Multi-Layer Laminate of Fibreglass Thermoplastic Composite Reinforced with Fused Filament Fabrication TPU Layers

Abstract

1. Introduction

2. Materials and Testing Procedure

2.1. Raw Materials and Specimens Manufacture

2.1.1. TPU

2.1.2. Composite Laminates

2.2. Mechanical Testing Methodology

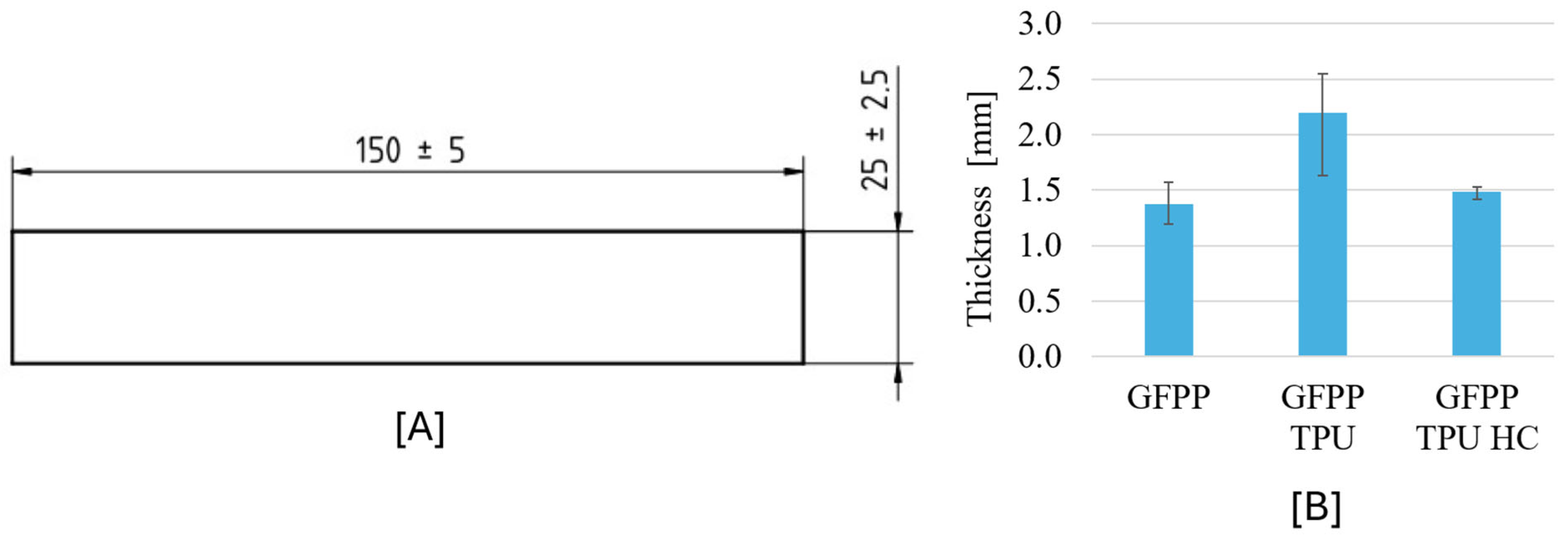

2.2.1. Tensile Testing

2.2.2. Three-Point Bending Testing

2.3. Thermal Characterization Procedure

3. Results Analysis

3.1. Thermal Characterization

3.1.1. TPU Differential Scanning Calorimetry Analysis (DSC)

3.1.2. Composite Laminates Differential Thermal Analysis (DTA)/Thermogravimetric Analysis (TG)

3.2. Surface Morphology

3.3. Mechanical Testing Results

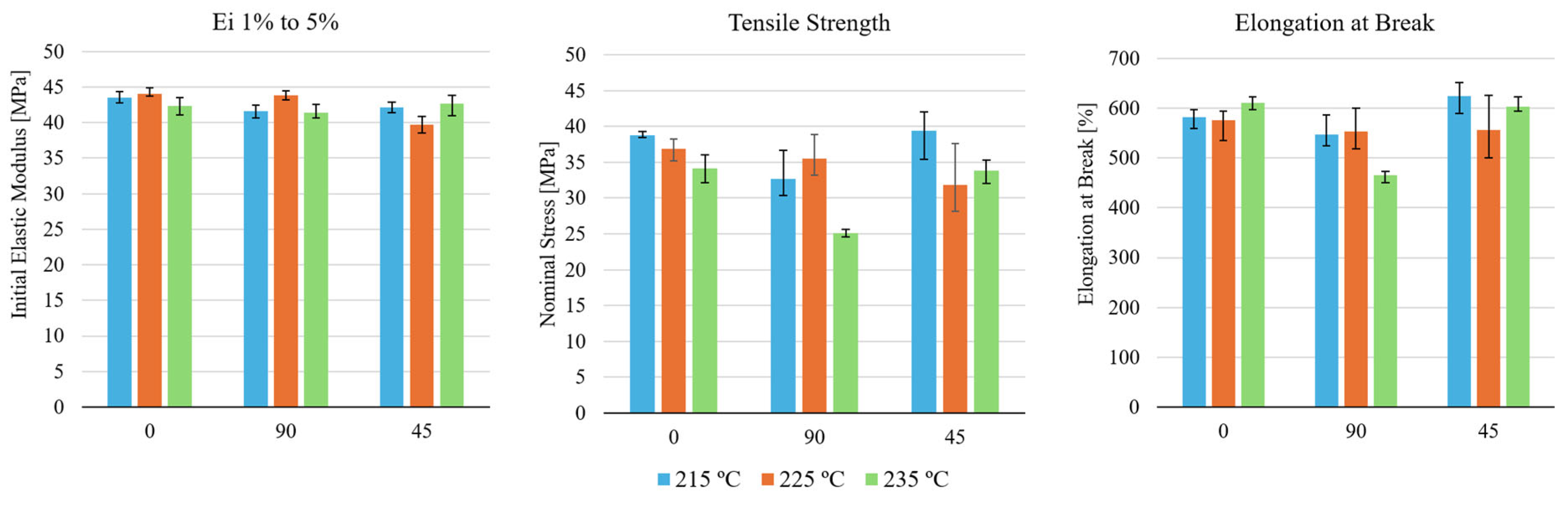

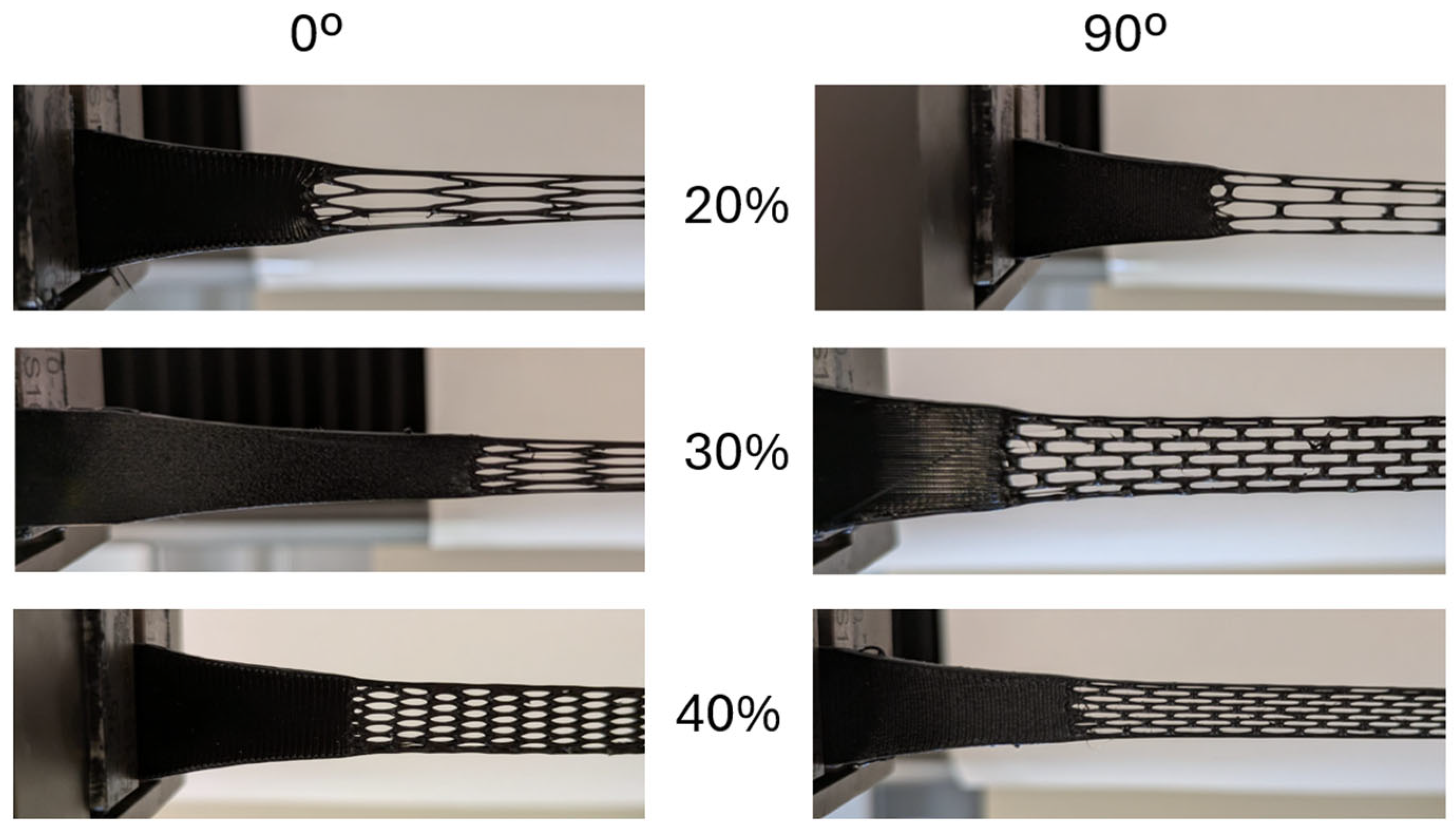

3.3.1. Tensile Testing

3.3.2. Three-Point Bending Test

4. Conclusions

- Strong adhesion between GFPP and TPU layers was achieved without voids.

- Honeycomb layers allowed for more cohesive laminate manufacture.

- Bulk TPU layers were prone to delamination and significantly reduced bending stiffness. In some specimens, good adhesion was achieved, meaning the manufacturing process can be optimized.

- Laminates with a honeycomb TPU interlayer exhibited the highest resistance to delamination and fibre breakage, attributed to improved adhesion between the TPU and the polypropylene matrix.

- Honeycomb reinforcement also enhanced bending deformation capacity and overall ductility, displayed by the high elastic recovery and the lower maximum-to-final nominal stress ratio.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, L.; Zhou, Y.; Jin, F.; Hou, Z. Influence of Polymer Matrices on the Tensile and Impact Properties of Long Fiber-Reinforced Thermoplastic Composites. Polymers 2023, 15, 408. [Google Scholar] [CrossRef] [PubMed]

- Vaidya, U. Thermoplastic Composites for Aerospace Applications. JEC Compos. Mag. 2015, 52, 41–44. [Google Scholar] [CrossRef]

- Krueger, R.; Bergan, A. Advances in Thermoplastic Composites Over Three Decades—A Literature Review; NASA: Washington, DC, USA, 2024. [Google Scholar]

- Mallick, P.K. Thermoplastics and Thermoplastic-Matrix Composites for Lightweight Automotive Structures. Mater. Des. Manuf. Lightweight Veh. 2010, 174–207. [Google Scholar] [CrossRef]

- Bilge, K.; Papila, M. Interlayer Toughening Mechanisms of Composite Materials. In Toughening Mechanisms in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 263–294. ISBN 9781782422914. [Google Scholar]

- Shivakumar, K.; Panduranga, R. Interleaved Polymer Matrix Composites—A Review. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013. [Google Scholar]

- Woo, E.M.; Mao, K.L. Evaluation of Interlaminar-Toughened Poly(Ether Imide)-Modified Epoxy/Carbon Fiber Composites. Polym. Compos. 1996, 17, 799–805. [Google Scholar] [CrossRef]

- Masters, J.E. Improved Impact and Delamination Resistance through Interleafing. Mech. Corros. Prop. Ser. A Key Eng. Mater. 1989, 37, 317–347. [Google Scholar] [CrossRef]

- Bilge, K.; Venkataraman, S.; Menceloglu, Y.Z.; Papila, M. Global and Local Nanofibrous Interlayer Toughened Composites for Higher In-Plane Strength. Compos. Part A Appl. Sci. Manuf. 2014, 58, 73–76. [Google Scholar] [CrossRef]

- Alderliesten, R.C.; Homan, J.J. Fatigue and Damage Tolerance Issues of Glare in Aircraft Structures. Int. J. Fatigue 2006, 28, 1116–1123. [Google Scholar] [CrossRef]

- Boyd, S.E.; Bogetti, T.A.; Staniszewski, J.M.; Lawrence, B.D.; Walter, M.S. Enhanced Delamination Resistance of Thick-Section Glass-Epoxy Composite Laminates Using Compliant Thermoplastic Polyurethane Interlayers. Compos. Struct. 2018, 189, 184–191. [Google Scholar] [CrossRef]

- Tsotsis, T.K. Interlayer Toughening of Composite Materials. Polym. Compos. 2009, 30, 70–86. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in Additive Manufacturing on New Materials: A Review. J. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Vicente, C.M.S.; Sardinha, M.; Reis, L.; Ribeiro, A.; Leite, M. Large-Format Additive Manufacturing of Polymer Extrusion-Based Deposition Systems: Review and Applications. Prog. Addit. Manuf. 2023, 8, 1257–1280. [Google Scholar] [CrossRef]

- Dave, H.K.; Davim, J.P. (Eds.) Fused Deposition Modeling 3D Printing; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Pulipaka, A.; Gide, K.M.; Beheshti, A.; Bagheri, Z.S. Effect of 3D Printing Process Parameters on Surface and Mechanical Properties of FFF-Printed PEEK. J. Manuf. Process. 2023, 85, 368–386. [Google Scholar] [CrossRef]

- Zhang, Z.; Gao, X. Polypropylene Random Copolymer Based Composite Used for Fused Filament Fabrication: Printability and Properties. Polymers 2022, 14, 1106. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and Performance of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Harper, C.A. Handbook of Plastics, Elastomers and Composites, 4th ed.; McGraw-Hill Handbooks: Columbus, OH, USA, 2002; ISBN 9780071384766. [Google Scholar]

- Xu, T.; Shen, W.; Lin, X.; Xie, Y.M. Mechanical Properties of Additively Manufactured Thermoplastic Polyurethane (TPU) Material Affected by Various Processing Parameters. Polymers 2020, 12, 3010. [Google Scholar] [CrossRef]

- Sardinha, M.; Ferreira, L.; Diogo, H.; Ramos, T.R.P.; Reis, L.; Vaz, M.F. Material Extrusion of TPU: Thermal Characterization and Effects of Infill and Extrusion Temperature on Voids, Tensile Strength and Compressive Properties. Rapid Prototyp. J. 2025, 31, 62–81. [Google Scholar] [CrossRef]

- Arifvianto, B.; Nur Iman, T.; Tulung Prayoga, B.; Dharmastiti, R.; Agus Salim, U.; Mahardika, M. Tensile Properties of the FFF-Processed Thermoplastic Polyurethane (TPU) Elastomer. Int. J. Adv. Manuf. Technol. 2021, 117, 1709–1719. [Google Scholar] [CrossRef]

- Tomé, P.; Sardinha, M.; Vaz, F.M.; Reis, L. Design and Stiffness Assessment of Non-Pneumatic Bicycle Tyres with Latticed Cores Produced by Fused Filament Fabricationsite. J. Mater. Des. Appl. 2025, 14644207251345056. [Google Scholar]

- Mian, S.H.; Abouel Nasr, E.; Moiduddin, K.; Saleh, M.; Alkhalefah, H. An Insight into the Characteristics of 3D Printed Polymer Materials for Orthoses Applications: Experimental Study. Polymers 2024, 16, 403. [Google Scholar] [CrossRef] [PubMed]

- Ultrafuse BASF TPU 95A Details. Available online: https://Forward-Am.Com/Material-Portfolio/Ultrafuse-Filaments-for-Fused-Filaments-Fabrication-Fff/Flexible-Filaments/Ultrafuse-Tpu-95a/ (accessed on 15 July 2025).

- Sardinha, M.; Ferreira, L.; Ramos, T.; Reis, L.; Vaz, M.F. Challenges on Extrusion-Based Additive Manufacturing of Thermoplastic Polyurethane. Eng. Manuf. Lett. 2024, 2, 45–52. [Google Scholar] [CrossRef]

- ASTM International D638-14; Standard Test Method for Tensile Properties of Plastics. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2014. [CrossRef]

- Pham, R.D.; Hütter, G. Influence of Topology and Porosity on Size Effects in Stripes of Cellular Material with Honeycomb Structure under Shear, Tension and Bending. Mech. Mater. 2021, 154, 103727. [Google Scholar] [CrossRef]

- Jin, T.; Zhou, Z.; Liu, Z.; Shu, X. Size Effects on the In-Plane Mechanical Behavior of Hexagonal Honeycombs. Sci. Eng. Compos. Mater. 2016, 23, 301–307. [Google Scholar] [CrossRef]

- Elhattab, K.; Bhaduri, S.B.; Sikder, P. Influence of Fused Deposition Modelling Nozzle Temperature on the Rheology and Mechanical Properties of 3D Printed β-Tricalcium Phosphate (TCP)/Polylactic Acid (PLA) Composite. Polymers 2022, 14, 1222. [Google Scholar] [CrossRef]

- COMFIL 30028-17 WG1-PP-700 Black Weave Twill 2/2. Available online: https://Www.Comfil.Biz/Comingled-Composites/Fabric/ (accessed on 15 July 2025).

- ASTM International D790-17; Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2017.

- Lorna, G.J.; Michael, A.F. Cellular Solids Structure and Properties, 2nd ed.; Cambridge Solid State Science Series; University of Cambridge: Cambridge, UK, 1997. [Google Scholar]

- Ragupathi, B.; Balle, F. Characterization of Glass-Fiber Reinforced Thermoplastic Composite after Ultrasonic Reconsolidation. Eur. J. Mater. 2024, 4, 2313316. [Google Scholar] [CrossRef]

- Achukwu, E.O.; Owen, M.M.; Danladi, A.; Dauda, B.M.; Romli, A.Z.; Shuib, S.B.; Ishiaku, U.S.; Hazizan, A.M. Recycling Effects on the Bending, Rheological, and Structural Properties of Glass Fiber-Reinforced Isotactic Polypropylene Composites. J. Reinf. Plast. Compos. 2024, 43, 532–546. [Google Scholar] [CrossRef]

- Okereke, M.I. Flexural Response of Polypropylene/E-Glass Fibre Reinforced Unidirectional Composites. Compos. Part B Eng. 2016, 89, 388–396. [Google Scholar] [CrossRef]

| Shore Hardness | Density [kg/m3] | Tensile Strength [MPa] | Elongation at Break [%] | Elastic Modulus [MPa] |

|---|---|---|---|---|

| 92A | 1149 | 44.2 | 661 | 48.4 |

| Glass Transition Temperature [°C] | Melting Temperature [°C] | Recommended Nozzle Temperature [°C] | ||

| −25 | 144 | 210–230 | ||

| Consolidation Temperature [°C] | Glass Fibre Content by Volume [%] | Nominal Weight [g/m2] | Density [kg/m3] | Thickness of Fully Consolidated Ply [mm] |

|---|---|---|---|---|

| 190–230 | 35% | 700 | 1560 | 0.47 |

| Composite Laminate | Abbreviation | Layer Sequence |

|---|---|---|

| Baseline glass fibre prepreg with polypropylene | GFPP | [(0/90)3] |

| GFPP with solid TPU layers | GFPP-TPU | [0/90/TPU/0/90/TPU/0/90] |

| GFPP with honeycomb-structured TPU layers | GFPP-TPU-HC | [0/90/TPU-HC/0/90/TPU-HC/0/90] |

| Tested Material | Melting Temperature Tm | Crystallization Temperature Tc |

|---|---|---|

| Filament TPU95A Ultrafuse | 172.1 °C | 155.1 °C |

| FFF extruded at 215 °C | 191.0 °C | 157.1 °C |

| FFF extruded at 225 °C | 190.1 °C | 161.6 °C |

| FFF extruded at 235 °C | 185.1 °C | 159.5 °C |

| Mass Fraction [%] | Volume Fraction [%] | |||

|---|---|---|---|---|

| Samples | Fibre Glass | Polymer | Fibre Glass | Polymer |

| GFPP | 62.5 | 37.5 | 37.7 | 62.3 |

| GFPP-TPU | 51.4 | 48.6 | 25.9 | 74.1 |

| GFPP-TPU-HC | 56.9 | 43.1 | 35.4 | 64.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duarte, A.P.; da Costa, P.R.; Freitas, M. Multi-Layer Laminate of Fibreglass Thermoplastic Composite Reinforced with Fused Filament Fabrication TPU Layers. Polymers 2025, 17, 2622. https://doi.org/10.3390/polym17192622

Duarte AP, da Costa PR, Freitas M. Multi-Layer Laminate of Fibreglass Thermoplastic Composite Reinforced with Fused Filament Fabrication TPU Layers. Polymers. 2025; 17(19):2622. https://doi.org/10.3390/polym17192622

Chicago/Turabian StyleDuarte, Ana Paula, Pedro R. da Costa, and Manuel Freitas. 2025. "Multi-Layer Laminate of Fibreglass Thermoplastic Composite Reinforced with Fused Filament Fabrication TPU Layers" Polymers 17, no. 19: 2622. https://doi.org/10.3390/polym17192622

APA StyleDuarte, A. P., da Costa, P. R., & Freitas, M. (2025). Multi-Layer Laminate of Fibreglass Thermoplastic Composite Reinforced with Fused Filament Fabrication TPU Layers. Polymers, 17(19), 2622. https://doi.org/10.3390/polym17192622