Development of an Empirical Model as a Prediction Tool for the Sound Absorption Performance of Wool/Soy Protein Biocomposites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

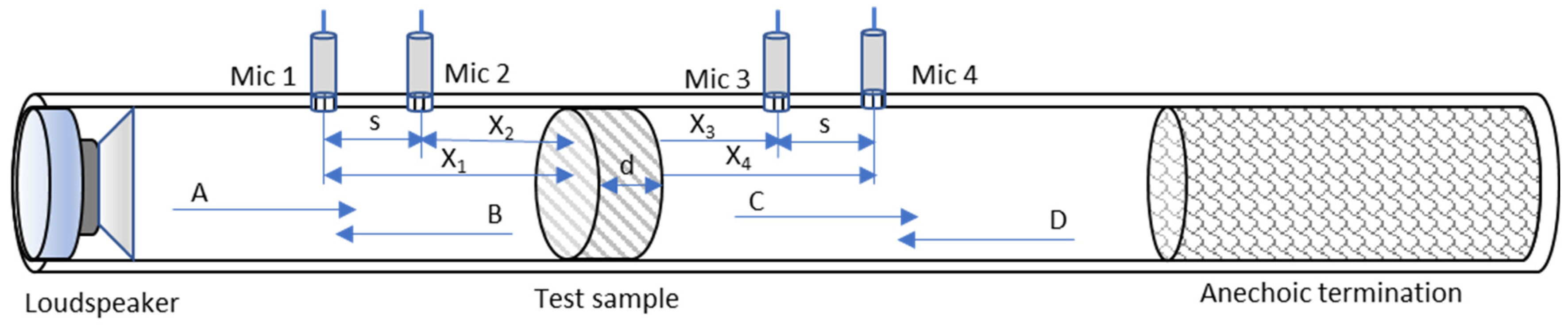

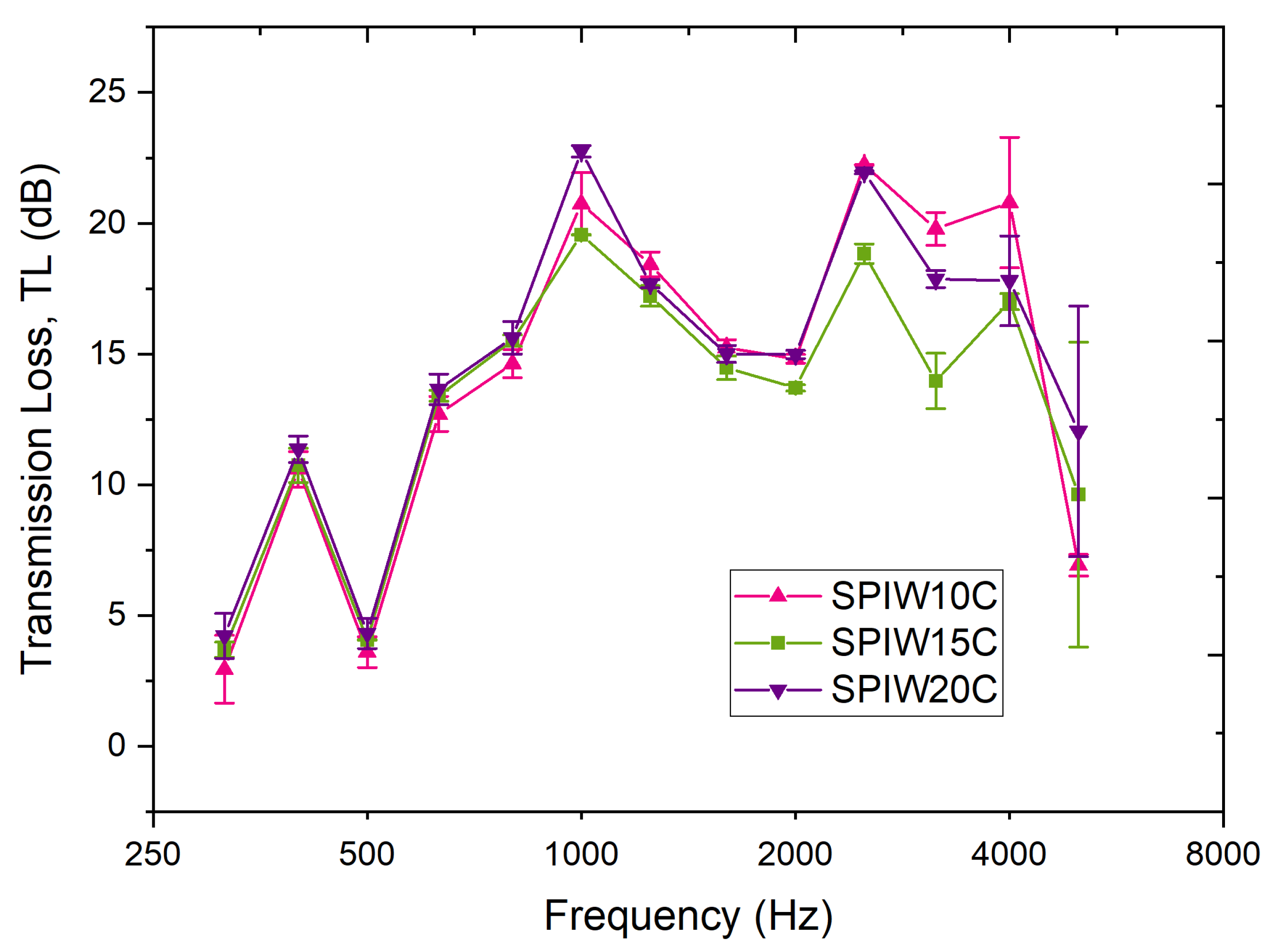

2.3. Measurements of Transmission Loss (TL)

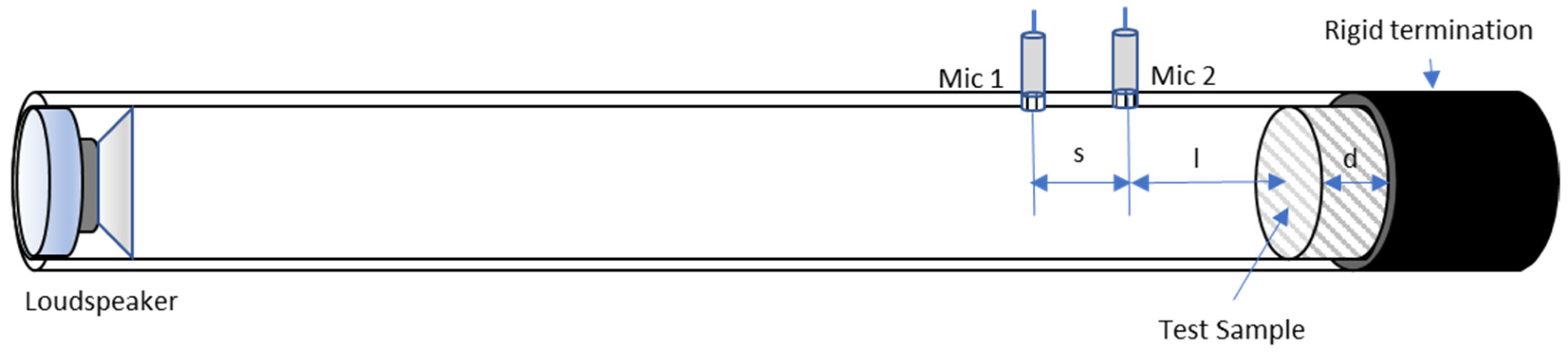

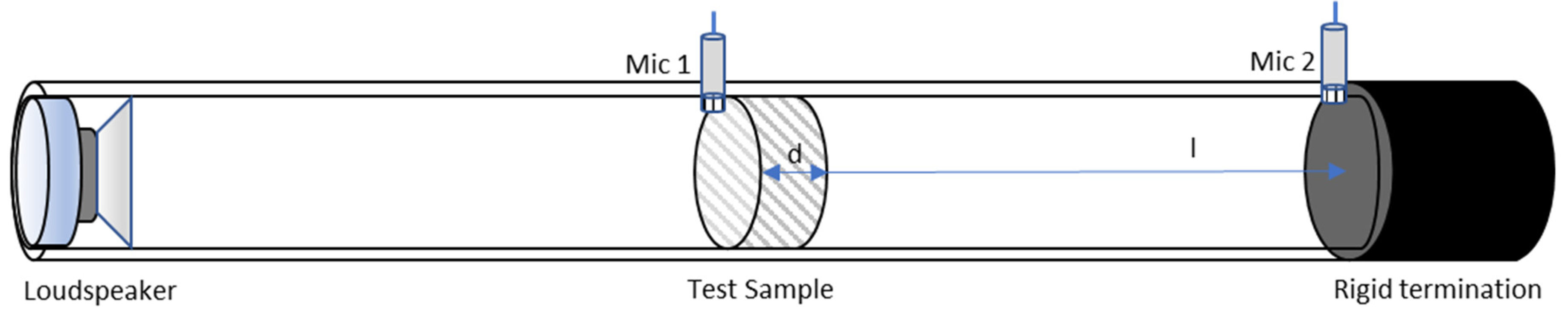

2.4. Measurements of Sound Absorption Coefficient

2.5. Measurements of Airflow Resistivity

2.6. Empirical Model

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

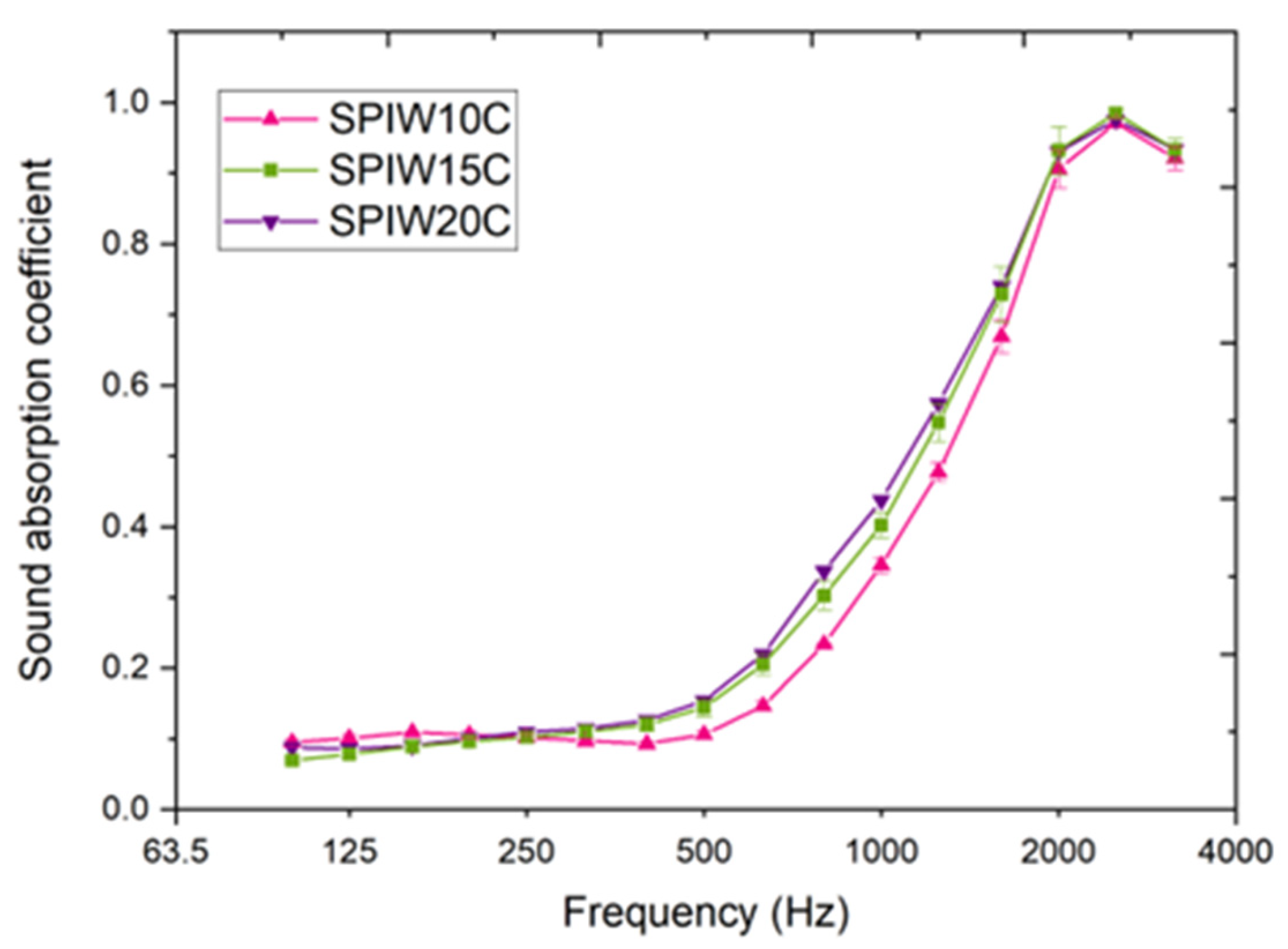

| SPIW10C | SPIW15C | SPIW20C | ||||

|---|---|---|---|---|---|---|

| f (Hz) | Mean | SD | Mean | SD | Mean | SD |

| 100 | 0.10 a | 0.01 | 0.09 a.b | 0.01 | 0.07 b | 0.00 |

| 125 | 0.10 a | 0.01 | 0.09 a.b | 0.00 | 0.08 b | 0.00 |

| 160 | 0.11 a | 0.00 | 0.09 b | 0.00 | 0.09 b | 0.01 |

| 200 | 0.11 a | 0.00 | 0.10 a | 0.00 | 0.10 a | 0.01 |

| 250 | 0.10 a | 0.00 | 0.11 a | 0.00 | 0.10 a | 0.01 |

| 315 | 0.10 a | 0.00 | 0.11 a | 0.01 | 0.11 a | 0.01 |

| 400 | 0.09 a | 0.00 | 0.13 a | 0.01 | 0.12 a | 0.01 |

| 500 | 0.11 a | 0.01 | 0.15 a | 0.01 | 0.14 a | 0.01 |

| 630 | 0.15 a | 0.01 | 0.22 b | 0.02 | 0.21 a.b | 0.02 |

| 800 | 0.23 a | 0.00 | 0.34 b | 0.03 | 0.30 a.b | 0.02 |

| 1000 | 0.35 a | 0.01 | 0.44 a | 0.04 | 0.40 a | 0.02 |

| 1250 | 0.48 a | 0.01 | 0.57 a | 0.04 | 0.55 a | 0.03 |

| 1600 | 0.67 a | 0.02 | 0.74 a | 0.02 | 0.73 a | 0.04 |

| 2000 | 0.91 a | 0.03 | 0.93 a | 0.01 | 0.93 a | 0.03 |

| 2500 | 0.97 a | 0.01 | 0.98 a | 0.01 | 0.99 a | 0.01 |

| 3150 | 0.92 a | 0.02 | 0.93 a | 0.02 | 0.93 a | 0.02 |

| SPIW10C | SPIW15C | SPIW20C | ||||

|---|---|---|---|---|---|---|

| f (Hz) | Mean | SD | Mean | SD | Mean | SD |

| 318.75 | 2.95 a | 1.30 | 3.70 a | 0.29 | 4.23 a | 0.86 |

| 400 | 10.59 a | 0.68 | 10.75 a | 0.66 | 11.37 a | 0.51 |

| 500 | 3.61 a | 0.59 | 4.07 a | 0.01 | 4.33 a | 0.58 |

| 630 | 12.71 a | 0.67 | 13.41 a | 0.21 | 13.65 a | 0.58 |

| 800 | 14.64 a | 0.54 | 15.52 a | 0.22 | 15.62 a | 0.62 |

| 1000 | 20.75 a.b | 1.19 | 19.56 a | 0.02 | 22.76 b | 0.22 |

| 1250 | 18.43 a | 0.47 | 17.22 b | 0.39 | 17.69 a.b | 0.16 |

| 1600 | 15.24 a | 0.31 | 14.48 a | 0.45 | 15.00 a | 0.32 |

| 2000 | 14.82 a | 0.16 | 13.71 b | 0.12 | 14.99 a | 0.16 |

| 2500 | 22.24 a | 0.01 | 18.84 b | 0.38 | 21.95 a | 0.06 |

| 3150 | 19.79 a | 0.63 | 13.98 b | 1.06 | 17.87 a | 0.33 |

| 4000 | 20.80 a | 2.50 | 17.01 a | 0.31 | 17.81 a | 1.72 |

| 5000 | 6.93 a | 0.41 | 9.62 a | 5.83 | 12.05 a | 4.79 |

References

- Chen, L.; Huang, L.; Hua, J.; Chen, Z.; Wei, L.; Osman, A.; Fawzy, S.; Rooney, D.; Dong, L.; Yap, P. Green construction for low-carbon cities: A review. Environ. Chem. Lett. 2023, 21, 1627–1657. [Google Scholar] [CrossRef]

- Schützenhofer, S.; Kovacic, I.; Rechberger, H.; Mack, S. Improvement of Environmental Sustainability and Circular Economy through Construction Waste Management for Material Reuse. Sustainability 2022, 14, 11087. [Google Scholar] [CrossRef]

- BUILD UP Team, European Commission. Circular Construction and Materials for a Sustainable Building Sector. Available online: https://build-up.ec.europa.eu/en/resources-and-tools/articles/circular-construction-and-materials-sustainable-building-sector (accessed on 5 May 2025).

- United Nations General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development. Resolution Adopted by the General Assembly on 25 September 2015. Available online: https://www.un.org/en/development/desa/population/migration/generalassembly/docs/globalcompact/A_RES_70_1_E.pdf (accessed on 5 May 2025).

- Papadopoulos, A.M. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- I-LOOP LIFE on LIFE Public Database, European Commission. Insulation Glass Wool Circular Economy Approach. Reference: LIFE18 ENV/FR/000046|Acronym: I-LOOP LIFE. Available online: https://webgate.ec.europa.eu/life/publicWebsite/project/LIFE18-ENV-FR-000046/insulation-glass-wool-circular-economy-approach (accessed on 5 May 2025).

- Adediran, A.; Lemougna, P.; Yliniemi, J.; Tanskanen, P.; Kinnunen, P.; Roning, J.; Illikainen, M. Recycling glass wool as a fluxing agent in the production of clay- and waste-based ceramics. J. Clean. Prod. 2021, 289, 125673. [Google Scholar] [CrossRef]

- Fellner, J.; Lederer, J.; Scharff, C.; Laner, D. Present Potentials and Limitations of a Circular Economy with Respect to Primary Raw Material Demand. J. Ind. Ecol. 2017, 21, 494–496. [Google Scholar] [CrossRef]

- Smol, M.; Marcinek, P.; Koda, E. Drivers and Barriers for a Circular Economy (CE) Implementation in Poland—A Case Study of Raw Materials Recovery Sector. Energies 2021, 14, 2219. [Google Scholar] [CrossRef]

- Camilli, F.; Focacci, M.; Dal Prà, A.; Bortolu, S.; Ugolini, F.; Vagnoni, E.; Duce, P. Turning Waste Wool into a Circular Resource: A Review of Eco-Innovative Applications in Agriculture. Agronomy 2025, 15, 446. [Google Scholar] [CrossRef]

- Porubská, M.; Koóšová, K.; Braniša, J. The Application of Sheep Wool in the Building Industry and in the Removal of Pollutants from the Environment. Processes 2024, 12, 963. [Google Scholar] [CrossRef]

- Sun, Y.; Li, B.; Zhang, Y.; Dou, H.; Fan, W.; Wang, S. The progress and prospect for sustainable development of waste wool resources. Text. Res. J. 2023, 93, 468–485. [Google Scholar] [CrossRef]

- Parlato, M.C.M.; Porto, S.M.C. Organized Framework of Main Possible Applications of Sheep Wool Fibers in Building Components. Sustainability 2020, 12, 761. [Google Scholar] [CrossRef]

- Popescu, C.; Stanescu, M.D. Eco-Friendly Processing of Wool and Sustainable Valorization of This Natural Bioresource. Sustainability 2024, 16, 4661. [Google Scholar] [CrossRef]

- Altieri, R.; Esposito, A. Evaluation of the fertilizing effect of olive mill waste compost in short-term crops. Int. Biodeterior. Biodegrad. 2010, 64, 124–128. [Google Scholar] [CrossRef]

- D’Addabbo, T.; Papajová, I.; Sasanelli, N.; Radicci, V.; Renčo, M. Suppression of root-knot nematodes in potting mixes amended with different composted biowastes. Helminthologia 2011, 48, 278–287. [Google Scholar] [CrossRef]

- Urdanpilleta, M.; Leceta, I.; Guerrero, P.; de la Caba, K. Sustainable Sheep Wool/Soy Protein Biocomposites for Sound Absorption. Polymers 2022, 14, 5231. [Google Scholar] [CrossRef] [PubMed]

- Urdanpilleta, M.; del Rey, R.; Leceta, I.; Rodríguez, J.C.; Alba, J.; Guerrero, P. Empirical modelling of the acoustic behavior of sheep wool/soy protein biocomposites. J. Build. Eng. 2024, 89, 109290. [Google Scholar] [CrossRef]

- Urdanpilleta, M.; Leceta, I.; Martín-Garín, A.; Millán-García, J.A.; Guerrero, P.; Caba, K.D.L. Valorized sheep wool biocomposites towards a more sustainable building sector: Thermal insulation, sound absorption, and resistance against insects. Dev. Built Environ. 2025, 21, 100608. [Google Scholar] [CrossRef]

- ASTM E2611-19; Standard Test Method for Measurements of Normal Incidence Sound Transmission of Acoustical Materials Based on the Transfer Matrix Method. ASTM International: West Conshohocken, PA, USA, 2019.

- UNE-EN-ISO 10534-2:2024; Determination of Sound Absorption Coefficient and Impedance in Impedances Tubes—Part 2: Transfer-Function Method. ISO Publishing: Geneva, Switzerland, 2024.

- Fattahi, M.; Taban, E.; Soltani, P.; Berardi, U.; Khavanin, A.; Zaroushani, V. Waste corn husk fibers for sound absorption and thermal insulation applications: A step towards sustainable buildings. J. Build. Eng. 2023, 77, 107468. [Google Scholar] [CrossRef]

- ISO 9053-1:2020; Acoustics—Determination of Airflow Resistance—Part 1: Static Airflow Method. ISO Publishing: Geneva, Switzerland, 2020.

- Crocker, M.J.; Arenas, J.P. Use of sound-absorbing materials. In Handbook of Noise and Vibrations; Crocker, M.J., Ed.; John Wiley and Sons: New York, NY, USA, 2007; pp. 696–713. [Google Scholar]

- Ingard, K.U.; Dear, T.A. Measurement of acoustic flow resistance. J. Sound Vib. 1985, 103, 567–572. [Google Scholar] [CrossRef]

- Delany, M.; Bazley, E. Acoustical properties of fibrous absorbent materials. Appl. Acoust. 1970, 3, 105–116. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Predicting the sound absorption of natural materials: Best-fit inverse laws for the acoustic impedance and the propagation constant. Appl. Acoust. 2017, 115, 131–138. [Google Scholar] [CrossRef]

- Allard, J.F.; Atalla, N. Propagation of Sound in Porous Media: Modelling Sound Absorbing Materials, 3rd ed.; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Budtova, T.; Lokki, T.; Malakooti, S.; Rege, A.; Lu, H.; Milow, B.; Vapaavuori, J.; Vivod, S.L. Acoustic properties of aerogels: Current status and prospects. Adv. Eng. Mater. 2023, 25, 2201137. [Google Scholar] [CrossRef]

- Minetto Garcia Duarte, M.; Zoppi, R.A.; Serpa, A.L. Optimizing acoustic performance: Electrospun Polycaprolactone fiber mat associated with melamine foam and fiber glass wool. Fibers Polym. 2024, 25, 457–472. [Google Scholar] [CrossRef]

- Figueiredo, A.; Vela, G.; Ascensão, G.; Vettorazzi, E.; Vicente, R.; Oliveira, M. Development of an innovative biocomposite using coconut fibres and bio-based binder for thermal and acoustic aplications in buildings. J. Clean. Prod. 2025, 491, 144834. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Alba, J.; Tarrés, Q.; Espinach, F.X.; Mutjé, P.; Delgado-Aguilar, M. Characterization of CaCO3 Filled Poly(lactic) Acid and Bio Polyethylene Materials for Building Applications. Polymers 2021, 13, 3323. [Google Scholar] [CrossRef]

- Reixach, R.; Del Rey, R.; Alba, J.; Arbat, G.; Espinach, F.X.; Mutjé, P. Acoustic properties of agroforestry waste orange pruning fibers reinforced polypropylene composites as an alternative to laminated gypsum boards. Constr. Build. Mater. 2015, 77, 124–129. [Google Scholar] [CrossRef]

- Building Technical Code, Ministry of Transport, Mobility and Urban Agenda, Spanish Government. 2006. Available online: https://www.codigotecnico.org/ (accessed on 5 May 2025).

- UNE-EN ISO 12354-1:2018; Building Acoustics—Estimation of Acoustic Performance of Buildings from the Performance of Elements—Part 1: Airborne Sound Insulation Between Rooms (ISO 12354-1:2017). ISO Publishing: Geneva, Switzerland, 2018.

- Putra, A.; Oliveira, T.; Souli, M.; Kassim, D.H. Characterizing and modeling of acoustical performance of natural sound absorber. In Multiphysics Simulations in Automotive and Aerospace Applications; Academic Press: Cambridge, MA, USA, 2021; pp. 49–64. [Google Scholar]

- Putra, A.; Othman, M.N.; Oliveira, T.; Souli, M.H.; Kassim, D.H.; Herawan, S. Waste Durian Husk Fibers as Natural Sound Absorber: Performance and Acoustic Characterization. Buildings 2022, 12, 1112. [Google Scholar] [CrossRef]

| Samples | Density (kg/m3) | Thickness (mm) | Mean TL (dB) | Airflow Resistivity (kPa s m−2) | Airflow Resistance (Pa s m−1) |

|---|---|---|---|---|---|

| SPIW10C | 72 ± 8 | 16.9 ± 0.9 | 14.1 | 14 ± 5 | 200 ± 100 |

| SPIW15C | 62 ± 1 | 21.7 ± 0.4 | 13.2 | 15 ± 2 | 330 ± 50 |

| SPIW20C | 67 ± 3 | 18.8 ± 0.5 | 14.6 | 18 ± 2 | 330 ± 60 |

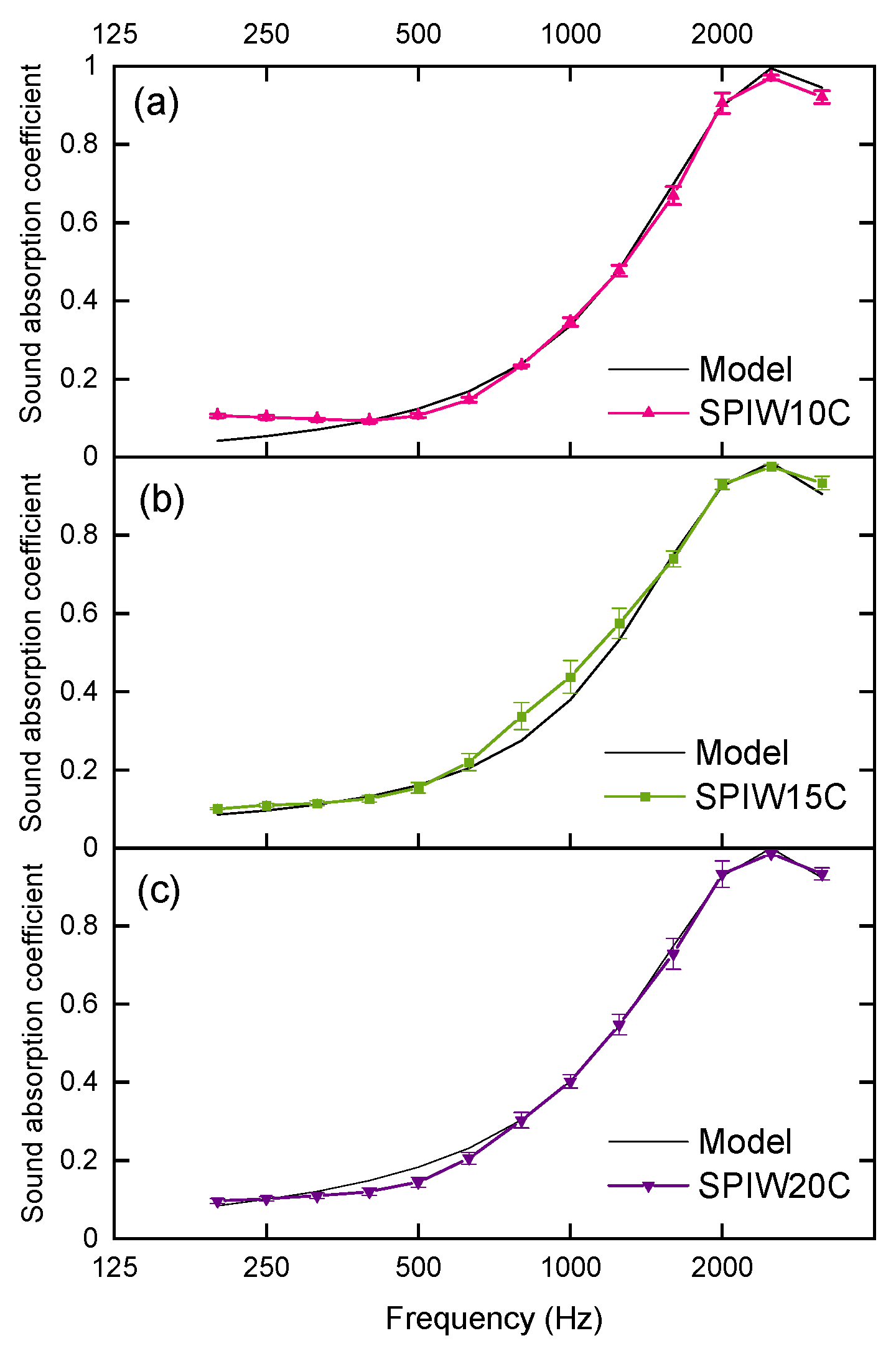

| Samples | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | ε |

|---|---|---|---|---|---|---|---|---|---|

| SPIW10C | 0.8449 | 0.4074 | 0.0227 | 0.0098 | 0.4344 | 0.0602 | 0.4441 | 0.6054 | 1.8012 |

| SPIW15C | 0.5927 | 0.1071 | 0.2424 | 0.1297 | 0.5499 | 0.1220 | 0.3297 | 0.3919 | 1.5930 |

| SPIW20C | 0.4150 | 0.6861 | 0.1369 | 0.0260 | 0.2859 | 0.2873 | 0.1350 | 0.9966 | 2.1308 |

| * | 0.0571 | 0.7540 | 0.0870 | 0.7320 | 0.1890 | 0.5950 | 0.0978 | 0.7000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alba, J.; Urdanpilleta, M.; del Rey, R.; Leceta, I.; Guerrero, P.; de la Caba, K. Development of an Empirical Model as a Prediction Tool for the Sound Absorption Performance of Wool/Soy Protein Biocomposites. Polymers 2025, 17, 2666. https://doi.org/10.3390/polym17192666

Alba J, Urdanpilleta M, del Rey R, Leceta I, Guerrero P, de la Caba K. Development of an Empirical Model as a Prediction Tool for the Sound Absorption Performance of Wool/Soy Protein Biocomposites. Polymers. 2025; 17(19):2666. https://doi.org/10.3390/polym17192666

Chicago/Turabian StyleAlba, Jesús, Marta Urdanpilleta, Romina del Rey, Itsaso Leceta, Pedro Guerrero, and Koro de la Caba. 2025. "Development of an Empirical Model as a Prediction Tool for the Sound Absorption Performance of Wool/Soy Protein Biocomposites" Polymers 17, no. 19: 2666. https://doi.org/10.3390/polym17192666

APA StyleAlba, J., Urdanpilleta, M., del Rey, R., Leceta, I., Guerrero, P., & de la Caba, K. (2025). Development of an Empirical Model as a Prediction Tool for the Sound Absorption Performance of Wool/Soy Protein Biocomposites. Polymers, 17(19), 2666. https://doi.org/10.3390/polym17192666