Mater-Bi-Based Biocomposites Reinforced with Lemongrass: A Comparison Between Leaf- and Culm-Derived Particles

Abstract

1. Introduction

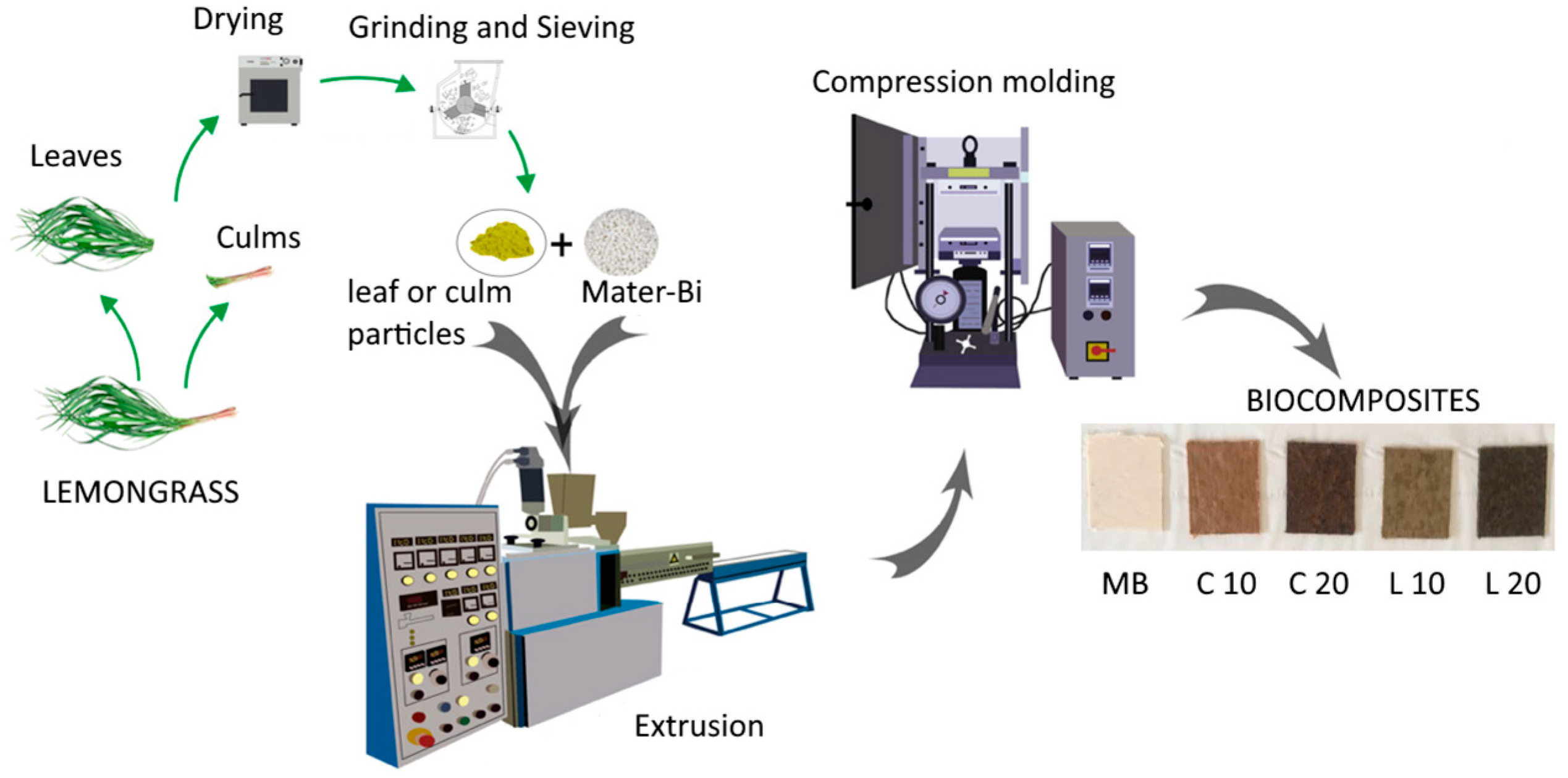

2. Experimental

2.1. Materials and Methods

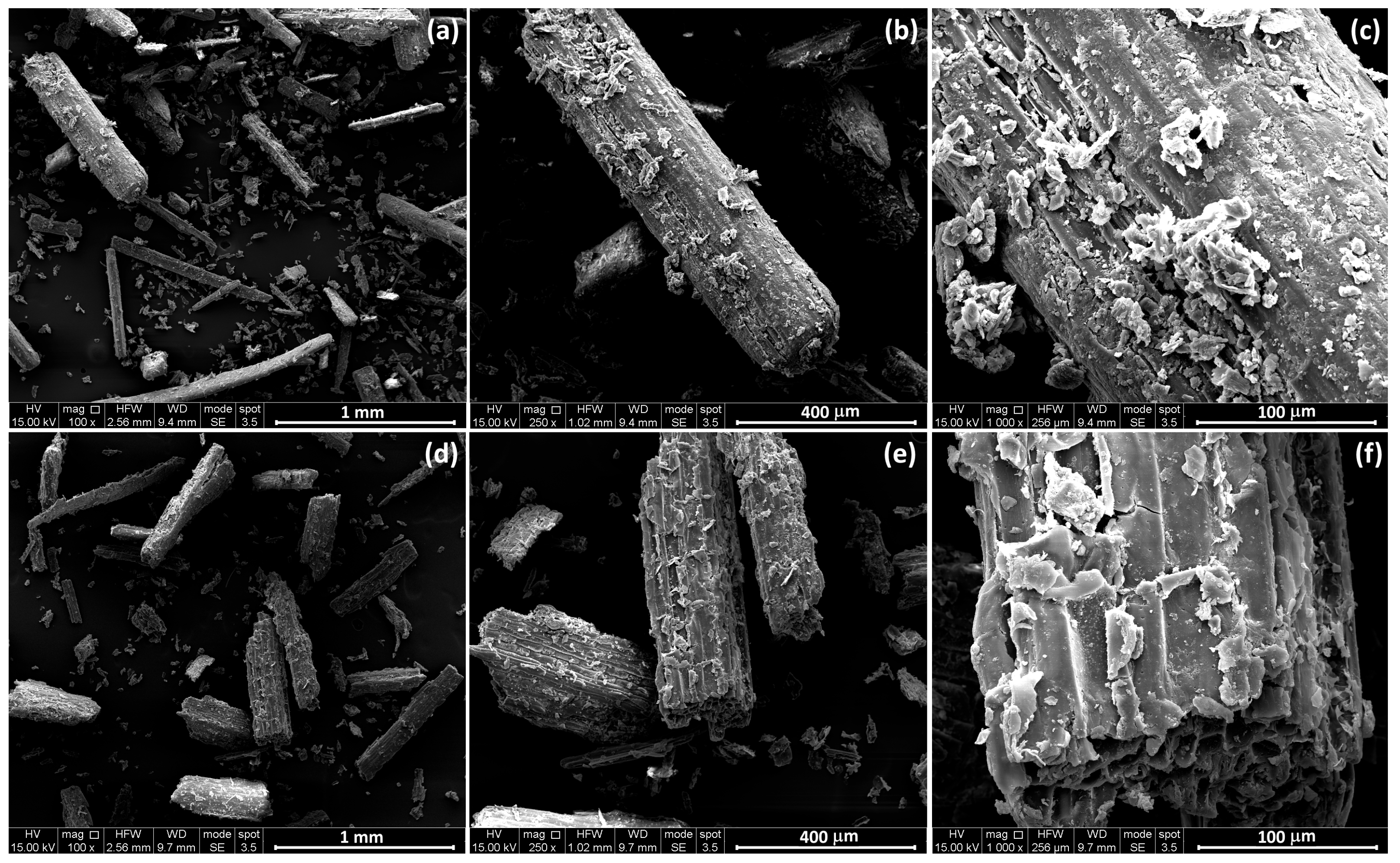

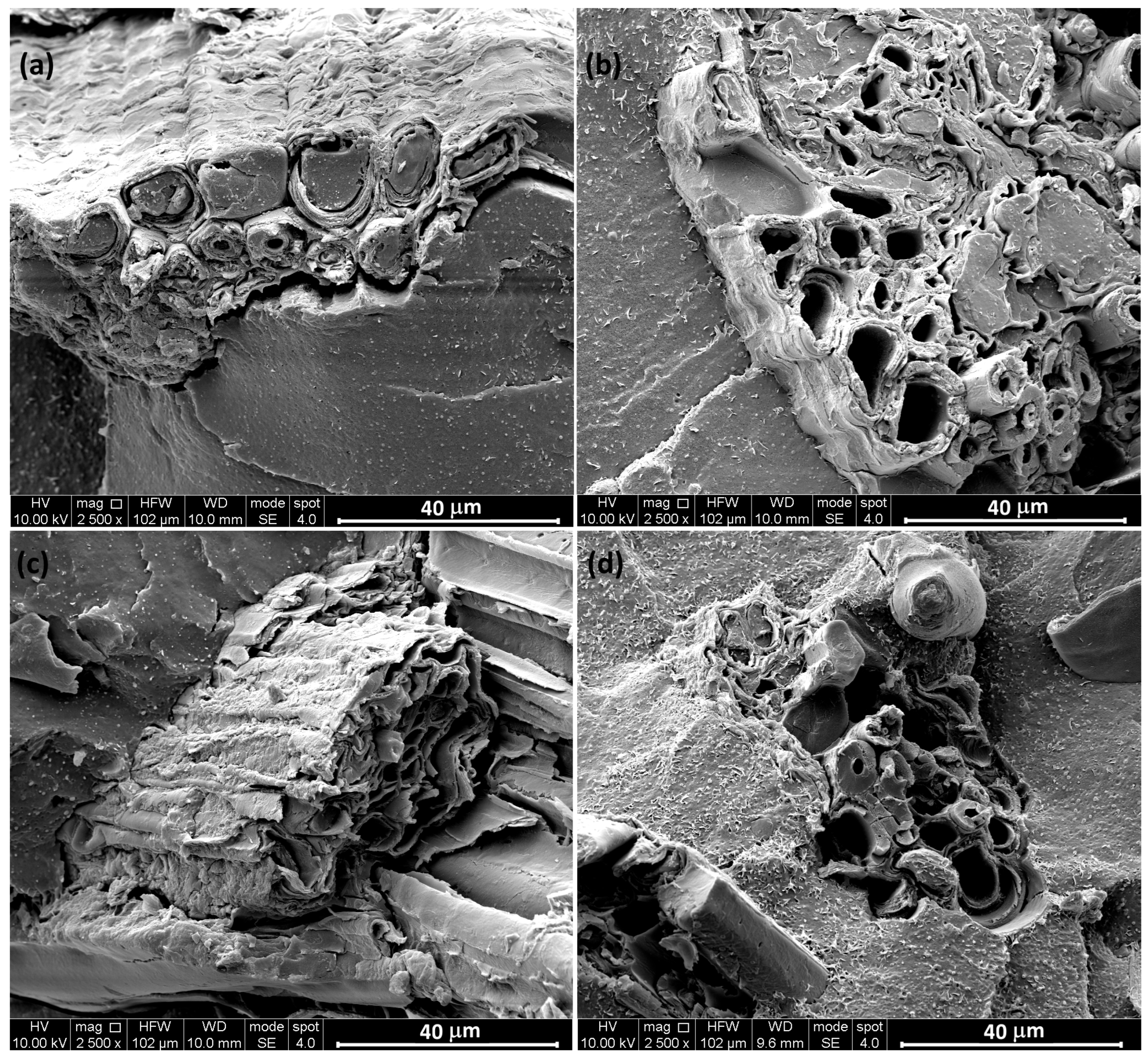

2.2. Morphological Analysis

2.3. Density and Void Content Measurements

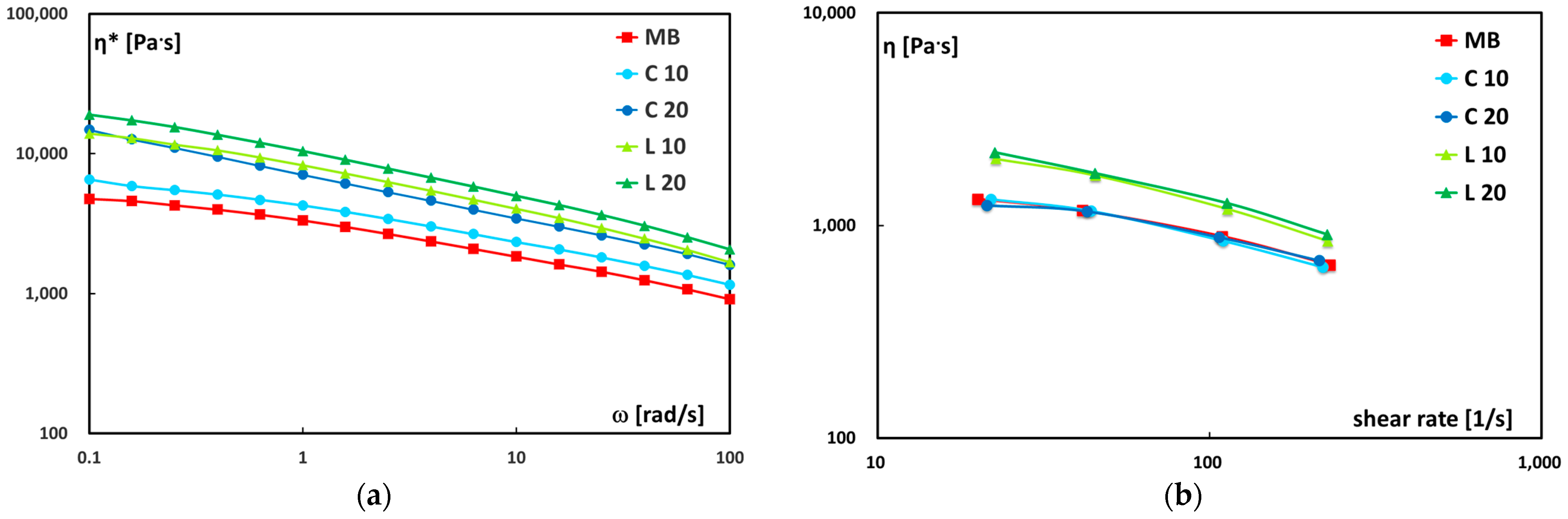

2.4. Rheological Characterization

2.5. Mechanical Characterization

2.6. Calorimetric Analysis

3. Results

3.1. Morphological Features

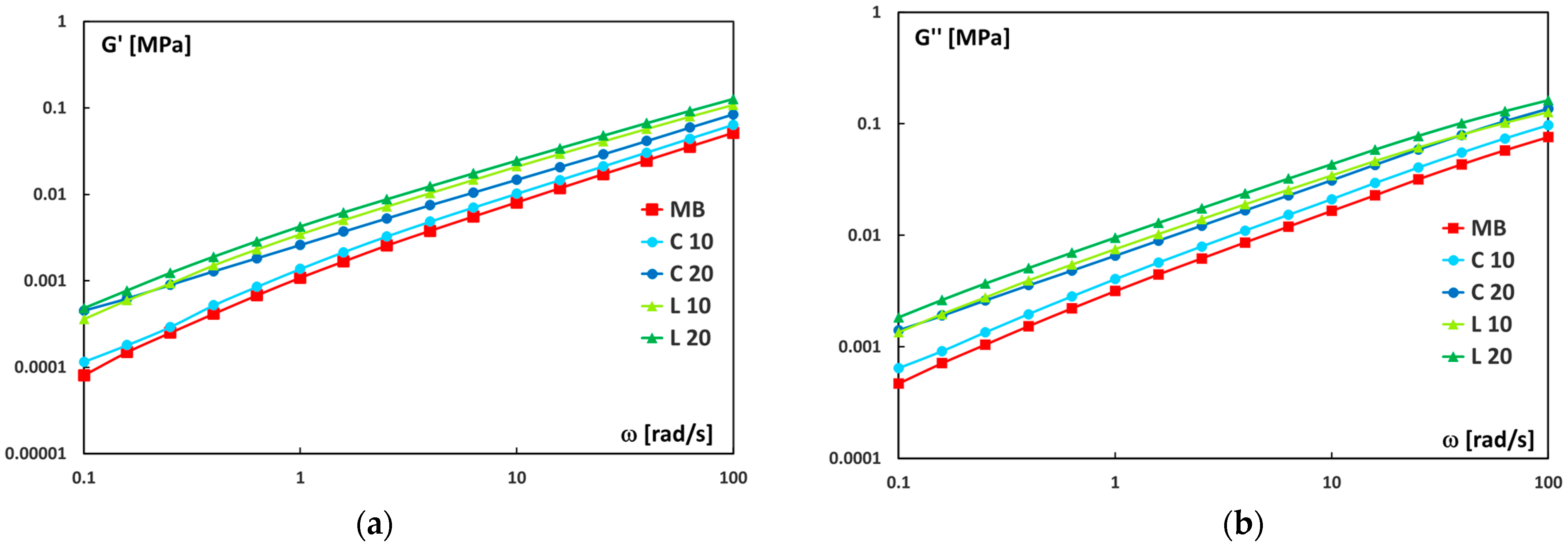

3.2. Rheological Behavior

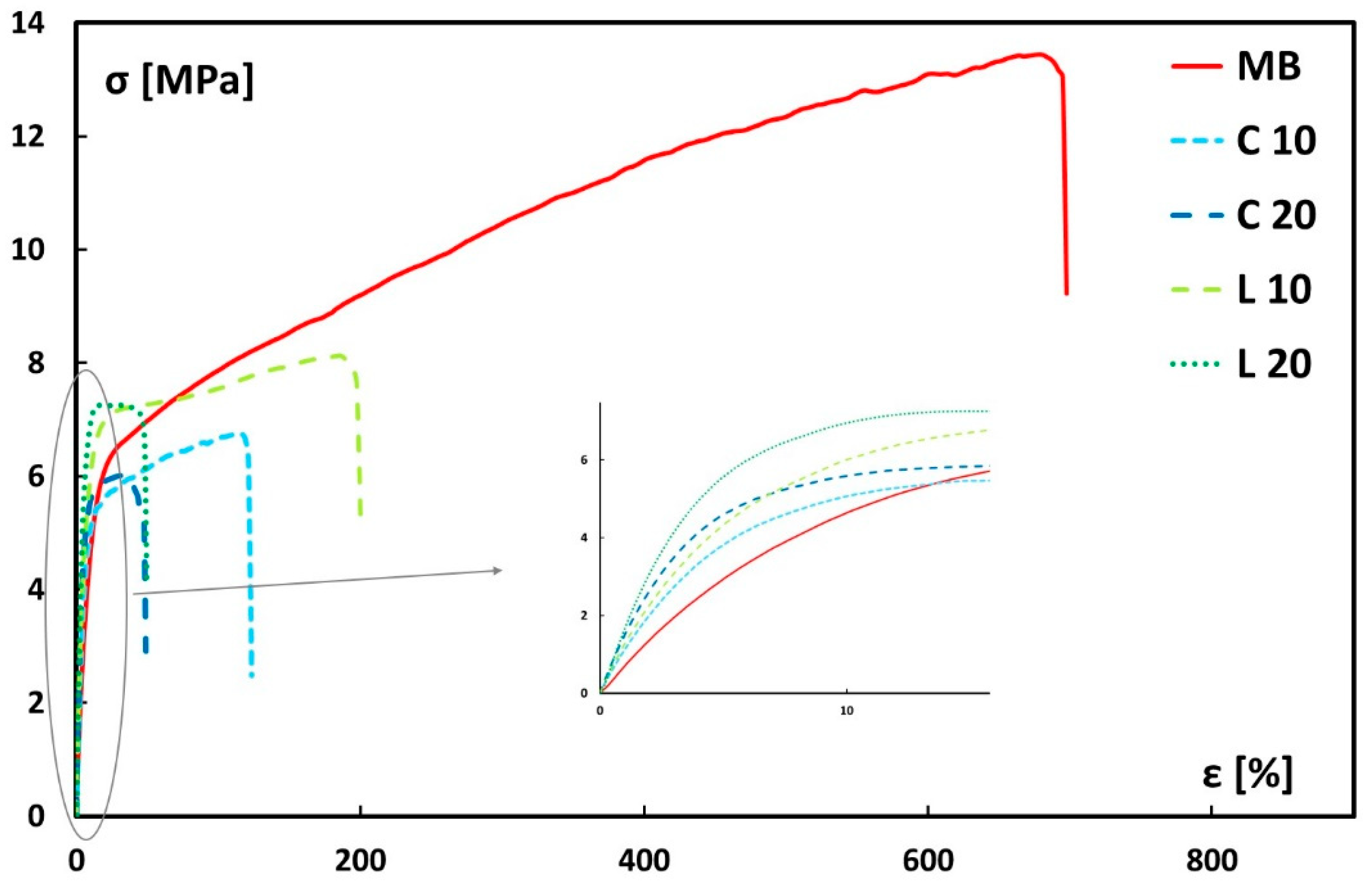

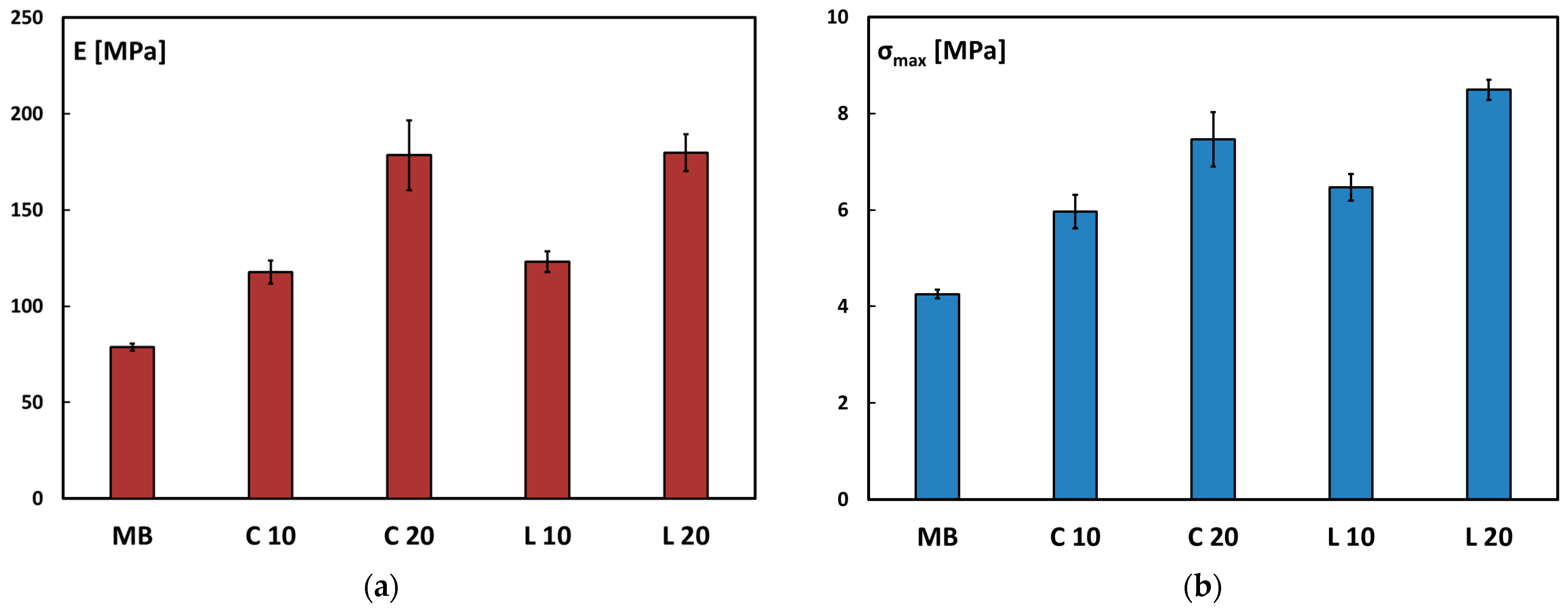

3.3. Quasi-Static Mechanical Properties

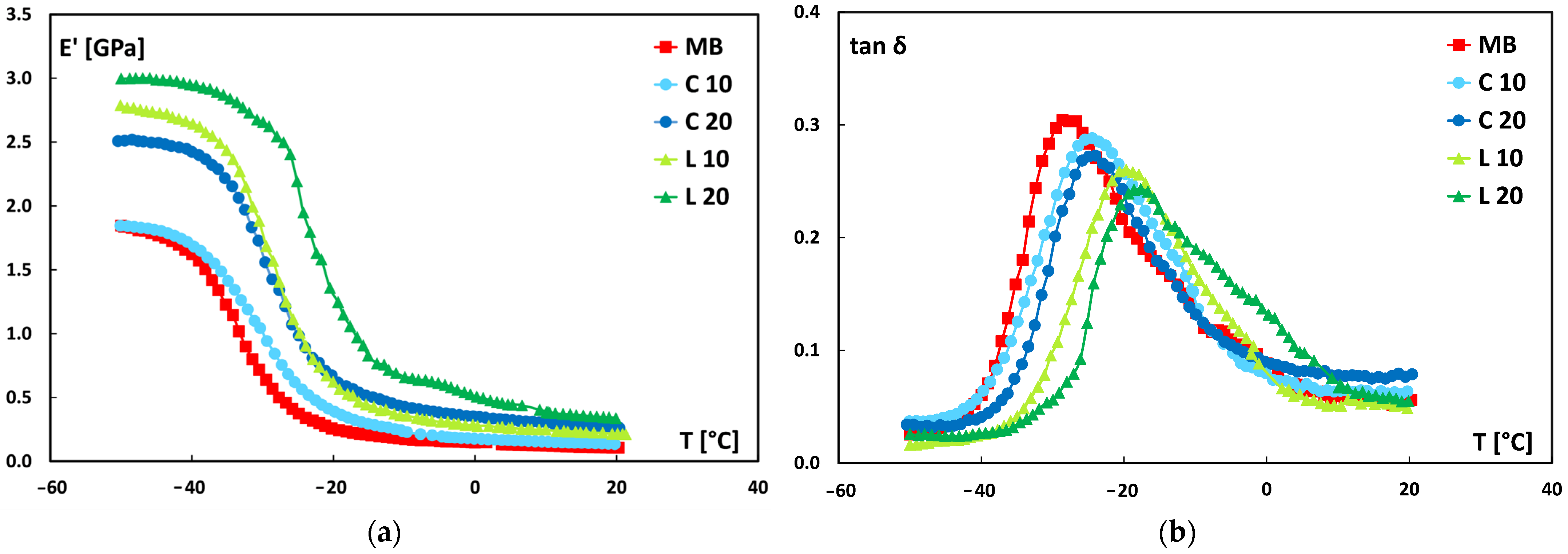

3.4. Dynamic-Mechanical Properties

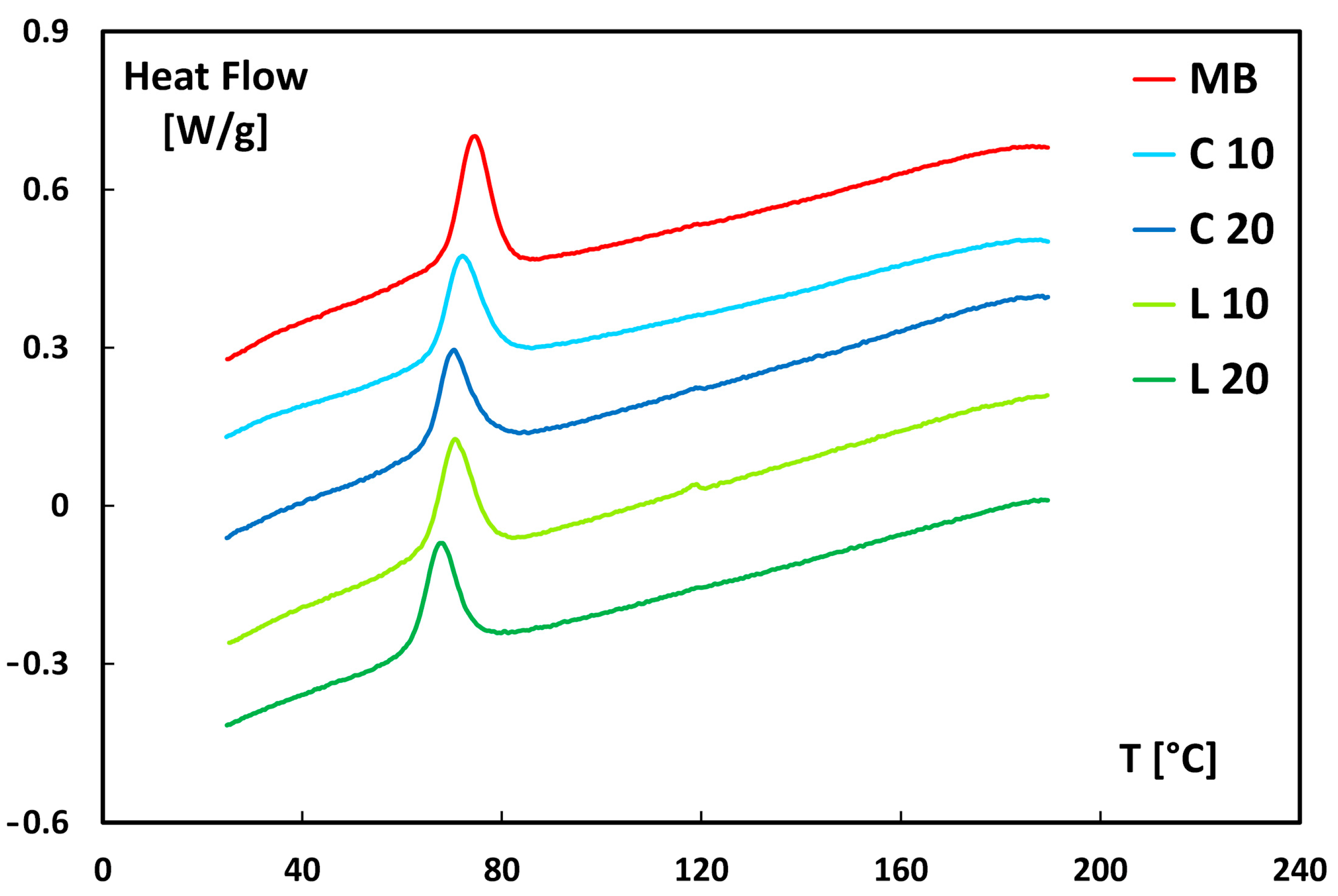

3.5. Thermal Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Vinod, A.; Sanjay, M.R.; Suchart, S.; Jyotishkumar, P. Renewable and sustainable biobased materials: An assessment on biofibers, biofilms, biopolymers and biocomposites. J. Clean. Prod. 2020, 258, 120978. [Google Scholar] [CrossRef]

- Hoffmann, R.; Morais, D.D.S.; Braz, C.J.F.; Haag, K.; Wellen, R.M.R.; Canedo, E.L.; de Carvalho, L.H.; Koschek, K. Impact of the natural filler babassu on the processing and properties of PBAT/PHB films. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105472. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I. Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly(ethylene terephthalate) (Bio-PET): Recent Developments in Bio-Based Polymers Analogous to Petroleum-Derived Ones for Packaging and Engineering Applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef]

- Ritzen, L.; Sprecher, B.; Bakker, C.; Balkenende, R. Bottlenecks in establishing the environmental impact of bio-based plastics: A case study of bio-based polyethylene and bio-based polyethylene terephthalate. J. Clean. Prod. 2025, 496, 145126. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Reixach, R.; Espinach, F.X.; Méndez, J.A. Maleic Anhydride Polylactic Acid Coupling Agent Prepared from Solvent Reaction: Synthesis, Characterization and Composite Performance. Materials 2022, 15, 1161. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Ceraulo, M.; Testa, P.; Morreale, M. Biodegradable polymers for the production of nets for agricultural product packaging. Materials 2021, 14, 323. [Google Scholar] [CrossRef] [PubMed]

- Jin, F.L.; Hu, R.R.; Park, S.J. Improvement of thermal behaviors of biodegradable poly(lactic acid) polymer: A review. Compos. Part B Eng. 2019, 164, 287–296. [Google Scholar] [CrossRef]

- Bulatović, V.O.; Mandić, V.; Kučić Grgić, D.; Ivančić, A. Biodegradable Polymer Blends Based on Thermoplastic Starch. J. Polym. Environ. 2021, 29, 492–508. [Google Scholar] [CrossRef]

- Sarasini, F.; Fiore, V. A systematic literature review on less common natural fibres and their biocomposites. J. Clean. Prod. 2018, 195, 240–267. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Lemita, N.; Deghboudj, S.; Rokbi, M.; Rekbi, F.M.L.; Halimi, R. Characterization and analysis of novel natural cellulosic fiber extracted from Strelitzia reginae plant. J. Compos. Mater. 2022, 56, 99–114. [Google Scholar] [CrossRef]

- Dalmis, R.; Kilic, G.B.; Seki, Y.; Koktas, S.; Keskin, O.Y. Characterization of a novel natural cellulosic fiber extracted from the stem of Chrysanthemum morifolium. Cellulose 2020, 27, 8621–8634. [Google Scholar] [CrossRef]

- Narayanasamy, P.; Balasundar, P.; Senthil, S.; Sanjay, M.R.; Siengchin, S.; Khan, A.; Asiri, A.M. Characterization of a novel natural cellulosic fiber from Calotropis gigantea fruit bunch for ecofriendly polymer composites. Int. J. Biol. Macromol. 2020, 150, 793–801. [Google Scholar] [CrossRef] [PubMed]

- Haque, A.N.M.A.; Remadevi, R.; Naebe, M. Lemongrass (Cymbopogon): A review on its structure, properties, applications and recent developments. Cellulose 2018, 25, 5455–5477. [Google Scholar] [CrossRef]

- Kamaruddin, Z.H.; Jumaidin, R.; Selamat, M.Z.; Ilyas, R.A. Characteristics and Properties of Lemongrass (Cymbopogan citratus): A Comprehensive Review. J. Nat. Fibers 2021, 19, 8101–8118. [Google Scholar] [CrossRef]

- Tran, T.H.; Tran, T.K.N.; Ngo, T.C.Q.; Pham, T.N.; Bach, L.G.; Phan, N.Q.A.; Le, T.H.N. Color and composition of beauty products formulated with lemongrass essential oil: Cosmetics formulation with lemongrass essential oil. Open Chem. 2021, 19, 820–829. [Google Scholar] [CrossRef]

- Kaur, H.; Dutt, D.; Tyagi, C.H. Optimization of soda pulping process of lignocellulosic residues of lemon and sofia grasses produced after steam distillation. BioResources 2011, 6, 103–120. [Google Scholar] [CrossRef]

- Robbins, S.R.J. Selected markets for the essential oils of lemongrass, citronella and eucalyptus. In Essential Oils Marketing; Crown Publishing: New York, NY, USA, 1983; pp. 54–68. [Google Scholar]

- Mukarram, M.; Choudhary, S.; Khan, M.A.; Poltronieri, P.; Khan, M.M.A.; Ali, J.; Kurjak, D.; Shahid, M. Lemongrass essential oil components with antimicrobial and anticancer activities. Antioxidants 2022, 11, 20. [Google Scholar] [CrossRef]

- Lima, L.R.; Andrade, F.K.; Alves, D.R.; de Morais, S.M.; Vieira, R.S. Anti-acetylcholinesterase and toxicity against Artemia salina of chitosan microparticles loaded with essential oils of Cymbopogon flexuosus, Pelargonium x ssp and Copaifera officinalis. Int. J. Biol. Macromol. 2021, 167, 1361–1370. [Google Scholar] [CrossRef]

- Alfa, I.M.; Dahunsi, S.O.; Iorhemen, O.T.; Okafor, C.C.; Ajayi, S.A. Comparative evaluation of biogas production from Poultry droppings, Cow dung and Lemon grass. Bioresour. Technol. 2014, 157, 270–277. [Google Scholar] [CrossRef]

- Nur Firdaus, M.Y.; Osman, H.; Metselaar, H.S.C.; Rozyanty, A.R. A simple method for the production of pure crystalline silica from lemon grass. BioResources 2015, 11, 1270–1279. [Google Scholar] [CrossRef]

- Sharma, N.; Godiyal, R.D.; Bhawana; Thapliyal, B.P.; Anupam, K. Insight into papermaking characteristics of D0EPD1-bleached soda, soda-AQ and kraft pulps of citronella grass (Cymbopogon winterianus Jowitt). Biomass Convers. Biorefinery 2022, 12, 427–440. [Google Scholar] [CrossRef]

- Babarinde, A.; Ogundipe, K.; Sangosanya, K.T.; Akintola, B.D.; Hassan, A.-O.E. Comparative study on the biosorption of Pb(II), Cd(II) and Zn(II) using Lemon grass (Cymbopogon citratus): Kinetics, isotherms and thermodynamics. Chem. Int. 2016, 2, 89–102. [Google Scholar]

- Fiore, V.; Badagliacco, D.; Sanfilippo, C.; Pirrone, R.; Siengchin, S.; Rangappa, S.M.; Botta, L. Lemongrass plant as potential sources of reinforcement for biocomposites: A preliminary experimental comparison between leaf and culm fibers. J. Polym. Environ. 2022, 30, 4726–4737. [Google Scholar] [CrossRef]

- Sundaram, R.S.; Rajamoni, R.; Suyambulingam, I.; Isaac, R. Comprehensive characterization of industrially discarded Cymbopogon flexuosus stem fiber reinforced unsaturated polyester composites: Effect of fiber length and weight fraction. J. Nat. Fibers 2021, 19, 7241–7256. [Google Scholar] [CrossRef]

- Jing, H.; He, H.; Liu, H.; Huang, B.; Zhang, C. Study on properties of polylactic acid/lemongrass fiber biocomposites prepared by fused deposition modeling. Polym. Compos. 2021, 42, 973–986. [Google Scholar] [CrossRef]

- Raja, S.; Rajesh, R.; Indran, S.; Divya, D.; Suganya Priyadharshini, G. Characterization of industrial discarded novel Cymbopogon flexuosus stem fiber: A potential replacement for synthetic fiber. J. Ind. Text. 2021, 51, 1207S–1234S. [Google Scholar] [CrossRef]

- Soma Sundaram Pillai, R.; Rajamoni, R.; Suyambulingam, I.; Rajamony Suthies Goldy, I.; Divakaran, D. Synthesis and characterization of cost-effective industrial discarded natural ceramic particulates from Cymbopogon flexuosus plant shoot for potential polymer/metal matrix reinforcement. Polym. Bull. 2021, 79, 8765–8806. [Google Scholar] [CrossRef]

- Bekele, L.D.; Zhang, W.; Liu, Y.; Duns, G.J.; Yu, C.; Jin, L.; Li, X.; Jia, Q.; Chen, J. Preparation and characterization of lemongrass fiber (Cymbopogon species) for reinforcing application in thermoplastic composites. BioResources 2017, 12, 5664–5681. [Google Scholar] [CrossRef]

- Kurien, R.A.; Koshy, C.P.; Santhosh, A.; Kurup, G.B.; Paul, D.; Reji, G.S. A study on vetiver fiber and lemongrass fiber reinforced composites. Mater. Today Proc. 2022, 68, 2640–2645. [Google Scholar] [CrossRef]

- Mamatha, B.S.; Ramkumar, V.R.; Kiran, M.C.; Uday, D.N. Mechanical, thermal and durability properties of lemongrass –poplar particle board. Constr. Build. Mater. 2025, 489, 142160. [Google Scholar] [CrossRef]

- Raquez, J.M.; Nabar, Y.; Srinivasan, M.; Shin, B.Y.; Narayan, R.; Dubois, P. Maleated thermoplastic starch by reactive extrusion. Carbohydr. Polym. 2008, 74, 159–169. [Google Scholar] [CrossRef]

- Bastioli, C. Properties and applications of mater-Bi starch-based materials. Polym. Degrad. Stab. 1998, 59, 263–272. [Google Scholar] [CrossRef]

- Titone, V.; Rapisarda, M.; Pulvirenti, L.; Napoli, E.; Impallomeni, G.; Botta, L.; Mistretta, M.C.; Rizzarelli, P. Sustainable biocomposites based on Mater-Bi and grape pomace for a circular economy: Performance evaluation and degradation in soil. Polym. Degrad. Stab. 2025, 231, 111091. [Google Scholar] [CrossRef]

- Rapisarda, M.; Titone, V.; Pulvirenti, L.; Napoli, E.; Impallomeni, G.; Botta, L.; Leanza, M.; Rizzarelli, P.; Mistretta, M.C. Insights into the accelerated aging of sustainable biocomposites based on Mater-Bi and grape pomace. Polym. Degrad. Stab. 2025, 241, 111551. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O. Structure, performance, and photooxidative stability of Mater-Bi/brewers’ spent grain composites as a function of filler thermomechanical and chemical modification. Ind. Crops Prod. 2025, 224, 120421. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O.; Aniśko, J.; Sulima, P.; Andrzej Przyborowski, J.; Reza Saeb, M. The impact of thermomechanical and chemical treatment of waste Brewers’ spent grain and soil biodegradation of sustainable Mater-Bi-Based biocomposites. Waste Manag. 2022, 154, 260–271. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O.; Sulima, P.; Przyborowski, J.A.; Kowalkowska-Zedler, D. Mater-Bi/Brewers’ Spent Grain Biocomposites—Novel Approach to Plant-Based Waste Filler Treatment by Highly Efficient Thermomechanical and Chemical Methods. Materials 2022, 15, 7099. [Google Scholar] [CrossRef] [PubMed]

- Elfehri Borchani, K.; Carrot, C.; Jaziri, M. Biocomposites of Alfa fibers dispersed in the Mater-Bi® type bioplastic: Morphology, mechanical and thermal properties. Compos. Part A Appl. Sci. Manuf. 2015, 78, 371–379. [Google Scholar] [CrossRef]

- Scaffaro, R.; Citarrella, M.C.; Morreale, M. Green Composites Based on Mater-Bi® and Solanum lycopersicum Plant Waste for 3D Printing Applications. Polymers 2023, 15, 325. [Google Scholar] [CrossRef] [PubMed]

- Rabe, S.; Sanchez-Olivares, G.; Pérez-Chávez, R.; Schartel, B. Natural keratin and coconut fibres from industrial wastes in flame retarded thermoplastic starch biocomposites. Materials 2019, 12, 344. [Google Scholar] [CrossRef]

- Du, J.; Yang, S.; Zhu, Q.; Wu, Y.; Guo, J.; Jiang, J. Preparation and characterization of thermoplastic starch/bamboo shoot processing by-product microcrystalline cellulose composites. Biomass Convers. Biorefinery 2023, 13, 12105–12114. [Google Scholar] [CrossRef]

- Chandrasekar, C.M.; Krishnamachari, H.; Farris, S.; Romano, D. Development and characterization of starch-based bioactive thermoplastic packaging films derived from banana peels. Carbohydr. Polym. Technol. Appl. 2023, 5, 100328. [Google Scholar] [CrossRef]

- Ali, A.; Ali, S.; Yu, L.; Liu, H.; Khalid, S.; Hussain, A.; Qayum, M.M.N.; Ying, C. Preparation and characterization of starch-based composite films reinforced by apricot and walnut shells. J. Appl. Polym. Sci. 2019, 136, 47978. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A new eco-friendly chemical treatment of natural fibres: Effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos. Part B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Abdan, K.; Ishak, M.R. Effect of Alkali and Silane Treatments on Mechanical and Fibre-matrix Bond Strength of Kenaf and Pineapple Leaf Fibres. J. Bionic Eng. 2016, 13, 426–435. [Google Scholar] [CrossRef]

- Agarwal, B.; Broutman, L.; Chandrashekhara, K. Analysis and Performance of Fiber Composites; John Wiley: Hoboken, NJ, USA, 1990; ISBN 9780471268918. [Google Scholar]

- Ludueña, L.; Vázquez, A.; Alvarez, V. Effect of lignocellulosic filler type and content on the behavior of polycaprolactone based eco-composites for packaging applications. Carbohydr. Polym. 2012, 87, 411–421. [Google Scholar] [CrossRef]

| Material | Real Density [g/cm3] | Theoretical Density [g/cm3] | Voids Content [%] |

|---|---|---|---|

| MB | 1.260 ± 0.008 | N.A. | N.A. |

| L 10 | 1.208 ± 0.007 | 1.246 | 3.11 |

| L 20 | 1.180 ± 0.005 | 1.233 | 4.33 |

| C 10 | 1.161 ± 0.009 | 1.231 | 5.63 |

| C 20 | 1.123 ± 0.008 | 1.203 | 6.67 |

| Material | Tensile Modulus [MPa] | Tensile Strength [MPa] | Strain at Break [%] |

|---|---|---|---|

| MB | 62.6 ± 3.8 | 13.4 ± 0.5 | 670 ± 80 |

| L 10 | 113.3 ± 3.4 | 8.3 ± 0.4 | 200 ± 60 |

| L 20 | 178.9 ± 7.6 | 7.2 ± 0.1 | 50 ± 20 |

| C 10 | 95.7 ± 4.7 | 6.9 ± 0.3 | 150 ± 40 |

| C 20 | 140.0 ± 5.3 | 5.9 ± 0.1 | 49 ± 15 |

| Material | ΔHc [J/g] | Tc (°C) |

|---|---|---|

| MB | −13.3 | 74.5 |

| L 10 | −11.9 | 70.6 |

| L 20 | −10.9 | 67.5 |

| C 10 | −12.0 | 72.1 |

| C 20 | −12.1 | 70.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceraulo, M.; Botta, L.; Sanfilippo, C.; Rangappa, S.M.; Siengchin, S.; Fiore, V. Mater-Bi-Based Biocomposites Reinforced with Lemongrass: A Comparison Between Leaf- and Culm-Derived Particles. Polymers 2025, 17, 2909. https://doi.org/10.3390/polym17212909

Ceraulo M, Botta L, Sanfilippo C, Rangappa SM, Siengchin S, Fiore V. Mater-Bi-Based Biocomposites Reinforced with Lemongrass: A Comparison Between Leaf- and Culm-Derived Particles. Polymers. 2025; 17(21):2909. https://doi.org/10.3390/polym17212909

Chicago/Turabian StyleCeraulo, Manuela, Luigi Botta, Carmelo Sanfilippo, Sanjay Mavinkere Rangappa, Suchart Siengchin, and Vincenzo Fiore. 2025. "Mater-Bi-Based Biocomposites Reinforced with Lemongrass: A Comparison Between Leaf- and Culm-Derived Particles" Polymers 17, no. 21: 2909. https://doi.org/10.3390/polym17212909

APA StyleCeraulo, M., Botta, L., Sanfilippo, C., Rangappa, S. M., Siengchin, S., & Fiore, V. (2025). Mater-Bi-Based Biocomposites Reinforced with Lemongrass: A Comparison Between Leaf- and Culm-Derived Particles. Polymers, 17(21), 2909. https://doi.org/10.3390/polym17212909