Influence of Draft Angle Design on Surface Texture–Dimensional Accuracy Coupling in Injection-Molded Commodity and Engineering Polymers with Semi-Crystalline and Amorphous Characteristics

Abstract

1. Introduction

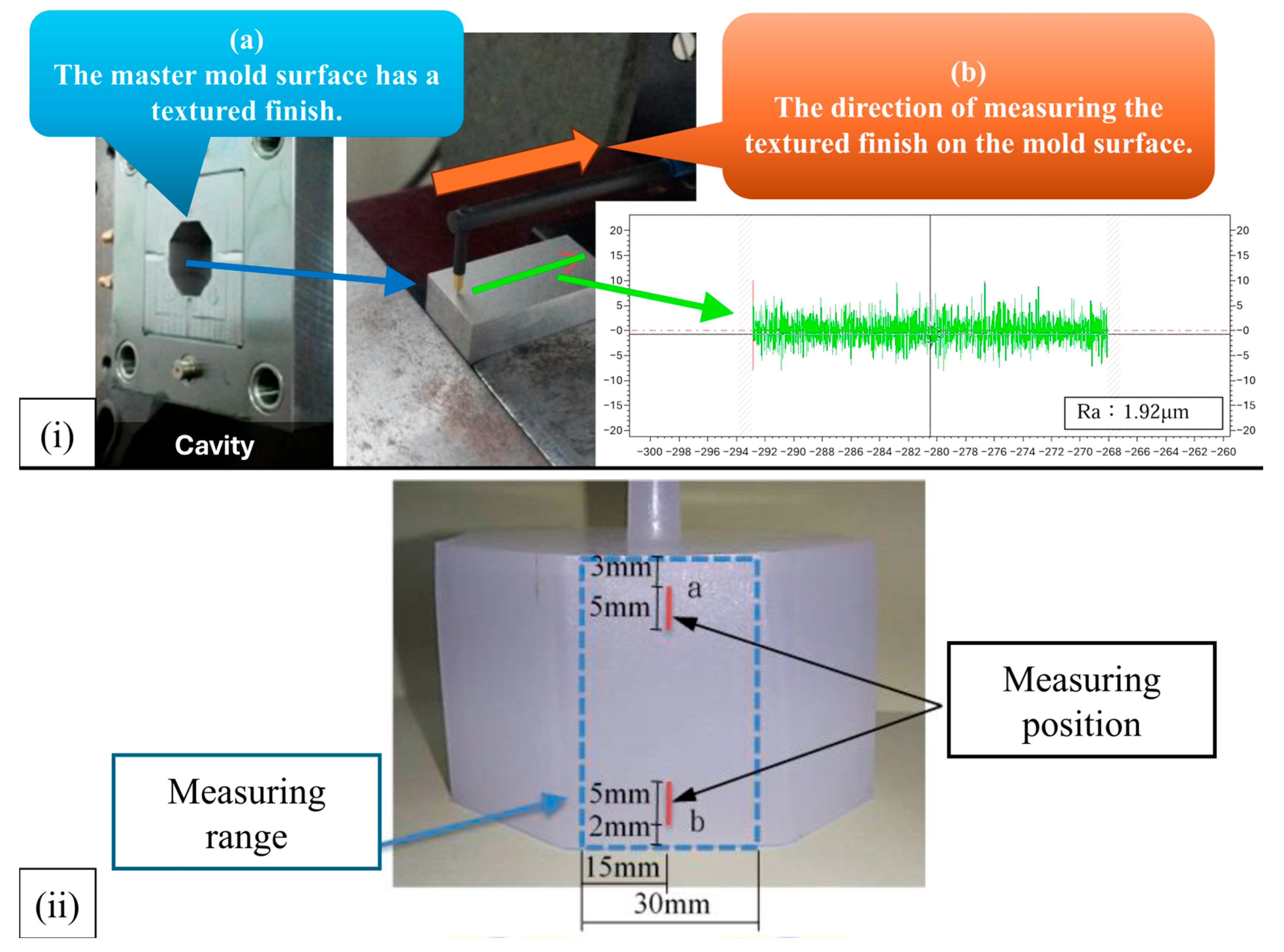

2. Materials and Methods

2.1. Geometrical Product and Its Mold Design

2.2. Molding Material and Its Equipment

2.3. Measurement System and Related Information

3. Results

4. Discussion

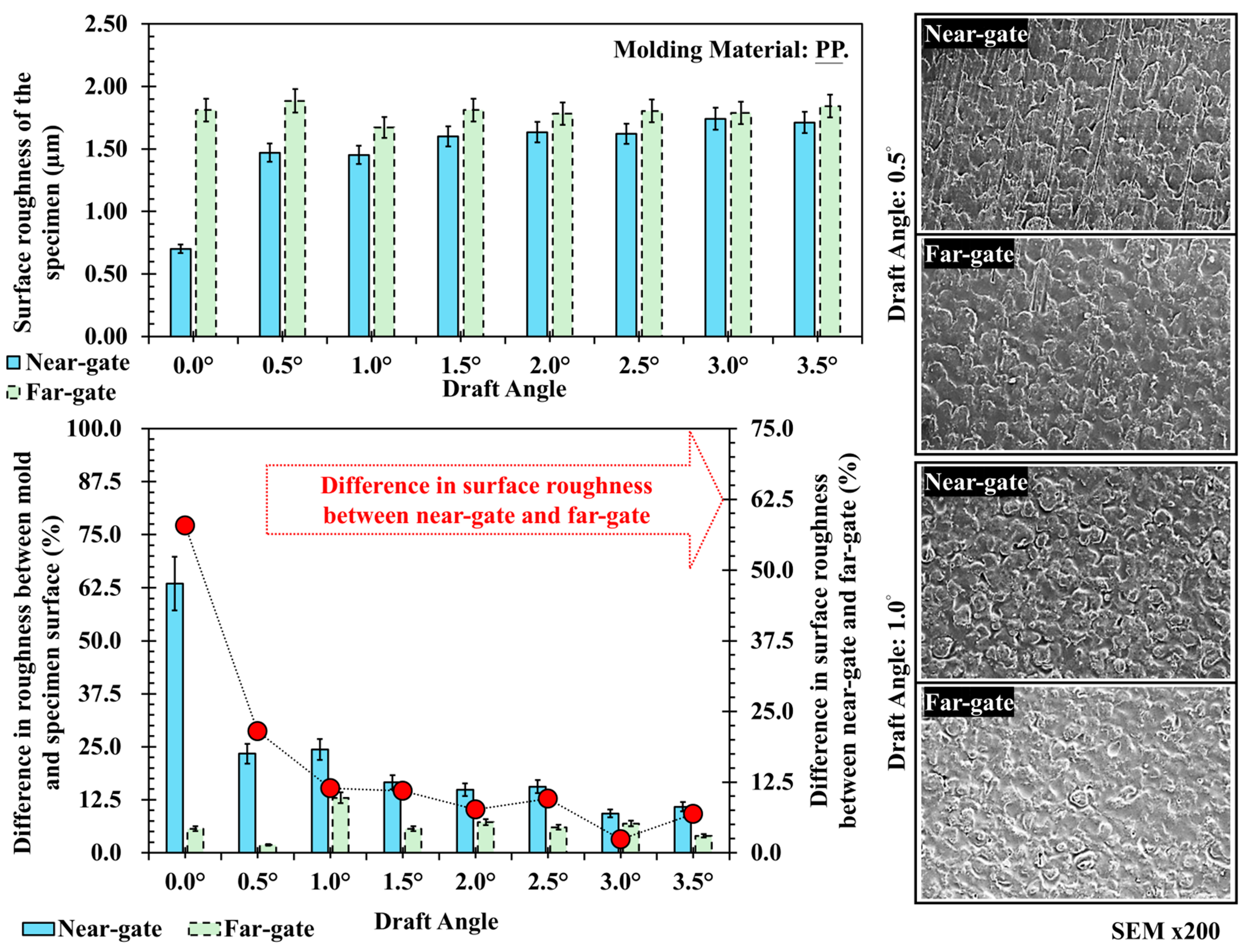

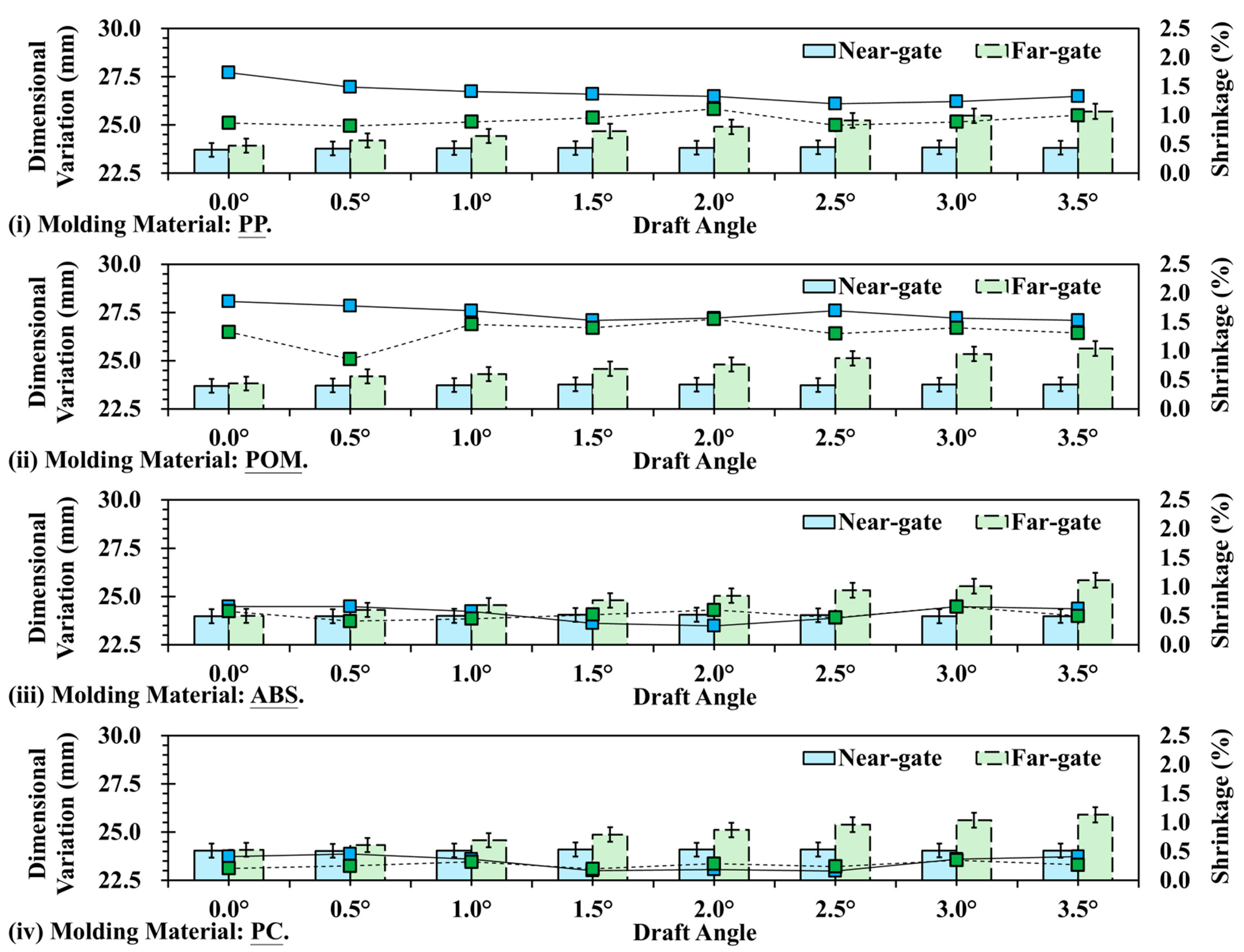

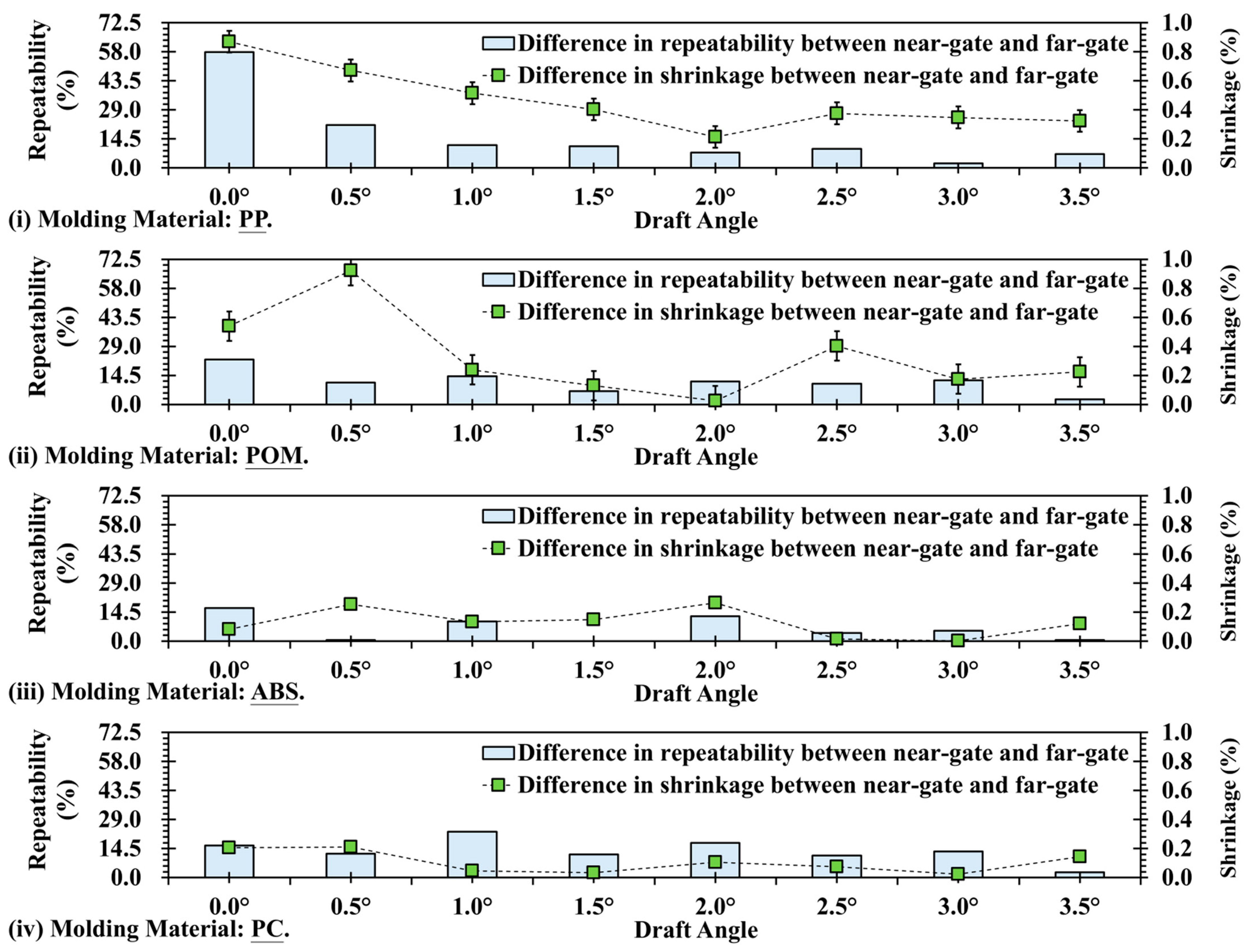

- Draft angle strongly improves texture clarity but has a limited impact on global deformation trends. Increasing draft angle enhances texture retention at the near-gate location while only gradually moderating overall shrinkage. For PP, near-gate roughness rises from about 0.7 μm at 0° and stabilizes with angle, whereas far-gate roughness remains around 1.6 to 1.8 μm.

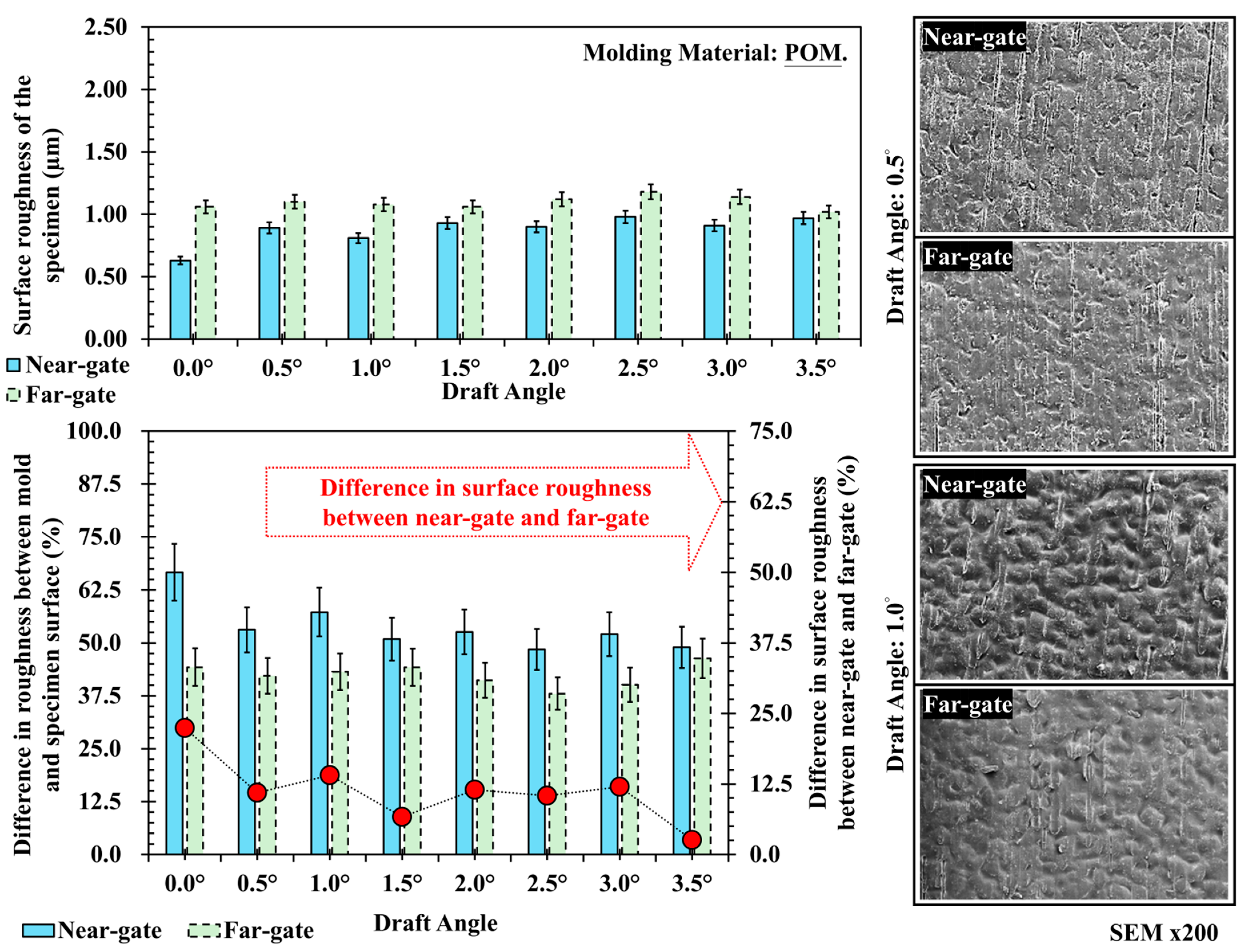

- Crystalline polymers exhibit higher roughness and shrinkage than amorphous polymers. Roughness is as follows: PP roughness is greater than POM and that of ABS is greater than PC. Shrinkage is more pronounced in crystalline materials with an overall order of POM, PP, ABS, and PC, consistent with crystallization-induced local shrinkage and higher ejection friction.

- Draft angle effectively narrows near-gate and far-gate discrepancies, especially for crystalline polymers. In PP and POM, increasing draft angle markedly reduces differences in roughness and shrinkage. For PP, replication difference exceeds 50 percent at 0° and drops below 10 percent beyond 2°. For POM, the initial difference of about 25 percent reaches a minimum around 1.5° to 2.0°.

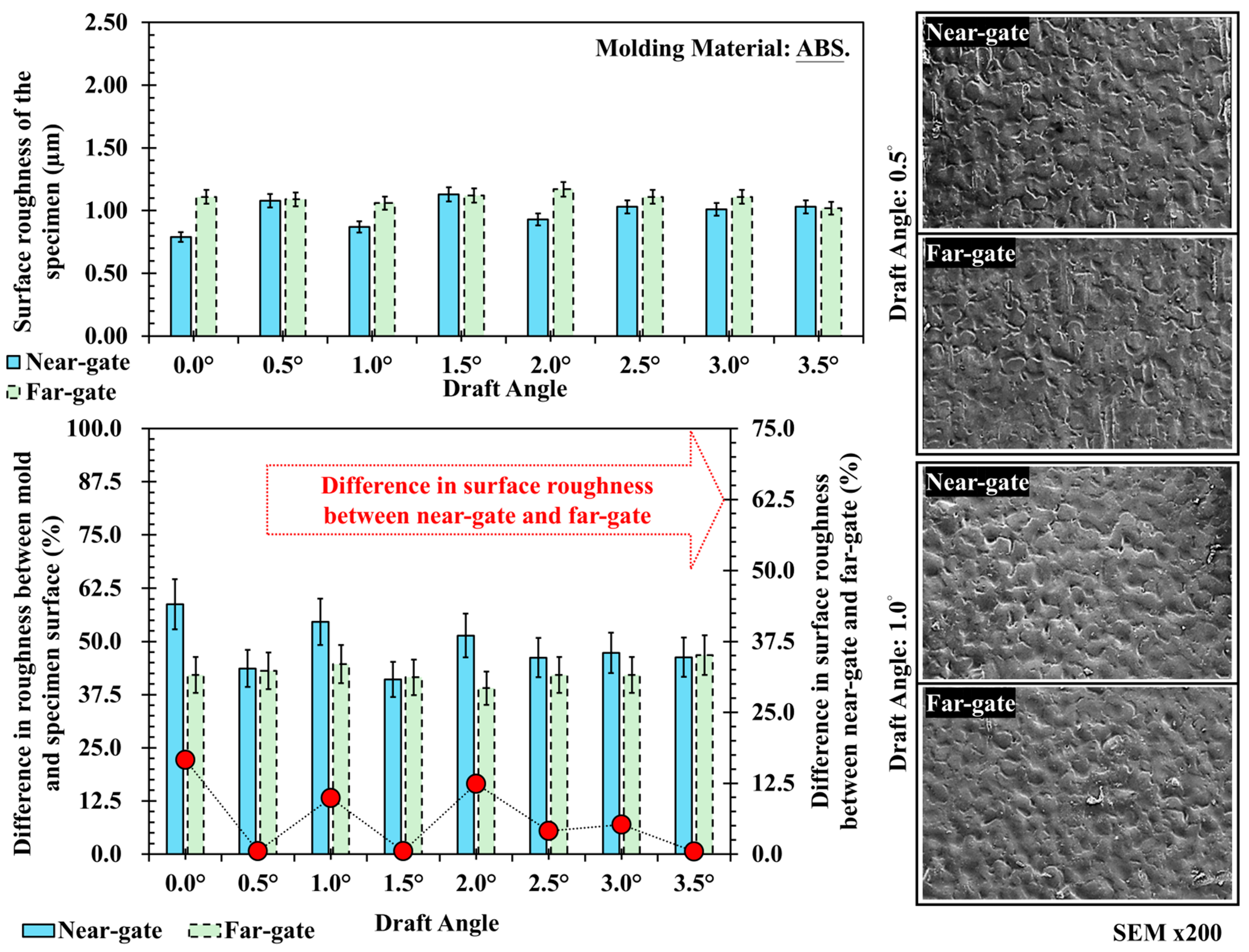

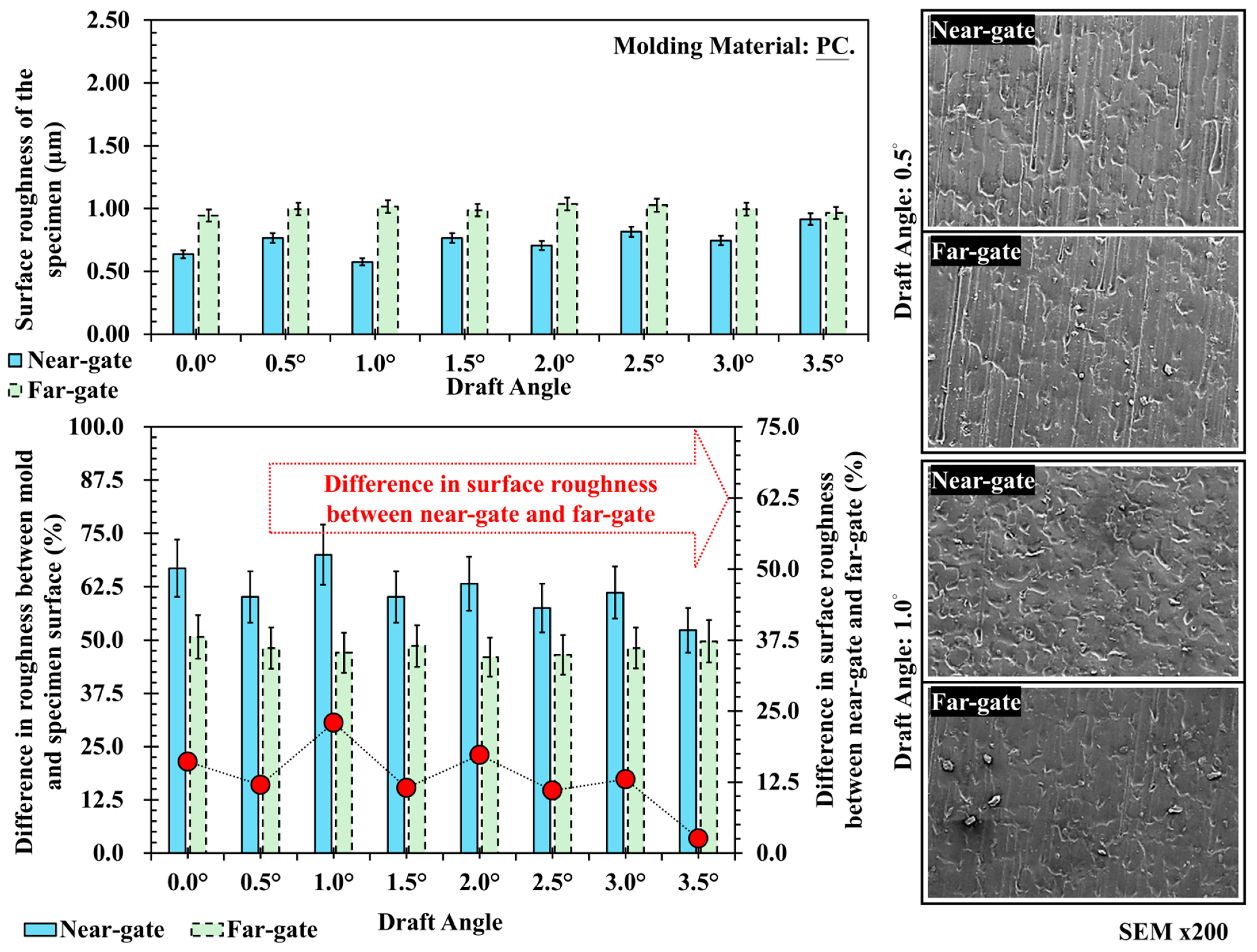

- Amorphous polymers are less sensitive to draft angles and maintain low roughness with high dimensional stability. ABS and PC show roughness ranges of about 0.8 to 1.1 μm and 0.7 to 1.0 μm, respectively, and shrinkage of about 0.05 to 0.15 mm with small variations across angles. ABS occasionally exhibits a peak replication difference above 35 percent near 2.0°, likely due to localized flow or friction. PC fluctuates between about 10 and 30 percent, reflecting high-temperature molding with local cooling and friction effects.

- Larger draft angles should be used for crystalline polymers, and moderate angles should be used for amorphous polymers while prioritizing mold finish and filling control. Practical ranges are about 1.5° to 2.5° for PP and POM to lower demolding friction and improve near–far consistency. For ABS and PC, about 0.5° to 1.5° is generally sufficient, with emphasis on mold surface quality and stable filling pressure to avoid local defects.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gim, J.; Turng, L.-S. A review of current advancements in high surface quality injection molding: Measurement, influencing factors, prediction, and control. Polym. Test. 2022, 115, 107718. [Google Scholar] [CrossRef]

- Linke, B.; Das, J. Aesthetics and Gloss of Ground Surfaces: A Review on Measurement and Generation. J. Manuf. Sci. Eng. 2016, 138, 064501. [Google Scholar] [CrossRef]

- Du, P.; MacDonald, E.F. Eye-Tracking Data Predict Importance of Product Features and Saliency of Size Change. J. Mech. Des. 2014, 136, 081005. [Google Scholar] [CrossRef]

- Burdin, L.; Brulez, A.-C.; Mazurczyk, R.; Leclercq, J.-L.; Benayoun, S. Texturing injection molds using microelectronics techniques. Surf. Coat. Technol. 2025, 502, 131989. [Google Scholar] [CrossRef]

- Stoica, I.; Albu, R.M.; Hulubei, C.; Astanei, D.G.; Burlica, R.; Mersal, G.A.M.; Seaf Elnasr, T.A.; Barzic, A.I.; Elnaggar, A.Y. A New Texturing Approach of a Polyimide Shielding Cover for Enhanced Light Propagation in Photovoltaic Devices. Nanomaterials 2022, 12, 3249. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Yi, A.; Choi, J.; Ko, D.-H.; Kim, H.J. Texturing of polydimethylsiloxane surface for anti-reflective films with super-hydrophobicity in solar cell application. Appl. Surf. Sci. 2022, 584, 152625. [Google Scholar] [CrossRef]

- Masato, D.; Piccolo, L.; Lucchetta, G.; Sorgato, M. Texturing Technologies for Plastics Injection Molding: A Review. Micromachines 2022, 13, 1211. [Google Scholar] [CrossRef] [PubMed]

- Macdonald, D.A.; Harman, R.; Evans, A.A. Replicating surface texture: Preliminary testing of molding compound accuracy for surface measurements. J. Archaeol. Sci. Rep. 2018, 18, 839–846. [Google Scholar] [CrossRef]

- Jadhav, G.; Gaval, V.; Solanke, S.; Divekar, M.; Darade, N.; Satpute, A.; Goutham, G.P. Weld-lines and its strength evaluation in injection molded parts: A review. Polym. Eng. Sci. 2023, 63, 3523–3536. [Google Scholar] [CrossRef]

- Reddy, V.V.; Krishna, A.V.; Sjögren, A.; Rosén, B.-G. Characterisation and analysis of the surface texture of injection-moulded automotive interior ABS and PP components. Int. J. Adv. Manuf. Techol. 2023, 128, 4579–4592. [Google Scholar] [CrossRef]

- Ungar, L.Y.; Sudolsky, M.D. Tapping into boundary scan resources for vehicle health management. In Proceedings of the 2016 IEEE AUTOTESTCON, Anaheim, CA, USA, 12–15 September 2016. [Google Scholar] [CrossRef]

- Francesco, M.; Giovanni, L.; Marco, S. Analysis of the effect of draft angle and surface roughness on ejection forces in micro injection molding. Mater. Res. Proc. 2024, 41, 2686–2694. [Google Scholar] [CrossRef]

- Murata, Y.; Nakanishi, T.; Hirai, N.; Kawanishi, F.; Ibuki, H. Development of Mold for Demolding Resistance Measurement in Polyme. Sens. Mater. 2019, 31, 3099–3110. [Google Scholar] [CrossRef]

- Harris, R.; Hopkinson, N.; Newlyn, H.; Hague, R.; Dickens, P. Layer thickness and draft angle selection for stereolithography injection mould tooling. Int. J. Prod. Res. 2010, 40, 719–729. [Google Scholar] [CrossRef]

- Cedorge, T.; Colton, J. Draft angle and surface roughness effects on stereolithography molds. Polym. Eng. Sci. 2000, 40, 1581–1588. [Google Scholar] [CrossRef]

| Parameter | PP | POM | ABS | PC |

|---|---|---|---|---|

| Barrel heating-film temperature (melt temperature) | 200 °C | 250 °C | 200 °C | 250 °C |

| Mold heating, water temperature (mold temperature) | 50 °C | 70 °C | 50 °C | 70 °C |

| Plasticizing time | 7 s | 10 s | 7 s | 12 s |

| Injection time | 0.75 s | 1.25 s | 0.72 s | 1 s |

| Screw speed | 100 rpm | 100 rpm | 100 rpm | 100 rpm |

| Back pressure | 5 bar | 5 bar | 5 bar | 5 bar |

| Material usage | 32 mm | 32 mm | 32 mm | 32 mm |

| Injection pressure | 100% | 100% | 100% | 100% |

| Injection speed | 70 mm/s | 70 mm/s | 70 mm/s | 70 mm/s |

| Packing pressure switching point | 10 mm | 10 mm | 10 mm | 10 mm |

| Packing pressure | 20% | 20% | 20% | 20% |

| Packing time | 10 s | 10 s | 10 s | 10 s |

| Cooling time | 10 s | 10 s | 10 s | 10 s |

| Material: PP. | Surface Roughness (µm) | Dimensional Variation (mm) | Shrinkage (%) | |||||||||

| Near-Gate | Far-Gate | Near-Gate | Far-Gate | Near-Gate | Far-Gate | |||||||

| EXP. | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA |

| 0.0 | 0.70 | 0.0019% | 1.81 | 0.0020% | 23.72 | 0.15034% | 23.93 | 0.08603% | 1.74 | 0.06579% | 0.87 | 0.01827% |

| 0.5 | 1.47 | 0.0026% | 1.88 | 0.0001% | 23.78 | 0.15110% | 24.20 | 0.08798% | 1.49 | 0.04824% | 0.82 | 0.01623% |

| 1.0 | 1.45 | 0.0036% | 1.67 | 0.0019% | 23.80 | 0.15135% | 24.44 | 0.08973% | 1.41 | 0.04320% | 0.89 | 0.01912% |

| 1.5 | 1.60 | 0.0020% | 1.81 | 0.0020% | 23.81 | 0.15148% | 24.69 | 0.09158% | 1.37 | 0.04078% | 0.96 | 0.02224% |

| 2.0 | 1.63 | 0.0001% | 1.78 | 0.0012% | 23.82 | 0.15161% | 24.91 | 0.09322% | 1.33 | 0.03844% | 1.11 | 0.02974% |

| 2.5 | 1.62 | 0.0023% | 1.80 | 0.0068% | 23.85 | 0.15199% | 25.24 | 0.09570% | 1.20 | 0.03129% | 0.83 | 0.01663% |

| 3.0 | 1.74 | 0.0009% | 1.79 | 0.0014% | 23.84 | 0.15186% | 25.48 | 0.09753% | 1.24 | 0.03341% | 0.89 | 0.01912% |

| 3.5 | 1.71 | 0.0012% | 1.84 | 0.0018% | 23.82 | 0.15161% | 25.71 | 0.09930% | 1.33 | 0.03844% | 1.00 | 0.02413% |

| Material: POM. | Surface roughness (µm) | Dimensional variation (mm) | Shrinkage (%) | |||||||||

| Near-gate | Far-gate | Near-gate | Far-gate | Near-gate | Far-gate | |||||||

| EXP. | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA |

| 0.0 | 0.64 | 0.0621% | 1.07 | 0.0617% | 23.69 | 0.14996% | 23.82 | 0.13693% | 1.86 | 0.05197% | 1.33 | 0.04269% |

| 0.5 | 0.90 | 0.0562% | 1.11 | 0.0584% | 23.71 | 0.15021% | 24.19 | 0.14122% | 1.78 | 0.04760% | 0.86 | 0.01785% |

| 1.0 | 0.82 | 0.0617% | 1.09 | 0.0562% | 23.73 | 0.15046% | 24.30 | 0.14251% | 1.70 | 0.04342% | 1.46 | 0.05144% |

| 1.5 | 0.94 | 0.0725% | 1.07 | 0.0562% | 23.77 | 0.15097% | 24.58 | 0.14581% | 1.53 | 0.03517% | 1.40 | 0.04730% |

| 2.0 | 0.91 | 0.0617% | 1.13 | 0.0617% | 23.76 | 0.15084% | 24.80 | 0.14843% | 1.57 | 0.03703% | 1.55 | 0.05798% |

| 2.5 | 0.99 | 0.0617% | 1.19 | 0.0617% | 23.73 | 0.15046% | 25.12 | 0.15229% | 1.70 | 0.04342% | 1.30 | 0.04079% |

| 3.0 | 0.92 | 0.0617% | 1.15 | 0.0617% | 23.76 | 0.15084% | 25.35 | 0.15509% | 1.57 | 0.03703% | 1.40 | 0.04730% |

| 3.5 | 0.98 | 0.0617% | 1.03 | 0.0617% | 23.77 | 0.15097% | 25.63 | 0.15853% | 1.53 | 0.03517% | 1.31 | 0.04142% |

| Material: ABS. | Surface roughness (µm) | Dimensional variation (mm) | Shrinkage (%) | |||||||||

| Near-gate | Far-gate | Near-gate | Far-gate | Near-gate | Far-gate | |||||||

| EXP. | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA |

| 0.0 | 0.79 | 0.0566% | 1.11 | 0.0582% | 23.98 | 0.15365% | 24.00 | 0.01051% | 0.66 | 0.05197% | 0.58 | 0.00812% |

| 0.5 | 1.08 | 0.0566% | 1.09 | 0.0573% | 23.98 | 0.15365% | 24.30 | 0.01051% | 0.66 | 0.04760% | 0.41 | 0.00406% |

| 1.0 | 0.87 | 0.0573% | 1.06 | 0.0566% | 24.00 | 0.15391% | 24.55 | 0.00812% | 0.58 | 0.04342% | 0.45 | 0.00489% |

| 1.5 | 1.13 | 0.0582% | 1.12 | 0.0566% | 24.05 | 0.15455% | 24.80 | 0.00330% | 0.37 | 0.03517% | 0.52 | 0.00653% |

| 2.0 | 0.93 | 0.0595% | 1.17 | 0.0582% | 24.06 | 0.15468% | 25.04 | 0.00263% | 0.33 | 0.03703% | 0.60 | 0.00869% |

| 2.5 | 1.03 | 0.0595% | 1.11 | 0.0582% | 24.03 | 0.15429% | 25.33 | 0.00511% | 0.46 | 0.04342% | 0.47 | 0.00533% |

| 3.0 | 1.01 | 0.0582% | 1.11 | 0.0566% | 23.98 | 0.15365% | 25.54 | 0.01051% | 0.66 | 0.03703% | 0.66 | 0.01051% |

| 3.5 | 1.03 | 0.0582% | 1.02 | 0.0566% | 23.99 | 0.15378% | 25.84 | 0.00928% | 0.62 | 0.03517% | 0.50 | 0.00603% |

| Material: PC. | Surface roughness (µm) | Dimensional variation (mm) | Shrinkage (%) | |||||||||

| Near-gate | Far-gate | Near-gate | Far-gate | Near-gate | Far-gate | |||||||

| EXP. | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA |

| 0.0 | 0.64 | 0.0855% | 0.95 | 0.0828% | 24.04 | 0.15442% | 24.09 | 0.15506% | 0.41 | 0.00449% | 0.21 | 0.00118% |

| 0.5 | 0.77 | 0.0828% | 1.00 | 0.0855% | 24.03 | 0.15429% | 24.34 | 0.15830% | 0.46 | 0.00565% | 0.25 | 0.00167% |

| 1.0 | 0.58 | 0.0828% | 1.02 | 0.0882% | 24.05 | 0.15455% | 24.58 | 0.16144% | 0.37 | 0.00366% | 0.32 | 0.00274% |

| 1.5 | 0.77 | 0.0828% | 0.99 | 0.0868% | 24.10 | 0.15519% | 24.88 | 0.16540% | 0.17 | 0.00077% | 0.20 | 0.00107% |

| 2.0 | 0.71 | 0.0828% | 1.04 | 0.0882% | 24.10 | 0.15519% | 25.12 | 0.16861% | 0.19 | 0.00096% | 0.29 | 0.00225% |

| 2.5 | 0.82 | 0.0828% | 1.03 | 0.0882% | 24.10 | 0.15519% | 25.39 | 0.17225% | 0.16 | 0.00068% | 0.24 | 0.00154% |

| 3.0 | 0.75 | 0.0828% | 1.00 | 0.0830% | 24.05 | 0.15455% | 25.62 | 0.17539% | 0.37 | 0.00366% | 0.35 | 0.00327% |

| 3.5 | 0.92 | 0.0828% | 0.97 | 0.0830% | 24.04 | 0.15442% | 25.90 | 0.17924% | 0.41 | 0.00449% | 0.27 | 0.00195% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.-L.; Huang, P.-W.; Huang, Y.-S. Influence of Draft Angle Design on Surface Texture–Dimensional Accuracy Coupling in Injection-Molded Commodity and Engineering Polymers with Semi-Crystalline and Amorphous Characteristics. Polymers 2025, 17, 2892. https://doi.org/10.3390/polym17212892

Chen H-L, Huang P-W, Huang Y-S. Influence of Draft Angle Design on Surface Texture–Dimensional Accuracy Coupling in Injection-Molded Commodity and Engineering Polymers with Semi-Crystalline and Amorphous Characteristics. Polymers. 2025; 17(21):2892. https://doi.org/10.3390/polym17212892

Chicago/Turabian StyleChen, Hui-Li, Po-Wei Huang, and Yu-Shan Huang. 2025. "Influence of Draft Angle Design on Surface Texture–Dimensional Accuracy Coupling in Injection-Molded Commodity and Engineering Polymers with Semi-Crystalline and Amorphous Characteristics" Polymers 17, no. 21: 2892. https://doi.org/10.3390/polym17212892

APA StyleChen, H.-L., Huang, P.-W., & Huang, Y.-S. (2025). Influence of Draft Angle Design on Surface Texture–Dimensional Accuracy Coupling in Injection-Molded Commodity and Engineering Polymers with Semi-Crystalline and Amorphous Characteristics. Polymers, 17(21), 2892. https://doi.org/10.3390/polym17212892