Methyltrimethoxysilane Vapor Deposition Strategy for Preparing Superelastic and Hydrophobic Flexible Polyurethane Foams

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

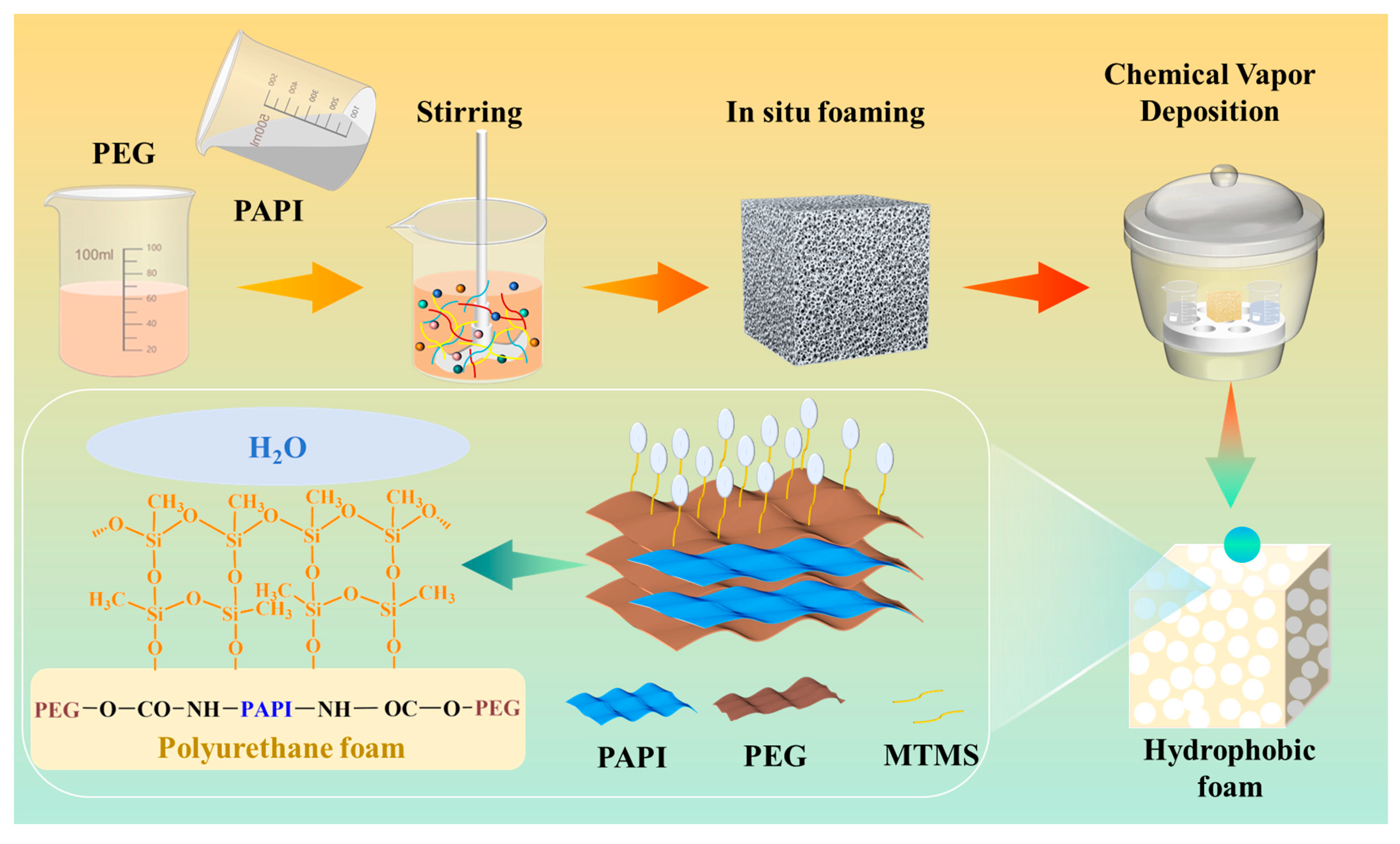

2.2. Preparation of Flexible Polyurethane Foam

2.3. Preparation of PUF @ MTMS Composite Foam

2.4. Characterization Methods

3. Characterization and Testing

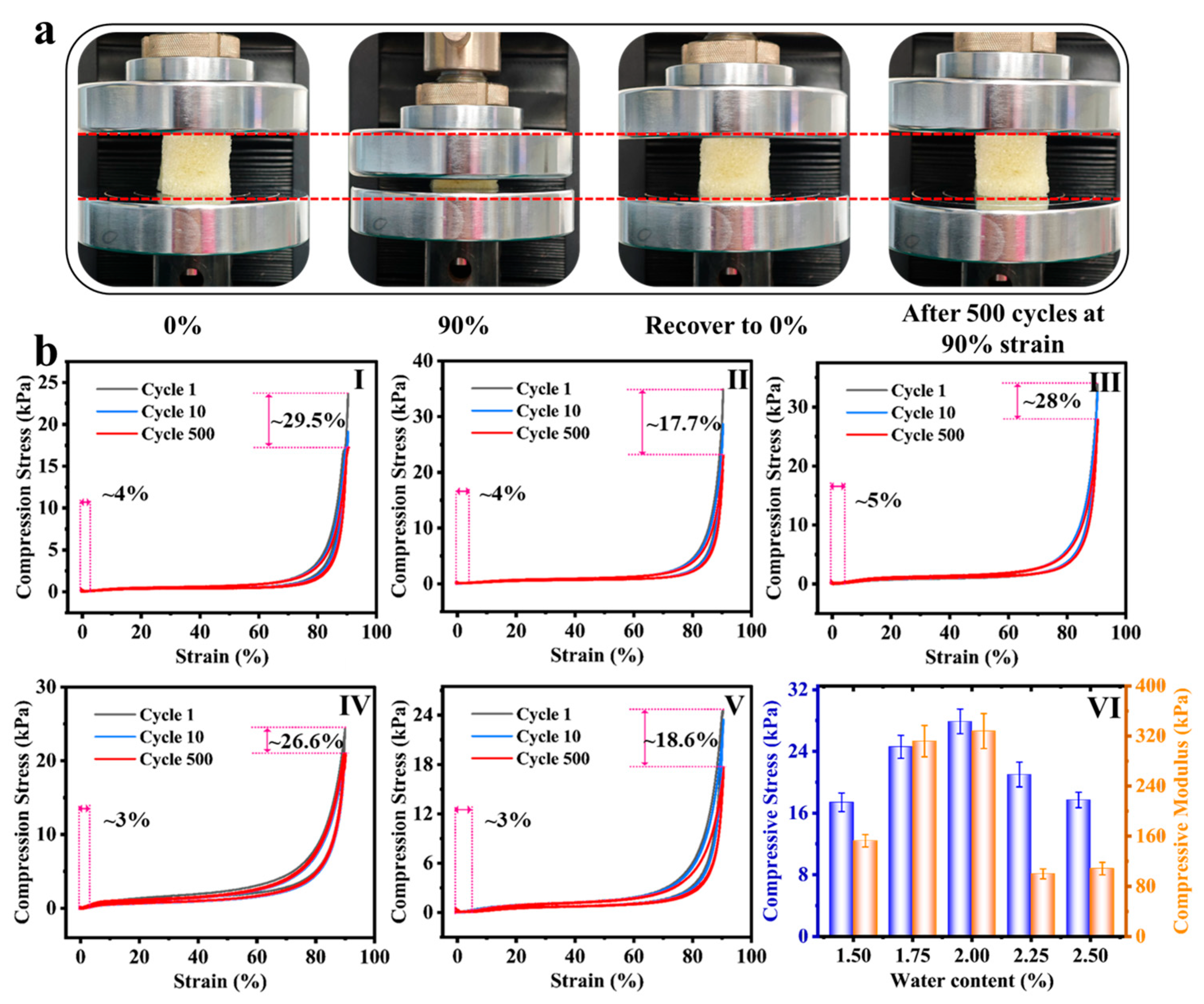

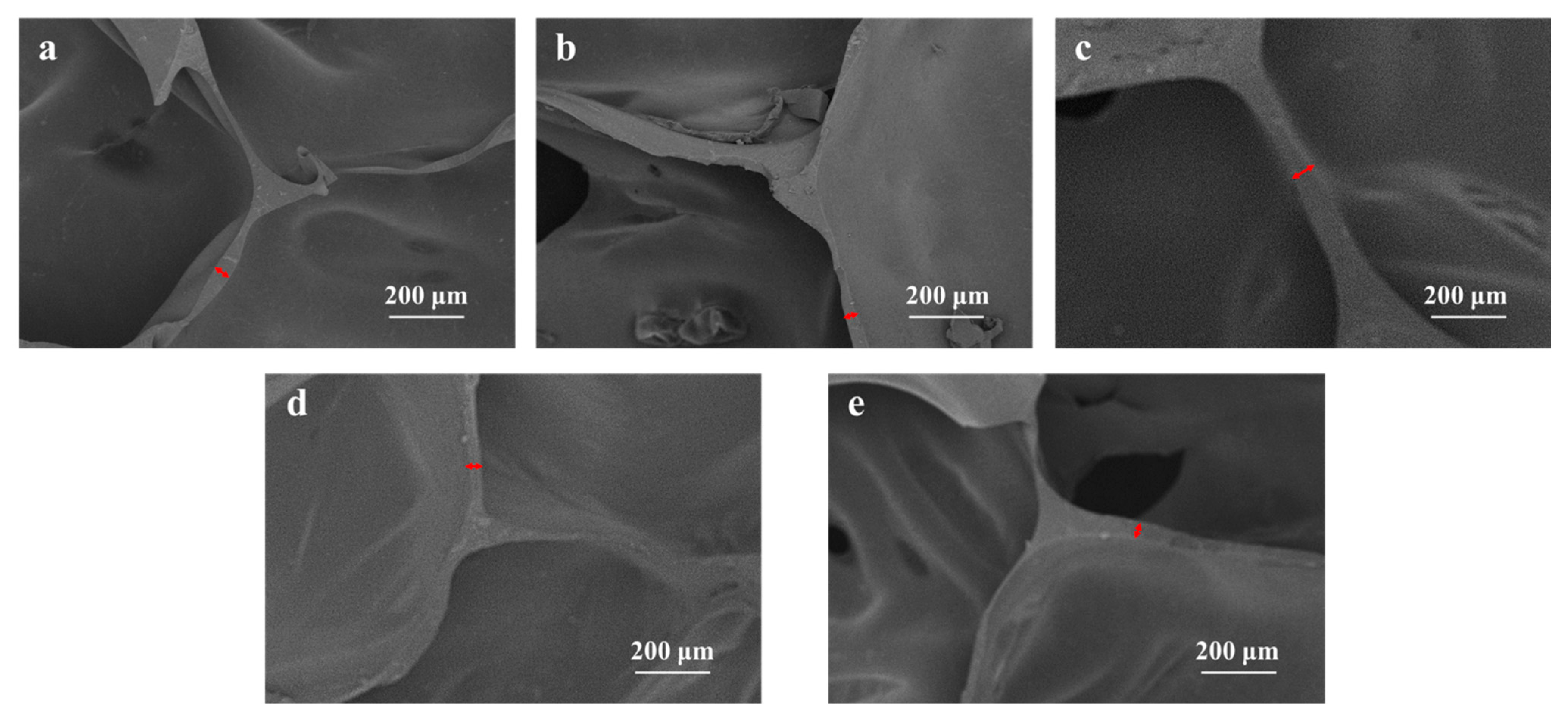

3.1. Mechanical Properties of PUF

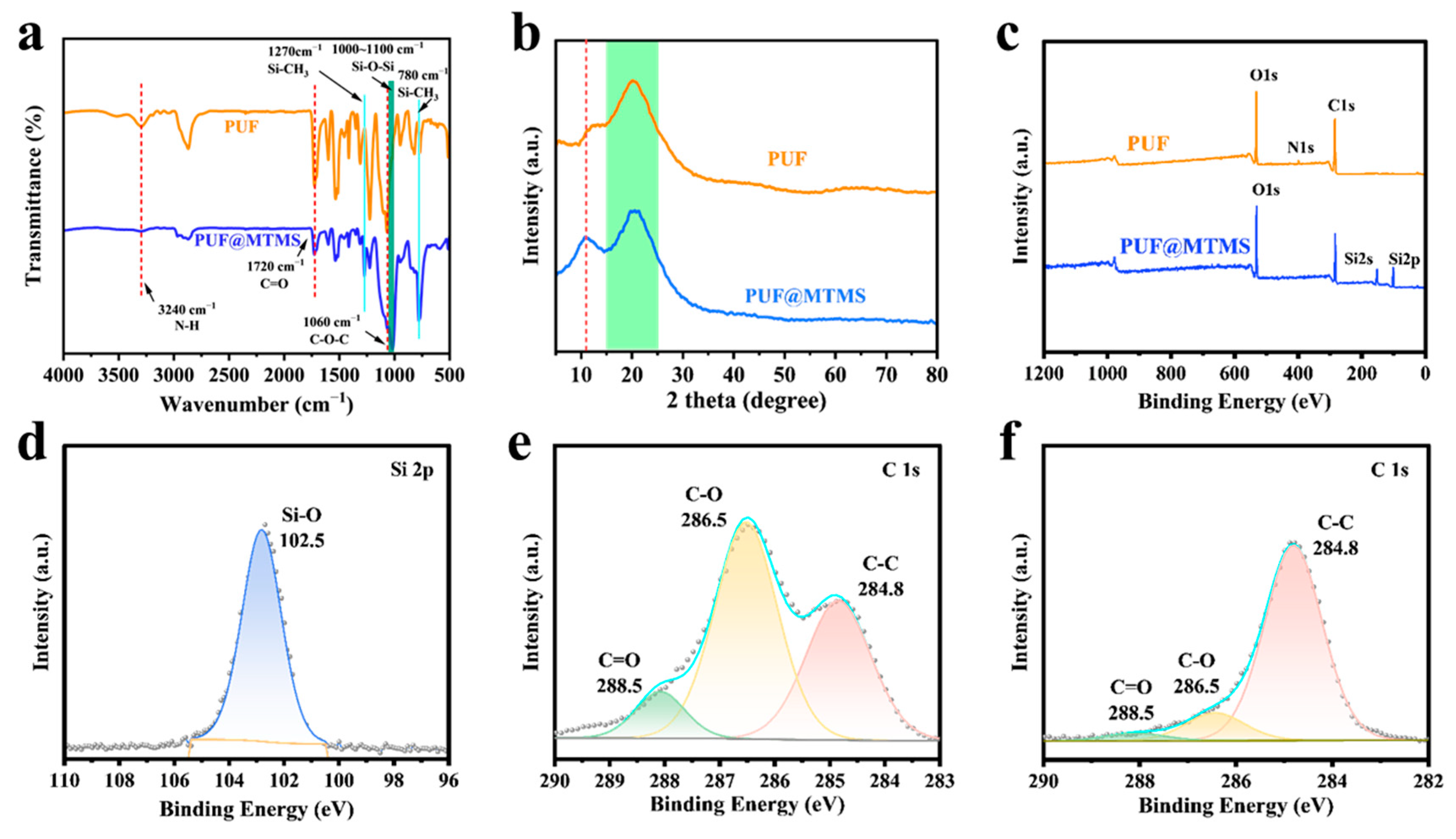

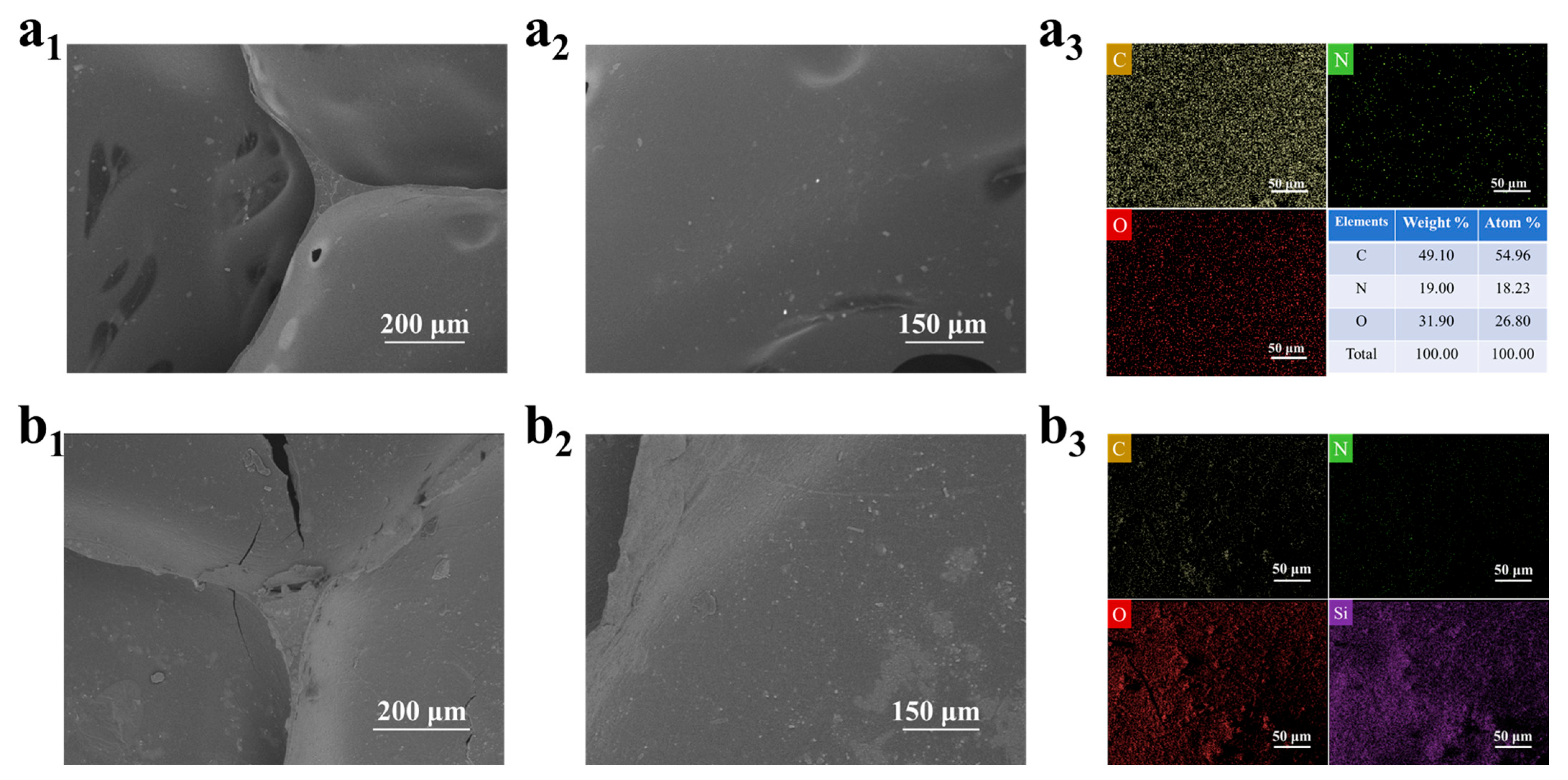

3.2. Analysis of the Characterization Results of PUF @ MTMS

3.3. Hydrophobicity of PUF @ MTMS

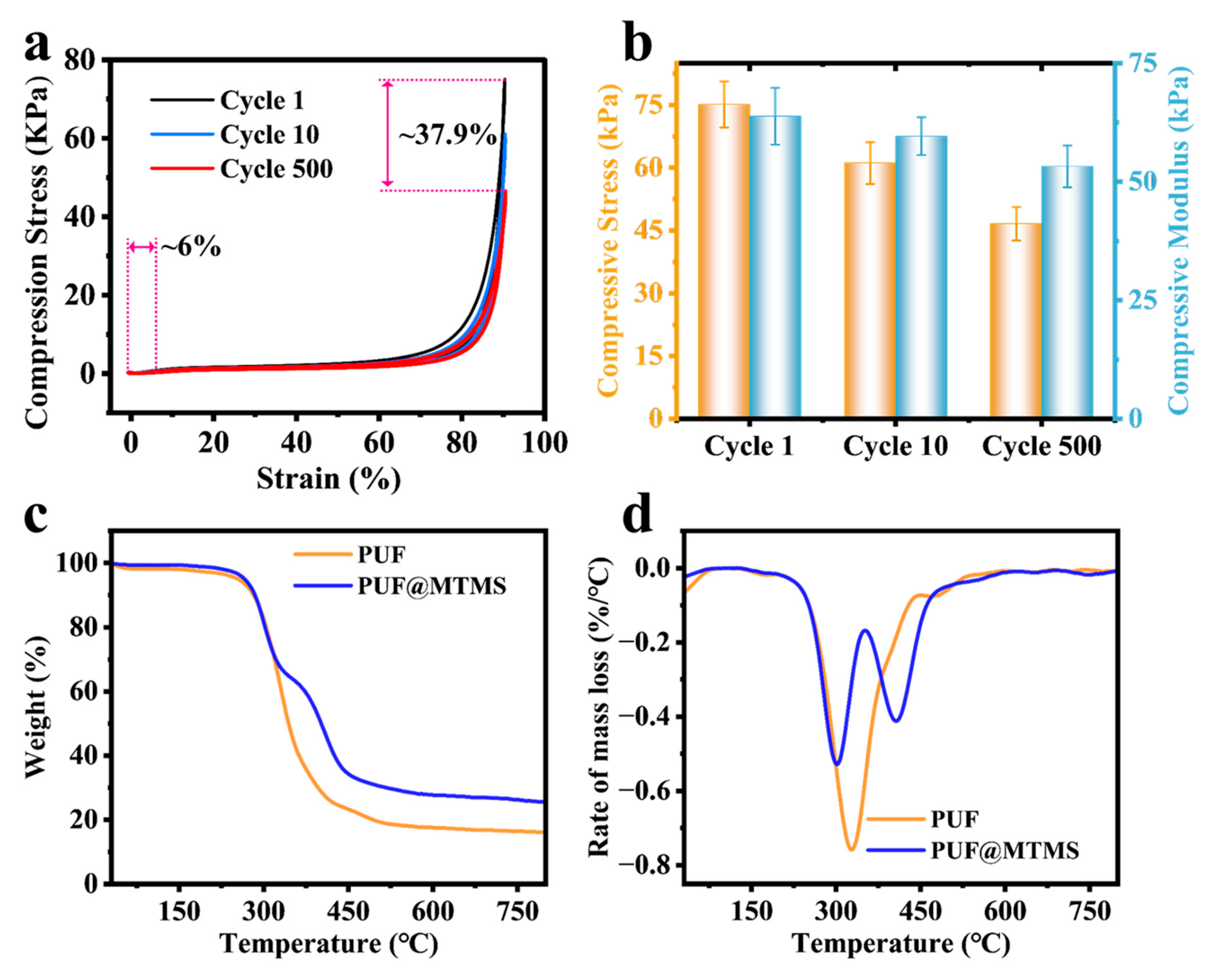

3.4. Mechanical Properties and Thermal Stability of PUF @ MTMS

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Maamoun, A.A.; Naeim, D.M.; Mahmoud, A.A.; Esawi, A.M.; Arafa, M. Improving the performance of triboelectric nanogenerators using flexible polyurethane nanocomposites foam filled with montmorillonite. Nano Energy 2024, 124, 109426. [Google Scholar] [CrossRef]

- Huang, S.-Y.; Lou, C.-W.; Yan, R.; Lin, Q.; Li, T.-T.; Chen, Y.-S.; Lin, J.-H. Investigation on structure and impact-resistance property of polyurethane foam filled three-dimensional fabric reinforced sandwich flexible composites. Compos. Part. B Eng. 2017, 131, 43–49. [Google Scholar] [CrossRef]

- Zhai, Y.; Yu, Y.; Zhou, K.; Yun, Z.; Huang, W.; Liu, H.; Xia, Q.; Dai, K.; Zheng, G.; Liu, C.; et al. Flexible and wearable carbon black/thermoplastic polyurethane foam with a pinnate-veined aligned porous structure for multifunctional piezoresistive sensors. Chem. Eng. J. 2020, 382, 122985. [Google Scholar] [CrossRef]

- Chen, S.; Li, S.; Ye, Z.; Zhang, Y.; Gao, S.; Rong, H.; Zhang, J.; Deng, L.; Dong, A. Superhydrophobic and superhydrophilic polyurethane sponge for wound healing. Chem. Eng. J. 2022, 446, 136985. [Google Scholar] [CrossRef]

- Zhang, M.; Zhou, S.; Zhang, T.; Li, J.; Xue, L.; Liang, B.; Xing, D. Shark skin and mussel-inspired polyurethane hydrogel sponge for wounds with infection and exudate. J. Colloid Interface Sci. 2025, 693, 137658. [Google Scholar] [CrossRef] [PubMed]

- Xu, R.; Wang, D.; Dou, L.H.; Cui, J.Q.; He, L.; Feng, F.Q.; Liu, F.F. Preparation and properties of self-healing polyurethane wood coatings with borate ester bonds. J. For. Eng. 2024, 9, 3, 54–60. [Google Scholar]

- Krishnan, V.G.; Fiorucci, L.; Sarbu, A.; Drenckhan-Andreatta, W. Characterizing the foaming process of polymers: Review of experimental methods. Adv. Colloid Interface Sci. 2025, 343, 103579. [Google Scholar] [CrossRef]

- Zhu, F.; Zhan, H.; Wang, C.; Fu, B.; Zhou, J. Design of bio-based P-N synergistic aerogels: Integrating phosphorylated chitosan into sodium alginate for fire-safe thermal insulation. J. Bioresour. Bioprod. 2025. [Google Scholar] [CrossRef]

- Li, P.; Liu, H.; Xu, Y.-J.; Wang, D.-Y.; Liu, Y.; Zhu, P. Flame-retardant and antibacterial flexible polyurethane foams with high resilience based on a P/N/Si-containing system. J. Mater. Sci. Technol. 2024, 182, 141–151. [Google Scholar] [CrossRef]

- Nandy, A.; Houl, Y.; Zhao, W.; D’SOuza, N.A. Thermal heat transfer and energy modeling through incorporation of phase change materials (PCMs) into polyurethane foam. Renew. Sustain. Energy Rev. 2023, 182, 113410. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, K.; Zhao, G.; Deng, H.; Fu, Q. The preparation of high performance Multi-functional porous sponge through a biomimic coating strategy based on polyurethane dendritic colloids. Chem. Eng. J. 2022, 438, 135659. [Google Scholar] [CrossRef]

- Feng, J.; Nguyen, S.T.; Fan, Z.; Duong, H.M. Advanced fabrication and oil absorption properties of super-hydrophobic recycled cellulose aerogels. Chem. Eng. J. 2015, 270, 168–175. [Google Scholar] [CrossRef]

- Rao, A.V.; Bhagat, S.D.; Hirashima, H.; Pajonk, G.M. Synthesis of flexible silica aerogels using methyltrimethoxysilane (MTMS) precursor. J. Colloid Interface Sci. 2006, 300, 279–285. [Google Scholar]

- Sha, X.; Chen, L.; Jia, Y.; Zhao, H.; Zuo, S.; Yuan, P.; Chen, G. Preparation and properties of sustainable superhydrophobic cotton fabrics modified with lignin nanoparticles, tannic acid and methyltrimethoxysilane. Chem. Eng. J. 2024, 499, 155797. [Google Scholar] [CrossRef]

- Wang, X.; Jang, J.; Su, Y.; Liu, J.; Zhang, H.; He, Z.; Ni, Y. Starting materials, processes and characteristics of bio-based foams: A review. J. Bioresour. Bioprod. 2024, 9, 160–173. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, J.; Leng, W.; Huang, Q.; Liu, H. Effect of alkoxysilane treatment on dimensional stability of poplar. J. For. Eng. 2024, 9, 61–66. [Google Scholar]

- Li, X.; Cao, H.; Zhang, Y. Structures and physical properties of rigid polyurethane foams with Water as the sole blowing agent. Sci. China, Ser. B Chem. 2006, 49, 363–370. [Google Scholar] [CrossRef]

- Bourguignon, M.; Grignard, B.; Detrembleur, C. Water-Induced Self-Blown Non-Isocyanate Polyurethane Foams. Angew. Chem. Int. Edit. 2022, 61, e202213422. [Google Scholar] [CrossRef]

- Peyrton, J.; Avérous, L. Structure-properties relationships of cellular materials from biobased polyurethane foams. Mat. Sci. Eng. R Rep. 2021, 145, 1006008. [Google Scholar] [CrossRef]

- Ou, J.; Wang, F.; Li, W.; Yan, M.; Amirfazli, A. Methyltrimethoxysilane as a multipurpose chemical for durable superhydrophobic cotton fabric. Prog. Org. Coat. 2020, 146, 105700. [Google Scholar] [CrossRef]

- Xu, T.; Zhang, H.; Hess, D.W.; Chai, X.; Xu, K.; Yang, X.; Xie, L. A fluorine-free approach for fabricating superhydrophobic coatings on bamboo using methyltrimethoxysilane (MTMS) under alkaline conditions. Prog. Org. Coat. 2025, 203, 109170. [Google Scholar] [CrossRef]

- Yan, B.; Chen, X.; Yao, R.; Wang, Y.; Lin, Z.; Xu, L.; Wu, Z.; Peng, X.; Chen, T. Compressible CNT Ink-Wrapped Thermoplastic Polyurethane Sponge for Piezoresistive Sensing and Solar Steam Generation. ACS Appl. Polym. Mater. 2024, 6, 14436–14446. [Google Scholar] [CrossRef]

- Duan, X.; Huo, H.; Li, H.; Gao, Y.; Shi, H.; Kuang, F.; Chen, Y.; Wan, J.; Shen, J.; Du, G.; et al. Fabricating ultra-robust hydrogels with adhesive properties by restraining crack propagation with bamboo cellulose-based carbon nanomaterials. J. Bioresour. Bioprod. 2025, 16, 42. [Google Scholar] [CrossRef]

- Hu, C.; Xue, T.; Ma, R.; Chai, B.; Zhang, S.; Wei, Q.; Wang, M.; Jiang, Q.; Mei, Y. Fabrication of biomimetic polyurethane sponges with superhydrophobic, magnetic response and flame retardant properties for efficient oil-water separation. J. Environ. Chem. Eng. 2025, 13, 116230. [Google Scholar] [CrossRef]

- Liang, L.; Xue, Y.; Wu, Q.; Dong, Y.; Meng, X. Self-assembly modification of polyurethane sponge for application in oil/water separation. Rsc. Adv. 2019, 9, 40378–40387. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Jian, Y.; Shao, M.; Cheng, Y.; Liu, J.; Liu, Y.; Hess, D.W.; Wan, H.; Xie, L. A novel two-step strategy to construct multifunctional superhydrophobic wood by liquid-vapor phase deposition of methyltrimethoxysilane for improving moisture resistance, anti-corrosion and mechanical strength. Colloids Surf. A Physicochem. Eng. Asp. 2023, 666, 131314. [Google Scholar] [CrossRef]

- Park, Y.S.; Choi, J.; Kim, B.S.; Baeck, S.-H.; Shim, S.E.; Qian, Y. Synergistic effects of P and Si on the flame retardancy in a polymethylsilsesquioxane aerogel prepared under ambient pressure drying. J. Therm. Anal. Calorim. 2023, 148, 7623–7632. [Google Scholar] [CrossRef]

- Hu, L.; Pu, Z.; Tian, Y.; Zheng, X.; Cheng, J.; Zhong, J. Preparation and properties of fluorinated silicon two-component polyurethane hydrophobic coatings. Polym. Int. 2020, 69, 448–456. [Google Scholar] [CrossRef]

- Liu, S.-H.; Shen, M.-Y.; Kuan, C.-F.; Kuan, H.-C.; Ke, C.-Y.; Chiang, C.-L. Improving Thermal Stability of Polyurethane through the Addition of Hyperbranched Polysiloxane. Polymers 2019, 11, 697. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, Z.; Liu, W. Robust mussel-inspired superhydrophobic sponge with eco-friendly photothermal effect for crude oil/seawater separation. J. Hazard. Mater. 2024, 461, 132592. [Google Scholar] [CrossRef]

- Wang, E.; Huang, W.; Miao, Y.; Jia, L.; Liang, Y.; Wang, S.; Zhang, W.; Zou, L.-H.; Zhong, Y.; Huang, J. Conductive and superhydrophobic lignin/carbon nanotube coating with nest-like structure for deicing, oil absorption and wearable piezoresistive sensor. Int. J. Biol. Macromol. 2024, 278, 134886. [Google Scholar] [CrossRef]

- Wu, X.; Huang, S.; Zhang, Y.; Shi, L.; Luo, Y.; Deng, X.; Liu, Q.; Li, Z. Flame retardant polyurethane sponge/MTMS aerogel composites with improved mechanical properties under ambient pressure drying. J. Nanopart. Res. 2020, 22, 221. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Yu, L.; Tong, Z.; Chen, L.; Liu, H.; Li, X. Thermal degradation and stability of starch under different processing conditions. Starch Stärke 2012, 65, 48–60. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Webster, D.C. Thermal stability and flame retardancy of polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Wi, S.; Berardi, U.; Loreto, S.D.; Kim, S. Microstructure and thermal characterization of aerogel–graphite polyurethane spray-foam composite for high efficiency thermal energy utilization. J. Hazard. Mater. 2020, 397, 122656. [Google Scholar] [CrossRef]

- Tang, W.; Liang, G.; Wang, L.; Yuan, Y.; Dessie, W.; Liu, F.; Qin, Z.; Wang, Y.; Xiao, A.; Jin, X. Multi-functional flame retardant coatings comprising chitosan/ gelatin and sodium phytate for rigid polyurethane foams. J. Clean. Prod. 2023, 394, 136371. [Google Scholar] [CrossRef]

- Wu, X.; Fan, M.; Shen, X.; Cui, S.; Tan, G. Silica aerogels formed from soluble silicates and methyl trimethoxysilane (MTMS) using CO2 gas as a gelation agent. Ceram. Int. 2018, 44, 821–829. [Google Scholar] [CrossRef]

- Sim, Y.L.; Lee, J.; Oh, S.M.; Kim, D.B.; Kim, K.; Baeck, S.-H.; Shim, S.E.; Qian, Y. Mitigation of Silicon Contamination in Fuel Cell Gasket Materials through Silica Surface Treatment. Polymers 2024, 16, 914. [Google Scholar] [CrossRef]

| Sample | PEG-400 (g) | Water (g) | AK-8805 (g) | DBDL (g) | TEA (g) | PAPI (g) |

|---|---|---|---|---|---|---|

| W1.5 | 100 | 1.5 | 2 | 1.125 | 0.375 | 69.48 |

| W1.75 | 100 | 1.75 | 2 | 1.125 | 0.375 | 72.20 |

| W2 | 100 | 2 | 2 | 1.125 | 0.375 | 74.92 |

| W2.25 | 100 | 2.25 | 2 | 1.125 | 0.375 | 77.67 |

| W2.5 | 100 | 2.5 | 2 | 1.125 | 0.375 | 80.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, H.; Ma, H.; Jing, T.; Zhai, B.; Dong, Y.; Jiang, S.; Han, X. Methyltrimethoxysilane Vapor Deposition Strategy for Preparing Superelastic and Hydrophobic Flexible Polyurethane Foams. Polymers 2025, 17, 2814. https://doi.org/10.3390/polym17212814

Feng H, Ma H, Jing T, Zhai B, Dong Y, Jiang S, Han X. Methyltrimethoxysilane Vapor Deposition Strategy for Preparing Superelastic and Hydrophobic Flexible Polyurethane Foams. Polymers. 2025; 17(21):2814. https://doi.org/10.3390/polym17212814

Chicago/Turabian StyleFeng, Hongyu, Haijing Ma, Tian Jing, Bohan Zhai, Yanyan Dong, Shaohua Jiang, and Xiaoshuai Han. 2025. "Methyltrimethoxysilane Vapor Deposition Strategy for Preparing Superelastic and Hydrophobic Flexible Polyurethane Foams" Polymers 17, no. 21: 2814. https://doi.org/10.3390/polym17212814

APA StyleFeng, H., Ma, H., Jing, T., Zhai, B., Dong, Y., Jiang, S., & Han, X. (2025). Methyltrimethoxysilane Vapor Deposition Strategy for Preparing Superelastic and Hydrophobic Flexible Polyurethane Foams. Polymers, 17(21), 2814. https://doi.org/10.3390/polym17212814