Ultrasonic-Assisted Synthesis and Cytocompatibility Assessment of TiO2/SiO2 Nanoparticles-Impregnated Gum Arabic Nanocomposite: Edible Coating of Dates for Shelf-Life Extension

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Chemicals

2.2. Synthesis of Biogenic Silica Nanostructures

2.3. Synthesis of SiO2/TiO2 Embedded in Gum Arabic

2.4. Characterization of SiO2/TiO2 Embedded in Gum Arabic

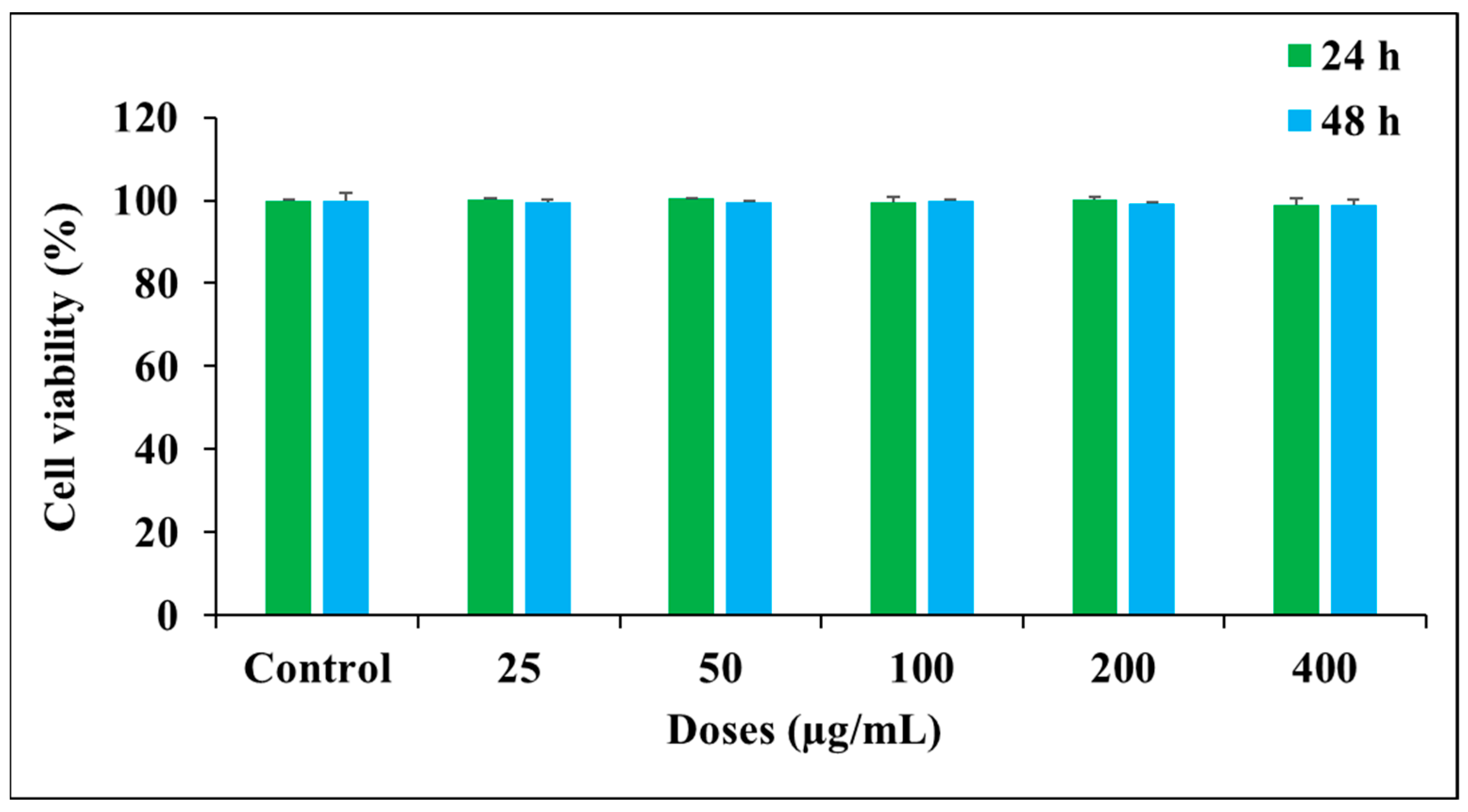

2.5. Cytocompatibility Assessment

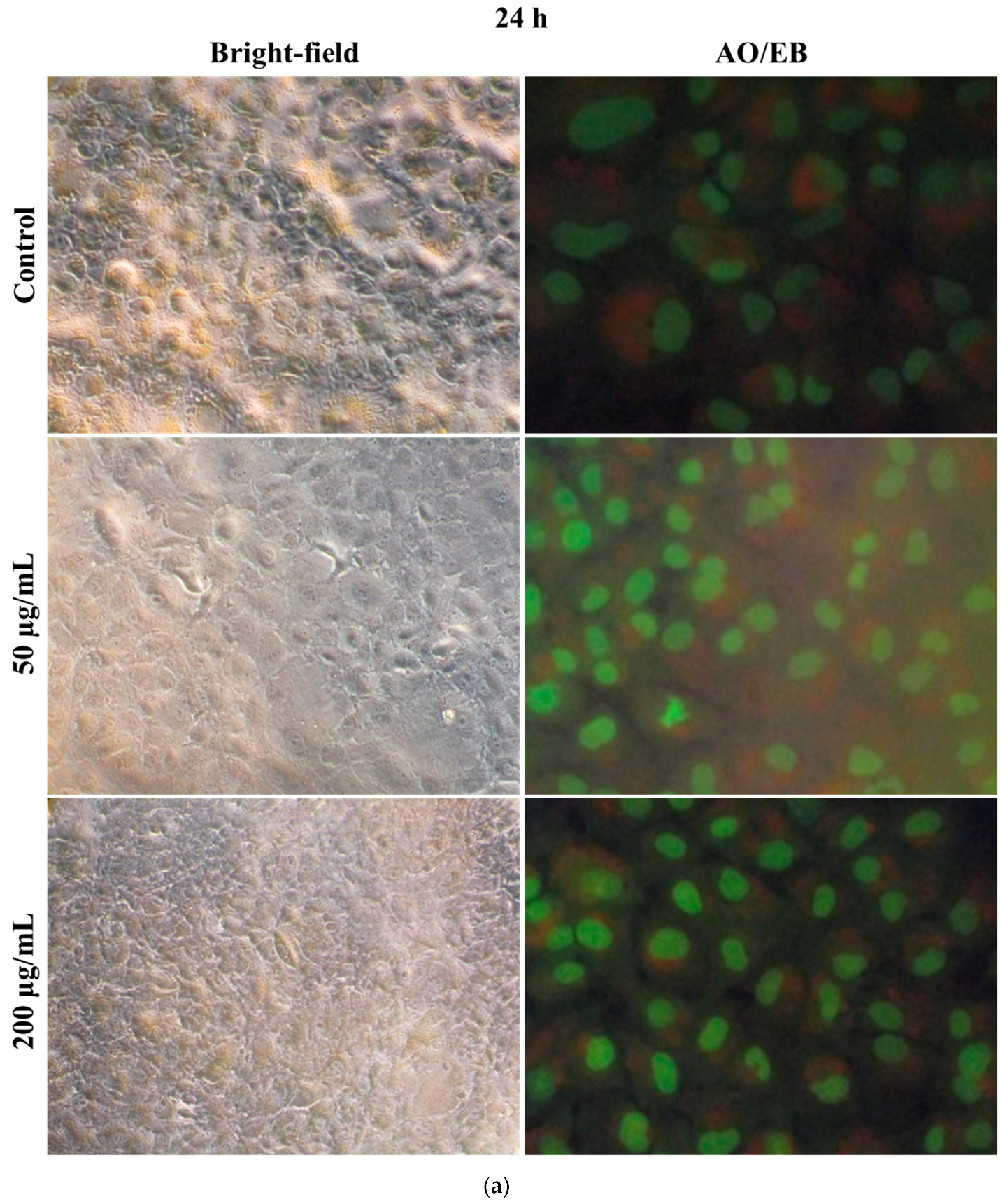

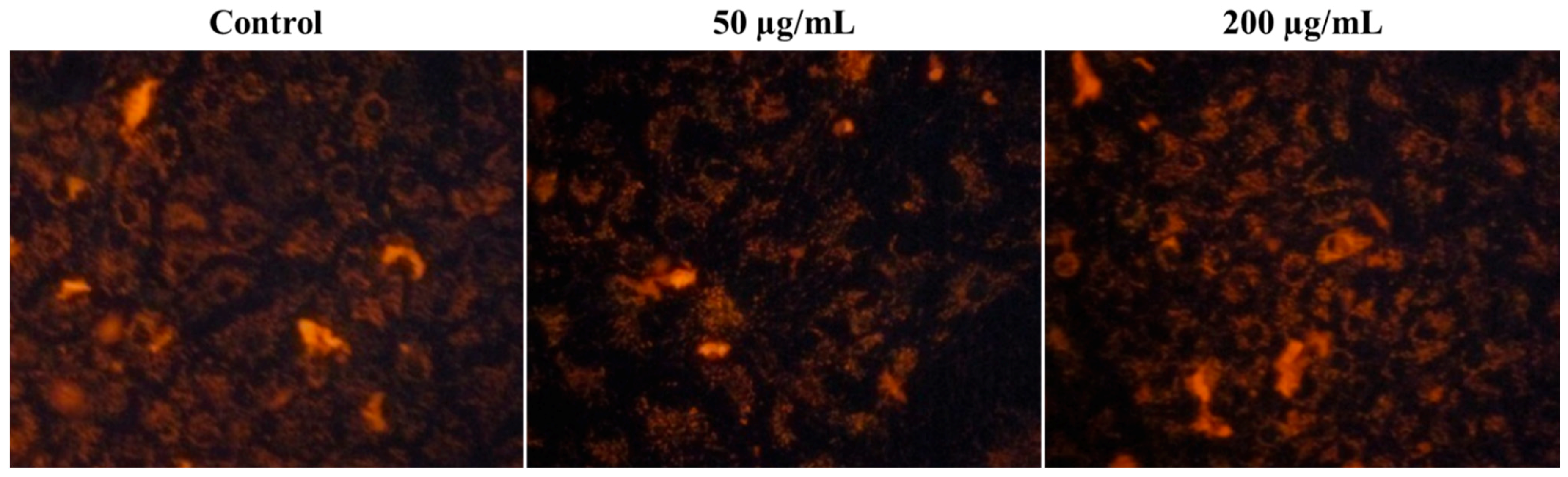

2.6. Microscopic Assessment of Cell Morphology

2.7. Coating

2.8. Color

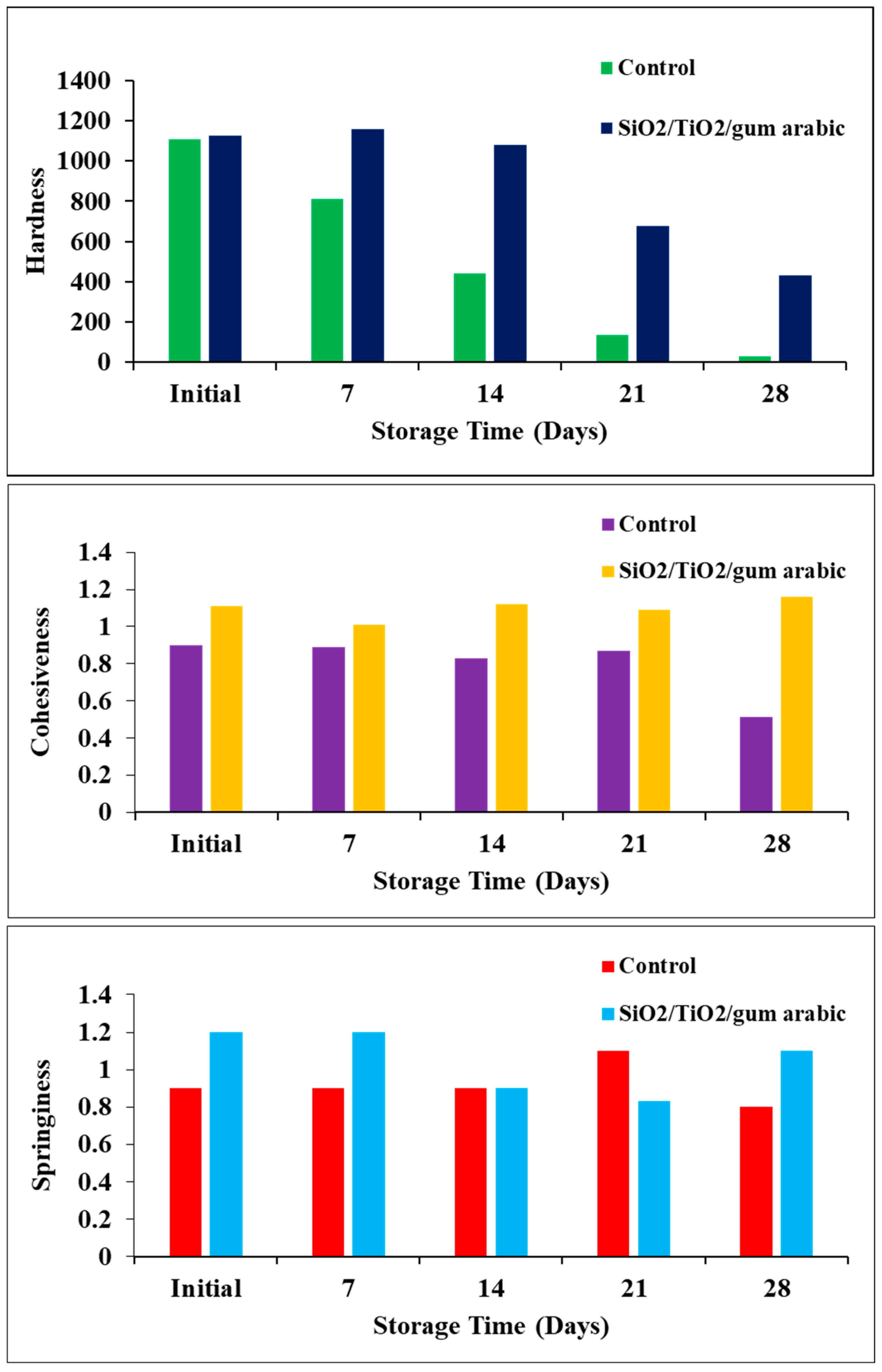

2.9. Firmness

2.10. Statistical Analysis

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raju, P.S.; Chauhan, O.P.; Bawa, A.S. Postharvest handling systems and storage of vegetables. In Handbook of Vegetables and Vegetable Processing; Wiley: Hoboken, NJ, USA, 2018; pp. 247–264. [Google Scholar]

- De Corato, U. Improving the shelf-life and quality of fresh and minimally-processed fruits and vegetables for a modern food industry: A comprehensive critical review from the traditional technologies into the most promising advancements. Crit. Rev. Food Sci. Nutr. 2020, 60, 940–975. [Google Scholar] [CrossRef]

- El-Ramady, H.R.; Domokos-Szabolcsy, É.; Abdalla, N.A.; Taha, H.S.; Fári, M. Postharvest management of fruits and vegetables storage. Sustain. Agric. Rev. 2015, 15, 65–152. [Google Scholar]

- Brecht, J.K.; Sargent, S.A.; Kader, A.A.; Mitcham, E.J.; Maul, F.; Brecht, P.E.; Menocal, O. Mango Postharvest Best Management Practices Manual: HS1185. 2020. Available online: https://edis.ifas.ufl.edu/publication/HS1185 (accessed on 27 November 2024).

- Shewfelt, R.L.; Prussia, S.E. Challenges in handling fresh fruits and vegetables. In Postharvest Handling; Academic Press: Cambridge, MA, USA, 2022; pp. 167–186. [Google Scholar]

- Shakeel, Q.; Shaheen, M.R.; Ali, S.; Ahmad, A.; Raheel, M.; Bajwa, R.T. Postharvest management of fruits and vegetables. In Applications of Biosurfactant in Agriculture; Academic Press: Cambridge, MA, USA, 2022; pp. 1–16. [Google Scholar]

- Suresh, B.V.; Shireesha, Y.; Kishore, T.S.; Dwivedi, G.; Haghighi, A.T.; Patro, E.R. Natural energy materials and storage systems for solar dryers: State of the art. Sol. Energy Mater. Sol. Cells 2023, 255, 112276. [Google Scholar] [CrossRef]

- Iturralde-García, R.D.; Cinco-Moroyoqui, F.J.; Martínez-Cruz, O.; Ruiz-Cruz, S.; Wong-Corral, F.J.; Borboa-Flores, J.; Cornejo-Ramírez, Y.I.; Bernal-Mercado, A.T.; Del-Toro-Sánchez, C.L. Emerging Technologies for Prolonging Fresh-Cut Fruits’ Quality and Safety during Storage. Horticulturae 2022, 8, 731. [Google Scholar] [CrossRef]

- Bancal, V.; Ray, R.C. Overview of Food Loss and Waste in Fruits and Vegetables: From Issue to Resources. In Fruits and Vegetable Wastes: Valorization to Bioproducts and Platform Chemicals; Springer Nature: Singapore, 2022; pp. 3–29. [Google Scholar]

- Kitinoja, L.; Saran, S.; Roy, S.K.; Kader, A.A. Postharvest technology for developing countries: Challenges and opportunities in research, outreach and advocacy. J. Sci. Food Agric. 2011, 91, 597–603. [Google Scholar] [CrossRef]

- Riva, S.C.; Opara, U.O.; Fawole, O.A. Recent developments on postharvest application of edible coatings on stone fruit: A review. Sci. Hortic. 2020, 262, 109074. [Google Scholar] [CrossRef]

- Panahirad, S.; Dadpour, M.; Peighambardoust, S.H.; Soltanzadeh, M.; Gullón, B.; Alirezalu, K.; Lorenzo, J.M. Applications of carboxymethyl cellulose-and pectin-based active edible coatings in preservation of fruits and vegetables: A review. Trends Food Sci. Technol. 2021, 110, 663–673. [Google Scholar] [CrossRef]

- La, D.D.; Nguyen-Tri, P.; Le, K.H.; Nguyen, P.T.; Nguyen, M.D.B.; Vo, A.T.; Nguyen, M.T.; Chang, S.W.; Tran, L.D.; Chung, W.J.; et al. Effects of antibacterial ZnO nanoparticles on the performance of a chitosan/gum arabic edible coating for post-harvest banana preservation. Prog. Org. Coat. 2021, 151, 106057. [Google Scholar] [CrossRef]

- Kumar, N.; Pratibha Prasad, J.; Yadav, A.; Upadhyay, A.; Neeraj Shukla, S.; Petkoska, A.T.; Heena Suri, S.; Gniewosz, M. Recent trends in edible packaging for food applications—Perspective for the future. Food Eng. Rev. 2023, 15, 718–747. [Google Scholar] [CrossRef]

- Wang, J.; Wang, B.; Jiang, W.; Zhao, Y. Quality and shelf life of mango (Mangifera indica L. cv. Tainong’) coated by using chitosan and polyphenols. Food Sci. Technol. Int. 2007, 13, 317–322. [Google Scholar] [CrossRef]

- Han, C.; Lederer, C.; McDaniel, M.; Zhao, Y. Sensory evaluation of fresh strawberries (Fragaria ananassa) coated with chitosan-based edible coatings. J. Food Sci. 2005, 70, S172–S178. [Google Scholar] [CrossRef]

- Correa-Pacheco, Z.N.; Bautista-Baños, S.; de Lorena Ramos-García, M.; del Carmen Martínez-González, M.; Hernández-Romano, J. Physicochemical characterization and antimicrobial activity of edible propolis-chitosan nanoparticle films. Prog. Org. Coat. 2019, 137, 105326. [Google Scholar] [CrossRef]

- Abu-Shama, H.S.; Abou-Zaid, F.O.F.; El-Sayed, E.Z. Effect of using edible coatings on fruit quality of Barhi date cultivar. Sci. Hortic. 2020, 265, 109262. [Google Scholar] [CrossRef]

- Alshatwi, A.A.; Athinarayanan, J.; Periasamy, V.S.; Alatiah, K.A. Date fruits-assisted synthesis and biocompatibility assessment of nickel oxide nanoparticles anchored onto graphene sheets for biomedical applications. Appl. Biochem. Biotechnol. 2017, 181, 725–734. [Google Scholar] [CrossRef] [PubMed]

- Yahia, E.M.; Lobo, M.G.; Kader, A.A. Harvesting and postharvest technology of dates. In Dates: Postharvest Science, Processing Technology and Health Benefits; Wiley: Hoboken, NJ, USA, 2013; pp. 105–135. [Google Scholar]

- Tang, Z.X.; Shi, L.E.; Aleid, S.M. Date fruit: Chemical composition, nutritional and medicinal values, products. J. Sci. Food Agric. 2013, 93, 2351–2361. [Google Scholar] [CrossRef]

- Siddiq, M.; Greiby, I. Overview of date fruit production, postharvest handling, processing, and nutrition. In Dates: Postharvest science, Processing Technology and Health Benefits; Wiley: Hoboken, NJ, USA, 2013; pp. 1–28. [Google Scholar]

- El-Ansary, M.A.; Omar, A.K.; Salama, A.; Helal, S.M. Assessment of fruit defects and economic loss of some soft date palm cultivars (Phoenix dactylifera L.) in north delta, Egypt. Appl. Ecol. Environ. Res. 2019, 17, 5965–5974. [Google Scholar] [CrossRef]

- Shenasi, M.; Aidoo, K.E.; Candlish, A.A. Microflora of date fruits and production of aflatoxins at various stages of maturation. Int. J. Food Microbiol. 2002, 79, 113–119. [Google Scholar] [CrossRef] [PubMed]

- Rahemi, M.; Roustai, F.; Sedaghat, S. Use of Edible Coatings to Preserve Date Fruits (Phoenix dactylofera L.). J. Packag. Technol. Res. 2020, 4, 79–84. [Google Scholar] [CrossRef]

- Salajegheh, F.; Tajeddin, B.; Panahi, B.; Karimi, H. Effect of edible coatings based on zein and chitosan and the use of Roman aniseed oil on the microbial activity of Mazafati dates. J. Food Bioprocess Eng. 2020, 3, 178–184. [Google Scholar]

- Yousef, A.R.; El-Moniem, E.A.A.A.; Mahmoud, T.S.M. Edible coating of soy protein or gelatin as a carrier of thyme oil for maintaining quality of ‘barhee ‘dates fruits during cold storage. Plant Arch. 2020, 20, 9311–9322. [Google Scholar]

- Mehyar, G.F.; El Assi, N.M.; Alsmairat, N.G.; Holley, R.A. Effect of edible coatings on fruit maturity and fungal growth on Berhi dates. Int. J. Food Sci. Technol. 2014, 49, 2409–2417. [Google Scholar] [CrossRef]

- Le, K.H.; Nguyen, M.D.B.; Dai Tran, L.; Thi, H.P.N.; Van Tran, C.; Van Tran, K.; Thi, H.P.N.; Thi, N.D.; Yoon, Y.S.; Nguyen, D.D.; et al. A novel antimicrobial ZnO nanoparticles-added polysaccharide edible coating for the preservation of postharvest avocado under ambient conditions. Prog. Org. Coat. 2021, 158, 106339. [Google Scholar] [CrossRef]

- Ramírez-Concepción, H.R.; Anaya-Esparza, L.M.; de Lourdes García-Magaña, M.; Yahia, E.M.; Meza-Espinoza, L.; Montalvo-González, E. The effects of chitosan-TiO2 and chitosan-TiO2-ZnO-MgO hybrid coatings on the shelf life of jackfruit bulbs (Artocarpus heterophyllus Lam). Int. J. Food Sci. Technol. 2023, 58, 6708–6717. [Google Scholar] [CrossRef]

- Prasad, N.; Thombare, N.; Sharma, S.C.; Kumar, S. Gum arabic–A versatile natural gum: A review on production, processing, properties and applications. Ind. Crops Prod. 2022, 187, 115304. [Google Scholar] [CrossRef]

- De, A.; Nayak, A.K.; Kundu, A.; Das, B.; Samanta, A. Gum arabic-based nanomaterials in drug delivery and biomedical applications. In Biopolymer-Based Nanomaterials in Drug Delivery and Biomedical Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 165–182. [Google Scholar]

- Patel, S.; Goyal, A. Applications of natural polymer gum arabic: A review. Int. J. Food Prop. 2015, 18, 986–998. [Google Scholar] [CrossRef]

- Sang, L.; Zhao, Y.; Burda, C. TiO2 nanoparticles as functional building blocks. Chem. Rev. 2014, 114, 9283–9318. [Google Scholar] [CrossRef] [PubMed]

- Dubey, R.S.; Rajesh, Y.B.R.D.; More, M.A. Synthesis and characterization of SiO2 nanoparticles via sol-gel method for industrial applications. Mater. Today Proc. 2015, 2, 3575–3579. [Google Scholar] [CrossRef]

- Zhang, W.; Ahari, H.; Zhang, Z.; Jafari, S.M. Role of silica (SiO2) nano/micro-particles in the functionality of degradable packaging films/coatings and their application in food preservation. Trends Food Sci. Technol. 2023, 133, 75–86. [Google Scholar] [CrossRef]

- Athinarayanan, J.; Periasamy, V.S.; Qasem, A.A.; Al-Shagrawi, R.A.; Alshatwi, A.A. Synthesis of SiO2 nanostructures from Pennisetum glaucum and their effect on osteogenic differentiation for bone tissue engineering applications. J. Mater. Sci. Mater. Med. 2019, 30, 23. [Google Scholar] [CrossRef]

- Athinarayanan, J.; Periasamy, V.S.; Alshatwi, A.A. Unveiling the biocompatible properties of date palm tree (Phoenix dactylifera L.) biomass-derived lignin nanoparticles. ACS Omega 2022, 7, 19270–19279. [Google Scholar] [CrossRef] [PubMed]

- Athinarayanan, J.; Alshatwi, A.A.; Periasamy, V.S. Biocompatibility analysis of Borassus flabellifer biomass-derived nanofibrillated cellulose. Carbohydr. Polym. 2020, 235, 115961. [Google Scholar] [CrossRef] [PubMed]

- Zhao, N.; Yan, L.; Zhao, X.; Chen, X.; Li, A.; Zheng, D.; Zhou, X.; Dai, X.; Xu, F.J. Versatile types of organic/inorganic nanohybrids: From strategic design to biomedical applications. Chem. Rev. 2018, 119, 1666–1762. [Google Scholar] [CrossRef]

- Athinarayanan, J.; Periasamy, V.S.; Alhazmi, M.; Alatiah, K.A.; Alshatwi, A.A. Synthesis of biogenic silica nanoparticles from rice husks for biomedical applications. Ceram. Int. 2015, 41, 275–281. [Google Scholar] [CrossRef]

- Athinarayanan, J.; Periasamy, V.S.; Alhazmi, M.; Alshatwi, A.A. Synthesis and biocompatibility assessment of sugarcane bagasse-derived biogenic silica nanoparticles for biomedical applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2017, 105, 340–349. [Google Scholar] [CrossRef] [PubMed]

- Sandhya, M.; Ramasamy, D.; Sudhakar, K.; Kadirgama, K.; Harun, W.S.W. Ultrasonication an intensifying tool for preparation of stable nanofluids and study the time influence on distinct properties of graphene nanofluids–A systematic overview. Ultrason. Sonochemistry 2021, 73, 105479. [Google Scholar] [CrossRef] [PubMed]

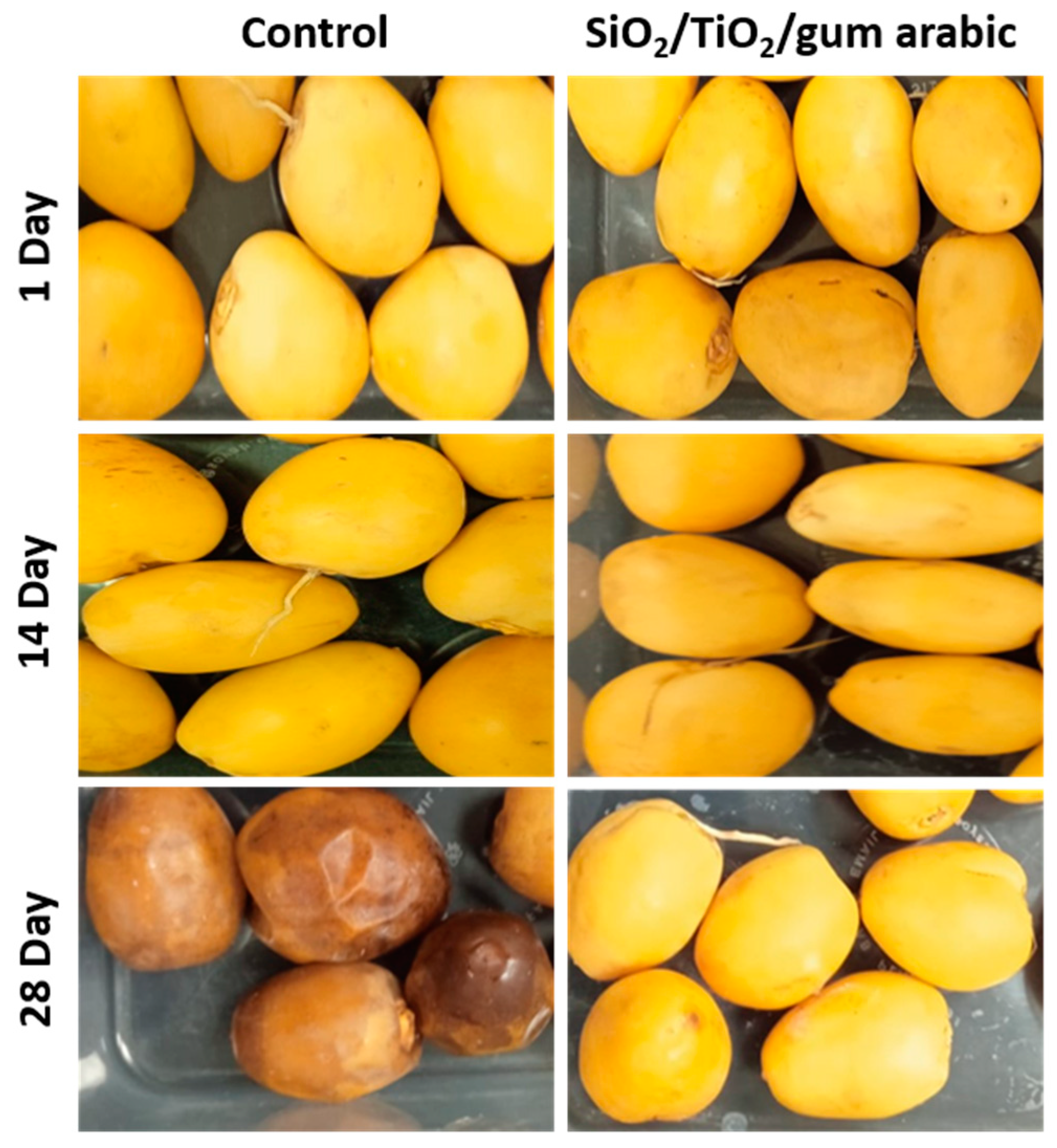

| Storage Time (Days) | L* | a* | b* | |||

|---|---|---|---|---|---|---|

| Control | SiO2/TiO2/gum Arabic | Control | SiO2/TiO2/gum Arabic | Control | SiO2/TiO2/gum Arabic | |

| 0 | 56.97 | 62.63 | 8.22 | 7.49 | 34.64 | 40.08 |

| 7 | 54.75 | 62.05 | 9.26 | 5.13 | 35.54 | 36.98 |

| 14 | 53.34 | 61.42 | 7.36 | 6.93 | 37.71 | 42.62 |

| 21 | 43.70 | 59.78 | 7.11 | 8.15 | 22.67 | 42.71 |

| 28 | 34.45 | 54.07 | 5.85 | 8.23 | 15.92 | 38.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Athinarayanan, J.; Periasamy, V.S.; Alshatwi, A.A. Ultrasonic-Assisted Synthesis and Cytocompatibility Assessment of TiO2/SiO2 Nanoparticles-Impregnated Gum Arabic Nanocomposite: Edible Coating of Dates for Shelf-Life Extension. Polymers 2025, 17, 161. https://doi.org/10.3390/polym17020161

Athinarayanan J, Periasamy VS, Alshatwi AA. Ultrasonic-Assisted Synthesis and Cytocompatibility Assessment of TiO2/SiO2 Nanoparticles-Impregnated Gum Arabic Nanocomposite: Edible Coating of Dates for Shelf-Life Extension. Polymers. 2025; 17(2):161. https://doi.org/10.3390/polym17020161

Chicago/Turabian StyleAthinarayanan, Jegan, Vaiyapuri Subbarayan Periasamy, and Ali A. Alshatwi. 2025. "Ultrasonic-Assisted Synthesis and Cytocompatibility Assessment of TiO2/SiO2 Nanoparticles-Impregnated Gum Arabic Nanocomposite: Edible Coating of Dates for Shelf-Life Extension" Polymers 17, no. 2: 161. https://doi.org/10.3390/polym17020161

APA StyleAthinarayanan, J., Periasamy, V. S., & Alshatwi, A. A. (2025). Ultrasonic-Assisted Synthesis and Cytocompatibility Assessment of TiO2/SiO2 Nanoparticles-Impregnated Gum Arabic Nanocomposite: Edible Coating of Dates for Shelf-Life Extension. Polymers, 17(2), 161. https://doi.org/10.3390/polym17020161