consisting of the wear debris from the partial smoothening of the track floor; the implication is that although the subsurface remains considerably impaired, the continued sliding tenders the deteriorated material by rendering an appreciable restriction to an enormous penetration depth increment even though the continued high-wear track width is maintained.

Moisture governs the tribological response primarily through interfacial processes rather than wear scar geometry alone. Gravimetric uptake up to 8.54% sets the degree of epoxy plasticization and interfacial hydration; at about 14 days a moisture-mediated third body stabilizes at the interface, lowering interfacial shear and producing a pronounced minimum in the steady-state μ. With further immersion, progressive hydrolysis and fiber/matrix debonding increase debris generation and three-body abrasion, which widens and deepens the wear track even as μ partially recovers. Factorial ANOVA ranks immersion time as the dominant factor for both width and depth, with frequency secondary and sliding distance minor, indicating that moisture-controlled interphase integrity, rather than sliding geometry, governs damage evolution. It is important to stress that the observed transient transfer film and the intrinsic wear resistance of the fibers are not mutually exclusive phenomena; rather, their protective effectiveness changes with the state of the matrix and the fiber–matrix interface. Initially (unaged to 7-day) moisture-assisted plasticization mobilizes matrix material and debris which consolidate into a lubricious, water-mediated tribofilm. That film reduces local shear strength and spreads contact over a larger area, thereby temporarily shielding embedded fibers from direct metal contact and lowering COF (

Figure 11 and

Figure 12). However, the long-term protective effect of that film depends on the integrity of the matrix and the interfacial adhesion: progressive hydrolytic attack (14–21 day) weakens the bond between fibers and resin so that fibers become deboned and protrude or detach. Fibers are exposed; they no longer act as ideal load-bearing reinforcements. They are directly subjected to abrasive three-body action, fibrillation, pull-out, and fracture. In other words, fibers are theoretically more wear resistant than the matrix when fully embedded and bonded, but once exposure and debonding occur their effective resistance can fall sharply because new wear modes (fiber fragmentation and three-body abrasion) dominate. This sequence reconciles the temporary COF reduction and transient narrowing seen at short/intermediate immersion with the dramatic widening, deepening, and catastrophic fiber damage observed at longer immersion.

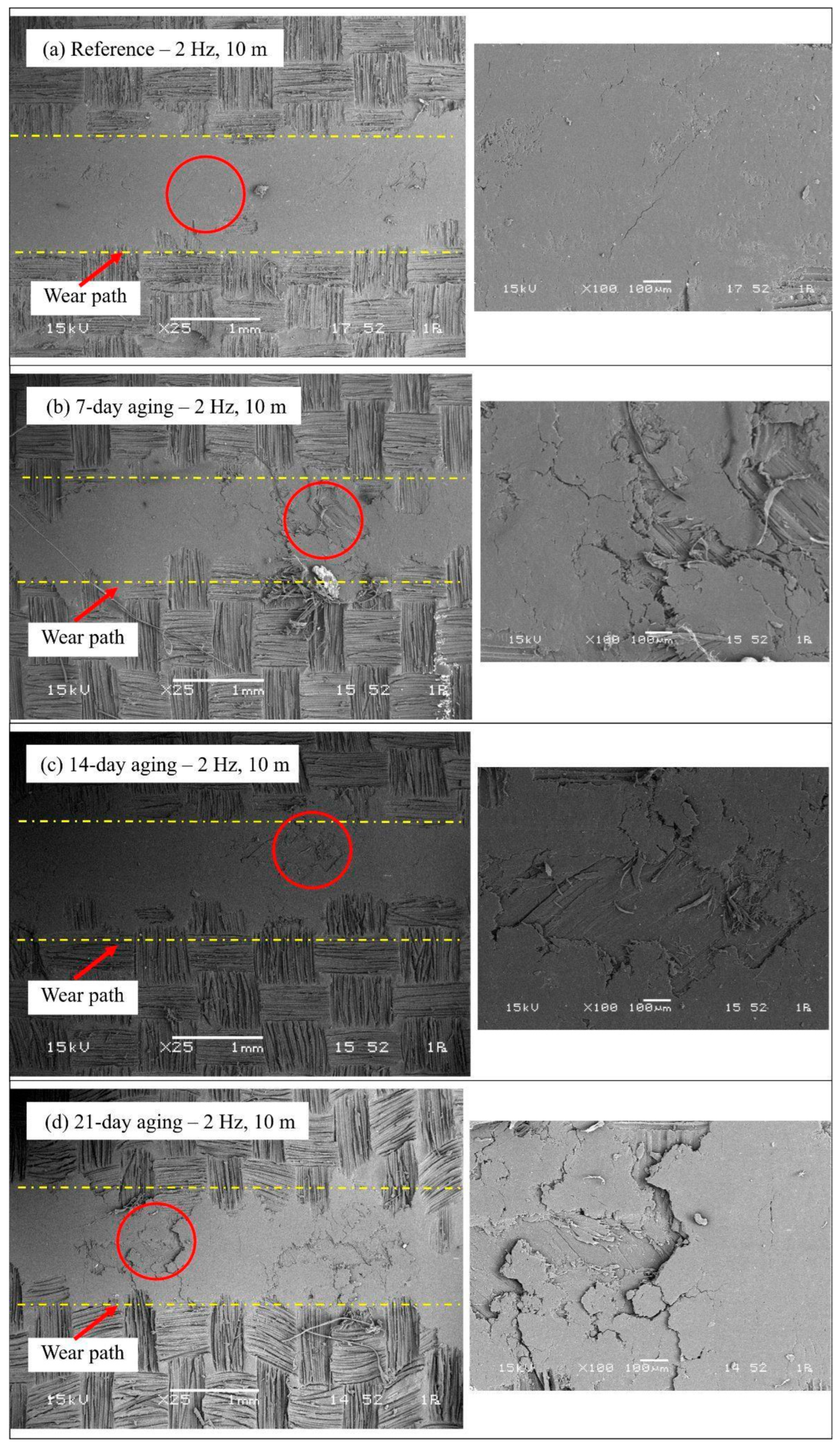

The SEM micrographs for the 2 Hz reciprocating tests (

Figure 12) indicate an evident and faster development of wear damage compared to the 1 Hz case, triggered by the enhanced frictional energy input. The unaged material (

Figure 12a) already presents a substantially more damaged surface compared to the 1 Hz one, showing apparent matrix plowing and first fiber ruptures, testifying to an accelerated abrasive-adhesive wear mechanism from the very first. After 7 days of immersion (

Figure 12b), there is the onset of an original transient regime characterized by the flattening and densification of the surface layer; this points to the establishment of a stable tribofilm where the plasticization triggered by the moisture, coupled with the elevation of the frequency, encourages the densification of the wear debris, momentarily alleviating the friction and confining the penetration. Unfortunately, this protective action is erased by 14 days of immersion (

Figure 12c), where the surface presents catastrophic degradation. The micrograph exhibits wide distribution of the matrix ripping, heavy fiber fragmenting, and extensive fiber pull-out, caused by the combined action of progressed interfacial hydrolysis and the strong cyclic stressing by the frequency up to 2 Hz. The damage by 21 days (

Figure 12d) is up to the saturation level, showing an inconsistent morphology consisting of deep grooves that are plowed away, exposed bundles toward the surface, and an inconsistent distribution consisting of packed-down regions mixed up with recently broken-down ones, highlighting an autonomous cycle material elimination overruling the stability of the compaction action by the most severe combination of environmental and mechanical inputs.

The SEM images therefore must be read in the context of concurrent chemical and mechanical transformations triggered by water immersion. Chemically, absorbed water initiates two linked processes: (i) reversible plasticization of the epoxy network through hydrogen bonding to polar groups (reducing local glass transition and stiffness) and (ii) slower hydrolytic scission of susceptible bonds at the fiber–matrix interface and within the near-surface resin leading to irrevocable interfacial weakening. Mechanically, plasticization lowers the matrix’s cohesive strength and promotes microcrack nucleation under cyclic shear, while hydrolysis and interfacial debonding reduce interlaminar shear transfer so that fibers progressively relocate from a load-bearing to a loose/exposed state. On the SEM this converts early-stage matrix plowing and compacted transfer-film appearance (7 days) into later-stage signatures of interfacial failure with widened grooves, ragged exposed fibers, fibrillation, fiber fragmenting and pull-out (14–21 days). In addition, the compacted debris layer seen at the longest exposures reflects a mechanical saturation where three-body abrasion and debris compaction compete: the debris both protects (by filling the groove) and abrades (by acting as hard third bodies) depending on its composition and consolidation state. The wear mechanisms deciphered by the SEM micrographs in

Figure 11 and

Figure 12 are very much reinforced by evidence from the current published research materials on hygrothermal degradation for polymer-type composites. The noticed migration from frail abrasion when still unaged to harsh fragmentation from the resin, coupled with the interfacial degradation by 14 days’ immersion, is the direct outcome from the plasticizing resin coupled with the interfacial degradation, an well-reported phenomenon by the research material conducted on the epoxy type material under the influence of water aging [

18]. In addition, the novel transient formation of the smoothed and compacted tribofilm present at 7 days for the 2 Hz case (

Figure 12b) is consistent with reported hydrothermally triggered boundary lubrication capable of transiently diminishing wear and friction, as reported for multi-filler epoxy composites under hygrothermal loading [

23]. Lastly, the catastrophic debonding of the fibers from the matrix and the saturation behavior with increased immersion time are consistent with processes where progressive hydrolytic weakening of the fiber–matrix interface catastrophically leads to dominance by three-body abrasion and loss of structural integrity, consistent with reported tribological studies on aged fiber-reinforced composites [

24].

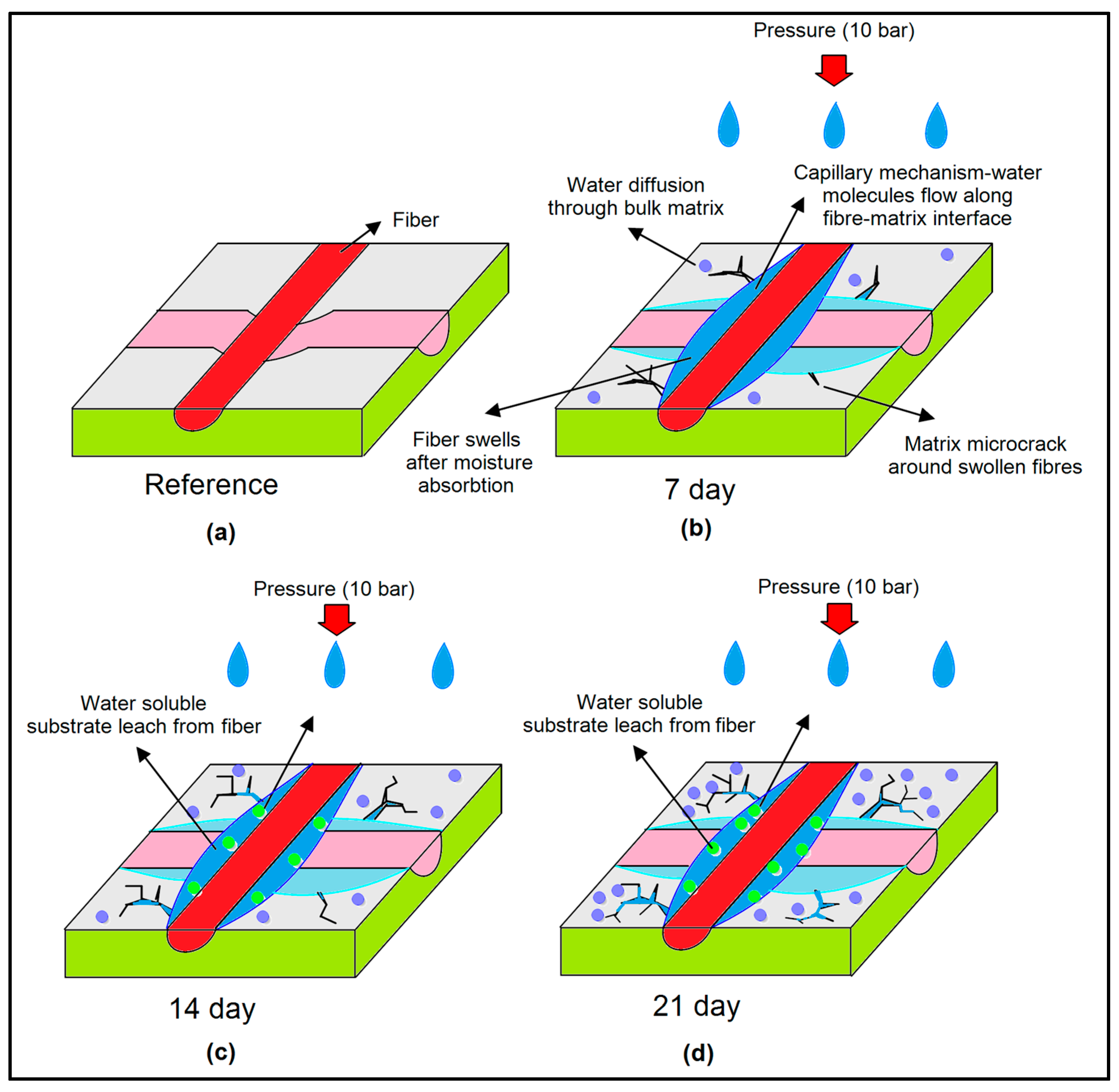

Figure 13 illustrates the moisture-induced gradual degradation mechanism of the hybrid composite when immersed in water at 10 bar pressures. As can be seen, water uptake at 7 days, 14 days, and 21 days altered the fiber–matrix interface, matrix integrity, and wear scar morphology. The diagram relates these microstructural changes to the measured tribological response, demonstrating that interface swelling, plasticization, debonding, tribofilm formation, and finally, three-body wear control both the coefficient of friction and wear severity.

In the unaged state, in

Figure 13a, the glass/Kevlar hybrid epoxy laminate shows full interfacial integrity and the epoxy matrix remains in high-stiffness condition. The woven fibers are well anchored and there is no evidence of matrix microcracking or fiber to matrix debonding in the wear track. The reciprocating wear scar at this stage is shallow and moderately narrow, which indicates limited plastic flow and minimal interfacial failure. During sliding the load is transferred efficiently across the intact fiber to matrix boundary so local stiffness and interlaminar shear strength remain high.

In

Figure 13b during 7-day immersion under 10 bar pressurized water, the sample is in the transient uptake regime in which water diffuses through the epoxy matrix and preferentially along the fiber to matrix interface. Capillary pathways at locally hydrophilic Kevlar-rich regions promote local matrix plasticization and swelling around the fibers. This initiates microcracks and the first stages of interfacial debonding. Mechanically the interfacial shear strength and effective near-surface stiffness begin to drop because the matrix can no longer clamp the fibers as rigidly as in the dry state. The slightly softened moisture-plasticized matrix and fine debris begin to smear and compact in the reciprocating groove, and this produces an early hydrated transfer layer. The compacted debris layer distributes contact stress more uniformly which can transiently suppress stick–slip and partially lower friction relative to the dry reference.

In

Figure 13c during 14-day immersion representing intermediate quasi-equilibrium swelling, the laminate has absorbed substantially more water. The epoxy is now significantly plasticized and fiber to matrix interfaces are partially hydrolyzed and weakened. The reciprocating wear scar becomes markedly wider and deeper which reflects lateral plowing and easy penetration into the softened and poorly supported interphase. At the same time this heavily plasticized debris rich surface compacts into a coherent hydrated tribofilm that acts as a low shear third body. Fourteen day immersion therefore marks the stage where mechanical integrity is strongly degraded with loss of stiffness and interfacial cohesion geometric wear is severe with track widening and deepening, but tribological behavior is paradoxically most favorable in terms of friction reduction because a stable lubricious tribolayer is present.

In

Figure 13d during 21-day immersion representing near saturation and degradation saturation, the laminate approaches quasi-saturation of water uptake. The matrix is extensively plasticized and fiber to matrix adhesion is strongly compromised, and widespread interfacial debonding fiber exposure and resin fragmentation are observed. Only marginal additional deepening occurs which indicates a damage saturation state in which further penetration is limited by debris compaction and polishing of the groove. At 21 days the laminate is therefore both mechanically compromised with a largely collapsed interphase and tribologically less efficient than the 14 -day state showing higher and more erratic friction despite the already widened and stabilized wear scar geometry.

3.5. Factorial Contribution Analysis

Factorial analysis is a comprehensive statistical method employed to quantify the relative contribution and interaction of multiple experimental factors on some measured response. In engineering and materials science, it is a widely used tool for identifying factors that significantly affect performance by determining which process parameters have significant effects on performance outputs, allowing systematic optimization instead of running on a trial-and-error basis. By breaking the total variance in the experimental outcomes into the contributions of individual factors as well as their interactions, the factorial analysis provides the quantitative foundation on the complicated cause–effect relationships under multi-parameter systems.

In the present work, factorial contribution analysis was utilized in assessing the contributions of significant test parameters—immersion days, sliding frequency, and track length—on hybrid glass/Kevlar epoxy composite wear responses. Of particular interest was the determination of the contributions of these factors towards variability in scratch depth and scratch width, which are significant indicators of tribological degradation. Beyond identifying main effects, the method also estimates factor interactions (synergistic or antagonistic). In order to ensure statistical robustness and incorporation of reproducible patterns, the analysis was conducted on data obtained from three separate independent experimental sets, thus providing a robust basis on which the spontaneous tribo-decorators’ wear could be interpreted under varied hygrothermal as well as mechanical conditions.

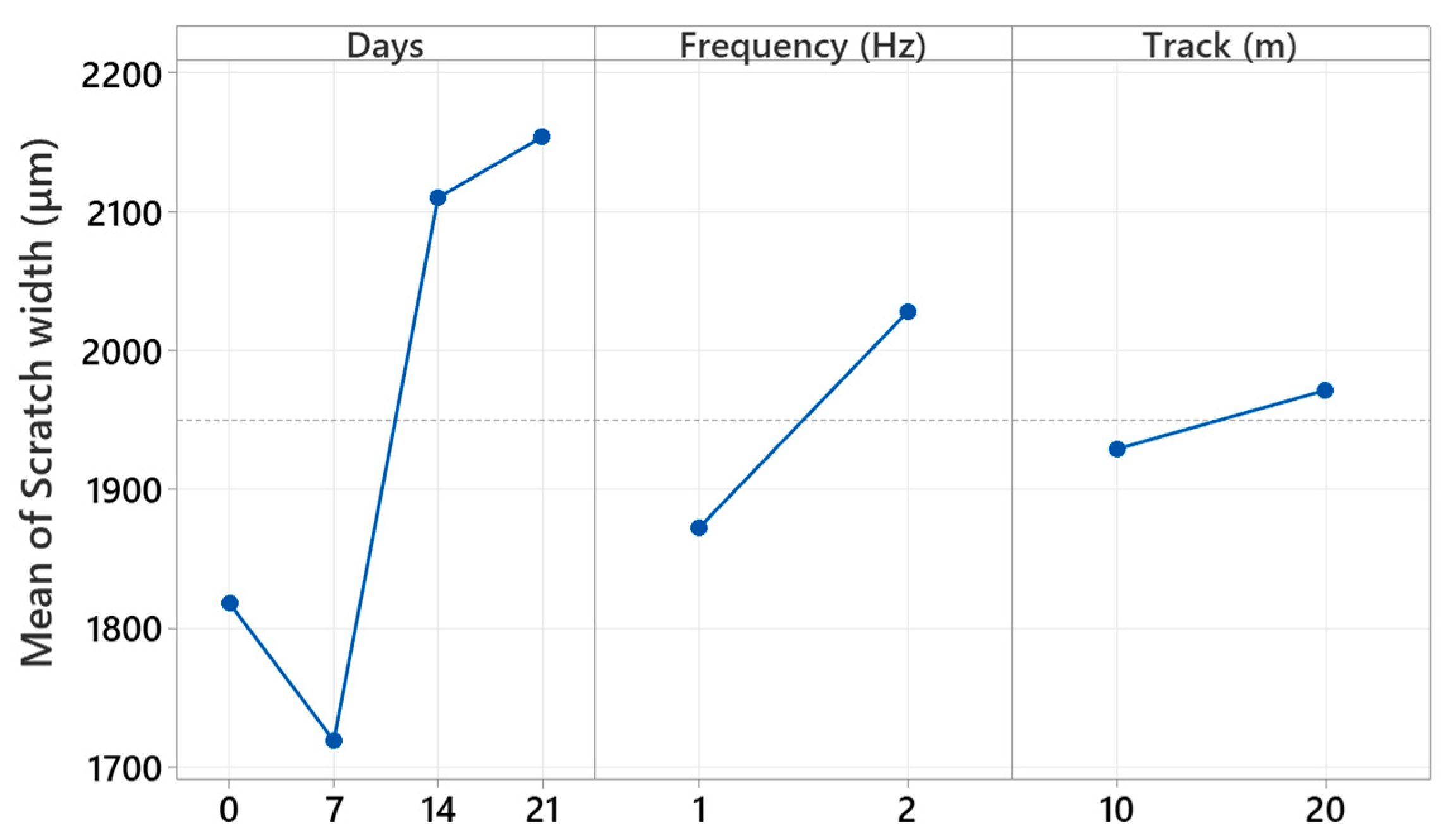

Table 2 presents the general factorial regression results obtained to establish the relative experimental parameter contribution towards the scatter in scratch width values. It consists of the following factors: immersion days, reciprocating frequency, and track length, along with the two- and three-way interactions among the factors. The regression model accounted for 99.85% of the total variance, establishing a very reliable correspondence between the experimental data and the statistical model. Out of the individual factors, the immersion duration (Days) has the highest influential character, contributing the highest towards the total variation, which is 73.69%, followed by frequency (12.99%) and track length (0.96%). High values of significant F-values and

p-values (

p < 0.05) for all the primary factors further establish their statistical relevance. Interaction terms, especially Days × Frequency, also indicate a significant contribution (11.82%), providing evidence towards the existence of a synergy between the time of exposure and the sliding frequency on the scratch width. The low error contribution (0.15%) indicates uniform data and supports the model’s predictive capability.

Figure 14 presents the main effect plots from the factorial analysis, which represent the autonomous effect of each test parameter on the measured scratch width. The plots indicate that immersion time has the highest impact, and increasing the scratch width is significant, as the aging time goes from 0 to 14 days and levels off towards the end at 21 days. This trend is representative of the hydrolytic softening and interface degradation reactions that occur in the composites, causing the wear tracks to be wider. The frequency factor also presents a positive trend, such that the increasing the reciprocating frequency (2 Hz) produces the wider scratch due to the increased frictional energy input and raised dynamic contact stresses. Conversely, the track length presents a generally minor but consistent effect, such that increased sliding extends the surface deformation through a cumulative material removal process. Overall, the main effect plots validate that immersion time is the overwhelming parameter that determines surface damage, and the frequency and track length serve as the second-order contributors determining the extent and morphology of the wear response.

Table 3 shows the general factorial regression results carried out for assessing the relative importance of immersion time, reciprocating frequency, and track length on the hybrid glass/Kevlar epoxy scratch depth. The regression model yields high determination coefficients, explaining 99.70% of the total variability, signifying high association between the factors and the experimental results. Among the linear terms, immersion days display the highest effect, contributing 87.96% towards the total contribution, followed by frequency (4.96%) and track length (1.67%). These outcomes imply that increased water immersion substantially deepens the scratch penetration owing to the softening of the matrix and weakening of the interface, whereas increased frequencies augment the mechanical degradation owing to enhanced local stresses and heat production. Two-way and three-way interaction terms, specifically Days × Frequency, are found statistically significant (

p < 0.05) as well, signifying that the combined environmental as well as the effects of the mechanics work towards the enhancement of wear severity in a synergistic fashion. Very low error fraction (0.30%) further validates the robustness and the reproducibility of the data. In general, the factorial regression outcomes validate that the immersion time is the leading factor that affects the scratch depth, followed by significant, though lower, effects by the reciprocating frequency as well as the sliding distance.

Figure 15 presents the principal effects of immersion time, reciprocating frequency, and track length on the scratch depth, as obtained from the factorial regression analysis. Trends in the plots indicate that the immersion days have the greatest effect on scratch depth. A significant increase is observed up to 14 days of submerged time in water, equivalent to hydrolytic softening of the epoxy matrix and sequential fiber/matrix debonding, allowing deeper material infiltration on sliding. After the saturation point at more than 14 days, the depth values tend towards equilibrium, suggesting a saturation phase or phase when surface degradation and debris hardening would level further penetration. Also, the reciprocating frequency is found using a reasonable effect test to by and large have deeper scratches at 2 Hz compared to testing at 1 Hz, due to high frictional heat generation and cyclic inversion of the stressing concentrations. However, the track length is found with a relatively small effect, showing a moderate increase in depth with increasing sliding distance due to the build-up of the wear and surface fatigue. Overall, the results validate that the time of immersion is the key determinant that governs the evolution of the subsurface damage, whereas the reciprocating frequency and track length are the moderators that control the extent of the deformation induced by the wear.

Figure 16 is the radar plot showing the relative factorial impact on the following parameters: immersion days (D), reciprocating frequency (F), and track length (T), by the scratch depth and scratch width variability. The radar plot summarizes the relative influence of each factor on the overall visualization of the influence from each factor on the wear-related surface property of the hybrid composite system. The distribution on the radar is very clear such that the immersion time (D) is the leading one on both scratch width and depth, creating the longest axis on the plot. This leading is a clear indication of the association between the hydrothermal conditioning and the breakdown on the interfacial bonding in the epoxy matrix, which controls the level on the surface and subsurface deformation.

Reciprocating frequency (F) also presents a high, second-order effect, specifically apparent in the scratch width measurements, showing that increased sliding speed amplifies frictional energy dissipation and stress, hence increasing surface deterioration. Track length (T) is, however, a minor contributory factor towards the combined variation, meaning that increased distance between slides has little impact on altering the underlying wear mechanism, rather influencing the cumulative wear. The radar plot thereby summarizes the percentage hierarchy of factor influences, verifying the immersion days as the chief cause of wear severity, with frequency and track length acting as supplementary parameters that vary the intensity of the damage under varied test conditions.