Composite Polymeric Sucker Rod Guides: State-of-Practice, Causes of Failure, and Circular Economy Opportunities

Abstract

1. Introduction

- (1)

- What are the current performance limitations of polymeric sucker rod guides used in oil and gas wells?

- (2)

- What are the dominant degradation and failure mechanisms affecting their service life under downhole conditions?

- (3)

- What potential recycling and circular economy pathways can be developed for these polymeric components to support sustainability within the oil and gas industry?

2. Sucker Rod Pumping System

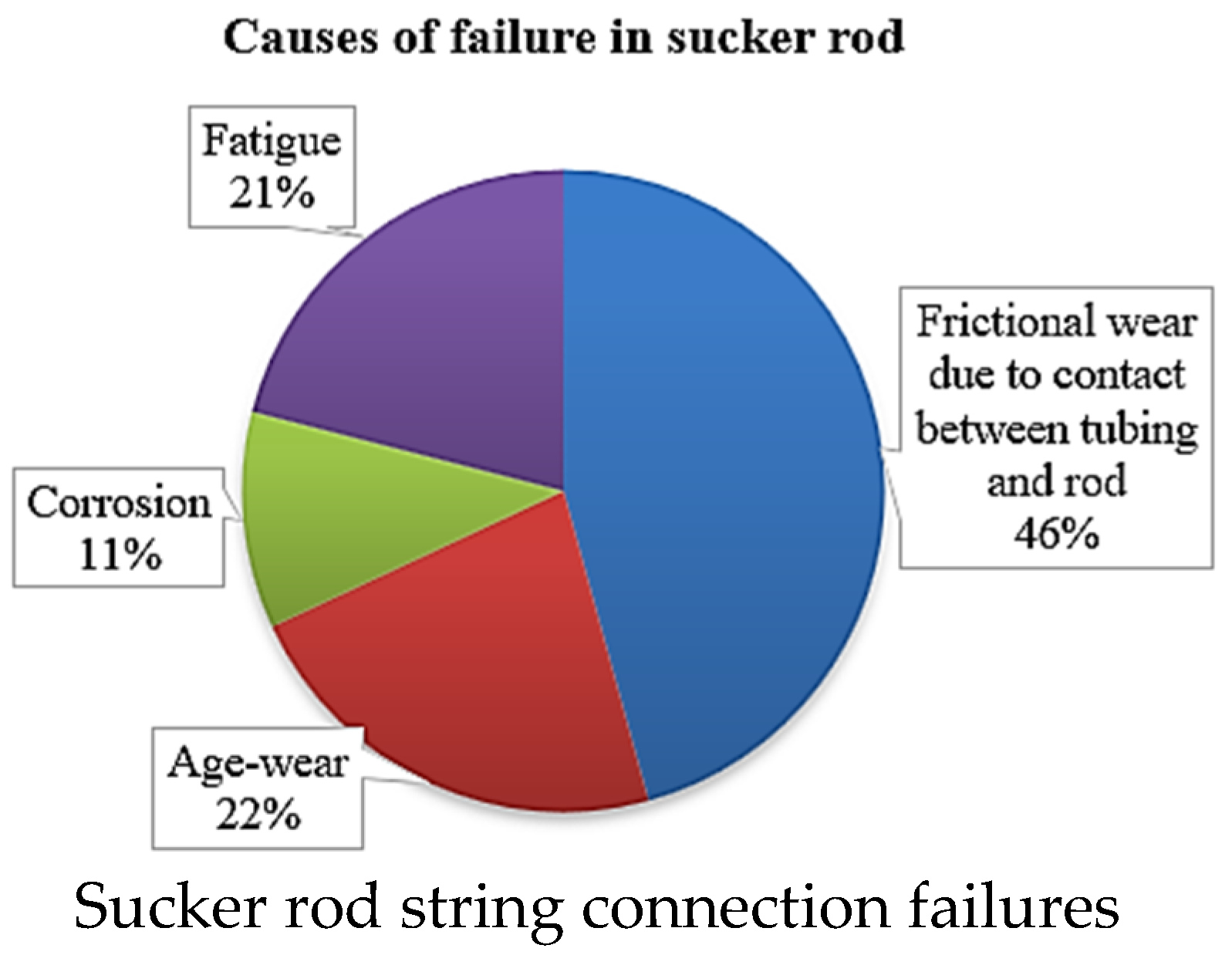

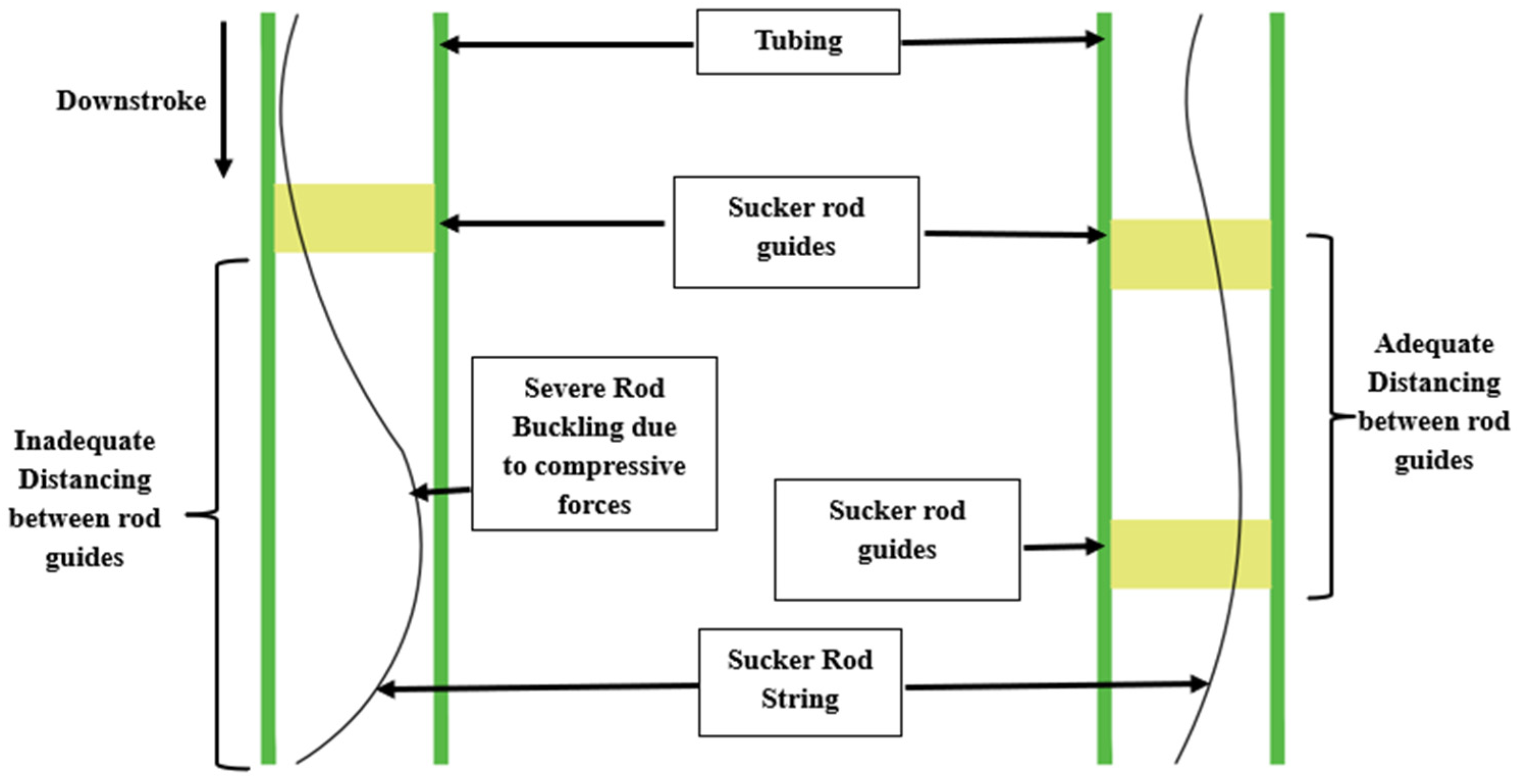

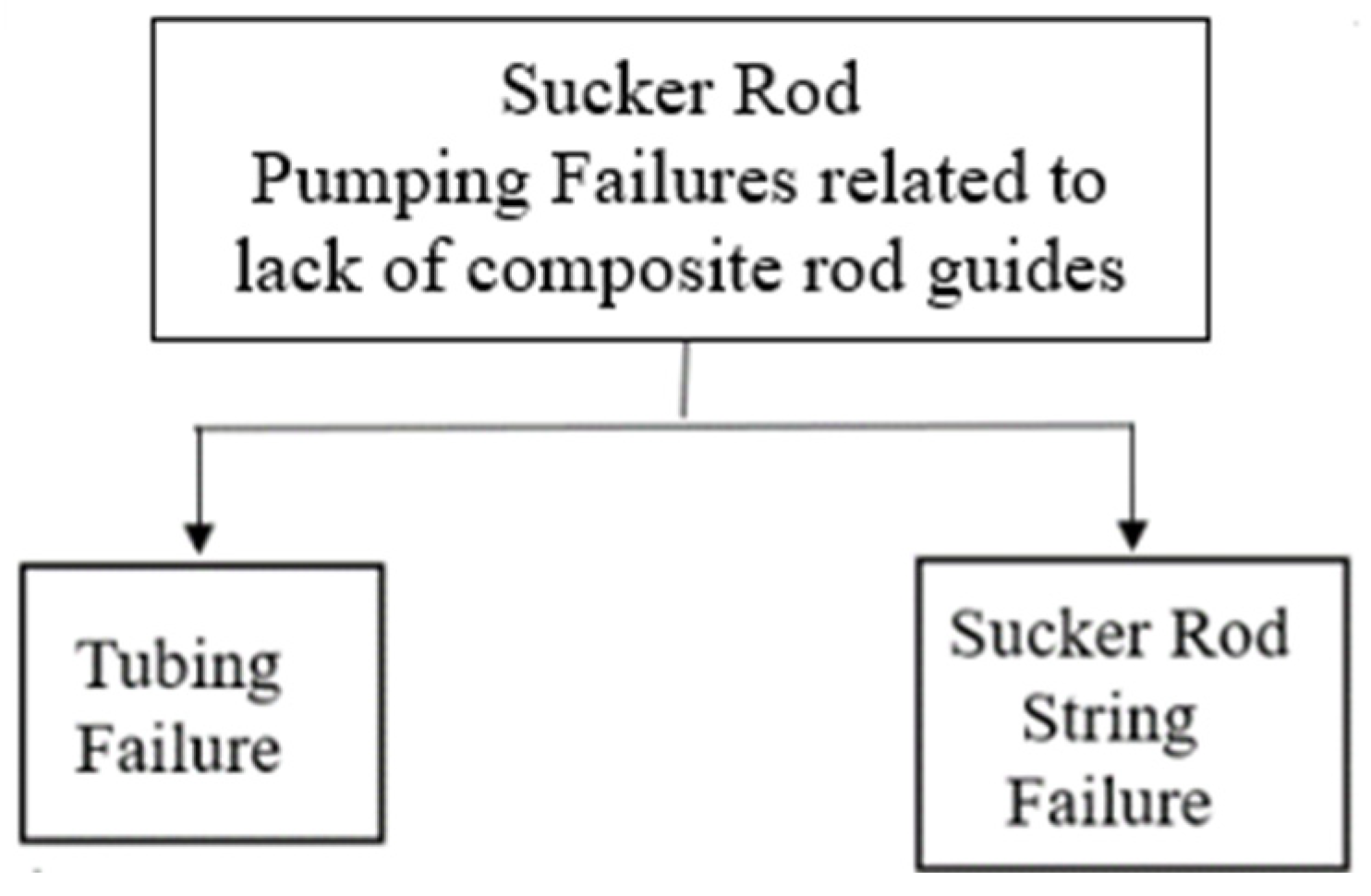

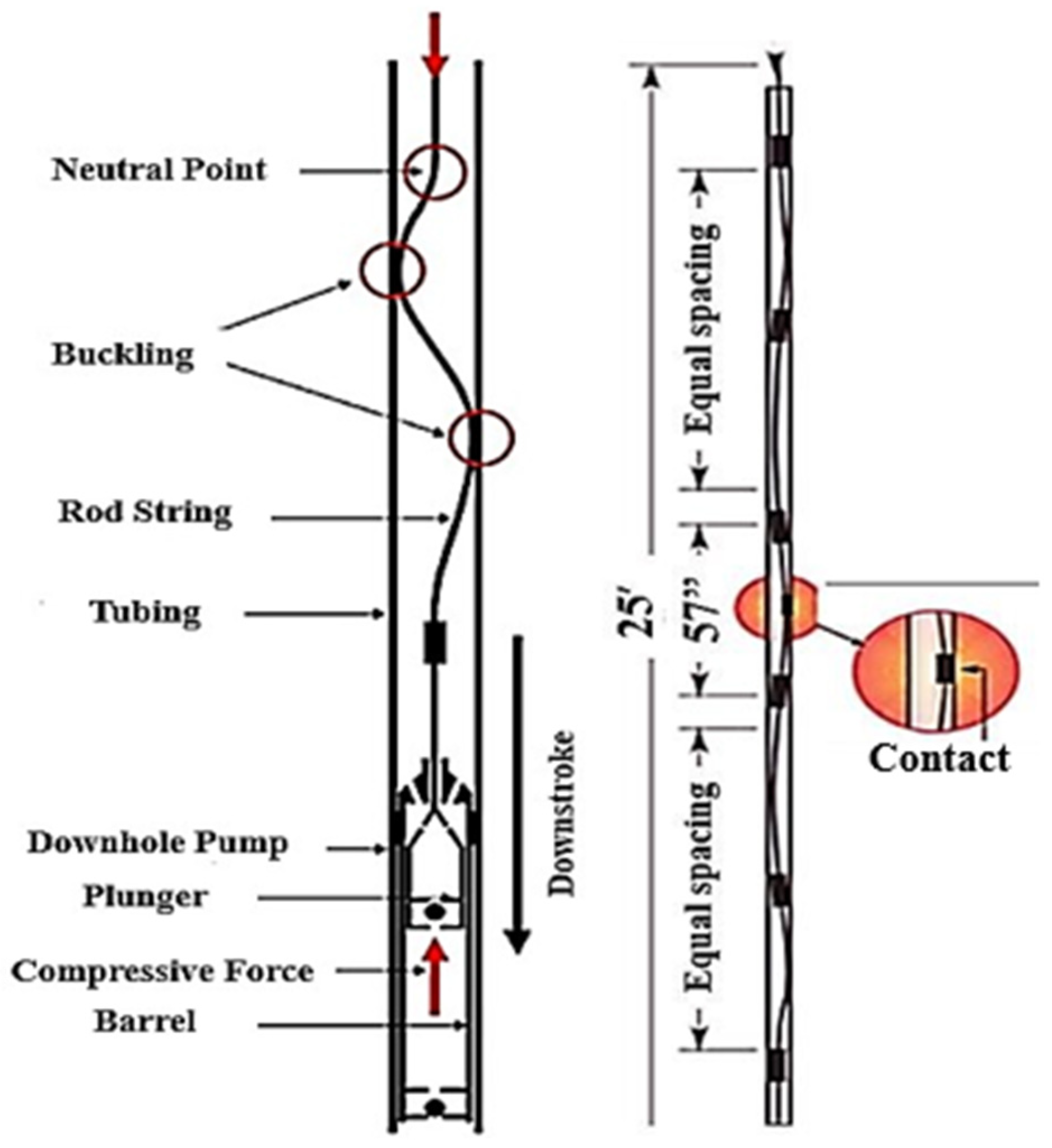

2.1. Failure of Sucker Rod Pumping Systems

2.2. Use of Polymer Sucker Rod Guides to Mitigate Downhole Failures

3. Characteristics of Polymer Rod Guides

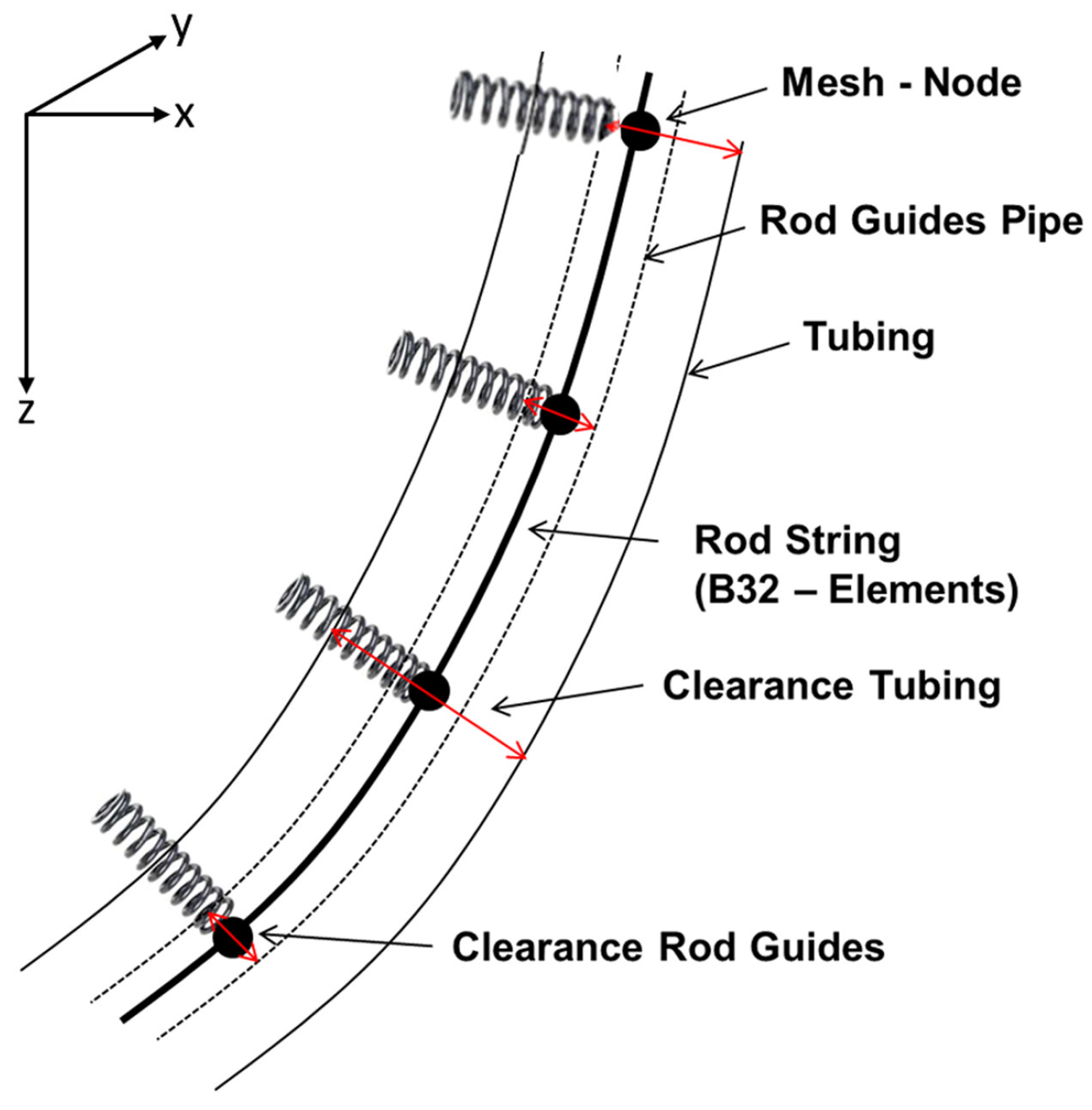

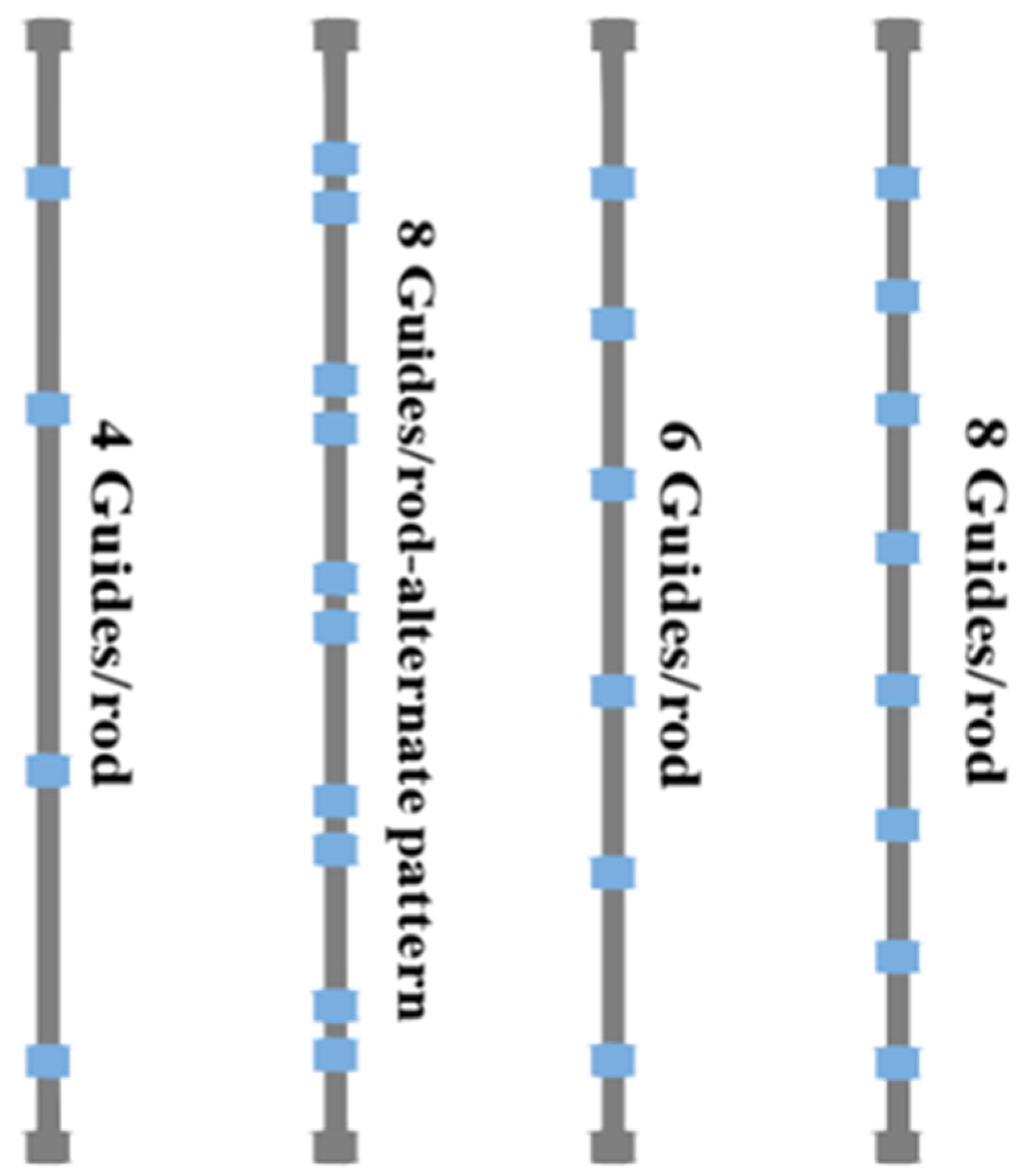

3.1. Location of Polymeric Rod Guide Installation

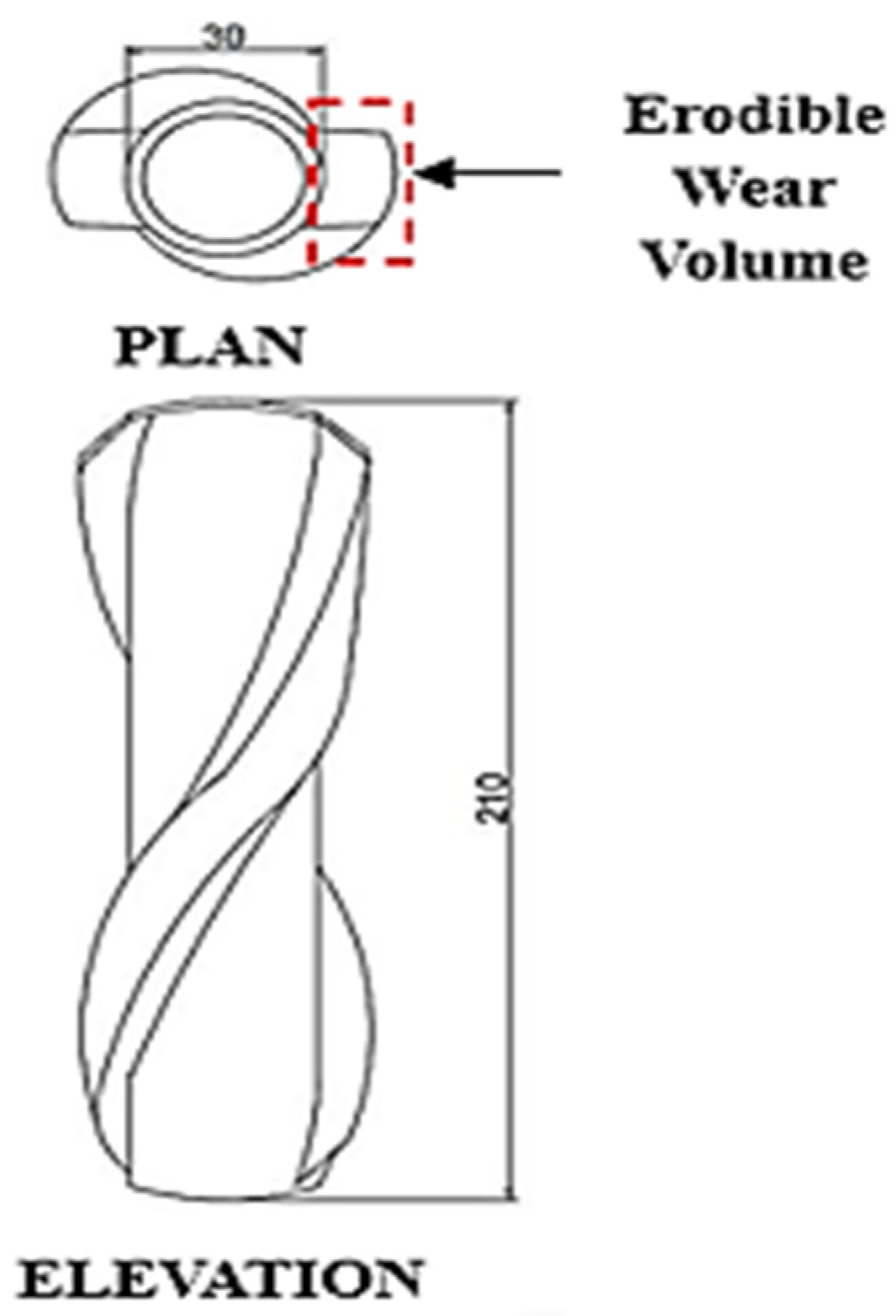

3.2. Design of Polymer Rod Guides

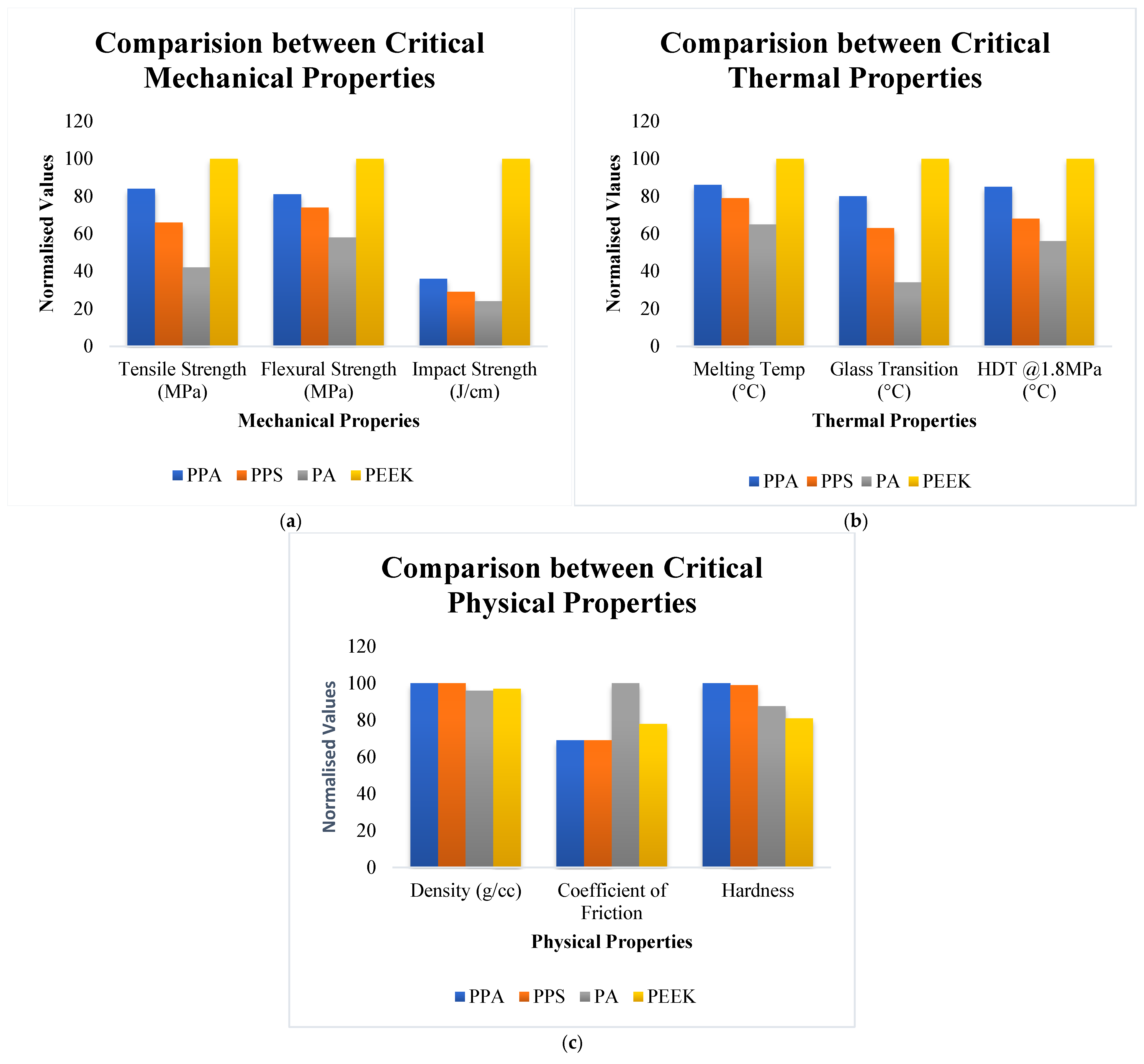

3.3. Literature Review on Polymer Rod Guide Materials and Types

3.4. Regulatory and Performance Standards for Polymeric Rod Guides

3.5. Manufacturing Techniques for Polymeric Rod Guides

4. Polymer Rod Guide Failure

Wear Characteristics of Polymer Rod Guides

5. Effect of Contaminants on Thermoplastics

6. Recycling Methods for Polymer Rod Guides

- Primary (commonly conducted in-plant) recycling or closed-loop recycling processes which reuse waste products from a single homogeneous source in their original form without any modification. It is advantageous due to lower energy consumption, reduced resource utilisation, low cost, and simple techniques [107,108].

- Secondary recycling involves recovering plastic waste through mechanical processes. Mechanical recycling includes sorting, shredding, washing, and extruding post-consumer plastic [109]. Mwanza [108] and Grigore [110] indicated that mixing secondary recycled materials with virgin materials can yield excellent results, provided contaminants have been removed from the source.

- Quaternary (energy recovery) recycling is a process whereby plastic waste is incinerated and used for energy recovery to generate heat and electricity. It is generally employed when mechanical recycling is not feasible due to severe heterogeneity, which leads to separation difficulties, excessive contamination, or deteriorated polymeric properties.

7. Identified Research Gaps

- Lack of thermal degradation data: The existing literature mainly discusses mechanical wear and erosion, while systematic evaluation of thermal degradation at elevated downhole temperatures is absent. Understanding thermal stability and changes in mechanical properties with temperature is crucial for predicting the long-term performance of thermoplastic rod guides.

- Absence of microstructural and chemical characterisation: No published work has examined the microstructural or chemical changes in used rod guides through techniques such as SEM, FTIR, or DSC. These analyses are necessary to determine degradation pathways, fibre-matrix interfacial failure, and the extent of chemical attack caused by oilfield contaminants.

- Lack of a standardised testing framework: There is no established testing standard for evaluating polymeric rod guides under combined mechanical, thermal, and chemical stress. The absence of these benchmark testing parameters, such as wear rate, friction coefficient, or temperature limits, makes performance comparison between materials and field studies difficult.

- No defined recycling or reuse strategies: Used composite rod guides are currently discarded in landfills due to the absence of established recycling methods. There are no studies assessing their mechanical recyclability, potential reuse as feedstock, or environmental impact through a lifecycle perspective.

- Limited modelling and predictive approaches: No studies have attempted to model the wear behaviour, material degradation, and rod–tubing interaction using simulations or finite element methods. Therefore, development of such predictive tools would enable performance forecasting and design optimisation for various well conditions.

8. Challenges

8.1. Lack of Research and Development on Polymer Rod Guides

8.2. Lack of Characterisation Studies

8.3. Wide Range of Polymeric Rod Guides Materials

9. Research Opportunities

9.1. Degradation Mechanism of Polymeric Rod Guides

9.2. Increased Recyclability of Used Polymer Rod Guides

9.3. Study on Different Thermoplastics

- To better understand their recyclability and compatibility with similar plastics.

- To help identify the potential for commingling with different plastics.

- To ensure the sustainability of sources for waste rod guide resources and support investments in the recycling industry.

10. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cao, P.-F.; Mangadlao, J.D.; Advincula, R.C. Stimuli-Responsive Polymers and their Potential Applications in Oil-Gas Industry. Polym. Rev. 2015, 55, 706–733. [Google Scholar] [CrossRef]

- Fakher, S.; Khlaifat, A.; Hossain, M.E.; Nameer, H. A comprehensive review of sucker rod pumps’ components, diagnostics, mathematical models, common failures and mitigations. J. Pet. Explor. Prod. Technol. 2021, 11, 3815–3839. [Google Scholar] [CrossRef]

- Romero, O.J.; Almeida, P. Numerical simulation of the sucker-rod pumping system: Simulación numérica de un sistema de bombeo mecánico. Ing. E Investig. 2014, 34, 4–11. [Google Scholar] [CrossRef]

- Dave, M.K.; Mustafa, M.G. Performance Evaluations of the Different Sucker Rod Artificial Lift Systems. In Proceedings of the SPE Symposium: Production Enhancement and Cost Optimisation, Kuala Lumpur, Malaysia, 7–8 November 2017. [Google Scholar] [CrossRef]

- Allison, A.P.; Leal, C.F.; Boland, M.R. Solving Gas Interference Issues with Sucker Rod Pumps in the Permian Basin. In Proceedings of the SPE Artificial Lift Conference and Exhibition—Americas, The Woodlands, TX, USA, 28–30 August 2018. [Google Scholar] [CrossRef]

- Kumar, A.; Upadhyay, R.; Kumar, S. Tubing and Rod Failure Analysis in Rod Pumped Wells in an Indian Western Oil Field. SPE J. 2023, 28, 1481–1501. [Google Scholar] [CrossRef]

- Zhang, J.; Zeng, W.; Guo, Y.; Gao, Q.; Yang, Z.; Li, D.; Wang, X.; Zhang, L. Fracture Failure Analysis of Type HL Sucker Rod in H2S-CO2 Environment. In Proceedings of the CORROSION 2020, online, 14–18 June 2020. [Google Scholar] [CrossRef]

- Clemens, L.; Tobias, P.; Viorica, S.; Mikhail, P.; Herbert, H. Sucker Rod String Rod Guide Service Life Estimation. In Proceedings of the SPE Annual Caspian Technical Conference and Exhibition, Astana, Kazakhstan, 31 October–2 November 2018. [Google Scholar] [CrossRef]

- Dove, J.; Smith, Z.D. Using Sucker Rod Pump Repair Data to Optimize Rod Lift Design. In Proceedings of the SPE North America Artificial Lift Conference and Exhibition, The Woodlands, TX, USA, 25–27 October 2016. [Google Scholar] [CrossRef]

- Permanschlager, T. Friction and Wear Analysis Between Sucker Rod Guides and Tubing. Master’s Thesis, University of Leoben, Leoben, Austria, 2018. Available online: https://pure.unileoben.ac.at/en/publications/friction-and-wear-analysis-between-sucker-rod-guides-and-tubing (accessed on 14 May 2024).

- Clarke, F.; Malone, L. Sucker Rod Pumping in the Eagle Ford Shale Field Study. In Proceedings of the SPE North America Artificial Lift Conference and Exhibition, The Woodlands, TX, USA, 25–27 October 2016. [Google Scholar] [CrossRef]

- Davis, R.; Naguib, M.; Snider, B. Understanding and Mitigating Downhole Corrosion and Wear Failures; Western Falcon Energy Services: Humble, TX, USA, 2016; Available online: https://westernfalcon.com/wp-content/uploads/2018/10/Final-SWPSC-2016-Corrosion-and-Wear-Western-Falcon.pdf (accessed on 22 May 2024).

- Eisner, P.; Langbauer, C.; Fruhwirth, R. Sucker rod pump downhole dynamometer card determination based on a novel finite element method. Liq. Gaseous Energy Resour. 2021, 1, 2–220. [Google Scholar] [CrossRef]

- Langbauer, C.; Fruhwirth, R.K.; Volker, L. Sucker Rod Antibuckling System: Development and Field Application. SPE Prod. Oper. 2021, 36, 327–342. [Google Scholar] [CrossRef]

- Langbauer, C.; Antretter, T. Finite Element Based Optimization and Improvement of the Sucker Rod Pumping System. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 13–16 November 2017. [Google Scholar] [CrossRef]

- Takacs, G. (Ed.) Chapter 3—Sucker-Rod Pumping System Components and Their Operation. In Sucker-Rod Pumping Handbook; Gulf Professional Publishing: Boston, MA, USA, 2015; pp. 57–246. [Google Scholar] [CrossRef]

- Correa, S.; Pertuz, G.; Cuellar, H.; Moreno, L.F.; Salazar, J.I.; Romero, J. Successful PCP Applications in High Deviated Wells: Breaking Away the Paradigm of PCP Only for Vertical or Low Deviated Wells in Colombia. In Proceedings of the SPE Artificial Lift Conference-Americas, Cartagena, Colombia, 21–22 May 2013. [Google Scholar] [CrossRef]

- Khadav, S.; Agarwal, S.; Kumar, P.; Pandey, N.; Parasher, A.; Kumar, S.; Agarwal, V.; Tiwari, S. System Run Life Improvement for Rod Driven PCP in High Deviation Well. In Proceedings of the SPE Artificial Lift Conference and Exhibition—Americas, The Woodlands, TX, USA, 28–30 August 2018. [Google Scholar] [CrossRef]

- Mo, Y.; Xu, J. Design and Optimization for Sucker Rod Pumping System in Deviated Wells. In Proceedings of the SPE/AAPG Western Regional Meeting, Long Beach, CA, USA, 19–22 June 2000. [Google Scholar] [CrossRef]

- Neustadt, W.; Doppelreiter, D. Increasing Lifetime of Oil Production Tubings. Master’s Thesis, University of Leoben, Leoben, Austria, 2007. Available online: https://pureadmin.unileoben.ac.at/ws/portalfiles/portal/2274282/AC06051444n01vt.pdf (accessed on 3 July 2024).

- Abdalla, R. Rod Pump System Performance And Evaluation; Meleiha Oil Fild-Agiba Petroleum Company: Western Desert, Egypt; Cairo University: Giza, Egypt, 2016. [Google Scholar] [CrossRef]

- Murtha, T.P.; Pirtle, J.; Beaulieu, W.B.; Waldrop, J.R.; Wood, H.V. New High-Performance Field-Installed Sucker Rod Guides. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 27–30 September 1987. [Google Scholar] [CrossRef]

- Takacs, G. Sucker-Rod Pumping Handbook; Gulf Professional Publishing: Houston, TX, USA, 2015. [Google Scholar] [CrossRef]

- Narso, C.K. Molded Rod Guide: Solution to Minimize Tubing Leak Problems in SRP Wells. 2018. Available online: https://archives.datapages.com/data/ipa_pdf/2018/IPA18-347-E.htm#purchaseoptions (accessed on 14 May 2024).

- Shembekar, A.P.; Yu, J.; Zhang, M.; Griffin, C.; Ray, D. Recycling Continuous Glass Fibre-Reinforced Polyamide 6 Laminates via Compression Moulding. Polymers 2025, 17, 2160. [Google Scholar] [CrossRef] [PubMed]

- Done, J.; Bugg, D. PEEK-Blend Rod Guides Extend Service Life in High Temperature Wells. Champion X Artificial Lift. 2022. Available online: https://www.championx.com/contents/NOR_High%20Temp%20Guide_BR_0422.pdf (accessed on 28 June 2024).

- Rao, V.L. Polyether Ketones. J. Macromol. Sci. Part C 1995, 35, 661–712. [Google Scholar] [CrossRef]

- Nam, C.-Y.; Im, D.; Lee, J.-H.; Kim, J.; Cho, K.-Y.; Yoon, H.-G. Advancing Compatibility and Interfacial Interaction Between PEEK and GNPs Through a Strategic Approach Using Pyrene-Functionalized PDMAEMA-b-PMMA Copolymer. Polymers 2025, 17, 1599. [Google Scholar] [CrossRef]

- Lopez, L.C.; Wilkes, G.L. Poly(p-Phenylene Sulfide)—An Overview of an Important Engineering Thermoplastic. J. Macromol. Sci. Part C 1989, 29, 83–151. [Google Scholar] [CrossRef]

- Li, Y.; Chen, B.; Chen, G.; Wu, X. The global oil supply chain: The essential role of non-oil product as revealed by a comparison between physical and virtual oil trade patterns. Resour. Conserv. Recycl. 2021, 175, 105836. [Google Scholar] [CrossRef]

- Castro-Amoedo, R.; Granacher, J.; Kantor, I.; Dahmen, A.; Barbosa-Povoa, A.; Maréchal, F. On the role of system integration in plastic waste management. Resour. Conserv. Recycl. 2024, 201, 107295. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Inoue, Y.; Okamoto, H. Estimation method to achieve desired mechanical properties with minimum virgin polymer in plastics recycling. Resour. Conserv. Recycl. 2024, 211, 107856. [Google Scholar] [CrossRef]

- Xu, T.; Lv, Q.; Sheng, G.; Zhang, Y.; Liu, Y.; Shi, L. Evolving patterns and drivers of waste plastic trade in key global economies. Resour. Conserv. Recycl. 2024, 206, 107606. [Google Scholar] [CrossRef]

- Huang, Z.; Deng, S.; Zhang, Q.; Zhao, R.; Li, S.; Veselovskaya, J.; Kozlov, D.; Wang, J. Closing plastic loop with CCUS: Life cycle assessment of a novel strategy for plastic sustainable transition and negative emissions. Resour. Conserv. Recycl. 2024, 208, 107738. [Google Scholar] [CrossRef]

- Cabernard, L.; Pfister, S.; Oberschelp, C.; Hellweg, S. Growing environmental footprint of plastics driven by coal combustion. Nat. Sustain. 2021, 5, 139–148. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Change 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Pilapitiya, P.N.T.; Ratnayake, A.S. The world of plastic waste: A review. Clean. Mater. 2024, 11, 100220. [Google Scholar] [CrossRef]

- Cho, W.Y.; Lee, P.C. Refining Biodegradability Assessments of Polymers Through Microbial Biomolecule Quantification. Polymers 2025, 17, 2376. [Google Scholar] [CrossRef]

- Takayama, T.; Takahashi, R.; Konno, N.; Sato, N. Evaluation of Polypropylene Reusability Using a Simple Mechanical Model Derived from Injection-Molded Products. Polymers 2025, 17, 2107. [Google Scholar] [CrossRef]

- Charitopoulou, M.-A.; Koutroumpi, S.; Achilias, D.S. Thermal Characterization and Recycling of Polymers from Plastic Packaging Waste. Polymers 2025, 17, 1786. [Google Scholar] [CrossRef]

- van der Hulst, M.K.; Ottenbros, A.B.; van der Drift, B.; Ferjan, Š.; van Harmelen, T.; Schwarz, A.E.; Worrell, E.; van Zelm, R.; Huijbregts, M.A.; Hauck, M. Greenhouse gas benefits from direct chemical recycling of mixed plastic waste. Resour. Conserv. Recycl. 2022, 186, 106582. [Google Scholar] [CrossRef]

- Pienknagura Dolberg, E. Implementation of a Digital Sucker Rod Pumping Unit for Research and Educational Purposes. Master’s Thesis, University of Oklahoma, Norman, OK, USA, 2019. Available online: https://shareok.org/server/api/core/bitstreams/0ed26fd7-282c-48a8-a82d-5926bba71647/content (accessed on 22 May 2024).

- Osaretin, C.A.; Iqbal, T.; Butt, S.; Osaretin, C.A.; Iqbal, T.; Butt, S. Optimal sizing and techno-economic analysis of a renewable power system for a remote oil well. AIMS Electron. Electr. Eng. 2020, 4, 132–153. [Google Scholar] [CrossRef]

- Eisner, P.; Langbauer, C.; Fruhwirth, R.K. Comparison of a novel finite element method for sucker rod pump downhole dynamometer card determination based on real world dynamometer cards. Upstream Oil Gas Technol. 2022, 9, 100078. [Google Scholar] [CrossRef]

- Alina, T. Comparison of Sucker Rod String Design Methods, Types and Applications. Master’s Thesis, University of Leoben, Leoben, Austria, 2018. [Google Scholar]

- Duan, D.L.; Geng, Z.; Jiang, S.L.; Li, S. Failure mechanism of sucker rod coupling. Eng. Fail. Anal. 2014, 36, 166–172. [Google Scholar] [CrossRef]

- Eid, A.; Mohamed, N. Sucker Rods Failure Mechanisms, Methods of Avoiding them. In Proceedings of the Middle East Technical Conference and Exhibition, Paper presented at the Middle East Technical Conference and Exhibition, Manama, Bahrain, 9–12 March 1981. [Google Scholar] [CrossRef]

- Jegbefume, O.; Bang, J.; Ledroz, A.; Shoup, R.; Vincent, R.; Earley, J. Rod-Guide Placement Based on High-Resolution Tortuosity Analysis of Production Tubing. In Proceedings of the SPE Artificial Lift Conference and Exhibition—Americas, The Woodlands, TX, USA, 28–30 August 2018. [Google Scholar] [CrossRef]

- Langbauer, C. Sucker Rod Anti—Buckling System Analysis. Ph.D. Thesis, Montanuniversität, Leoben, Austria, 2015. Available online: https://pureadmin.unileoben.ac.at/ws/portalfiles/portal/2291665/AC12694451n01.pdf (accessed on 15 May 2024).

- Zhang, Q.; Wang, X.; Li, W.; Xiao, Z.; Yue, Q.; Zhu, Y. Buckling of a twisted rod with centralizers in a tubing. J. Pet. Sci. Eng. 2021, 204, 108731. [Google Scholar] [CrossRef]

- Nurmohamed, D.; Lien, H.C.; Kisoensingh, S. Case Study for Reducing Tubing Failures in Suriname’s Tambaredjo Field. In Proceedings of the SPE Energy Resources Conference, Port of Spain, Trinidad and Tobago, 9–11 June 2014. [Google Scholar] [CrossRef]

- Hein, N.W.; Rowlan, O.L. Dog Leg Serverity (DLS) and Side Load (SL) Recommendations to Drilling. 2019. Available online: https://www.spegcs.org/media/files/files/8be6e28b/swpsc-2019-dog-leg-serverity-dls-and-side-load-sl-recommendations-to-drilling-hein-rowlan.pdf (accessed on 28 May 2024).

- Araújo, R.; Xavier-de-Souza, S. A simulation model for dynamic behavior of directional sucker-rod pumping wells: Implementation, analysis, optimization. J. Pet. Explor. Prod. Technol. 2021, 11, 2635–2659. [Google Scholar] [CrossRef]

- Goyal, P.; Sinha, N.; Singhal, C.P.; Manchalwar, V.V.; Rao, K.R. Radial stress analysis as a tool for determining tubing and rod failure location in deviated SRP wells-Application to wells of Indian Onshore. In Proceedings of the 22nd Annual India Oil & Gas Review Summit & International Exhibition, Mumbai, India, 13–15 December 2023; Available online: https://www.researchgate.net/publication/376758027_Radial_stress_analysis_as_a_tool_for_determining_tubing_and_rod_failfai_location_in_deviated_SRP_wells_-Application_to_wells_of_Indian_onshore_Institute_of_Oil_and_Gas_Production_Technology (accessed on 29 May 2024).

- Jiang, J.; Wan, X.; Li, K.; Du, J.; Liu, Y.; Jing, J.; Li, J. Research progress of sucker rod fracture detection and prediction model. Eng. Fail. Anal. 2024, 159, 108119. [Google Scholar] [CrossRef]

- He, X.; Guo, F.; Tang, K.; Ge, T. Crystallization Kinetics of Modified Nanocellulose/Monomer Casting Nylon Composites. Polymers 2023, 15, 719. [Google Scholar] [CrossRef] [PubMed]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K. Durability characteristics and property prediction of glass fibre reinforced mixed plastics composites. Compos. Part B Eng. 2017, 116, 16–29. [Google Scholar] [CrossRef]

- Ishak, Z.A.M.; Ishak, T.S.A.M.; Yow, B.N.; Ishiaku, U.S.; Karger-Kocsis, J. Short glass fibre reinforcedpoly(butylene terephthalate) Part 2–Effect of hygrothermal aging onmechanical properties. Plast. Rubber Compos. 2000, 29, 271–277. [Google Scholar] [CrossRef]

- Rotter, G.; Ishida, H. FTIR separation of nylon-6 chain conformations: Clarification of the mesomorphous and γ-crystalline phases. J. Polym. Sci. Part B Polym. Phys. 1992, 30, 489–495. [Google Scholar] [CrossRef]

- Guo, X.; Liu, L.; Feng, H.; Li, D.; Xia, Z.; Yang, R. Flame Retardancy of Nylon 6 Fibers: A Review. Polymers 2023, 15, 2161. [Google Scholar] [CrossRef]

- Shukla, D.; Negi, Y.S.; Uppadhyaya, J.S.; Kumar, V. Synthesis and Modification of Poly(ether ether ketone) and their Properties: A Review. Polym. Rev. 2012, 52, 189–228. [Google Scholar] [CrossRef]

- Wielgus, G.; Kajzer, W.; Kajzer, A. The Use of Non-Degradable Polymer (Polyetheretherketone) in Personalized Orthopedics—Review Article. Polymers 2025, 17, 2158. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, S.K. Simulation and Design of Nylon 6 Reactors. J. Macromol. Sci. Part C 1986, 26, 183–247. [Google Scholar] [CrossRef]

- Deporter, J.K.; Baird, D.G.; Wilkes, G.L. The Effects of Thermal History on the Properties of Semicrystalline Thermoplastic Composites: A review of Experimental and Numerical Investigations. J. Macromol. Sci. Part C 1993, 33, 1–79. [Google Scholar] [CrossRef]

- Online Materials Information Resource—MatWeb. Available online: https://www.matweb.com/index.aspx (accessed on 28 June 2024).

- Charles, J.; Ramkumaar, G.R.; Azhagiri, S.; Gunasekaran, S. FTIR and Thermal Studies on Nylon-66 and 30% Glass Fibre Reinforced Nylon-66. J. Chem. 2008, 6, 909017. [Google Scholar] [CrossRef]

- CP Lab Safety. Nylon Chemical Compatibility Chart. Available online: https://www.calpaclab.com/nylon-chemical-compatibility-chart/?srsltid=AfmBOooey7By5tMVF3sb12qckovlJjZqA6U8se6-cA98yLbZotdR3KFU (accessed on 24 December 2024).

- Plastics International. Plastics Chemical Compatibility Chart. Available online: https://vp-sci.com/wp-content/uploads/Plastics-Intl-Chemical-Resistance-Guide2.pdf (accessed on 24 December 2024).

- Venoor, V.; Park, J.H.; Kazmer, D.O.; Sobkowicz, M.J. Understanding the Effect of Water in Polyamides: A Review. Polym. Rev. 2021, 61, 598–645. [Google Scholar] [CrossRef]

- (API) RP 11AR; Recommended Practice for Care and Use of Subsurface Pumps. American Petroleum Institute: Washington, DC, USA, 2000.

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ISO 527; Plastics—Determination of Tensile Properties (ISO 527-1:2019—Part 1: General principles). International Organization for Standardization: Geneva, Switzerland, 2019.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ISO 178; Plastics—Determination of flexural properties (ISO 178:2010). International Organization for Standardization: Geneva, Switzerland, 2010.

- ASTM D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2024.

- ISO 180; Plastics—Determination of Izod Impact Strength (ISO 180:2023). International Organization for Standardization: Geneva, Switzerland, 2023.

- ASTM D-648; Standard Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position. ASTM International: West Conshohocken, PA, USA, 2018.

- ISO 75; Plastics—Determination of Temperature of Deflection under Load (ISO 75-1:2020—Part 1: General Test Method). International Organization for Standardization: Geneva, Switzerland, 2020.

- Duromer Products Pty Ltd. Duralon N6 25G HS BK106L Technical Data Sheet; Duromer Products Pty Ltd.: Sydney, Australia, 2014; Private Technical Data Sheet; See Product Family; Available online: https://www.duromer.com/products/duralon/ (accessed on 18 September 2025).

- Vaidya, U.K.; Chawla, K.K. Processing of fibre reinforced thermoplastic composites. Int. Mater. Rev. 2008, 53, 185–218. [Google Scholar] [CrossRef]

- Singh, G.; Verma, A. A Brief Review on injection moulding manufacturing process. Mater. Today Proc. 2017, 4, 1423–1433. [Google Scholar] [CrossRef]

- Liu, S.-J.; Chen, Y.-S. The manufacturing of thermoplastic composite parts by water-assisted injection-molding technology. Compos. Part Appl. Sci. Manuf. 2004, 35, 171–180. [Google Scholar] [CrossRef]

- Aliyeva, N.; Sas, H.S.; Okan, B.S. Recent developments on the overmolding process for the fabrication of thermoset and thermoplastic composites by the integration of nano/micron-scale reinforcements. Compos. Part Appl. Sci. Manuf. 2021, 149, 106525. [Google Scholar] [CrossRef]

- Becerra-Borges, Y.E.; Cazón-Martín, A.; Rodriguez-Ferradas, M.I.; Morer-Camo, P.; Etxaniz-Sein, U.; Manchado, J.C.; Candal, M.V. Transforming plastic injection molding with additive manufacturing: A novel systematic review of innovative approaches to insert production. Rapid Prototyp. J. 2024, 31, 200–217. [Google Scholar] [CrossRef]

- Pheysey, J.; De Cola, F.; Martinez-Hergueta, F. Short fibre/unidirectional hybrid thermoplastic composites: Experimental characterisation and digital analysis. Compos. Part Appl. Sci. Manuf. 2024, 181, 108121. [Google Scholar] [CrossRef]

- Campbell, F.C. Chapter 11—Commercial Composite Processes: These Commercial Processes Produce Far More Parts than the High-performance Processes. In Manufacturing Processes for Advanced Composites; Campbell, F.C., Ed.; Elsevier Science: Amsterdam, The Netherlands, 2004; pp. 399–438. [Google Scholar] [CrossRef]

- Verstraete, G.; Mertens, P.; Grymonpré, W.; Van Bockstal, P.; De Beer, T.; Boone, M.; Van Hoorebeke, L.; Remon, J.; Vervaet, C. A comparative study between melt granulation/compression and hot melt extrusion/injection molding for the manufacturing of oral sustained release thermoplastic polyurethane matrices. Int. J. Pharm. 2016, 513, 602–611. [Google Scholar] [CrossRef]

- Ghanbari, A.; Jalili, N.S.; Haddadi, S.A.; Arjmand, M.; Nofar, M. Mechanical properties of extruded glass fiber reinforced thermoplastic polyolefin composites. Polym. Compos. 2020, 41, 3748–3757. [Google Scholar] [CrossRef]

- Kunchimon, S.Z.; Tausif, M.; Goswami, P.; Cheung, V. Polyamide 6 and thermoplastic polyurethane recycled hybrid Fibres via twin-screw melt extrusion. J. Polym. Res. 2019, 26, 162. [Google Scholar] [CrossRef]

- Lyu, Y.; Wu, J.; Zhang, H.; Brádaigh, C.M.Ó.; Yang, D. Effects of thermal process conditions on crystallinity and mechanical properties in material extrusion additive manufacturing of discontinuous carbon fibre reinforced polyphenylene sulphide composites. J. Compos. Mater. 2023, 57, 3775–3787. [Google Scholar] [CrossRef]

- Tseng, J.-W.; Liu, C.-Y.; Yen, Y.-K.; Belkner, J.; Bremicker, T.; Liu, B.H.; Sun, T.-J.; Wang, A.-B. Screw extrusion-based additive manufacturing of PEEK. Mater. Des. 2018, 140, 209–221. [Google Scholar] [CrossRef]

- Guo, P.; Wang, Y.; Duan, M.; Pang, D.; Li, N. Research and application of methods for effectiveness evaluation of mine cooling system. Int. J. Min. Sci. Technol. 2015, 25, 649–654. [Google Scholar] [CrossRef]

- Mihalyi, S.; Sykacek, E.; Campano, C.; Hernández-Herreros, N.; Rodríguez, A.; Mautner, A.; Prieto, M.; Quartinello, F.; Guebitz, G.M. Bio-upcycling of viscose/polyamide textile blends waste to biopolymers and fibers. Resour. Conserv. Recycl. 2024, 208, 107712. [Google Scholar] [CrossRef]

- Banjo, A.D.; Agrawal, V.; Auad, M.L.; Celestine, A.-D.N. Moisture-induced changes in the mechanical behavior of 3D printed polymers. Compos. Part C Open Access 2022, 7, 100243. [Google Scholar] [CrossRef]

- Xie, H.; Zhao, X.; Liu, J.; Zhang, R.; Xue, D. Influence of different mining layouts on the mechanical properties of coal. Int. J. Min. Sci. Technol. 2012, 22, 749–755. [Google Scholar] [CrossRef]

- Frank, H.; Ting, R.; Naj, A. Evolution and application of in-seam drilling for gas drainage. Int. J. Min. Sci. Technol. 2013, 23, 543–553. [Google Scholar] [CrossRef]

- Salam, A.H.; Alsaif, B.; Hussain, S.M.S.; Khan, S.; Kamal, M.S.; Patil, S.; Al-Shalabi, E.W.; Hassan, A.M. Advances in Understanding Polymer Retention in Reservoir Rocks: A Comprehensive Review. Polym. Rev. 2024, 64, 1387–1413. [Google Scholar] [CrossRef]

- Liang, S.; Li, X.; Mao, Y.; Li, C. Time-domain characteristics of overlying strata failure under condition of longwall ascending mining. Int. J. Min. Sci. Technol. 2013, 23, 207–211. [Google Scholar] [CrossRef]

- Elshorbagy, W.; Alkamali, A. Solid waste generation from oil and gas industries in United Arab Emirates. J. Hazard. Mater. 2005, 120, 89–99. [Google Scholar] [CrossRef]

- Thiounn, T.; Smith, R.C. Advances and approaches for chemical recycling of plastic waste. J. Polym. Sci. 2020, 58, 1347–1364. [Google Scholar] [CrossRef]

- Rai, P.K.; Sonne, C.; Brown, R.J.C.; Younis, S.A.; Kim, K.-H. Adsorption of environmental contaminants on micro- and nano-scale plastic polymers and the influence of weathering processes on their adsorptive attributes. J. Hazard. Mater. 2022, 427, 127903. [Google Scholar] [CrossRef] [PubMed]

- Budsaereechai, S.; Hunt, A.J.; Ngernyen, Y. Catalytic pyrolysis of plastic waste for the production of liquid fuels for engines. RSC Adv. 2019, 9, 5844–5857. [Google Scholar] [CrossRef]

- Kharbanda, O.P.; Stallworthy, E.A. Waste Management: Towards a Sustainable Society; Gower Publishing Ltd.: Farnham, UK, 1993; Volume 13. [Google Scholar] [CrossRef]

- Bloemhof-Ruwaard, J.M.; Van Wassenhove, L.N.; Gabel, H.L.; Weaver, P.M. An environmental life cycle optimization model for the European pulp and paper industry. Omega 1996, 24, 615–629. [Google Scholar] [CrossRef]

- Wong, S.L.; Ngadi, N.; Abdullah, T.A.T.; Inuwa, I.M. Current state and future prospects of plastic waste as source of fuel: A review. Renew. Sustain. Energy Rev. 2015, 50, 1167–1180. [Google Scholar] [CrossRef]

- Maris, J.; Bourdon, S.; Brossard, J.-M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Mwanza, B.G.M. Introduction to Recycling; Springer: Singapore, 2021; pp. 1–13. [Google Scholar] [CrossRef]

- Uekert, T.; Singh, A.; DesVeaux, J.S.; Ghosh, T.; Bhatt, A.; Yadav, G.; Afzal, S.; Walzberg, J.; Knauer, K.M.; Nicholson, S.R.; et al. Technical, Economic, Environmental Comparison of Closed-Loop Recycling Technologies for Common Plastics. ACS Sustain. Chem. Eng. 2023, 11, 965–978. [Google Scholar] [CrossRef]

- Grigore, M.E. Methods of Recycling, Properties and Applications of Recycled Thermoplastic Polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef]

- Fukushima, K.; Lecuyer, J.M.; Wei, D.S.; Horn, H.W.; Jones, G.O.; Al-Megren, H.A.; Alabdulrahman, A.M.; Alsewailem, F.D.; McNeil, M.A.; Rice, J.E.; et al. Advanced chemical recycling of poly(ethylene terephthalate) through organocatalytic aminolysis. Polym. Chem. 2013, 4, 1610–1616. [Google Scholar] [CrossRef]

- Kunwar, B.; Cheng, H.N.; Chandrashekaran, S.R.; Sharma, B.K. Plastics to fuel: A review. Renew. Sustain. Energy Rev. 2016, 54, 421–428. [Google Scholar] [CrossRef]

- Rahimi, A.; García, J.M. Chemical recycling of waste plastics for new materials production. Nat. Rev. Chem. 2017, 1, 46. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- Saleem, J.; Riaz, M.A.; Gordon, M. Oil sorbents from plastic wastes and polymers: A review. J. Hazard. Mater. 2018, 341, 424–437. [Google Scholar] [CrossRef] [PubMed]

- Syamsiro, M.; Saptoadi, H.; Norsujianto, T.; Noviasri, P.; Cheng, S.; Alimuddin, Z.; Yoshikawa, K. Fuel Oil Production from Municipal Plastic Wastes in Sequential Pyrolysis and Catalytic Reforming Reactors. Energy Procedia 2014, 47, 180–188. [Google Scholar] [CrossRef]

- Budris, K. Burning Waste is a Bad Idea. So Why is Rhode Island Taking Time to Study It? Conservation Law Foundation. Available online: https://www.clf.org/blog/burning-waste-bad-idea/ (accessed on 26 February 2025).

- Seo, Y.-H.; Lee, K.-H.; Shin, D.-H. Investigation of catalytic degradation of high-density polyethylene by hydrocarbon group type analysis. J. Anal. Appl. Pyrolysis 2003, 70, 383–398. [Google Scholar] [CrossRef]

- Verma, R.; Vinoda, K.S.; Papireddy, M.; Gowda, A.N.S. Toxic Pollutants from Plastic Waste—A Review. Procedia Environ. Sci. 2016, 35, 701–708. [Google Scholar] [CrossRef]

- Fleischmann, M.; Beullens, P.; Bloemhof-Ruwaard, J.M.; Vanwassenhove, L.N. The Impact of Product Recovery on Logistics Network Design. Prod. Oper. Manag. 2001, 10, 156–173. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. The valorization of plastic solid waste (PSW) by primary to quaternary routes: From re-use to energy and chemicals. Prog. Energy Combust. Sci. 2010, 36, 103–129. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Eriksson, O.; Finnveden, G. Plastic waste as a fuel—CO2-neutral or not? Energy Environ. Sci. 2009, 2, 907–914. [Google Scholar] [CrossRef]

- Arena, U. Process and technological aspects of municipal solid waste gasification. A review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef]

- Zia, K.M.; Bhatti, H.N.; Bhatti, I.A. Methods for polyurethane and polyurethane composites, recycling and recovery: A review. React. Funct. Polym. 2007, 67, 675–692. [Google Scholar] [CrossRef]

- Muthu, S.S. 1—Introduction to sustainability and the textile supply chain and its environmental impact. In Assessing the Environmental Impact of Textiles and the Clothing Supply Chain, 2nd ed.; Muthu, S.S., Ed.; The Textile Institute Book Series; Woodhead Publishing: London, UK, 2020; pp. 1–32. [Google Scholar] [CrossRef]

- Pickin, J.; Wardle, C.; O’Farrell, K.; Stovell, L.; Nyunt, P.; Guazzo, S.; Lin, Y.; Caggiati-Shortell, G.; Chakma, P.; Edwards, C.; et al. National Waste Report 2022; The Department of Climate Change, Energy, the Environment and Water: Canberra, Australia, 2022. Available online: https://www.dcceew.gov.au/sites/default/files/documents/national-waste-report-2022.pdf (accessed on 1 July 2024).

- Callewaert, P.; Raadal, H.L. How should we move towards plastic circularity? Resour. Conserv. Recycl. 2024, 209, 107798. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Liu, L.; Barlaz, M.A.; Johnson, J.X. Economic and environmental comparison of emerging plastic waste management technologies. Resour. Conserv. Recycl. 2024, 205, 107531. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Li, Y.-D.; Zeng, J.-B. Progress in Toughening Poly(Lactic Acid) with Renewable Polymers. Polym. Rev. 2017, 57, 557–593. [Google Scholar] [CrossRef]

- Kamal, M.S.; Sultan, A.S.; Al-Mubaiyedh, U.A.; Hussein, I.A. Review on Polymer Flooding: Rheology, Adsorption, Stability, Field Applications of Various Polymer Systems. Polym. Rev. 2015, 55, 491–530. [Google Scholar] [CrossRef]

- Joustra, J.; Brans, K.; Villegas, I.F.; Sinke, J.; Teuwen, J. Reverse forming thermoplastic composites: Design and process development. Compos. Part C Open Access 2025, 16, 100550. [Google Scholar] [CrossRef]

- Das, S.C.; La Rosa, A.D.; Goutianos, S.; Grammatikos, S. Glass fibre hybridization to improve the durability of circular flax fibre reinforced composites with off-the-shelf recyclable polymer matrix systems for large scale structural applications. Compos. Part C Open Access 2024, 14, 100491. [Google Scholar] [CrossRef]

- Qiao, Y.; Ko, S.; Ramos, J.L.; Nickerson, E.K.; Denny, A.C.; Schuler, G.M.; Brown, N.L.; Guzman, A.; Moriel, C.E.; Pallaka, M.R.; et al. Effects of processing temperature, pressure, fiber volume fraction on mechanical and morphological behaviors of fully-recyclable uni-directional thermoplastic polymer-fiber-reinforced polymers. Compos. Part C Open Access 2024, 14, 100497. [Google Scholar] [CrossRef]

- Gong, H.; Kizil, M.S.; Chen, Z.; Amanzadeh, M.; Yang, B.; Aminossadati, S.M. Advances in fibre optic based geotechnical monitoring systems for underground excavations. Int. J. Min. Sci. Technol. 2019, 29, 229–238. [Google Scholar] [CrossRef]

- Das, S.C.; La Rosa, A.D.; Goutianos, S.; Grammatikos, S. Effect of accelerated weathering on the performance of natural fibre reinforced recyclable polymer composites and comparison with conventional composites. Compos. Part C Open Access 2023, 12, 100378. [Google Scholar] [CrossRef]

- Post, W.; Susa, A.; Blaauw, R.; Molenveld, K.; Knoop, R.J.I. A Review on the Potential and Limitations of Recyclable Thermosets for Structural Applications. Polym. Rev. 2020, 60, 359–388. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.-J. Plastics in the context of the circular economy and sustainable plastics recycling: Comprehensive review on research development, standardization and market. Compos. Part C Open Access 2021, 6, 100168. [Google Scholar] [CrossRef]

- Department of Sustainability, Environment, Water, and Encycle Consulting Pty Ltds. A Study into Commercial & Industrial (C&I) Waste and Recycling in Australia by Industry Division. Department of Sustainability, Environment, Water, Population and Communities. 2013. Available online: https://www.dcceew.gov.au/environment/protection/waste/publications/commercial-industrial-waste-recycling-australia (accessed on 1 July 2024).

- Kazemi, M.; Kabir, S.F.; Fini, E.H. State of the art in recycling waste thermoplastics and thermosets and their applications in construction. Resour. Conserv. Recycl. 2021, 174, 105776. [Google Scholar] [CrossRef]

- Elvers, D.; Song, C.H.; Steinbüchel, A.; Leker, J. Technology Trends in Biodegradable Polymers: Evidence from Patent Analysis. Polym. Rev. 2016, 56, 584–606. [Google Scholar] [CrossRef]

- Kopparthy, S.D.S.; Netravali, A.N. Review: Green composites for structural applications. Compos. Part C Open Access 2021, 6, 100169. [Google Scholar] [CrossRef]

- Ghosh, A. Performance modifying techniques for recycled thermoplastics. Resour. Conserv. Recycl. 2021, 175, 105887. [Google Scholar] [CrossRef]

- Ragupathi, B.; Bacher, M.F.; Balle, F. Separation and reconsolidation of thermoplastic glass fiber composites by power ultrasonics. Resour. Conserv. Recycl. 2023, 198, 107122. [Google Scholar] [CrossRef]

- Ralston, J.C.; Hargrave, C.O.; Dunn, M.T. Longwall automation: Trends, challenges and opportunities. Int. J. Min. Sci. Technol. 2017, 27, 733–739. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, G.; Ma, X.; Ren, D.; Nie, M.; Han, R. Polyamide 6 as a Liner Material for Type IV Hydrogen Storage Cylinders: Performance Challenges and Modification Strategies. Polymers 2025, 17, 1848. [Google Scholar] [CrossRef] [PubMed]

- Saleem, J.; Moghal, Z.K.B.; Tahir, F.; McKay, G. Sustainable Valorization of Plastic Waste and Palm Fronds into Chemically Activated Carbon–Polymer Composite. Polymers 2025, 17, 2356. [Google Scholar] [CrossRef] [PubMed]

- Qian, C.; Zhou, M.; Wei, J.; Ye, P.; Yang, X. Pyrolysis and co-pyrolysis of lignite and plastic. Int. J. Min. Sci. Technol. 2014, 24, 137–141. [Google Scholar] [CrossRef]

| Sl. No | Type of Guide | Pictorial Illustration |

|---|---|---|

| 1 | Wheeled rod guides |  |

| 2 | Snap-on guides |  |

| 3 | Moulded guides |  |

| Sl. No | Material Property | Rod Guide Materials | |||||

|---|---|---|---|---|---|---|---|

| PPA | PPS | PA | PEEK | ||||

| PA6 | PA12 | ||||||

| 1 | Tensile Yield Strength | 68.9–233 MPa | 33.1–203 MPa | 12.2–1500 MPa | 12–140 MPa | 180 MPa | |

| 2 | Flexural Strength | 103–326 MPa | 53.1–339 MPa | 29–800 MPa | 120–185 MPa | 265 MPa | |

| 3 | Flexural Modulus | 1.5–14.1 GPa | 1.2–30.1 GPa | 0.724–18.5 GPa | 3.7–7.1 GPa | 11.1 GPa | |

| 4 | Izod Notched Impact Strength | 0.37–3.74 J/cm | 0.27–3.15 J/cm | 0.370–3.36 J/cm | 1.07–1.80 J/cm | 0.214–11.4 J/cm | |

| 5 | Hardness | 114–125 | 114–123 | 80–121 | 109–110 | 85–109 | |

| 6 | Coefficient of Friction | 0.220–0.290 | 0.150–0.350 | 0.150–0.610 | 0.02–0.67 | 0.15–0.4 | |

| 7 | Melting Temperature | 246–340 °C | 260–282 °C | 178–368 °C | 165–185 °C | 342 °C | |

| 8 | Glass Transition Temperature | 95–135 °C | 90 °C | 5–67 °C | 48.8 °C | 143 °C | |

| 9 | HDT at load at 1.8 MPa | 155–320 °C | 105–272 °C | 65–290 °C | 90–177 °C | ≥280 °C | |

| 10 | Density | 1.34–1.75 g/cc | 1.4–1.69 g/cc | 1.20–1.67 g/cc | 1.15–1.96 g/cc | 1.50 g/cc | |

| 11 | Moisture Absorption @ Saturation | 4.2–4.5% | 0.02% | 1–8.2% | 1–1.4% | 0.18% | |

| 12 | Resistance to | Hot Oiling | Yes | Yes | Yes | Yes | Yes |

| Sweet Crude | Yes | Yes | Yes | Yes | Yes | ||

| Sour Crude | Yes | Yes | No | No | Yes | ||

| Sand | No | Yes | Yes | Yes | Yes | ||

| Water | Yes | Yes | No | Yes | Yes | ||

| Brine | No | Yes | No | Yes | Yes | ||

| Recycling Method | Steps Involved | Advantages | Disadvantages | Comment | Reference |

|---|---|---|---|---|---|

| Primary (In-Plant) Recycling | Collection of waste; Sorting; Direct reuse in manufacturing without altering the material | Low energy consumption; Minimal processing; Cost effective | Limited to clean, homogeneous waste | Suitable for uncontaminated in-plant waste; Most efficient in terms of energy and cost; Not suitable for used composite rod guides requiring pretreatment | [32,122] |

| Secondary (Mechanical) Recycling | Collection; Sorting; Cleaning; Shredding; Melting and extrusion into new products | Reduces the volume of waste; Moderate energy requirement; Extends lifecycle of the material | Degradation of polymer properties over multiple recycling cycles; Energy requirement for melting and reprocessing | Suitable for mixed or contaminated nylon waste; Is suitable for composite rod guides after cleaning/treatment procedures | [32,114] |

| Tertiary (Chemical) Recycling | Collection; Sorting; Depolymerization (hydrolysis, pyrolysis); Purification of monomers; Repolymerisation; Utilisation in new products | Recovers monomers for polymer production; Removes contaminants for heavily degraded mixed nylon waste | High energy consumption; Expensive; Complex processing | Suitable for heavily contaminated waste; Can cause air emission; Use of incinerators not environmentally friendly; Loss of economic value | [113,123] |

| Quaternary (Energy Recovery) Recycling | Collection; Sorting; Incineration for energy (heat/electricity) | Generates energy from waste; Reduces landfill | Not a recycling methodology; Releases toxic emissions; Loss of value of the material | Causes environmental concerns; Only used when contamination or heterogeneity prevents other recycling methods | [124,125] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamang, C.G.; Manalo, A.; Burey, P.; Ferdous, W.; Shelley, T.; Patel, M.; Chapman, T. Composite Polymeric Sucker Rod Guides: State-of-Practice, Causes of Failure, and Circular Economy Opportunities. Polymers 2025, 17, 2932. https://doi.org/10.3390/polym17212932

Tamang CG, Manalo A, Burey P, Ferdous W, Shelley T, Patel M, Chapman T. Composite Polymeric Sucker Rod Guides: State-of-Practice, Causes of Failure, and Circular Economy Opportunities. Polymers. 2025; 17(21):2932. https://doi.org/10.3390/polym17212932

Chicago/Turabian StyleTamang, Chundu Gyem, Allan Manalo, Paulomi (Polly) Burey, Wahid Ferdous, Tristan Shelley, Mayur Patel, and Tony Chapman. 2025. "Composite Polymeric Sucker Rod Guides: State-of-Practice, Causes of Failure, and Circular Economy Opportunities" Polymers 17, no. 21: 2932. https://doi.org/10.3390/polym17212932

APA StyleTamang, C. G., Manalo, A., Burey, P., Ferdous, W., Shelley, T., Patel, M., & Chapman, T. (2025). Composite Polymeric Sucker Rod Guides: State-of-Practice, Causes of Failure, and Circular Economy Opportunities. Polymers, 17(21), 2932. https://doi.org/10.3390/polym17212932