Oxidative Upgrading of Heavy Oil Residues with Polymer-Based Wastes for Sustainable Bitumen Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Objects

2.2. Methodology and Laboratory Setup for the Oxidation of Heavy Oil Residues with the Addition of Modifiers

2.3. Bitumen Characterization Methods

2.4. Methodology of FT-IR Spectroscopic Analysis

2.5. Methodology of NMR Spectroscopic Analysis

2.6. Methodology of Thermal Analysis

2.7. Methodology of Frequency Sweep Test

3. Results and Discussion

3.1. Physical and Mechanical Characteristics of Bitumen Oxidation Products

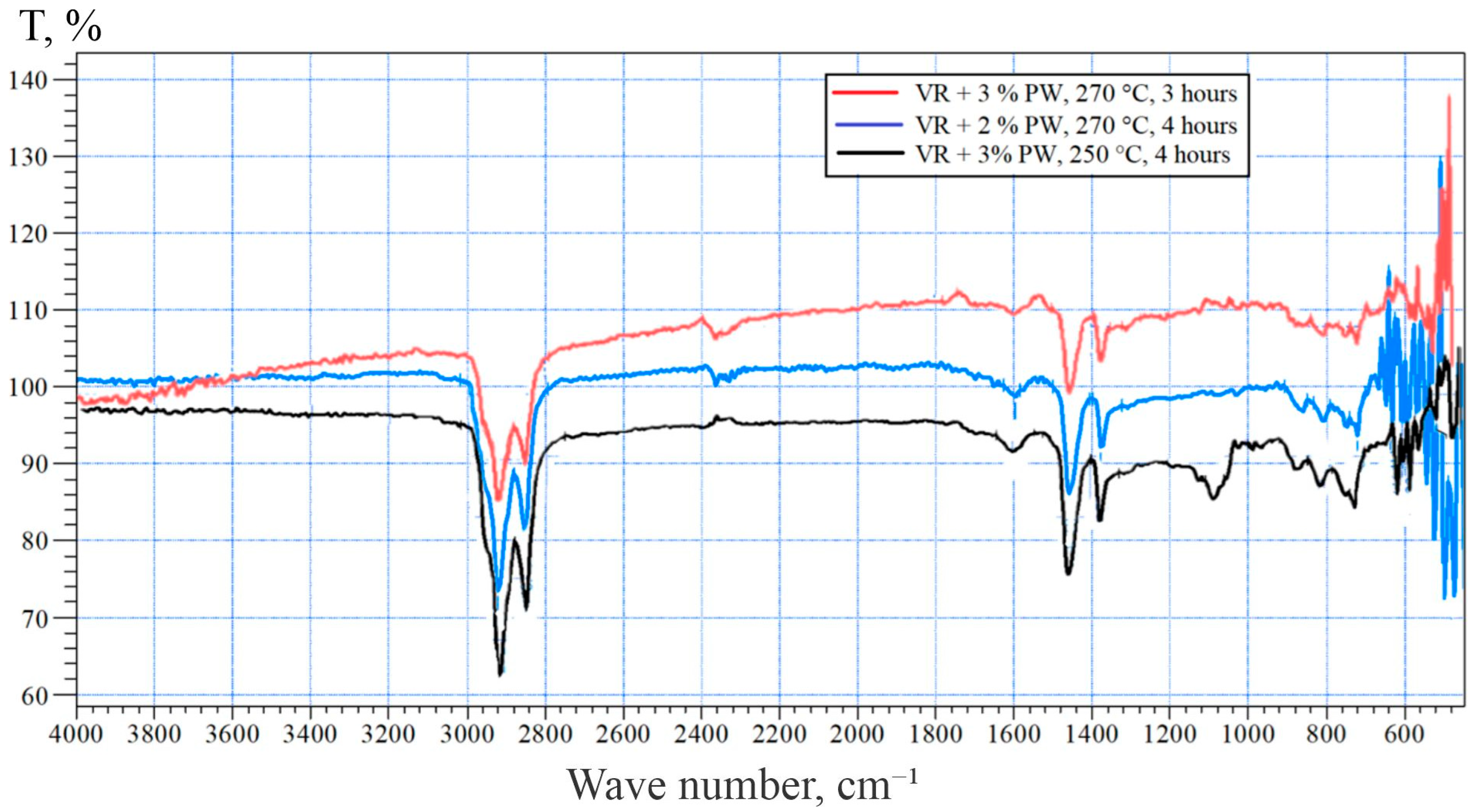

3.2. FT-IR Spectroscopic Analysis of Bitumen Samples

- Sample 1 (B-3-250-4), produced at 250 °C for 4 h with 3% polymer, exhibited moderate carbonyl and sulfoxide bands, suggesting balanced oxidation. The well-defined aliphatic peaks imply successful integration of the polyethylene waste.

- Sample 2 (B-2-270-4), obtained at 270 °C for 4 h with 2% polymer, showed a similarly strong carbonyl peak with slightly lower sulfoxide intensity, consistent with OMB 100/130 standards [32].

- Sample 3 (B-3-270-3), oxidized at 270 °C for 3 h with 3% polymer, demonstrated stronger carbonyl and sulfoxide absorption, indicating a higher degree of oxidation. This is consistent with the physical properties corresponding to OMB 70/100 grade.

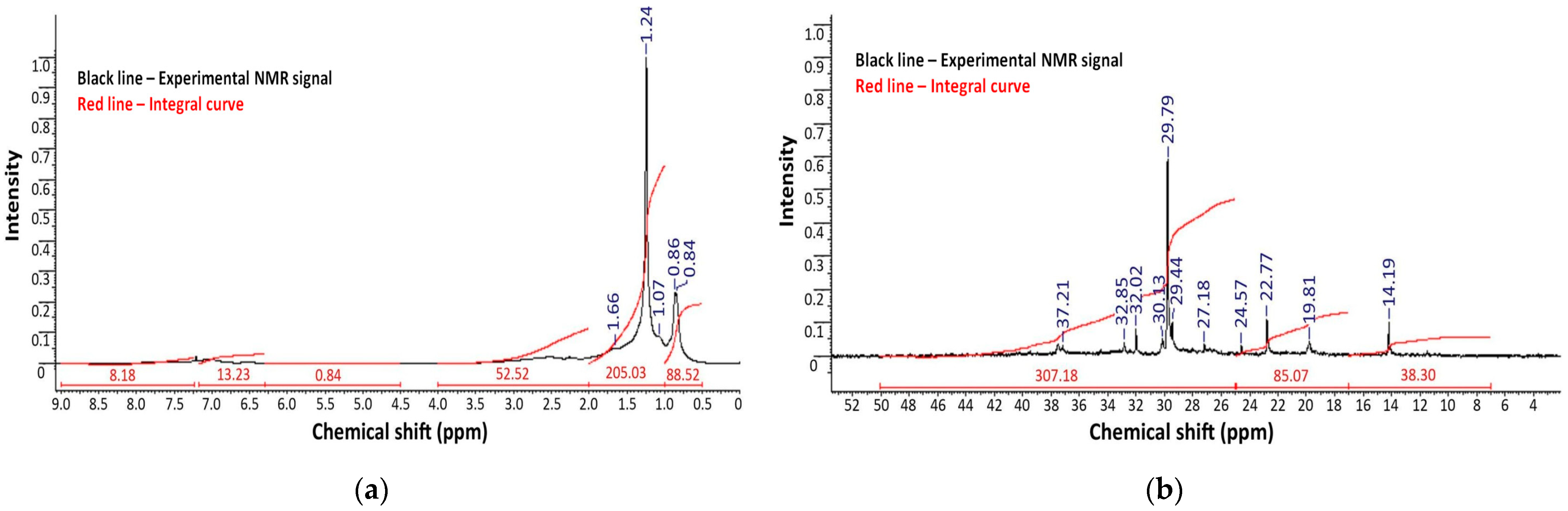

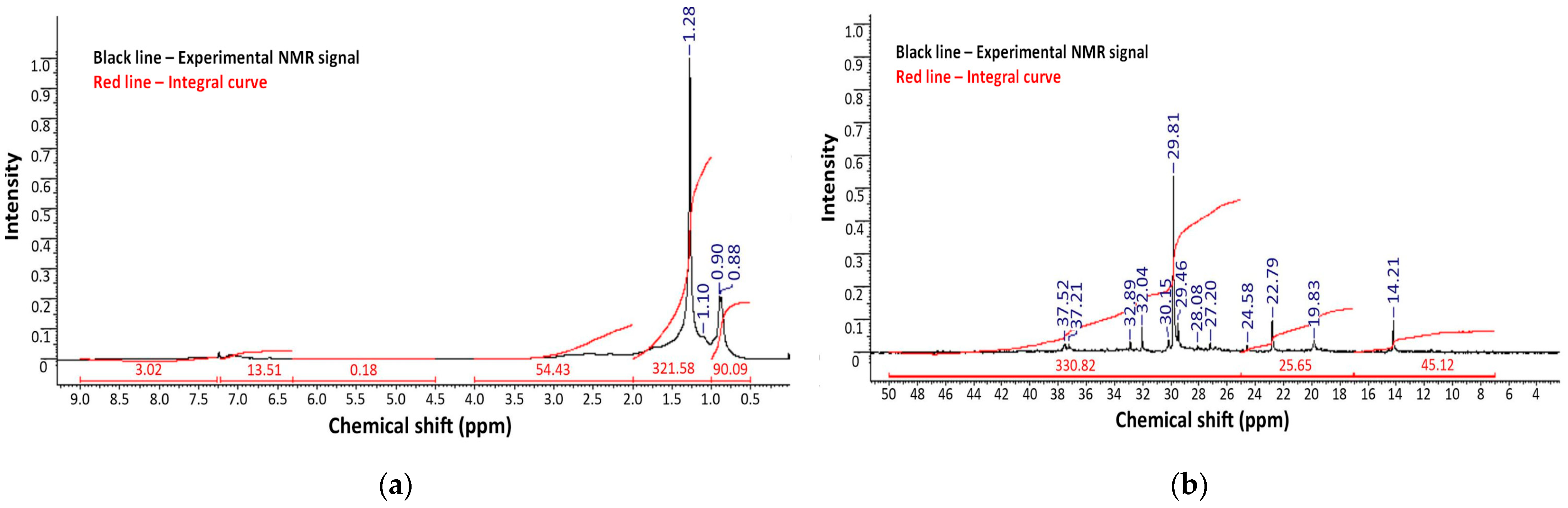

3.3. Nuclear Magnetic Resonance Spectroscopy Analysis

3.4. Analysis of Thermal Properties of the Bitumen Samples

3.5. Rheological Characteristics of the Bitumen Samples

4. Conclusions

- The study confirmed that incorporating 2–3 wt.% polymer-based waste in the oxidation of heavy oil residues significantly improves the physical and mechanical properties of the resulting bitumen.

- The optimal oxidation conditions were identified as 270 °C for 4 h with 2% polymer waste, resulting in products that meet the OMB 100/130 grade requirements according to RP RK 218-189-2022.

- FTIR spectroscopy revealed key functional groups formed during oxidation, such as carbonyl and sulfoxide bands, which correlate with enhanced oxidative aging and structural modification of the bitumen.

- NMR spectroscopy further demonstrated chemical transformations, including increased aromaticity and the appearance of oxygenated functionalities, confirming the deeper oxidation and successful integration of polyethylene fragments.

- Thermal analyses demonstrated that both bitumen samples experienced stability up to 350 °C, followed by significant decomposition of resins and asphaltenes, with distinctive carbon oxidation behavior above 600 °C.

- Rheological evaluation confirmed that both oxidized polymer-modified bitumens exhibit enhanced performance; however, B-2-270-4 demonstrated superior rigidity, reduced temperature sensitivity, and greater structural stability across the operational frequency range studied.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Šišková, A.O.; Peer, P.; Andicsová, A.E.; Jordanov, I.; Rychter, P. Circulatory Management of Polymer Waste: Recycling into Fine Fibers and Their Applications. Materials 2021, 14, 4694. [Google Scholar] [CrossRef]

- Imanbayev, Y.; Bussurmanova, A.; Ongarbayev, Y.; Serikbayeva, A.; Sydykov, S.; Tabylganov, M.; Akkenzheyeva, A.; Izteleu, N.; Mussabekova, Z.; Amangeldin, D.; et al. Modification of Bitumen with Recycled PET Plastics from Waste Materials. Polymers 2022, 14, 4719. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Rossi, C.O. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Austruy, F.; Tileuberdi, Y.; Ongarbaev, Y.; Mansurov, Z. Study of Production of Rubber-Bitumen Compounds. Eurasian Chem. Technol. J. 2012, 14, 133–138. [Google Scholar] [CrossRef]

- Asphalt Institute; Eurobitume. The Bitumen Industry: A Global Perspective, 4th ed.; IS-230; Asphalt Institute Inc.; European Bitumen Association–Eurobitume: Brussels, Belgium, 2024; pp. 1–68. ISBN 978-1-934154-80-9. [Google Scholar]

- Ongarbayev, Y.; Teltayev, B.; Tileuberdi, Y.; Mansurov, Z.; Rossi, C.O.; Calandra, P.; Seilkhanov, T.; Zhambolova, A.; Imanbayev, Y. Combined Oxidized Bitumen: Technology, Chemistry and Properties. ES Mater. Manuf. 2024, 24, 1072. [Google Scholar] [CrossRef]

- Vakhin, A.V.; Cherkasova, E.I.; Safiulina, A.G.; Islamova, G.G.; Petrov, S.M.; Bashkirtseva, N.Y. Catalytic oxidation of heavy residual oil by pulsed nuclear magnetic resonance. Processes 2021, 9, 158. [Google Scholar] [CrossRef]

- Djimasbe, R.; Galiullin, E.A.; Varfolomeev, M.A.; Fakhrutdinov, R.Z.; Al-Muntaser, A.A.; Farhadian, A. Experimental study of non-oxidized and oxidized bitumen obtained from heavy oil. Sci. Rep. 2021, 11, 8107. [Google Scholar] [CrossRef]

- Soenen, H.; Lu, X.; Laukkanen, O.V. Oxidation of Bitumen: Molecular Characterization and Influence on Rheological Properties. Rheol. Acta 2016, 55, 315–326. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Modification of Road Bitumens with Thermoplastic Polymers. Polym. Test. 2000, 20, 77–86. [Google Scholar] [CrossRef]

- Herrington, P.R. Oxidation of Bitumen in the Presence of a Constant Concentration of Oxygen. Pet. Sci. Technol. 1998, 16, 1061–1084. [Google Scholar] [CrossRef]

- Airey, G.D. Rheological Properties of Styrene Butadiene Styrene Polymer Modified Road Bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Lesueur, D. The Colloidal Structure of Bitumen: Consequences on the Rheology and Mechanisms of Bitumen Modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Firoozifar, S.H.; Foroutan, S. Foroutan, S. The Effect of Asphaltene on Thermal Properties of Bitumen. Chem. Eng. Res. Des. 2011, 89, 2044–2048. [Google Scholar] [CrossRef]

- Qin, Y.; Meng, Y.; Lei, J.; Fu, T.; Xu, R.; Yang, X.; Zhao, Q.; Xi, C. Study on the Microscopic Characteristics and Rheological Properties of Thermal-Oxidative Aged and Virgin-Old Recycled Asphalts. Eur. Polym. J. 2021, 154, 110499. [Google Scholar] [CrossRef]

- Obi, N.I.; Razali, M.N.; Nour, A.H. The Potentials of Emulsified Modified Bitumen (EMB) for Coating and Insulation: An Overview. Mater. Today Proc. 2022, 57, 1288–1295. [Google Scholar] [CrossRef]

- Porto, M.; Angelico, R.; Caputo, P.; Abe, A.A.; Teltayev, B.; Rossi, C.O. The Structure of Bitumen: Conceptual Models and Experimental Evidences. Materials 2022, 15, 905. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer Modification of Bitumen: Advances and Challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- McNally, T. Polymer Modified Bitumen: Properties and Characterisation; Woodhead Publishing: Cambridge, UK, 2011; pp. 1–417. [Google Scholar]

- Dehouche, N.; Kaci, M.; Mokhtar, K.A. Influence of Thermo-Oxidative Aging on Chemical Composition and Physical Properties of Polymer Modified Bitumens. Constr. Build. Mater. 2012, 26, 350–356. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, H.; Jiang, X.; Polaczyk, P.; Xiao, R.; Zhang, M.; Huang, B. The Utilization of Waste Plastics in Asphalt Pavements: A Review. Clean. Mater. 2021, 2, 100031. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Biligiri, K.P.; Giustozzi, F. Effect of Various Compatibilizers on the Storage Stability, Thermochemical and Rheological Properties of Recycled Plastic-Modified Bitumen. Int. J. Pavement Res. Technol. 2024, 17, 854–867. [Google Scholar] [CrossRef]

- Filippi, S.; Cappello, M.; Merce, M.; Polacco, G. Effect of Nanoadditives on Bitumen Aging Resistance: A Critical Review. J. Nanomater. 2018, 2018, 2469307. [Google Scholar] [CrossRef]

- Grynyshyn, O.; Donchenko, M.; Khlibyshyn, Y.; Poliak, O. Investigation of Petroleum Bitumen Resistance to Aging. Chem. Chem. Technol. 2021, 15, 438–442. [Google Scholar] [CrossRef]

- Köfteci, Ş.; Ahmedzade, P.; Kultayev, B. Performance Evaluation of Bitumen Modified by Various Types of Waste Plastics. Constr. Build. Mater. 2014, 73, 592–602. [Google Scholar] [CrossRef]

- Prosperi, E.; Bocci, E. A Review on Bitumen Aging and Rejuvenation Chemistry: Processes, Materials and Analyses. Sustainability 2021, 13, 6523. [Google Scholar] [CrossRef]

- GOST 33136-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Method for Determination of Needle Penetration Depth”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2015.

- GOST 33142-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Determination of the Softening Point. Ring and Ball Method”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2015.

- GOST 33138-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Method for Determination of Tensile Properties”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2015.

- AASHTO T 315; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2020.

- EN 14770; Bitumen and Bituminous Binders—Determination of Complex Shear Modulus and Phase Angle Using a Dynamic Shear Rheometer (DSR). European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- R RK 218-189-2022; Recommendations on the Technology for Producing Oxidized Modified Bitumens. Committee for Technical Regulation and Metrology: Astana, Kazakhstan, 2022.

| Indicator | Heavy Oil Residue |

|---|---|

| Content of the oil fractions, mass. %: | |

| Paraffinic–naphthenic | 25.9 ± 0.2 |

| Light aromatic | 9.9 ± 0.1 |

| Medium aromatic | 2.8 ± 0.1 |

| Heavy aromatic | 18.1 ± 0.1 |

| Content of resin fractions, mass. %: | |

| Neutral resins | 11.2 ± 0.1 |

| Acidic resins | 20.3 ± 0.2 |

| Content of asphaltenes, mass. % | 11.8 ± 0.1 |

| Fractional compositions, mass. %: | |

| The beginning of boiling—180 °C | 7.0 ± 0.1 |

| 200–350 °C | 32.9 ± 0.2 |

| 350 °C—end of boiling | 60.1 ± 0.2 |

| Indicator | Result |

|---|---|

| Tensile strength, MPa | 8.9 |

| Relative elongation at break, % | 210 |

| Frost resistance, °C | −45 |

| Physical and Mechanical Properties | Modifier Content, Oxidation Temperature, Oxidation Time, and Requirements | Normative Document on Test Methods | ||||

| 3%, 250 °C, 4 h | 2 %, 270 °C, 4 h | Requirements for OMB 100/130 | 3 %, 270 °C, 3 h | Requirements for OMB 70/100 | ||

| Sample Name | B-3-250-4 | B-2-270-4 | B-3-270-3 | |||

| Penetration at 25 °C, 0.1 mm | 117 | 128 | 101–130 | 100 | 71–100 | GOST 33136-2014 [27] |

| Softening point, °C | 49 | 48 | 48 | 54 | 52 | GOST 33142-2014 [28] |

| Ductility at 25 °C, cm | 23 | 39 | 14 | 30 | 12 | GOST 33138-2014 [29] |

| Bitumen grade according to P RK 218-189-2022 | OMB 100/130 | OMB 70/100 | - | |||

| Sample | 1H NMR Observations | 13C NMR Observations | Conclusion |

|---|---|---|---|

| Heavy oil residue | Broad, unresolved peaks; dominant –CH2– and –CH3 (0.8–2.0 ppm); minor aromatics (6.5–8.0 ppm) | Intense aliphatic carbons (10–50 ppm); weak aromatic signals (120–150 ppm) | High aliphatic hydrocarbon content, slight aromatic component |

| Polyethylene | Sharp peaks ~1.3 ppm (–CH2–), ~0.9 ppm (terminal –CH3); no aromatics | Clear –CH2– (~30 ppm) and terminal carbons | Linear polyethylene |

| B-3-250-4 | Reduced aliphatic signals; stronger aromatics; weak ~9–10 ppm (–CHO/–COOH) | Carbonyl carbons (170–200 ppm); enhanced aromatics | Moderate oxidation, partial aromatization |

| B-2-270-4 | Weaker aliphatic signals than Sample 1; stronger aromatics and oxidized groups | More intense carbonyl and aromatic signals | Deeper oxidation, pronounced aromatization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tileuberdi, Y.; Ongarbayev, Y.; Kabylbekova, A.; Kanzharkan, E.; Imanbayev, Y.; Zhambolova, A.; Mukatayeva, Z.; Shadin, N. Oxidative Upgrading of Heavy Oil Residues with Polymer-Based Wastes for Sustainable Bitumen Production. Polymers 2025, 17, 2747. https://doi.org/10.3390/polym17202747

Tileuberdi Y, Ongarbayev Y, Kabylbekova A, Kanzharkan E, Imanbayev Y, Zhambolova A, Mukatayeva Z, Shadin N. Oxidative Upgrading of Heavy Oil Residues with Polymer-Based Wastes for Sustainable Bitumen Production. Polymers. 2025; 17(20):2747. https://doi.org/10.3390/polym17202747

Chicago/Turabian StyleTileuberdi, Yerbol, Yerdos Ongarbayev, Aisulu Kabylbekova, Ernar Kanzharkan, Yerzhan Imanbayev, Ainur Zhambolova, Zhazira Mukatayeva, and Nurgul Shadin. 2025. "Oxidative Upgrading of Heavy Oil Residues with Polymer-Based Wastes for Sustainable Bitumen Production" Polymers 17, no. 20: 2747. https://doi.org/10.3390/polym17202747

APA StyleTileuberdi, Y., Ongarbayev, Y., Kabylbekova, A., Kanzharkan, E., Imanbayev, Y., Zhambolova, A., Mukatayeva, Z., & Shadin, N. (2025). Oxidative Upgrading of Heavy Oil Residues with Polymer-Based Wastes for Sustainable Bitumen Production. Polymers, 17(20), 2747. https://doi.org/10.3390/polym17202747