Sustainable Concrete with Waste Tire Rubber and Recycled Steel Fibers: Experimental Insights and Hybrid PINN–CatBoost Prediction

Abstract

1. Introduction

2. Materials and Methods

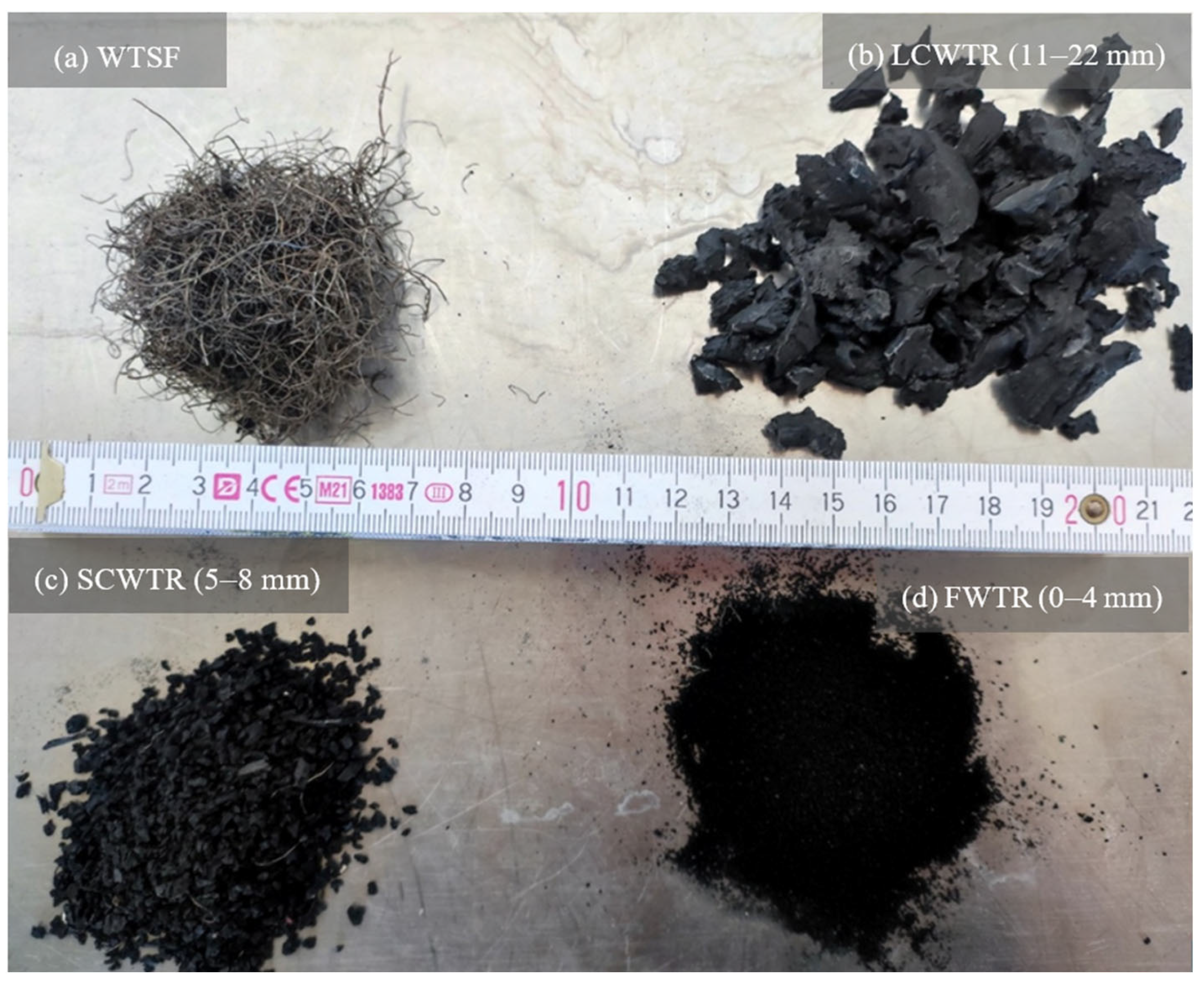

2.1. Details of Materials

2.2. Details of Production

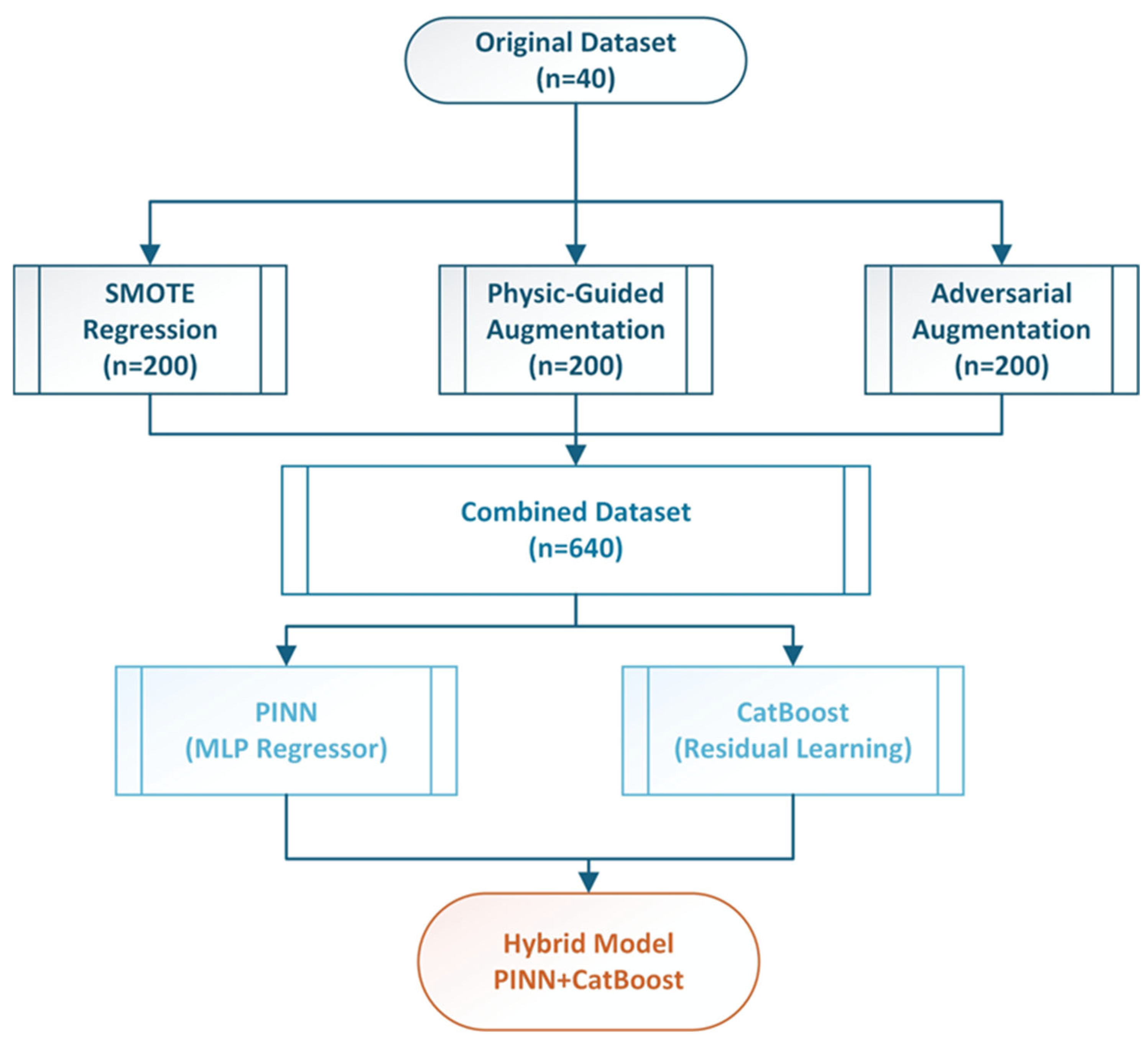

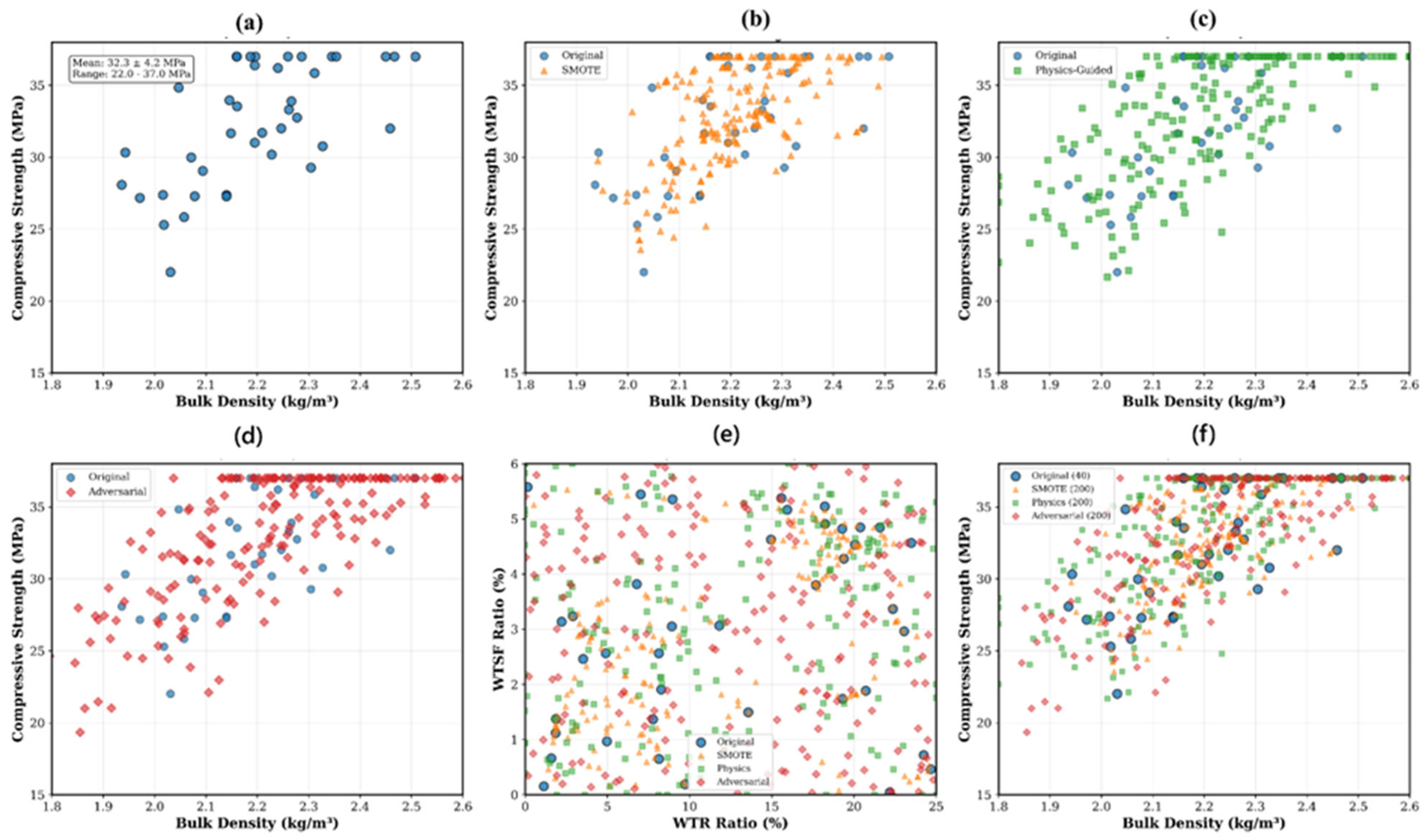

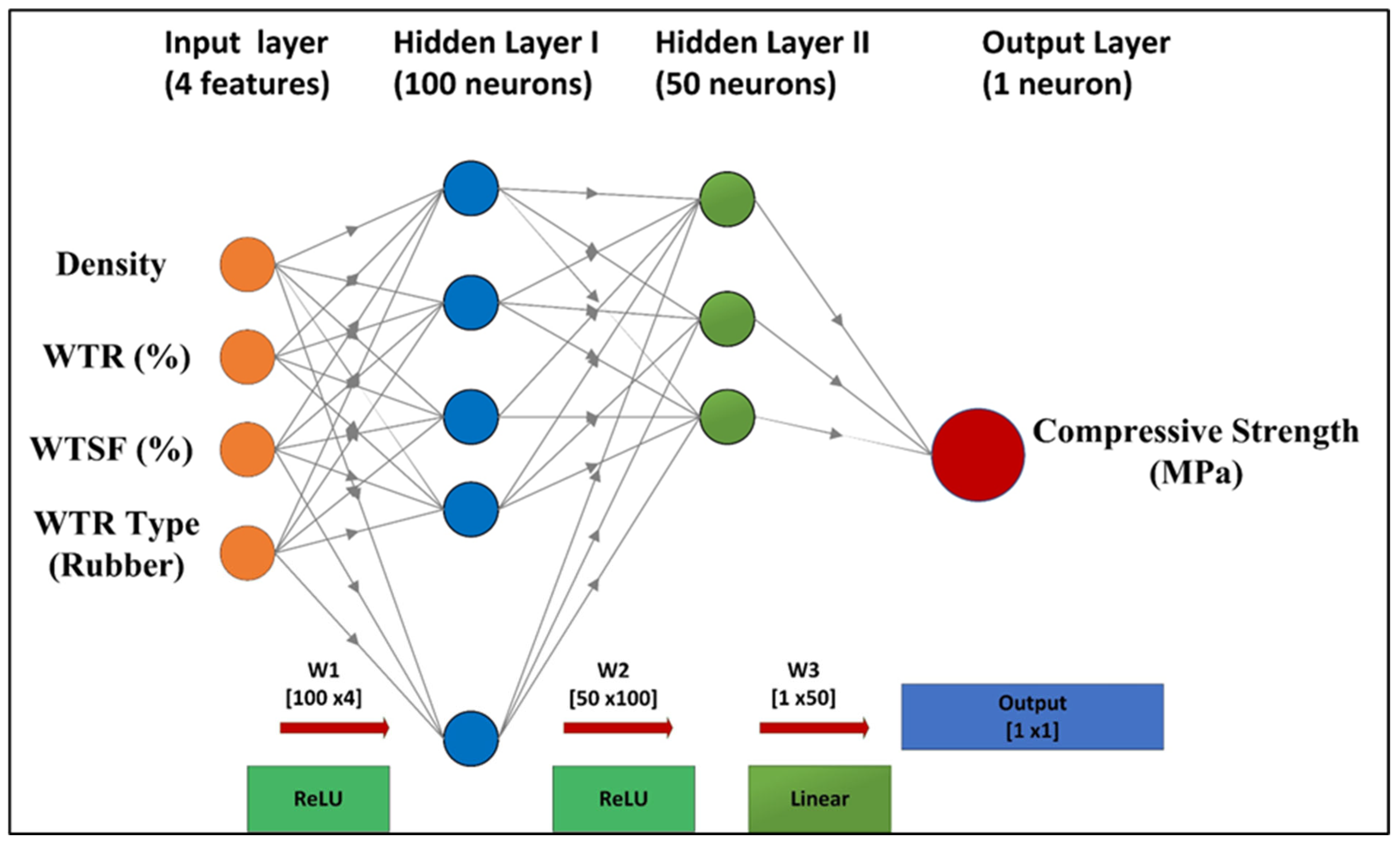

3. Hybrid PINN-CatBoost Prediction

4. Results and Discussion

4.1. Micro-Structure

4.2. Analysis Results

5. Conclusions

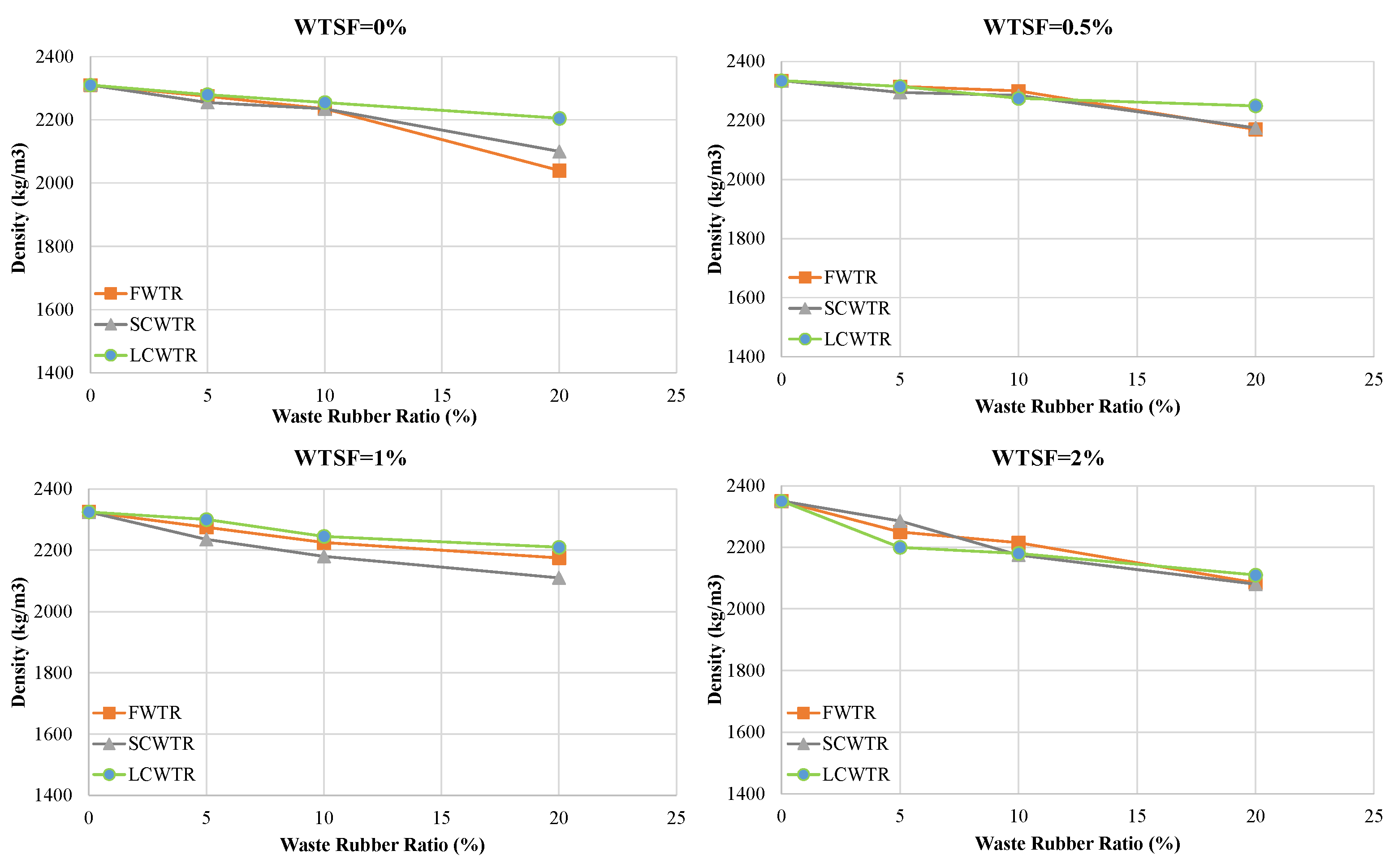

- The addition of waste rubber has systematically reduced the density of the concrete. At a replacement rate of 20% WTR, the density loss reached approximately 13% compared to the control concrete. The steel fiber admixture, especially at ratios of 0.5–1.0%, partially compensated for density losses due to its high specific gravity.

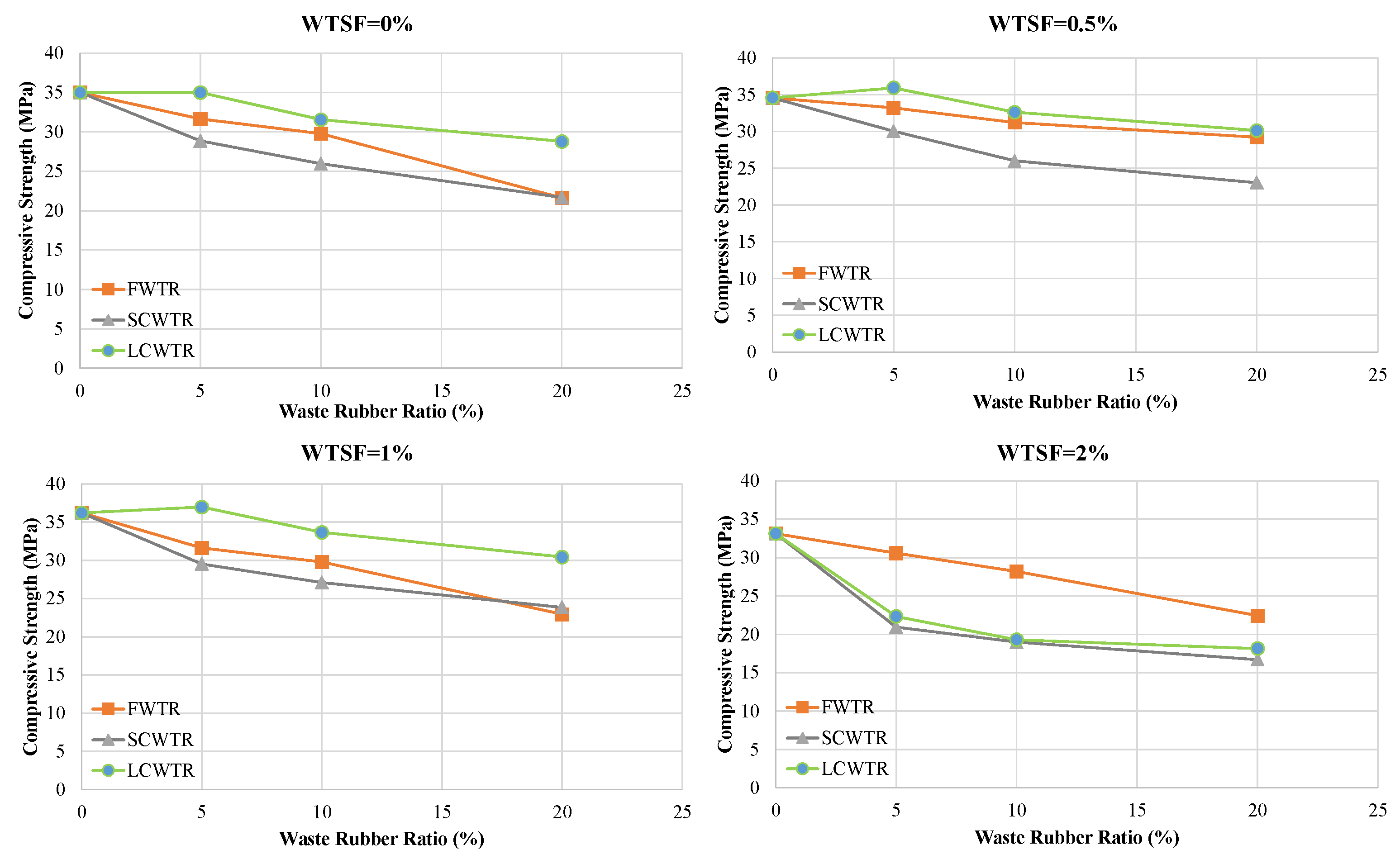

- As the WTR replacement ratio increases, the pressure resistance decreases significantly. Among the WTR types, the most negative effect was observed with FWTR while the least negative effect was obtained with LCWTR.

- Low-to-medium fiber ratios (0.5–1.0%) slightly increased strength. In contrast, a high fiber content (2.0%) significantly reduced strength. These results show that moderate fiber content improves performance through crack bridging, while excessive fiber use limits mechanical properties by compromising homogeneity.

- The highest compressive strength was obtained in the 5LCWTR–1WTSF mixture, while the lowest strength was measured in the 20FWTR–2WTSF mixture.

- Pearson correlation analysis has shown a strong positive relationship between density and strength (r ≈ 0.77). This finding confirms that density losses are parallel to decreases in mechanical performance.

- FWTR formed a weak matrix interface due to its high surface area, leading to mechanical losses. In contrast, LCWTR provided enhanced mechanical interlocking, resulting in relatively better results. Steel fiber reinforcement, when used at the optimum level (0.5–1.0%), improved both density and strength.

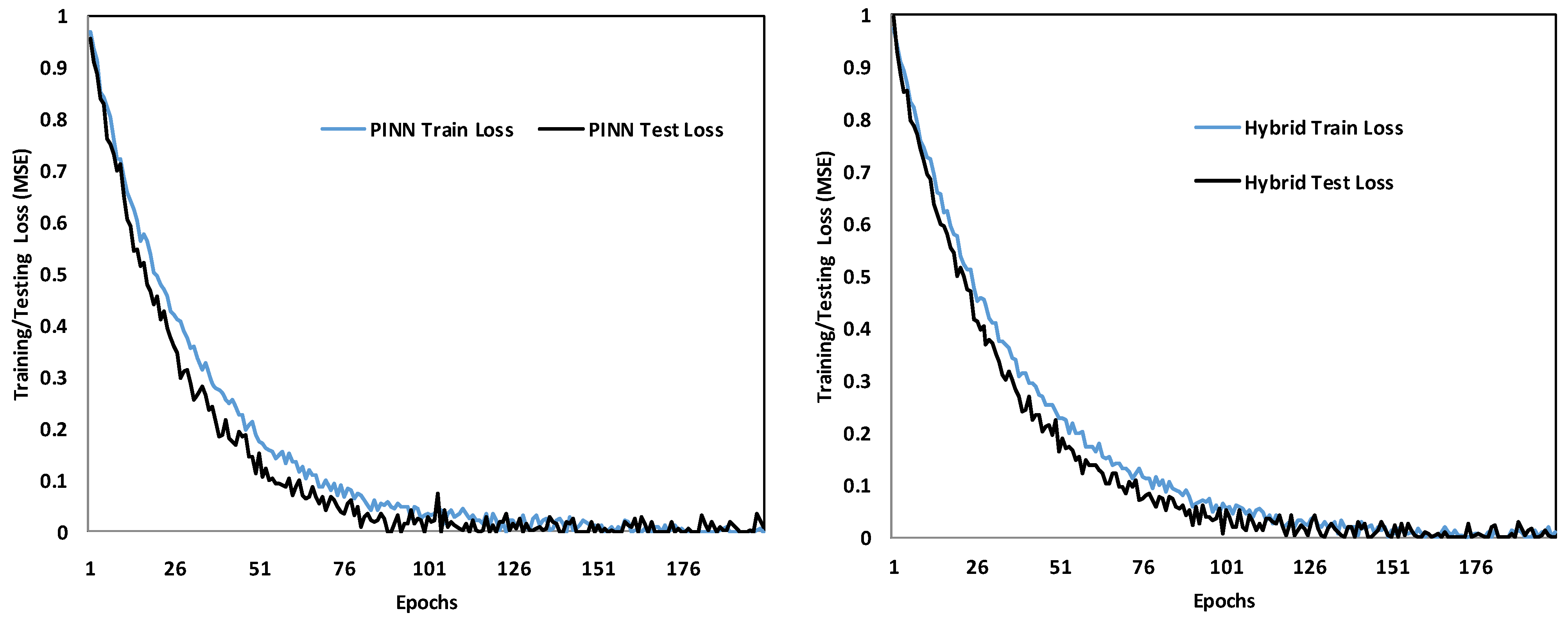

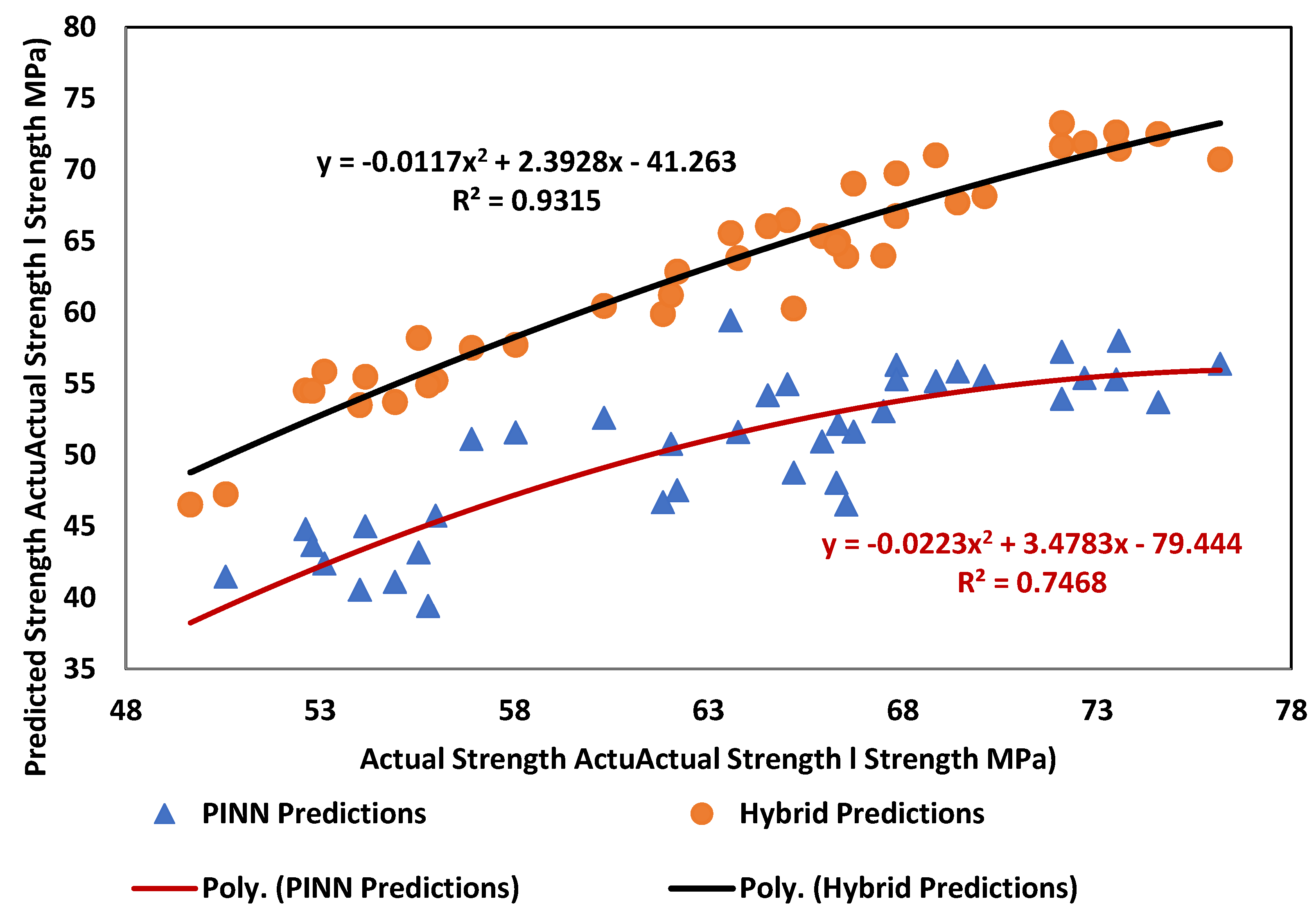

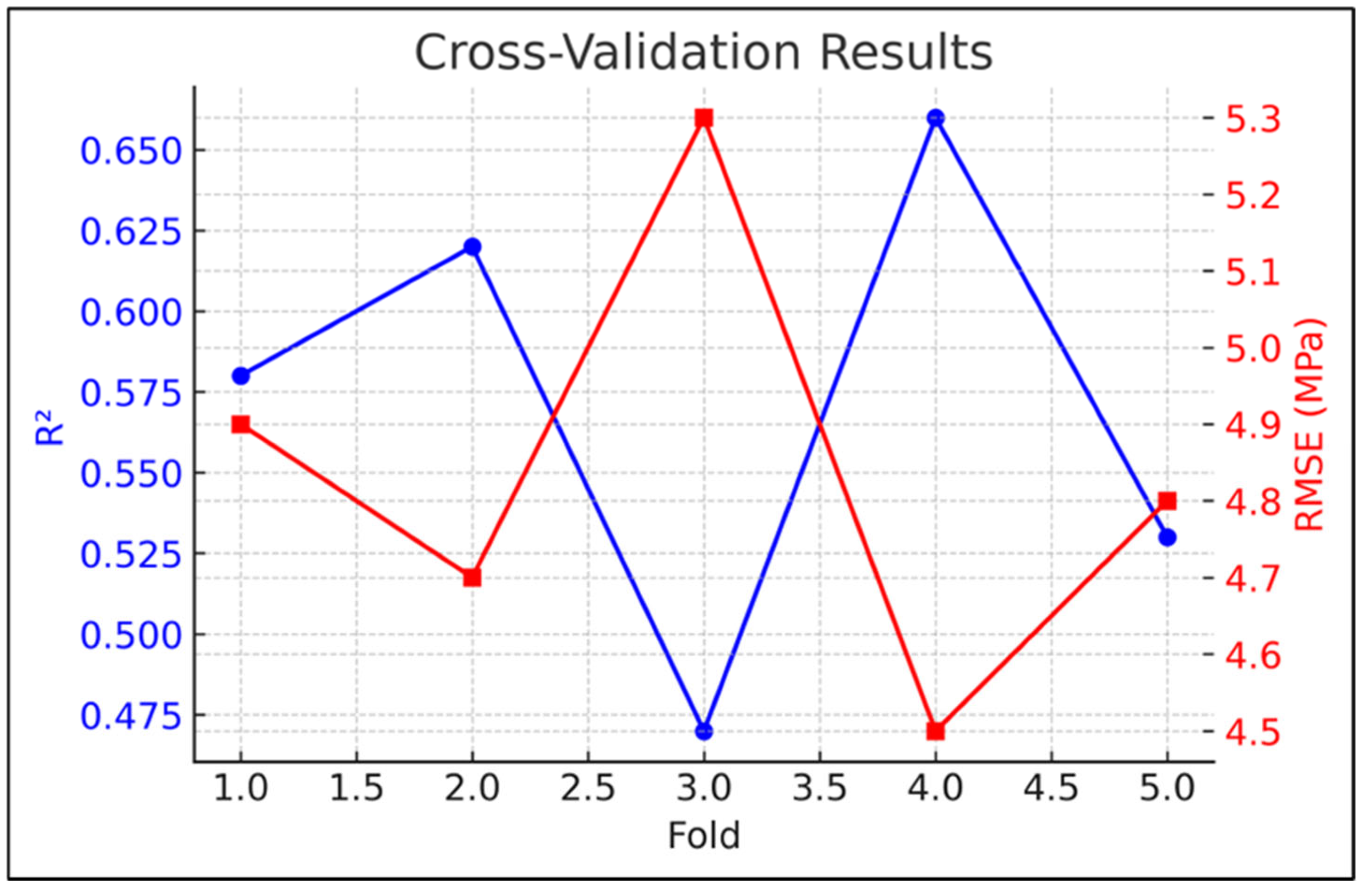

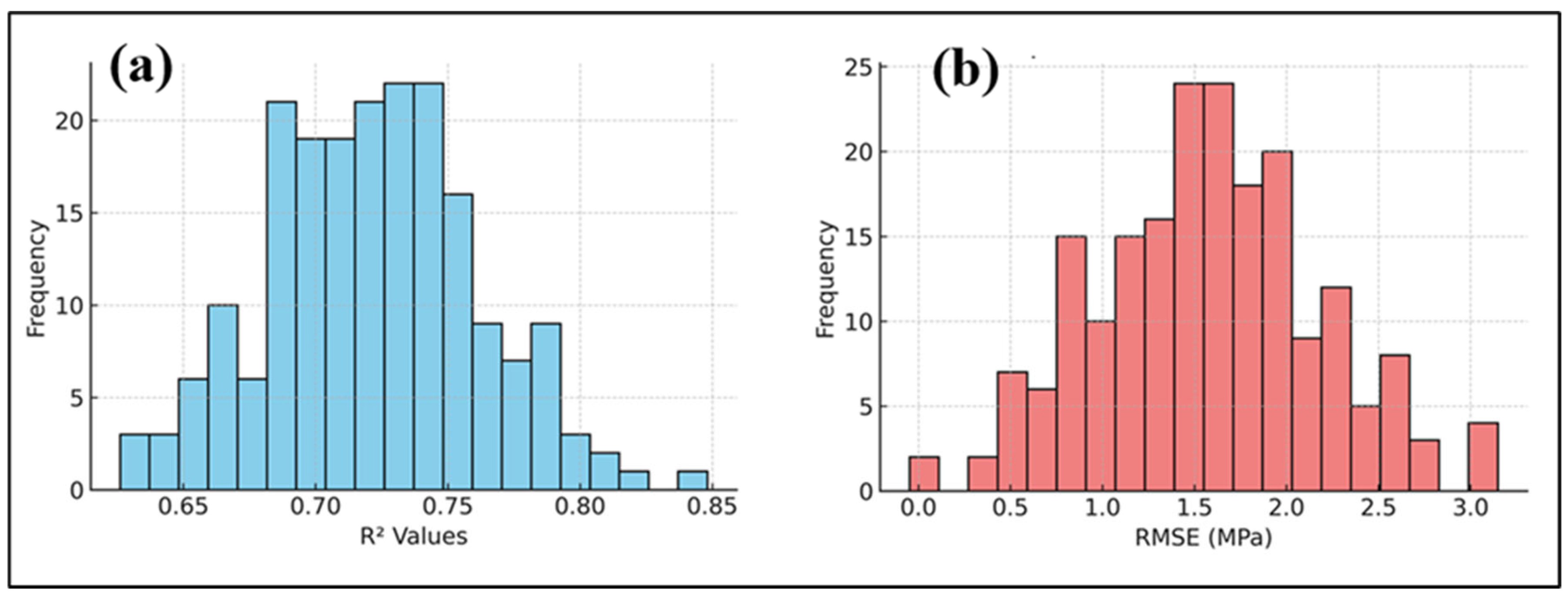

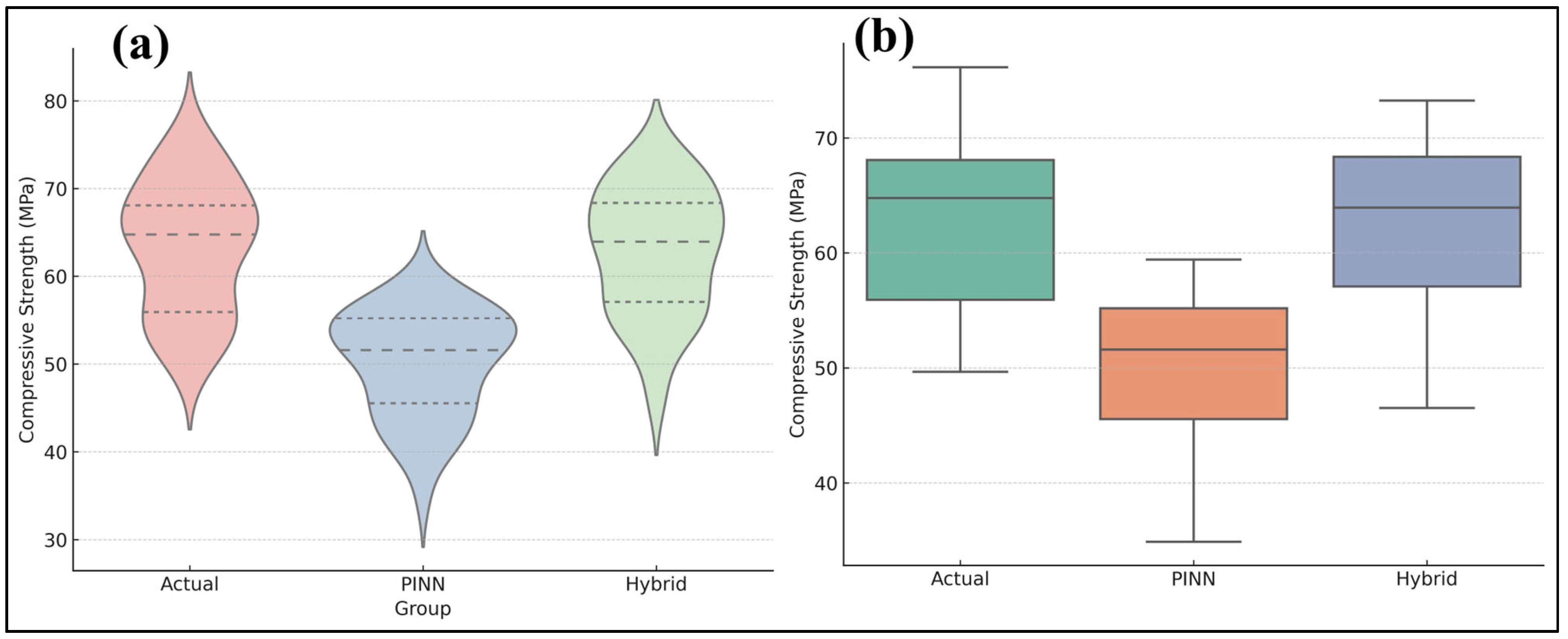

- The standalone PINN model obtained satisfactory accuracy (R2 ≈ 0.75) yet demonstrated unstable convergence and challenges in modeling nonlinear effects at elevated WTR ratios and excessive fiber contents. However the Hybrid PINN–CatBoost model significantly outperformed the independent PINN, attaining superior predictive accuracy (R2 ≈ 0.93, RMSE ≈ 1.57 MPa) and exhibiting enhanced stability in convergence during stratified cross-validation and bootstrap resampling.

- Hybrid predictions effectively identified both the advantageous limits of fiber reinforcement and the adverse limits of excessive rubber substitution, closely correlating with experimental findings. The analysis using explainable AI techniques, specifically SHAP, indicated that density and WTR content were the primary determinants of compressive strength, whereas steel fiber dosage had a beneficial effect until saturation was reached.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Azevedo, F.; Pacheco-Torgal, F.; Jesus, C.; Barroso de Aguiar, J.L.; Camões, A.F. Properties and durability of HPC with tyre rubber wastes. Constr. Build. Mater. 2012, 34, 186–191. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Ding, Y.; Jalali, S. Properties and durability of concrete containing polymeric wastes (tyre rubber and polyethylene terephthalate bottles): An overview. Constr. Build. Mater. 2012, 30, 714–724. [Google Scholar] [CrossRef]

- Alyousef, R.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P.; Alabduljabbar, H. Potential use of recycled plastic and rubber aggregate in cementitious materials for sustainable construction: A review. J. Clean. Prod. 2021, 329, 129736. [Google Scholar] [CrossRef]

- Karunarathna, S.; Linforth, S.; Kashani, A.; Liu, X.; Ngo, T. Effect of recycled rubber aggregate size on fracture and other mechanical properties of structural concrete. J. Clean. Prod. 2021, 314, 128230. [Google Scholar] [CrossRef]

- Mei, J.; Xu, G.; Ahmad, W.; Khan, K.; Amin, M.N.; Aslam, F.; Alaskar, A. Promoting sustainable materials using recycled rubber in concrete: A review. J. Clean. Prod. 2022, 373, 133927. [Google Scholar] [CrossRef]

- Castillo, R.; Alva, A.; París-Viviana, O.; Bosch, M. A Systematic Bibliometric Review Analysis of Research on the Use of Waste Rubber Tyres in Building and Construction Materials and Their Applications. Polymers 2025, 17, 2480. [Google Scholar] [CrossRef]

- Roychand, R.; Gravina, R.J.; Zhuge, Y.; Ma, X.; Youssf, O.; Mills, J.E. A comprehensive review on the mechanical properties of waste tire rubber concrete. Constr. Build. Mater. 2020, 237, 117651. [Google Scholar] [CrossRef]

- Rashad, A.M. A comprehensive overview about recycling rubber as fine aggregate replacement in traditional cementitious materials. Int. J. Sustain. Built Environ. 2016, 5, 46–82. [Google Scholar] [CrossRef]

- Strukar, K.; Kalman Šipoš, T.; Miličević, I.; Bušić, R. Potential use of rubber as aggregate in structural reinforced concrete element—A review. Eng. Struct. 2019, 188, 452–468. [Google Scholar] [CrossRef]

- Ecemis Ali, S.; Madenci, E.; Karalar, M.; Fayed, S.; Fayed, S.; Ozkilic Yasin, O. Shear performance of reinforced concrete beams with rubber as form of fiber from waste tire. Steel Compos. Struct. 2024, 51, 337–349. [Google Scholar]

- Gesoglu, M.; Güneyisi, E.; Hansu, O.; İpek, S.; Asaad, D.S. Influence of waste rubber utilization on the fracture and steel–concrete bond strength properties of concrete. Constr. Build. Mater. 2015, 101, 1113–1121. [Google Scholar] [CrossRef]

- Reda Taha, M.M.; El-Dieb, A.S.; Abd El-Wahab, M.A.; Abdel-Hameed, M.E. Mechanical, fracture, and microstructural investigations of rubber concrete. J. Mater. Civ. Eng. 2008, 20, 640–649. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Xiao, J.; Youssf, O. Dynamic performance of rubberised concrete and its structural applications—An overview. Eng. Struct. 2021, 234, 111990. [Google Scholar] [CrossRef]

- Gerges, N.N.; Issa, C.A.; Fawaz, S.A. Rubber concrete: Mechanical and dynamical properties. Case Stud. Constr. Mater. 2018, 9, e00184. [Google Scholar] [CrossRef]

- Karimi, H.R.; Aliha, M.R.M.; Khedri, E.; Mousavi, A.; Salehi, S.M.; Haghighatpour, P.J.; Ebneabbasi, P. Strength and cracking resistance of concrete containing different percentages and sizes of recycled tire rubber granules. J. Build. Eng. 2023, 67, 106033. [Google Scholar] [CrossRef]

- Xue, J.; Shinozuka, M. Rubberized concrete: A green structural material with enhanced energy-dissipation capability. Constr. Build. Mater. 2013, 42, 196–204. [Google Scholar] [CrossRef]

- Skripkiūnas, G.; Grinys, A.; Miškinis, K. Damping properties of concrete with rubber waste additives. Mater. Sci. 2009, 15, 266–272. [Google Scholar]

- Kaewunruen, S.; Li, D.; Chen, Y.; Xiang, Z. Enhancement of Dynamic Damping in Eco-Friendly Railway Concrete Sleepers Using Waste-Tyre Crumb Rubber. Materials 2018, 11, 1169. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Wang, R.; Lei, Y. Performance enhancement of rubberised concrete via surface modification of rubber: A review. Constr. Build. Mater. 2019, 227, 116691. [Google Scholar] [CrossRef]

- Guo, S.; Dai, Q.; Si, R.; Sun, X.; Lu, C. Evaluation of properties and performance of rubber-modified concrete for recycling of waste scrap tire. J. Clean. Prod. 2017, 148, 681–689. [Google Scholar] [CrossRef]

- Youssf, O.; Mills, J.E.; Hassanli, R. Assessment of the mechanical performance of crumb rubber concrete. Constr. Build. Mater. 2016, 125, 175–183. [Google Scholar] [CrossRef]

- Shaaban, I.G.; Rizzuto, J.P.; El-Nemr, A.; Bohan, L.; Ahmed, H.; Tindyebwa, H. Mechanical Properties and Air Permeability of Concrete Containing Waste Tires Extracts. J. Mater. Civ. Eng. 2021, 33, 04020472. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef] [PubMed]

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Fu, C.; Ye, H.; Wang, K.; Zhu, K.; He, C. Evolution of mechanical properties of steel fiber-reinforced rubberized concrete (FR-RC). Compos. Part B Eng. 2019, 160, 158–166. [Google Scholar] [CrossRef]

- Aksoylu, C.; Özkılıç, Y.O.; Hadzima-Nyarko, M.; Işık, E.; Arslan, M.H. Investigation on Improvement in Shear Performance of Reinforced-Concrete Beams Produced with Recycled Steel Wires from Waste Tires. Sustainability 2022, 14, 13360. [Google Scholar] [CrossRef]

- Yan, J.; Gao, Y.; Tang, M.; Ding, N.; Xu, Q.; Peng, M.; Zhao, H. Experimental Study on the Mechanical Properties of Recycled Spiral Steel Fiber-Reinforced Rubber Concrete. Buildings 2024, 14, 897. [Google Scholar] [CrossRef]

- Lai, D.; Demartino, C.; Xiao, Y. High-strain rate compressive behavior of Fiber-Reinforced Rubberized Concrete. Constr. Build. Mater. 2022, 319, 125739. [Google Scholar] [CrossRef]

- Amin, M.N.; Khan, K.; Nazar, S.; Deifalla, A.F. Application of waste recycle tire steel fibers as a construction material in concrete. Rev. Adv. Mater. Sci. 2023, 62, 20220319. [Google Scholar] [CrossRef]

- Alsaif, A.; Koutas, L.; Bernal, S.A.; Guadagnini, M.; Pilakoutas, K. Mechanical performance of steel fibre reinforced rubberised concrete for flexible concrete pavements. Constr. Build. Mater. 2018, 172, 533–543. [Google Scholar] [CrossRef]

- Alsaif, A.; Alharbi, Y.R. Strength, durability and shrinkage behaviours of steel fiber reinforced rubberized concrete. Constr. Build. Mater. 2022, 345, 128295. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Aiello, M.A. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–57. [Google Scholar] [CrossRef]

- Sengul, O. Mechanical behavior of concretes containing waste steel fibers recovered from scrap tires. Constr. Build. Mater. 2016, 122, 649–658. [Google Scholar] [CrossRef]

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Fiber-reinforced concrete with low content of recycled steel fiber: Shear behaviour. Constr. Build. Mater. 2018, 161, 141–155. [Google Scholar] [CrossRef]

- Chen, M.; Si, H.; Fan, X.; Xuan, Y.; Zhang, M. Dynamic compressive behaviour of recycled tyre steel fibre reinforced concrete. Constr. Build. Mater. 2022, 316, 125896. [Google Scholar] [CrossRef]

- Zia, A.; Zhang, P.; Holly, I. Effectiveness of hybrid discarded tire/Industrial steel fibers for improving the sustainability of concrete structures. Constr. Build. Mater. 2023, 378, 131226. [Google Scholar] [CrossRef]

- Peng, M.; Gao, Y.; Wei, J.; Han, Y.; Chen, X.; Kou, X. Experimental study on mechanical properties and toughness of recycled steel fiber rubber concrete. Case Stud. Constr. Mater. 2024, 21, e03858. [Google Scholar] [CrossRef]

- Dong, S.; Zhao, Q.; Zhu, H. Mechanical properties and constitutive model of steel fiber-reinforced rubberized concrete. Constr. Build. Mater. 2022, 327, 126720. [Google Scholar] [CrossRef]

- Eisa, A.S.; Elshazli, M.T.; Nawar, M.T. Experimental investigation on the effect of using crumb rubber and steel fibers on the structural behavior of reinforced concrete beams. Constr. Build. Mater. 2020, 252, 119078. [Google Scholar] [CrossRef]

- Ul Islam, M.M.; Li, J.; Roychand, R.; Saberian, M.; Chen, F. A comprehensive review on the application of renewable waste tire rubbers and fibers in sustainable concrete. J. Clean. Prod. 2022, 374, 133998. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Kamchoom, V.; Hanandeh, S.; Anandha Kumar, S.; Zabala Vizuete, R.F.; Santillán Murillo, R.O.; Polo, S.M.Z.; Castillo, R.M.T.; Ebid, A.M.; Awoyera, P.; et al. Physics-informed modeling of splitting tensile strength of recycled aggregate concrete using advanced machine learning. Sci. Rep. 2025, 15, 7135. [Google Scholar] [CrossRef] [PubMed]

- Ramezan Khani, M. Data-Efficient Machine Learning for Predicting Compressive Strength of Fibre-Reinforced Concrete with Waste Rubber and Recycled Aggregate Using Continual and Transfer Learning. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2024. [Google Scholar]

- Dadashi, F.; Naderpour, H.; Mirrashid, M. Mechanical Property Prediction in Silica Fume and Crumb Rubber–Modified Concrete: Soft Computing and Experimental Approach. Pract. Period. Struct. Des. Constr. 2024, 29, 04024049. [Google Scholar] [CrossRef]

- Tufail, R.F.; Farooq, D.; Javed, M.F.; Mehmood, T.; Maqsoom, A.; Ashraf, H.; Deifalla, A.F.; Ahmad, J. Prediction of the rubberized concrete behavior: A comparison of gene expression programming and response surface method. Sci. Eng. Compos. Mater. 2023, 30, 20220222. [Google Scholar] [CrossRef]

- Wakjira, T.G.; Abushanab, A.; Alam, M.S. Hybrid machine learning model and predictive equations for compressive stress-strain constitutive modelling of confined ultra-high-performance concrete (UHPC) with normal-strength steel and high-strength steel spirals. Eng. Struct. 2024, 304, 117633. [Google Scholar] [CrossRef]

- Kazemi, F.; Shafighfard, T.; Yoo, D.-Y. Data-Driven Modeling of Mechanical Properties of Fiber-Reinforced Concrete: A Critical Review. Arch. Comput. Methods Eng. 2024, 31, 2049–2078. [Google Scholar] [CrossRef]

- Haddad, A.Z.H.; Al-Kamal, M.K. Quantifying the Φ-factor in HSC columns with ternary hybrid composites: An integrated experimental, multiscale AI, and physics-informed neural network approach. Asian J. Civ. Eng. 2025, 1–13. [Google Scholar] [CrossRef]

- Padwad, H.; Puri, N.; Sahare, S.A.; Gote, A.C.; Patil, T.R.; Kakade, N.T. Hybrid metaheuristic optimization algorithm for prediction of fatigue life performance of fiber-reinforced concrete. Asian J. Civ. Eng. 2025, 26, 3245–3256. [Google Scholar] [CrossRef]

- Huang, X.-Y.; Wu, K.-Y.; Wang, S.; Lu, T.; Lu, Y.-F.; Deng, W.-C.; Li, H.M. Compressive Strength Prediction of Rubber Concrete Based on Artificial Neural Network Model with Hybrid Particle Swarm Optimization Algorithm. Materials 2022, 15, 3934. [Google Scholar] [CrossRef]

- Dauji, S.; Bhargava, K. Estimation of concrete characteristic strength from limited data by bootstrap. J. Asian Concr. Fed. 2016, 2, 81–94. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, W.; Chen, Y.; Mi, Y.; Lei, J.; Sun, L. Predicting the compressive strength of high-performance concrete using an interpretable machine learning model. Sci. Rep. 2024, 14, 28346. [Google Scholar] [CrossRef]

- Vu-Bac, N.; Le-Anh, T.; Rabczuk, T. A Machine Learning based uncertainty quantification for compressive strength of high-performance concrete. Front. Struct. Civ. Eng. 2025, 19, 824–836. [Google Scholar] [CrossRef]

- Tipu, R.K.; Bansal, S.; Batra, V.; Suman Patel, G.A. Ensemble machine learning models for predicting concrete compressive strength incorporating various sand types. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 222. [Google Scholar] [CrossRef]

- Elhishi, S.; Elashry, A.M.; El-Metwally, S. Unboxing machine learning models for concrete strength prediction using XAI. Sci. Rep. 2023, 13, 19892. [Google Scholar] [CrossRef]

- Rahman, M.A.; Zhang, T.; Lu, Y. PINN-CHK: Physics-informed neural network for high-fidelity prediction of early-age cement hydration kinetics. Neural Comput. Appl. 2024, 36, 13665–13687. [Google Scholar] [CrossRef]

- Varghese, S.; Anand, R.; Paliwal, G. Physics-Informed Neural Network for Concrete Manufacturing Process Optimization. arXiv 2024, arXiv:2408.14502. [Google Scholar] [CrossRef]

| Name | Water (kg) | Cement (kg) | Coarse Agg. (kg) (11.2–22.4 mm) | Coarse Agg. (kg) (4–11.2 mm) | Fine Agg. (kg) (0–4 mm) | Rubber Form | Rubber Ratio | Rubber Weight (kg) | S. F. Ratio | S. F. Weight (kg) | S.P. (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0WTR-0WTSF | 195 | 345.45 | 328.5 | 401.5 | 1095 | - | 0% | - | 0% | - | 4.2 |

| 5SCWTR-0WTSF | 195 | 345.45 | 328.5 | 346.75 | 1095 | SCWTR | 5% | 20.494 | 0% | - | 4.2 |

| 5FWTR-0WTSF | 195 | 345.45 | 328.5 | 401.5 | 1040.25 | FWTR | 5% | 20.494 | 0% | - | 4.2 |

| 5LCWTR-0WTSF | 195 | 345.45 | 312.075 | 401.5 | 1095 | LCWTR | 5% | 6.102 | 0% | - | 4.2 |

| 10SCWTR-0WTSF | 195 | 345.45 | 328.5 | 292 | 1095 | SCWTR | 10% | 40.988 | 0% | - | 4.2 |

| 10FWTR-0WTSF | 195 | 345.45 | 328.5 | 401.5 | 985.5 | FWTR | 10% | 40.988 | 0% | - | 4.2 |

| 10LCWTR-0WTSF | 195 | 345.45 | 295.65 | 401.5 | 1095 | LCWTR | 10% | 12.205 | 0% | - | 4.2 |

| 20SCWTR-0WTSF | 195 | 345.45 | 328.5 | 182.5 | 1095 | SCWTR | 20% | 81.975 | 0% | - | 4.2 |

| 20FWTR-0WTSF | 195 | 345.45 | 328.5 | 401.5 | 876 | FWTR | 20% | 81.975 | 0% | - | 4.2 |

| 20LCWTR-0WTSF | 195 | 345.45 | 262.8 | 401.5 | 1095 | LCWTR | 20% | 24.409 | 0% | - | 4.2 |

| 0WTR-0.5WTSF | 195 | 345.45 | 328.5 | 401.5 | 1095 | - | 0% | - | 0.50% | 11.848 | 4.2 |

| 5SCWTR-0.5WTSF | 195 | 345.45 | 328.5 | 346.75 | 1095 | SCWTR | 5% | 20.494 | 0.50% | 11.848 | 4.2 |

| 5FWTR-0.5WTSF | 195 | 345.45 | 328.5 | 401.5 | 1040.25 | FWTR | 5% | 20.494 | 0.50% | 11.848 | 4.2 |

| 5LCWTR-0.5WTSF | 195 | 345.45 | 312.075 | 401.5 | 1095 | LCWTR | 5% | 6.102 | 0.50% | 11.848 | 4.2 |

| 10SCWTR-0.5WTSF | 195 | 345.45 | 328.5 | 292 | 1095 | SCWTR | 10% | 40.988 | 0.50% | 11.848 | 4.2 |

| 10FWTR-0.5WTSF | 195 | 345.45 | 328.5 | 401.5 | 985.5 | FWTR | 10% | 40.988 | 0.50% | 11.848 | 4.2 |

| 10LCWTR-0.5WTSF | 195 | 345.45 | 295.65 | 401.5 | 1095 | LCWTR | 10% | 12.205 | 0.50% | 11.848 | 4.2 |

| 20SCWTR-0.5WTSF | 195 | 345.45 | 328.5 | 182.5 | 1095 | SCWTR | 20% | 81.975 | 0.50% | 11.848 | 4.2 |

| 20FWTR-0.5WTSF | 195 | 345.45 | 328.5 | 401.5 | 876 | FWTR | 20% | 81.975 | 0.50% | 11.848 | 4.2 |

| 20LCWTR-0.5WTSF | 195 | 345.45 | 262.8 | 401.5 | 1095 | LCWTR | 20% | 24.409 | 0.50% | 11.848 | 4.2 |

| 0WTR-1WTSF | 195 | 345.45 | 328.5 | 401.5 | 1095 | - | 0% | - | 1% | 23.697 | 4.2 |

| 5SCWTR-1WTSF | 195 | 345.45 | 328.5 | 346.75 | 1095 | SCWTR | 5% | 20.494 | 1% | 23.697 | 4.2 |

| 5FWTR-1WTSF | 195 | 345.45 | 328.5 | 401.5 | 1040.25 | FWTR | 5% | 20.494 | 1% | 23.697 | 4.2 |

| 5LCWTR-1WTSF | 195 | 345.45 | 312.075 | 401.5 | 1095 | LCWTR | 5% | 6.102 | 1% | 23.697 | 4.2 |

| 10SCWTR-1WTSF | 195 | 345.45 | 328.5 | 292 | 1095 | SCWTR | 10% | 40.988 | 1% | 23.697 | 4.2 |

| 10FWTR-1WTSF | 195 | 345.45 | 328.5 | 401.5 | 985.5 | FWTR | 10% | 40.988 | 1% | 23.697 | 4.2 |

| 10LCWTR-1WTSF | 195 | 345.45 | 295,65 | 401.5 | 1095 | LCWTR | 10% | 12.205 | 1% | 23.697 | 4.2 |

| 20SCWTR-1WTSF | 195 | 345.45 | 328.5 | 182.5 | 1095 | SCWTR | 20% | 81.975 | 1% | 23.697 | 4.2 |

| 20FWTR-1WTSF | 195 | 345.45 | 328.5 | 401.5 | 876 | FWTR | 20% | 81.975 | 1% | 23.697 | 4.2 |

| 20LCWTR-1WTSF | 195 | 345.45 | 262.8 | 401.5 | 1095 | LCWTR | 20% | 24.409 | 1% | 23.697 | 4.2 |

| 0WTR-2WTSF | 195 | 345.45 | 328.5 | 401.5 | 1095 | - | 0% | - | 2% | 47.393 | 4.2 |

| 5SCWTR-2WTSF | 195 | 345.45 | 328.5 | 346.75 | 1095 | SCWTR | 5% | 20.494 | 2% | 47.393 | 4.2 |

| 5FWTR-2WTSF | 195 | 345.45 | 328.5 | 401.5 | 1040.25 | FWTR | 5% | 20.494 | 2% | 47.393 | 4.2 |

| 5LCWTR-2WTSF | 195 | 345.45 | 312.075 | 401.5 | 1095 | LCWTR | 5% | 6.102 | 2% | 47.393 | 4.2 |

| 10WTR-2WTSF | 195 | 345.45 | 328.5 | 292 | 1095 | SCWTR | 10% | 40.988 | 2% | 47.393 | 4.2 |

| 10FWTR-2WTSF | 195 | 345.45 | 328.5 | 401.5 | 985.5 | FWTR | 10% | 40.988 | 2% | 47.393 | 4.2 |

| 10LCWTR-2WTSF | 195 | 345.45 | 295.65 | 401.5 | 1095 | LCWTR | 10% | 12.205 | 2% | 47.393 | 4.2 |

| 20SCWTR-2WTSF | 195 | 345.45 | 328.5 | 182.5 | 1095 | SCWTR | 20% | 81.975 | 2% | 47.393 | 4.2 |

| 20FWTR-2WTSF | 195 | 345.45 | 328.5 | 401.5 | 876 | FWTR | 20% | 81.975 | 2% | 47.393 | 4.2 |

| 20LCWTR-2WTSF | 195 | 345.45 | 262.8 | 401.5 | 1095 | LCWTR | 20% | 24.409 | 2% | 47.393 | 4.2 |

| Element (%) | WTSF | FWTR + WTSF | LCWTR + WTSF | SCWTR + WTSF |

|---|---|---|---|---|

| O (Oxygen) | 50.26 | 50.72 | 40.59 | 54.89 |

| Ca (Calcium) | 23.55 | 28.16 | 13.53 | 25.15 |

| Si (Silisium) | 5.59 | 4.69 | 3.34 | 5.44 |

| Fe (Iron) | 8.62 | 3.14 | 5.16 | 2.72 |

| C (Carbon) | 10.26 | 11.81 | 36.41 | 10.16 |

| Al (Aluminum) | 1.73 | 1.48 | 0.98 | 1.64 |

| # | WTSF (%) | WTR (%) | Name | Average Density (kg/m3) | Average Compressive Strength (MPa) |

|---|---|---|---|---|---|

| 1 | 0 | 0 | 0WTR-0WTSF | 2310 | 34.98 |

| 2 | 0 | 5 | 5SCWTR-0WTSF | 2275 | 31.63 |

| 3 | 0 | 10 | 10SCWTR-0WTSF | 2235 | 29.79 |

| 4 | 0 | 20 | 20SCWTR-0WTSF | 2040 | 21.62 |

| 5 | 0 | 5 | 5FWTR-0WTSF | 2255 | 28.85 |

| 6 | 0 | 10 | 10FWTR-0WTSF | 2235 | 25.95 |

| 7 | 0 | 20 | 20FWTR-0WTSF | 2100 | 21.65 |

| 8 | 0 | 5 | 5LCWTR-0WTSF | 2280 | 34.98 |

| 9 | 0 | 10 | 10LCWTR-0WTSF | 2255 | 31.54 |

| 10 | 0 | 20 | 20LCWTR-0WTSF | 2205 | 28.77 |

| 11 | 0.5 | 0 | 0WTR-0.5WTSF | 2335 | 34.56 |

| 12 | 0.5 | 5 | 5SCWTR-0.5WTSF | 2345 | 33.20 |

| 13 | 0.5 | 10 | 10SCWTR-0.5WTSF | 2300 | 31.21 |

| 14 | 0.5 | 20 | 20SCWTR-0.5WTSF | 2170 | 29.21 |

| 15 | 0.5 | 5 | 5FWTR-0.5WTSF | 2295 | 30.03 |

| 16 | 0.5 | 10 | 10FWTR-0.5WTSF | 2285 | 25.99 |

| 17 | 0.5 | 20 | 20FWTR-0.5WTSF | 2175 | 23.04 |

| 18 | 0.5 | 5 | 5LCWTR-0.5WTSF | 2355 | 35.92 |

| 19 | 0.5 | 10 | 10LCWTR-0.5WTSF | 2375 | 32.61 |

| 20 | 0.5 | 20 | 20LCWTR-0.5WTSF | 2250 | 30.13 |

| 21 | 1 | 0 | 0WTR-1WTSF | 2325 | 36.20 |

| 22 | 1 | 5 | 5SCWTR-1WTSF | 2275 | 31.63 |

| 23 | 1 | 10 | 10SCWTR-1WTSF | 2225 | 29.78 |

| 24 | 1 | 20 | 20SCWTR-1WTSF | 2175 | 22.95 |

| 25 | 1 | 5 | 5FWTR-1WTSF | 2235 | 29.53 |

| 26 | 1 | 10 | 10FWTR-1WTSF | 2180 | 27.09 |

| 27 | 1 | 20 | 20FWTR-1WTSF | 2010 | 23.85 |

| 28 | 1 | 5 | 5LCWTR-1WTSF | 2300 | 36.98 |

| 29 | 1 | 10 | 10LCWTR-1WTSF | 2245 | 33.66 |

| 30 | 1 | 20 | 20LCWTR-1WTSF | 2210 | 30.41 |

| 31 | 2 | 0 | 0WTR-2WTSF | 2350 | 33.12 |

| 32 | 2 | 5 | 5SCWTR-2WTSF | 2250 | 30.57 |

| 33 | 2 | 10 | 10SCWTR-2WTSF | 2215 | 28.18 |

| 34 | 2 | 20 | 20SCWTR-2WTSF | 2085 | 22.44 |

| 35 | 2 | 5 | 5FWTR-2WTSF | 2285 | 20.96 |

| 36 | 2 | 10 | 10FWTR-2WTSF | 2175 | 18.98 |

| 37 | 2 | 20 | 20FWTR-2WTSF | 2080 | 16.72 |

| 38 | 2 | 5 | 5LCWTR-2WTSF | 2200 | 22.33 |

| 39 | 2 | 10 | 10LCWTR-2WTSF | 2180 | 19.30 |

| 40 | 2 | 20 | 20LCWTR-2WTSF | 2110 | 18.14 |

| WTR Type | Substitute (%) | 0% WTSF (Reference) | 0.5–1.0% WTSF (Increase) | 2.0% WTSF (Decrease) |

|---|---|---|---|---|

| FWTR | 5 | 28.85 MPa | 30.03 MPa (+4.1%)/29.53 MPa (+2.4%) | 20.96 MPa (−27.3%) |

| 10 | 25.95 MPa | 25.99 MPa (+0.2%)/27.09 MPa (+4.4%) | 18.98 MPa (−26.8%) | |

| 20 | 21.65 MPa | 23.04 MPa (+6.4%)/23.85 MPa (+10.2%) | 16.72 MPa (−22.8%) | |

| SCWTR | 5 | 31.63 MPa | 33.20 MPa (+5.0%)/31.63 MPa (0%) | 30.57 MPa (−3.4%) |

| 10 | 29.79 MPa | 31.21 MPa (+4.8%)/29.78 MPa (≈0%) | 28.18 MPa (−5.4%) | |

| 20 | 21.62 MPa | 29.21 MPa (+35.0%)/22.95 MPa (+6.1%) | 22.44 MPa (+3.8%) | |

| LCWTR | 5 | 34.98 MPa | 35.92 MPa (+2.7%)/36.98 MPa (+5.7%) | 22.33 MPa (−36.2%) |

| 10 | 31.54 MPa | 32.61 MPa (+3.4%)/33.66 MPa (+6.7%) | 19.30 MPa (−38.8%) | |

| 20 | 28.77 MPa | 30.13 MPa (+4.7%)/30.41 MPa (+5.7%) | 18.14 MPa (−36.9%) |

| Source of Variation | df | F-Value | p-Value | Significance |

|---|---|---|---|---|

| WTR type | 2 | 19.84 | <0.001 | *** |

| WTSF (%) | 3 | 27.42 | <0.001 | *** |

| Interaction (WTRXWTSF) | 6 | 4.91 | 0.0017 | ** |

| Residual error | 36 | - | - | - |

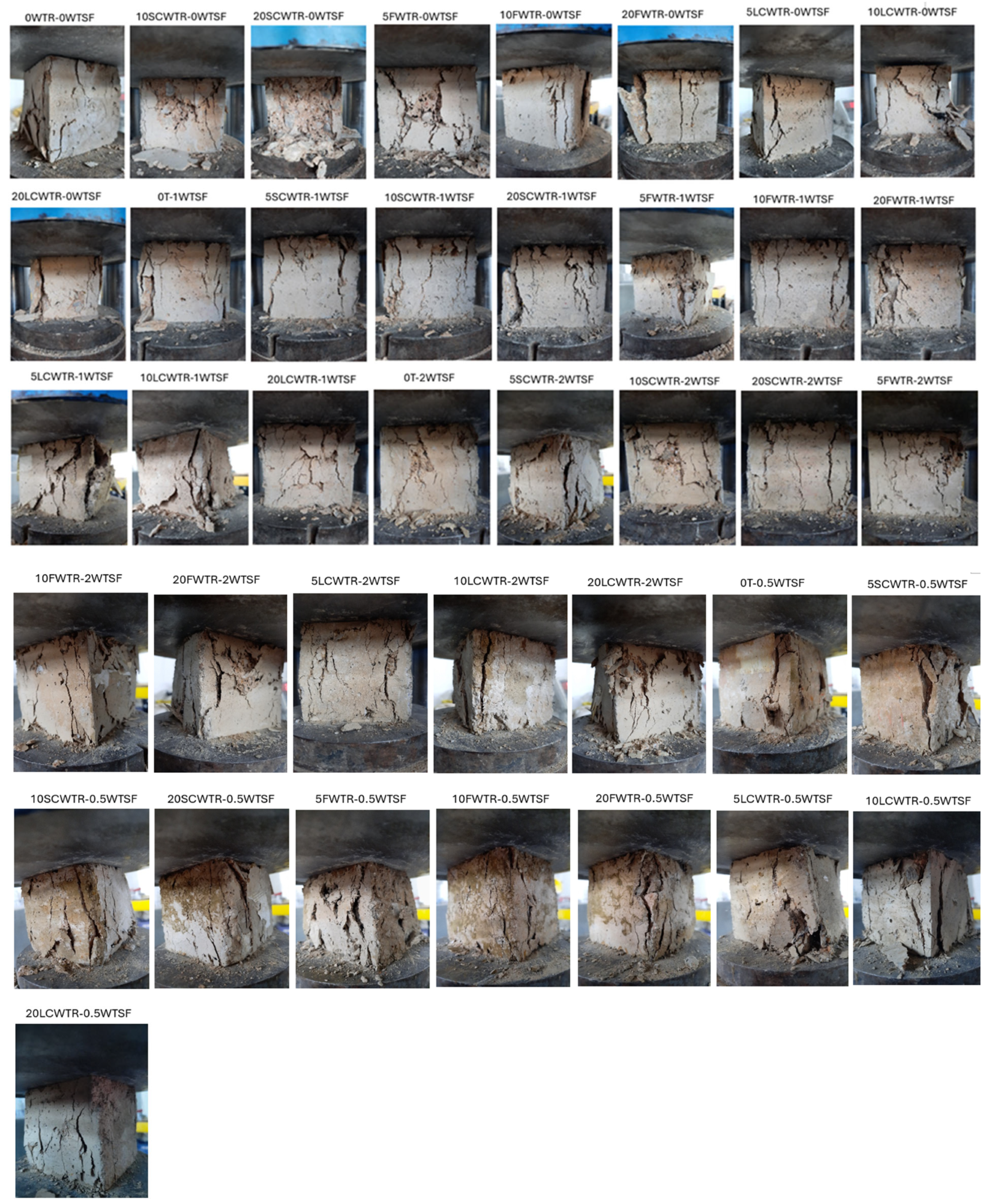

| Mix ID | WTR Type | WTSF Ratio | Compressive Strength (MPa) | Failure Mode | Observations |

|---|---|---|---|---|---|

| 0WTR-0WTSF | - | - | 34.98 | Brittle splitting | Sudden vertical cracks along loading axis; clean fracture surfaces with limited energy absorption; typical of plain concrete. |

| 10FWTR-0WTSF | Fine (10%) | 0 | 25.95 | Brittle–weak ITZ | Wide cracks and aggregate–paste separation due to weak rubber–cement interface; low density and high porosity accelerate brittle failure. |

| 5LCWTR-1WTSF | Large (5%) | 1% | 36.98 | Ductile–bridging | Multiple fine cracks with gradual propagation; clear evidence of steel fiber pull-out; Fibers bridge cracks and enhance post-peak load capacity. |

| 20FWTR-2WTSF | Fine (20%) | 2% | 16.72 | Brittle–heterogeneous | Severe segregation, fiber clumping, and a weak matrix, local crushing and block-type collapse, loss of homogeneity that explains the sharp strength reduction. |

| Feature | Mean SHAP Value | RI (%) | Effect Direction |

|---|---|---|---|

| Bulk density (p) | 0.091 | 41.3 | Positive—higher density increases strength |

| WTR (%) | 0.067 | 30.4 | Negative—higher WTR reduces strength |

| WTSF (%) | 0.039 | 17.7 | Positive up to 1%, negative beyond 2% |

| WTR Type | 0.023 | 10.6 | Positive—coarse particles (LCWTR, SCWTR) mitigate losses |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ecemiş, A.S.; Yildizel, S.A.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Aksoylu, C.; Madenci, E.; Özkılıç, Y.O. Sustainable Concrete with Waste Tire Rubber and Recycled Steel Fibers: Experimental Insights and Hybrid PINN–CatBoost Prediction. Polymers 2025, 17, 2910. https://doi.org/10.3390/polym17212910

Ecemiş AS, Yildizel SA, Beskopylny AN, Stel’makh SA, Shcherban’ EM, Aksoylu C, Madenci E, Özkılıç YO. Sustainable Concrete with Waste Tire Rubber and Recycled Steel Fibers: Experimental Insights and Hybrid PINN–CatBoost Prediction. Polymers. 2025; 17(21):2910. https://doi.org/10.3390/polym17212910

Chicago/Turabian StyleEcemiş, Ali Serdar, Sadik Alper Yildizel, Alexey N. Beskopylny, Sergey A. Stel’makh, Evgenii M. Shcherban’, Ceyhun Aksoylu, Emrah Madenci, and Yasin Onuralp Özkılıç. 2025. "Sustainable Concrete with Waste Tire Rubber and Recycled Steel Fibers: Experimental Insights and Hybrid PINN–CatBoost Prediction" Polymers 17, no. 21: 2910. https://doi.org/10.3390/polym17212910

APA StyleEcemiş, A. S., Yildizel, S. A., Beskopylny, A. N., Stel’makh, S. A., Shcherban’, E. M., Aksoylu, C., Madenci, E., & Özkılıç, Y. O. (2025). Sustainable Concrete with Waste Tire Rubber and Recycled Steel Fibers: Experimental Insights and Hybrid PINN–CatBoost Prediction. Polymers, 17(21), 2910. https://doi.org/10.3390/polym17212910