Development and Characterization of Sustainable Biocomposites from Wood Fibers, Spent Coffee Grounds, and Ammonium Lignosulfonate

Abstract

1. Introduction

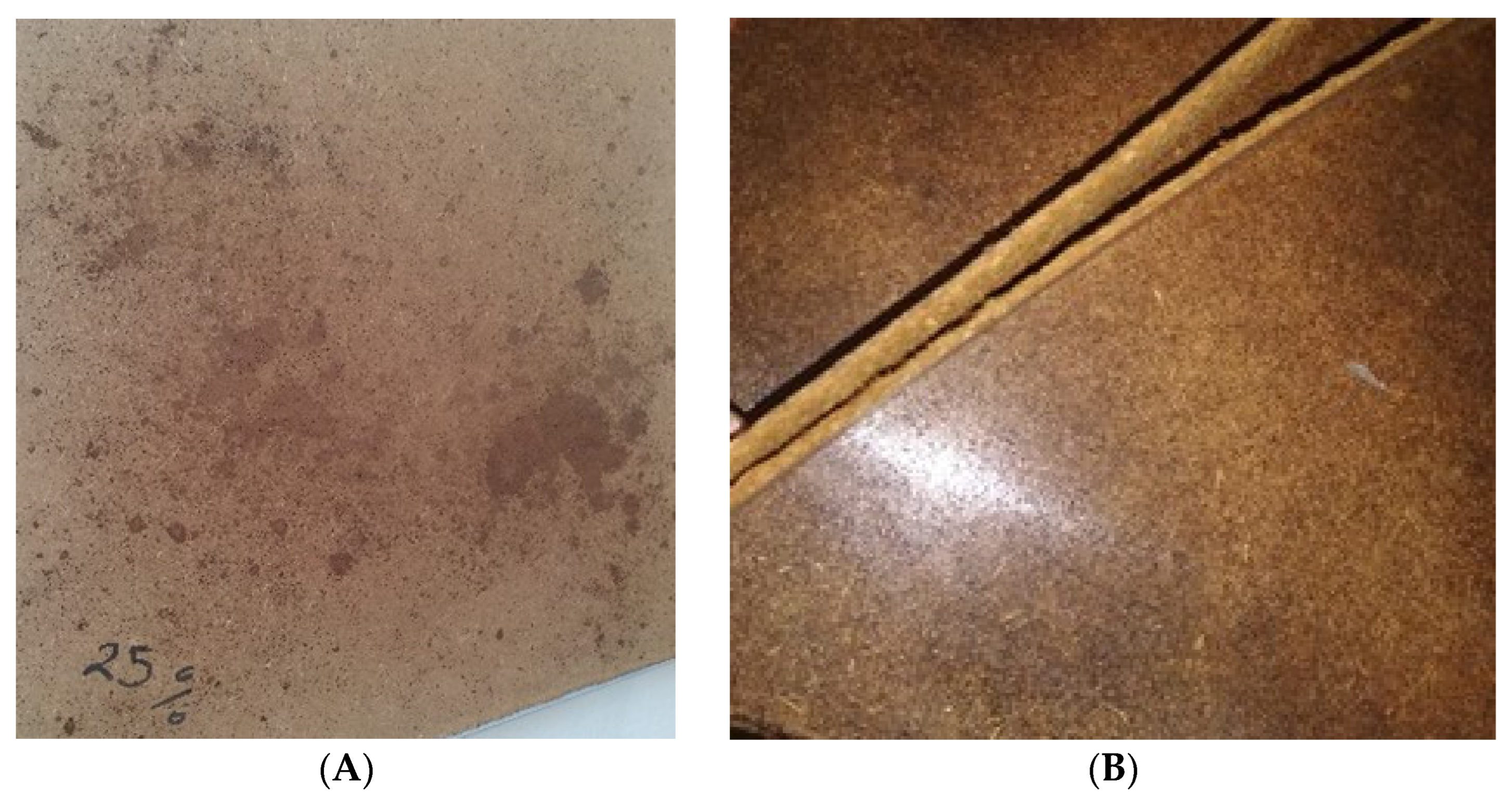

2. Materials and Methods

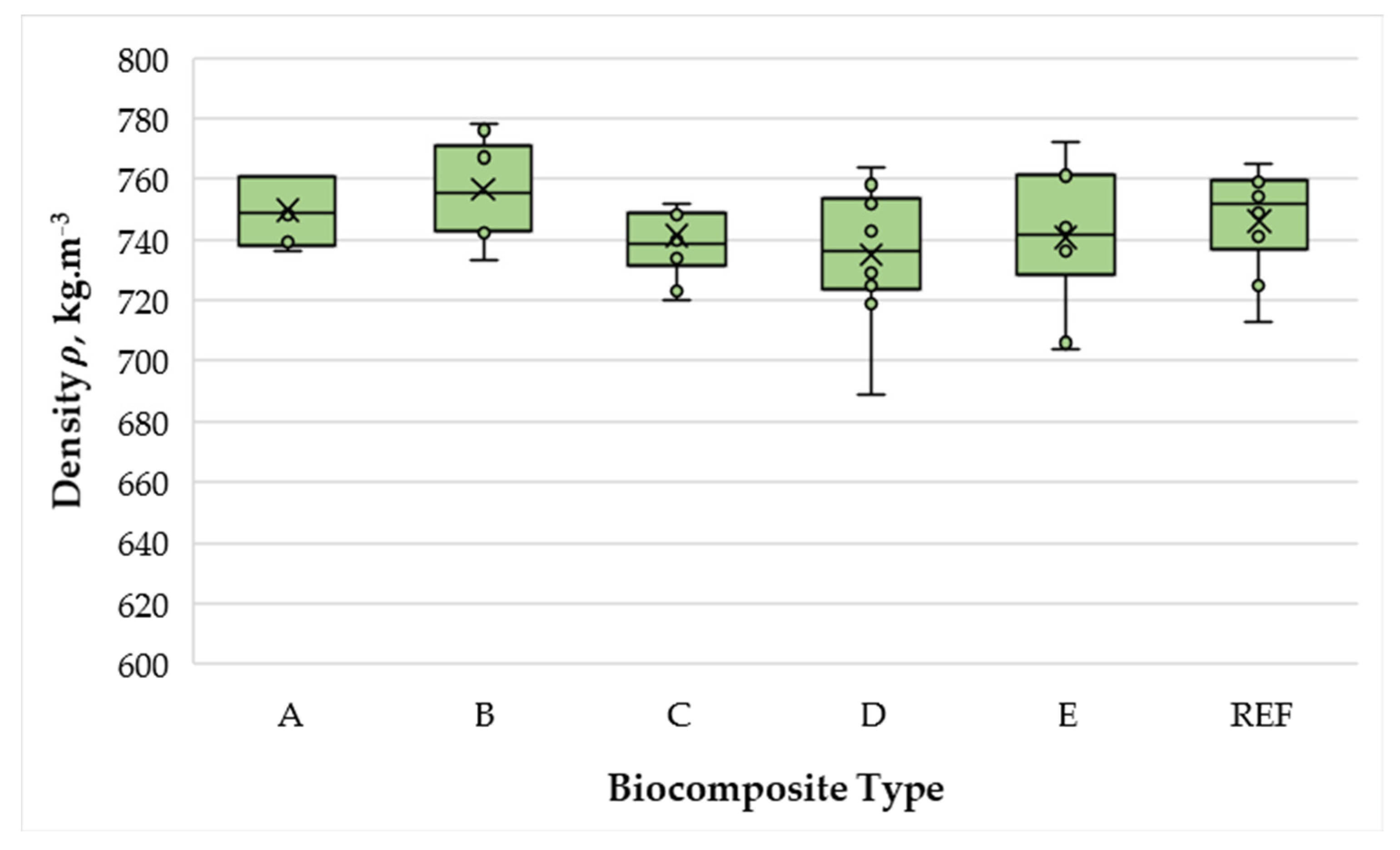

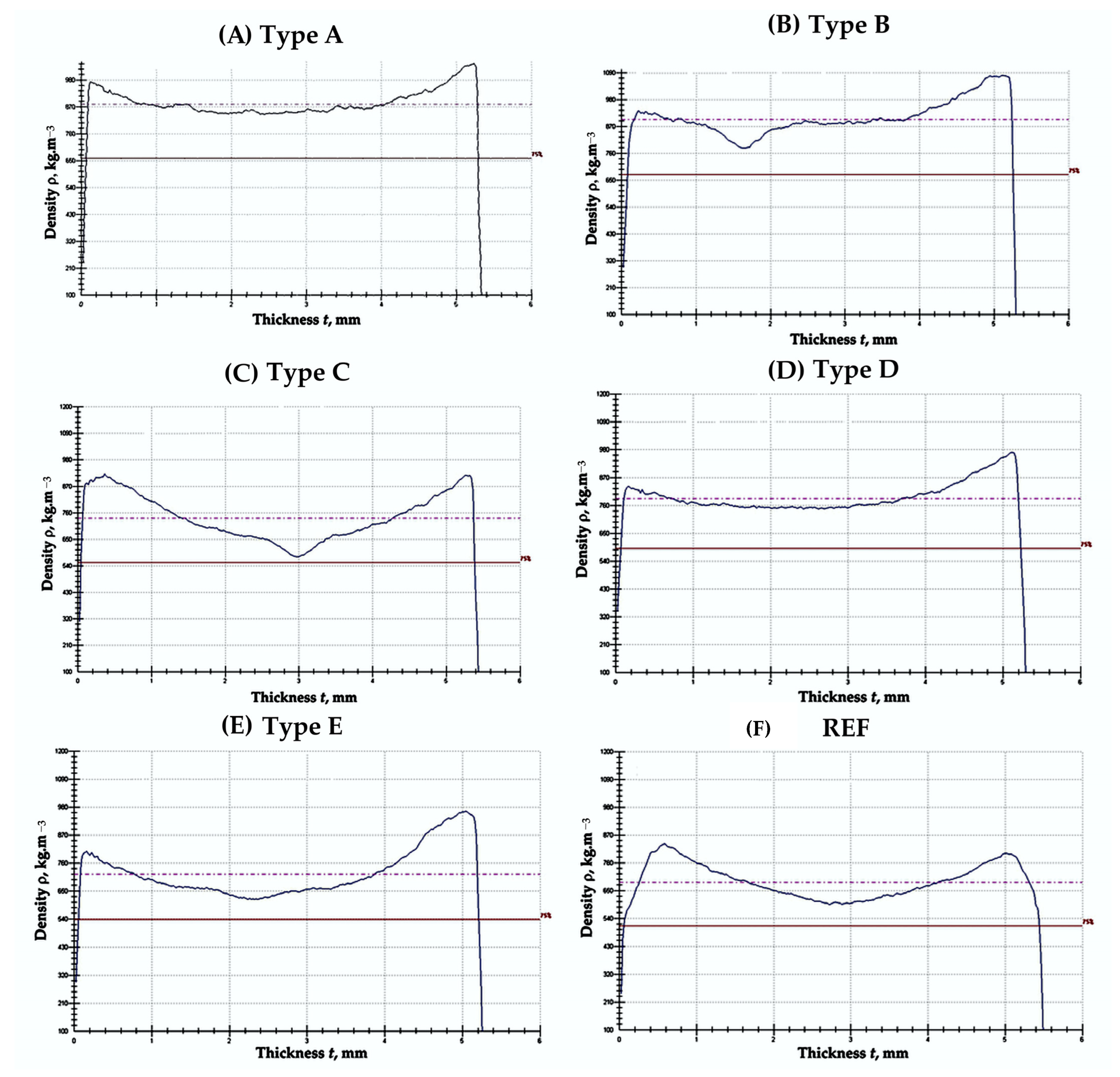

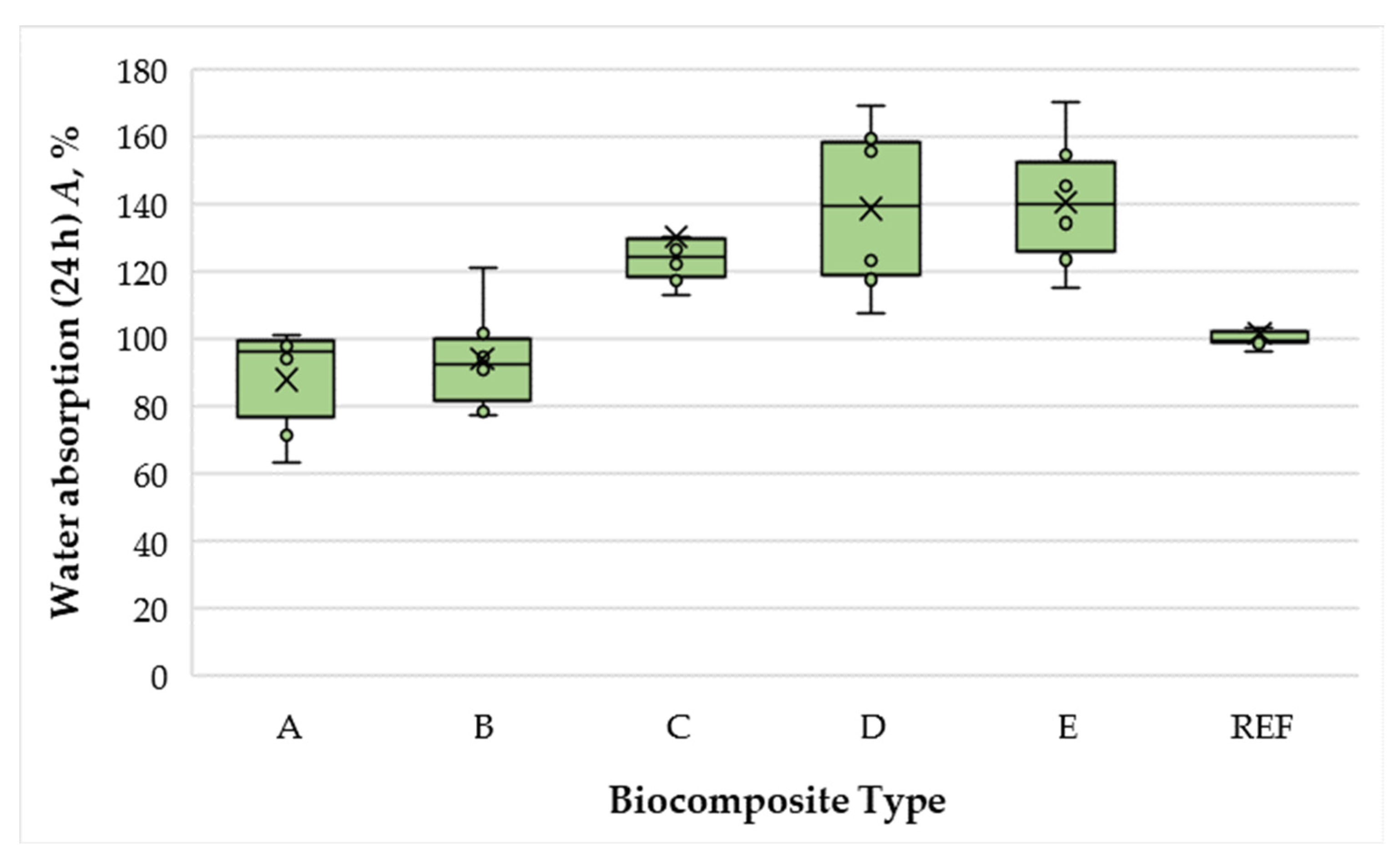

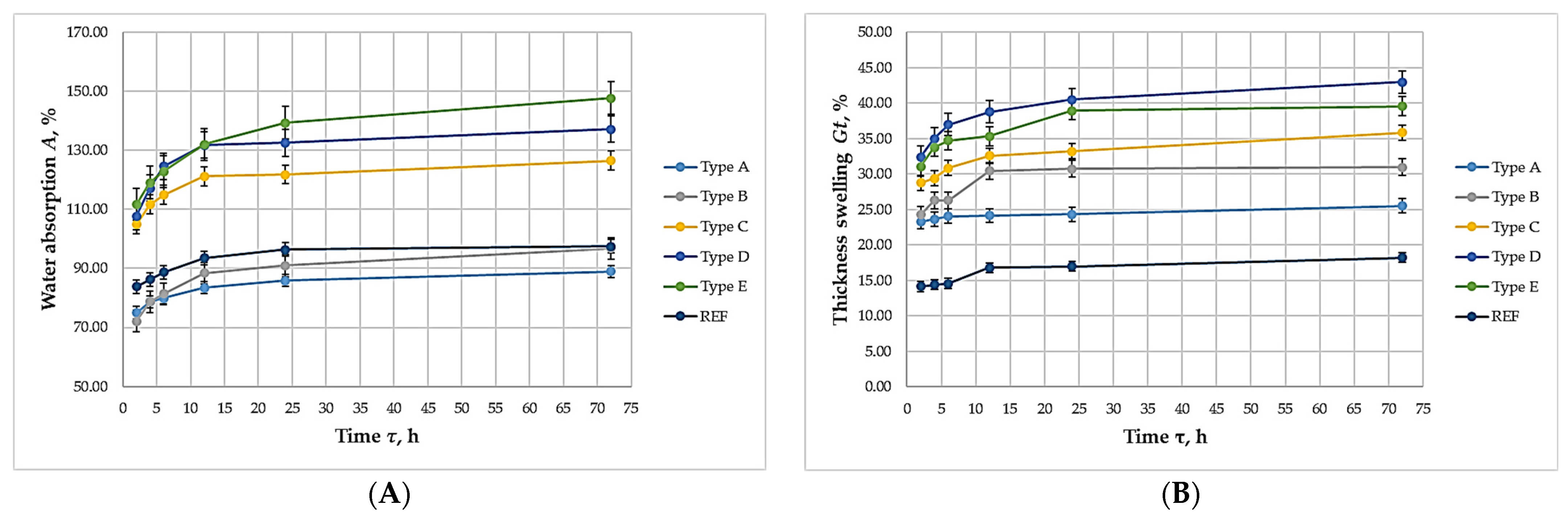

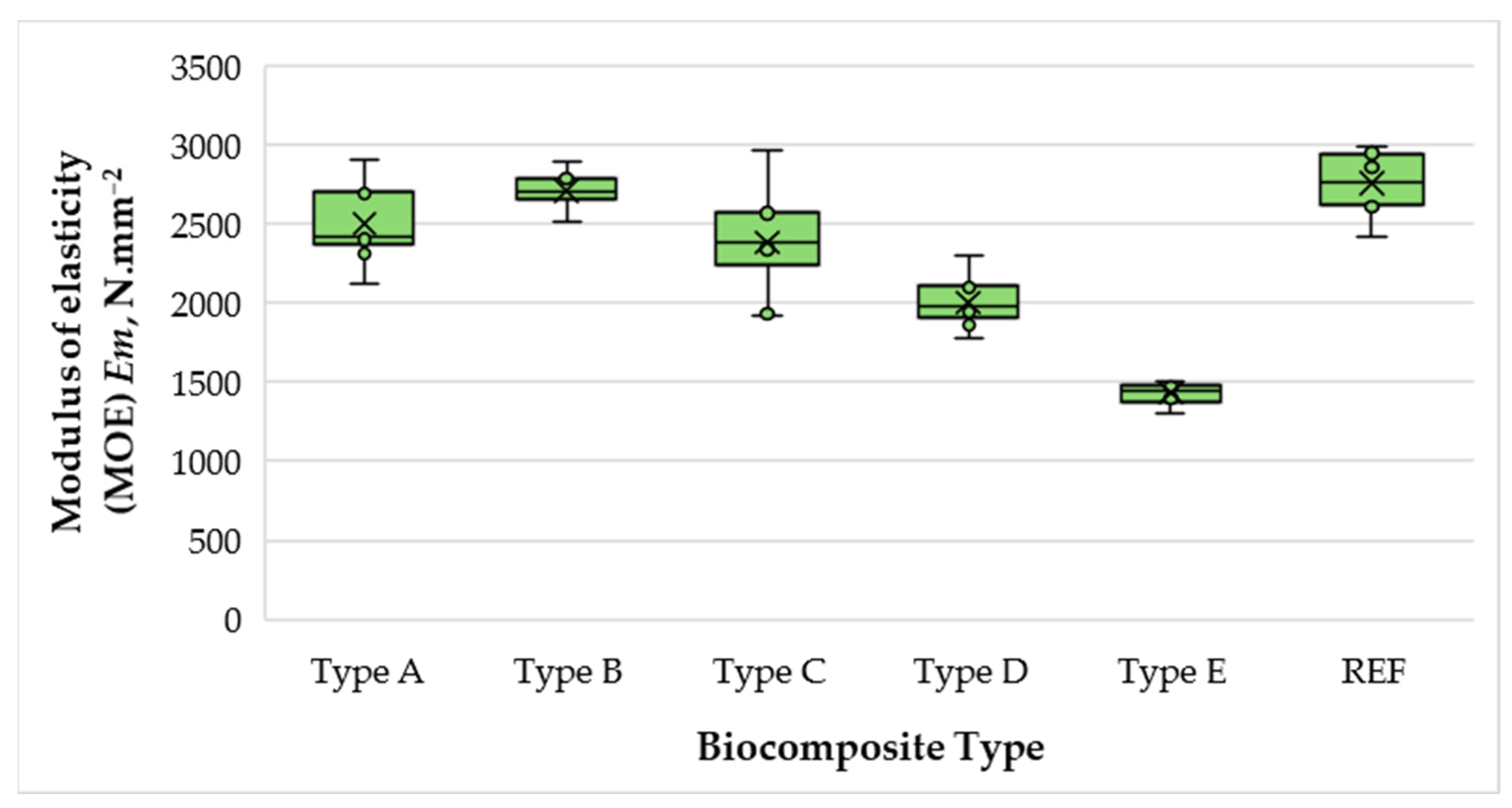

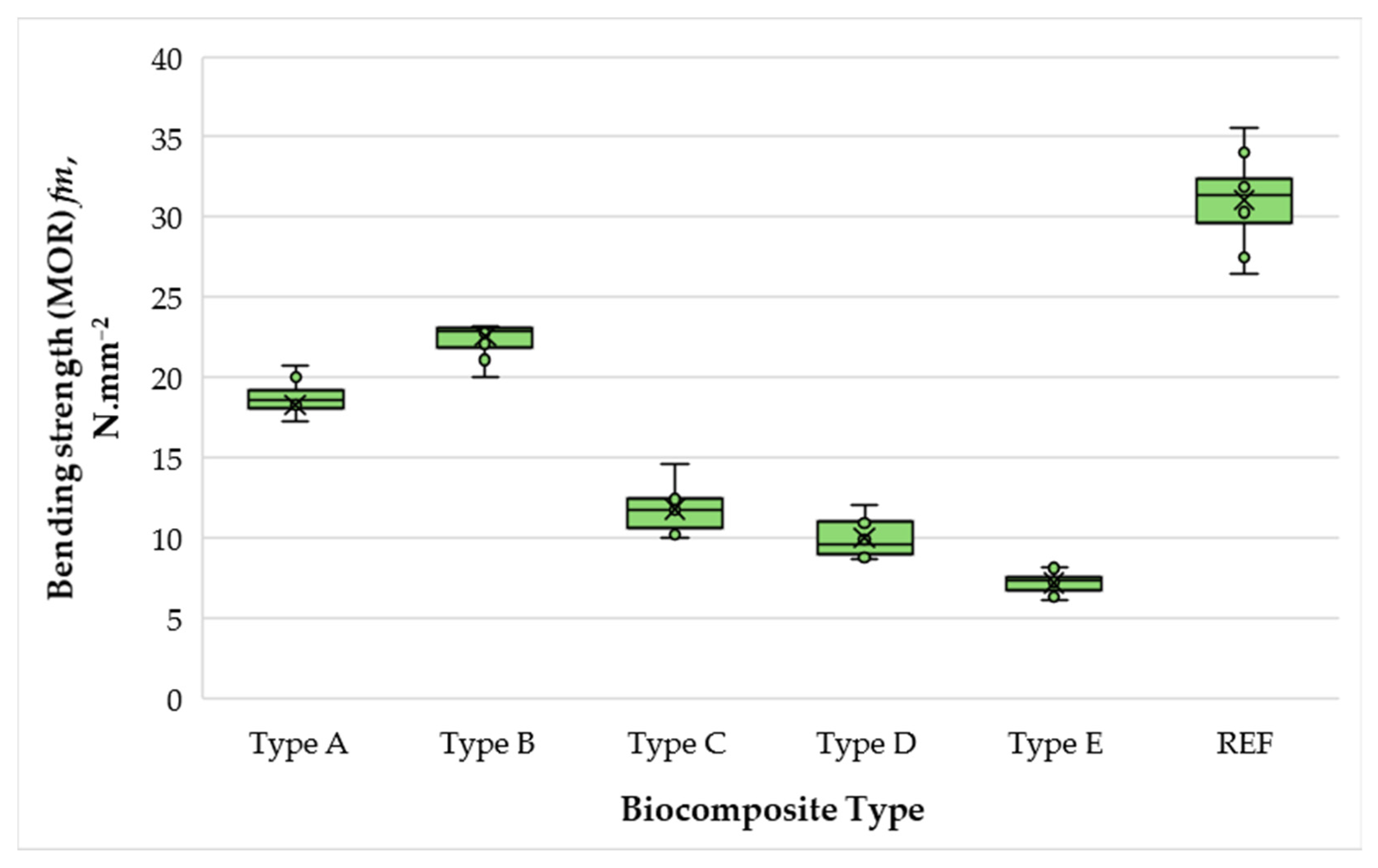

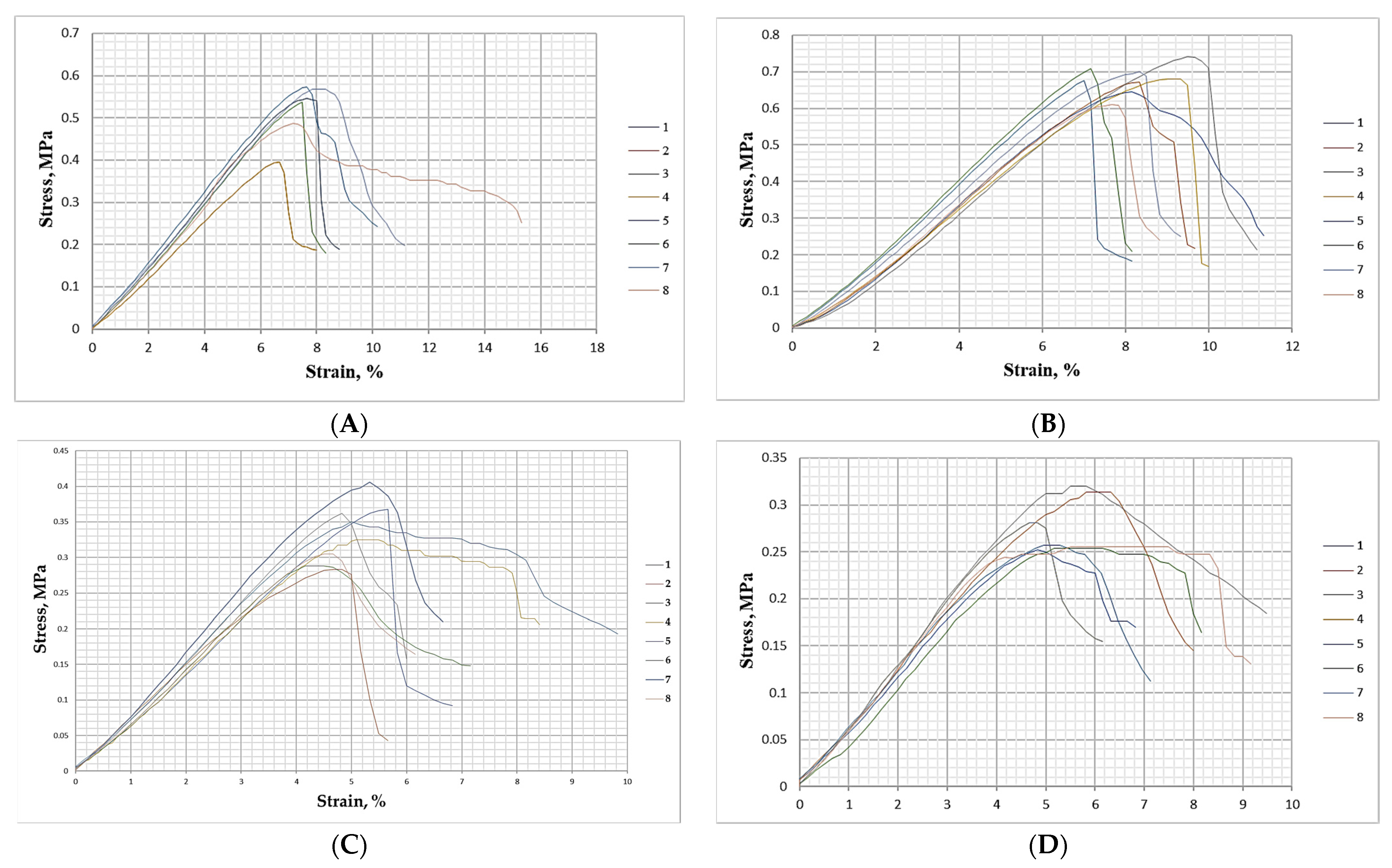

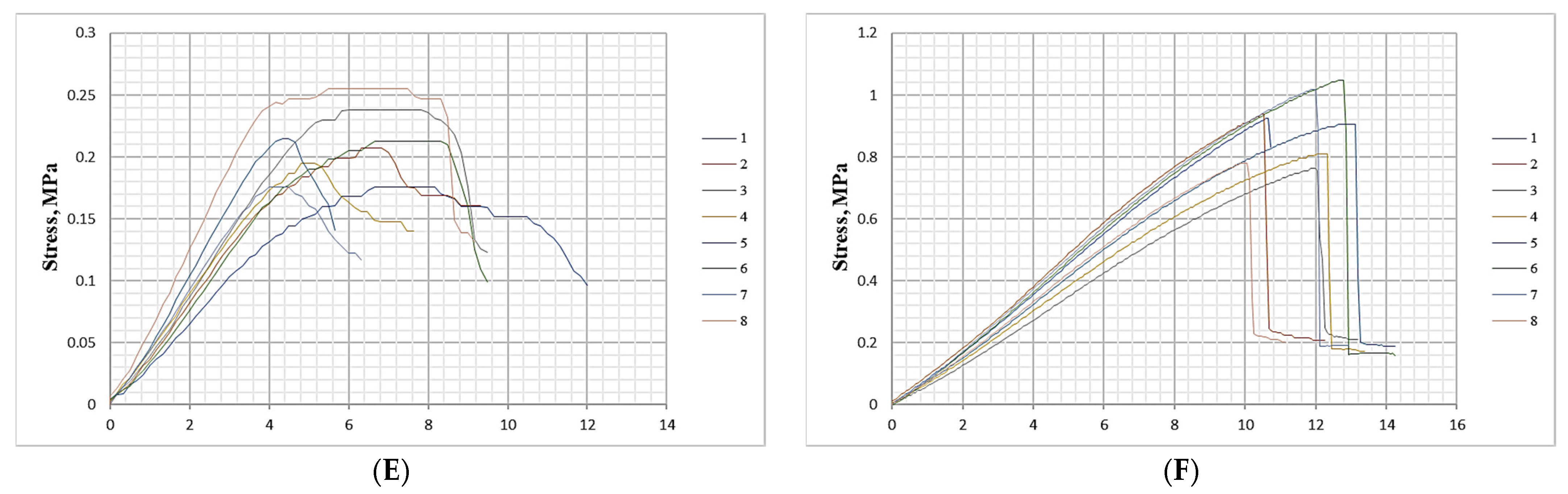

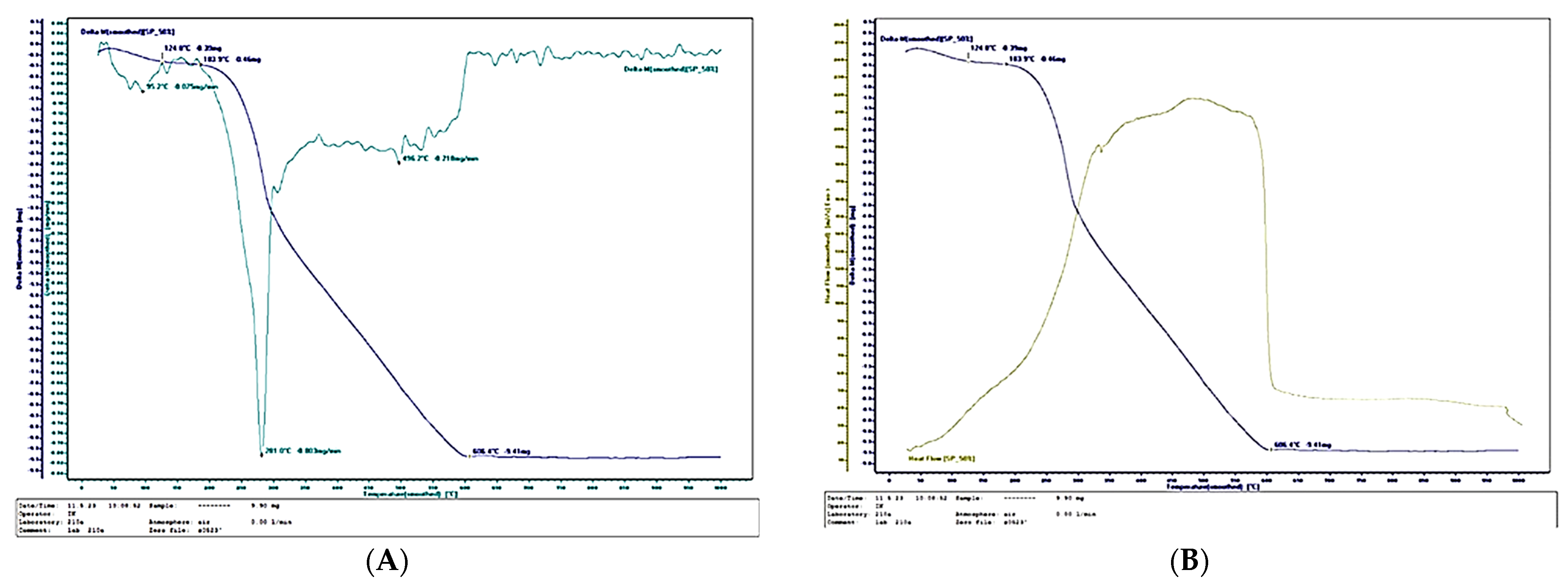

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, J.D.; Kim, J.; Lee, S. Study of Recycled Spent Coffee Grounds as Aggregates in Cementitious Materials. Recent Prog. Mater. 2023, 5, 007. [Google Scholar] [CrossRef]

- Colantoni, A.; Paris, E.; Bianchini, L.; Ferri, S.; Marcantonio, V.; Carnevale, M.; Palma, A.; Civitarese, V.; Gallucci, F. Spent coffee ground characterization, pelletization test and emissions assessment in the combustion process. Sci. Rep. 2021, 11, 5119. [Google Scholar] [CrossRef]

- Santiago-Medina, F.J.; Rosales-Rivera, A.; Cruz, J.; Herrera, R.; Salazar, R. Mechanical Properties of Cement-Based Composites Reinforced with Spent Coffee Grounds. Constr. Build. Mater. 2018, 187, 227–239. [Google Scholar] [CrossRef]

- Silva, M.A.; Nebra, S.A.; Machado Silva, M.J.; Sanchez, C.G. The use of biomass residues in the Brazilian soluble coffee industry. Biomass Bioenergy 1998, 14, 457–467. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Donnoli, A.; Bonderenko, E.; Oliva, P.; Gill, B.; Lockrey, S.; Siddique, R. Recycling of spent coffee grounds in construction materials: A review. J. Clean. Prod. 2021, 289, 125837. [Google Scholar] [CrossRef]

- McNutt, J.; He, Q.S. Spent coffee grounds: A review on current utilization. J. Ind. Eng. Chem. 2019, 71, 78–88. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Martins, S.; Teixeira, J.A. Production, Composition, and Application of Coffee and Its Industrial Residues. Food Bioprocess Technol 2011, 4, 661–672. [Google Scholar] [CrossRef]

- Caetano, N.S.; Silva, V.F.M.; Melo, A.C.; Martins, A.A.; Mata, T.M. Spent coffee grounds for biodiesel production and other applications. Clean Technol. Environ. Policy 2014, 16, 1423–1430. [Google Scholar] [CrossRef]

- Waisarikit, A.; Suadaung, N.; Khantho, B.; Hadad, B.; Ross, G.M.; Topham, P.D.; Ross, S.; Mahasaranon, S. Extracted Spent Coffee Grounds as a Performance-Enhancing Additive for Poly(Lactic Acid) Biodegradable Nursery Bags in Agriculture. Polymers 2025, 17, 561. [Google Scholar] [CrossRef] [PubMed]

- Bejenari, V.; Danu, M.; Ipate, A.-M.; Zaltariov, M.-F.; Rusu, D.; Lisa, G. Composite Materials Based on Spent Coffee Grounds and Paper Pulp. J. Compos. Sci. 2024, 8, 491. [Google Scholar] [CrossRef]

- Janowski, G.; Frącz, W.; Bąk, Ł.; Sikora, J.W.; Tomczyk, A.; Mrówka-Nowotnik, G.; Mossety-Leszczak, B. Effect of Coffee Grounds Content on Properties of PHBV Biocomposites Compared to Similar Composites with Other Fillers. Polymers 2025, 17, 764. [Google Scholar] [CrossRef]

- Ahmed, H.; Abolore, R.S.; Jaiswal, S.; Jaiswal, A.K. Toward Circular Economy: Potentials of Spent Coffee Grounds in Bioproducts and Chemical Production. Biomass 2024, 4, 286–312. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Cordeiro, N.; Belgacem, M.N.; Torres, I.C.; Moura, J.C.V.P. Chemical Composition and Pulping of Coffee Husks. Ind. Crops Prod. 2004, 19, 147–154. [Google Scholar] [CrossRef]

- Gonçalves, F.A.; Paiva, R.M.; Pasa, T.B.C.; Paiva, J.M.F.; Oliveira, F.D. Spent Coffee Grounds as a Renewable Source for Bio-Based Polyols. Ind. Crops Prod. 2017, 107, 13–19. [Google Scholar] [CrossRef]

- Campos-Vega, R.; Loarca-Piña, G.; Vergara-Castañeda, H.A.; Oomah, B.D. Spent Coffee Grounds: A Review on Current Research and Future Prospects. Trends Food Sci. Technol. 2015, 45, 24–36. [Google Scholar] [CrossRef]

- Lage-Rivera, S.; Ares-Pernas, A.I.; Dopico-García, S.; Covas, J.; Abad, M.J. Comparing Lignin and Spent Coffee Grounds as Bio-Fillers in PLA 3D-Printable Filaments. Polym. Compos. 2024, 45, 14566–14579. [Google Scholar] [CrossRef]

- Gaidukova, G.; Gaidukovs, S.; Grase, L.; Platnieks, O.; Sereda, A.; Andriotis, E.G.; Antonova, M.; Yamaguchi, K.; Enachescu, M. Spent Coffee Waste as a Renewable Source for the Production of Polymer Composite Fillers. RSC Adv. 2021, 11, 2391–2404. [Google Scholar] [CrossRef]

- Yu, W.; Yuan, T.; Yao, Y.; Deng, Y.; Wang, X. PLA/Coffee Grounds Composite for 3D Printing and Its Properties. Forests 2023, 14, 367. [Google Scholar] [CrossRef]

- Masssijaya, S.Y.; Lubis, M.A.R.; Nissa, R.C.; Nurhamiyah, Y.; Nugroho, P.; Antov, P.; Lee, S.-H.; Papadopoulos, A.N.; Kusumah, S.S.; Karlinasari, L. Utilization of Spent Coffee Grounds as a Sustainable Resource for the Synthesis of Bioplastic Composites with Polylactic Acid, Starch, and Sucrose. J. Compos. Sci. 2023, 7, 512. [Google Scholar] [CrossRef]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and pMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef]

- Dunky, M. Adhesives in the Wood Industry. In Handbook of Adhesive Technology, 2nd ed.; Pizzi, A., Mittal, K.L., Eds.; Marcel Dekker: New York, NY, USA, 2003; pp. 521–577. [Google Scholar] [CrossRef]

- Dunky, M. Urea–Formaldehyde (UF) Adhesive Resins for Wood. Int. J. Adhes. Adhes. 1998, 18, 95–107. [Google Scholar] [CrossRef]

- Pizzi, A.; Papadopoulos, A.N.; Policardi, F. Wood Composites and Their Polymer Binders. Polymers 2020, 12, 1115. [Google Scholar] [CrossRef] [PubMed]

- Protano, C.; Buomprisco, G.; Cammalleri, V.; Pocino, R.N.; Marotta, D.; Simonazzi, S.; Cardoni, F.; Petyx, M.; Iavicoli, S.; Vitali, M. The Carcinogenic Effects of Formaldehyde Occupational Exposure: A Systematic Review. Cancers 2022, 14, 165. [Google Scholar] [CrossRef] [PubMed]

- Hemmilä, V.; Adamopoulos, S.; Hosseinpourpia, R.; Ahmed, S.A. Ammonium Lignosulfonate Adhesives for Particleboards with pMDI and Furfuryl Alcohol as Crosslinkers. Polymers 2019, 11, 1633. [Google Scholar] [CrossRef]

- Gonçalves, S.; Paiva, N.T.; Martins, J.; Carvalho, L.H.; Magalhães, F.D. Fast-Curing 3-Layer Particleboards with Lignosulfonate and pMDI Adhesives. Forests 2024, 15, 948. [Google Scholar] [CrossRef]

- Kropat, M.; Liao, M.; Park, H.; Salem, K.S.; Johnson, S.; Argyropoulos, D.S. A perspective of lignin processing and utilization technologies for composites and plastics with emphasis on technical and market trends. BioResources 2021, 16, 2084–2115. [Google Scholar] [CrossRef]

- Cheng, S.; Wilks, C.; Yuan, Z.; Leitch, M.; Xu, C. Hydrothermal Decomposition of Alkaline Lignin in Hot-Compressed Water and Ethanol. Bioresour. Technol. 2012, 123, 280–288. [Google Scholar] [CrossRef]

- Kouisni, L.; Holt-Hindle, P.; Maki, K.; Paleologou, M. The Lignoforce System™: A New Process for the Production of High-Quality Lignin for Use in Value-Added Applications. J. Sci. Technol. For. Prod. Process. 2012, 2, 6–10. [Google Scholar]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of Hemicellulose, Cellulose and Lignin Pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Gosselink, R.J.A.; Abächerli, A.; Semke, H.; Malherbe, R.; Käuper, P.; Nadif, A.; van Dam, J.E.G. Analytical Protocols for Characterization of Sulphur-Free Lignin. Ind. Crops Prod. 2004, 19, 271–281. [Google Scholar] [CrossRef]

- Tanase-Opedal, M.; Espinosa, E.; Rodríguez, A.; Chinga-Carrasco, G. Lignin: A Biopolymer from Forestry Biomass for Biocomposites and 3D Printing. Materials 2019, 12, 3006. [Google Scholar] [CrossRef]

- Pizzi, A. Recent Developments in Eco-Efficient Bio-Based Adhesives for Wood Bonding: Opportunities and Issues. J. Adhes. Sci. Technol. 2006, 20, 829–846. [Google Scholar] [CrossRef]

- Effendi, A.; Gerhauser, H.; Bridgwater, A.V. Production of Renewable Phenolic Resins by Thermochemical Conversion of Biomass: A Review. Renew. Sustain. Energy Rev. 2008, 12, 2092–2116. [Google Scholar] [CrossRef]

- Widsten, P.; Kandelbauer, A. Lignin-Based Wood Adhesives. Rev. Adhes. Adhes. 2014, 2, 253–277. [Google Scholar] [CrossRef]

- Gosselink, R.J.A.; van Dam, J.E.G.; de Jong, E.; Gellerstedt, G.; Scott, E.L.; Sanders, J.P.M. Effect of periodate on lignin for wood adhesive application. Holzforschung 2011, 65, 155–162. [Google Scholar] [CrossRef]

- Mittal, M.; Sharma, C.B. Studies on lignin-based adhesives for plywood panels. Polym. Int. 1991, 29, 7–8. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Fan, M. Lignin in Straw and Its Applications as an Adhesive. Int. J. Adhes. Adhes. 2014, 48, 92–101. [Google Scholar] [CrossRef]

- Hu, L.; Pan, H.; Zhou, Y.; Zhang, M. Methods to Improve Lignin-Based Adhesives for Wood Applications: A Review. Ind. Crops Prod. 2011, 33, 259–265. [Google Scholar] [CrossRef]

- Belgacem, M.N.; Gandini, A. Lignins as Components in Polymers. Prog. Polym. Sci. 2008, 33, 568–576. [Google Scholar] [CrossRef]

- Moreno, A.I.; Sipponen, M.H. Lignin-Based Smart Materials: A Roadmap to Processing and Synthesis for Current and Future Applications. Materials 2020, 13, 1775. [Google Scholar] [CrossRef]

- Zhou, X.; Zheng, F.; Lv, C.; Tang, L.; Wei, K.; Liu, X. Properties of formaldehyde-free environmentally friendly lignocellulosic composites made from poplar fibres and oxygen-plasma-treated enzymatic hydrolysis lignin. Compos. Part B Eng. 2013, 53, 369–375. [Google Scholar] [CrossRef]

- Ferdosian, F.; Pan, Z.; Gao, G.; Zhao, B. Bio-Based Adhesives and Evaluation for Wood Composites Application. Polymers 2017, 9, 70. [Google Scholar] [CrossRef]

- Naron, D.R.; Collard, F.X.; Tyhoda, L.; Görgens, J.F. Characterisation of Lignins from Different Sources for Application as Bio-Based Adhesives. Ind. Crops Prod. 2017, 109, 236–242. [Google Scholar] [CrossRef]

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Development of Sustainable Bio-Adhesives for Engineered Wood Panels—A Review. RSC Adv. 2017, 7, 38604–38630. [Google Scholar] [CrossRef]

- Gao, S.; Cheng, Z.; Zhou, X.; Liu, Y.; Chen, R.; Wang, J.; Wang, C.; Chu, F.; Xu, F.; Zhang, D. Unexpected Role of Amphiphilic Lignosulfonate to Improve the Storage Stability of Urea–Formaldehyde Resin and Its Application as Adhesives. Int. J. Biol. Macromol. 2020, 161, 755–762. [Google Scholar] [CrossRef]

- Lourenço, A.; Gominho, J.; Marques, A.V.; Pereira, H. Comparison of Lignosulfonates and Kraft Lignin in the Production of Fiberboards. Ind. Crops Prod. 2013, 47, 227–233. [Google Scholar] [CrossRef]

- Reh, R.; Kristak, L.; Antov, P. Advanced Eco-Friendly Wood-Based Composites. Materials 2022, 15, 8651. [Google Scholar] [CrossRef] [PubMed]

- EN 323:2001; Wood-Based Panels—Determination of Density. European Committee for Standardization (CEN): Brussels, Belgium, 2001.

- EN 317:1998; Particleboards and Fibreboards—Determination of Swelling in Thickness After Immersion in Water. European Committee for Standardization (CEN): Brussels, Belgium, 1998.

- EN 310:1999; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 319:2001; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization (CEN): Brussels, Belgium, 2001.

- EN 622-5:2010; Fibreboards—Specifications—Part 5: Requirements for Dry Process Boards (MDF). European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- EN 312:2010; Particleboards—Specifications. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- Hussin, M.H.; Abd Latif, N.H.; Hamidon, T.S.; Idris, N.N.; Hashim, R.; Appaturi, J.N.; Brosse, N.; Ziegler-Devin, I.; Chrusiel, L.; Fatriasari, W.; et al. Latest advancements in high-performance bio-based wood adhesives: A critical review. J. Mater. Res. Technol. 2022, 21, 3909–3946. [Google Scholar] [CrossRef]

- Lytvyn, I.; Bekhta, N.; Kusniak, I.; Bekhta, P.; Sedliačik, J. Properties of Particleboards with Partial Replacement of MUF Resin by Sodium and Magnesium Lignosulfonates. Wood Res. 2025, 70, 456–469. [Google Scholar] [CrossRef]

- Cai, Z.; Birkeland, M.; Wescott, J.M.; O’Dell, J.; Winandy, J.E. Effects of press sizes on internal steam pressure during particleboard hot-pressing process. For. Prod. J. 2009, 59, 40–44. [Google Scholar]

- Antov, P.; Mantanis, G.I.; Savov, V. Development of Wood Composites from Recycled Fibres Bonded with Magnesium Lignosulfonate. Forests 2020, 11, 613. [Google Scholar] [CrossRef]

- Kubo, S.; Kadla, J.F. Hydrogen Bonding in Lignin: A Fourier Transform Infrared Model Compound Study. Biomacromolecules 2005, 6, 2815–2821. [Google Scholar] [CrossRef]

- Oliaei, E.; Berthold, F.; Berglund, L.A.; Lindström, T. Eco-Friendly High-Strength Composites Based on Hot-Pressed Lignocellulose Microfibrils or Fibers. ACS Sustain. Chem. Eng. 2021, 9, 1899–1910. [Google Scholar] [CrossRef]

- Kelly, M.W. Critical Literature Review of Relationships Between Processing Parameters and Physical Properties of Particleboard; Gen. Tech. Rep. FPL-10; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1977; 65p. [Google Scholar]

- Hubbe, M.; Pizzi, A.; Zhang, H.; Halis, R. Critical links governing performance of self-binding and natural binders for hot-pressed reconstituted lignocellulosic board without added formaldehyde: A review. BioResources 2018, 13, 2049–2115. [Google Scholar] [CrossRef]

- Gul, W.; Ahmad, N.; Mohammad, S.; Salah, B.; Ullah, S.S.; Khurram, M.; Khan, R. Impact of moisture content, closing speed, and pressurizing speed on the performance of medium density fiberboard (MDF). Front. Mater. 2023, 10, 1195789. [Google Scholar] [CrossRef]

- Pintiaux, T.; Viet, D.; Vandenbossche, V.; Rigal, L.; Rouilly, A. Binderless materials obtained by thermo-compressive processing of lignocellulosic fibers: A comprehensive review. BioResources 2015, 10, 1915–1963. [Google Scholar] [CrossRef]

- Kim, S.; Kim, H.-J. Thermal Degradation Behavior of Urea–Formaldehyde Resin Adhesives with Different Formaldehyde to Urea Molar Ratios. J. Appl. Polym. Sci. 2005, 97, 1963–1970. [Google Scholar] [CrossRef]

- Kunaver, M.; Jasiukaitytė, E.; Čuk, N.; Medved, S. The Fast Pyrolysis of Lignocellulosic Biomass: The Effect of Lignin Content. Bioresour. Technol. 2010, 101, 112–119. [Google Scholar] [CrossRef]

- Madyaratri, E.W.; Ridho, M.R.; Aristri, M.A.; Lubis, M.A.R.; Iswanto, A.H.; Nawawi, D.S.; Antov, P.; Kristak, L.; Majlingová, A.; Fatriasari, W. Recent Advances in the Development of Fire-Resistant Biocomposites—A Review. Polymers 2022, 14, 362. [Google Scholar] [CrossRef]

- Iswanto, A.H.; Manurung, H.; Sohail, A.; Lee, S.H.; Antov, P.; Nawawi, D.S.; Latifah, S.; Kayla, D.S.; Kusumah, S.S.; Lubis, M.A.R.; et al. Thermo-Mechanical, Physico-Chemical, Morphological, and Fire Characteristics of Eco-Friendly Particleboard Manufactured with Phosphorylated Lignin Addition. J. Renew. Mater. 2024, 12, 1311–1341. [Google Scholar] [CrossRef]

- Li, M.; Prabhakar, M.N.; Park, J.; Song, J. Flame-retardant innovations in bio-based treatments for lignocellulosic natural fibers: A review. Int. J. Biol. Macromol. 2025, 311, 143728. [Google Scholar] [CrossRef] [PubMed]

- Balea, G.; Lunguleasa, A.; Zeleniuc, O.; Coşereanu, C. Three Adhesive Recipes Based on Magnesium Lignosulfonate, Used to Manufacture Particleboards with Low Formaldehyde Emissions and Good Mechanical Properties. Forests 2022, 13, 737. [Google Scholar] [CrossRef]

- Gonçalves, S.; Paiva, N.T.; Martins, J.; Magalhães, F.D.; Carvalho, L.H. Effect of Lignosulphonates on the Moisture Resistance of Phenol–Formaldehyde Resins for Exterior Plywood. Materials 2024, 17, 3715. [Google Scholar] [CrossRef] [PubMed]

| Biocomposite Type | SCG Content, % | ALS Content, % | UF Resin Content |

|---|---|---|---|

| A | 20 | 20 | 0 |

| B | 25 | 25 | 0 |

| C | 30 | 30 | 0 |

| D | 35 | 35 | 0 |

| E | 37.5 | 37.5 | 0 |

| REF | 0 | 0 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savov, V.; Antov, P.; Kostadinova-Slaveva, A.; Yusein, J.; Dudeva, V.; Todorova, E.; Petrin, S. Development and Characterization of Sustainable Biocomposites from Wood Fibers, Spent Coffee Grounds, and Ammonium Lignosulfonate. Polymers 2025, 17, 2589. https://doi.org/10.3390/polym17192589

Savov V, Antov P, Kostadinova-Slaveva A, Yusein J, Dudeva V, Todorova E, Petrin S. Development and Characterization of Sustainable Biocomposites from Wood Fibers, Spent Coffee Grounds, and Ammonium Lignosulfonate. Polymers. 2025; 17(19):2589. https://doi.org/10.3390/polym17192589

Chicago/Turabian StyleSavov, Viktor, Petar Antov, Alexsandrina Kostadinova-Slaveva, Jansu Yusein, Viktoria Dudeva, Ekaterina Todorova, and Stoyko Petrin. 2025. "Development and Characterization of Sustainable Biocomposites from Wood Fibers, Spent Coffee Grounds, and Ammonium Lignosulfonate" Polymers 17, no. 19: 2589. https://doi.org/10.3390/polym17192589

APA StyleSavov, V., Antov, P., Kostadinova-Slaveva, A., Yusein, J., Dudeva, V., Todorova, E., & Petrin, S. (2025). Development and Characterization of Sustainable Biocomposites from Wood Fibers, Spent Coffee Grounds, and Ammonium Lignosulfonate. Polymers, 17(19), 2589. https://doi.org/10.3390/polym17192589