Polymer Versus Cementitious Matrix Composites for Retrofitting Reinforced Concrete Columns—A State-of-the-Art Review

Abstract

1. Introduction

2. Characterization of FRP and FRCM Materials

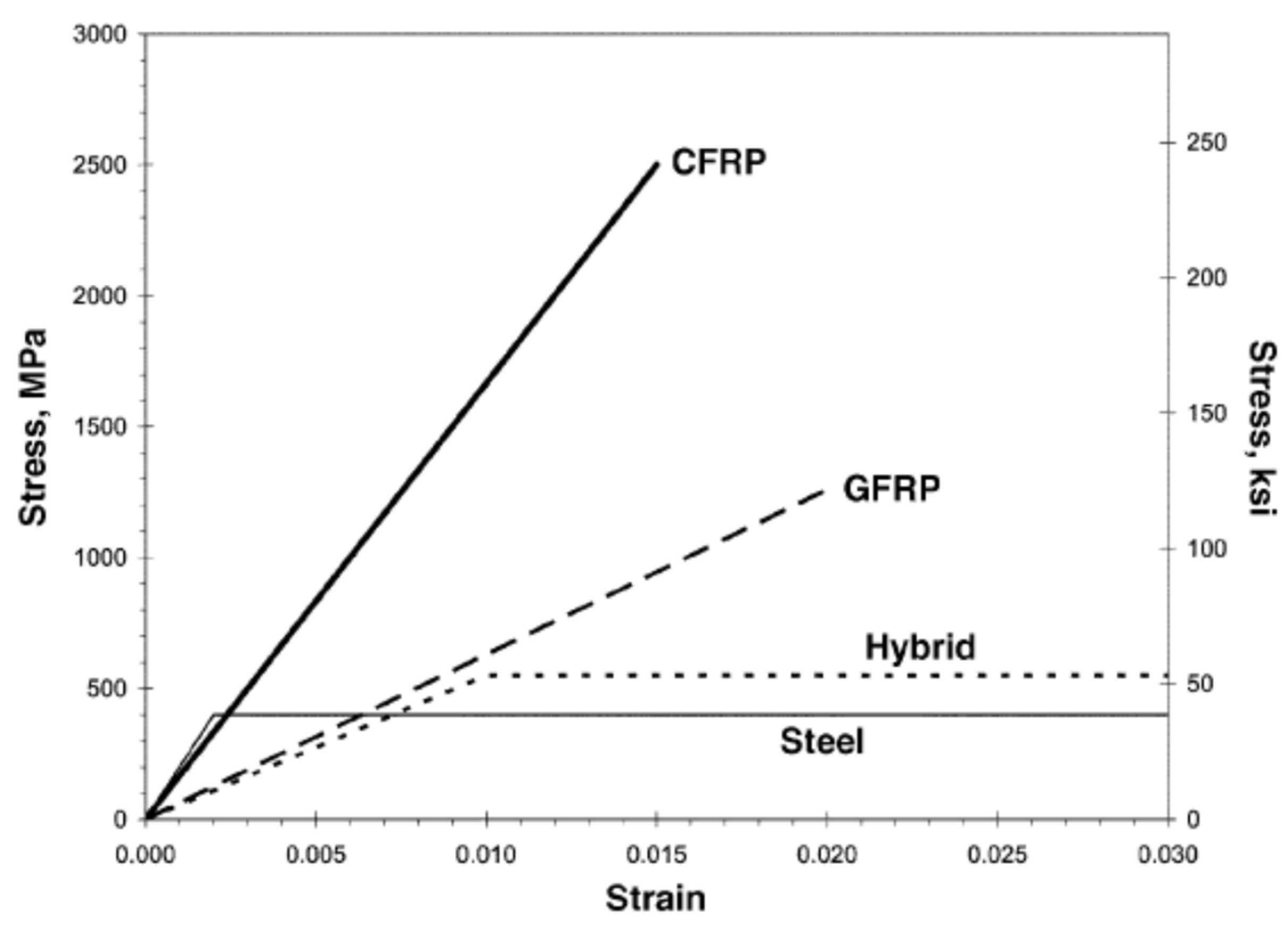

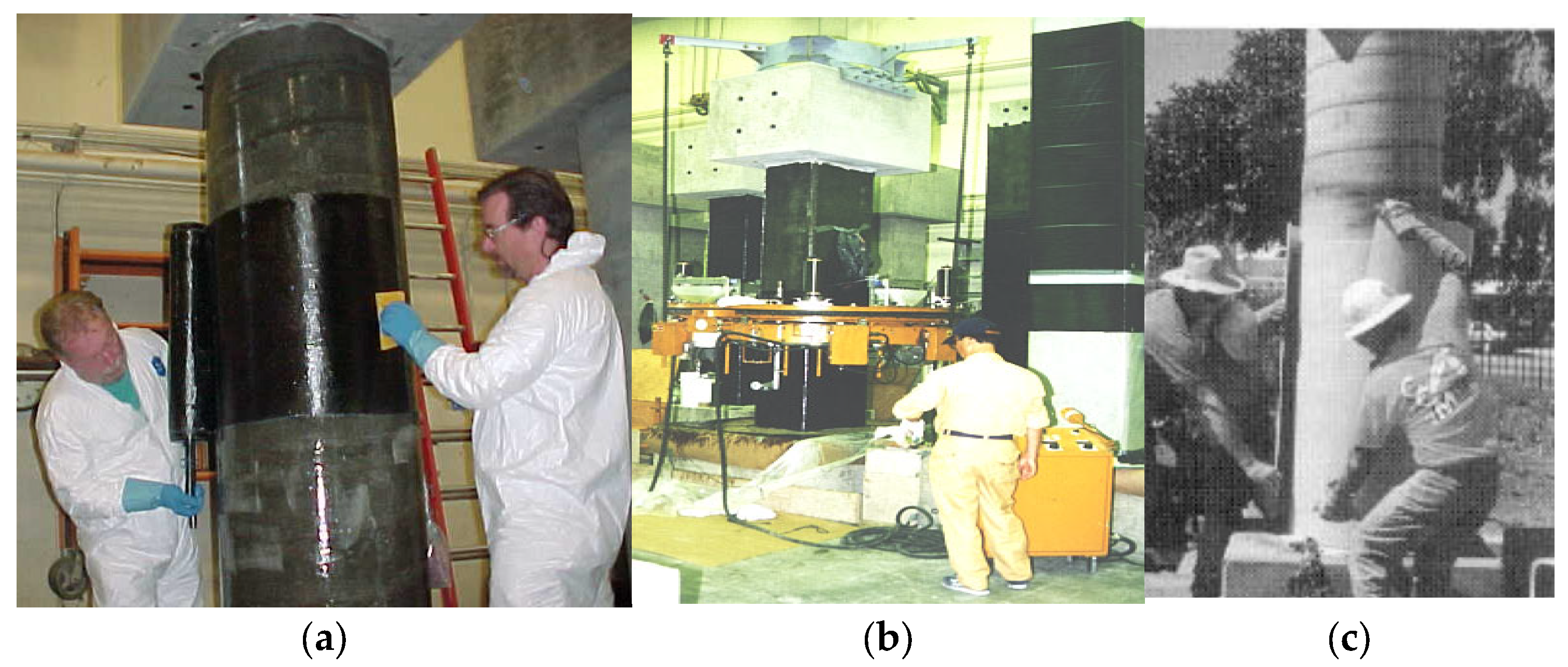

2.1. FRP Composites

2.2. FRCM Composites

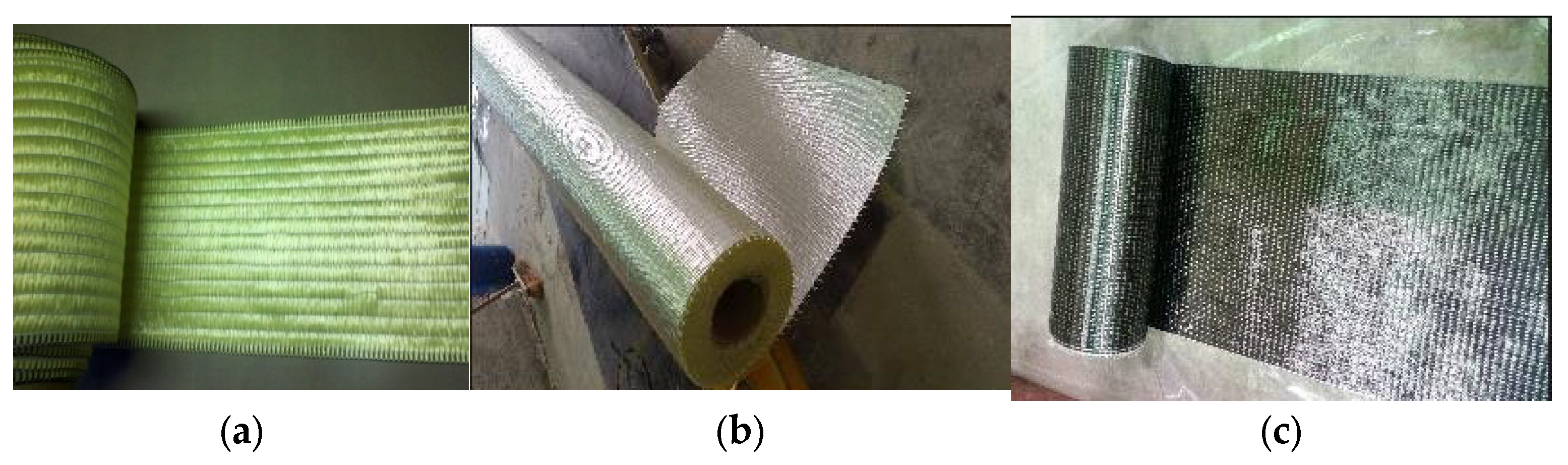

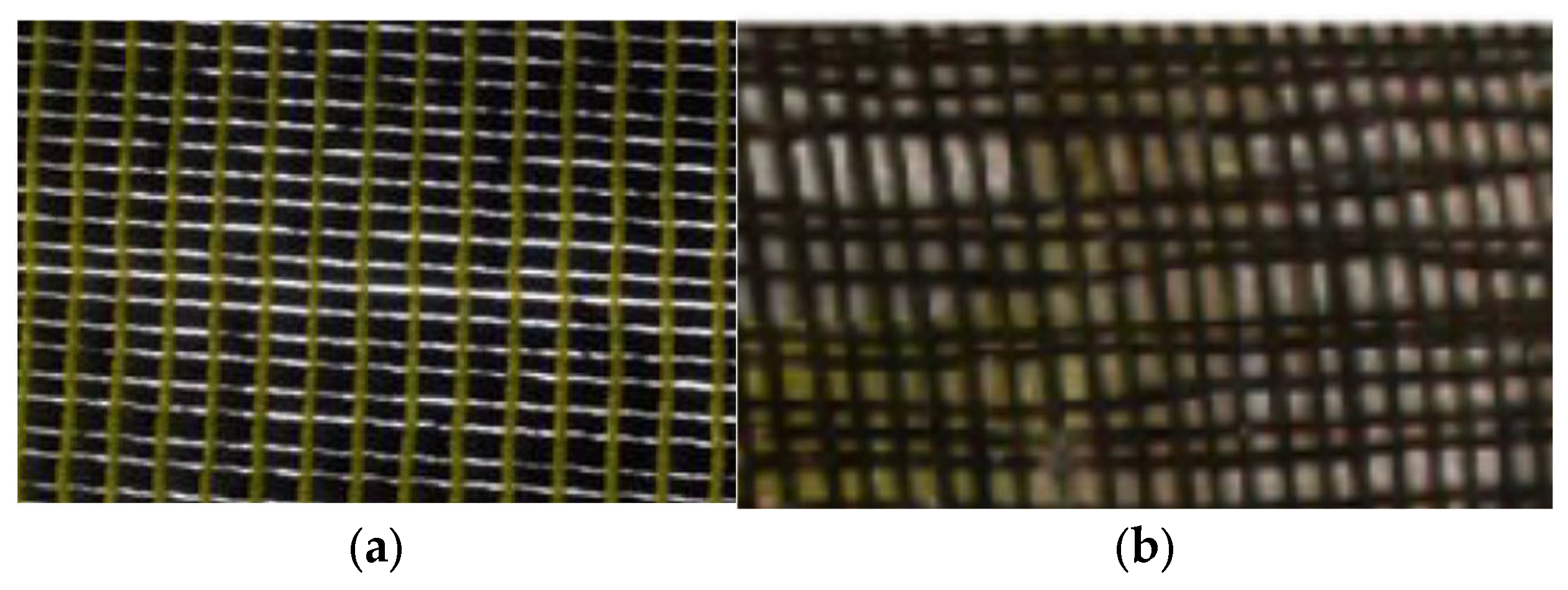

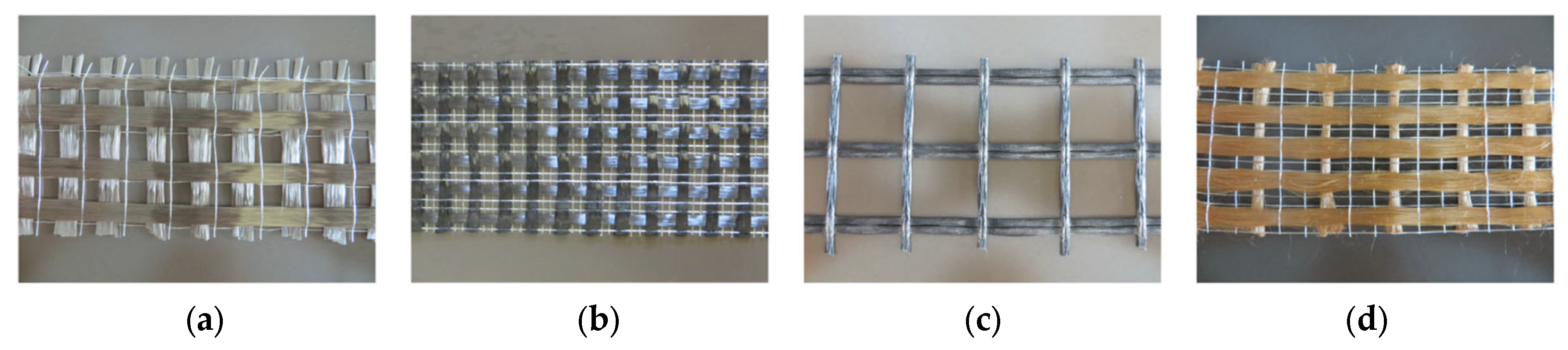

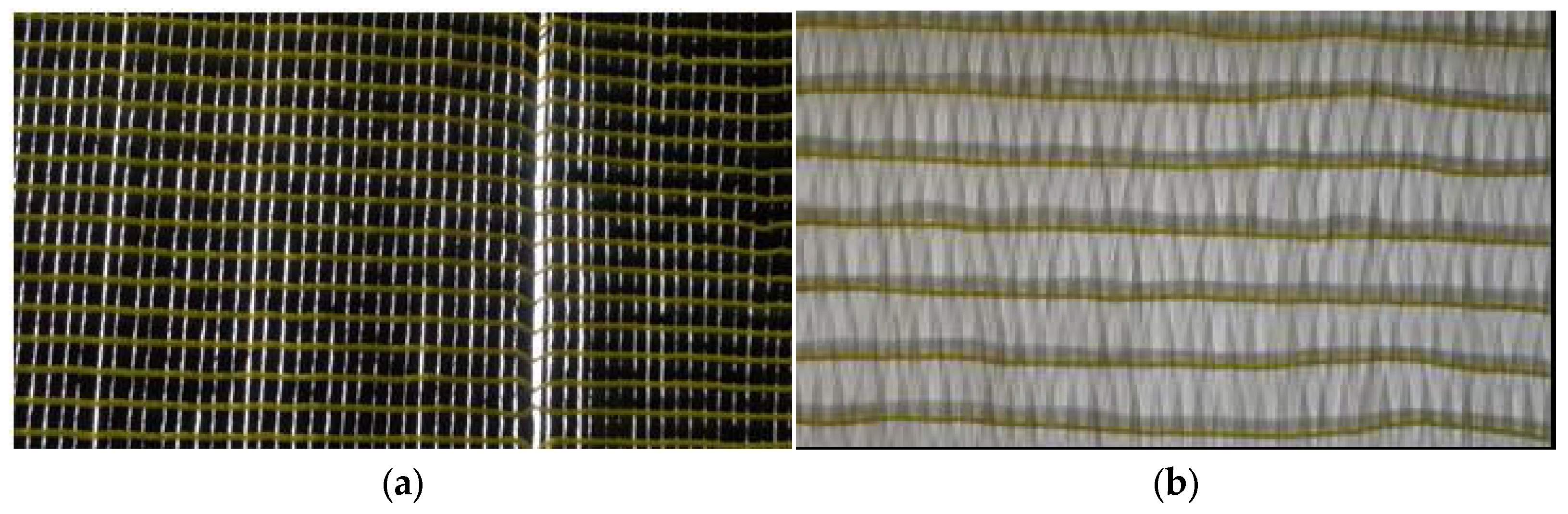

2.2.1. Fabrics and Textiles

2.2.2. Mortars

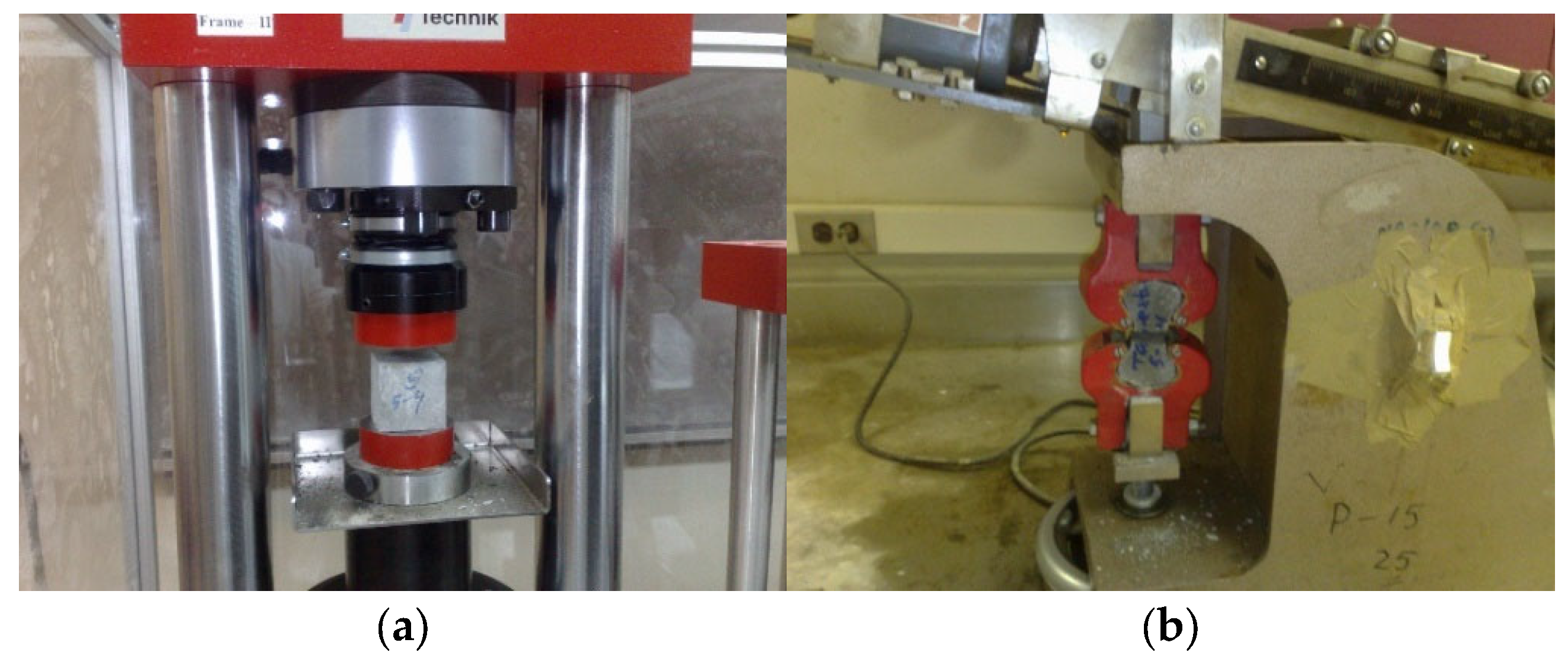

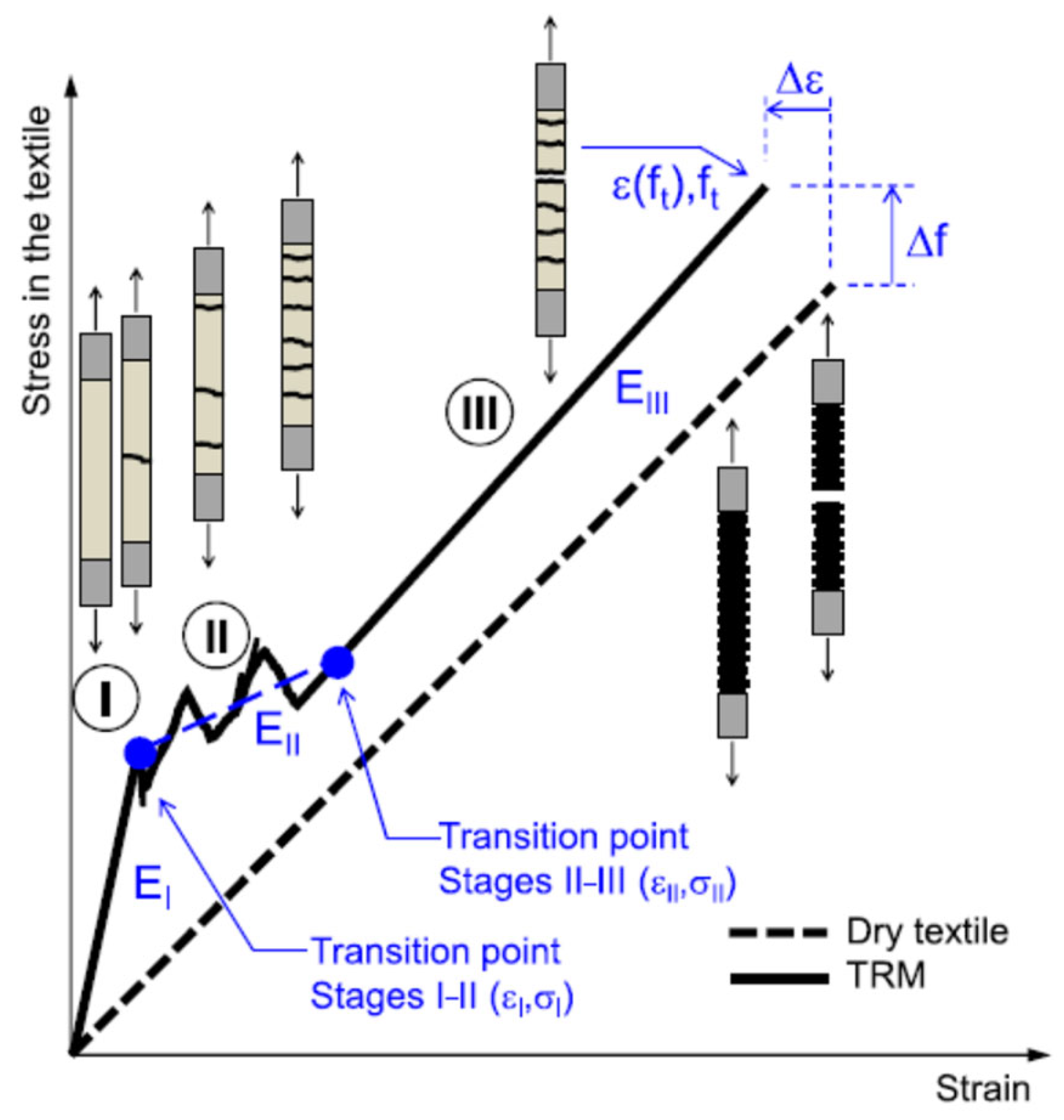

2.2.3. Composite Properties

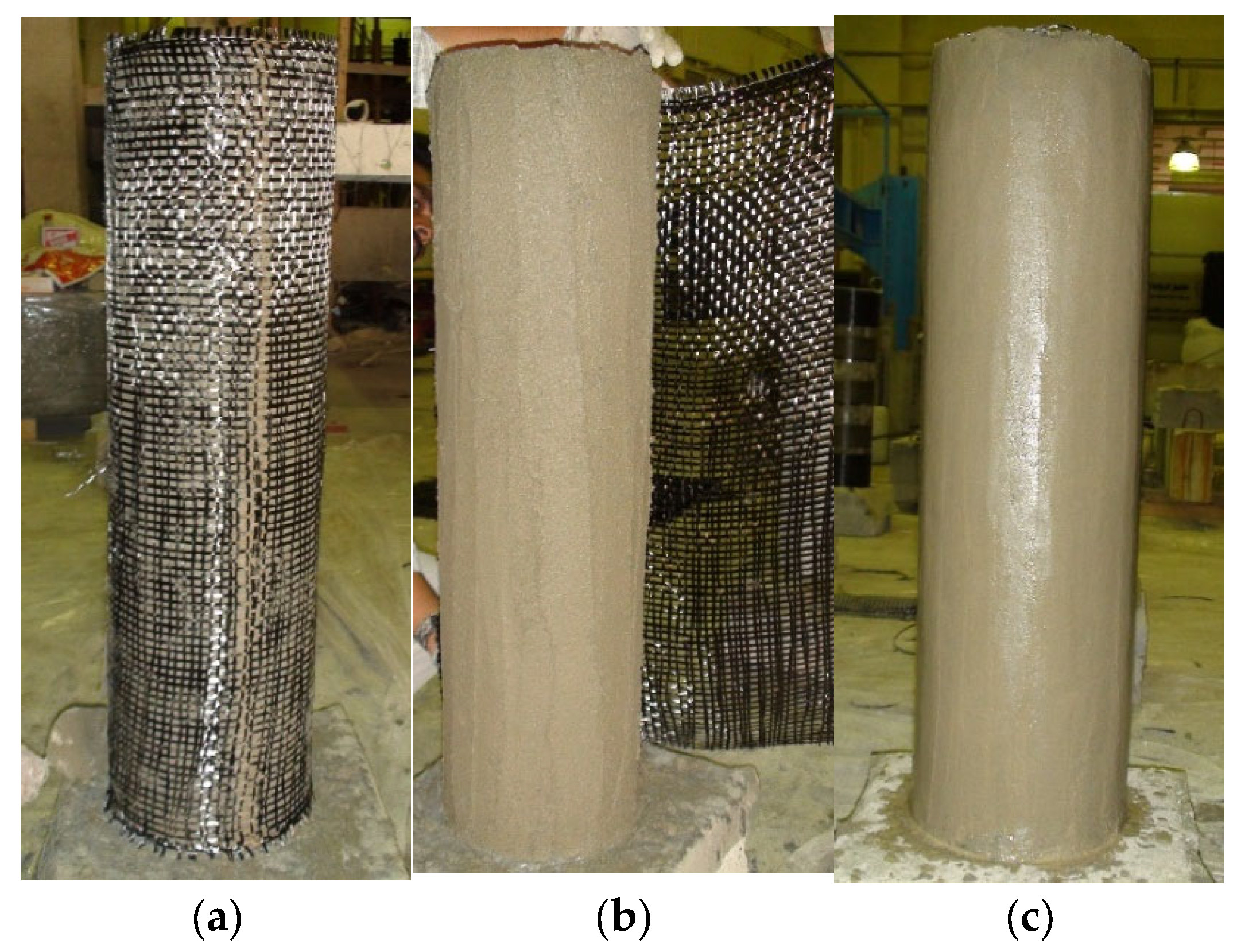

2.2.4. Installation Procedure

3. FRP Versus FRCM Composites in Confinement of RC Columns

3.1. Summary of Conducted Research

3.2. Discussion of Main Findings

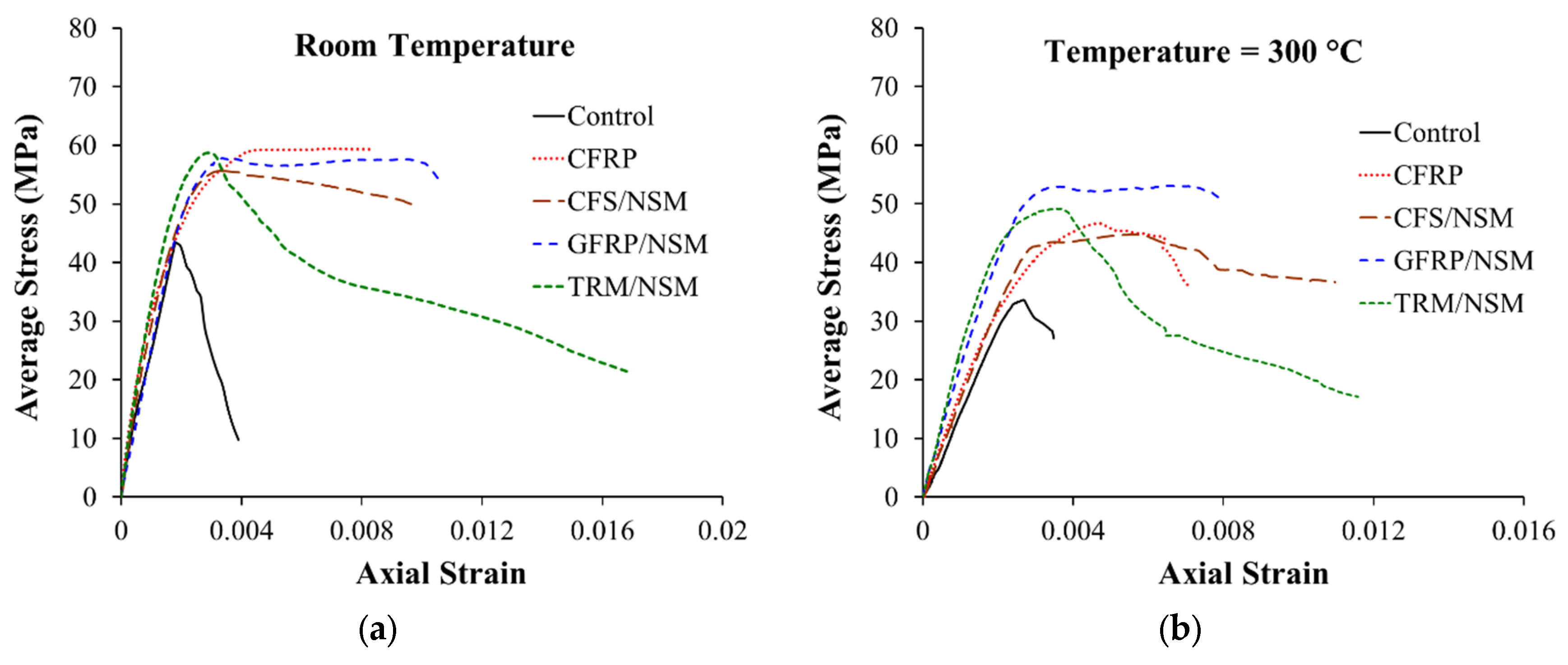

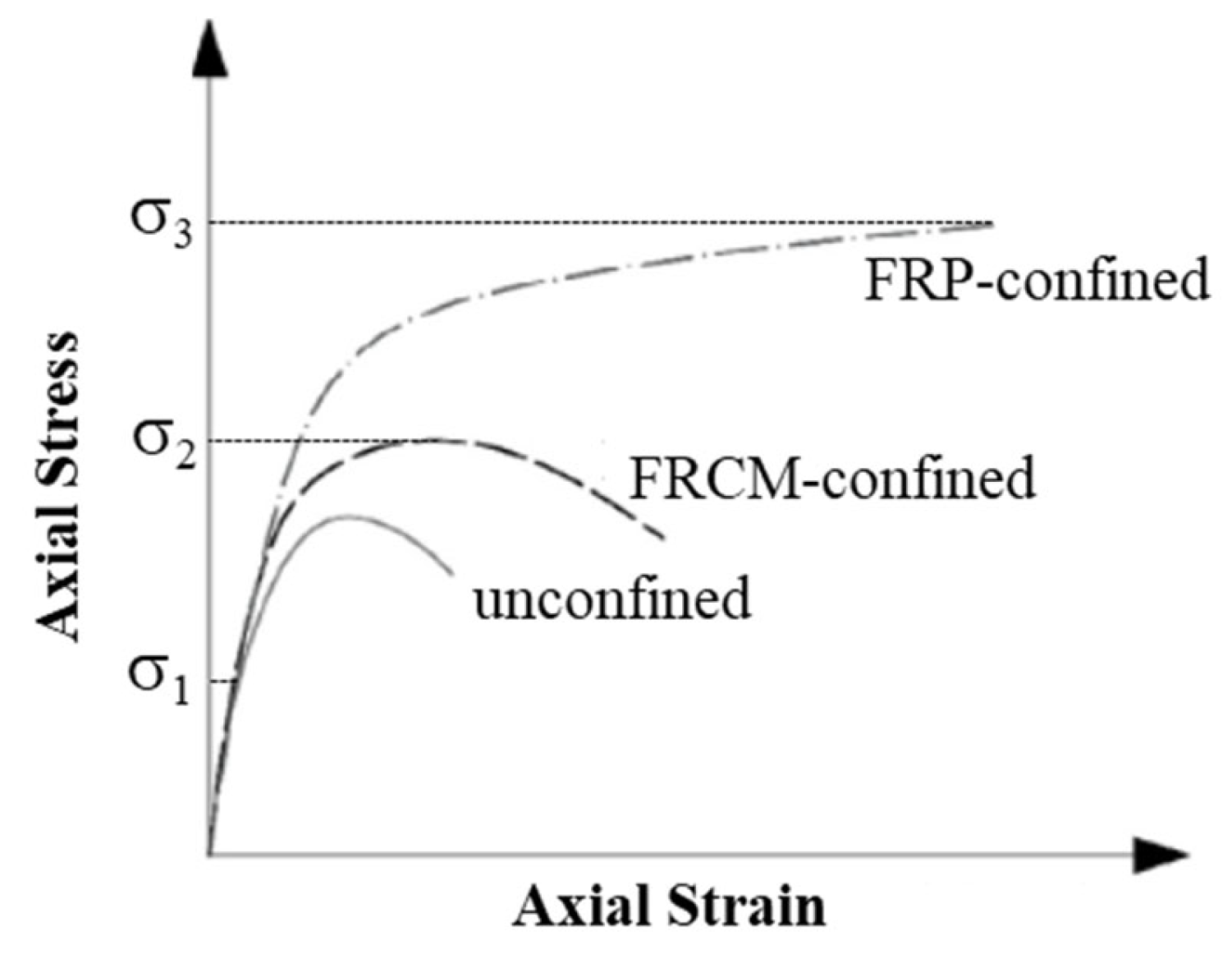

3.2.1. Overall Behavior

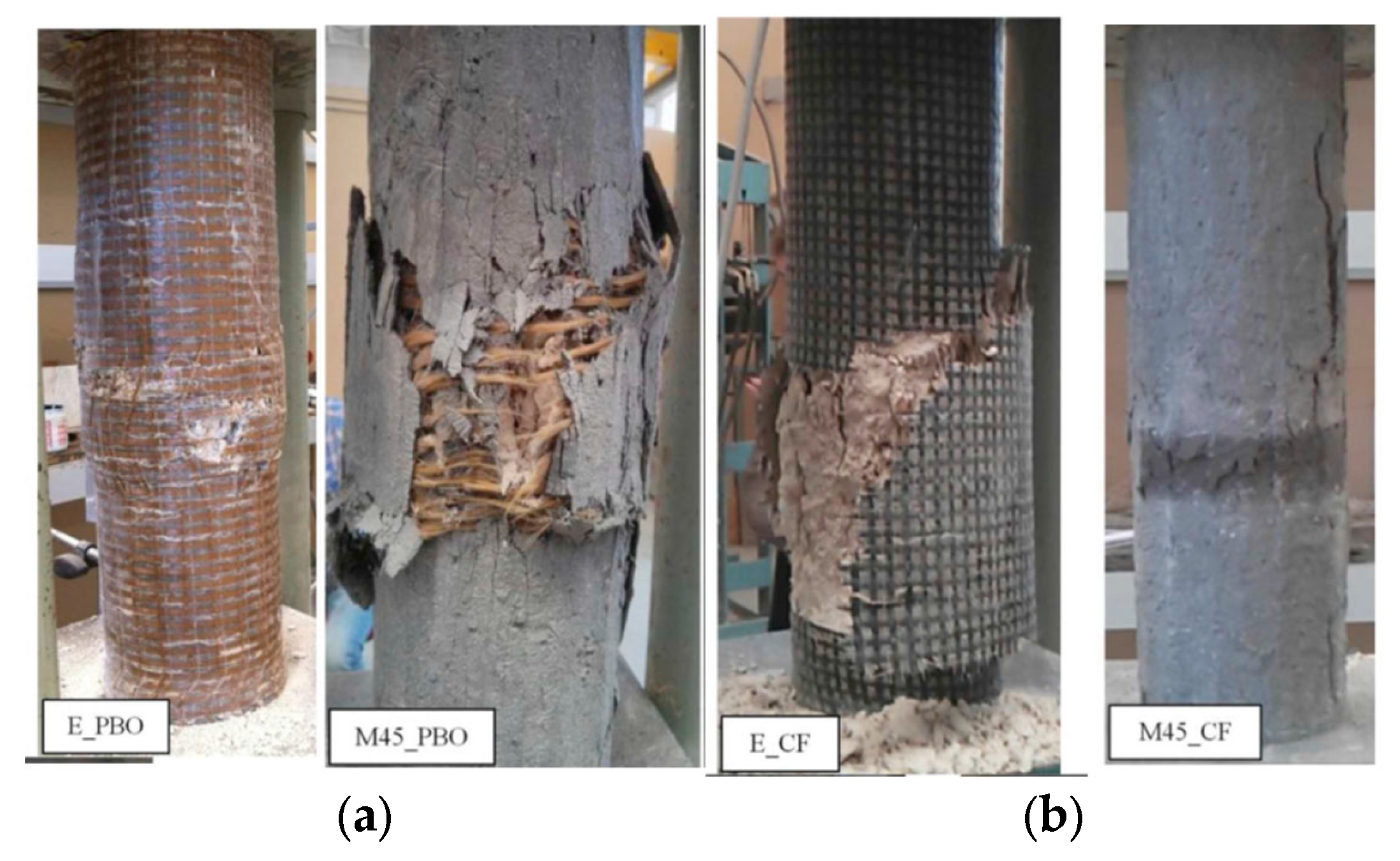

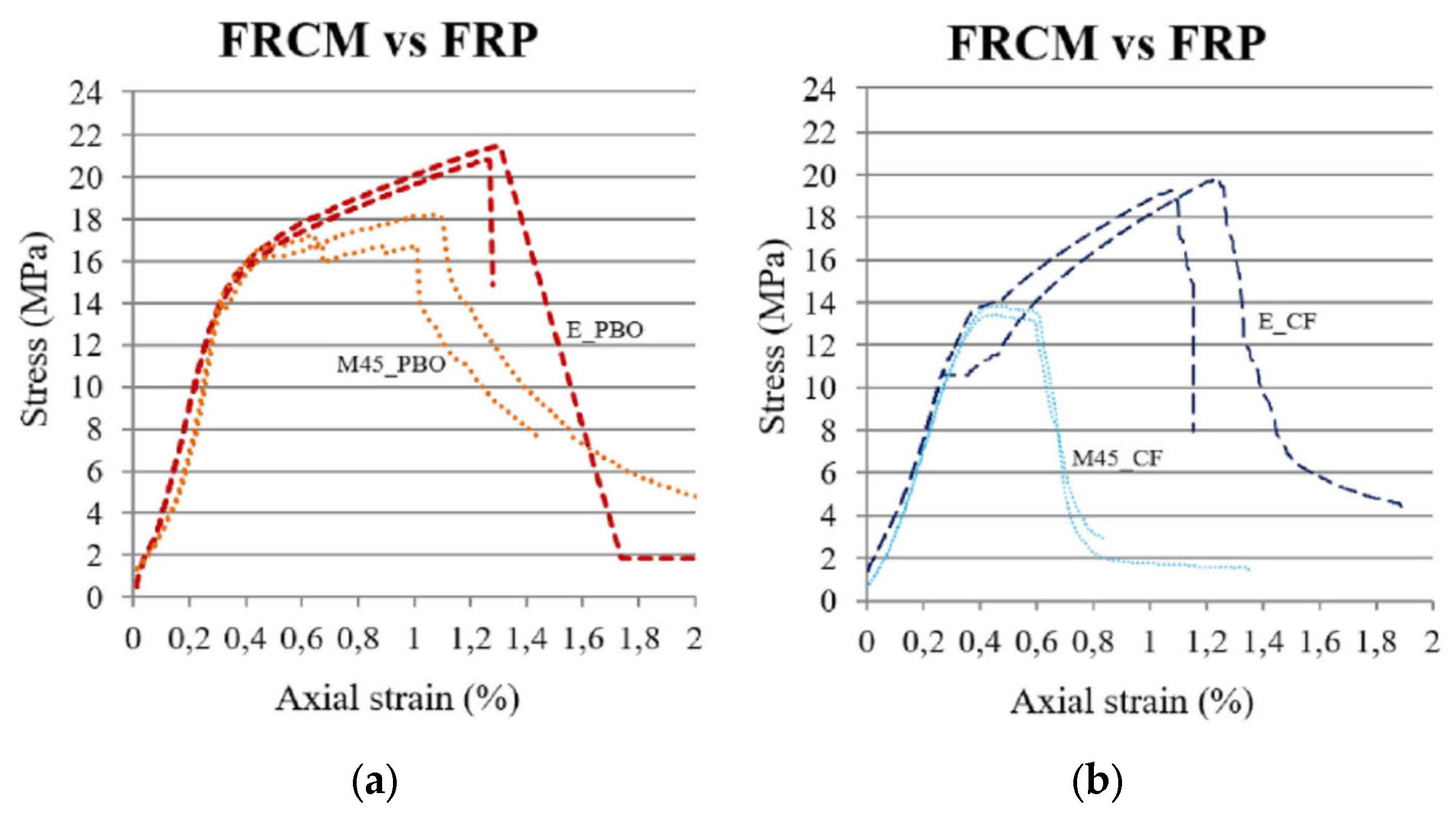

3.2.2. FRP vs. FRCM Confinement for Columns Tested at Ambient Temperature

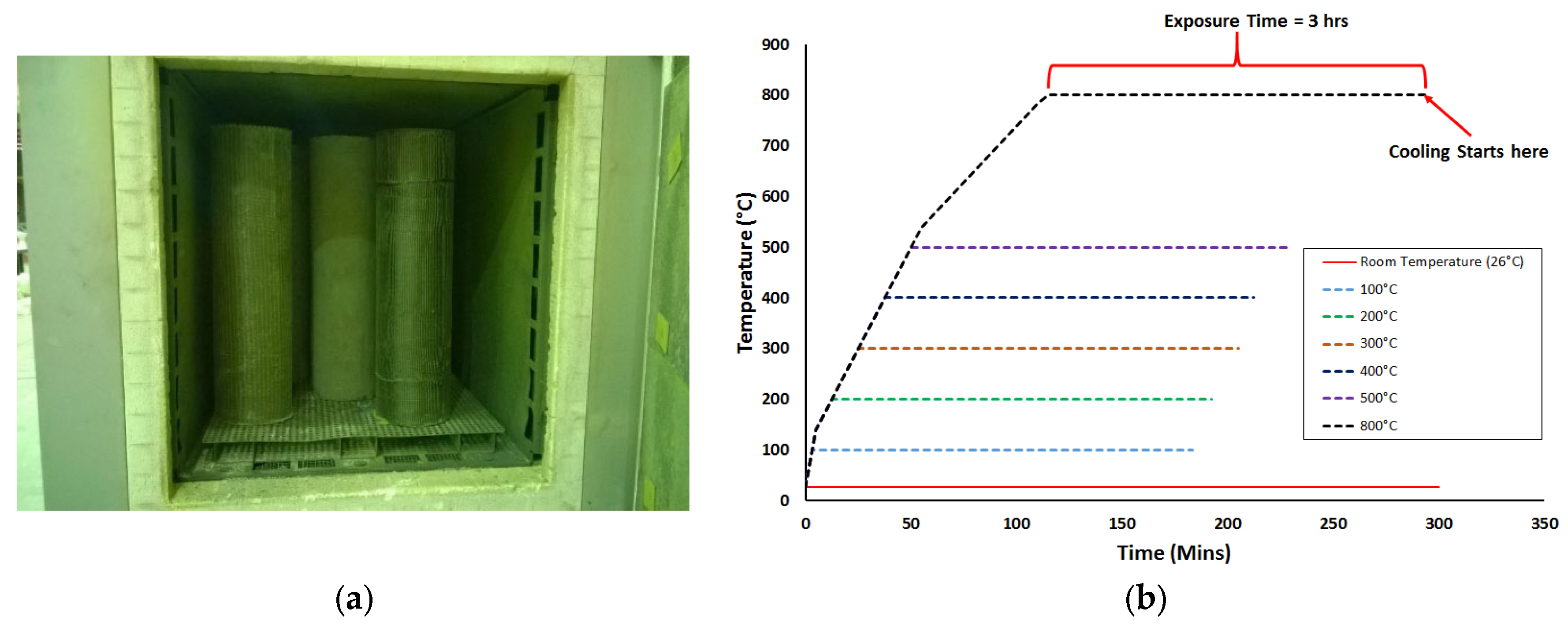

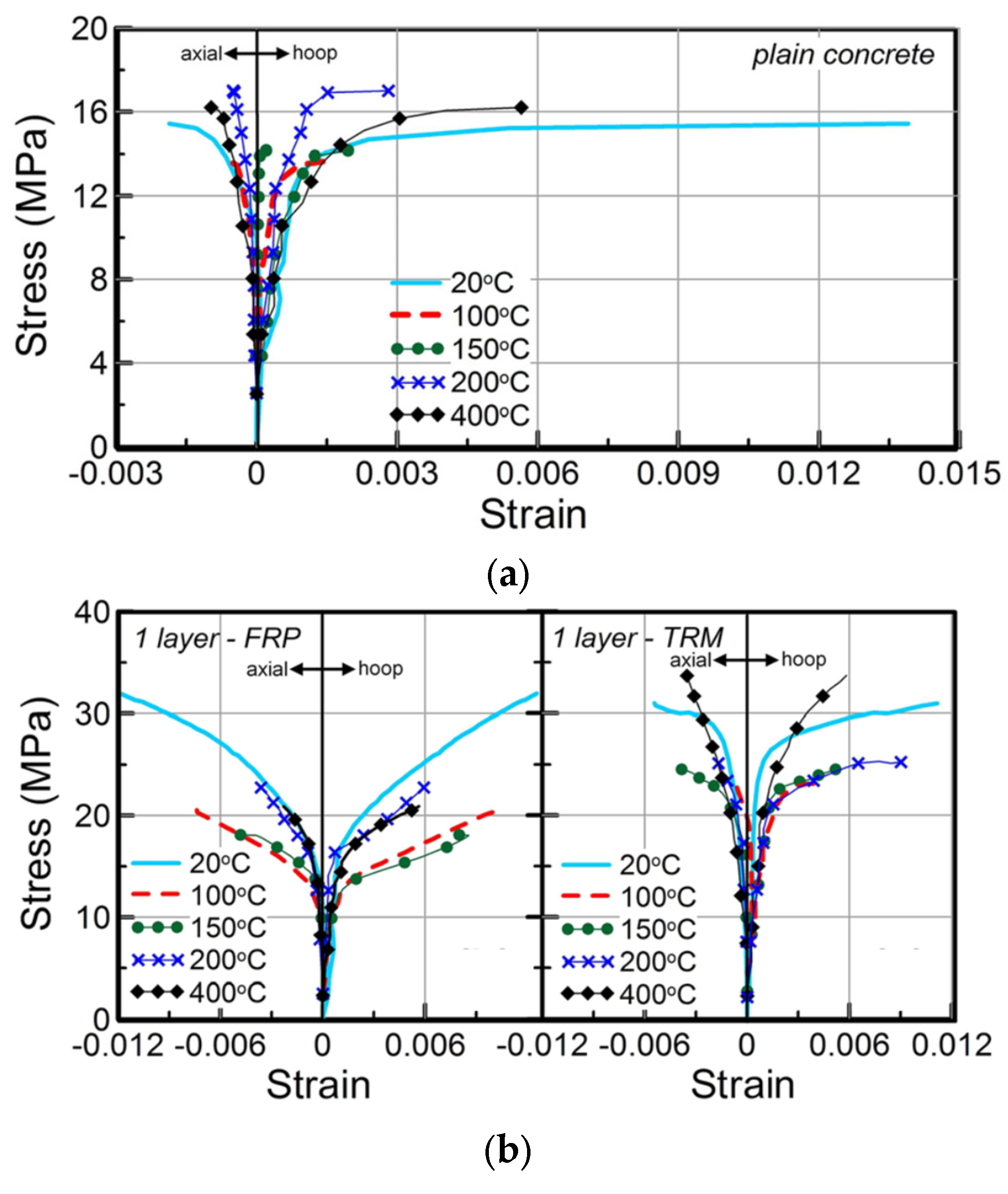

3.2.3. FRP vs. FRCM Confinement for Columns Exposed to High Temperature

- (a)

- Columns tested for residual capacity after cooling

- (b)

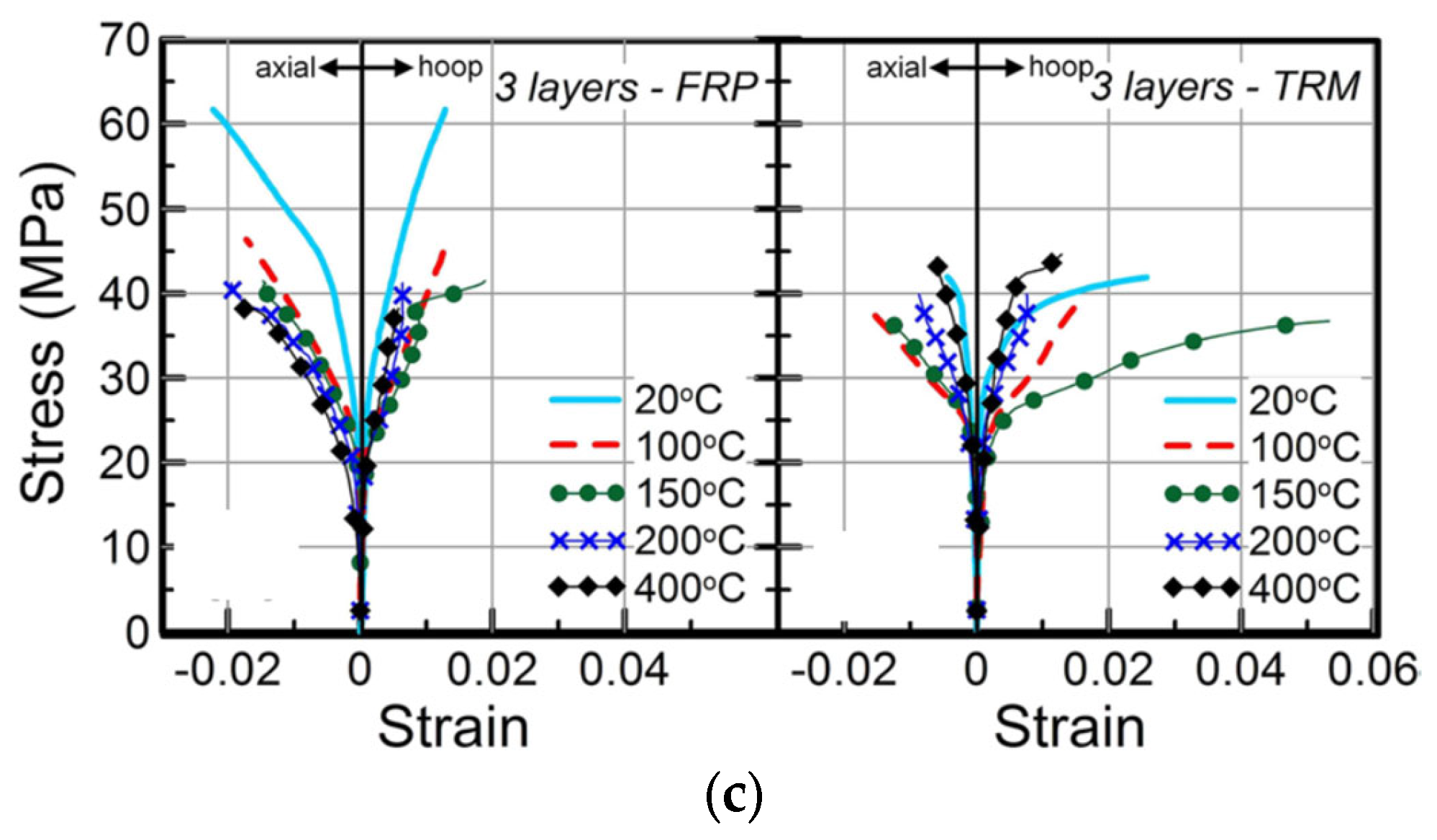

- Columns tested at elevated temperature

4. Prediction Models for FRCM-Confined Concrete Columns

5. Conclusions and Recommendations

- A considerable gain in axial compressive strength and ductility was observed for specimens confined using FRCM jackets and tested under uniaxial compression. The gain in strength was proportional to the number of layers, and was dependent on the tensile strength of mortar, which determined the ultimate mode of failure to be either fiber rupture or debonding.

- As discussed within the review report, the effectiveness of FRCM jackets was to a much lesser extent when compared with their resin-impregnated counterpart, FRP, by an order of approximately 74% for strength and 83% for ultimate strains.

- Columns upgraded with one or two FRCM layers displayed the least FRCM versus FRP effectiveness ratio, with an average ratio of 0.62. However, for the columns strengthened with three or more FRCM layers, the average effectiveness ratio was 0.86.

- The failure modes of FRCM-confined specimens were far less abrupt and less explosive compared to those of FRP-confined specimens. This could be attributed to the rupture of individual fiber bundles, which is of a slow progressing nature.

- Compared to its effectiveness at ambient temperatures, FRCM composites display good performance as a confining material even at elevated temperatures, wherein the axial capacity of concrete columns was increased, and an effectiveness ratio of 84% was maintained after exposure to a temperature of 300 °C for 3 h.

- FRP-strengthened columns performed well after their exposure to 300 °C for three hours, as they maintained from 80% to 92% of their axial capacity at room temperature. In fact, externally bonded FRP composites were capable of increasing the axial load capacity of RC columns on the condition that the epoxy resin decomposition temperature is not exceeded at the FRP level.

- In view of the design of strengthening schemes for the axial strengthening of RC columns, FRCM composites may be used. However, when designing the FRCM systems, it is recommended to use the properties of the bare textile alone, ignoring the contribution of the mortar. When it comes to the number of layers, at least three FRCM layers for the confinement of RC columns, along with polymer-modified cementitious mortar, should be used. In this case, the analytical models available in the literature (summarized in Table 7) can be directly applied to design an FRCM composite system for the axial strengthening of circular RC columns. However, reliable confinement models are not available for FRCM-strengthened square and rectangular columns. In this regard, the design guidelines used for the axial strengthening of RC columns using externally bonded FRP composites may be directly applied to FRCM composites, but with the introduction of a strength knockdown factor of 0.64 (estimated from Table 4 as m − σ, where m = mean value and σ = standard deviation).

- The behavior and performance of FRCM-strengthened RC columns need to be studied during exposure to the standard fire test as per ASTM E119 [101].

- We must conduct more experimental work on FRCM-strengthened square and rectangular columns, and, hence, devise analytical confinement models.

- The efficiency of FRCM compared with externally bonded FRP composites for strengthening wall-like RC columns under axial compression needs to be experimentally studied.

- Future research should focus on developing standardized thermal exposure protocols, including defined temperature ramp rates, hold durations, and the distinction between oven setpoints and in situ temperatures at the jacket or core.

- Further studies are also needed to examine the confinement behavior of rectangular sections with varying corner radii and anchorage configurations to optimize the stress transfer and prevent premature debonding.

- The long-term durability of FRCM systems should be evaluated under cyclic wet–dry and freeze–thaw conditions for different mortar compositions to better understand the degradation mechanisms and ensure a reliable performance in aggressive environments.

- Further experimental studies are recommended to enable a reliable comparison of the confinement effectiveness of FRP- and FRCM-confined concrete tested at elevated temperatures and after cooling.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sezen, H. Effectiveness of repair and strengthening methods for reinforced concrete columns and beam-column joints. In Structures Congress; American Society of Civil Engineers: Chicago, IL, USA, 2012; Volume 10, pp. 2015–2024. [Google Scholar]

- ACI 546.1R; Guide to Concrete Repair. American Concrete Institute (ACI) Committee 546. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- Escrig, C.; Gil, L.; Bernat-Maso, E.; Puigvert, F. Experimental and analytical study of reinforced concrete beams shear strengthened with different types of textile-reinforced mortar. Constr. Build. Mater. 2015, 83, 248–260. [Google Scholar] [CrossRef]

- Tan, K.H. Beam strengthening by external post-tensioning: Design recommendations. IES J. Part A Civ. Struct. Eng. 2016, 7, 219–228. [Google Scholar]

- Triantafillou, T.C.; Papanicolaou, C.G.; Zissimopoulos, P.; Laourdekis, T. Concrete confinement with textile reinforced mortar (TRM) jackets. ACI Struct. J. 2006, 103, 28–37. [Google Scholar]

- ACI 549.4R-13; Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures. American Concrete Institute: Farmington Hills, MI, USA, 2013.

- Available online: https://civilengineeringtotalconceptcom.wordpress.com/2021/04/15/rcc-column-jacketing/ (accessed on 20 October 2025).

- Kaplan, H.; Yilmaz, S. Seismic Strengthening of Reinforced Concrete Buildings. In Earthquake Resistant Structures—Design, Assessment and Rehabilitation; Abbas, M., Ed.; InTech: Vienna, Austria, 2012. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Almusallam, T.H.; Elsanadedy, H.M.; Iqbal, R.A. Effect of elevated temperature environments on the residual axial capacity of RC columns strengthened with different techniques. Constr. Build. Mater. 2016, 115, 345–361. [Google Scholar] [CrossRef]

- Maazoun, A.; Matthys, S.; Lecompte, D.; Vantomme, J. New technique to protect RC structures against explosions. In Proceedings of the 19th FEA Research Symposium, Mülheim an der Ruhr, Germany, 9–11 September 2019; Abstracts. Faculty of Engineering and Architecture, Ghent University: Ghent, Belgium, 2019. [Google Scholar]

- Júlio, E.N.B.S.; Branco, F.A.B. Reinforced concrete jacketing—Interface influence on cyclic loading response. ACI Struct. J. 2008, 105, 471–477. [Google Scholar]

- Bournas, D.; Triantafillou, T. Strengthening of reinforced concrete columns with near-surface-mounted FRP or stainless steel. ACI Struct. J. 2009, 106, 495–505. [Google Scholar]

- Fib Bulletin 14. In Externally Bonded FRP Reinforcement for RC Structures; Technical Report prepared by the Working Party EBR of Task Group 9.3; International Federation for Structural Concrete: Lausanne, Switzerland, 2001.

- Triantafillou, T.C.; Papanicolaou, C.G. Shear strengthening of reinforced concrete members with textile reinforced mortar (TRM) jackets. Mater. Struct. 2006, 39, 93–103. [Google Scholar] [CrossRef]

- Papanicolaou, C.G.; Triantafillou, T.C.; Papathanasiou, M.; Karlos, K. Textile reinforced mortar (TRM) versus FRP as strengthening material of URM walls: Out-of-plane cyclic loading. Mater. Struct. 2008, 41, 143–157. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Abbas, H.; Almusallam, T.H.; Al-Salloum, Y.A. Organic versus inorganic matrix composites for bond-critical strengthening applications of RC structures–State-of-the-art review. Compos. Part B Eng. 2019, 174, 106947. [Google Scholar] [CrossRef]

- Triantafillou, T. Strengthening of existing concrete structures: Concepts and structural behavior. In Textile Fibre Composites in Civil Engineering; Woodhead Publishing: Cambridge, UK, 2016; pp. 303–322. [Google Scholar]

- ACI440R; Report on fiber-reinforced polymer (FRP) reinforcement for concrete structures. American Concrete Institute (ACI) Committee 440: Farmington Hills, MI, USA, 2007.

- D’Ambrisi, A.; Focacci, F. Flexural strengthening of RC beams with cement-based composites. J. Compos. Constr. 2011, 15, 707–720. [Google Scholar] [CrossRef]

- Ombres, L. Flexural analysis of reinforced concrete beams strengthened with a cement based high strength composite material. Compos. Struct. 2011, 94, 143–155. [Google Scholar] [CrossRef]

- Si Larbi, A.; Agbossou, A.; Hamelin, P. Experimental and numerical investigations about textile-reinforced concrete and hybrid solutions for repairing and/or strengthening reinforced concrete beams. Compos. Struct. 2013, 99, 152–162. [Google Scholar] [CrossRef]

- Babaeidarabad, S.; Loreto, G.; Nanni, A. Flexural strengthening of RC beams with an externally bonded fabric-reinforced cementitious matrix. J. Compos. Constr. 2014, 18, 04014009. [Google Scholar] [CrossRef]

- Gil, L.; Escrig, C.; Bernat, E. Bending performance of concrete beams strengthened with textile reinforced mortar TRM. Key Eng. Mater. 2014, 601, 203–206. [Google Scholar] [CrossRef]

- Aljazaeri, Z.R.; Myers, J.J. Fatigue and flexural behavior of reinforced concrete beams strengthened with a fiber reinforced cementitious matrix. J. Compos. Constr. 2015, 21, 04016075. [Google Scholar] [CrossRef]

- Silfwerbrand, J.L. Failure, distress and repair of concrete structures. In Failure, Distress and Repair of Concrete Structures; Delatte, N., Ed.; CRC Press: Boca Rotan, FL, USA, 2009. [Google Scholar]

- GangaRao, H.V.S.; Vijay, P.V. Feasibility Review of FRP Materials for Structural Applications; Engineering Research & Development Center—US Army Corps of Engineers: Vicksburg, MS, USA, 2010.

- ASTM D3039/D3039M-08ASTM; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2008.

- ACI 440.2R-08; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute: Farmington Hills, MI, USA, 2008.

- Elsanadedy, H.M. Seismic Performance and Analysis of Ductile Composite-Jacketed Reinforced Concrete Bridge Columns. Ph.D. Thesis, University of California, Irvine, CA, USA, 2002. [Google Scholar]

- Available online: https://www.openpr.com/news/1952224/global-aramid-fiber-reinforced-polymer-afrp-market-huge (accessed on 23 October 2025).

- Johnson, J.W. Resin matrices and their contribution to composite properties. Philos. Trans. R. Soc. Lond. 1980, A294, 487–494. [Google Scholar]

- ACI 503.4; Proposed ACI Standard 503.4: Standard Specification for Repairing Concrete with Epoxy Mortars. American Concrete Institute: Farmington Hills, MI, USA, 1978.

- Papanicolaou, C.G.; Triantafillou, T.C.; Papathanasiou, M.; Karlos, K. Textile reinforced mortar (TRM) versus FRP as strengthening material of URM walls: In-plane cyclic loading. Mater. Struct. 2007, 40, 1081–1097. [Google Scholar] [CrossRef]

- Bournas, D.A.; Triantafillou, T.C.; Zygouris, K.; Stavropoulos, F. Textile-reinforced mortar versus FRP jacketing in seismic retrofitting of RC columns with continuous or lap-spliced deformed bars. J. Compos. Constr. 2009, 13, 360–371. [Google Scholar] [CrossRef]

- Colajanni, P.; Fossetti, M.; MacAluso, G. Effects of confinement level, cross-section shape and corner radius on the cyclic behavior of CFRCM confined concrete columns. Constr. Build. Mater. 2014, 55, 379–389. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Papanicolaou, C.G. Textile reinforced mortars (TRM) versus fibre reinforced polymers (FRP) as strengthening materials of concrete structures. In Proceedings of the Seventh International Symposium of the Fiber-Reinforced Polymer Reinforcement for Reinforced Concrete Structures (FRPRCS), Kansas City, MO, USA, 6–9 November 2005; pp. 99–118. [Google Scholar]

- Al-Salloum, Y.A.; Siddiqui, N.A.; Elsanadedy, H.M.; Abadel, A.A.; Aqel, M.A. Textile-reinforced mortar versus FRP as strengthening material for seismically deficient RC beam-column joints. J. Compos. Constr. 2011, 15, 920–933. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Siddiqui, N.A.; Elsanadedy, H.M.; Abadel, A.A.; Aqel, M.A. Experimental and numerical study for the shear strengthening of reinforced concrete beams using textile-reinforced mortar. J. Compos. Constr. 2012, 16, 74–90. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Almusallam, T.H.; Alsayed, S.H.; Al-Salloum, Y.A. Flexural strengthening of RC beams using textile reinforced mortar—Experimental and numerical study. Compos. Struct. 2013, 97, 40–55. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Al-Salloum, Y.A.; Alrubaidi, M.A.; Almusallam, T.H.; Siddiqui, N.A.; Abbas, H. Upgrading of precast RC beam-column joints using innovative FRP/steel hybrid technique for progressive collapse prevention. Constr. Build. Mater. 2021, 268, 121130. [Google Scholar] [CrossRef]

- ICC Evaluation Service. AC434—Acceptance criteria for masonry and concrete strengthening using fiber-reinforced cementitious matrix (FRCM) composite systems. J. Chem. Inf. Model. 2013, 53. [Google Scholar]

- Loreto, G.; Leardini, L.; Arboleda, D.; Nanni, A. Performance of RC slab-type elements strengthened with fabric-reinforced cementitious-matrix composites. J. Compos. Constr. 2013, 18, A4013003. [Google Scholar] [CrossRef]

- Yao, Y.; Zhu, D.; Zhang, H.; Li, G.; Mobasher, B.; Asce, M. Tensile behaviors of basalt, carbon, glass, and aramid fabrics under various strain rates. J. Mater. Civ. Eng. 2016, 28, 04016081. [Google Scholar] [CrossRef]

- Michels, J.; Zwicky, D.; Scherer, J.; Harmanci, Y.E.; Motavalli, M. Structural strengthening of concrete with fiber reinforced cementitious matrix (FRCM) at ambient and elevated temperature—Recent investigations in Switzerland. Adv. Struct. Eng. 2014, 17, 1785–1800. [Google Scholar] [CrossRef]

- ASTM C109/C109M; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). American Society for Testing and Materials: West Conshohocken, PA, USA, 2008.

- ASTM C190; Method of Test for Tensile Strength of Hydraulic Cement Mortars. American Society for Testing and Materials: West Conshohocken, PA, USA, 1985.

- de Felice, G.; D’Antino, T.; De Santis, S.; Meriggi, P.; Roscini, F. Lessons Learned on the Tensile and Bond Behavior of Fabric Reinforced Cementitious Matrix (FRCM) Composites. Front. Built Environ. 2020, 6. [Google Scholar] [CrossRef]

- Arboleda, D.; Carozzi, F.G.; Nanni, A.; Poggi, C. Testing procedures for the uniaxial tensile characterization of fabric-reinforced cementitious matrix composites. J. Compos. Constr. 2016, 20, 04015063. [Google Scholar] [CrossRef]

- Alsayed, S.H.; Al-Salloum, Y.A.; Almusallam, T.H.; Khan, M.I. Classification and Testing Performance of Concrete Repair Materials for Durable Repair Under Local Environmental Conditions; Final Report, Applied National Research Program, Research No. DSR-AR-2-42; King Saud University: Riyadh, Saudi Arabia, 2008. [Google Scholar]

- Caggegi, C.; Carozzi, F.G.; De Santis, S.; Fabbrocino, F.; Focacci, F.; Hojdys, L.; Lanoye, E.; Zuccarino, L. Experimental analysis on tensile and bond properties of PBO and aramid fabric reinforced cementitious matrix for strengthening masonry structures. Compos. Part B 2017, 127, 175–195. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Bellini, A.; D’Antino, T.; de Felice, G.; Focacci, F.; Hojdys, L.; Laghi, L.; Lanoye, E.; Micelli, F.; Panizza, M.; et al. Experimental investigation of tensile and bond properties of Carbon-FRCM composites for strengthening masonry elements. Compos. Part B 2017, 128, 100–119. [Google Scholar] [CrossRef]

- De Santis, S.; Carozzi, F.G.; de Felice, G.; Poggi, C. Test methods for textile reinforced mortar systems. Compos. Part B 2017, 127, 121–132. [Google Scholar] [CrossRef]

- De Santis, S.; de Felice, G. Tensile behaviour of mortar-based composites for externally bonded reinforcement systems. Compos. Part B 2015, 68, 401–413. [Google Scholar] [CrossRef]

- Ebead, U.; Shrestha, K.C.; Afzal, M.S.; El Refai, A.; Nanni, A. Effectiveness of fabric- reinforced cementitious matrix in strengthening reinforced concrete beams. J. Compos. Constr. 2015, 1, 1–14. [Google Scholar] [CrossRef]

- Billows, T.N.S. Flexural Strengthening of Reinforced Concrete Beams with Fabric Reinforced Cementitious Mortar: Effect of Reinforcement Ratios. Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2016. [Google Scholar]

- Wu, H.C.; Sun, P. Fiber Reinforced Cement Based Composite Sheets for Structural Retrofit. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures (BBFS 2005), Hong Kong, China, 7–9 December 2005; Chen, J.F., Teng, J.G., Eds.; International Institute for FRP in Construction: Hong Kong, China; pp. 343–348. [Google Scholar]

- Bournas, D.A.; Lontou, P.V.; Papanicolaou, C.G.; Triantafillou, T.C. Textile-reinforced mortar versus fiber-reinforced polymer confinement in reinforced concrete columns. ACI Struct. J. 2007, 104, 740–748. [Google Scholar]

- Di Ludovico, M.; Prota, A.; Manfredi, G. Structural upgrade using basalt fibers for concrete confinement. J. Compos. Constr. 2010, 14, 541–552. [Google Scholar] [CrossRef]

- De Caso y Basalo, F.; Matta, F.; Nanni, A. Fiber reinforced cement-based composite system for concrete confinement. Constr. Build. Mater. 2012, 32, 55–65. [Google Scholar] [CrossRef]

- Donnini, J.; Spagnuolo, S.; Corinaldesi, V. A comparison between the use of FRP, FRCM and HPM for concrete confinement. Compos. Part B Eng. 2019, 160, 586–594. [Google Scholar] [CrossRef]

- Cerniauskas, G.; Tetta, Z.; Bournas, D.A.; Bisby, L.A. Concrete confinement with TRM versus FRP jackets at elevated temperatures. Mater. Struct. 2020, 53, 58. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Khabaznia, M.; Tahmouresi, B. Effect of organic and inorganic matrix on the behavior of FRP-wrapped concrete cylinders. J. Rehabil. Civ. Eng. 2016, 4, 52–66. [Google Scholar]

- Cascardi, A.; Longo, F.; Micelli, F.; Aiello, M.A. Compressive strength of confined column with Fiber Reinforced Mortar (FRM): New design-oriented-models. Constr. Build. Mater. 2017, 156, 387–401. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Elsanadedy, H.M.; Abadel, A.A. Behavior of FRP-confined concrete after high temperature exposure. Constr. Build. Mater. 2011, 25, 838–850. [Google Scholar] [CrossRef]

- Elsanadedy, H.; Almusallam, T.; Al-Salloum, Y.; Iqbal, R. Effect of high temperature on structural response of reinforced concrete circular columns strengthened with fiber reinforced polymer composites. J. Compos. Mater. 2017, 51, 333–355. [Google Scholar] [CrossRef]

- Abbas, H.; Al-Salloum, Y.A.; Elsanadedy, H.M.; Almusallam, T.H. ANN models for prediction of residual strength of HSC after exposure to elevated temperature. Fire Saf. J. 2019, 106, 13–28. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Gao, Y. Composite jacketed concrete under uniaxial compression—Verification of simple design equations. J. Mater. Civ. Eng. 1997, 9, 185–193. [Google Scholar] [CrossRef]

- Samaan, M.; Mirmiran, A.; Shahawy, M. Model of concrete confined by fiber composites. J. Struct. Eng. 1998, 124, 1025–1031. [Google Scholar] [CrossRef]

- Miyauchi, K.; Inoue, S.; Kuroda, T.; Kobayashi, A. Strengthening effects of concrete columns with carbon fiber sheet. Trans. Jpn. Concr. Inst. 1999, 21, 143–150. [Google Scholar]

- Toutanji, H. Stress-strain characteristics of concrete columns externally confined with advanced fiber composite sheets. ACI Mater. J. 1999, 96, 397–404. [Google Scholar] [CrossRef]

- Saafi, M.; Toutanji, H.A.; Li, Z. Behavior of concrete columns confined with fiber reinforced polymer tubes. ACI Mater. J. 1999, 96, 500–509. [Google Scholar] [CrossRef]

- Au, C. Behavior of FRP-Confined Concrete. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2001. [Google Scholar]

- Teng, J.G.; Lam, L.; Chen, J.F. Strength models for fiber-reinforced plastic-confined concrete. J. Struct. Eng. 2002, 128, 612–623. [Google Scholar]

- De Lorenzis, L.; Tepfers, R. Comparative study of models on confinement of concrete cylinders with fiber-reinforced polymer composites. J. Compos. Constr. 2003, 7, 219–237. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.-G. Design-oriented stress–strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.-G. Design-oriented stress–strain model for FRP-confined concrete in rectangular columns. J. Reinf. Plast. Compos. 2003, 22, 1149–1169. [Google Scholar] [CrossRef]

- Gamage, J.C.P.H.; Wong, M.B.; Al-Mahadi, R. Performance of CFRP strengthened concrete members under elevated temperatures. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures (BBFS 2005), Hong Kong, China, 7–9 December 2005. [Google Scholar]

- Wu, G.; Lü, Z.T.; Wu, Z.S. Strength and ductility of concrete cylinders confined with FRP composites. Constr. Build. Mater. 2006, 20, 799–805. [Google Scholar] [CrossRef]

- Youssef, M.N.; Feng, M.Q.; Mosallam, A.S. Stress–strain model for concrete confined by FRP composites. Compos. Part B Eng. 2007, 38, 614–628. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Almusallam, T.H.; Alsayed, S.H.; Al-Salloum, Y.A. Experimental and FE study on RC one-way slabs upgraded with FRP composites. KSCE J. Civ. Eng. 2015, 19, 1024–1040. [Google Scholar] [CrossRef]

- Nisticò, N.; Monti, G. RC square sections confined by FRP: Analytical prediction of peak strength. Compos. Part B Eng. 2013, 45, 127–137. [Google Scholar] [CrossRef]

- Pour, A.F.; Shayanfar, J.; Keshtegar, B. Simplified design-oriented axial stress–strain model for FRP-confined normal- and high-strength concrete. Eng. Struct. 2018, 175, 501–513. [Google Scholar] [CrossRef]

- Djafar-Henni, I.; Kassoul, A. Stress–strain model of confined concrete with Aramid FRP wraps. Constr. Build. Mater. 2018, 186, 1016–1030. [Google Scholar] [CrossRef]

- Li, P.; Wei, Y.; Li, G. Cyclic stress–strain model for FRP-confined concrete considering post-peak softening. Constr. Build. Mater. 2018, 172, 1–13. [Google Scholar] [CrossRef]

- Guo, Y.-C.; Gao, W.-Y.; Zeng, J.-J.; Duan, Z.-J.; Ni, X.-Y.; Peng, K.-D. Compressive behavior of FRP ring-confined concrete in circular columns: Effects of specimen size and a new design-oriented stress-strain model. Constr. Build. Mater. 2019, 201, 350–368. [Google Scholar] [CrossRef]

- Bai, Y.-L.; Dai, J.-G.; Mohammadi, M.; Lin, G.; Mei, S.-J. Stiffness-based design-oriented compressive stress-strain model for large-rupture-strain (LRS) FRP-confined concrete. Compos. Struct. 2019, 223, 110953. [Google Scholar] [CrossRef]

- Lin, G.; Teng, J.-G. Advanced stress–strain model for FRP-confined concrete in square columns. Compos. Part B Eng. 2020, 197, 108152. [Google Scholar] [CrossRef]

- Saberi, H.; Miehe, C.; Kaliske, M. FRP-confined concrete model based on damage-plasticity and phase-field approaches. Comput. Struct. 2020, 239, 106285. [Google Scholar] [CrossRef]

- Yang, J.-Q.; Feng, P. Analysis-oriented models for FRP-confined concrete: 3D interpretation and general methodology. Eng. Struct. 2020, 216, 110749. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.-F. Axial strength of eccentrically loaded FRP-confined short concrete columns. Polymers 2020, 12, 1261. [Google Scholar] [CrossRef]

- Bai, Y.-L.; Mei, S.-J.; Li, P.; Xu, J. Cyclic stress-strain model for large-rupture strain fiber-reinforced polymer (LRS FRP)-confined concrete. J. Build. Eng. 2021, 42, 102459. [Google Scholar] [CrossRef]

- Keshtegar, B.; Gholampour, A.; Thai, D.K.; Taylan, O.; Trung, N.T. Hybrid regression and machine learning model for predicting ultimate condition of FRP-confined concrete. Compos. Struct. 2021, 262, 113644. [Google Scholar] [CrossRef]

- Cao, Y.; Zhao, G.; Zhang, Y.; Hou, C.; Mao, L. Unified Stress-Strain Model of FRP-Confined Square and Circle Rubber Concrete Columns. Materials 2022, 15, 1832. [Google Scholar] [CrossRef]

- Shayanfar, M.A.; Hosseini, S.M.; Farhadi, F. Stress–strain model for FRP-confined circular concrete columns. J. Compos. Constr. 2024, 28, 04023065. [Google Scholar] [CrossRef]

- Tariq, M.; Ahmed, S.; Khan, R. A theoretical model for predicting axial compressive behavior of FRP-confined concrete. MATEC Web Conf. 2024, 240, 01035. [Google Scholar] [CrossRef]

- Yang, J.; Feng, P.; Liu, X. Axial stress–strain model for concrete in partially FRP-confined columns. Constr. Build. Mater. 2024, 382, 129876. [Google Scholar]

- Di, Y.; Lin, S.; Zhao, Y.-G. Components interaction mechanism and strength of axially loaded FRP-confined concrete stub columns from energy path perspective. In Structures; Elsevier: Amsterdam, The Netherlands, 2025; Volume 71, p. 107981. [Google Scholar] [CrossRef]

- Wu, L.; Chen, J.; Zhang, Q. Research on stress–strain model of FRP-confined concrete. Buildings 2025, 15, 2716. [Google Scholar] [CrossRef]

- Ombres, L. Concrete confinement with a cement-based high-strength composite material. Compos. Struct. 2014, 109, 294–304. [Google Scholar] [CrossRef]

- Ombres, L.; Mazzuca, F. Confined concrete elements with cement-based composites: Confinement effectiveness and prediction models. J. Compos. Constr. 2017, 21, 04017032. [Google Scholar] [CrossRef]

- ASTM E119-01; Standard Methods of Fire Test of Building Construction and Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2001.

| Criterion | Performance Level of Different Types of Fibers * | ||

|---|---|---|---|

| E-glass | Aramid | Carbon | |

| Compressive strength | G | I | VG |

| Tensile strength | VG | VG | VG |

| Long-term response | A | G | VG |

| Modulus of elasticity | A | G | VG |

| Fatigue performance | A | G | VG |

| Resistance to alkaline environment | I | G | VG |

| Unit weight | A | E | G |

| Cost | VG | A | A |

| Mortar Type | Trade Name | Supplier | 28-Day Compressive Strength (MPa) | 28-Day Tensile Strength (MPa) | |

|---|---|---|---|---|---|

| Lab | Data Sheet | Lab | |||

| Polymer-modified cementitious mortar | Renderoc S | Fosam | 62.3 | 55.0 | 6.90 |

| SikaRep | Sika | 56.4 | 45.0 | 3.40 | |

| Mapegrout Thixotropic | Mapei | 66.0 | 60.0 | 3.94 | |

| Textile Used | EI (GPa) | EII (GPa) | EIII (GPa) | Ultimate Tensile Strength, ft (MPa) | Ultimate Tensile Strain, εt (%) |

|---|---|---|---|---|---|

| Carbon | 460–1575 | 68 | 50–186 | 970–1500 | 0.74–1.8 |

| Glass | 260–1310 | 16–71 | 55–110 | 870–1980 | 0.69–1.92 |

| PBO | 1180–1805 | 76 | 120–220 | 1550–3320 | 1.4–1.8 |

| Reference | Shape of Column | Control Column | FRCM-Strengthened Column | FRP-Strengthened Column | FRCM/FRP | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Col ID | (MPa) | Col ID | (MPa) | Failure Mode | Col ID | (MPa) | Failure Mode | Effectiveness Ratio | Ultimate Strain Ratio | ||||||

| [56] | C | - | 54.0 | - | 2 | 100 | 0.0295 | RP | - | 2 | 105 | 0.0394 | RP | 0.90 | 0.75 |

| [36] | C | B_C | 21.8 | B_MII2 | 2 | 27.4 | 0.0098 | RP | B_R2 | 2 | 33.5 | 0.0167 | RP | 0.48 | 0.59 |

| C | B_C | 21.8 | B_MII3 | 3 | 32.4 | 0.0108 | RP | B_R3 | 3 | 41.9 | 0.0255 | RP | 0.53 | 0.42 | |

| S | C_C | 14.3 | C_MII2 | 2 | 20.0 | 0.0118 | RP | C_R2 | 2 | 18.4 | 0.0124 | RP | 1.38 | 0.95 | |

| S | C_C | 14.3 | C_MII4 | 4 | 21.6 | 0.0176 | RP | C_R4 | 4 | 21.0 | 0.0203 | RP | 1.09 | 0.87 | |

| [57] | S | U_C | 15.3 | U_M4 | 4 | 26.6 | 0.0076 | RP | U_R2 | 2 | 30.6 | 0.0082 | RP | 0.74 | 0.93 |

| S | U_C | 15.3 | U_M6 | 6 | 31.6 | 0.0106 | RP | U_R3 | 3 | 34.7 | 0.0128 | RP | 0.84 | 0.83 | |

| S | s200_C | 22.9 | s200_M4 | 4 | 34.2 | 0.0112 | RP | s200_R2 | 2 | 37.3 | 0.0128 | RP | 0.79 | 0.88 | |

| S | s200_C | 22.9 | s200_M6 | 6 | 36.0 | 0.0133 | RP | s200_R3 | 3 | 44.7 | 0.0148 | RP | 0.60 | 0.90 | |

| S | s100_C | 24.1 | s100_M4 | 4 | 38.3 | 0.0126 | RP | s100_R2 | 2 | 42.0 | 0.0132 | RP | 0.79 | 0.95 | |

| S | s100_C | 24.1 | s100_M6 | 6 | 39.9 | 0.0150 | RP | s100_R3 | 3 | 45.2 | 0.0172 | RP | 0.75 | 0.87 | |

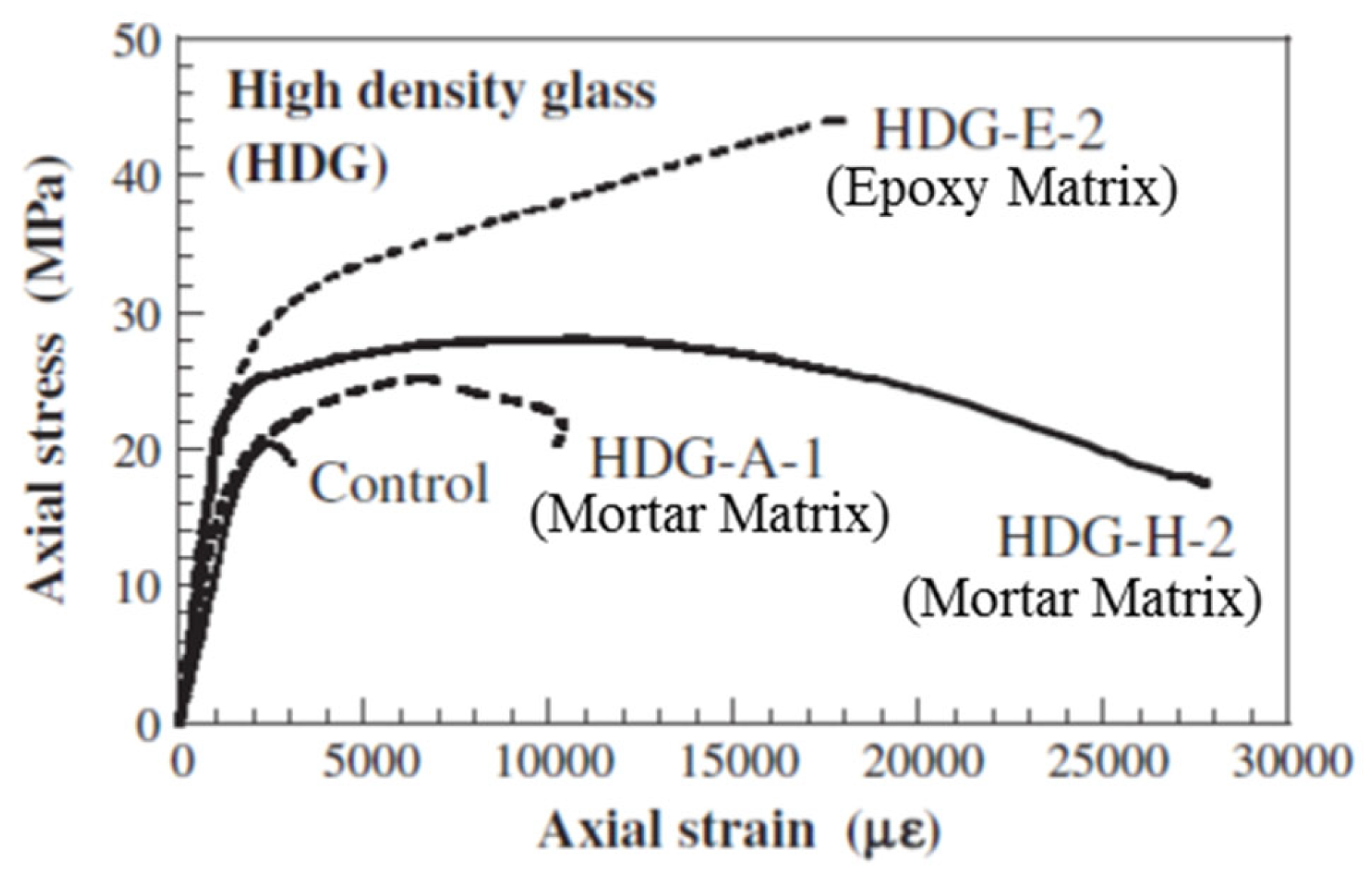

| [59] | C | Control | 20.4 | LDG-A | 2 | 26.9 | 0.0090 | DB | LDG-E | 2 | 36.7 | 0.0228 | RP | 0.40 | 0.39 |

| C | Control | 20.4 | LDG-H | 2 | 30.0 | 0.0079 | DB | LDG-E | 2 | 36.7 | 0.0228 | RP | 0.59 | 0.35 | |

| C | Control | 20.4 | HDG-A | 2 | 24.5 | 0.0135 | DB | HDG-E | 2 | 40.8 | 0.0157 | RP | 0.20 | 0.86 | |

| C | Control | 20.4 | HDG-H | 2 | 30.0 | 0.0075 | DB | HDG-E | 2 | 40.8 | 0.0157 | RP | 0.47 | 0.48 | |

| C | Control | 20.4 | BGP-A | 2 | 28.8 | 0.0027 | DB | BGP-E | 2 | 33.5 | 0.0177 | RP | 0.64 | 0.15 | |

| C | Control | 20.4 | BGP-H | 2 | 31.8 | 0.0068 | DB | BGP-E | 2 | 33.5 | 0.0177 | RP | 0.87 | 0.38 | |

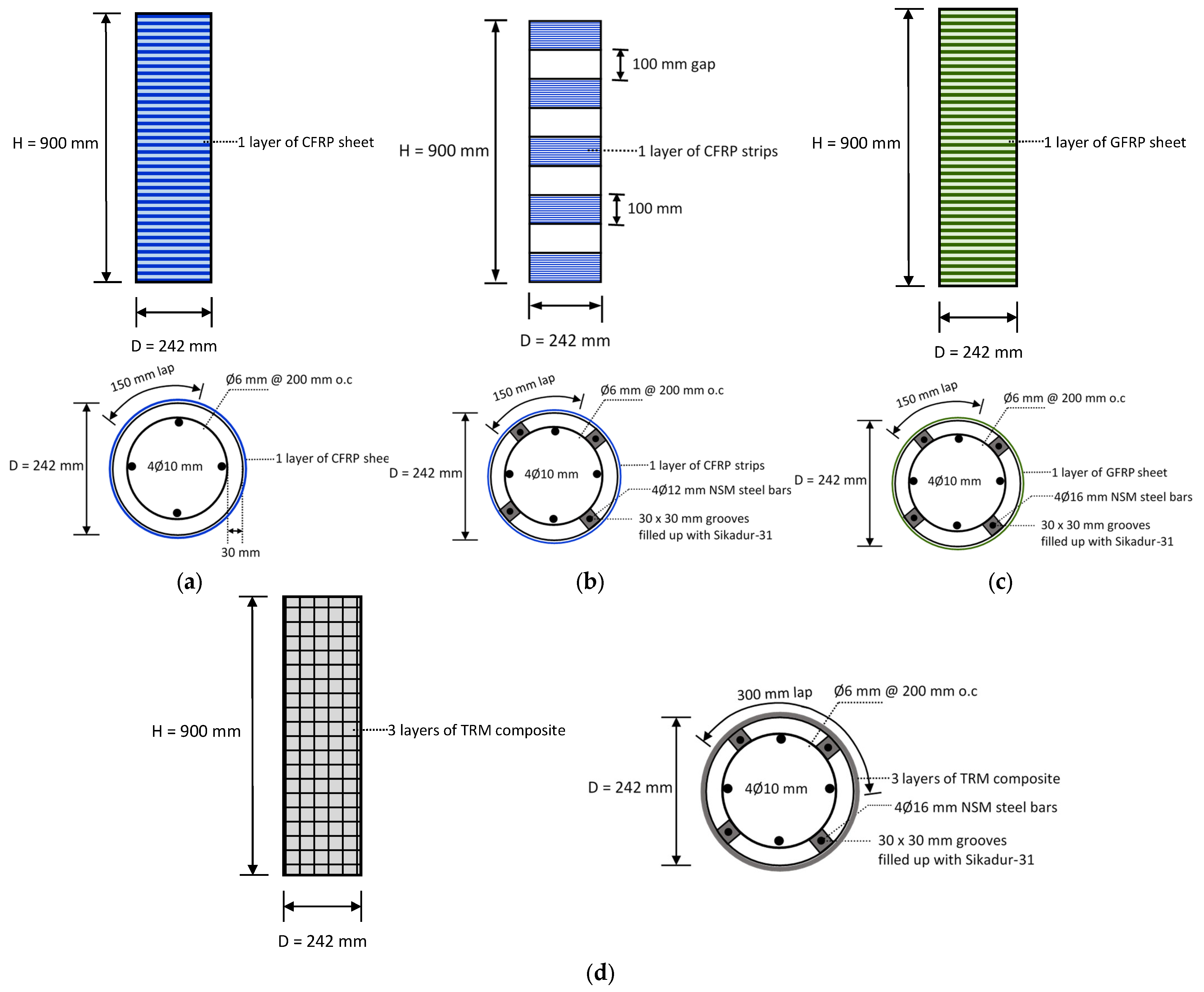

| [9] | C | C | 43.1 | FRCM/NSM | 3 | 58.7 | 0.0168 | RP | CF | 1 | 58.0 | 0.0076 | RP | 1.05 | 2.21 |

| C | C | 43.1 | FRCM/NSM | 3 | 58.7 | 0.0168 | RP | CFS/NSM | 1 | 55.7 | 0.0099 | RP | 1.24 | 1.7 | |

| C | C | 43.1 | FRCM/NSM | 3 | 58.7 | 0.0168 | RP | GF/NSM | 1 | 57.8 | 0.0106 | RP | 1.06 | 1.58 | |

| [60] | C | Ref | 11.405 | M45_PBO | 1 | 17.705 | 0.010895 | RP | E_PBO | 1 | 21.16 | 0.01265 | RP | 0.65 | 0.86 |

| C | Ref | 11.405 | M45_CF | 1 | 13.655 | 0.004845 | RP | E_CF | 1 | 19.57 | 0.01202 | RP | 0.28 | 0.40 | |

| Average of whole data | 0.74 ± 0.30 | 0.83 ± 0.48 | |||||||||||||

| Average for one or two layers of FRCM | 0.62 ± 0.33 | 0.56 ± 0.26 | |||||||||||||

| Average for three or more layers of FRCM | 0.86 ± 0.22 | 1.10 ± 0.51 | |||||||||||||

| Reference | Exposure Temp. (°C) | (MPa) | FRCM-Strengthened Column | FRP-Strengthened Column | FRCM/FRP | FRCM Effectiveness Due to Heating | FRP Effectiveness Due to Heating | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Col ID | (MPa) | Failure Mode | Col ID | (MPa) | Failure Mode | Effectiveness Ratio | Ultimate Strain Ratio | |||||||||

| [9] | 20 | 43.1 | FRCM/NSM | 3 | 58.7 | 0.0168 | RP | CF | 1 | 58 | 0.0076 | RP | 1.05 | 2.21 | 1 | 1 |

| 300 | 34.4 | FRCM/NSM-300 | 3 | 49.2 | 0.0116 | Mixed | CF-300 | 1 | 46.7 | 0.005 | Mixed | 1.20 | 2.32 | 0.84 | 0.81 | |

| 300 | 34.4 | FRCM/NSM-300 | 3 | 49.2 | 0.0116 | Mixed | CFS/NSM-300 | 1 | 44.8 | 0.0068 | Mixed | 1.42 | 1.71 | 0.84 | 0.80 | |

| 300 | 34.4 | FRCM/NSM-300 | 3 | 49.2 | 0.0116 | Mixed | GF/NSM-300 | 1 | 53.1 | 0.008 | Mixed | 0.79 | 1.45 | 0.84 | 0.92 | |

| Average of data tested after high temperature exposure | 0.84 ± 0.00 | 0.84 ± 0.07 | ||||||||||||||

| Reference | Exposure Temp. (°C) | (MPa) | FRCM-Strengthened Column | FRP-Strengthened Column | FRCM/FRP | FRCM Effectiveness Due to Heating | FRP Effectiveness Due to Heating | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Col ID | (MPa) | Failure Mode | Col ID | (MPa) | Failure Mode | Effectiveness Ratio | Ultimate Strain Ratio | |||||||||

| [61] | 20 | 16.1 | - | 1 | 31 | 0.0055 | RP | - | 1 | 32.5 | 0.012 | RP | 0.91 | 0.46 | 1.00 | 1.00 |

| 100 | 13.6 | - | 1 | 23.2 | 0.00074 | RP | - | 1 | 20.5 | 0.0074 | Mixed | 1.39 | 0.10 | 0.75 | 0.63 | |

| 150 | 14.2 | - | 1 | 24.5 | 0.004 | Mixed | - | 1 | 18.2 | 0.0048 | Mixed | 2.58 | 0.83 | 0.79 | 0.56 | |

| 200 | 17.1 | - | 1 | 25.6 | 0.00177 | RP | - | 1 | 22.9 | 0.00352 | Adhesive | 1.47 | 0.50 | 0.83 | 0.70 | |

| 400 | 16.2 | - | 1 | 31.5 | 0.0035 | Mixed/RP | - | 1 | 21.1 | 0.0023 | Adhesive | 3.12 | 1.52 | 1.02 | 0.65 | |

| 20 | 16.1 | - | 3 | 42.1 | 0.004 | RP | - | 3 | 62.8 | 0.0221 | RP | 0.56 | 0.18 | 1.00 | 1.00 | |

| 100 | 13.6 | - | 3 | 38.6 | 0.0152 | Mixed | - | 3 | 46.8 | 0.0168 | RP | 0.75 | 0.90 | 0.92 | 0.75 | |

| 150 | 14.2 | - | 3 | 36.9 | 0.0121 | RP | - | 3 | 41.9 | 0.014 | Mixed | 0.82 | 0.86 | 0.88 | 0.67 | |

| 200 | 17.1 | - | 3 | 40.5 | 0.008 | RP | - | 3 | 41.8 | 0.019 | Adhesive | 0.95 | 0.42 | 0.96 | 0.67 | |

| 400 | 16.2 | - | 3 | 45 | 0.0053 | Mixed | - | 3 | 38.5 | 0.0172 | Adhesive | 1.29 | 0.31 | 1.07 | 0.61 | |

| Average of data tested after high temperature exposure | 0.90 ± 0.11 | 0.66 ± 0.06 | ||||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsanadedy, H.; Abadel, A.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Polymer Versus Cementitious Matrix Composites for Retrofitting Reinforced Concrete Columns—A State-of-the-Art Review. Polymers 2025, 17, 2865. https://doi.org/10.3390/polym17212865

Elsanadedy H, Abadel A, Abbas H, Almusallam T, Al-Salloum Y. Polymer Versus Cementitious Matrix Composites for Retrofitting Reinforced Concrete Columns—A State-of-the-Art Review. Polymers. 2025; 17(21):2865. https://doi.org/10.3390/polym17212865

Chicago/Turabian StyleElsanadedy, Hussein, Aref Abadel, Husain Abbas, Tarek Almusallam, and Yousef Al-Salloum. 2025. "Polymer Versus Cementitious Matrix Composites for Retrofitting Reinforced Concrete Columns—A State-of-the-Art Review" Polymers 17, no. 21: 2865. https://doi.org/10.3390/polym17212865

APA StyleElsanadedy, H., Abadel, A., Abbas, H., Almusallam, T., & Al-Salloum, Y. (2025). Polymer Versus Cementitious Matrix Composites for Retrofitting Reinforced Concrete Columns—A State-of-the-Art Review. Polymers, 17(21), 2865. https://doi.org/10.3390/polym17212865