Effect of Printing Direction of 3D-Printed Nylon Under Abrasive Wear Conditions

Abstract

1. Introduction

2. Materials and Methods

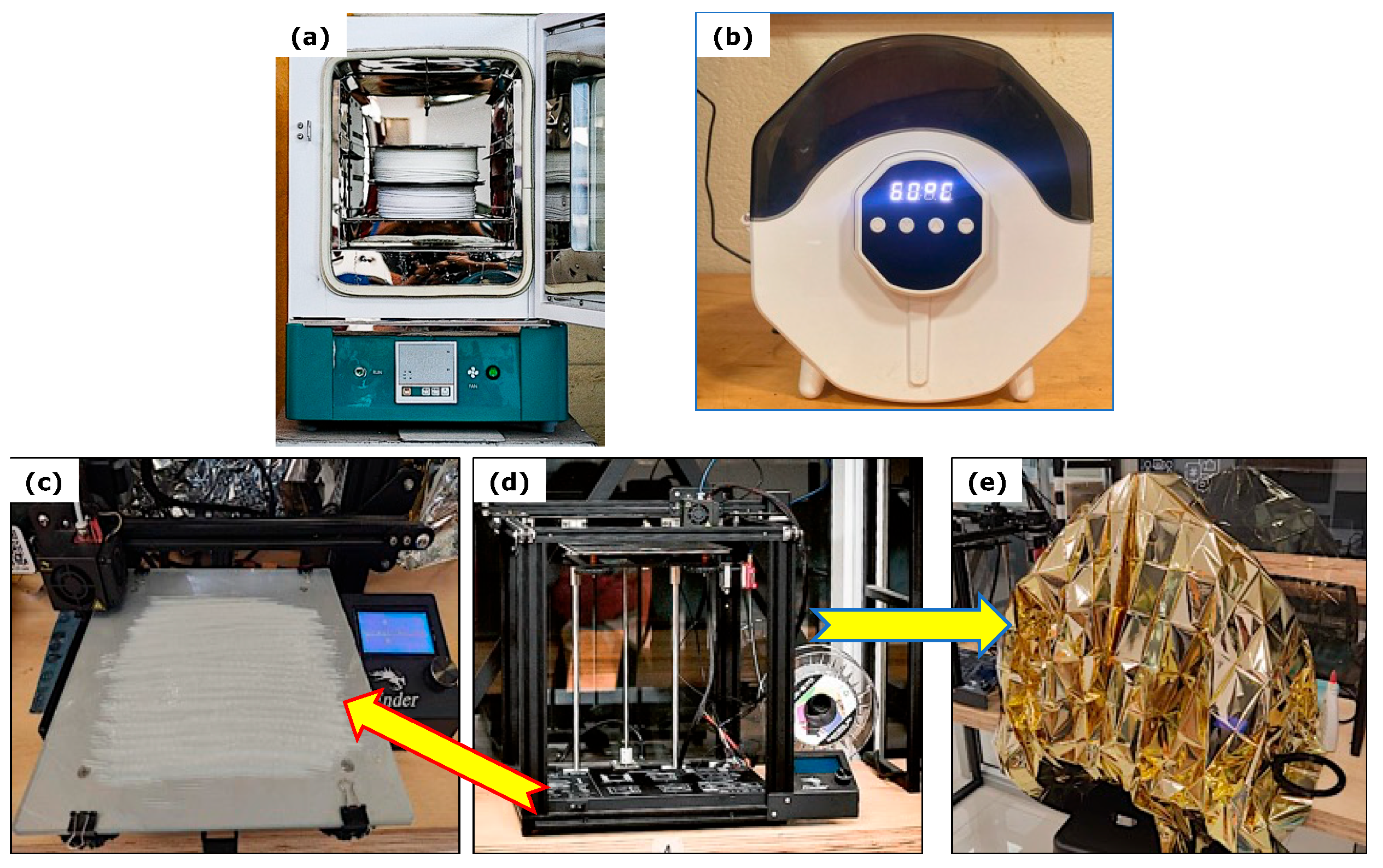

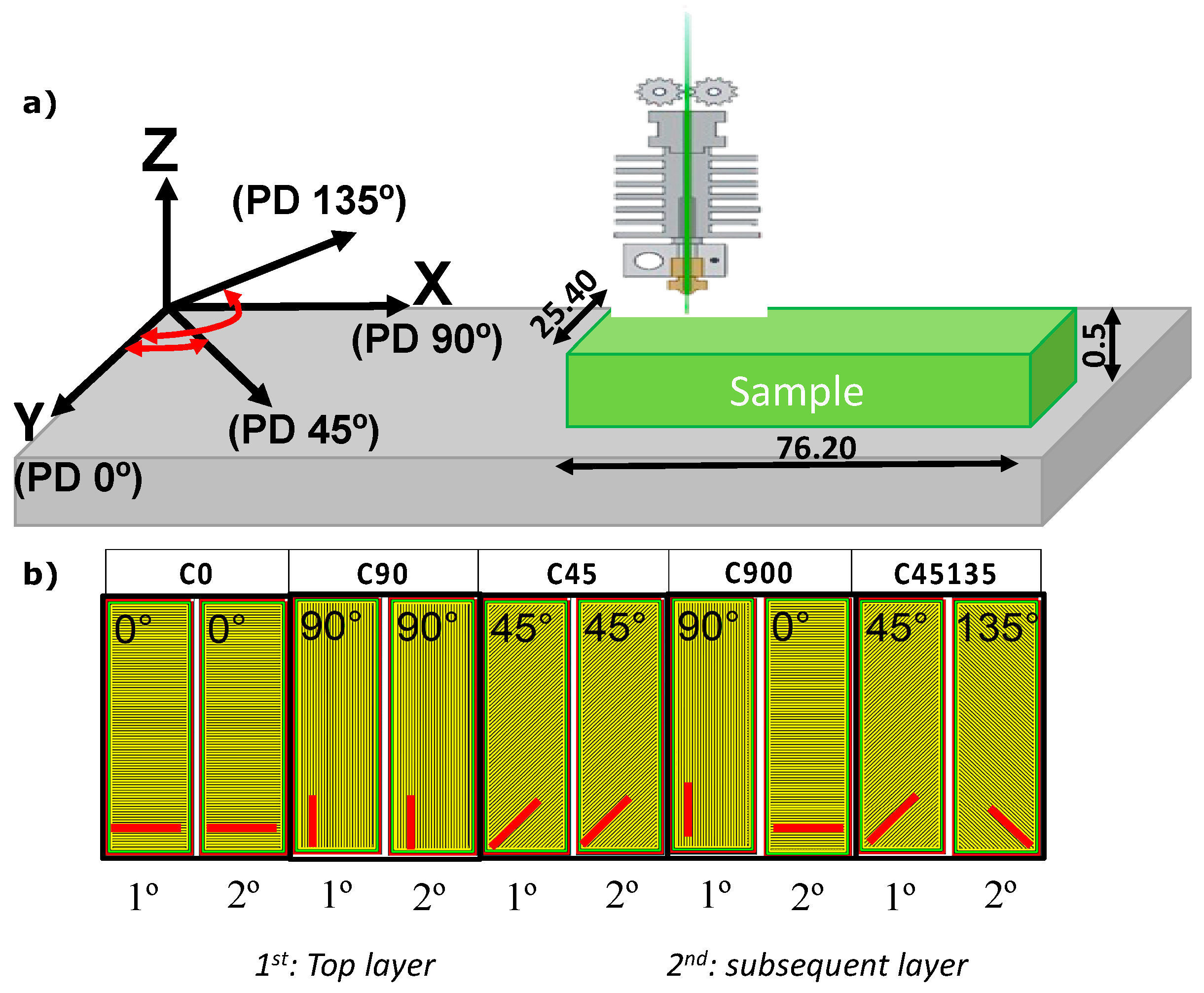

2.1. Manufacturing of Nylon Samples by 3D Printing Process

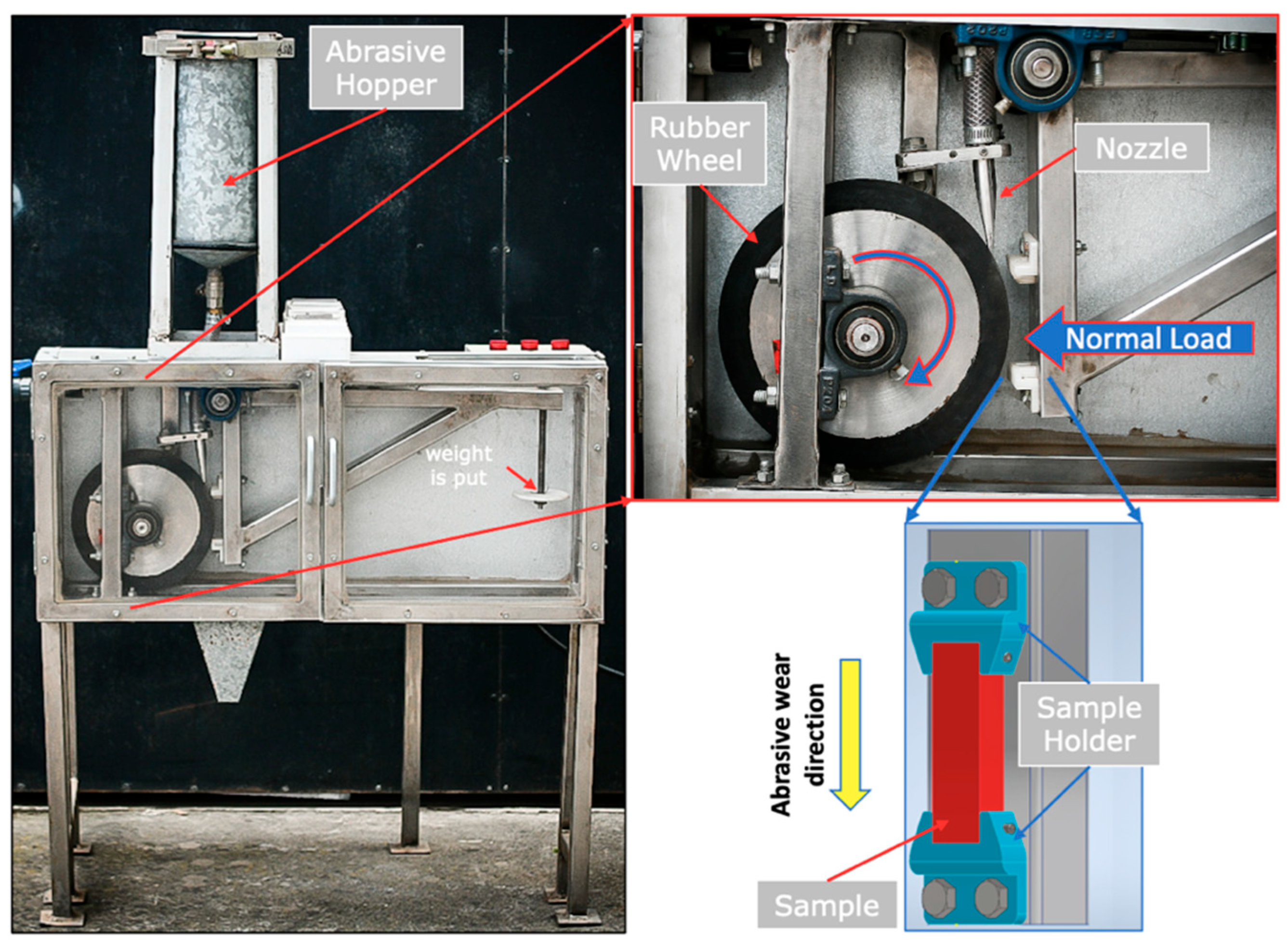

2.2. Wear Tests

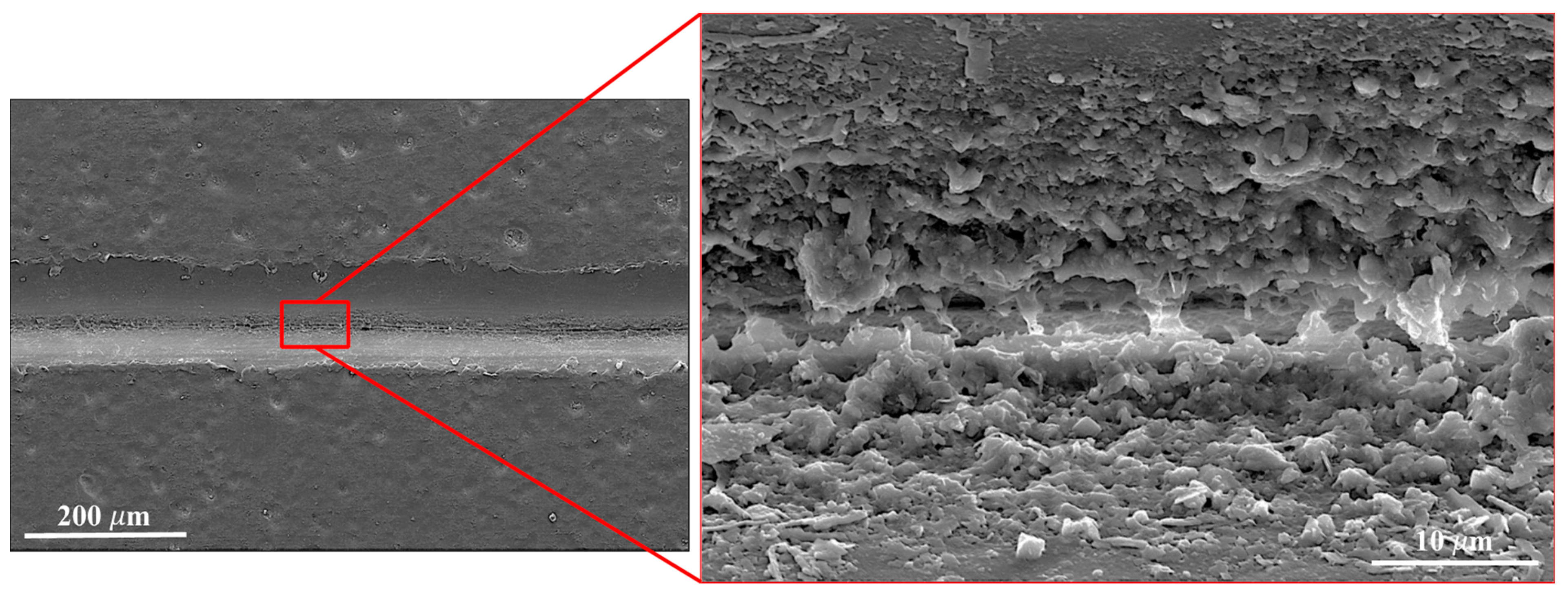

2.3. Characterization of Wear Tracks

2.4. Thermal Tests

3. Results

3.1. Morphological Analysis of the Samples

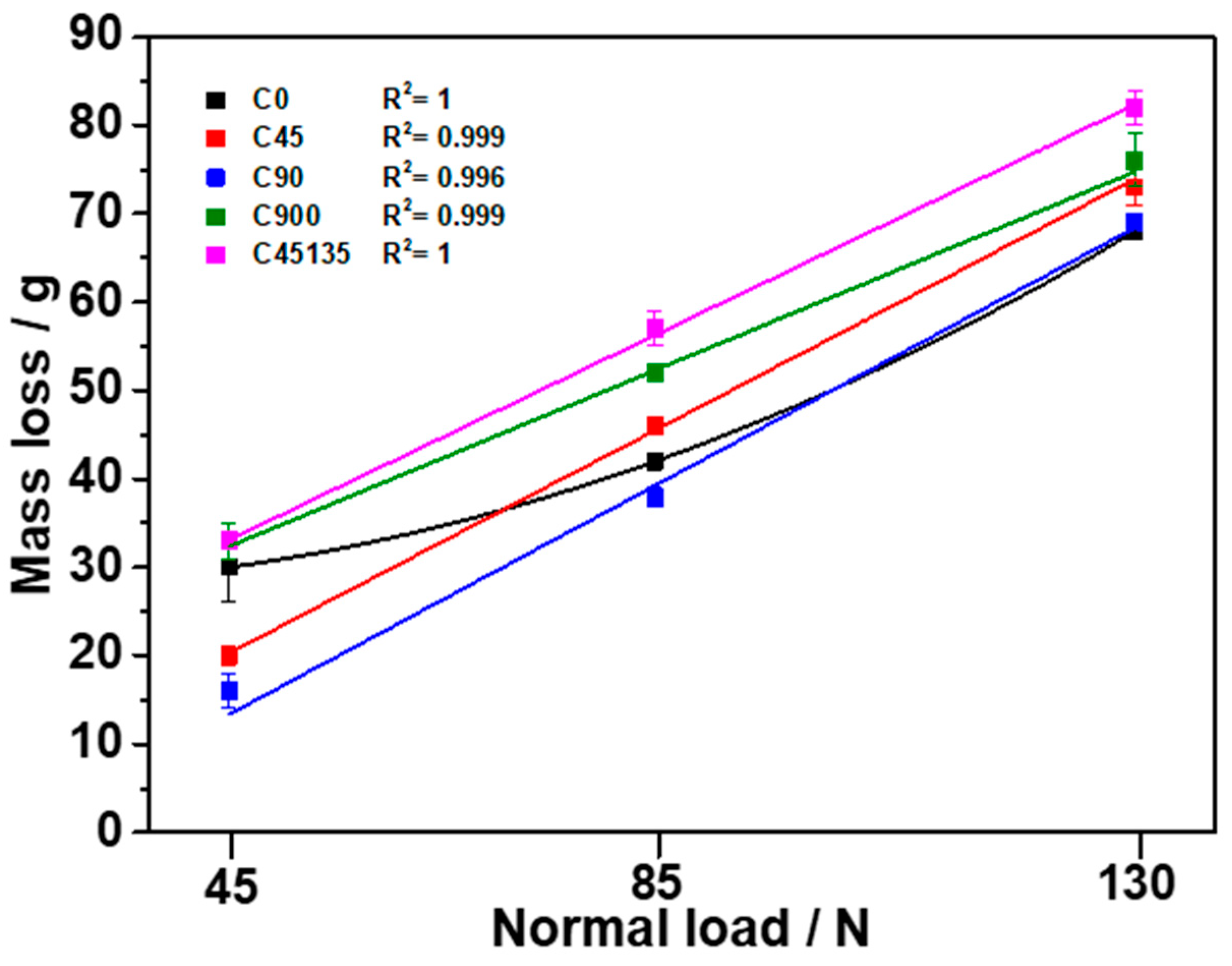

3.2. Abrasive Wear

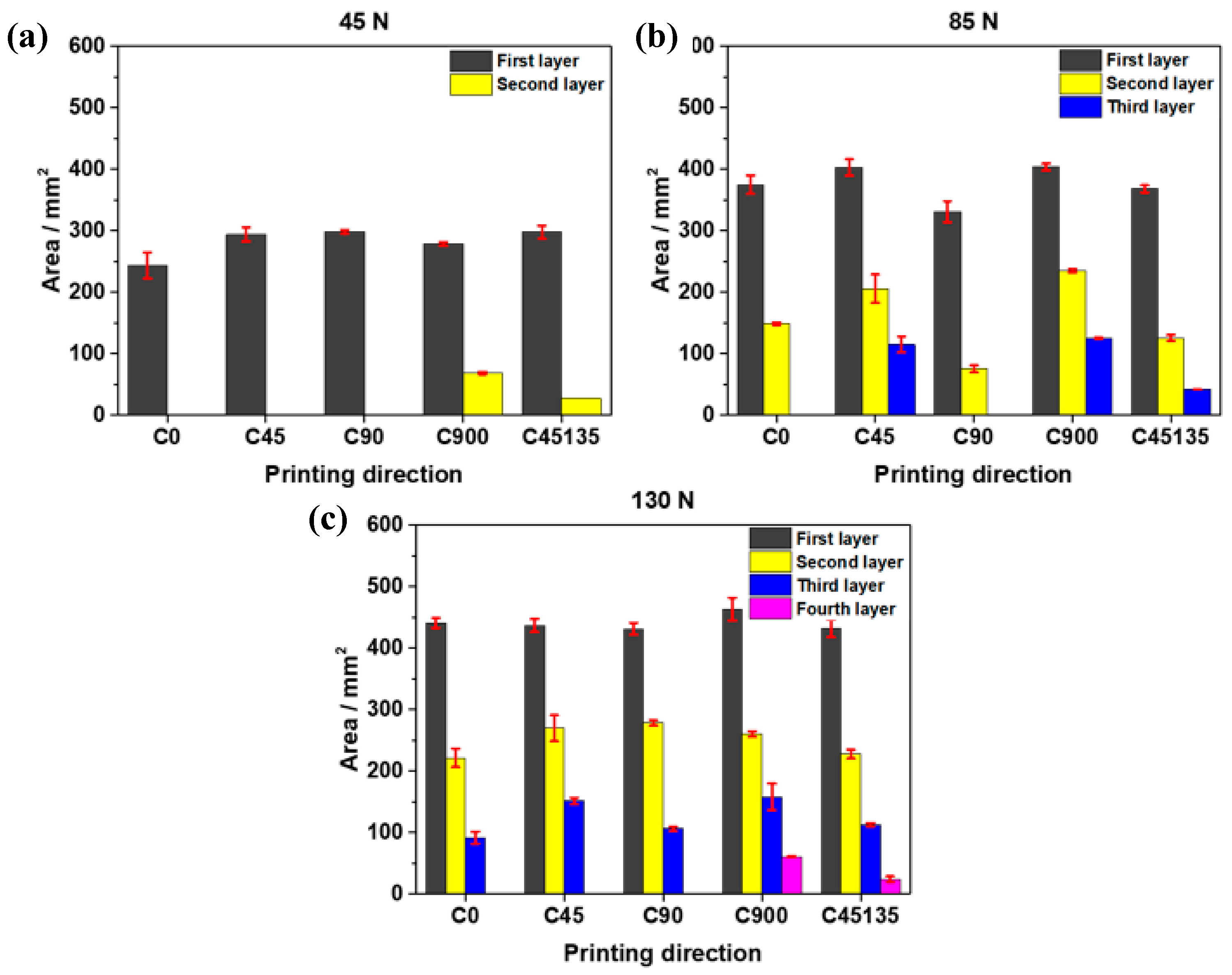

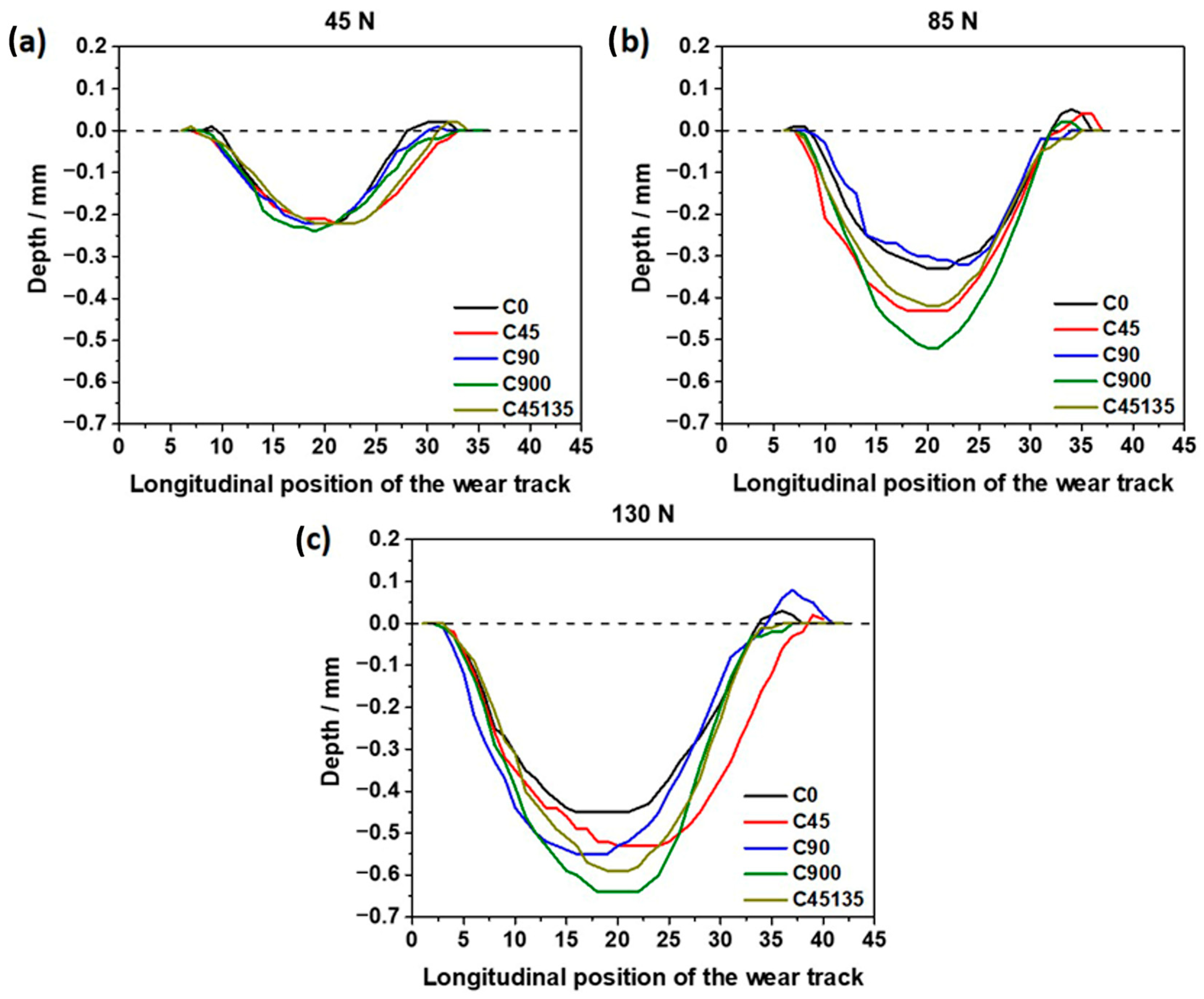

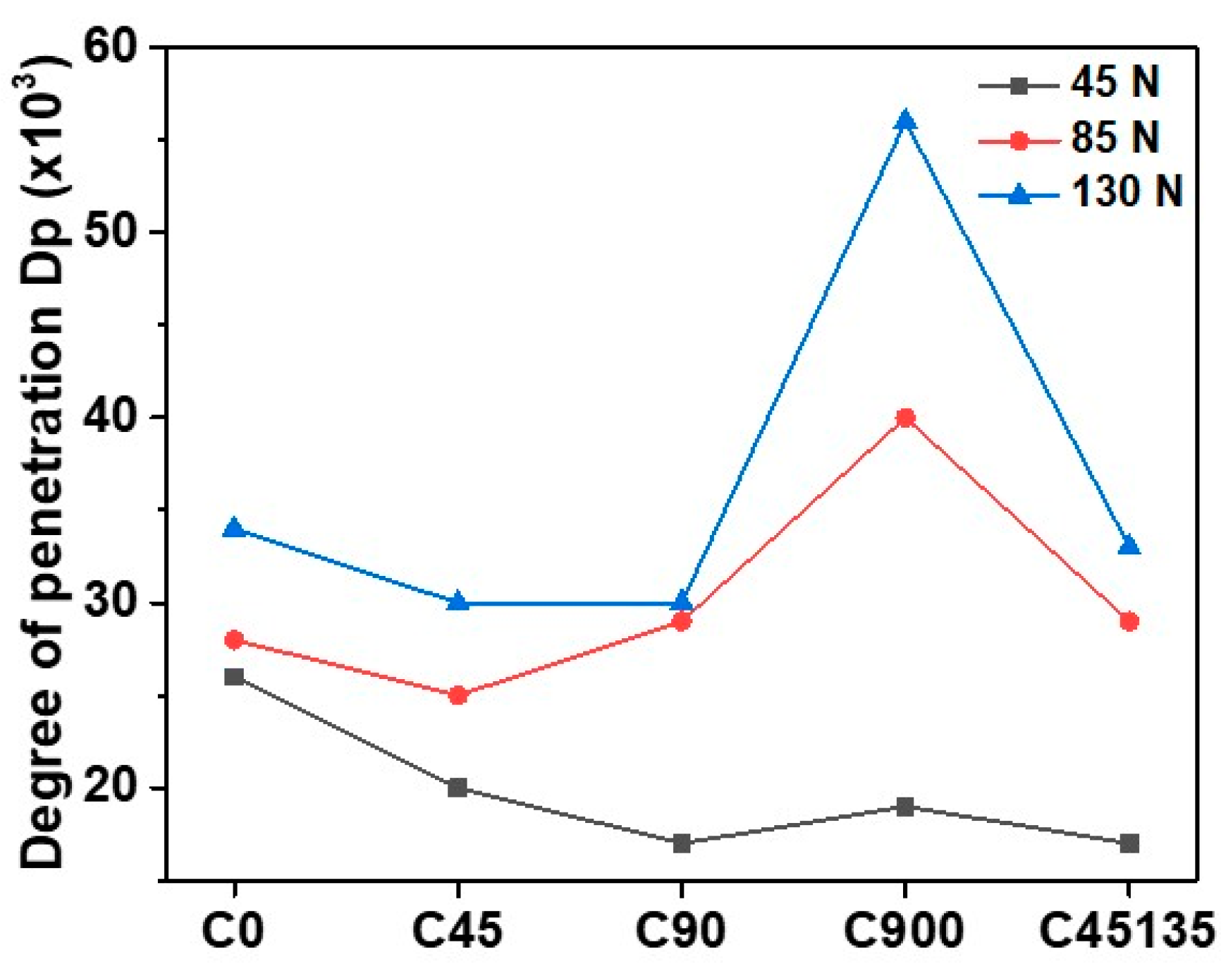

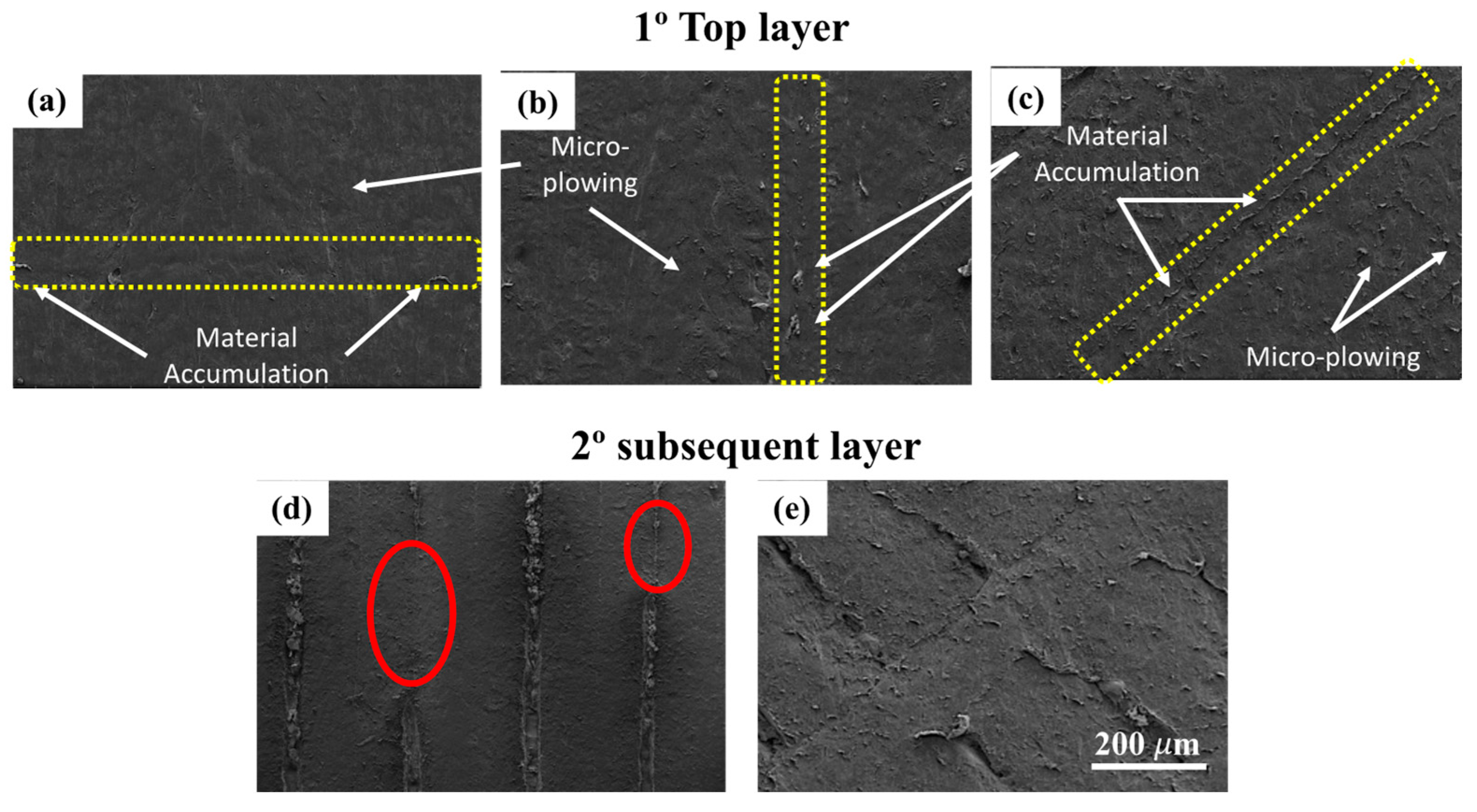

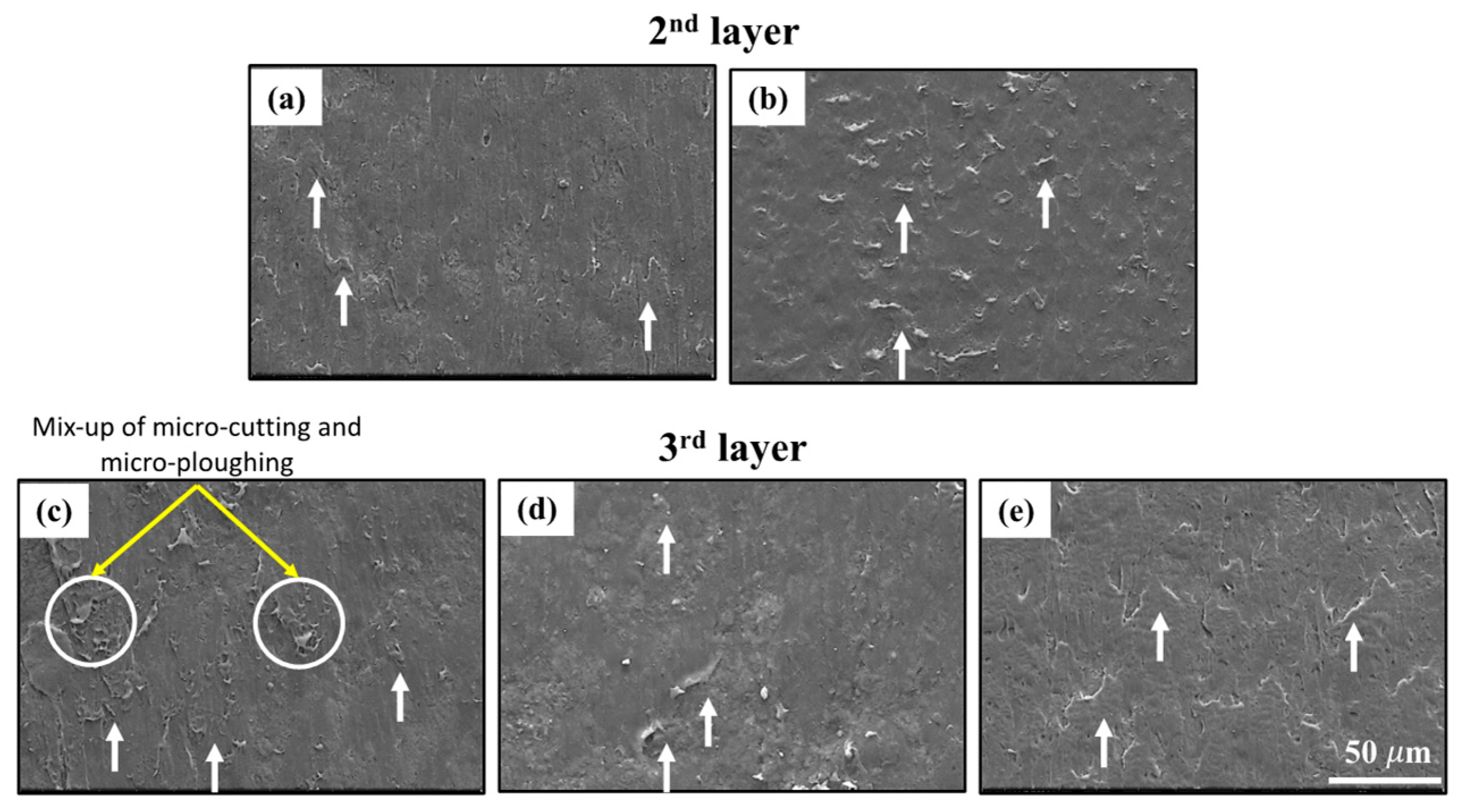

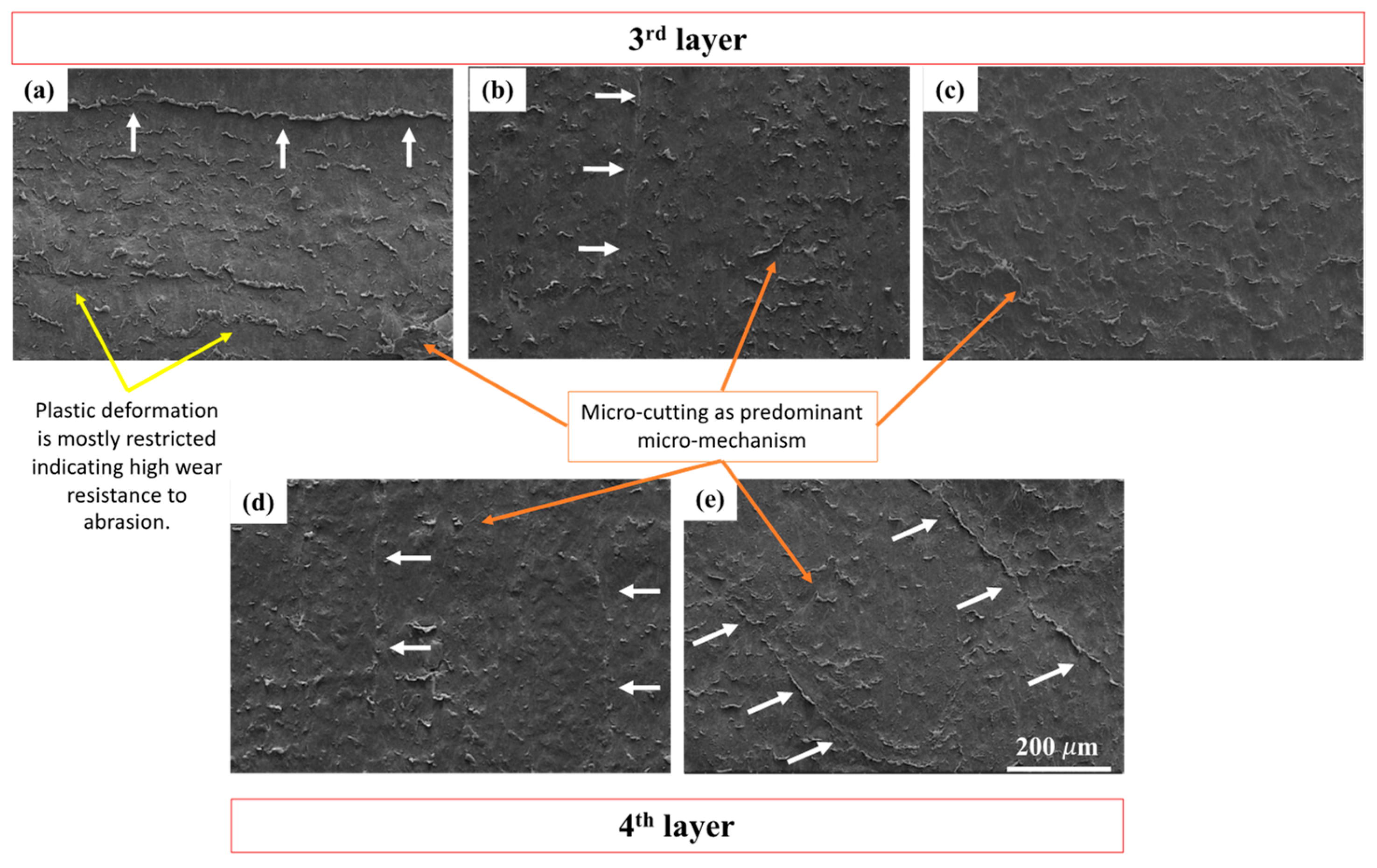

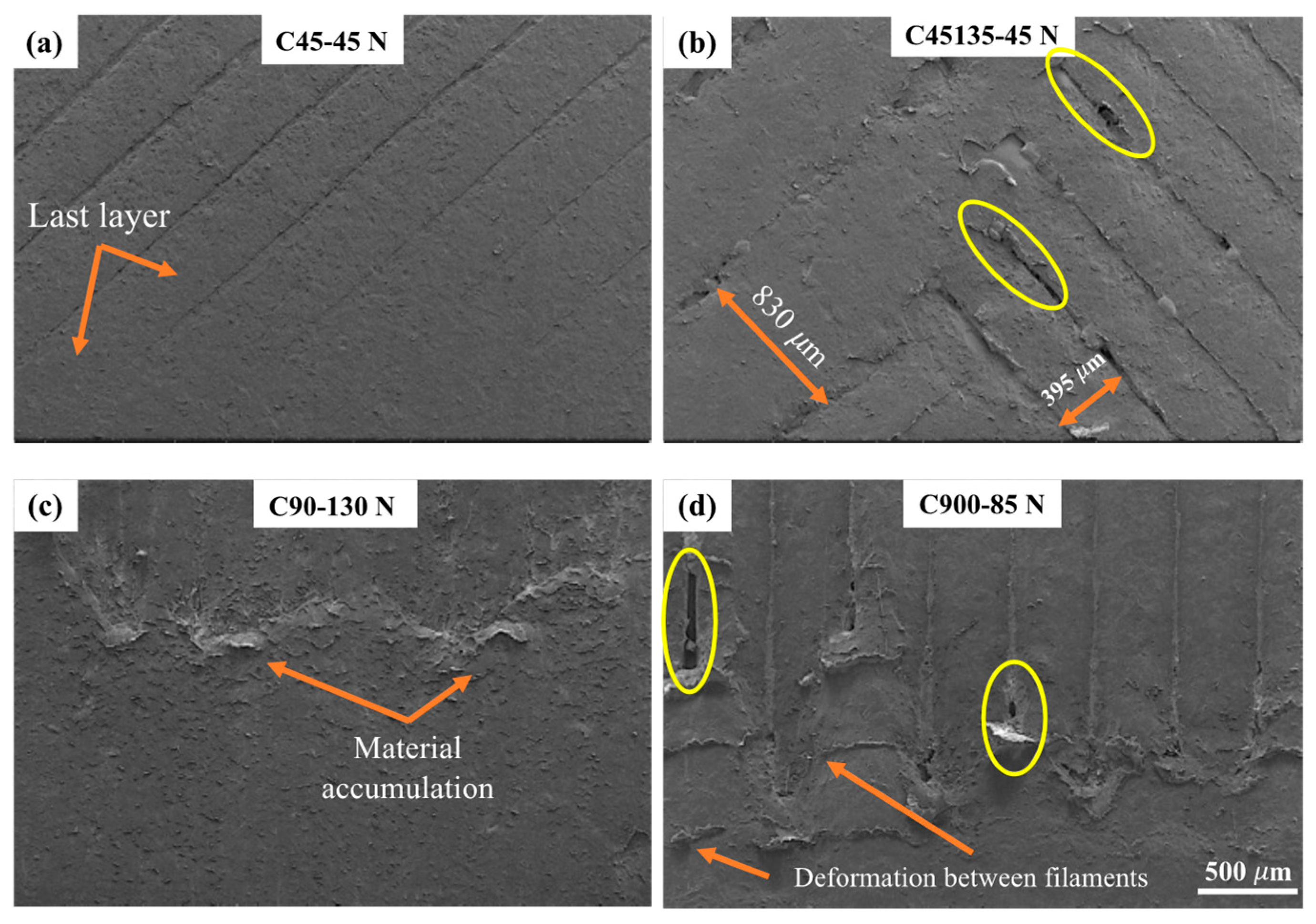

3.3. Wear Mechanisms

3.4. Thermal Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Waste Recycling in Additive Manufacturing: Recovery of Polypropylene from WEEE for the Production of 3D Printing Filaments. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Current Status and Applications of Additive Manufacturing in Dentistry: A Literature-Based Review. J. Oral Biol. Craniofacial Res. 2019, 9, 179–185. [Google Scholar] [CrossRef]

- Kermavnar, T.; Shannon, A.; O’Sullivan, L. The Application of Additive Manufacturing/3D Printing in Ergonomic Aspects of Product Design: A Systematic Review. Appl. Ergon. 2021, 97, 103528. [Google Scholar] [CrossRef]

- Chakraborty, S.; Biswas, M.C. 3D Printing Technology of Polymer-Fiber Composites in Textile and Fashion Industry: A Potential Roadmap of Concept to Consumer. Compos. Struct. 2020, 248, 112562. [Google Scholar] [CrossRef]

- Zhang, Y.; Purssell, C.; Mao, K.; Leigh, S. A Physical Investigation of Wear and Thermal Characteristics of 3D Printed Nylon Spur Gears. Tribol. Int. 2020, 141, 105953. [Google Scholar] [CrossRef]

- Yankin, A.; Serik, G.; Danenova, S.; Alipov, Y.; Temirgali, A.; Talamona, D.; Perveen, A. Optimization of Fatigue Performance of FDM ABS and Nylon Printed Parts. Micromachines 2023, 14, 304. [Google Scholar] [CrossRef] [PubMed]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM Process Parameters Influence over the Mechanical Properties of Polymer Specimens: A Review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Benamira, M.; Benhassine, N.; Ayad, A.; Dekhane, A. Investigation of Printing Parameters Effects on Mechanical and Failure Properties of 3D Printed PLA. Eng. Fail. Anal. 2023, 148, 107218. [Google Scholar] [CrossRef]

- Moradi, M.; Aminzadeh, A.; Rahmatabadi, D.; Rasouli, S.A. Statistical and Experimental Analysis of Process Parameters of 3D Nylon Printed Parts by Fused Deposition Modeling: Response Surface Modeling and Optimization. J. Mater. Eng. Perform. 2021, 30, 5441–5454. [Google Scholar] [CrossRef]

- Galeja, M.; Hejna, A.; Kosmela, P.; Kulawik, A. Static and Dynamic Mechanical Properties of 3D Printed ABS as a Function of Raster Angle. Materials 2020, 13, 297. [Google Scholar] [CrossRef]

- Sınmazçelik, T.; Fidan, S.; Ürgün, S. Effects of 3D Printed Surface Texture on Erosive Wear. Tribol. Int. 2020, 144, 106110. [Google Scholar] [CrossRef]

- Man, Z.; Wang, H.; He, Q.; Kim, D.-E.; Chang, L. Friction and Wear Behaviour of Additively Manufactured Continuous Carbon Fiber Reinforced PA6 Composites. Compos. Part B Eng. 2021, 226, 109332. [Google Scholar] [CrossRef]

- Portoacă, A.I.; Ripeanu, R.G.; Diniță, A.; Tănase, M. Optimization of 3D Printing Parameters for Enhanced Surface Quality and Wear Resistance. Polymers 2023, 15, 3419. [Google Scholar] [CrossRef]

- Mahmood, S.; Guo, E.; Sterling, A.J.; Schulze, K.D. Orientation Controls Tribological Performance of 3D-Printed Model Thermoplastics. Preprints 2023. [Google Scholar] [CrossRef]

- Hanon, M.M.; Zsidai, L. Comprehending the Role of Process Parameters and Filament Color on the Structure and Tribological Performance of 3D Printed PLA. J. Mater. Res. Technol. 2021, 15, 647–660. [Google Scholar] [CrossRef]

- Vaes, D.; Coppens, M.; Goderis, B.; Zoetelief, W.; Van Puyvelde, P. The Extent of Interlayer Bond Strength during Fused Filament Fabrication of Nylon Copolymers: An Interplay between Thermal History and Crystalline Morphology. Polymers 2021, 13, 2677. [Google Scholar] [CrossRef]

- Jain, P.A.K.; Sattar, S.; Mulqueen, D.; Pedrazzoli, D.; Kravchenko, S.G.; Kravchenko, O.G. Role of Annealing and Isostatic Compaction on Mechanical Properties of 3D Printed Short Glass Fiber Nylon Composites. Addit. Manuf. 2022, 51, 102599. [Google Scholar] [CrossRef]

- Puiggalí, J. Aliphatic Polyamides (Nylons): Interplay between Hydrogen Bonds and Crystalline Structures, Polymorphic Transitions and Crystallization. Polym. Cryst. 2021, 4, e10199. [Google Scholar] [CrossRef]

- Lewis, E.L.V.; Ward, I.M. Anisotropic Mechanical Properties of Drawn Nylon 6. I. The α Phase. J. Macromol. Sci. Part B 1980, 18, 1–46. [Google Scholar] [CrossRef]

- Pan, B.; Zhang, S.; Li, W.; Zhao, J.; Liu, J.; Zhang, Y.; Zhang, Y. Tribological and mechanical investigation of MC nylon reinforced by modified graphene oxide. Wear 2012, 294–295, 395–401. [Google Scholar] [CrossRef]

- Randhawa, K.; Patel, A. Influence of Boric Anhydride reinforcement on mechanical properties and abrasive wear of Nylon 6. Mater. Res. Express 2020, 7, 055303. [Google Scholar] [CrossRef]

- Torrado Perez, A.R.; Roberson, D.A.; Wicker, R.B. Fracture Surface Analysis of 3D-Printed Tensile Specimens of Novel ABS-Based Materials. J. Manuf. Mater. Process. 2018, 2, 12. [Google Scholar] [CrossRef]

- Ramian, J.; Ramian, J.; Dziob, D. Thermal Deformations of Thermoplast during 3D Printing: Warping in the Case of ABS. Materials 2021, 14, 7070. [Google Scholar] [CrossRef] [PubMed]

- ASTM Standards G65–04; Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus. ASTM International: West Conshohocken, PA, USA, 2004. [CrossRef]

- Kumar, S.; Panneerselvam, K. Two-body Abrasive Wear Behavior of Nylon 6 and Glass Fiber Reinforced (GFR) Nylon 6 Composite. Procedia Technol. 2016, 25, 1129–1136. [Google Scholar] [CrossRef]

- Hokkirigawa, K.; Kato, K. An Experimental and Theoretical Investigation of Ploughing, Cutting and Wedge Formation during Abrasive Wear. Tribol. Int. 1988, 21, 51–57. [Google Scholar] [CrossRef]

- Cuiffo, M.A.; Snyder, J.; Elliott, A.M.; Romero, N.; Kannan, S.; Halada, G.P. Impact of the Fused Deposition (FDM) Printing Process on Polylactic Acid (PLA) Chemistry and Structure. Appl. Sci. 2017, 7, 579. [Google Scholar] [CrossRef]

- Cadete, M.S.; Gomes, T.E.; Gonçalves, I.; Neto, V. Influence of 3D-Printing Deposition Parameters on Crystallinity and Morphing Properties of PLA-Based Materials. Prog. Addit. Manuf. 2025, 10, 127–137. [Google Scholar] [CrossRef]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Effect of Porosity and Crystallinity on 3D Printed PLA Properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef]

- Nagendra, J.; Srinath, M.K.; Sujeeth, S.; Naresh, K.S.; Prasad, M.S.G. Optimization of Process Parameters and Evaluation of Surface Roughness for 3D Printed Nylon-Aramid Composite. Mater. Today Proc. 2021, 44, 674–682. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Effect of Printing Temperature on Microstructure, Thermal Behavior and Tensile Properties of 3D Printed Nylon Using Fused Deposition Modeling. J. Appl. Polym. Sci. 2020, 138, e50162. [Google Scholar] [CrossRef]

- Zárybnická, L.; Machotová, J.; Pagáč, M.; Rychlý, J.; Vykydalová, A. The Effect of Filling Density on Flammability and Mechanical Properties of 3D-Printed Carbon Fiber-Reinforced Nylon. Polym. Test. 2023, 120, 107944. [Google Scholar] [CrossRef]

- Aziz, R.; Ul Haq, M.I.; Raina, A. Effect of Surface Texturing on Friction Behaviour of 3D Printed Polylactic Acid (PLA). Polym. Test. 2020, 85, 106434. [Google Scholar] [CrossRef]

- Dhakal, N.; Wang, X.; Espejo, C.; Morina, A.; Emami, N. Impact of Processing Defects on Microstructure, Surface Quality, and Tribological Performance in 3D Printed Polymers. J. Mater. Res. Technol. 2023, 23, 1252–1272. [Google Scholar] [CrossRef]

- Amirruddin, M.S.; Ismail, K.I.; Yap, T.C. Effect of Layer Thickness and Raster Angle on the Tribological Behavior of 3D Printed Materials. Mater. Today Proc. 2022, 48, 1821–1825. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Effect of Processing Parameters and Graphite Content on the Tribological Behaviour of 3D Printed Acrylonitrile Butadiene Styrene. Materwiss Werksttech 2015, 46, 1185–1195. [Google Scholar] [CrossRef]

- Chithambaram, K.; Senthilnathan, N. Effects of printing parameters on hardness and wear characteristics of 3D printed polyetheretherketone (PEEK) polymer. Mater. Lett. 2024, 356, 135588. [Google Scholar] [CrossRef]

- Ramesh, M.; Panneerselvam, K. Mechanical Investigation and Optimization of Parameter Selection for Nylon Material Processed by FDM. Mater. Today Proc. 2021, 46, 9303–9307. [Google Scholar] [CrossRef]

- Rezayat, H.; Zhou, W.; Siriruk, A.; Penumadu, D.; Babu, S. Structure–Mechanical Property Relationship in Fused Deposition Modelling. Mater. Sci. Technol. 2015, 31, 895–903. [Google Scholar] [CrossRef]

- Su, W.; Zhou, T.; Zhang, P.; Zhou, H.; Li, H.; Sui, Q. Effect of the Orientation of Laser Stripes on the Abrasion Resistance of Biomimetic Laser Textured Surfaces. Opt. Laser Technol. 2018, 107, 380–388. [Google Scholar] [CrossRef]

- Vázquez Martínez, J.M.; Piñero Vega, D.; Salguero, J.; Batista, M. Evaluation of the Printing Strategies Design on the Mechanical and Tribological Response of Acrylonitrile Styrene Acrylate (ASA) Additive Manufacturing Parts. Rapid Prototyp. J. 2022, 28, 479–489. [Google Scholar] [CrossRef]

- Keshavamurthy, R.; Tambrallimath, V.; Patil, S.; Rajhi, A.A.; Duhduh, A.A.; Khan, T.M.Y. Mechanical and Wear Studies of Boron Nitride-Reinforced Polymer Composites Developed via 3D Printing Technology. Polymers 2023, 15, 4368. [Google Scholar] [CrossRef] [PubMed]

- Zum Gahr, K.H. An Investigation on Low Stress Abrasive Wear Characteristics of High Performance Engineering Thermoplastic Polymers. Wear 1987, 121, 137–151. [Google Scholar] [CrossRef]

| Parameter | Description |

|---|---|

| Abrasive Type | SiO2 |

| Abrasive Size | 50 mesh (212–300 μm) |

| Repeatability | 3 |

| Rubber Wheel Speed | 200 rpm |

| Normal Load | 45, 85, and 130 N |

| Abrasive Mass Flow Rate | 311 g min−1 |

| Test Temperature | 25 °C ± 2 °C |

| Test Duration | 10 min |

| 45 N | 85 N | ||||

| Printing Direction | First Layer | Second Layer | First Layer | Second Layer | Third Layer |

| C0 | 243.1 ± 10.48 | - | 375.0 ± 6.01 | 148.8 ± 3.46 | - |

| C45 | 294.1 ± 11.39 | - | 402.8 ± 13.36 | 205.7 ± 22.93 | 115.1 ± 12.81 |

| C90 | 298.2 ± 3.34 | - | 331.3 ± 17.05 | 75.4 ± 5.56 | - |

| C900 | 278.7 ± 2.89 | 68.6 ± 2.12 | 403.7 ± 5.62 | 234.9 ± 2.45 | 125.1 ± 1.22 |

| C45135 | 29,815 ± 21.09 | 27.4 ± 0.87 | 368.2 ± 14.93 | 110.7 ± 1.86 | 41.8 ± 0.45 |

| 130 N | |||||

| Printing direction | First Layer | Second layer | Third layer | Fourth layer | |

| C0 | 441.0 ± 8.23 | 221.4 ± 15.11 | 91.5 ± 9.98 | - | |

| C45 | 436.7 ± 10.72 | 269.6 ± 21.19 | 141.2 ± 5.48 | - | |

| C90 | 431.4 ± 9.71 | 278.3 ± 4.39 | 106.1 ± 3.42 | - | |

| C900 | 463.5 ± 18.51 | 260.2 ± 4.81 | 158.0 ± 21.45 | 60.6 ± 0.93 | |

| C45135 | 432.1 ± 14.01 | 227.5 ± 7.22 | 112.6 ± 3.29 | 24.1 ± 4.68 | |

| Material | Ti °C | Tf °C | Ts1 °C | Ts2 °C | Enthalpy mVs/mg | Td °C |

|---|---|---|---|---|---|---|

| as-received Nylon | 174.1 | 224.5 | - | 214.3 | 237.6 | 440 |

| C0 pattern not exposed to abrasion | 125.6 | 232.1 | 170 | 212.8 | 511.1 | |

| C0 pattern exposed to abrasion | 109.1 | 230.4 | 145.1 | 214.1 | 486.4 | |

| C45135 pattern not exposed to abrasion | 89.3 | 225.5 | 133.0 | 216.4 | 332.4 | |

| C45135 pattern exposed to abrasion | 52.2 | 225.3 | 120.1 | 215.9 | 580.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Briones, F.; Valverde, B.; Donaire, R.; González, Á.; Antico, F.; Martínez, C. Effect of Printing Direction of 3D-Printed Nylon Under Abrasive Wear Conditions. Polymers 2025, 17, 2812. https://doi.org/10.3390/polym17212812

Briones F, Valverde B, Donaire R, González Á, Antico F, Martínez C. Effect of Printing Direction of 3D-Printed Nylon Under Abrasive Wear Conditions. Polymers. 2025; 17(21):2812. https://doi.org/10.3390/polym17212812

Chicago/Turabian StyleBriones, Francisco, Barbara Valverde, Ricardo Donaire, Álvaro González, Federico Antico, and Carola Martínez. 2025. "Effect of Printing Direction of 3D-Printed Nylon Under Abrasive Wear Conditions" Polymers 17, no. 21: 2812. https://doi.org/10.3390/polym17212812

APA StyleBriones, F., Valverde, B., Donaire, R., González, Á., Antico, F., & Martínez, C. (2025). Effect of Printing Direction of 3D-Printed Nylon Under Abrasive Wear Conditions. Polymers, 17(21), 2812. https://doi.org/10.3390/polym17212812