Resonance Frequency as an Indicator of the Damage in Carbon Composite Plates: Analysis on Composites Prepared with Conventional and Sustainable Resins Subjected to Impact Tests

Abstract

1. Introduction

1.1. Novel Composite Materials with Lower Impact on the Environment

1.2. Reducing the Carbon Footprint of Composite Materials by Assessing the Residual Elastic Properties for Reusing Components

2. Materials and Methods

2.1. Materials

2.2. Out-of-Plane Impact Tests

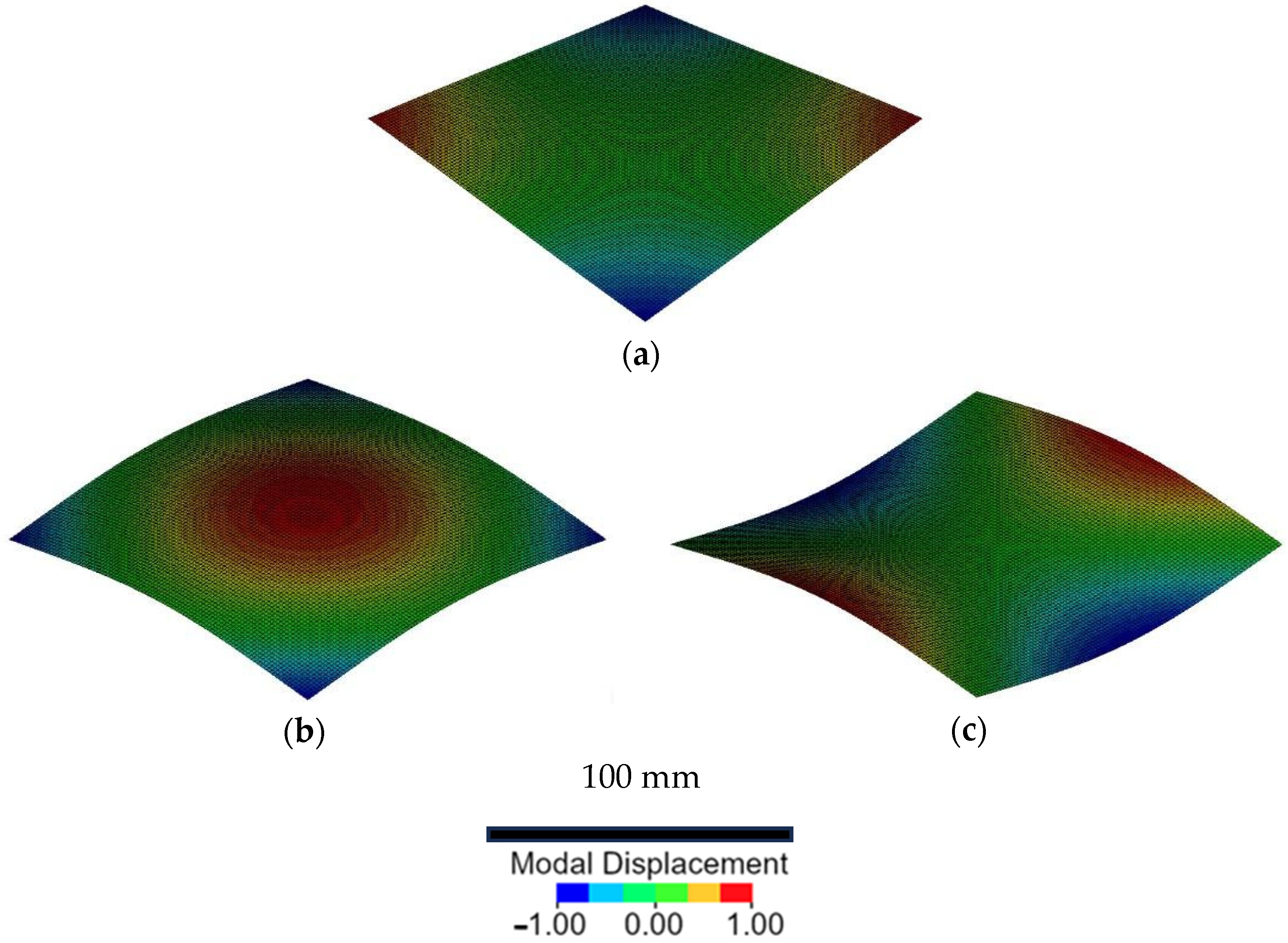

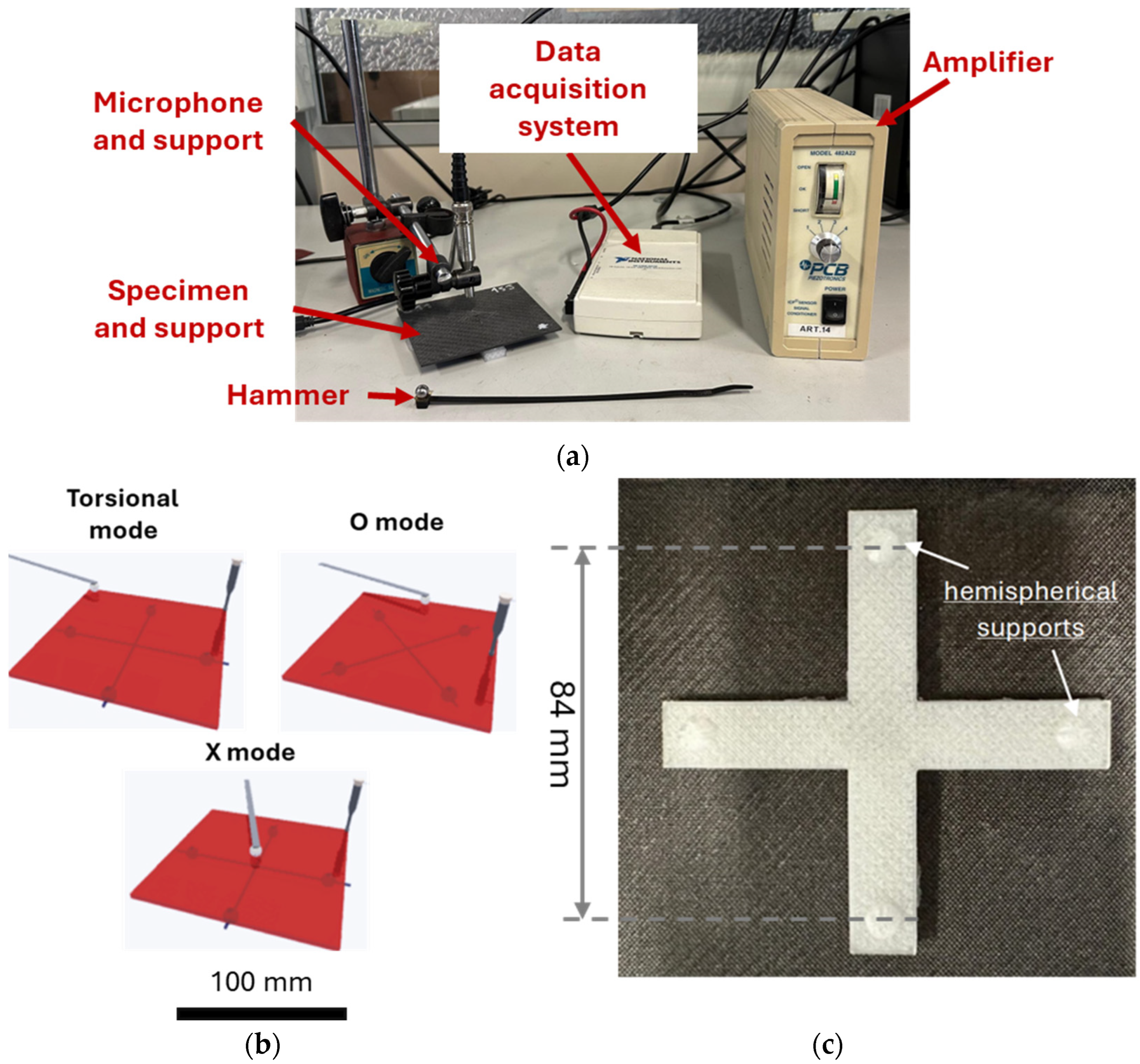

2.3. Impulse Excitation Technique

3. Results and Discussion

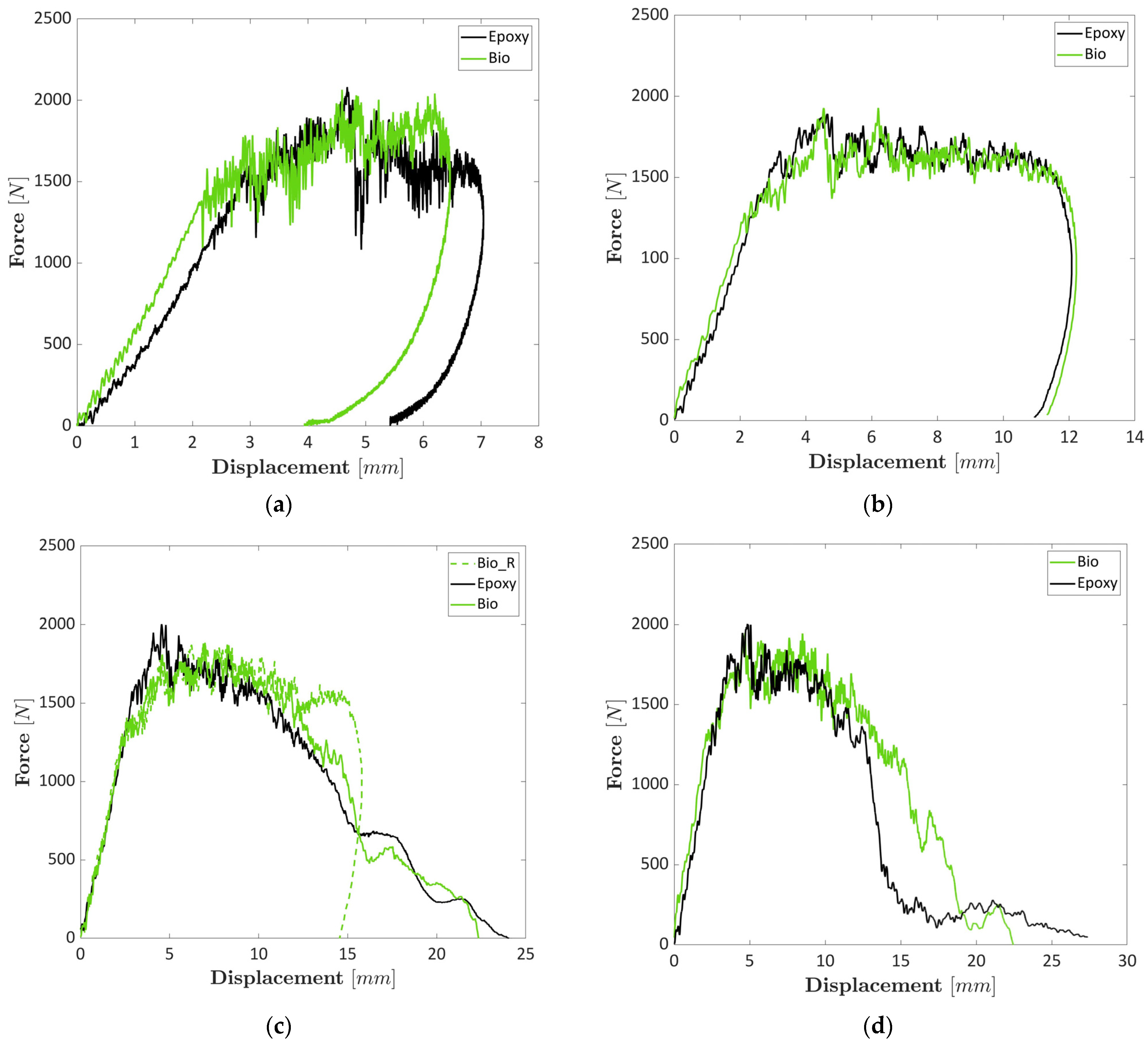

3.1. Perforation Tests

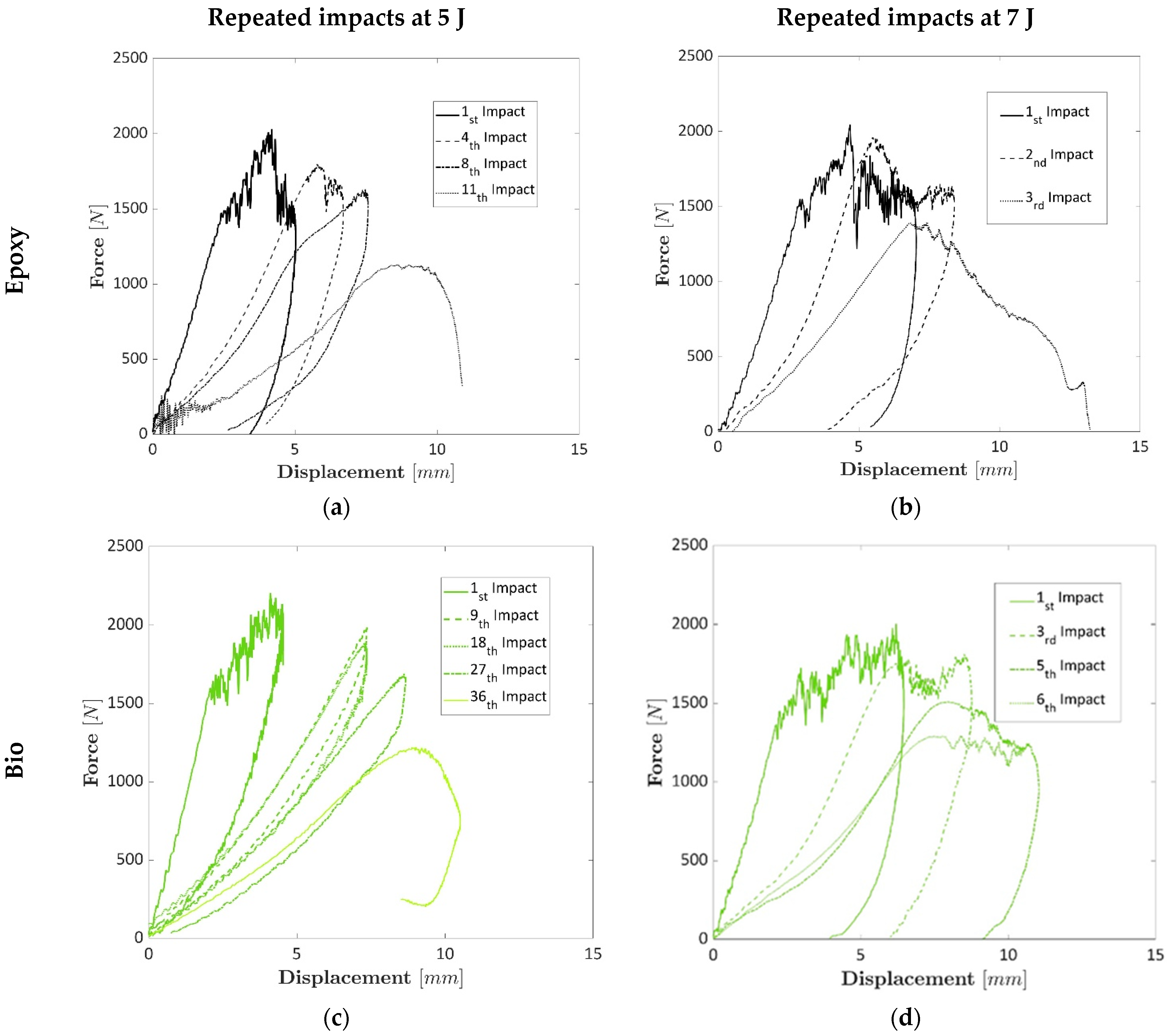

3.2. Repeated Impact Tests

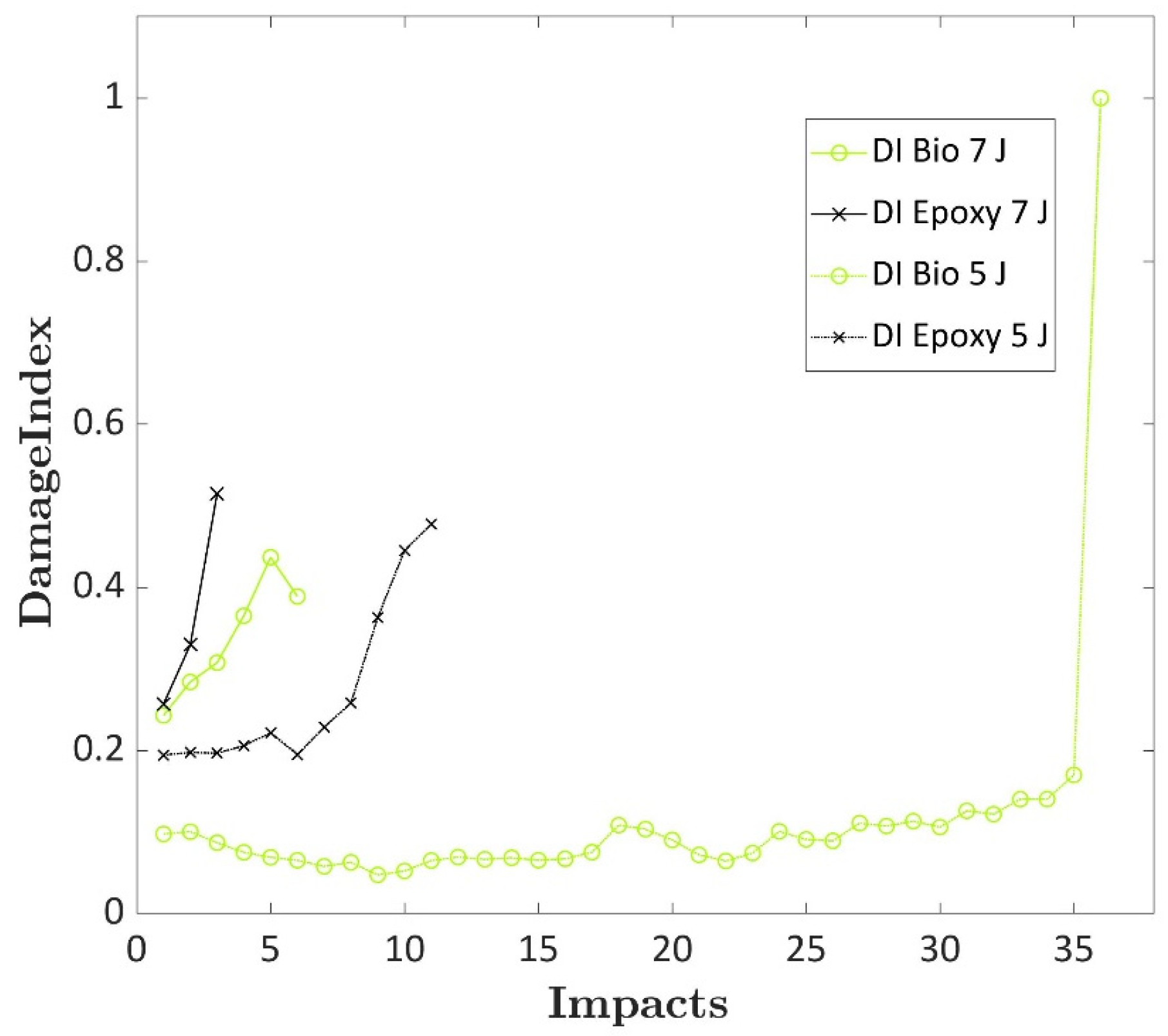

3.3. Damage Index

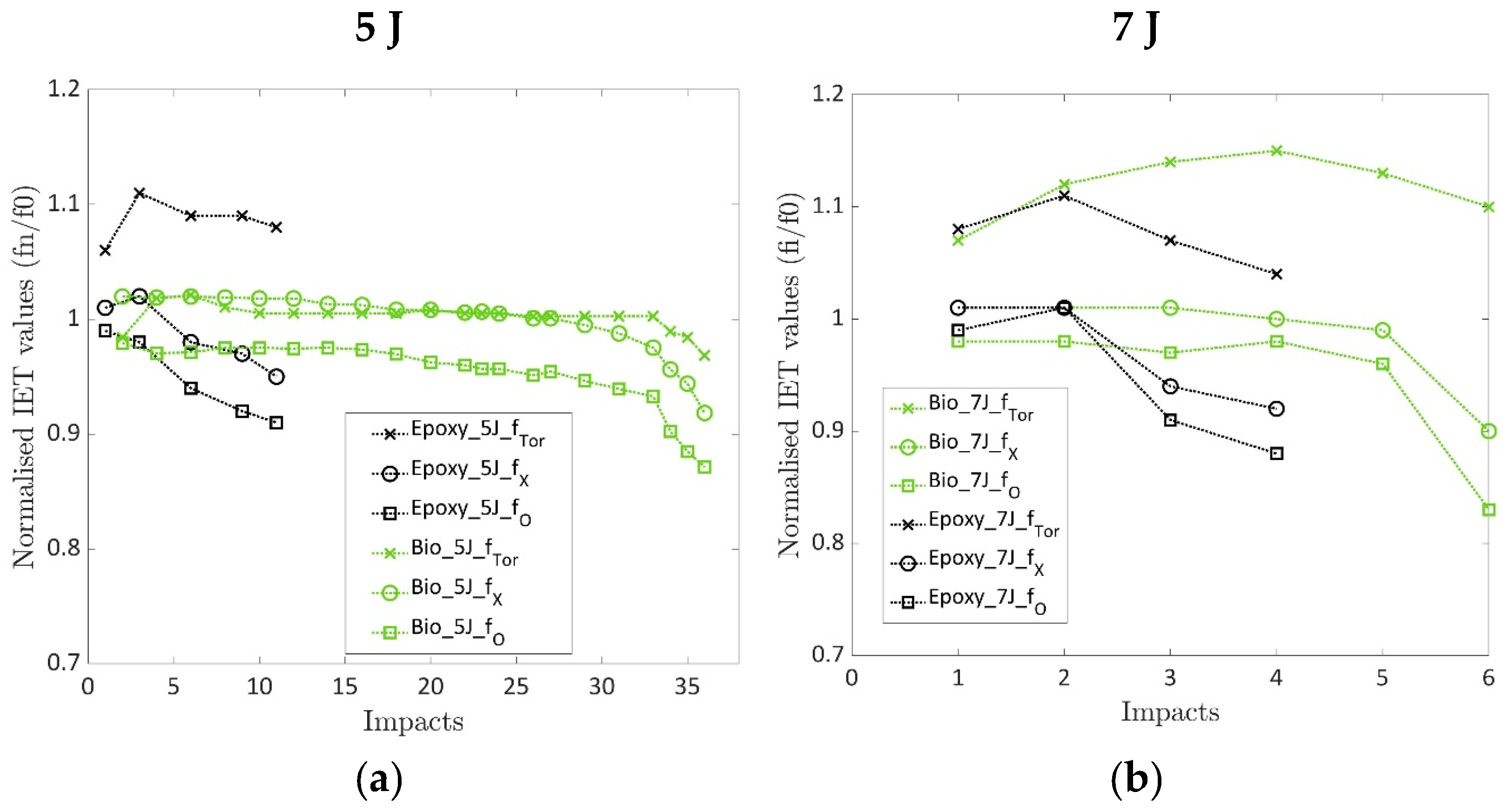

3.4. IET

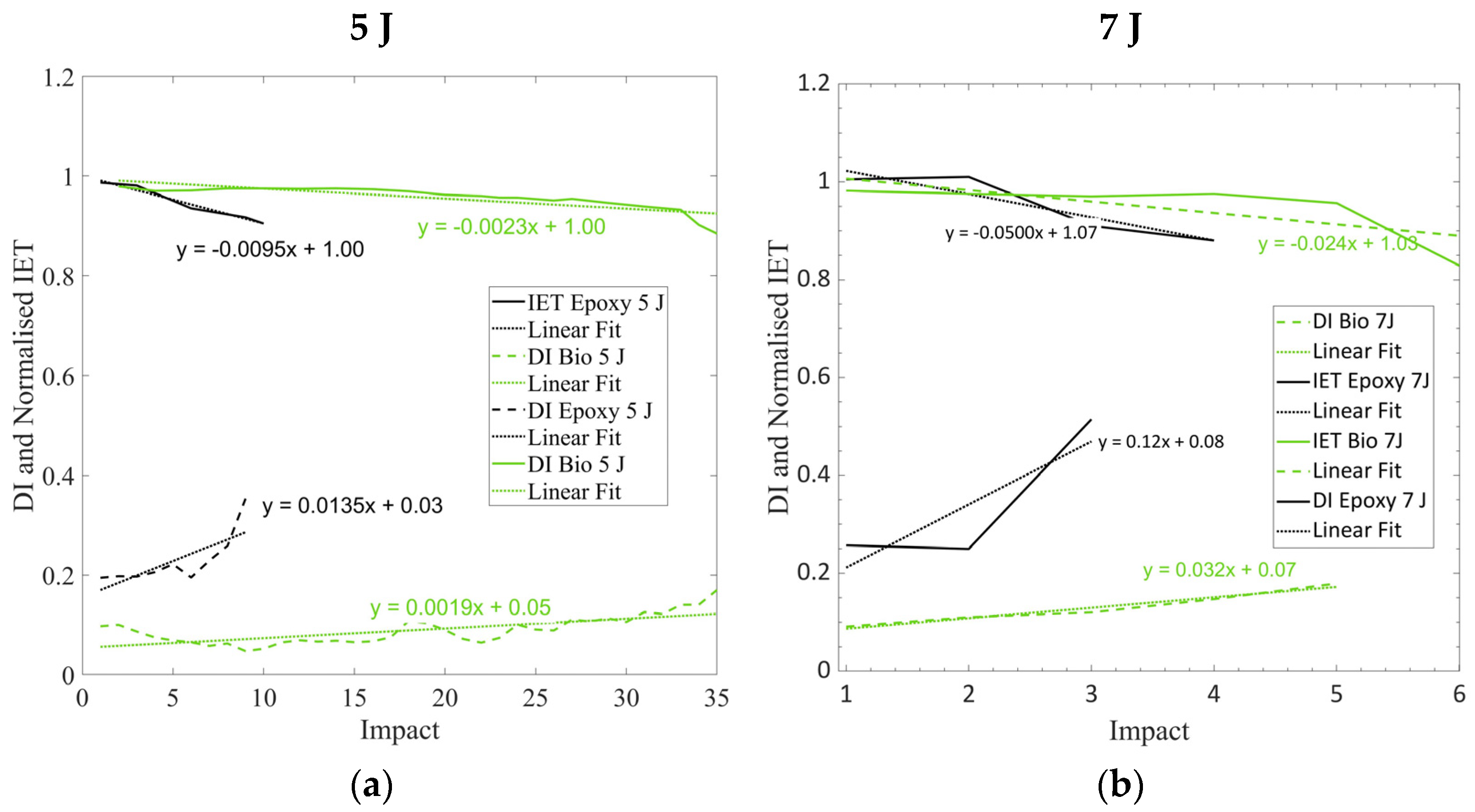

3.5. Comparisons Between IET and DI Index

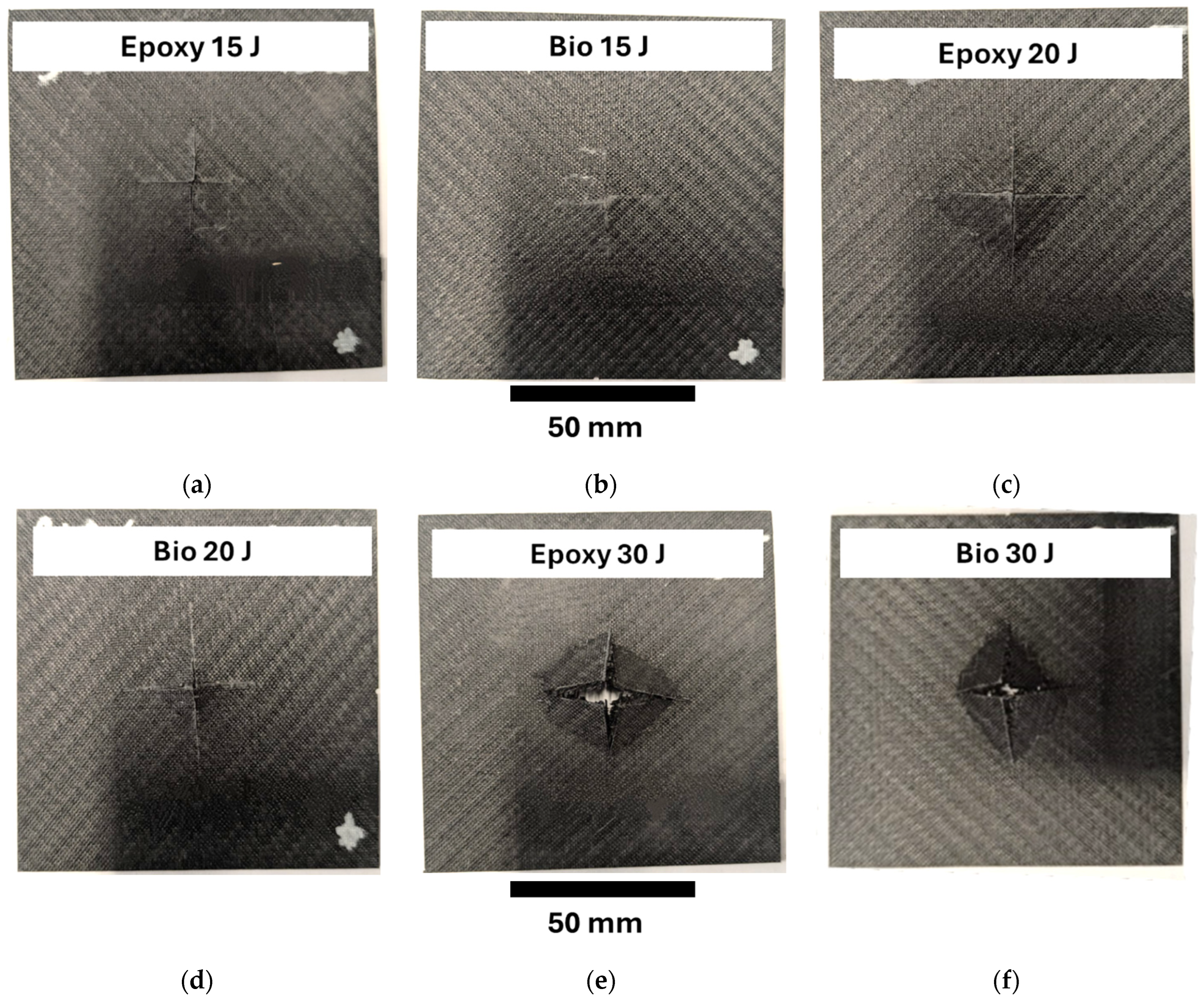

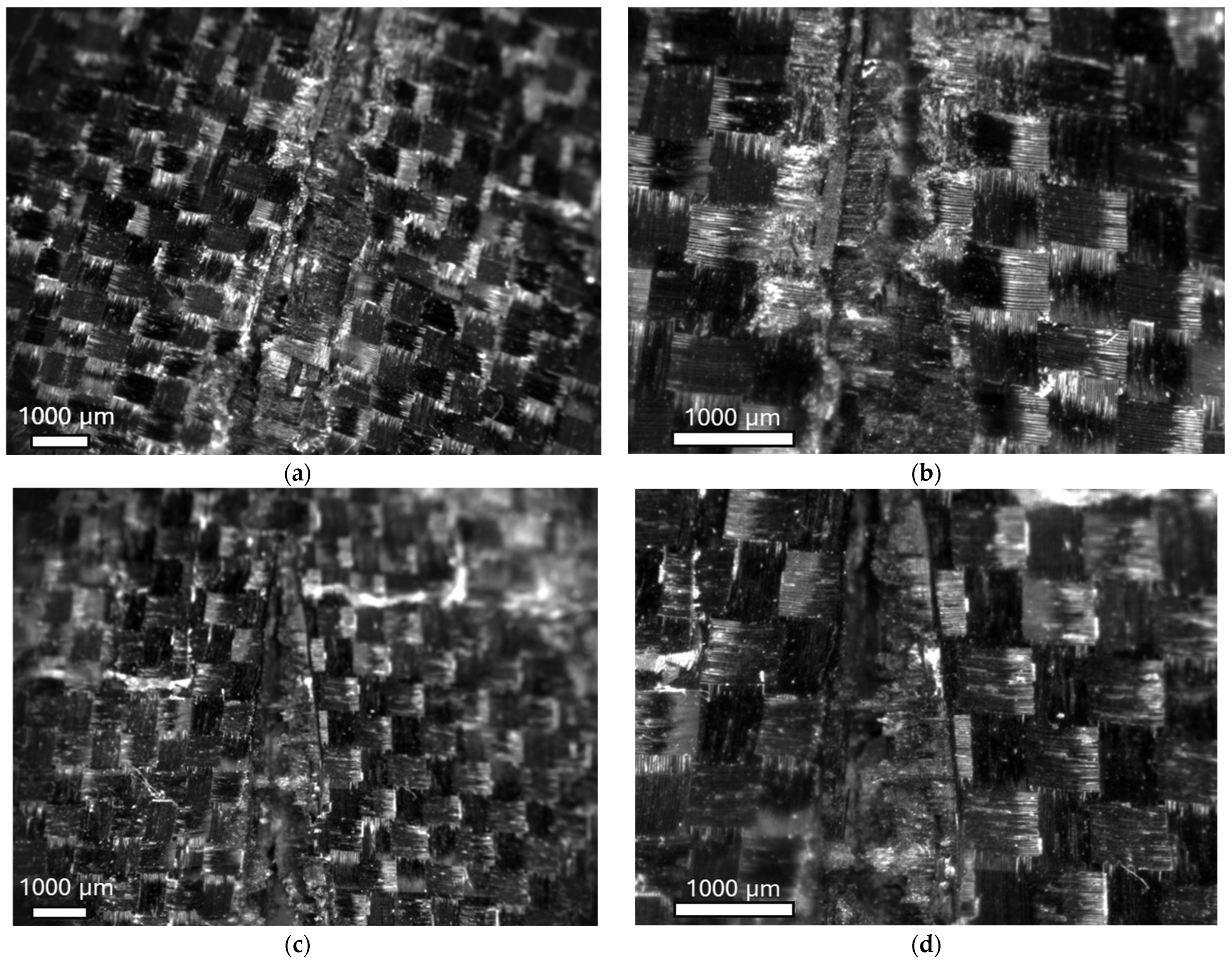

3.6. Fracture Surfaces

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dyer, W.E.; Kumru, B. Polymers as Aerospace Structural Components: How to Reach Sustainability? Macromol. Chem. Phys. 2023, 224, 2300186. [Google Scholar] [CrossRef]

- Mayyas, A.; Qattawi, A.; Omar, M.; Shan, D. Design for Sustainability in Automotive Industry: A Comprehensive Review. Renew. Sustain. Energy Rev. 2012, 16, 1845–1862. [Google Scholar] [CrossRef]

- Zero Emission Vehicles: First ‘Fit for 55’ Deal Will End the Sale of New CO2 Emitting Cars in Europe by 2035. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_6462 (accessed on 25 December 2024).

- Environmental Protection Agency (EPA). Control of Air Pollution from Aircraft Engines: Emission Standards and Test Procedures; Environmental Protection Agency: Washington, DC, USA, 2022.

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer Composite Materials: A Comprehensive Review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Ciampaglia, A.; Fiumarella, D.; Boursier Niutta, C.; Ciardiello, R.; Belingardi, G. Physics Based Data Driven Method for the Crashworthiness Design of Origami Composite Tubes. Int. J. Mech. Mater. Des. 2024, 20, 445–462. [Google Scholar] [CrossRef]

- Kočí, V.; Picková, E. Life Cycle Perspective of Liquid Epoxy Resin Use in the Automotive Industry. Pol. J. Environ. Stud. 2020, 29, 653–667. [Google Scholar] [CrossRef]

- Shubhra, Q.T.H.; Alam, A.K.M.M.; Quaiyyum, M.A. Mechanical Properties of Polypropylene Composites: A Review. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar] [CrossRef]

- Jogur, G.; Nawaz Khan, A.; Das, A.; Mahajan, P.; Alagirusamy, R. Impact Properties of Thermoplastic Composites. Text. Progress. 2018, 50, 109–183. [Google Scholar] [CrossRef]

- Di Matteo, P.; Iadarola, A.; Ciardiello, R.; Paolino, D.S.; Gazza, F.; Lambertini, V.G.; Brunella, V. Cross-Linking Reaction of Bio-Based Epoxy Systems: An Investigation into Cure Kinetics. Polymers 2024, 16, 2499. [Google Scholar] [CrossRef] [PubMed]

- Iadarola, A.; Matteo, P.D.; Ciardiello, R.; Gazza, F.; Lambertini, V.G.; Brunella, V.; Paolino, D.S. Quasi-Static and Dynamic Response of Cardanol Bio-Based Epoxy Resins: Effect of Different Bio-Contents. Procedia Struct. Integr. 2023, 47, 383–397. [Google Scholar] [CrossRef]

- Boursier Niutta, C.; Ciardiello, R.; Tridello, A.; Paolino, D.S. Epoxy and Bio-Based Epoxy Carbon Fiber Twill Composites: Comparison of the Quasi-Static Properties. Materials 2023, 16, 1601. [Google Scholar] [CrossRef] [PubMed]

- Del Bianco, G.; Giammaria, V.; Capretti, M.; Boria, S.; Lenci, S.; Ciardiello, R.; Castorani, V. Low-Velocity Impact of Carbon, Flax, and Hybrid Composites: Performance Comparison and Numerical Modeling. Compos. Struct. 2024, 344, 118318. [Google Scholar] [CrossRef]

- Giammaria, V.; Del Bianco, G.; Capretti, M.; Boria, S.; Vigna, L.; Calzolari, A.; Castorani, V. Geometry and Hybridization Effect on the Crashworthiness Performances of Carbon and Flax/Epoxy Composites. J. Compos. Sci. 2024, 8, 331. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, Y.; Ji, Y.; Wei, Y. Functional Epoxy Vitrimers and Composites. Prog. Mater. Sci. 2021, 120, 100710. [Google Scholar] [CrossRef]

- Niutta, C.B.; Tridello, A.; Paolino, D.S.; Belingardi, G. Residual Properties in Damaged Laminated Composites through Non-destructive Testing: A Review. Materials 2021, 14, 4513. [Google Scholar] [CrossRef] [PubMed]

- Nsengiyumva, W.; Zhong, S.; Lin, J.; Zhang, Q.; Zhong, J.; Huang, Y. Advances, Limitations and Prospects of Nondestructive Testing and Evaluation of Thick Composites and Sandwich Structures: A State-of-the-Art Review. Compos. Struct. 2021, 256, 112951. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L.; Lu, Y. Guided Lamb Waves for Identification of Damage in Composite Structures: A Review. J. Sound. Vib. 2006, 295, 753–780. [Google Scholar] [CrossRef]

- Pavlakovic, B.; Lowe, M.; Alleyne, O.; Cawley, P. Disperse: A General Purpose Program For Creating Dispersion Curves. In Review of Progress in Quantitative Nondestructive Evaluation; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Lammering, R. Observation of Piezoelectrically Induced Lamb Wave Propagation in Thin Plates by Use of Speckle Interferometry. Exp. Mech. 2010, 50, 377–387. [Google Scholar] [CrossRef]

- Niutta, C.B. Enhancement of a New Methodology Based on the Impulse Excitation Technique for the Non-destructive Determination of Local Material Properties in Composite Laminates. Appl. Sci. 2021, 11, 101. [Google Scholar] [CrossRef]

- Boursier Niutta, C.; Tridello, A.; Belingardi, G.; Paolino, D.S. Non-destructive Determination of Local Material Properties of Laminated Composites with the Impulse Excitation Technique. Compos. Struct. 2021, 262, 113607. [Google Scholar] [CrossRef]

- Niutta, C.B.; Tridello, A.; Ciardiello, R.; Belingardi, G.; Paolino, D.S. Assessment of Residual Elastic Properties of a Damaged Composite Plate with Combined Damage Index and Finite Element Methods. Appl. Sci. 2019, 9, 2579. [Google Scholar] [CrossRef]

- Ambu, R.; Aymerich, F.; Ginesu, F.; Priolo, P. Assessment of NDT Interferometric Techniques for Impact Damage Detection in Composite Laminates. Compos. Sci. Technol. 2006, 66, 199–205. [Google Scholar] [CrossRef]

- Hung, Y.Y.; Ho, H.P. Shearography: An Optical Measurement Technique and Applications. Mater. Sci. Eng. R Rep. 2005, 49, 61–87. [Google Scholar] [CrossRef]

- Harizi, W.; Chaki, S.; Bourse, G.; Ourak, M. Mechanical Damage Assessment of Glass Fiber-Reinforced Polymer Composites Using Passive Infrared Thermography. Compos. B Eng. 2014, 59, 74–79. [Google Scholar] [CrossRef]

- Montesano, J.; Fawaz, Z.; Bougherara, H. Use of Infrared Thermography to Investigate the Fatigue Behavior of a Carbon Fiber Reinforced Polymer Composite. Compos. Struct. 2013, 97, 76–83. [Google Scholar] [CrossRef]

- Ciampaglia, A.; Ciardiello, R.; Cesano, F.; Belingardi, G.; Brunella, V. Multifunctional Material Design for Strain Sensing: Carbon Black Effect on Mechanical and Electrical Properties of Polyamides. Compos. Struct. 2023, 304, 116373. [Google Scholar] [CrossRef]

- Lampani, L.; Sarasini, F.; Tirillò, J.; Gaudenzi, P. Analysis of Damage in Composite Laminates with Embedded Piezoelectric Patches Subjected to Bending Action. Compos. Struct. 2018, 202, 935–942. [Google Scholar] [CrossRef]

- Belingardi, G.; Cavatorta, M.P.; Paolino, D.S. A New Damage Index to Monitor the Range of the Penetration Process in Thick Laminates. Compos. Sci. Technol. 2008, 68, 2646–2652. [Google Scholar] [CrossRef][Green Version]

- Technical Datasheet IN2. Easy Composite. Available online: https://media.easycomposites.co.uk/datasheets/EC-TDS-IN2-Infusion-Resin.pdf (accessed on 25 December 2024).

- Technical Datasheet IB2. Easy Composite. Available online: https://media.easycomposites.eu/datasheets/EC-TDS-IB2-Epoxy-Infusion-Bio-Resin.pdf (accessed on 25 December 2024).

- Gerber, D.; Byerrum, R.; Gee, R.W. Glycerol Concentration in crop Plants. Plant Sci. 1988, 56, 31–38. [Google Scholar] [CrossRef]

- Miyuranga, K.A.V.; Arachchige, U.S.P.R.; Jayasinghe, R.A.; Samarakoon, G. Purification of Residual Glycerol from Biodiesel Production as a Value-Added Raw Material for Glycerolysis of Free Fatty Acids in Waste Cooking Oil. Energies 2022, 15, 8856. [Google Scholar] [CrossRef]

- ASTM D3039; Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D3410; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM D5379; Standard Test Method for Shear Properties of Composite Materials by the V-Notched Beam Method. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D5628-18; Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimens by Means of a Falling Dart (Tup or Falling Mass). ASTM International: West Conshohocken, PA, USA, 2024.

- Popov, I.I.; Shitikova, M.V. Impulse Excitation Technique and Its Application for Identification of Material Damping: An Overview. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 962. [Google Scholar]

- Mcintyre, M.E.; Woodhouse, J. On Measuring The Elastic And Damping Constants Of Orthotropic Sheet Materials. Acta Metall. 1988, 36, 1397–1416. [Google Scholar] [CrossRef]

- BuzzMac. Buzz-o-Sonic, 5.9 Manual; BuzzMac International: Portland, ME, USA, 2010. [Google Scholar]

| IN2 Carbon Composite | IB2 Carbon Composite | Standard (Velocity of the Test) | |

|---|---|---|---|

| Tensile Modulus [GPa] | 57.7 (±0.7) | 54.8 (±0.1) | ASTM D3039 [35] (2 mm/min) |

| Tensile Strength [MPa] | 715.5 (±4.5) | 650 (±5.0) | |

| Flexural Modulus [GPa] | 41.7 (±4) | 39.4 (±0.1) | ASTM D790 [36] (1 mm/min) |

| Flexural Strength [MPa] | 658 (±1.0) | 627 (±16.5) | |

| Compression Modulus [GPa] | 42.6 (±1.4) | 45.1 (±1.5) | ASTM D3410 [37] (1.3 mm/min) |

| Compression strength [MPa] | 448.5 (±7.5) | 462 (±11.0) | |

| Shear Modulus [GPa] | 4.1 (±0.1) | 3.8 (±0.1) | ASTM D5379 [38] (2 mm/min) |

| Shear Strength [MPa] | 58.1 (±0.5) | 60.4 (±1.4) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciardiello, R.; Boursier Niutta, C.; Tridello, A. Resonance Frequency as an Indicator of the Damage in Carbon Composite Plates: Analysis on Composites Prepared with Conventional and Sustainable Resins Subjected to Impact Tests. Polymers 2025, 17, 141. https://doi.org/10.3390/polym17020141

Ciardiello R, Boursier Niutta C, Tridello A. Resonance Frequency as an Indicator of the Damage in Carbon Composite Plates: Analysis on Composites Prepared with Conventional and Sustainable Resins Subjected to Impact Tests. Polymers. 2025; 17(2):141. https://doi.org/10.3390/polym17020141

Chicago/Turabian StyleCiardiello, Raffaele, Carlo Boursier Niutta, and Andrea Tridello. 2025. "Resonance Frequency as an Indicator of the Damage in Carbon Composite Plates: Analysis on Composites Prepared with Conventional and Sustainable Resins Subjected to Impact Tests" Polymers 17, no. 2: 141. https://doi.org/10.3390/polym17020141

APA StyleCiardiello, R., Boursier Niutta, C., & Tridello, A. (2025). Resonance Frequency as an Indicator of the Damage in Carbon Composite Plates: Analysis on Composites Prepared with Conventional and Sustainable Resins Subjected to Impact Tests. Polymers, 17(2), 141. https://doi.org/10.3390/polym17020141