Functional Data Analysis for the Structural, Chemical, Thermal, and Mechanical Properties of PA12 Additively Manufactured via SLS

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Manufacturing Conditions

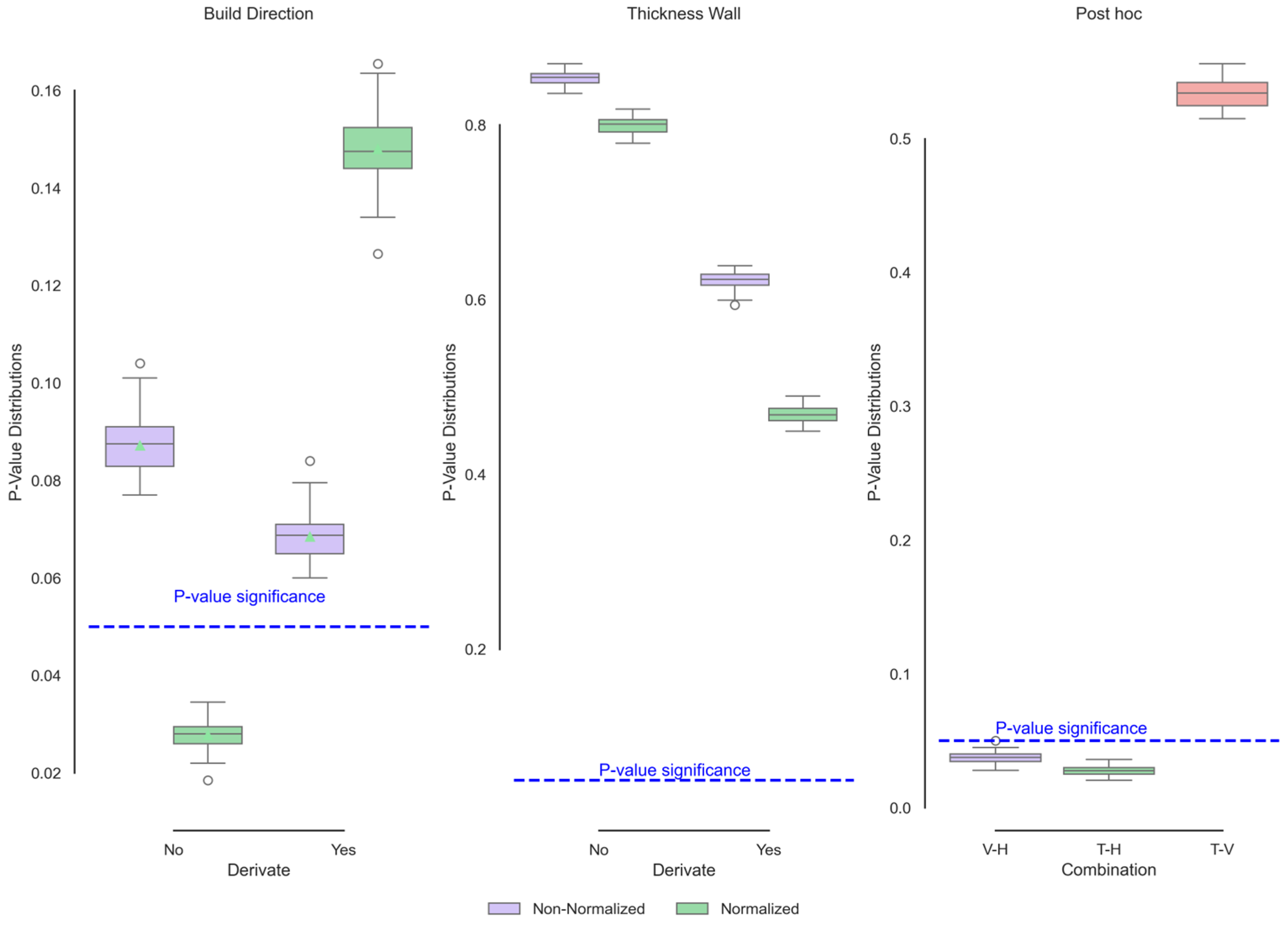

2.2. Experimental Design and Statistical Analyses

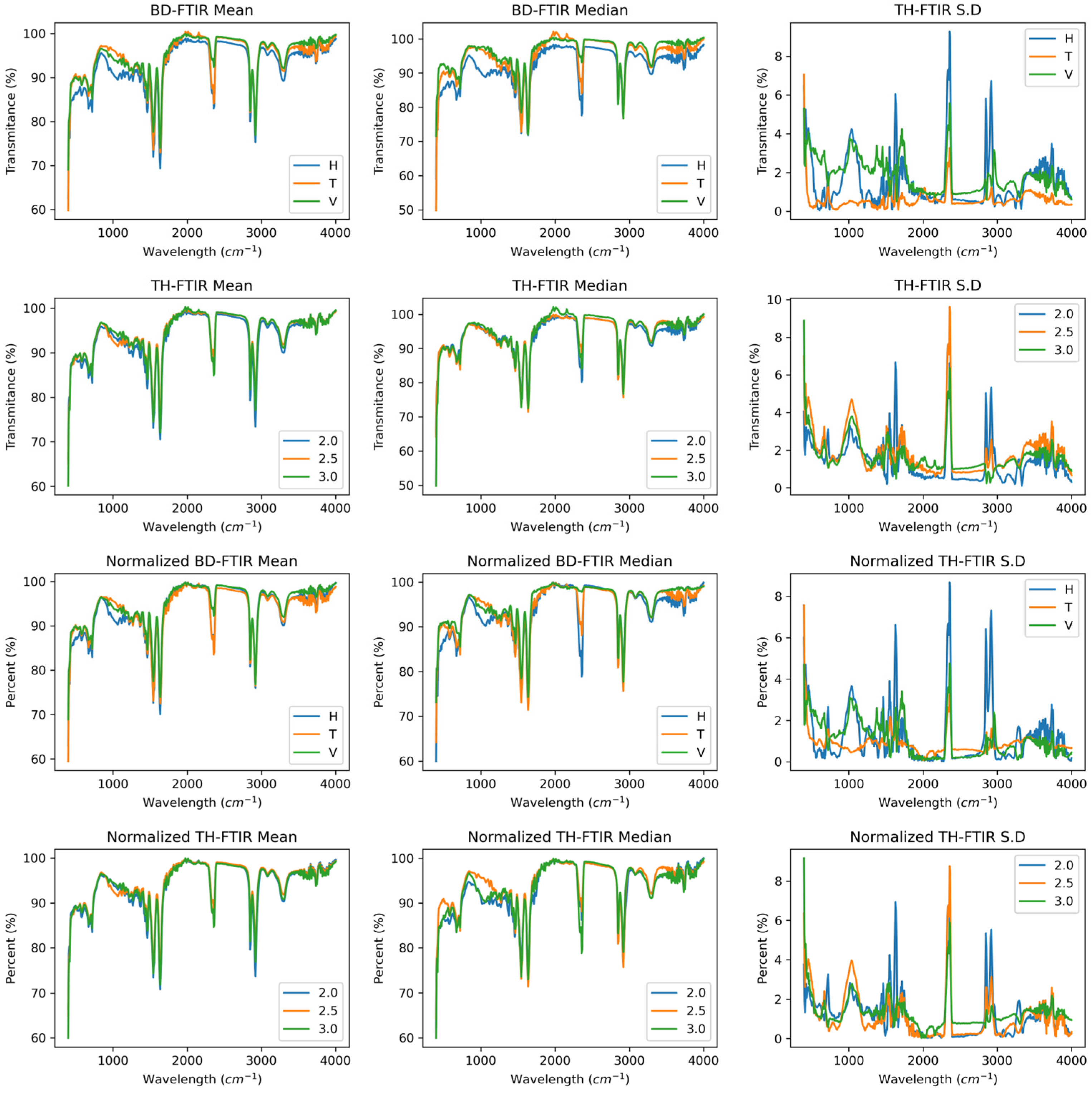

2.3. Transform Fourier Infrared (FTIR) Curves

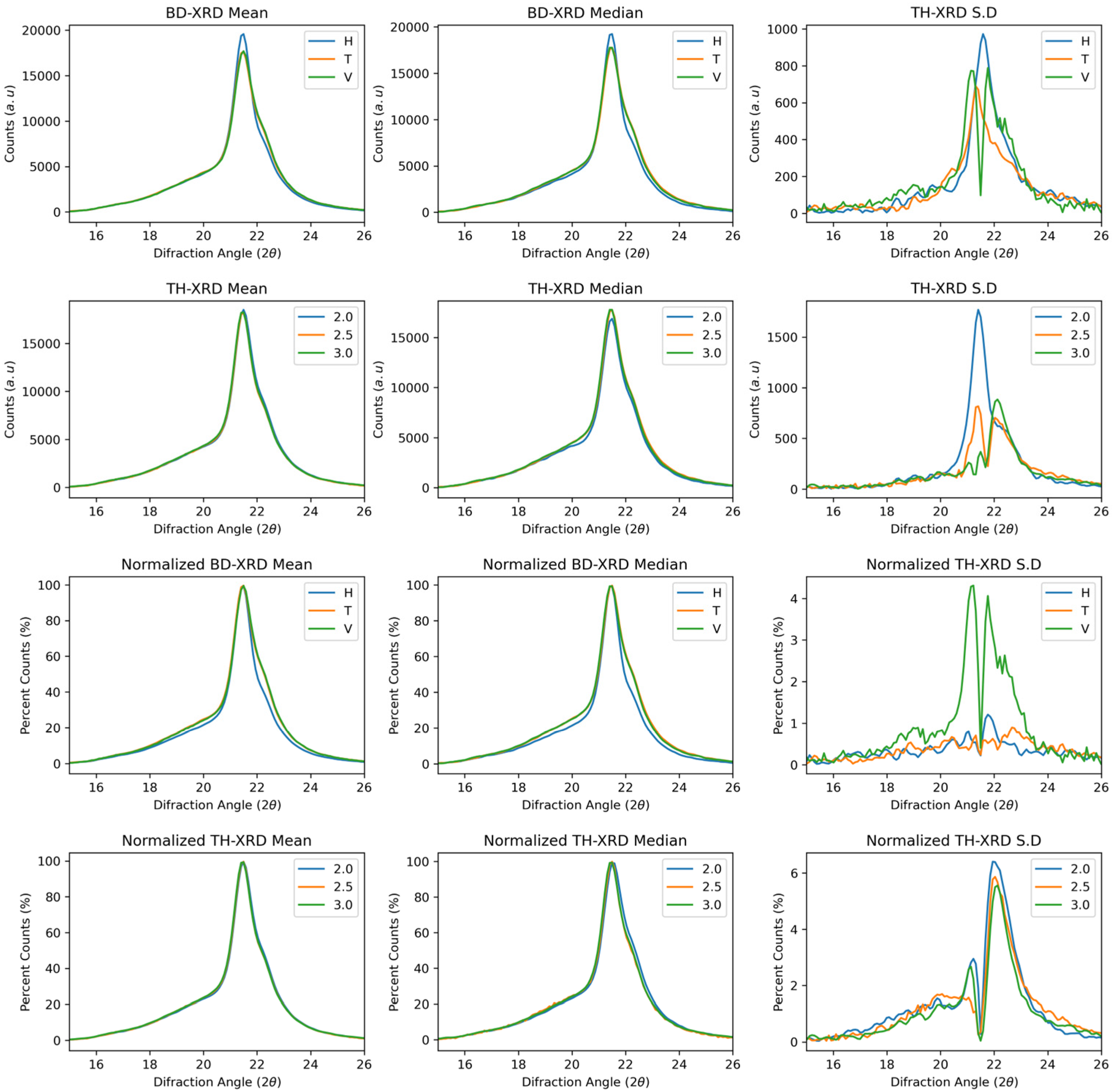

2.4. X-Ray Diffraction (XRD) Curves

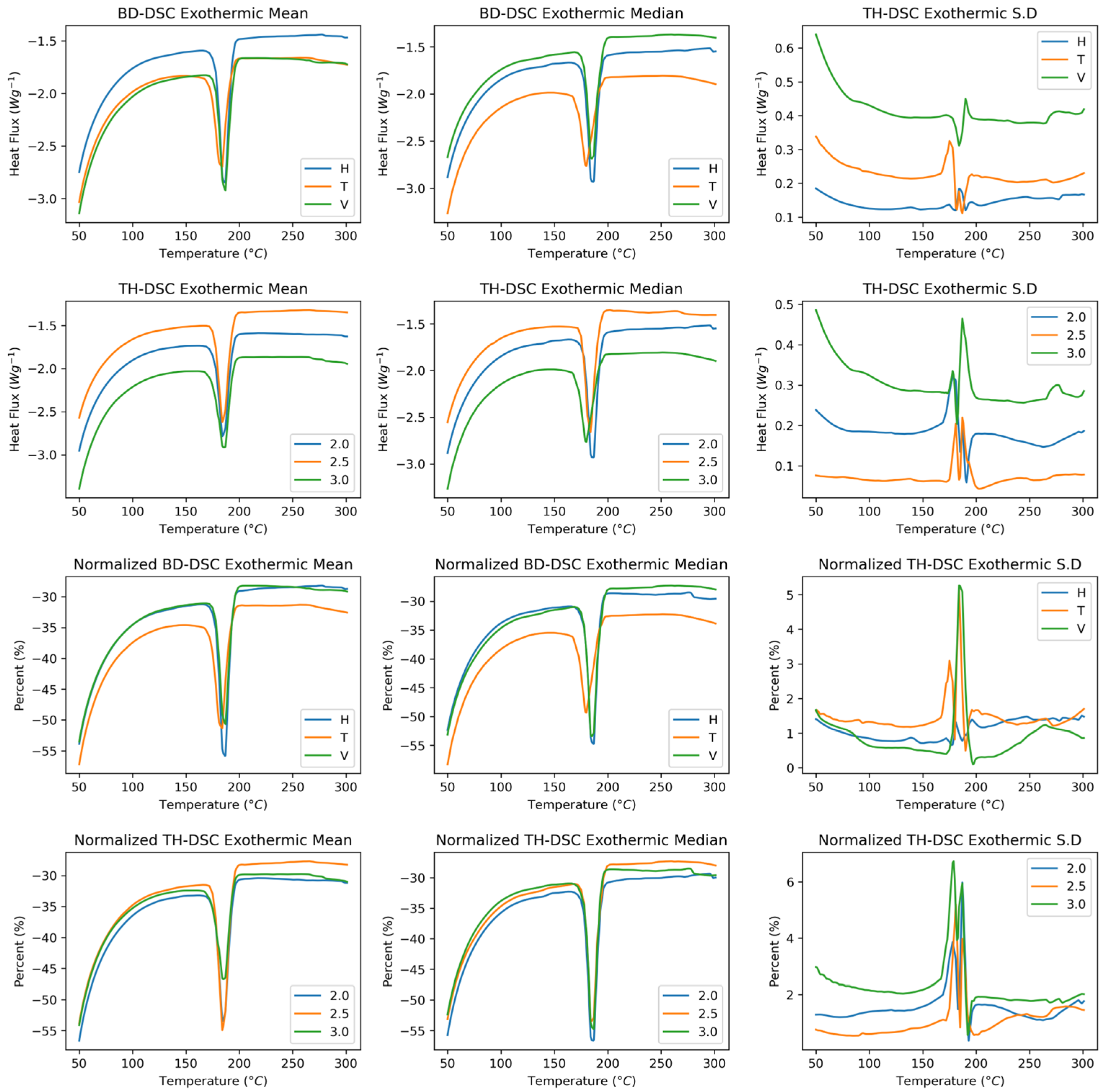

2.5. Differential Scanning Calorimetry (DSC) Curves

2.6. Stress–Strain Curves

2.7. Domain Discretisation

2.8. Functional Data Analysis

3. Results and Discussion

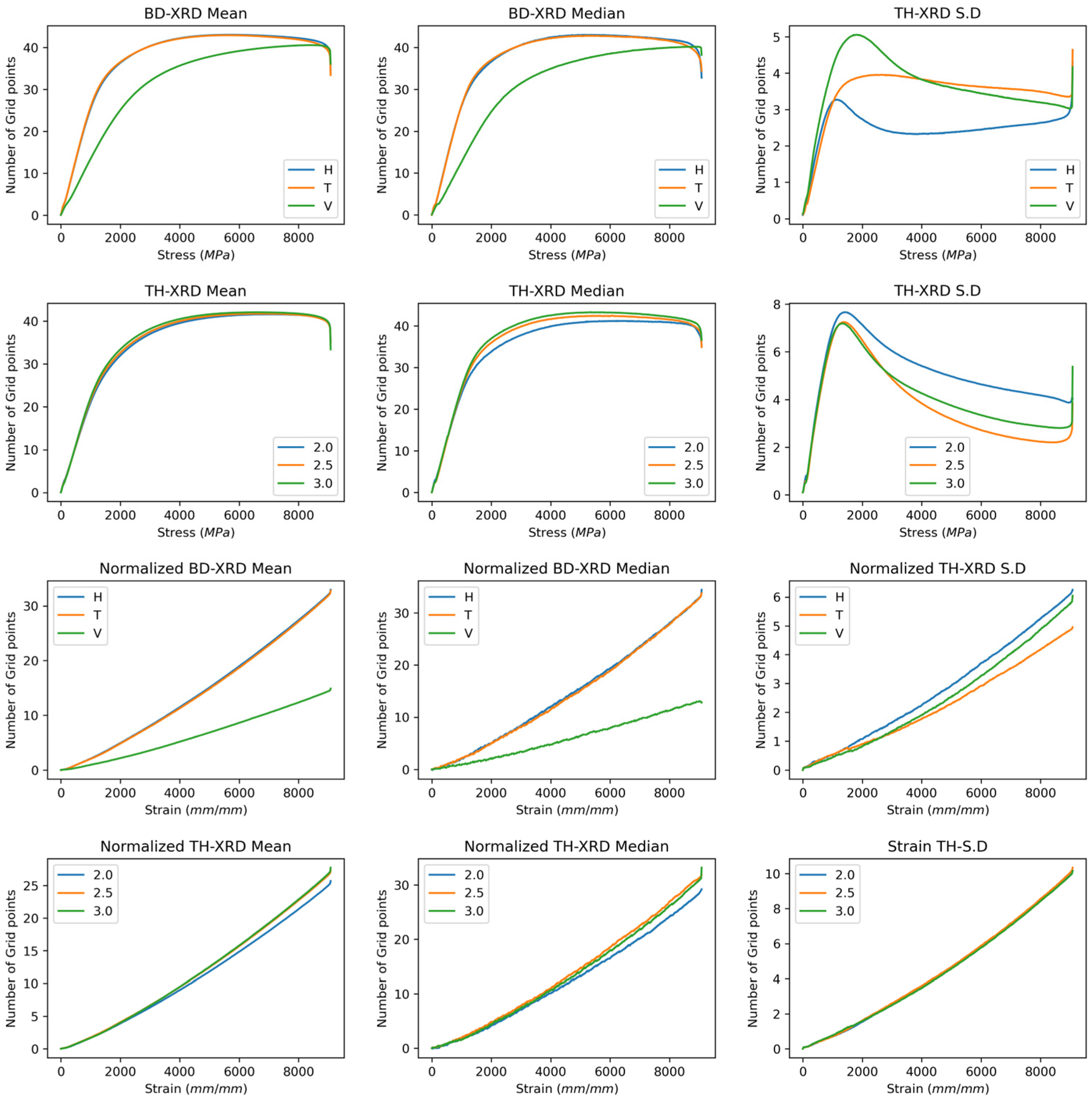

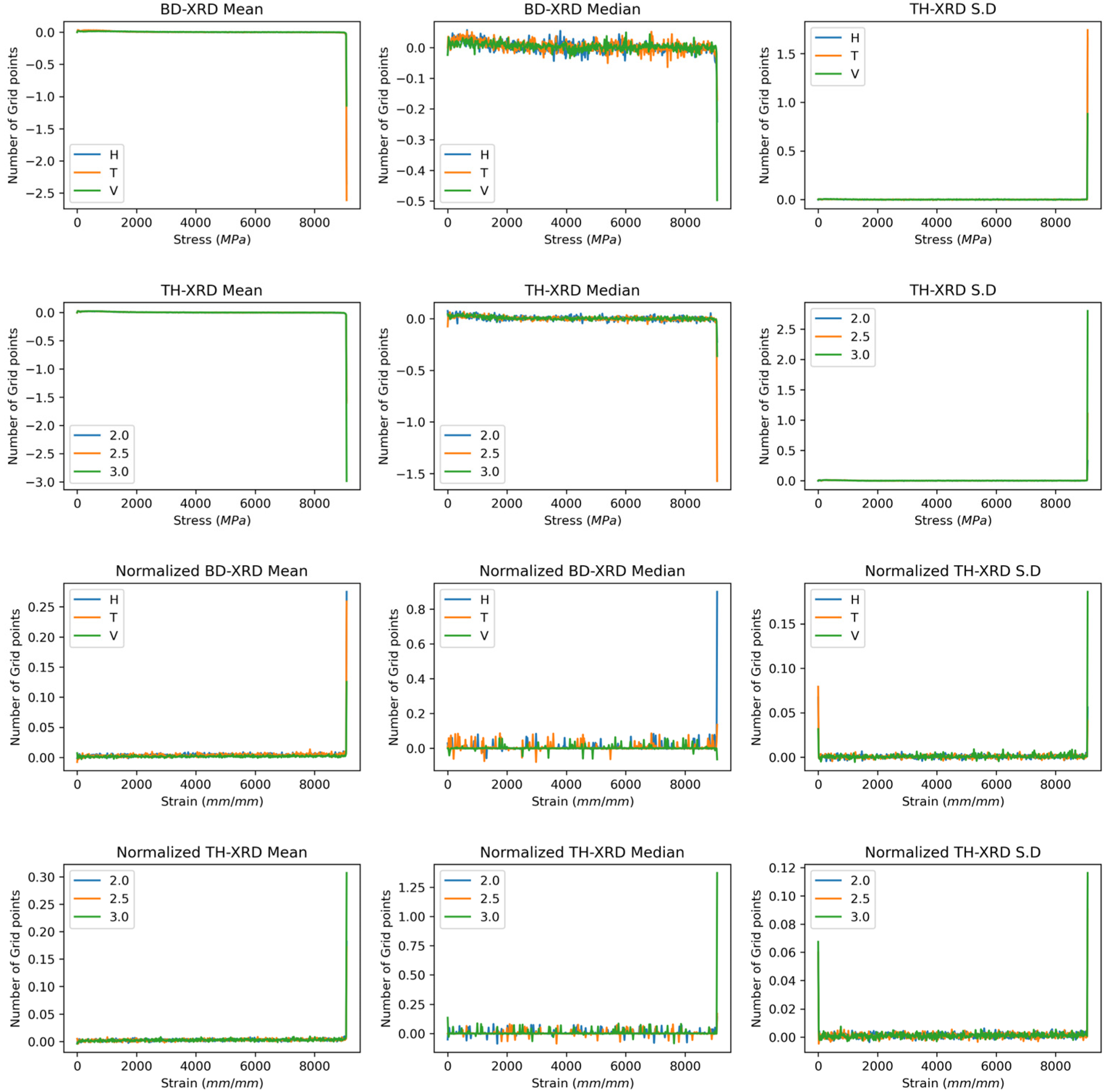

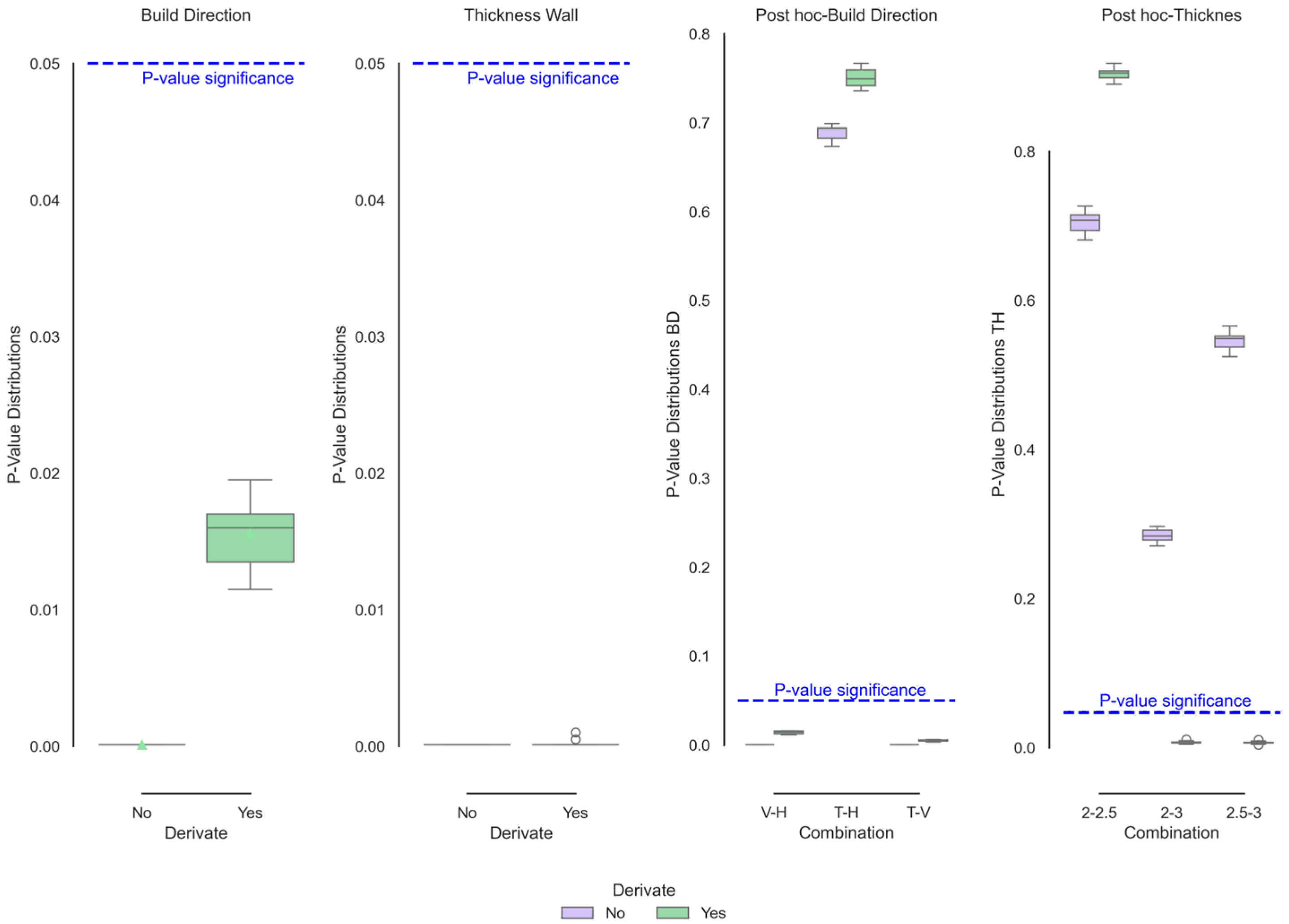

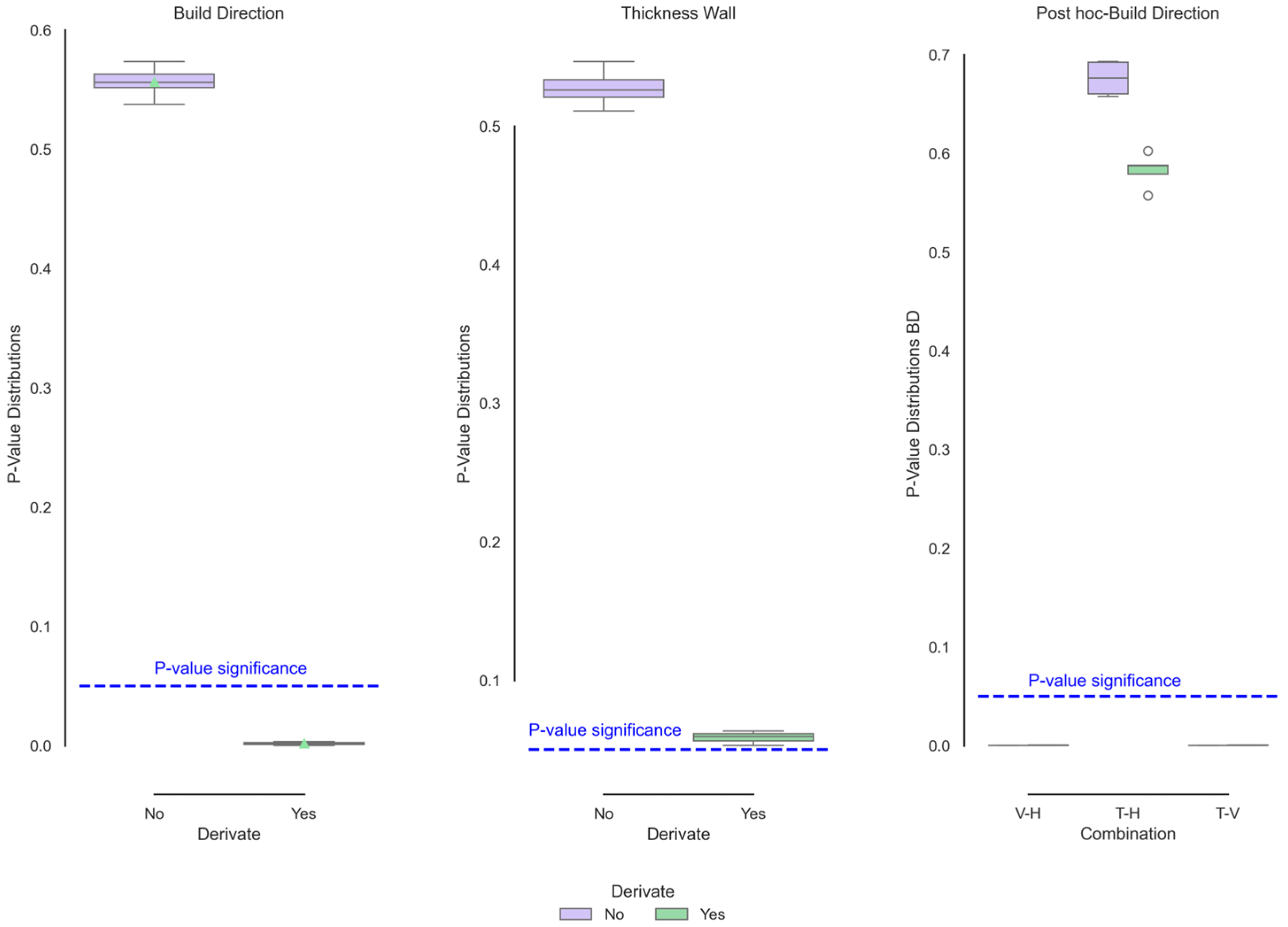

3.1. X-Ray Diffraction (XRD)

3.2. Spectrocospy Infrared Transmittance (FTIR-ATR)

3.3. Differential Scanning Calorimetry (DSC)

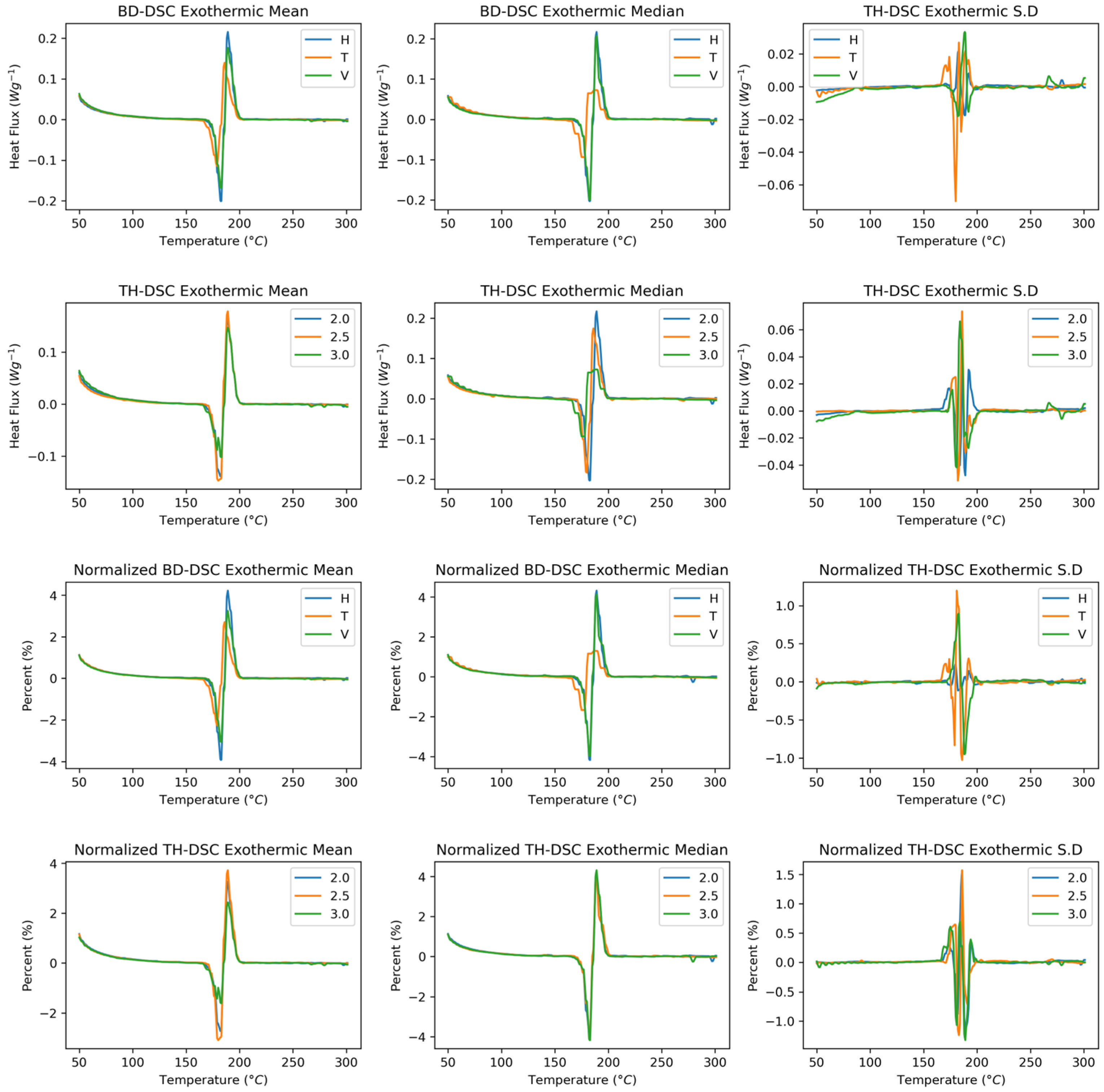

3.3.1. Exothermic Behaviour

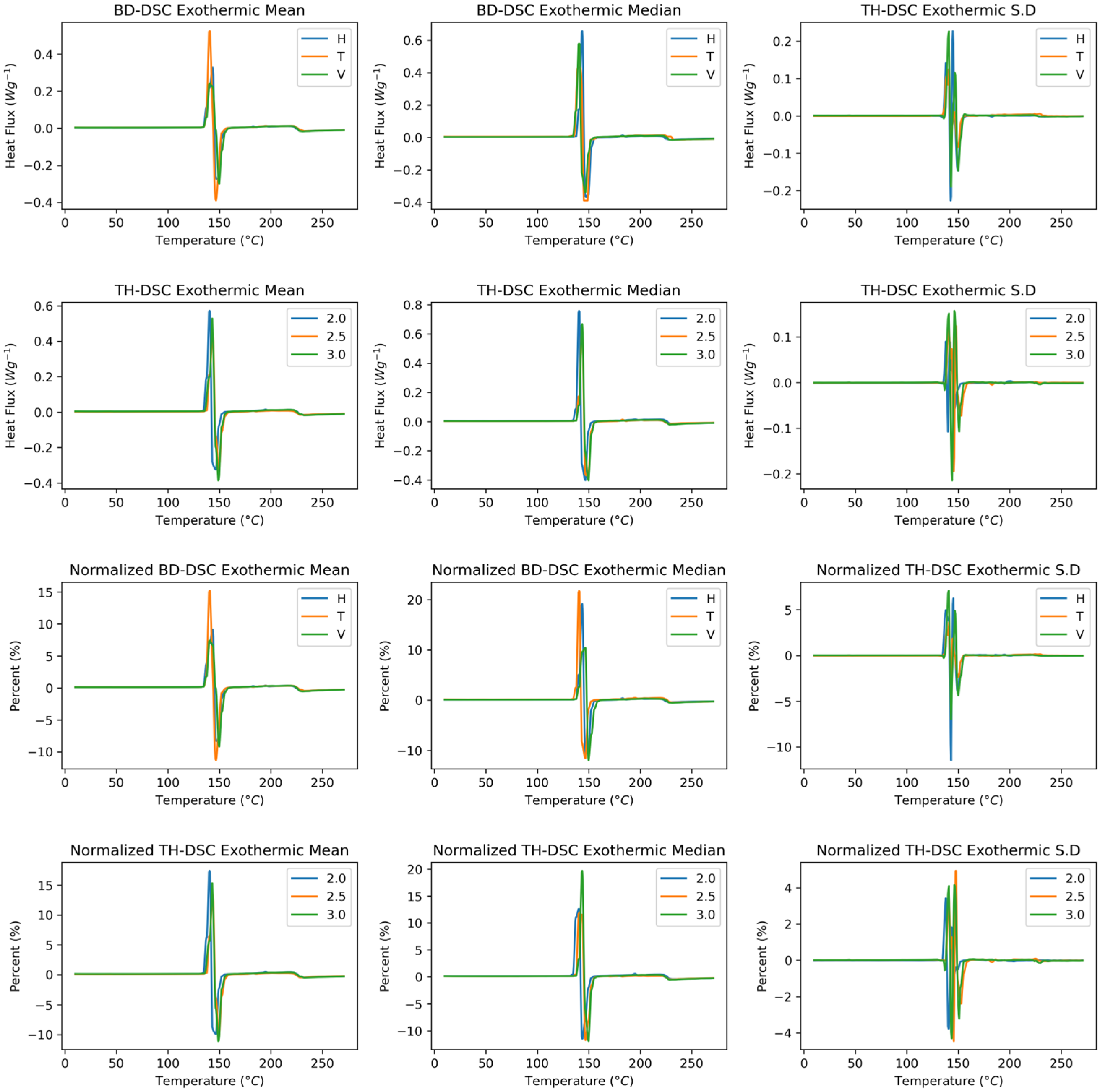

3.3.2. Endothermic Behaviour

3.4. Mechanical Properties

4. Conclusions

5. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Crapnell, R.D.; Kalinke, C.; Silva, L.R.G.; Stefano, J.S.; Williams, R.J.; Munoz, R.A.A.; Bonacin, J.A.; Janegitz, B.C.; Banks, C.E. Additive manufacturing electrochemistry: An overview of producing bespoke conductive additive manufacturing fi laments. Mater. Today 2023, 71, 73–90. [Google Scholar] [CrossRef]

- HUBS. Additive Manufacturing Trend Report 2021; 3D Hubs: Chicago, IL, USA, 2021. [Google Scholar]

- Vaneker, T.; Bernard, A.; Moroni, G.; Gibson, I.; Zhang, Y. Design for additive manufacturing: Framework and methodology. CIRP Ann. 2020, 69, 578–599. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customised Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Kruth, J.P.; Wang, X.; Laoui, T.; Froyen, L. Lasers and materials in selective laser sintering. Assem. Autom. 2006, 23, 357–371. [Google Scholar] [CrossRef]

- Nelson, J.C. Selective Laser Sintering: A Definition of the Process and an Empirical Sintering Model; UMI: Kampala, Uganda, 1993. [Google Scholar]

- ISO/ASTM 52900; Additive Manufacturing-General Principles-Terminology. ISO/ASTM: Geneva, Switzerland, 2015.

- Yan, C.; Shi, Y.; Li, Z.; Wen, S.; Wei, Q. Selective Laser Sintering Additive Manufacturing Technology; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Kozlovsky, K.; Schiltz, J.; Kreider, T.; Kumar, M.; Schmid, S. Mechanical Properties of Reused Nylon Feedstock for Powder-bed Additive Manufacturing in Orthopedics. Procedia Manuf. 2018, 26, 826–833. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Gong, G.; Ye, J.; Chi, Y.; Zhao, Z.; Wang, Z.; Xia, G.; Du, X.; Tian, H.; Yu, H.; Chen, C. Research status of laser additive manufacturing for metal: A review. J. Mater. Res. Technol. 2021, 15, 855–884. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Q.M. Dynamic compressive behaviour of cellular materials: A review of phenomenon, mechanism and modelling. Int. J. Impact. Eng. 2017, 112, 74–115. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, G.; Zheng, X.; Ni, Y.; Liu, F.; Liu, Y.; Xu, L.R. Efficient characterisation on the interlayer shear strengths of 3D printing polymers. J. Mater. Res. Technol. 2023, 22, 2768–2780. [Google Scholar] [CrossRef]

- Omar, M.R.; Ilman, M.; Chua, M.I.H. Effect of Polyamide-12 Material Compositions on Mechanical Properties and Surface Morphology of SLS 3D Printed Part. J. Mech. Eng. 2022, 19, 57–70. [Google Scholar] [CrossRef]

- Cai, C.; Tey, W.S.; Chen, J.; Zhu, W.; Liu, X.; Liu, T.; Zhao, L.; Zhou, K. Comparative study on 3D printing of polyamide 12 by selective laser sintering and multi jet fusion. J. Mater. Process. Technol. 2021, 288, 116882. [Google Scholar] [CrossRef]

- Mehdipour, F.; Gebhardt, U.; Kästner, M. Anisotropic and rate-dependent mechanical properties of 3D printed polyamide 12—A comparison between selective laser sintering and multi jet fusion. Results Mater. 2021, 11, 100213. [Google Scholar] [CrossRef]

- Imanian, M.E.; Biglari, F.R. Modelling and prediction of surface roughness and dimensional accuracy in SLS 3D printing of PVA/CB composite using the central composite design. J. Manuf. Process. 2022, 75, 154–169. [Google Scholar] [CrossRef]

- Major, Z.; Lackner, M.; Hössinger-Kalteis, A.; Lück, T. Characterisation of the Fatigue Behavior of SLS Thermoplastics. Procedia Struct. Integr. 2021, 34, 191–198. [Google Scholar] [CrossRef]

- Vasanthan, N.; Salem, D.R. FTIR Spectroscopic Characterisation of Structural Changes in Polyamide-6 Fibres during Annealing and Drawing. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 536–547. [Google Scholar] [CrossRef]

- Chen, Q. Collective model of chiral and wobbling modes in nuclei. Sci. Sin. Phys. Mech. Astron. 2016, 46, 012013. [Google Scholar] [CrossRef]

- Guinebretière, R. X-Ray Diffraction by Polycrystalline Materials; ISTE: London, UK, 2007. [Google Scholar]

- Yan, C.; Shi, Y.; Hao, L. Investigation into the differences in the selective laser sintering between amorphous and semicrystalline polymers. Int. Polym. Process. 2011, 26, 416–423. [Google Scholar] [CrossRef]

- Hiramatsu, N.; Haraguchi, K.; Hirakawa, S. Study of Transformations Among alpha, gamma and gamma prime forms in nylon 12 by X-ray and DSC. Jpn. J. Appl. Phys. 1983, 22, 335–339. [Google Scholar] [CrossRef]

- Gertheiss, J.; Rügamer, D.; Liew, B.X.W.; Greven, S. Functional Data Analysis: An Introduction and Recent Developments. Biom. J. 2024, 66, e202300363. [Google Scholar] [CrossRef] [PubMed]

- Khoo, T.H.; Pathmanathan, D.; Dabo-Niang, S. Spatial Autocorrelation of Global Stock Exchanges Using Functional Areal Spatial Principal Component Analysis. Mathematics 2023, 11, 674. [Google Scholar] [CrossRef]

- Qi, P.; Wang, F.; Huang, Y.; Yang, X. Integrating functional data analysis with case-based reasoning for hypertension prognosis and diagnosis based on real-world electronic health records. BMC Med. Inform. Decis. Mak. 2022, 22, 149. [Google Scholar] [CrossRef] [PubMed]

- Crainiceanu, C.M.; Goldsmith, J.; Leroux, A.; Leroux, C.E. Functional Data Analysis with R; Chapman & Hall: Boca Raton, FL, USA, 2024. [Google Scholar]

- Rodríguez, A.G.; Mora, E.E.; Tovar, C.A.N.; Velasco, M.A.; Bárcenas, E. Predicting ultimate tensile and break strength of SLS PA 12 parts using machine learning on tensile load–displacement data. Prog. Addit. Manuf. 2025, 10, 1–43. [Google Scholar] [CrossRef]

- ISO 527-1:2019(en); Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- Salmoria, G.; Leite, J.; Paggi, R. The microstructural characterisation of PA6/PA12 blend specimens fabricated by selective laser sintering. Polym. Test. 2009, 28, 746–751. [Google Scholar] [CrossRef]

- El Magri, A.; Bencaid, S.E.; Vanaei, H.R.; Vaudreuil, S. Effects of Laser Power and Hatch Orientation on Final Properties of PA12 Parts Produced by Selective Laser Sintering. Polymers 2022, 14, 3674. [Google Scholar] [CrossRef] [PubMed]

- Martynková, G.S.; Slíva, A.; Kratošová, G.; Barabaszová, K.Č.; Študentová, S.; Klusák, J.; Brožová, S.; Dokoupil, T.; Holešová, S. Polyamide 12 materials study of morpho-structural changes during laser sintering of 3d printing. Polymers 2021, 13, 810. [Google Scholar] [CrossRef] [PubMed]

- Kuracina, R.; Szabová, Z.; Buranská, E.; Pastierová, A.; Gogola, P.; Buranský, I. Determination of fire parameters of polyamide 12 powder for additive technologies. Polymers 2021, 13, 3014. [Google Scholar] [CrossRef]

- Dai, R.; Huang, M.; Ma, L.; Liu, W.; He, S.; Liu, H.; Zhu, C.; Wang, Y.; Zhang, Z.; Sun, A. Study on crystal structure and phase transitions of polyamide 12 via wide-angle X-ray diffraction with variable temperature. Adv. Compos. Hybrid Mater. 2020, 3, 522–529. [Google Scholar] [CrossRef]

- Lakraimi, R.; Abouchadi, H.; Janan, M.T.; Chehri, A.; Saadane, R. Thermal Modelling of Polyamide 12 Powder in the Selective Laser Sintering Process Using the Discrete Element Method. Materials 2023, 16, 753. [Google Scholar] [CrossRef]

- Chen, P.; Tang, M.; Zhu, W.; Yang, L.; Wen, S.; Yan, C.; Ji, Z.; Nan, H.; Shi, Y. Systematical mechanism of Polyamide-12 aging and its microstructural evolution during laser sintering. Polym. Test. 2018, 67, 370–379. [Google Scholar] [CrossRef]

- Wismans, M.; van Breemen, L.C.A.; Govaert, L.E.; Engels, T.A.P. The Effect of Thermal Residual Stress on the Stress State in a Short-Fibre Reinforced Thermoplastic. J. Mater. Eng. Perform. 2024, 33, 4160–4169. [Google Scholar] [CrossRef]

- Issametova, M.; Martyushev, N.V.; Zhastalap, A.; Sabirova, L.B.; Assemgul, U.; Tursynbayeva, A.; Abilezova, G. Determination of Residual Stresses in 3D-Printed Polymer Parts. Polymers 2024, 16, 2067. [Google Scholar] [CrossRef]

- Ma, N.; Liu, W.; Ma, L.; He, S.; Liu, H.; Zhang, Z.; Sun, A.; Huang, M.; Zhu, C. Crystal transition and thermal behavior of Nylon 12. E-Polymers 2020, 20, 346–352. [Google Scholar] [CrossRef]

- Rodriguez, A.G.; Peña, M.A.V.; Narváez-Tovar, C.A.; Mora, E.E. Experimental analysis of failure behaviour of PA12 specimens manufactured by SLS as a function of wall thickness and build direction. Rapid Prototyp. J. 2024, 30, 1537–1555. [Google Scholar] [CrossRef]

- Anjos, O.; Comesaña, M.M.; Caldeira, I.; Pedro, S.I.; Oller, P.E.; Canas, S. Application of functional data analysis and FTIR-ATR spectroscopy to discriminatewine spirits ageing technologies. Mathematics 2020, 8, 896. [Google Scholar] [CrossRef]

- Rodríguez, A.G.; Mora, E.E.; Velasco, M.A.; Tovar, C.A.N. Mechanical properties of polyamide 12 manufactured by means of SLS: Influence of wall thickness and build direction. Mater. Res. Express 2023, 10, 105304. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García Rodríguez, A.; Reyes, Y.G.; Espejo Mora, E.; Narváez Tovar, C.A.; Velasco Peña, M.A. Functional Data Analysis for the Structural, Chemical, Thermal, and Mechanical Properties of PA12 Additively Manufactured via SLS. Polymers 2025, 17, 2763. https://doi.org/10.3390/polym17202763

García Rodríguez A, Reyes YG, Espejo Mora E, Narváez Tovar CA, Velasco Peña MA. Functional Data Analysis for the Structural, Chemical, Thermal, and Mechanical Properties of PA12 Additively Manufactured via SLS. Polymers. 2025; 17(20):2763. https://doi.org/10.3390/polym17202763

Chicago/Turabian StyleGarcía Rodríguez, Alejandro, Yamid Gonzalo Reyes, Edgar Espejo Mora, Carlos Alberto Narváez Tovar, and Marco Antonio Velasco Peña. 2025. "Functional Data Analysis for the Structural, Chemical, Thermal, and Mechanical Properties of PA12 Additively Manufactured via SLS" Polymers 17, no. 20: 2763. https://doi.org/10.3390/polym17202763

APA StyleGarcía Rodríguez, A., Reyes, Y. G., Espejo Mora, E., Narváez Tovar, C. A., & Velasco Peña, M. A. (2025). Functional Data Analysis for the Structural, Chemical, Thermal, and Mechanical Properties of PA12 Additively Manufactured via SLS. Polymers, 17(20), 2763. https://doi.org/10.3390/polym17202763