Synergistic Effects of Artichoke Stem Waste and TiO2 Nanoparticles in Additively Manufactured Hybrid Polymer Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite Preparation

2.3. Characterization

3. Results and Discussion

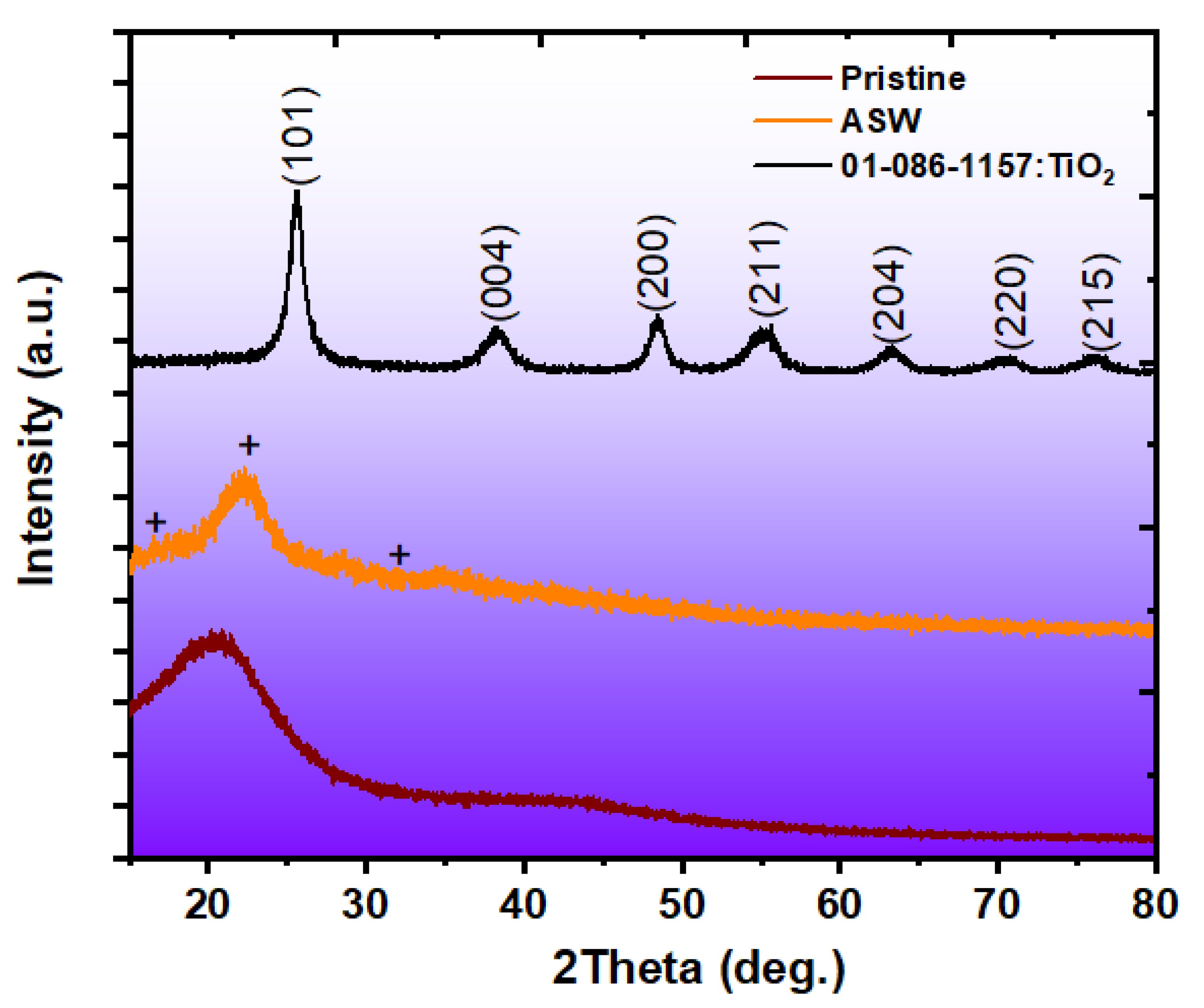

3.1. Characterization of Raw Materials

3.2. Characterization of Composites

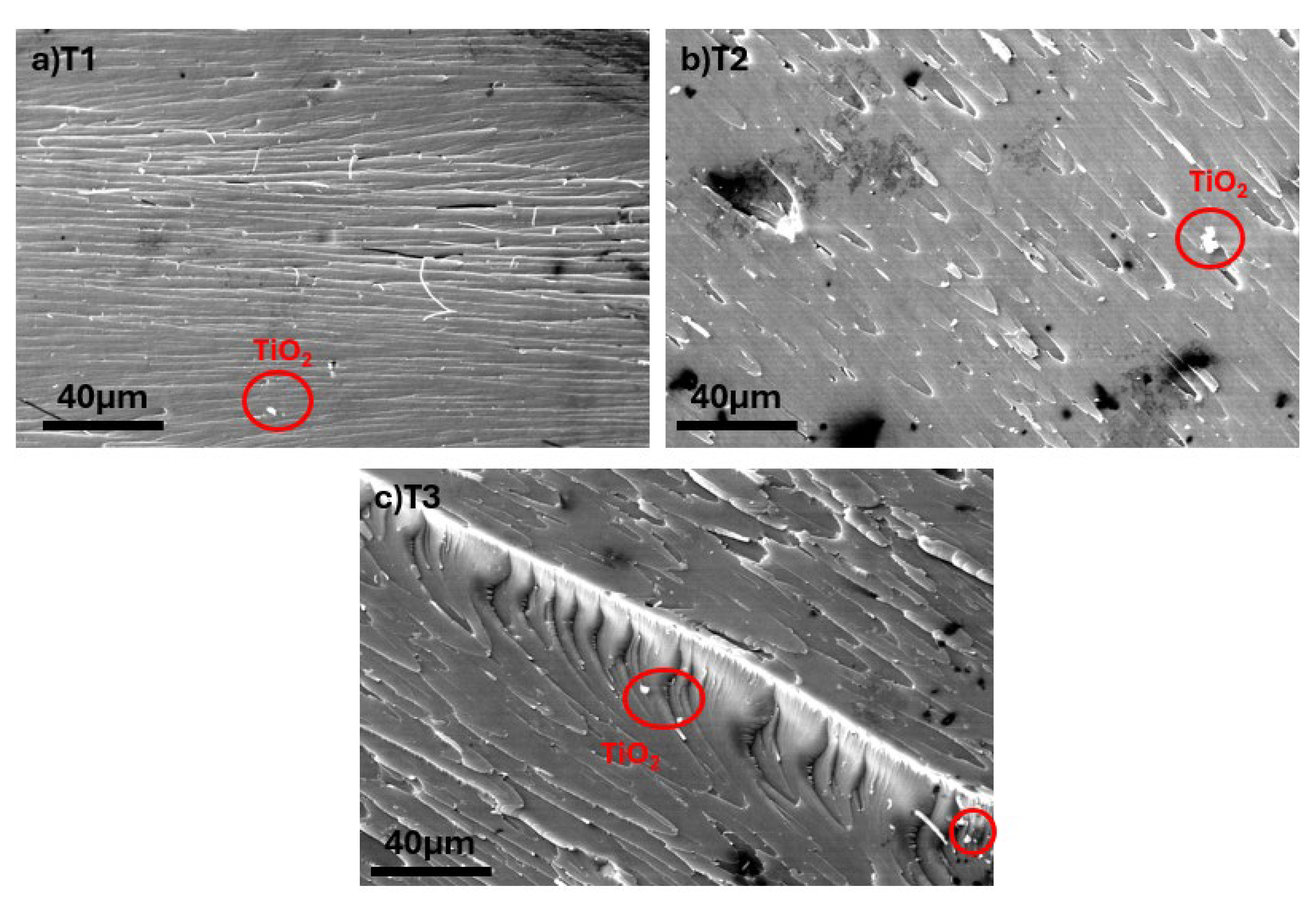

SEM Analysis

3.3. Thermogravimetric Analysis

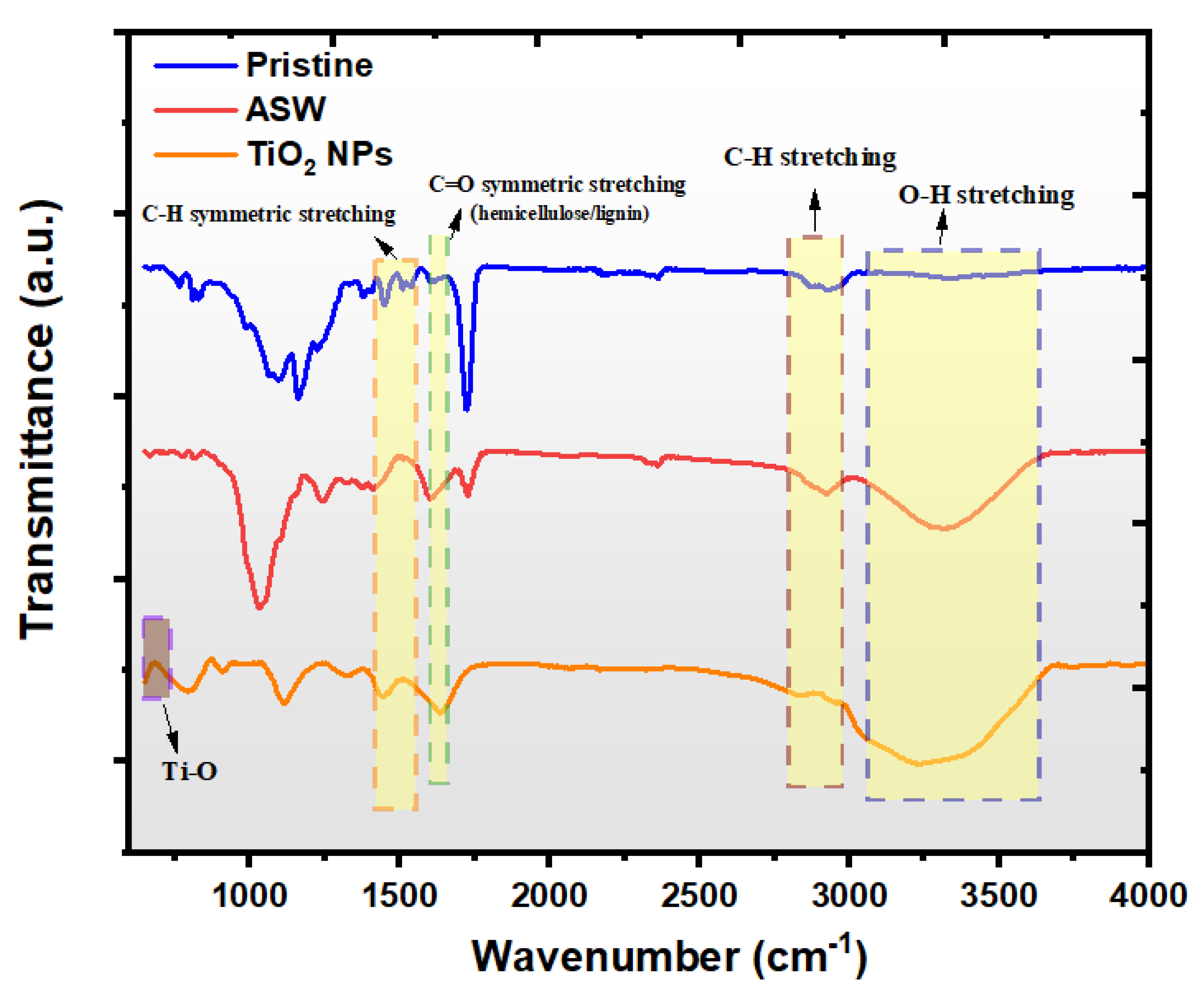

3.4. FT-IR Analysis

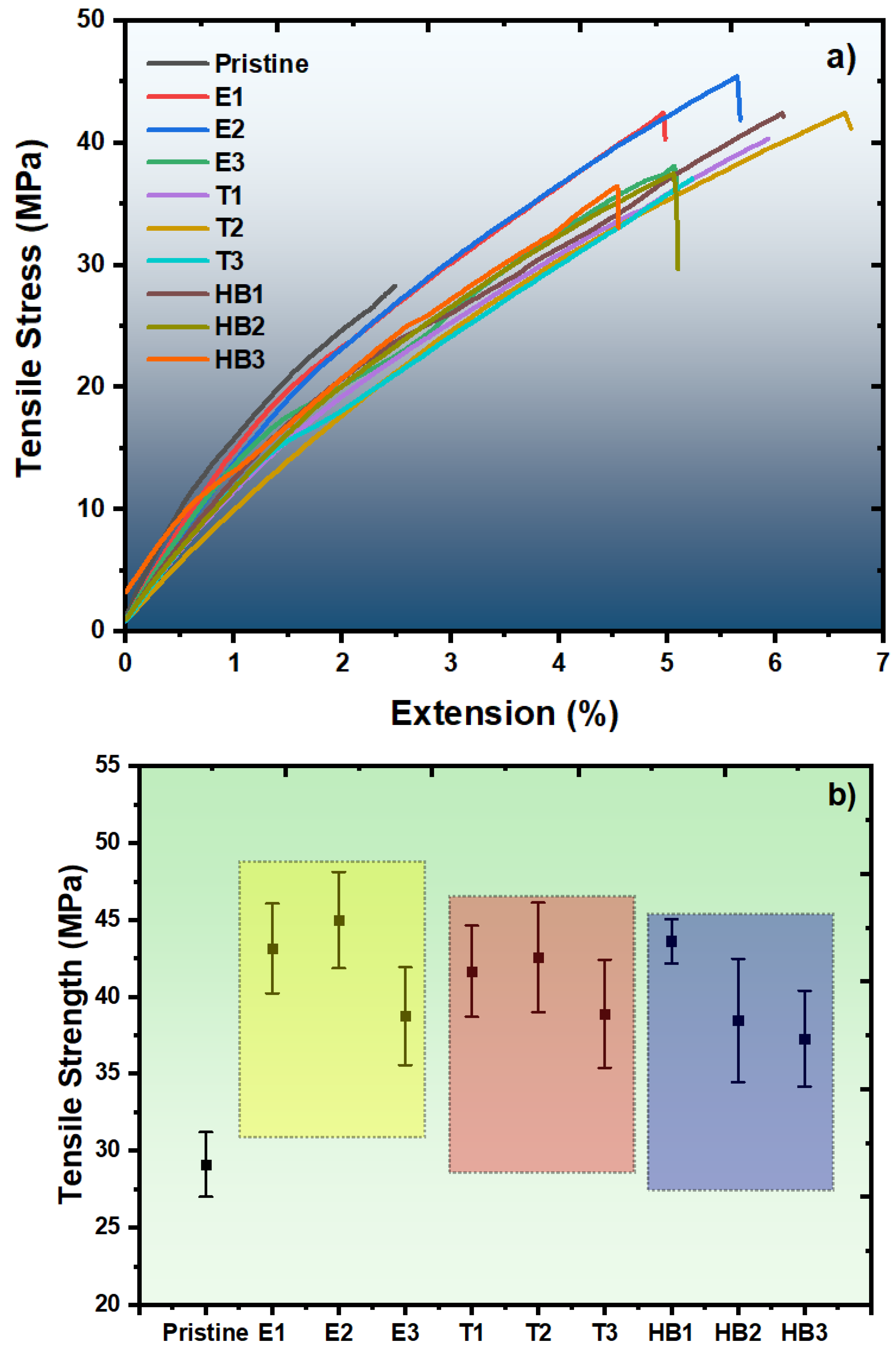

3.5. Tensile Test

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and Properties of Natural Fiber Polymer Composites: A Comprehensive Review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- T.G., Y.G.; Ballupete Nagaraju, S.; Puttegowda, M.; Verma, A.; Rangappa, S.M.; Siengchin, S. Biopolymer-Based Composites: An Eco-Friendly Alternative from Agricultural Waste Biomass. J. Compos. Sci. 2023, 7, 242. [Google Scholar] [CrossRef]

- Órbenes, G.; Rodríguez-Seoane, P.; Torres, M.D.; Chamy, R.; Zúñiga, M.E.; Domínguez, H. Valorization of Artichoke Industrial By-Products Using Green Extraction Technologies: Formulation of Hydrogels in Combination with Paulownia Extracts. Molecules 2021, 26, 4386. [Google Scholar] [CrossRef] [PubMed]

- Fiore, V.; Valenza, A.; Di Bella, G. Artichoke (Cynara cardunculus L.) Fibres as Potential Reinforcement of Composite Structures. Compos. Sci. Technol. 2011, 71, 1138–1144. [Google Scholar] [CrossRef]

- Dadalı, C.; Özcan, Y.; Ensari, İ.C. Multifactorial Optimization of Gluten-Free Cookie With Artichoke Bracts as Rice Flour Substitute and Transglutaminase. Food Sci. Nutr. 2025, 13, e70420. [Google Scholar] [CrossRef]

- De Diego-Díaz, B.; Peñas, F.J.; Fernández- Rodríguez, J. Sustainable Management of Lignocellulosic Wastes: Temperature Strategies for Anaerobic Digestion of Artichoke. J. Clean. Prod. 2021, 280, 124479. [Google Scholar] [CrossRef]

- Minichiello, C.; Pagliarini, E.; Baffoni, L.; Di Gioia, D.; Ferri, M.; Vannini, M.; Celli, A.; Saccani, A.; Sisti, L. Artichoke Bracts and Stems Residues as Active Filler for Poly(Butylene Succinate-Co-Adipate) (PBSA) Composites: From Agro-Waste to a New Sustainable Material. Polym. Compos. 2025. [Google Scholar] [CrossRef]

- Almeshari, B.; Junaedi, H.; Baig, M.; Almajid, A. Effect of Titanium Dioxide on the Mechanical Properties of 3D Printed Short Carbon-Fibers Composite. J. Mater. Res. Technol. 2024, 33, 8590–8597. [Google Scholar] [CrossRef]

- Güler, S. Mechanical, Thermal, and Photocatalytic Properties of TiO2/ZnO Hybrid Composites Fabricated via Additive Manufacturing. Recep Tayyip Erdoğan Üniversitesi Fen ve Mühendislik Bilim. Derg. 2024, 5, 149–158. [Google Scholar] [CrossRef]

- Iyer, T.; Nayak, S.Y.; Hiremath, A.; Heckadka, S.S.; Jaideep, J.P. Influence of TiO2 Nanoparticle Modification on the Mechanical Properties of Basalt-Reinforced Epoxy Composites. Cogent Eng. 2023, 10, 2227397. [Google Scholar] [CrossRef]

- Salehian, H.; Jenabali Jahromi, S.A. Effect of Titanium Dioxide Nanoparticles on Mechanical Properties of Vinyl Ester-Based Nanocomposites. J. Compos. Mater. 2015, 49, 2365–2373. [Google Scholar] [CrossRef]

- Güler, S.; Yavaş, A.; Özler, B.; Kilinç, A.Ç. Fabrication of 3D-Printed GNP/TiO2/Epoxy Composites: An Investigation on Mechanical and Photocatalytic Properties. Rapid Prototyp. J. 2024, 30, 1011–1022. [Google Scholar] [CrossRef]

- Bukichev, Y.S.; Bogdanova, L.M.; Lesnichaya, V.A.; Chukanov, N.V.; Golubeva, N.D.; Dzhardimalieva, G.I. Mechanical and Thermophysical Properties of Epoxy Nanocomposites with Titanium Dioxide Nanoparticles. Appl. Sci. 2023, 13, 4488. [Google Scholar] [CrossRef]

- Kılınç, A.Ç. Effect of Line-Width Parameter on the Tensile Strength, Surface Profile and Printing Time of 3D Printed PLA Parts. Balıkesir Üniversitesi Fen Bilim. Enstitüsü Derg. 2025, 27, 626–638. [Google Scholar] [CrossRef]

- Kilinc, A.C. Additive Manufacturing and Characterization of Continuous Nettle Fiber-Reinforced PLA Composites. Polymers 2025, 17, 2388. [Google Scholar] [CrossRef]

- Song, P.; Li, M.; Zhang, B.; Gui, X.; Han, Y.; Wang, L.; Zhou, W.; Guo, L.; Zhang, Z.; Li, Z.; et al. DLP Fabricating of Precision GelMA/HAp Porous Composite Scaffold for Bone Tissue Engineering Application. Compos. Part B Eng. 2022, 244, 110163. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Zhang, Y.; Kristiansen, P.M.; Islam, A.; Gilchrist, M.; Zhang, N. Advances in Precision Microfabrication through Digital Light Processing: System Development, Material and Applications. Virtual Phys. Prototyp. 2023, 18, e224810. [Google Scholar] [CrossRef]

- Deng, W.; Xie, D.; Liu, F.; Zhao, J.; Shen, L.; Tian, Z. DLP-Based 3D Printing for Automated Precision Manufacturing. Mob. Inf. Syst. 2022, 2022, 1–14. [Google Scholar] [CrossRef]

- Yang, C.-J. Optimizing Manufacturing Parameters of DLP Machine by Taguchi Method and Desirability Approach. Machines 2022, 10, 901. [Google Scholar] [CrossRef]

- Bucciarelli, A.; Paolelli, X.; De Vitis, E.; Selicato, N.; Gervaso, F.; Gigli, G.; Moroni, L.; Polini, A. VAT Photopolymerization 3D Printing Optimization of High Aspect Ratio Structures for Additive Manufacturing of Chips towards Biomedical Applications. Addit. Manuf. 2022, 60, 103200. [Google Scholar] [CrossRef]

- Tomczak, D.; Wichniarek, R.; Kuczko, W.; Górski, F. Manufacturing of Thin-Walled, Complex Polymer Parts by DLP Printing—The Influence of Process Parameters on Crosslinking Density. Bull. Polish Acad. Sci. Tech. Sci. 2023, 71, 145936. [Google Scholar] [CrossRef]

- Mathew, E.; Pitzanti, G.; Gomes dos Santos, A.L.; Lamprou, D.A. Optimization of Printing Parameters for Digital Light Processing 3D Printing of Hollow Microneedle Arrays. Pharmaceutics 2021, 13, 1837. [Google Scholar] [CrossRef]

- Saha, S.; Das, S.; Rahman, M.Z. Hybridization in Natural Fiber Composites: Enhanced Performance and Sustainability. Compos. Part B Eng. 2025, 308, 112986. [Google Scholar] [CrossRef]

- Xia, C.; Garcia, A.C.; Shi, S.Q.; Qiu, Y.; Warner, N.; Wu, Y.; Cai, L.; Rizvi, H.R.; D’Souza, N.A.; Nie, X. Hybrid Boron Nitride-Natural Fiber Composites for Enhanced Thermal Conductivity. Sci. Rep. 2016, 6, 34726. [Google Scholar] [CrossRef] [PubMed]

- Dejene, B.K. Advancing Natural Fiber-Reinforced Composites Through Incorporating ZnO Nanofillers in the Polymeric Matrix: A Review. J. Nat. Fibers 2024, 21, 2356015. [Google Scholar] [CrossRef]

- Roviello, G.; Occhicone, A.; De Gregorio, E.; Ricciotti, L.; Cioffi, R.; Ferone, C.; Tarallo, O. Geopolymer-Based Composite and Hybrid Materials: The Synergistic Interaction between Components. Sustain. Mater. Technol. 2025, 44, e01404. [Google Scholar] [CrossRef]

- Fong, A.; Wong, D.H.; Lau, S.; Debnath, S.; Anwar, M.; Davies, I.J.; Johar, M. Bin A Review on the Hybrid Polymer Composites Comprising Natural Fibre and Nanomaterial Reinforcement. J. Compos. Mater. 2025, 59, 2615–2646. [Google Scholar] [CrossRef]

- Balaji, D.; Kumar, P.S.; Bhuvaneshwari, V.; Rajeshkumar, L.; Singh, M.K.; Sanjay, M.R.; Siengchin, S. A Review on Effect of Nanoparticle Addition on Thermal Behavior of Natural Fiber–Reinforced Composites. Heliyon 2025, 11, e41192. [Google Scholar] [CrossRef]

- Hemath, M.; Mavinkere Rangappa, S.; Kushvaha, V.; Dhakal, H.N.; Siengchin, S. A Comprehensive Review on Mechanical, Electromagnetic Radiation Shielding, and Thermal Conductivity of Fibers/Inorganic Fillers Reinforced Hybrid Polymer Composites. Polym. Compos. 2020, 41, 3940–3965. [Google Scholar] [CrossRef]

- Lunetto, V.; Galati, M.; Settineri, L.; Iuliano, L. Sustainability in the Manufacturing of Composite Materials: A Literature Review and Directions for Future Research. J. Manuf. Process. 2023, 85, 858–874. [Google Scholar] [CrossRef]

- Llidó Barragán, A.; de la Calle Salas, A.; Parres García, F.; Crespo Amorós, J.E. Valorization of Cellulosic Waste from Artichoke for Incorporation into Biodegradable Polylactic Acid Matrices. Polymers 2024, 16, 2778. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose Crystallinity Index: Measurement Techniques and Their Impact on Interpreting Cellulase Performance. Biotechnol. Biofuels 2010, 3, 10. [Google Scholar] [CrossRef]

- French, A.D. Idealized Powder Diffraction Patterns for Cellulose Polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Yu, J.; Low, J.; Xiao, W.; Zhou, P.; Jaroniec, M. Enhanced Photocatalytic CO2 -Reduction Activity of Anatase TiO2 by Coexposed {001} and {101} Facets. J. Am. Chem. Soc. 2014, 136, 8839–8842. [Google Scholar] [CrossRef] [PubMed]

- Hanaor, D.A.H.; Sorrell, C.C. Review of the Anatase to Rutile Phase Transformation. J. Mater. Sci. 2011, 46, 855–874. [Google Scholar] [CrossRef]

- Popescu, C.-M.; Popescu, M.-C.; Singurel, G.; Vasile, C.; Argyropoulos, D.S.; Willfor, S. Spectral Characterization of Eucalyptus Wood. Appl. Spectrosc. 2007, 61, 1168–1177. [Google Scholar] [CrossRef]

- Schwanninger, M.; Rodrigues, J.C.; Pereira, H.; Hinterstoisser, B. Effects of Short-Time Vibratory Ball Milling on the Shape of FT-IR Spectra of Wood and Cellulose. Vib. Spectrosc. 2004, 36, 23–40. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A Review of Recent Developments in Natural Fibre Composites and Their Mechanical Performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Cazan, C.; Enesca, A.; Andronic, L. Synergic Effect of TiO2 Filler on the Mechanical Properties of Polymer Nanocomposites. Polymers 2021, 13, 2017. [Google Scholar] [CrossRef]

- Madsen, B.; Thygesen, A.; Lilholt, H. Plant Fibre Composites—Porosity and Stiffness. Compos. Sci. Technol. 2009, 69, 1057–1069. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A Review on the Tensile Properties of Natural Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Cantero, G.; Fernández, B.; Mondragon, I.; Gañán, P.; Kenny, J.M. Flax Fiber Surface Modifications: Effects on Fiber Physico Mechanical and Flax/Polypropylene Interface Properties. Polym. Compos. 2005, 26, 324–332. [Google Scholar] [CrossRef]

- Anaya-Esparza, L.M.; Ruvalcaba-Gómez, J.M.; Maytorena-Verdugo, C.I.; González-Silva, N.; Romero-Toledo, R.; Aguilera-Aguirre, S.; Pérez-Larios, A.; Montalvo-González, E. Chitosan-TiO2: A Versatile Hybrid Composite. Materials 2020, 13, 811. [Google Scholar] [CrossRef]

- Kan, W.H.; Chang, L. The Mechanisms behind the Tribological Behaviour of Polymer Matrix Composites Reinforced with TiO2 Nanoparticles. Wear 2021, 474–475, 203754. [Google Scholar] [CrossRef]

- Brandt, K.; Salikov, V.; Özcoban, H.; Staron, P.; Schreyer, A.; Prado, L.A.S.A.; Schulte, K.; Heinrich, S.; Schneider, G.A. Novel Ceramic–Polymer Composites Synthesized by Compaction of Polymer-Encapsulated TiO2-Nanoparticles. Compos. Sci. Technol. 2011, 72, 65–71. [Google Scholar] [CrossRef]

- Bangera, M.K.; Kotian, R.; N., R. Effect of Titanium Dioxide Nanoparticle Reinforcement on Flexural Strength of Denture Base Resin: A Systematic Review and Meta-Analysis. Jpn. Dent. Sci. Rev. 2020, 56, 68–76. [Google Scholar] [CrossRef]

- Afolabi, O.A.; Ndou, N. Synergy of Hybrid Fillers for Emerging Composite and Nanocomposite Materials—A Review. Polymers 2024, 16, 1907. [Google Scholar] [CrossRef]

- Ma, W.; Li, L.; Li, J.; Ren, X.; Gu, Z.; Huang, T. Antibacterial Pva Membranes Containing Tio2/N-halamine Nanoparticles. Adv. Polym. Technol. 2018, 37, 1390–1400. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal Stability of Natural Fibers and Their Polymer Composites. Iran. Polym. J. 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Esthappan, S.K.; Kuttappan, S.K.; Joseph, R. Thermal and Mechanical Properties of Polypropylene/Titanium Dioxide Nanocomposite Fibers. Mater. Des. 2012, 37, 537–542. [Google Scholar] [CrossRef]

- Chiu, C.-W.; Lin, C.-A.; Hong, P.-D. Melt-Spinning and Thermal Stability Behavior of TiO2 Nanoparticle/Polypropylene Nanocomposite Fibers. J. Polym. Res. 2011, 18, 367–372. [Google Scholar] [CrossRef]

- Ren, P.-G.; Si, X.-H.; Sun, Z.-F.; Ren, F.; Pei, L.; Hou, S.-Y. Synergistic Effect of BN and MWCNT Hybrid Fillers on Thermal Conductivity and Thermal Stability of Ultra-High-Molecular-Weight Polyethylene Composites with a Segregated Structure. J. Polym. Res. 2016, 23, 21. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Khandelwal, V.; Manik, G. Influence of Epoxidized Linseed Oil and Sisal Fibers on Structure–Property Relationship of Epoxy Biocomposite. Polym. Compos. 2018, 39(S4), E2595–E2605. [Google Scholar] [CrossRef]

- Karumuri, S.; Hiziroglu, S.; Kalkan, A.K. Thermoset-Cross-Linked Lignocellulose: A Moldable Plant Biomass. ACS Appl. Mater. Interfaces 2015, 7, 6596–6604. [Google Scholar] [CrossRef]

- Bittmann, B.; Haupert, F.; Schlarb, A.K. Preparation of TiO2/Epoxy Nanocomposites by Ultrasonic Dispersion and Their Structure Property Relationship. Ultrason. Sonochem. 2011, 18, 120–126. [Google Scholar] [CrossRef]

- Al Mahmud, M.Z.; Rabbi, S.M.F.; Islam, M.D.; Hossain, N. Synthesis and Applications of Natural Fiber-reinforced Epoxy Composites: A Comprehensive Review. SPE Polym. 2025, 6, e10161. [Google Scholar] [CrossRef]

- Suthenthiraveerappa, V.S.A.; Gopalan, V.; Pragasam, V.; Sampath, A.; Chinnaiyan, P.; Kalidas, V.K.; Pitchumani, S.V.; Kulendran, B.; Gopal, R. Tensile Properties of Basalt/Jute Fiber Reinforced Epoxy Composite. Cogent Eng. 2024, 11, 2348083. [Google Scholar] [CrossRef]

- Haque Protyai, M.I.; Adib, F.M.; Taher, T.I.; Karim, M.R.; Rashid, A. Bin Performance Evaluation of Kevlar Fiber Reinforced Epoxy Composite by Depositing Graphene/SiC/Al2O3 Nanoparticles. Hybrid Adv. 2024, 6, 100245. [Google Scholar] [CrossRef]

- Parbin, S.; Waghmare, N.K.; Singh, S.K.; Khan, S. Mechanical Properties of Natural Fiber Reinforced Epoxy Composites: A Review. Procedia Comput. Sci. 2019, 152, 375–379. [Google Scholar] [CrossRef]

- Mundhe, A.; Kandasubramanian, B. Advancements in Natural Fiber Composites: Innovative Chemical Surface Treatments, Characterizaton Techniques, Environmental Sustainability, and Wide-Ranging Applications. Hybrid Adv. 2024, 7, 100282. [Google Scholar] [CrossRef]

| Sample Code | Epoxy Resin (wt%) | ASW (wt%) | TiO2 NPs (wt%) |

|---|---|---|---|

| Pristine (cured epoxy) | 100 | - | - |

| E1 | 99.0 | 1.0 | - |

| E2 | 98.0 | 2.0 | - |

| E3 | 97.0 | 3.0 | - |

| T1 | 99.5 | - | 0.5 |

| T2 | 99.0 | - | 1.0 |

| T3 | 98.5 | - | 1.5 |

| HB1 | 98.5 | 1.0 | 0.5 |

| HB2 | 97.5 | 2.0 | 0.5 |

| HB3 | 96.5 | 3.0 | 0.5 |

| Parameters | Value |

|---|---|

| Initial Exposure | 70 s |

| Exposure Time | 10 s |

| Motor Speed | 1 mm/s |

| Turn Off Delay | 4 s |

| Rising Height | 6 mm |

| Bottom Exp | 10 layers |

| Layer Thickness | 10 micrometer |

| Sample Name | Onset Temp. (°C) | Residual Weight (%) |

|---|---|---|

| Pristine | 285 ± 1.1 | 7.5 ± 0.3 |

| E1 | 290 ± 1.1 | 8.4 ± 0.2 |

| E2 | 292 ± 1.0 | 8.2 ± 0.3 |

| E3 | 295 ± 1.3 | 8.6 ± 0.4 |

| T1 | 298 ± 1.4 | 10.4 ± 0.4 |

| T2 | 300 ± 1.5 | 11 ± 0.3 |

| T3 | 305 ± 0.9 | 11.6 ± 0.5 |

| HB1 | 304 ± 0.8 | 11.2 ± 0.3 |

| HB2 | 307 ± 1.1 | 11.9 ± 0.2 |

| HB3 | 309 ± 1.4 | 12.4 ± 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Güler, S. Synergistic Effects of Artichoke Stem Waste and TiO2 Nanoparticles in Additively Manufactured Hybrid Polymer Composites. Polymers 2025, 17, 2740. https://doi.org/10.3390/polym17202740

Güler S. Synergistic Effects of Artichoke Stem Waste and TiO2 Nanoparticles in Additively Manufactured Hybrid Polymer Composites. Polymers. 2025; 17(20):2740. https://doi.org/10.3390/polym17202740

Chicago/Turabian StyleGüler, Saadet. 2025. "Synergistic Effects of Artichoke Stem Waste and TiO2 Nanoparticles in Additively Manufactured Hybrid Polymer Composites" Polymers 17, no. 20: 2740. https://doi.org/10.3390/polym17202740

APA StyleGüler, S. (2025). Synergistic Effects of Artichoke Stem Waste and TiO2 Nanoparticles in Additively Manufactured Hybrid Polymer Composites. Polymers, 17(20), 2740. https://doi.org/10.3390/polym17202740