Development and Feasibility Assessment of a Sequential Antenna Deployment System Based on Fiber-Reinforced Shape Memory Polymer Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Proposed Deployment Mechanism

2.2. Shape Memory Polymer (SMP) Fabrication

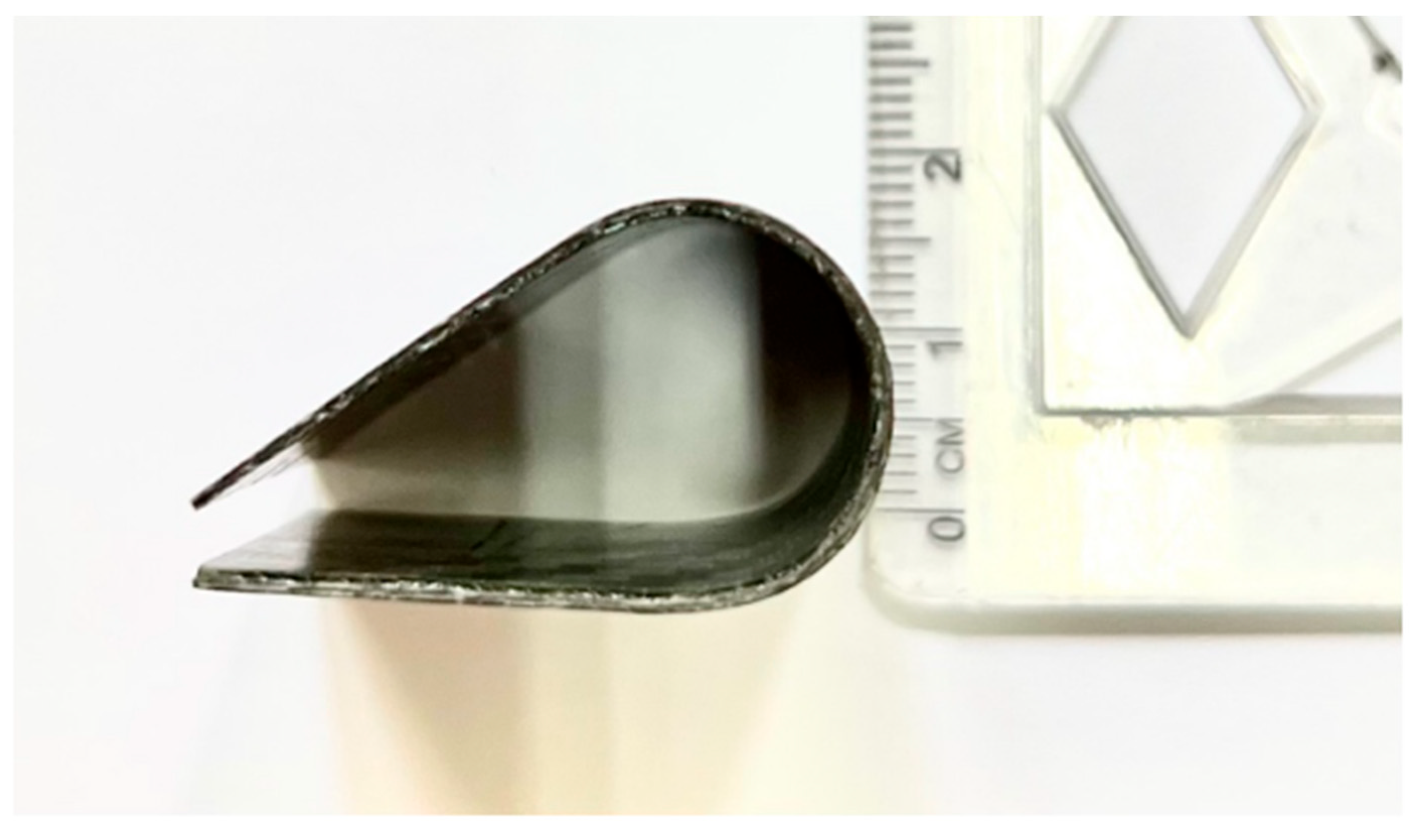

2.3. SMPC Fabrication and Curing

2.4. SMPC Programming

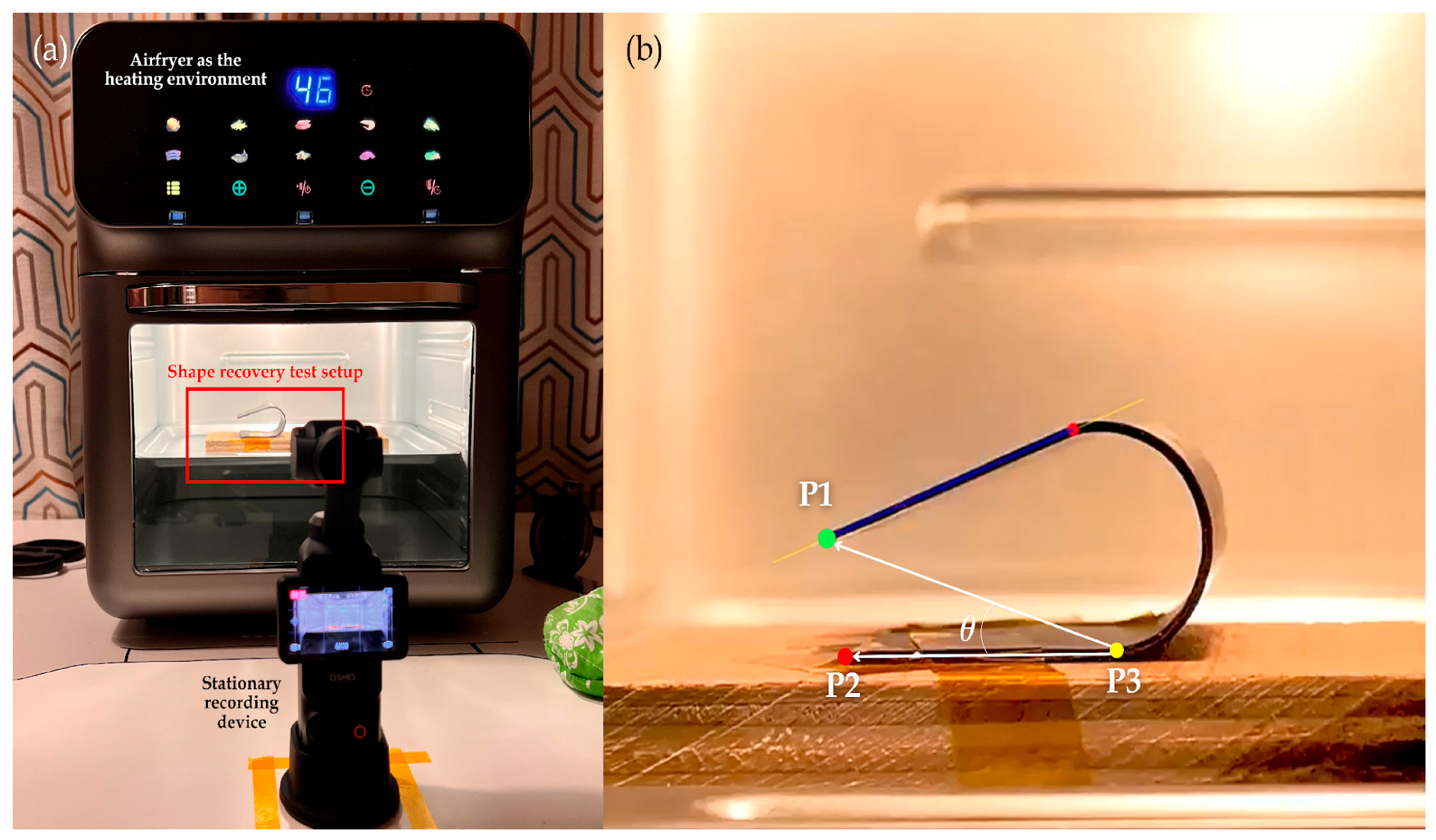

2.5. Shape Memory Behavior

2.5.1. Shape Fixity Ratio, Rf

2.5.2. Shape Recovery Ratio, Rr

2.6. Function Validation Through Deployment Testing

3. Results and Discussions

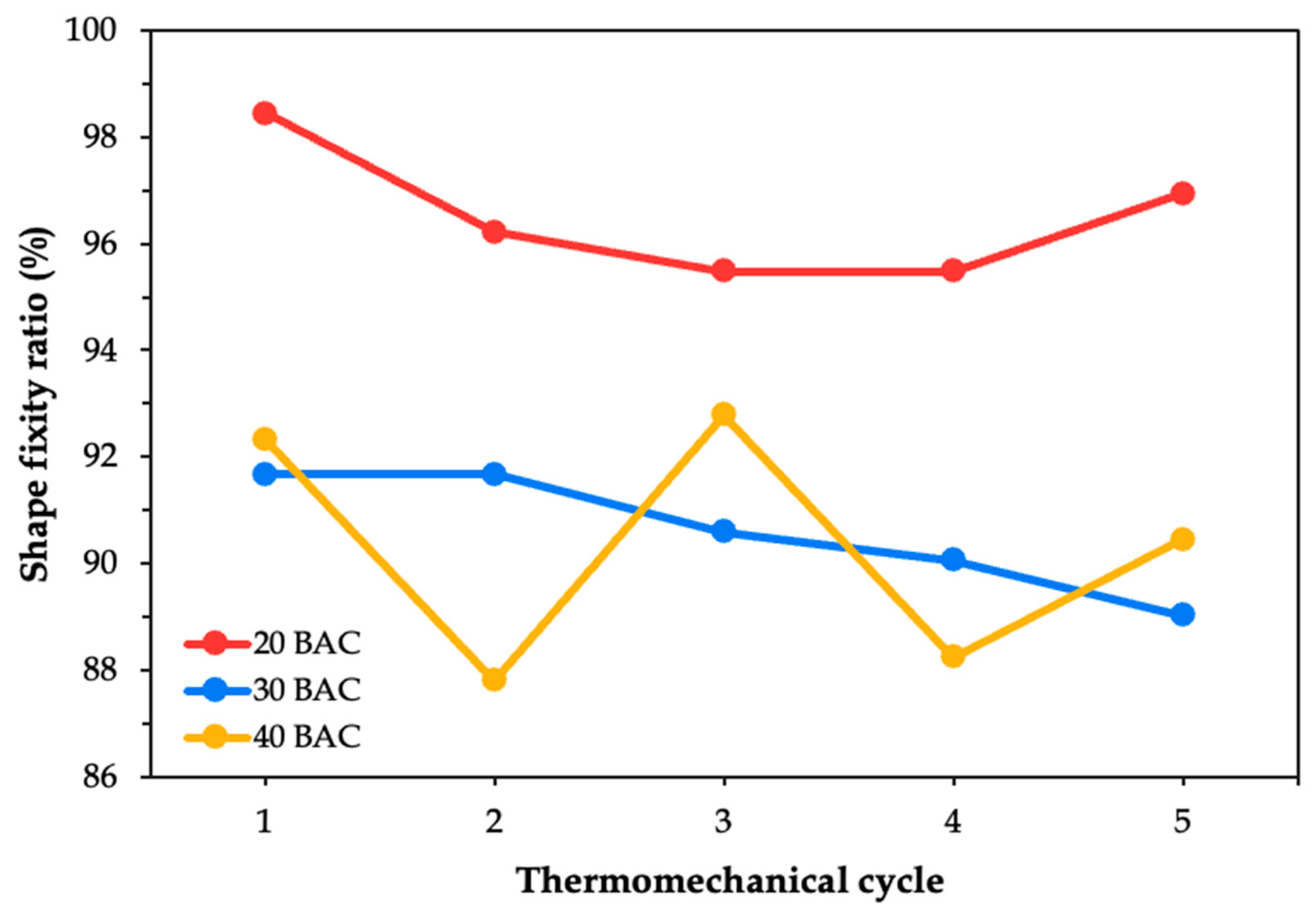

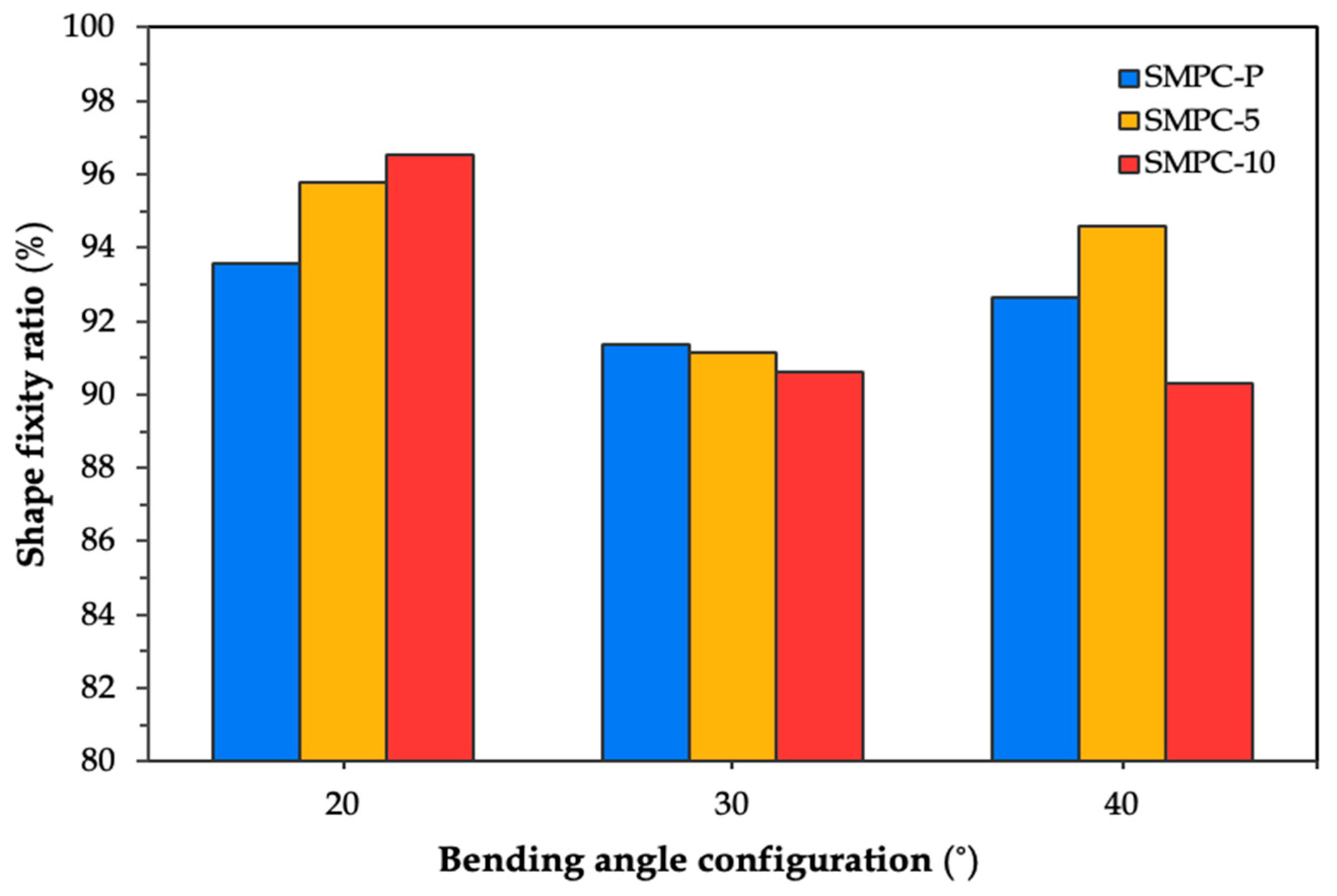

3.1. Shape Fixity Ratio

3.2. Shape Recovery Ratio

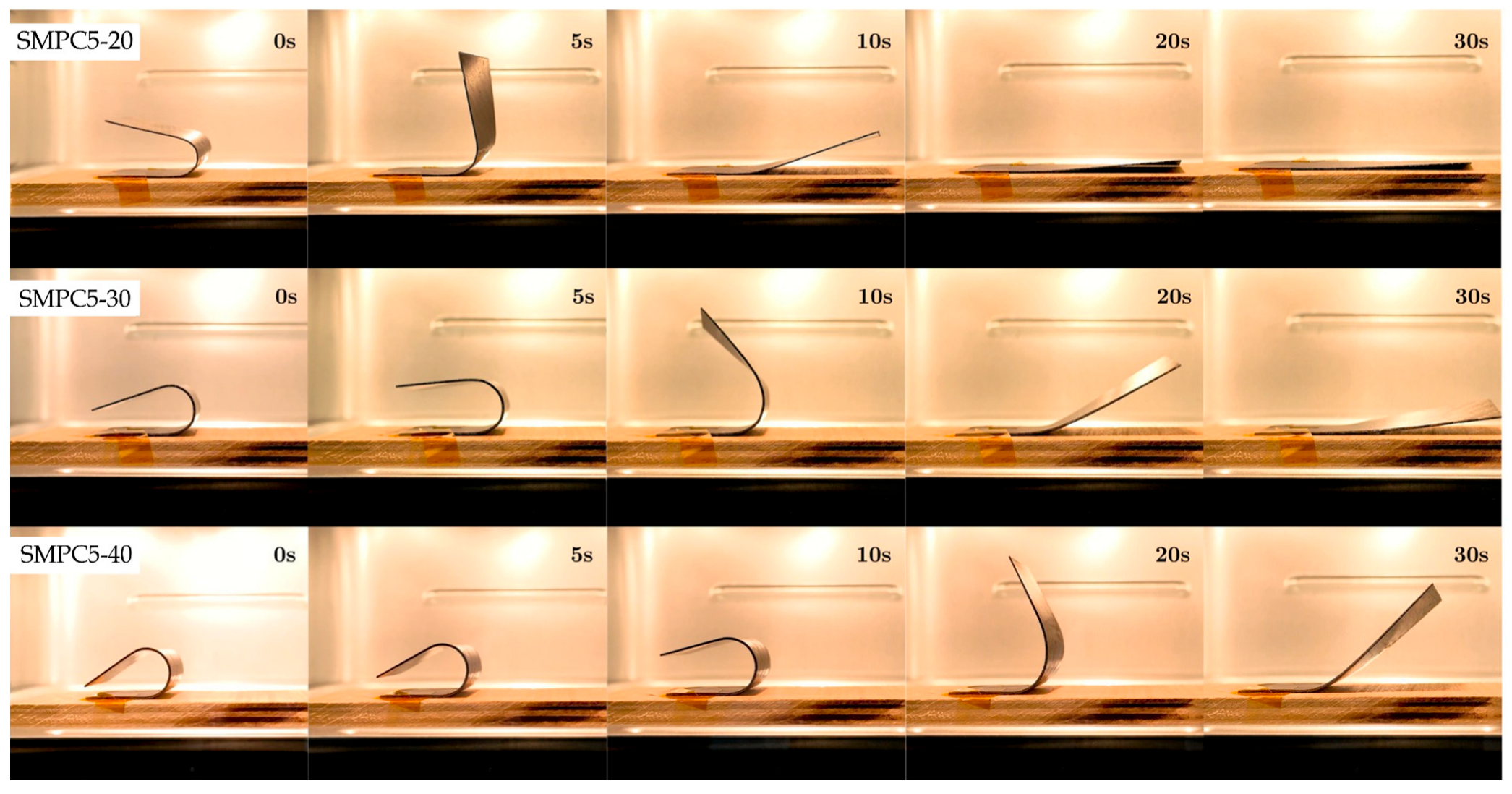

3.3. Function Validation Through Deployment Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile butadiene styrene |

| BAC | Bending angle configuration |

| CF | Carbon fiber-reinforced |

| DGEBA | Bisphenol A diglycidyl ether |

| LEO | Low Earth Orbit |

| PEG | Poly(ethylene glycol) |

| SMM | Shape memory material |

| SMP | Shape memory polymer |

| SMPC | Shape memory polymer composites |

| Tg | Glass transition temperature |

| UHF | Ultra high frequency |

| UV | Ultraviolet |

| VHF | Very high frequency |

References

- Malisuwan, S.; Kanchanarat, B. Small satellites for low-cost space access: Launch, deployment, integration, and in-space logistics. Am. J. Ind. Bus. Manag. 2022, 12, 1480–1497. [Google Scholar]

- Saeed, N.; Elzanaty, A.; Almorad, H.; Dahrouj, H.; Al-Naffouri, T.Y.; Alouini, M.S. CubeSat communications: Recent advances and future challenges. IEEE Commun. Surv. Tutor. 2020, 22, 1839–1862. [Google Scholar] [CrossRef]

- Philippine Space Agency. Satellite Development Perspectives from the Philippines and Argentina. PhilSA. Available online: https://philsa.gov.ph/news/satellite-development-perspectives-from-the-philippines-and-argentina/ (accessed on 21 August 2025).

- Li, X.; Sigen, A. Optimization of Deployable Antennas: Material, Structure and Drive Mode. Innov. Sci. Technol. 2024, 3, 55–65. [Google Scholar] [CrossRef]

- Abulgasem, S.; Tubbal, F.; Raad, R.; Theoharis, P.I.; Lu, S.; Iranmanesh, S. Antenna designs for CubeSats: A review. IEEE Access 2021, 9, 45289–45324. [Google Scholar] [CrossRef]

- Essoumati, S.; Gharnati, F.; Said, A.O. Study and Design of a Reliable Antenna Deployment System for Nanosatellites. In Proceedings of the 2024 International Microwave and Antenna Symposium (IMAS), Marrakech, Morocco, 21–23 October 2024; pp. 1–4. [Google Scholar]

- Rivera, A.; Stewart, A. Study of spacecraft deployables failures. In Proceedings of the 19th European Space Mechanisms and Tribology Symposium (ESMATS), Warsaw, Poland, 8–10 September 2021. [Google Scholar]

- Jacklin, S.A. Small-Satellite Mission Failure Rates; NASA/TM—2018-220034; NASA Ames Research Center: Moffett Field, CA, USA, 2019.

- Noto, J.; Doe, R.; Bellardo, J.; Cutler, J.; Higginbotham, S.; Kerr, R.; Puig-Suari, J.; Hinkley, D. A Failure Analysis of the ExoCube Cubesat. In Proceedings of the 13th Annual CubeSat Workshop, San Luis Obispo, CA, USA, 20 April 2016. [Google Scholar]

- Bhattarai, S.; Go, J.S.; Oh, H.U. Experimental CanSat platform for functional verification of burn wire triggering-based holding and release mechanisms. Aerospace 2021, 8, 192. [Google Scholar] [CrossRef]

- Salvatus, J.; Constante, M.A.; Violan, E.P.; Salces, A.; Paet, L.B.; Talampas, M.C.; Marciano, J.S. Development of deployable antennas for the Diwata-2 microsatellite’s amateur radio payload. In Proceedings of the 2017 IEEE International Conference on Communication, Networks and Satellite (COMNETSAT), Semarang, Indonesia, 5–7 October 2017; pp. 26–31. [Google Scholar]

- Belvin, W.K.; Straubel, M.; Wilkie, W.K.; Zander, M.E.; Fernandez, J.M.; Hillebrandt, M.F. Advanced Deployable Structural Systems for Small Satellites. In Proceedings of the NATO Specialists’ Meeting AVT-257-RSM-041: Best Practices for Risk Reduction for Overall Space Systems, Zaragoza, Spain, 26–28 September 2016; Volume 26, pp. 1–12. [Google Scholar]

- Costantine, J.; Tawk, Y.; Maqueda, I.; Sakovsky, M.; Olson, G.; Pellegrino, S.; Christodoulou, C.G. UHF Deployable Helical Antennas for CubeSats. IEEE Trans. Antennas Propag. 2016, 64, 3752–3759. [Google Scholar] [CrossRef]

- Sauder, J.; Gebara, C.; Reddy, N.H.; García-Mora, C.J. A framework for small satellite deployable structures and how to deploy them reliably. Commun. Eng. 2024, 3, 72. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, L.; Leng, J.; Liu, Y. Ultra-Light Release Device Integrated with Screen-Printed Heaters for CubeSat’s Deployable Solar Arrays. Compos. Struct. 2020, 232, 111561. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.V.; Filippova, O.V.; Tcherdyntsev, V.V.; Telyshev, D.V. Shape memory polymers as smart materials: A review. Polymers 2022, 14, 3511. [Google Scholar] [CrossRef]

- Iorio, L.; Bellisario, D.; Quadrini, F. Manufacturing and Testing of Shape Memory Polymer Composite Actuators. In Selected Topics in Manufacturing: Emerging Trends from the Perspective of AITeM’s Young Researchers; Springer Nature: Cham, Switzerland, 2023; pp. 141–157. [Google Scholar]

- Santo, L.; Quadrini, F.; Bellisario, D.; Iorio, L. Applications of Shape-Memory Polymers, and Their Blends and Composites. In Shape Memory Polymers, Blends and Composites: Advances and Applications; Springer: Singapore, 2019; pp. 311–329. [Google Scholar]

- Moskvichev, E.V.; Larichkin, A.Y. Study of the functional and mechanical properties of a shape memory polymer composite for a space antenna reflector. Inorg. Mater. 2021, 57, 1491–1496. [Google Scholar] [CrossRef]

- Jang, J.H.; Hong, S.B.; Kim, J.G.; Goo, N.S.; Yu, W.R. Accelerated testing method for predicting long-term properties of carbon fiber-reinforced shape memory polymer composites in a low earth orbit environment. Polymers 2021, 13, 1628. [Google Scholar] [CrossRef]

- Bouzoukis, K.P.; Moraitis, G.; Kostopoulos, V.; Lappas, V. An Overview of CubeSat Missions and Applications. Aerospace 2025, 12, 550. [Google Scholar] [CrossRef]

- Liu, T.; Liu, L.; Yu, M.; Li, Q.; Zeng, C.; Lan, X.; Leng, J. Integrative Hinge Based on Shape Memory Polymer Composites: Material, Design, Properties and Application. Compos. Struct. 2018, 206, 164–176. [Google Scholar] [CrossRef]

- Li, F.; Liu, L.; Lan, X.; Pan, C.; Liu, Y.; Leng, J.; Xie, Q. Ground and Geostationary Orbital Qualification of a Sunlight-Stimulated Substrate Based on Shape Memory Polymer Composite. Smart Mater. Struct. 2019, 28, 075023. [Google Scholar] [CrossRef]

- Ming, G.; Liu, L.; Liu, Y.; Leng, J. Space Deployable Parabolic Reflector Based on Shape Memory Polymer Composites. Compos. Struct. 2023, 304, 116327. [Google Scholar] [CrossRef]

- Li, F.; Scarpa, F.; Lan, X.; Liu, L.; Liu, Y.; Leng, J. Bending Shape Recovery of Unidirectional Carbon Fiber Reinforced Epoxy-Based Shape Memory Polymer Composites. Compos. Part A Appl. Sci. Manuf. 2019, 116, 169–179. [Google Scholar] [CrossRef]

- Mohammed, M.I.; El-Sayed, F. PEG’s Impact as a Plasticizer on the PVA Polymer’s Structural, Thermal, Mechanical, Optical, and Dielectric Characteristics. Opt. Quantum Electron. 2023, 55, 1141. [Google Scholar] [CrossRef]

- Li, Z.; Yang, Y.; Ma, L.; Liu, H.; Zhang, X. Shape Memory Epoxy Resin and Its Composite with Good Shape Memory Performance and High Mechanical Strength. Polym. Bull. 2023, 80, 1641–1655. [Google Scholar] [CrossRef]

- Margoy, D.; Gouzman, I.; Grossman, E.; Bolker, A.; Eliaz, N.; Verker, R. Epoxy-Based Shape Memory Composite for Space Applications. Acta Astronaut. 2021, 178, 908–919. [Google Scholar] [CrossRef]

- Bellisario, D.; Quadrini, F.; Iorio, L.; Santo, L.; Zhang, Z.; Li, X.; Dong, H.; Semitekolos, D.; Konstantopoulos, G.; Charitidis, C.A. Microscopic Testing of Carbon Fiber Laminates with Shape Memory Epoxy Interlayer. Mater. Today Commun. 2022, 32, 103854. [Google Scholar] [CrossRef]

- Kumar, S.S.; Akmal, J.S.; Salmi, M. 4D Printing of Shape Memory Polymer with Continuous Carbon Fiber. Prog. Addit. Manuf. 2024, 9, 1985–1995. [Google Scholar] [CrossRef]

- Jayalath, H.T.S.; Herath, M.; Epaarachchi, J. Cyanate esters as a high performing shape memory polymer: A review. Mater. Today Proc. 2022, 57, 693–700. [Google Scholar] [CrossRef]

- Singh, A.; Chamola, R.; Goyat, M.S.; Paul, B.; Das, S. Effect of polyethylene glycol on rheological, thermo-mechanical, and tribological behavior of epoxy. Polym. Eng. Sci. 2025, 65, 1433–1447. [Google Scholar] [CrossRef]

- Jayan, J.S.; Saritha, A.; Deeraj, B.D.S.; Joseph, K. Role of polyethylene glycol as a catalyst and a filler in epoxy systems. Top. Catal. 2024, 67, 218–231. [Google Scholar] [CrossRef]

- Li, G.; Xu, W. Thermomechanical behavior of thermoset shape memory polymer programmed by cold-compression: Testing and constitutive modeling. J. Mech. Phys. Solids 2011, 59, 1231–1250. [Google Scholar] [CrossRef]

- Ahmadi-Khaneghah, A.; Omidi-Ghallemohamadi, M.; Behniafar, H. PEG-Based Epoxy and Epoxy/Silica Networks: Thermal, Mechanical, and Thermo-Mechanical Investigations. Int. J. Adhes. Adhes. 2019, 95, 102433. [Google Scholar]

- Lei, M.; Chen, Z.; Lu, H.; Yu, K. Recent progress in shape memory polymer composites: Methods, properties, applications and prospects. Nanotechnol. Rev. 2019, 8, 327–351. [Google Scholar] [CrossRef]

- Jing, X.; Wei, J.; Liu, Y.; Song, B.; Liu, Y. Deployment Analysis of Aramid Fiber Reinforced Shape-Memory Epoxy Resin Composites. Eng. Sci. 2020, 11, 44–53. [Google Scholar] [CrossRef]

| Feature | Burn Wire | Spring- Loaded | Motorized | Proposed SMPC-Based |

|---|---|---|---|---|

| Deployment Shock (Lower is better) | High | High | Low | Low |

| Power Consumption (Lower is better) | Low | None | High | None |

| Mass & Complexity (Lower is better) | Low | Low | High | Low |

| Deployment Speed (No preference) | Fast | Fast | Slow | Slow |

| Reliability (Higher is better) | Moderate | High | High | Needs testing |

| Component | Question | Response |

|---|---|---|

| Deployment success | Did the antenna deploy? | YES or NO |

| Motion quality assessment | Does the antenna motion display jittery behavior? | YES or NO |

| Deployment completeness | What is the extent of BAC deployment achieved? | PARTIAL or COMPLETE |

| Structural inspection | Are there any visible cracks on the SMPC sample? | YES or NO * |

| Variable | Definition | Unit |

|---|---|---|

| Deployment time | Time it took for the antenna to fully deploy | seconds (s) |

| Activation temperature | Temperature at which the first SMPC release component begins to uncurl | Celsius (°C) |

| Bending Angle Configuration | Deployment Success | Motion Quality | Deployment Completeness | Structural Cracks |

|---|---|---|---|---|

| 20 | Yes | Partial Non-uniform Motion (SMPC-10) | Complete | None |

| 30 | Yes | Partial Non-uniform Motion (SMPC-10) | Complete | None |

| 40 | Yes | Partial Non-uniform Motion (SMPC-10) | Complete | None |

| Bending Angle (°) | Deployment Time (s) | Activation Temperature (°C) |

|---|---|---|

| 20 | 92 s | 60 |

| 30 | 116 s | 60 |

| 40 | 122 s | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De la Cruz, M.T.; Gamboa, R.G.P.; Dalisay, J.D.E.; Raguindin, R.K.M.; Magdaluyo, E.R., Jr. Development and Feasibility Assessment of a Sequential Antenna Deployment System Based on Fiber-Reinforced Shape Memory Polymer Composites. Polymers 2025, 17, 2797. https://doi.org/10.3390/polym17202797

De la Cruz MT, Gamboa RGP, Dalisay JDE, Raguindin RKM, Magdaluyo ER Jr. Development and Feasibility Assessment of a Sequential Antenna Deployment System Based on Fiber-Reinforced Shape Memory Polymer Composites. Polymers. 2025; 17(20):2797. https://doi.org/10.3390/polym17202797

Chicago/Turabian StyleDe la Cruz, Marylen T., Riana Gabrielle P. Gamboa, Jon Dewitt E. Dalisay, Ricky Kristan M. Raguindin, and Eduardo R. Magdaluyo, Jr. 2025. "Development and Feasibility Assessment of a Sequential Antenna Deployment System Based on Fiber-Reinforced Shape Memory Polymer Composites" Polymers 17, no. 20: 2797. https://doi.org/10.3390/polym17202797

APA StyleDe la Cruz, M. T., Gamboa, R. G. P., Dalisay, J. D. E., Raguindin, R. K. M., & Magdaluyo, E. R., Jr. (2025). Development and Feasibility Assessment of a Sequential Antenna Deployment System Based on Fiber-Reinforced Shape Memory Polymer Composites. Polymers, 17(20), 2797. https://doi.org/10.3390/polym17202797