A Low-Viscosity, Recyclable Polymer-Based Binder Strategy for Metal FDM: Toward High Powder Loading, Sustainable Processing, and Comprehensive Characterization of 17-4PH Stainless Steel Parts

Abstract

1. Introduction

2. Experimental Procedures

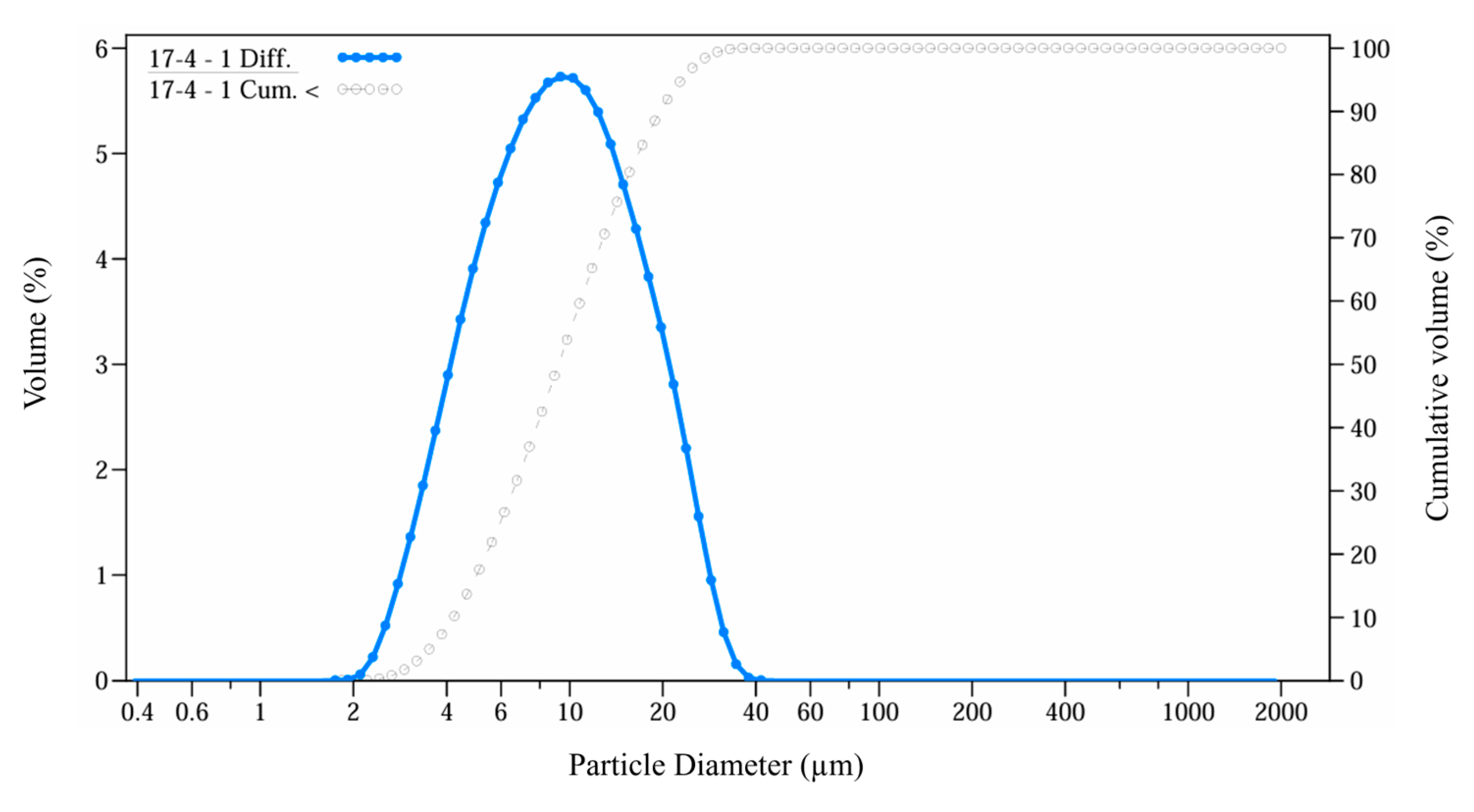

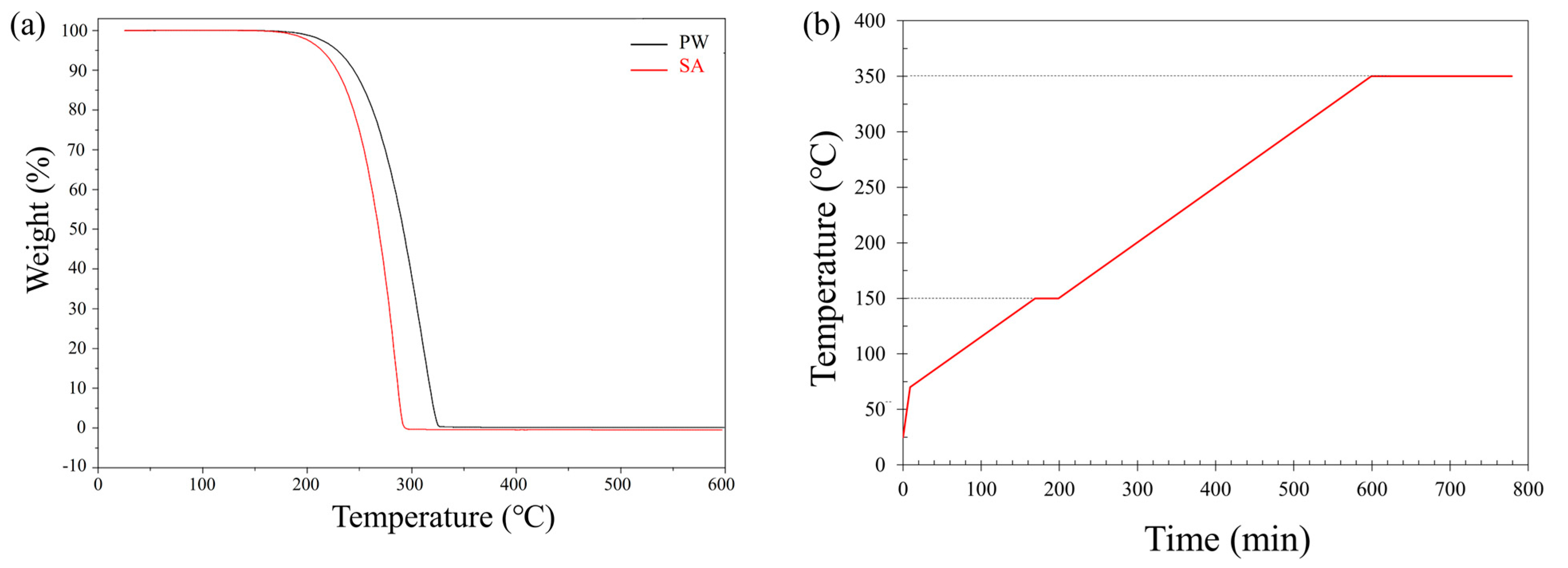

2.1. Materials

2.2. Feedstock Preparation

2.3. Rheological Measurement

2.4. FDM Printing

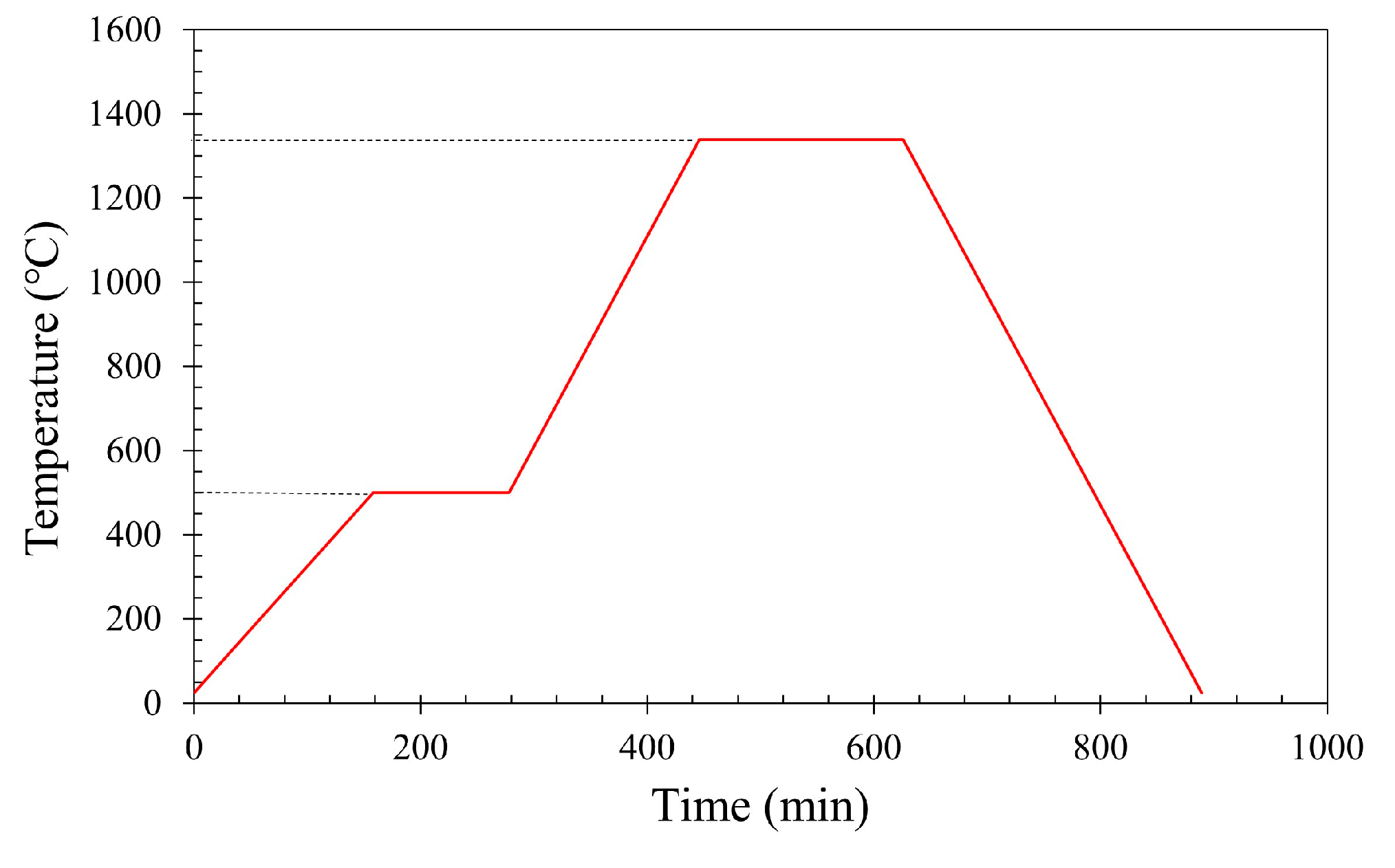

2.5. Post-Printing Thermal Processing

2.6. Scanning Electron Microscopy

2.7. Mechanical and Physical Analysis

2.8. Tribocorrosion

3. Results and Discussion

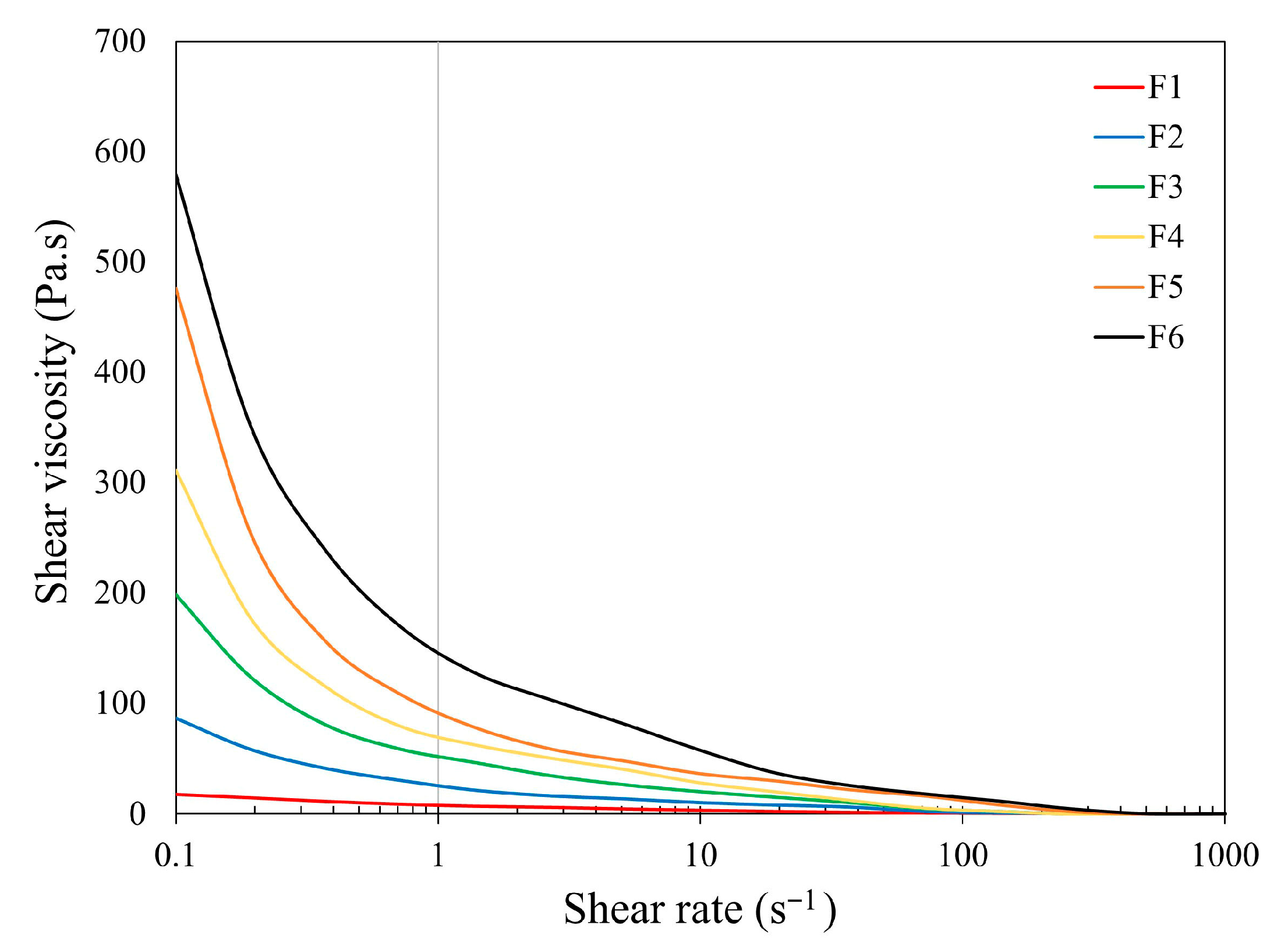

3.1. Feedstock Characterization

3.2. FDM Printability and Process Parameter Optimization

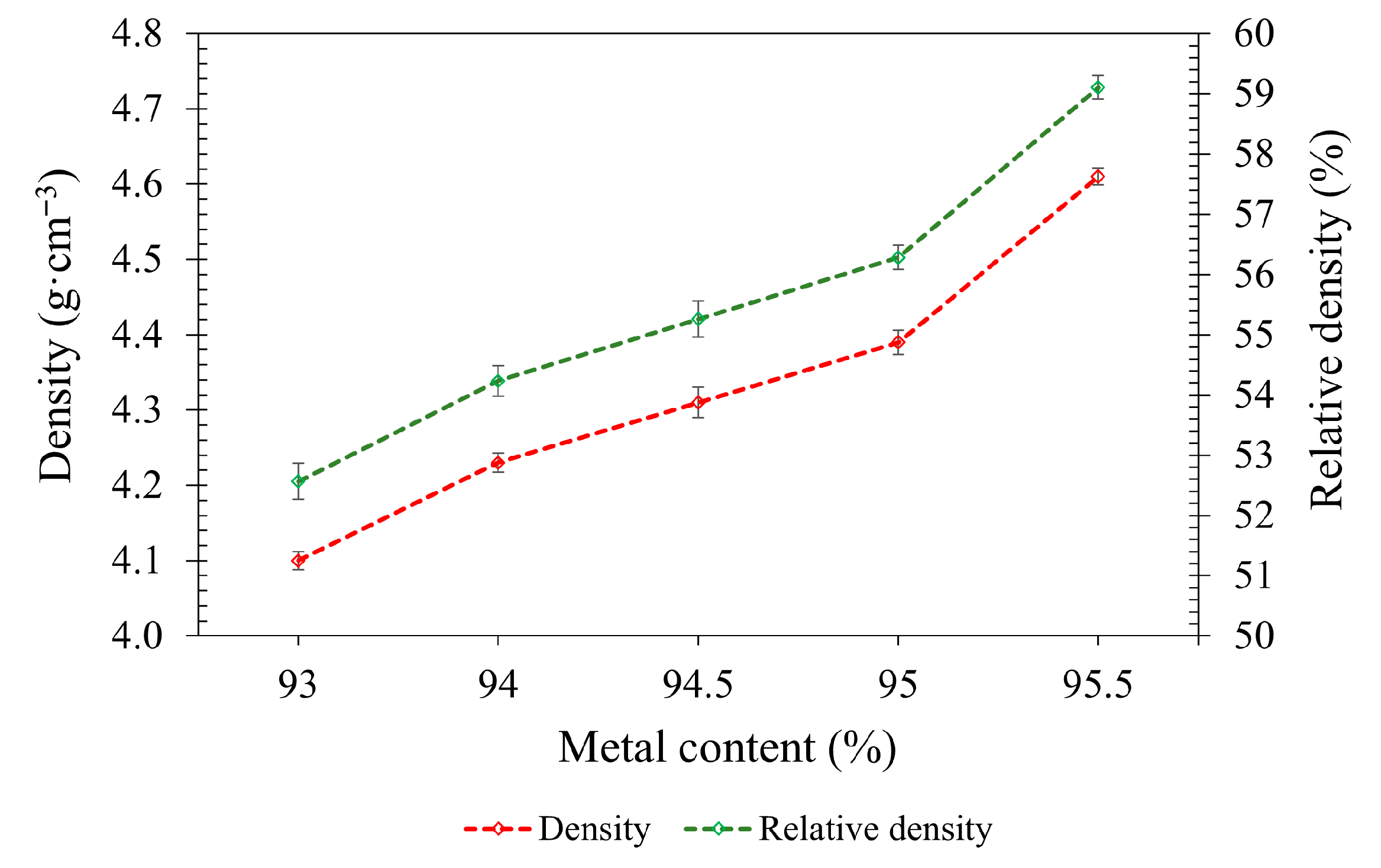

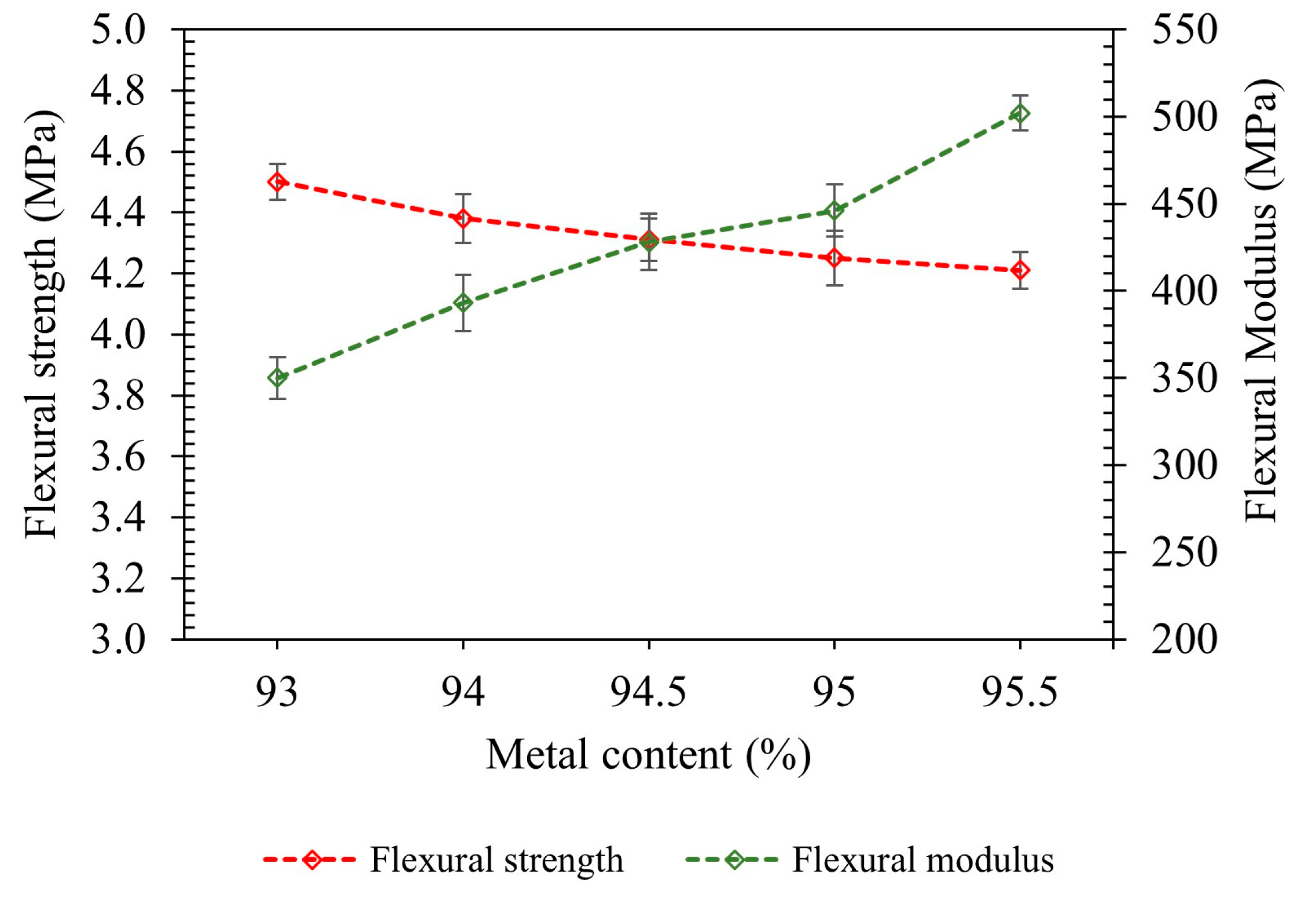

3.3. Green Part Properties

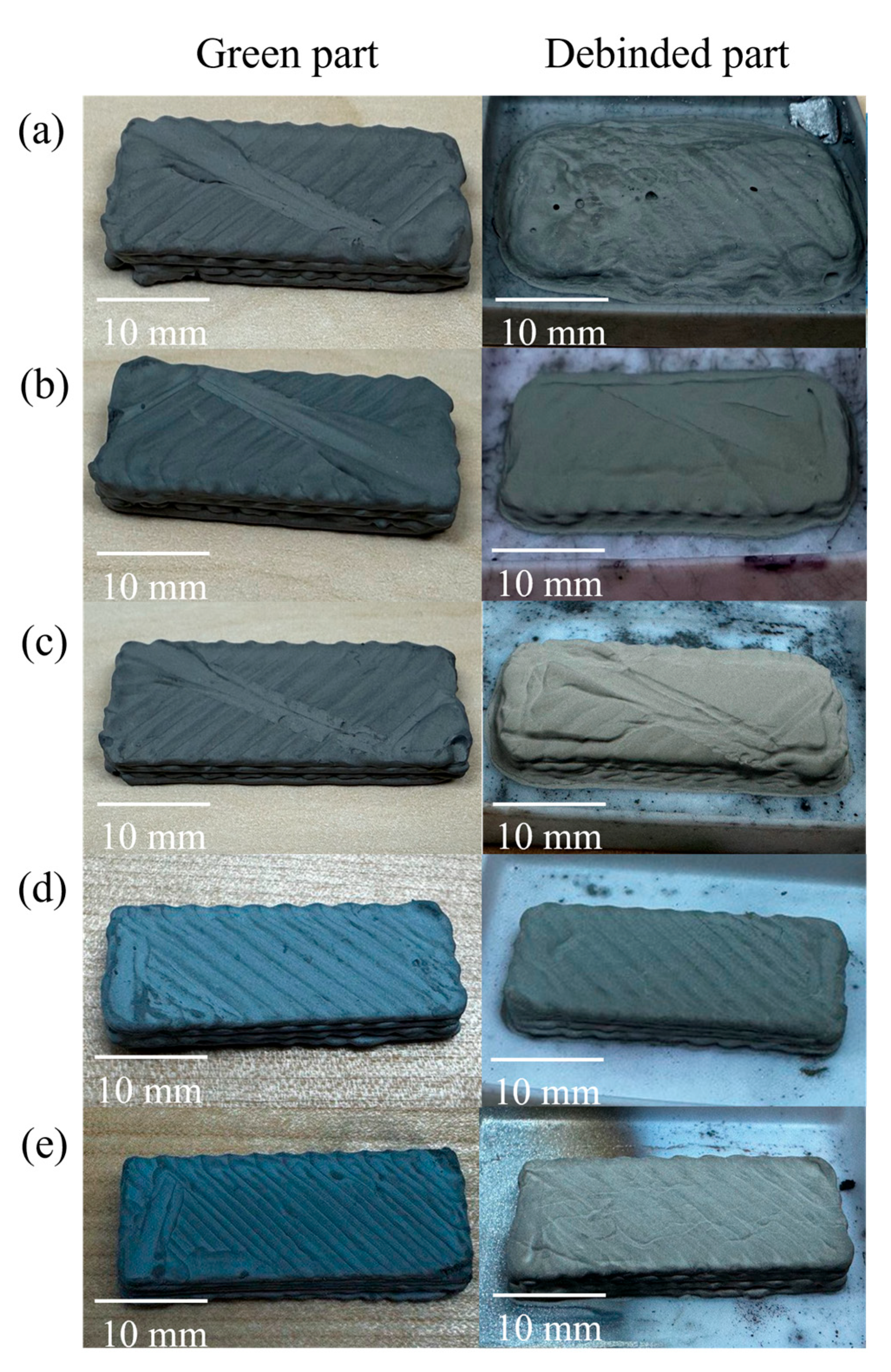

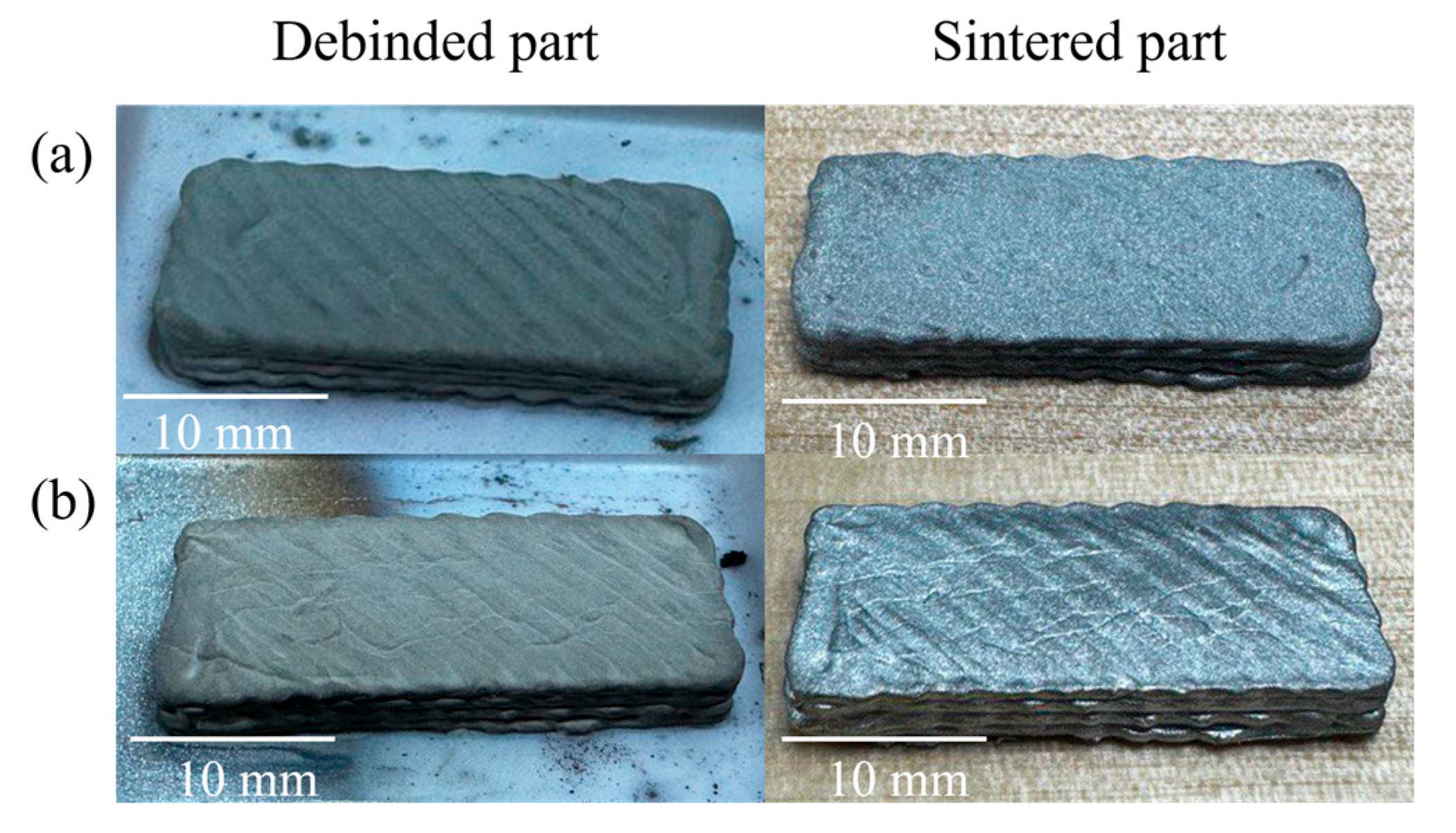

3.4. Debinding and Sintering Stability

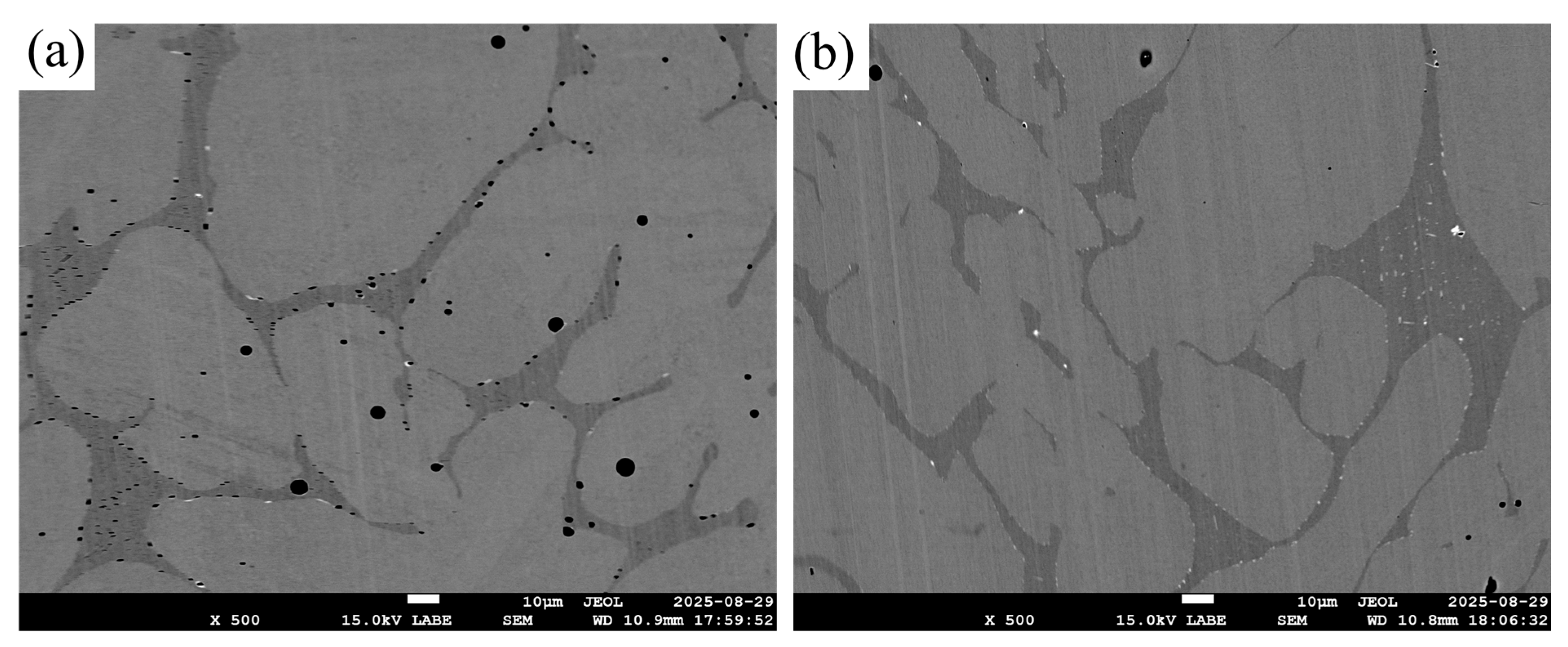

3.5. Sintered Part Properties

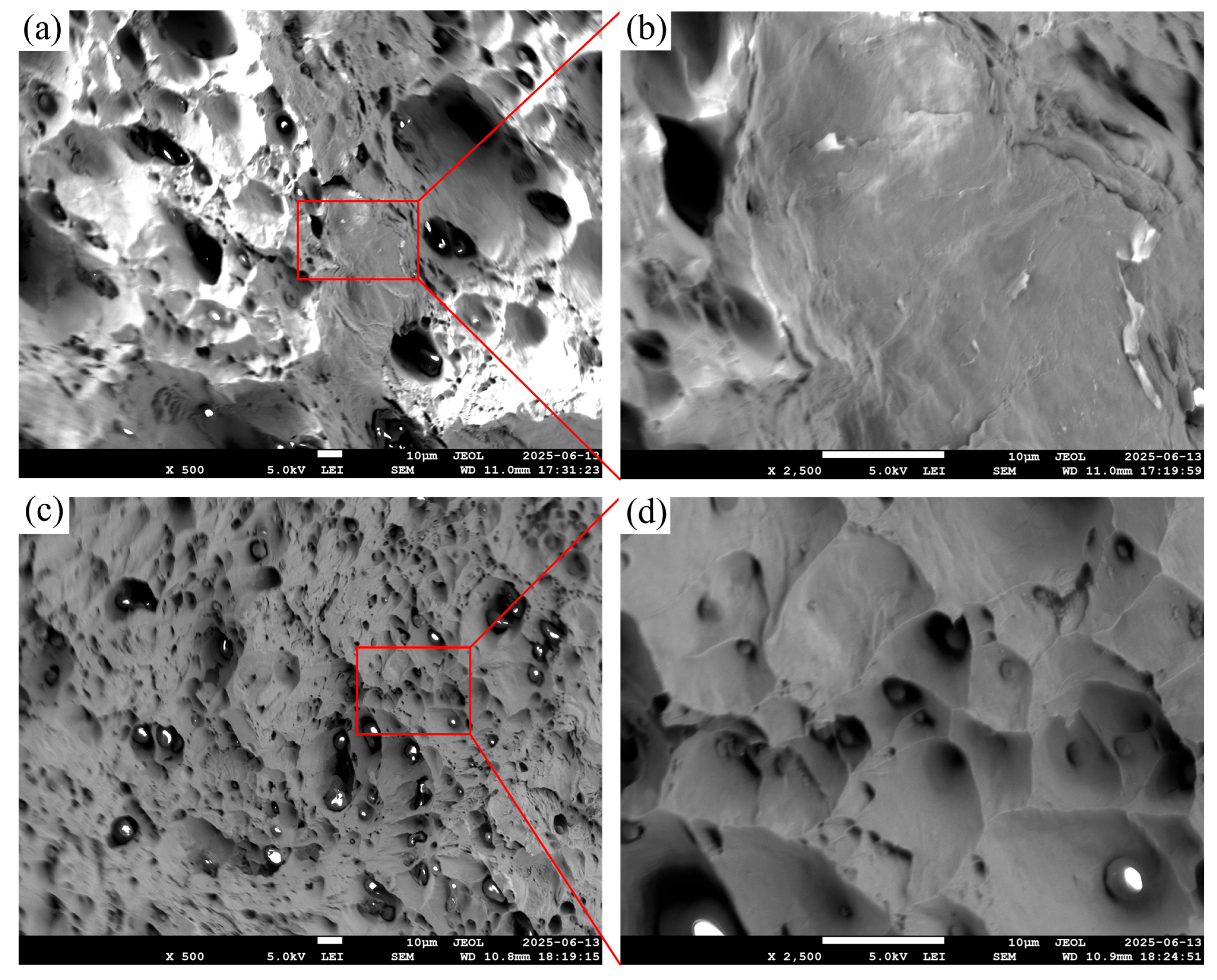

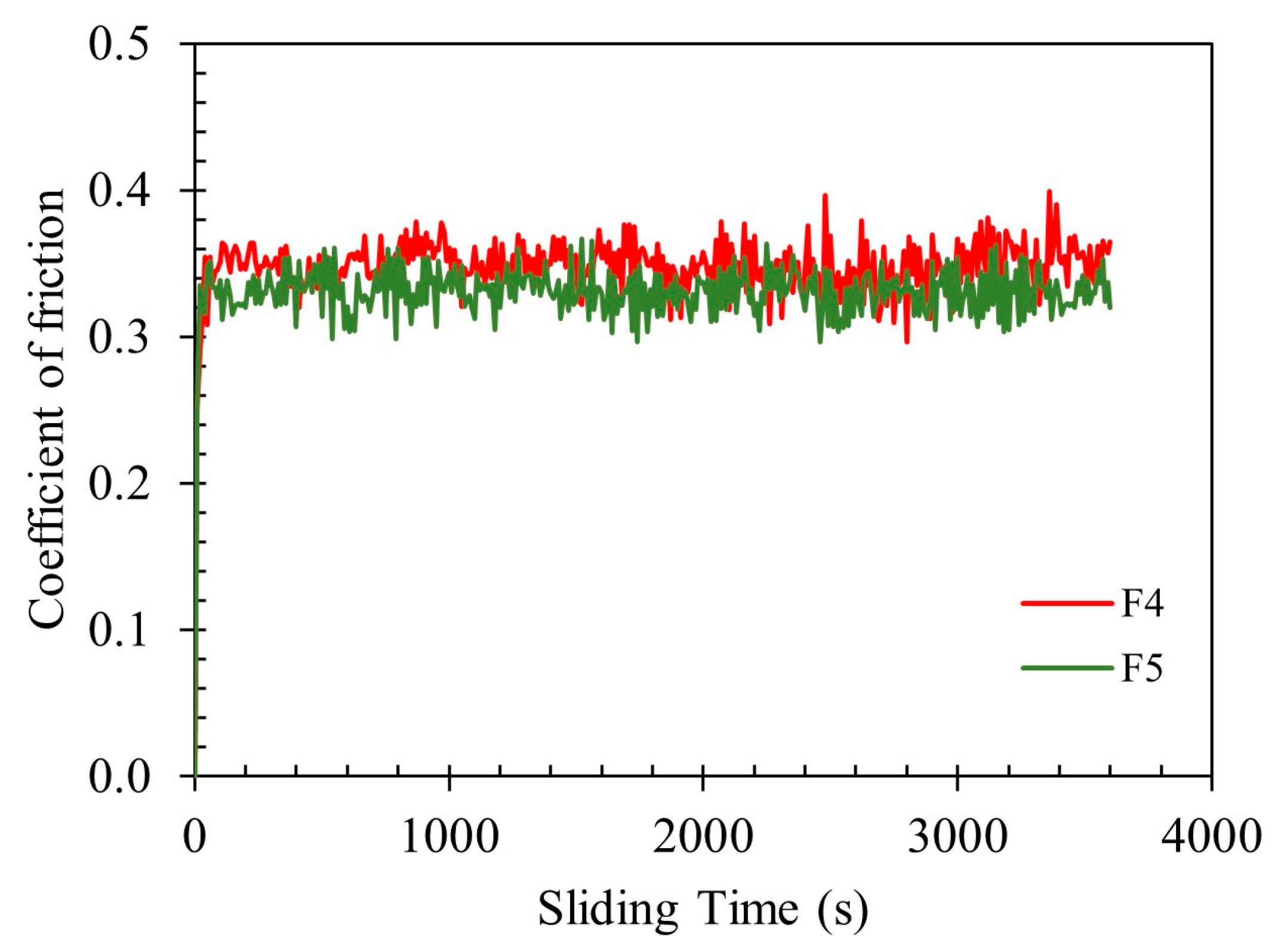

3.6. Tribocorrosion Performance

4. Conclusions

- Rheology showed shear-thinning for all formulations, with viscosity increasing sharply with solid loading.

- Increasing metallic loading by 2.5 wt.% improved flexural modulus by ≈33%, green density by ≈12%, whereas flexural strength reduced slightly by ≈6%.

- Only the 95.0 and 95.5 wt.% compositions maintained dimensional stability through debinding and sintering, indicating adequate green robustness and packing.

- Increasing the metal content from 95.0 to 95.5 wt.% improved as-sintered performance markedly, raising relative density by 4.1 percentage points and enhancing tensile properties (UTS +≈23%, YS +≈17%, and elongation +3.7 percentage points, ≈3.5×).

- Tribocorrosion performance improved with higher solid loading. Increasing the metal content from 95.0 to 95.5 wt.% reduced the wear coefficient by ≈38%, accompanied by a concomitant decrease in the coefficient of friction.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive Manufacturing: Expanding 3D Printing Horizon in Industry 4.0. Int. J. Interact. Des. Manuf. 2023, 17, 2221–2235. [Google Scholar] [CrossRef] [PubMed]

- Tangestani, R.; Sabiston, T.; Chakraborty, A.; Yuan, L.; Krutz, N.; Martin, É. An Efficient Track-Scale Model for Laser Powder Bed Fusion Additive Manufacturing: Part 2—Mechanical Model. Front. Mater. 2021, 8, 759669. [Google Scholar] [CrossRef]

- Tangestani, R.; Sabiston, T.; Chakraborty, A.; Muhammad, W.; Yuan, L.; Martin, É. An Efficient Track-Scale Model for Laser Powder Bed Fusion Additive Manufacturing: Part 1—Thermal Model. Front. Mater. 2021, 8, 753040. [Google Scholar] [CrossRef]

- Martin, É.; Muhammad, W.; Detor, A.J.; Spinelli, I.; Wessman, A.; Wei, D. “Strain-Annealed” Grain Boundary Engineering Process Investigated in Hastelloy-X. Materialia 2020, 9, 100544. [Google Scholar] [CrossRef]

- Chakraborty, A.; Tangestani, R.; Muhammad, W.; Sabiston, T.; Masse, J.P.; Batmaz, R.; Wessman, A.; Martin, É. Micro-Cracking Mechanism of RENÉ 108 Thin-Wall Components Built by Laser Powder Bed Fusion Additive Manufacturing. Mater. Today Commun. 2022, 30, 103139. [Google Scholar] [CrossRef]

- Chakraborty, A.; Muhammad, W.; Masse, J.P.; Tangestani, R.; Ghasri-Khouzani, M.; Wessman, A.; Martin, É. Role of Alloy Composition on Micro-Cracking Mechanisms in Additively Manufactured Ni-Based Superalloys. Acta Mater. 2023, 255, 119089. [Google Scholar] [CrossRef]

- Kohar, C.P.; Martin, É.; Connolly, D.S.; Patil, S.; Krutz, N.; Wei, D.; Inal, K. A New and Efficient Thermo-Elasto-Viscoplastic Numerical Implementation for Implicit Finite Element Simulations of Powder Metals: An Application to Hot Isostatic Pressing. Int. J. Mech. Sci. 2019, 155, 222–234. [Google Scholar] [CrossRef]

- Muhammad, W.; Batmaz, R.; Natarajan, A.; Martin, E. Effect of Binder Jetting Microstructure Variability on Low Cycle Fatigue Behavior of 316L. Mater. Sci. Eng. A 2022, 839, 142820. [Google Scholar] [CrossRef]

- Thatte, A.; Loghin, A.; Martin, E.; Dheeradhada, V.; Shin, Y.; Ananthasayanam, B. Multi-Scale Coupled Physics Models and Experiments for Performance and Life Prediction of Supercritical CO2 Turbomachinery Components. In Proceedings of the 5th International Symposium—sCO2 Power Cycles, San Antonio, TX, USA, 28–31 March 2016; Springer: Berlin/Heidelberg, Germany, 2016; Volume 1, pp. 1–24. [Google Scholar]

- Esmati, K.; Chakraborty, A.; Pendurti, S.; Natarajan, A.; Martin, É. Anisotropic Sintering Behavior of Stainless Steel 316L Printed by Binder Jetting Additive Manufacturing. Mater. Today Commun. 2024, 41, 110528. [Google Scholar] [CrossRef]

- Quelennec, X.; Martin, E.; Jiang, L.; Jonas, J.J. Work Hardening and Kinetics of Dynamic Recrystallization in Hot Deformed Austenite. Proc. J. Phys. Conf. Ser. 2010, 240, 012082. [Google Scholar] [CrossRef]

- Hu, Z.; Song, X.; Wei, C.; Liu, J. Behavior and Mechanisms for Sorptive Removal of Perfluorooctane Sulfonate by Layered Double Hydroxides. Chemosphere 2017, 187, 196–205. [Google Scholar] [CrossRef]

- Karunakaran, R.; Ortgies, S.; Tamayol, A.; Bobaru, F.; Sealy, M.P. Additive Manufacturing of Magnesium Alloys. Bioact. Mater. 2020, 5, 44–54. [Google Scholar] [CrossRef]

- Martin, E.; Jiang, L.; Godet, S.; Jonas, J. The Combined Effect of Static Recrystallization and Twinning on Texture in Magnesium Alloys AM30 and AZ31. Int. J. Mater. Res. 2009, 100, 576–583. [Google Scholar] [CrossRef]

- Zeng, Z.; Salehi, M.; Kopp, A.; Xu, S.; Esmaily, M.; Birbilis, N. Recent Progress and Perspectives in Additive Manufacturing of Magnesium Alloys. J. Magnes. Alloys 2022, 10, 1511–1541. [Google Scholar] [CrossRef]

- Karimialavijeh, H.; Chakraborty, A.; Azzi, M.; Proebstle, M.; Martin, E. Effect of Precipitation Hardening on the Microstructure, Mechanical, and Corrosion Properties of Additively Manufactured A20X Aluminum Alloy. Mater. Sci. Eng. A 2024, 913, 147033. [Google Scholar] [CrossRef]

- Chakraborty, A.; Martin, É.; Habibnejad-Korayem, M. Effect of Carbon on the Additive Manufacturability of Plasma-Atomized Aluminum Alloys: A Robust Powder Characterization Study. Powder Technol. 2025, 452, 120559. [Google Scholar] [CrossRef]

- Karimialavijeh, H.; Ghasri-Khouzani, M.; Chakraborty, A.; Pröbstle, M.; Martin, E. Direct Aging of Additively Manufactured A20X Aluminum Alloy. J. Alloys Compd. 2023, 968, 172071. [Google Scholar] [CrossRef]

- Im, S.; Ghasri-Khouzani, M.; Muhammad, W.; Batmaz, R.; Esmati, K.; Chakraborty, A.; Natarajan, A.; Martin, É. Evaluation of Different Sintering Agents for Binder Jetting of Aluminum Alloy. J. Mater. Eng. Perform. 2023, 32, 9550–9560. [Google Scholar] [CrossRef]

- Ghasri-Khouzani, M.; Karimialavijeh, H.; Pröbstle, M.; Batmaz, R.; Muhammad, W.; Chakraborty, A.; Sabiston, T.D.; Harvey, J.P. Martin Processability and Characterization of A20X Aluminum Alloy Fabricated by Laser Powder Bed Fusion. Mater. Today Commun. 2023, 35, 105555. [Google Scholar] [CrossRef]

- Chakraborty, A.; Lalh, M.; Martin, É.; Karimialavijeh, H.; Bejarano, A.; Wessman, A.; Zou, Y.; Habibnejad-Korayem, M. Influence of Carbon on the Rheology and Additive Manufacturability of Ti-6Al-4V Powders. Mater. Des. 2025, 253, 113833. [Google Scholar] [CrossRef]

- Jacob, J.; Pejak Simunec, D.; Kandjani, A.E.Z.; Trinchi, A.; Sola, A. A Review of Fused Filament Fabrication of Metal Parts (Metal FFF): Current Developments and Future Challenges. Technologies 2024, 12, 267. [Google Scholar] [CrossRef]

- Ramazani, H.; Kami, A. Metal FDM, a New Extrusion-Based Additive Manufacturing Technology for Manufacturing of Metallic Parts: A Review. Prog. Addit. Manuf. 2022, 7, 609–626. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Lin, Z.; Zhang, T. Creating Metal Parts by Fused Deposition Modeling and Sintering. Mater. Lett. 2020, 263, 127252. [Google Scholar] [CrossRef]

- Costa, J.M.; Sequeiros, E.W.; Vieira, M.F. Fused Filament Fabrication for Metallic Materials: A Brief Review. Materials 2023, 16, 7505. [Google Scholar] [CrossRef] [PubMed]

- Cho, Y.H.; Park, S.Y.; Kim, J.Y.; Lee, K.A. 17-4PH Stainless Steel with Excellent Strength–Elongation Combination Developed via Material Extrusion Additive Manufacturing. J. Mater. Res. Technol. 2023, 24, 3284–3299. [Google Scholar] [CrossRef]

- Hou, B.-X.; Sheu, H.-H.; Lin, M.-Y.; Lee, C.-Y.; Lee, H.-B. Corrosion and Wear Behavior of 17-4PH Stainless Steel Manufactured by Selective Laser Melting and Bulk Material After Solution Treatment. Coatings 2025, 15, 649. [Google Scholar] [CrossRef]

- Jones, J.; Vafadar, A.; Hashemi, R. A Review of the Mechanical Properties of 17-4PH Stainless Steel Produced by Bound Powder Extrusion. J. Manuf. Mater. Process. 2023, 7, 162. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Manonukul, A. A Review on Material Extrusion Additive Manufacturing of Metal and How It Compares with Metal Injection Moulding. Metals 2022, 12, 429. [Google Scholar] [CrossRef]

- Hrdina, K.E.; Halloran, J.W.; Oliveira, A.; Kaviany, M. Chemistry of Removal of Ethylene Vinyl Acetate Binders. J. Mater. Sci. 1998, 33, 2795–2803. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Slemenik Perše, L.; Nanni, F. Advancements in Metal Additive Manufacturing: A Comprehensive Review of Material Extrusion with Highly Filled Polymers. J. Manuf. Mater. Process. 2024, 8, 14. [Google Scholar] [CrossRef]

- Hufnagl, M. Influence of Binder Compositions, Solvents, and Material Extrusion Parameters on Aluminum Additive Manufacturing via SDS. Master’s Thesis, Polymer Engineering and Science Leoben, Montanuniversität, Leoben, Austria, 2024. [Google Scholar]

- Vukšić, M.; Bek, M.; Perše, L.S.; Kržmanc, M.M.; Kocjan, A.; Iveković, A. The Role of Paraffin Wax on the Properties and Printability of Ethylene Vinyl Acetate-Based Feedstocks for Alumina Fused Filament Fabrication. Open Ceram. 2023, 16, 100496. [Google Scholar] [CrossRef]

- Forstner, T.; Cholewa, S.; Drummer, D. Influence of Wax Addition on Feedstock Processing Behavior in Additive Manufacturing of Metals by Material Extrusion. Prog. Addit. Manuf. 2024, 9, 625–632. [Google Scholar] [CrossRef]

- Tadi, S.P.; Koppisetti, D.; Palisetti, V.K.T.; Palivela, B.C.; Mamilla, R.S. Polymer Based Binder Materials for Various Metal Injection Molding Processes: Salient Aspects and Recent Trends. J. Manuf. Process 2025, 133, 322–353. [Google Scholar] [CrossRef]

- Mao, Y.; Li, J.; Li, W.; Cai, D.; Wei, Q. Binder Jetting Additive Manufacturing of 316L Stainless-Steel Green Parts with High Strength and Low Binder Content: Binder Preparation and Process Optimization. J. Mater. Process Technol. 2021, 291, 117020. [Google Scholar] [CrossRef]

- German, R.M. Powder Injection Molding; Metal Powder Industries Federation: Princeton, NJ, USA, 1990; ISBN 978-0-918404-95-4. [Google Scholar]

- Hasib, A.G.; Niauzorau, S.; Xu, W.; Niverty, S.; Kublik, N.; Williams, J.; Chawla, N.; Song, K.; Azeredo, B. Rheology Scaling of Spherical Metal Powders Dispersed in Thermoplastics and Its Correlation to the Extrudability of Filaments for 3D Printing. Addit. Manuf. 2021, 41, 101967. [Google Scholar] [CrossRef]

- Oh, H.; Im, T.; Pyo, J.; Lee, J.S.; Lee, C.S. Study of Solid Loading of Feedstock Using Trimodal Iron Powders for Extrusion Based Additive Manufacturing. Sci. Rep. 2023, 13, 4819. [Google Scholar] [CrossRef] [PubMed]

- Abel, J.; Mannschatz, A.; Teuber, R.; Müller, B.; Al Noaimy, O.; Riecker, S.; Thielsch, J.; Matthey, B.; Weißgärber, T. Fused Filament Fabrication of Niti Components and Hybridization with Laser Powder Bed Fusion for Filigree Structures. Materials 2021, 14, 4399. [Google Scholar] [CrossRef]

- Cano, S.; Gonzalez-Gutierrez, J.; Sapkota, J.; Spoerk, M.; Arbeiter, F.; Schuschnigg, S.; Holzer, C.; Kukla, C. Additive Manufacturing of Zirconia Parts by Fused Filament Fabrication and Solvent Debinding: Selection of Binder Formulation. Addit. Manuf. 2019, 26, 117–128. [Google Scholar] [CrossRef]

- Momeni, V.; Luca, S.; Gonzalez-Gutierrez, J.; Cano, S.; Sueur, E.; Shahroodi, Z.; Schuschnigg, S.; Kukla, C.; Holzer, C. Binder System Composition on the Rheological and Magnetic Properties of Nd-Fe-B Feedstocks for Metal Injection Molding. Appl. Sci. 2024, 14, 5638. [Google Scholar] [CrossRef]

- Sadaf, M.; Cano, S.; Gonzalez-Gutierrez, J.; Bragaglia, M.; Schuschnigg, S.; Kukla, C.; Holzer, C.; Vály, L.; Kitzmantel, M.; Nanni, F. Influence of Binder Composition and Material Extrusion (MEX) Parameters on the 3D Printing of Highly Filled Copper Feedstocks. Polymers 2022, 14, 4962. [Google Scholar] [CrossRef]

- Gorjan, L.; Galusca, C.; Sami, M.; Sebastian, T.; Clemens, F. Effect of Stearic Acid on Rheological Properties and Printability of Ethylene Vinyl Acetate Based Feedstocks for Fused Filament Fabrication of Alumina. Addit. Manuf. 2020, 36, 101391. [Google Scholar] [CrossRef]

- Kareem, M.Q.; Mikó, T.; Gergely, G.; Gácsi, Z. A Review on the Production of 17-4PH Parts Using Press and Sinter Technology. Sci. Prog. 2023, 106, 368504221146060. [Google Scholar] [CrossRef] [PubMed]

- Kazior, J. Influence of Sintering Atmosphere, Temperature and the Solution-Annealing Treatment on the Properties of Precipitation-Hardening Sintered 17-4 PH Stainless Steel. Materials 2023, 16, 760. [Google Scholar] [CrossRef]

- Das, A.; Gilmer, E.L.; Biria, S.; Bortner, M.J. Importance of Polymer Rheology on Material Extrusion Additive Manufacturing: Correlating Process Physics to Print Properties. ACS Appl. Polym. Mater. 2021, 3, 1218–1249. [Google Scholar] [CrossRef]

- Strano, M.; Rane, K.; Briatico Vangosa, F.; Di Landro, L. Extrusion of Metal Powder-Polymer Mixtures: Melt Rheology and Process Stability. J. Mater. Process Technol. 2019, 273, 116250. [Google Scholar] [CrossRef]

- Ren, L.; Zhou, X.; Song, Z.; Zhao, C.; Liu, Q.; Xue, J.; Li, X. Process Parameter Optimization of Extrusion-Based 3D Metal Printing Utilizing PW-LDPE-SA Binder System. Materials 2017, 10, 305. [Google Scholar] [CrossRef]

- Thumsorn, S.; Prasong, W.; Kurose, T.; Ishigami, A.; Kobayashi, Y.; Ito, H. Rheological Behavior and Dynamic Mechanical Properties for Interpretation of Layer Adhesion in FDM 3D Printing. Polymers 2022, 14, 2721. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Khalil, K.A. Effect of Powder Loading on Metal Injection Molding Stainless Steels. J. Mater. Process Technol. 2007, 183, 432–439. [Google Scholar] [CrossRef]

- Singh, P.; Shaikh, Q.; Balla, V.K.; Atre, S.V.; Kate, K.H. Estimating Powder-Polymer Material Properties Used in Design for Metal Fused Filament Fabrication (DfMF3). Jom 2020, 72, 485–495. [Google Scholar] [CrossRef]

- O’Connor, H.; Singh, G.; Kumar, A.; Paetzold, R.; Celikin, M.; O’Cearbhaill, E.D. Fused Filament Fabrication Using Stainless Steel 316L-Polymer Blend: Analysis and Optimization for Green Density and Surface Roughness. Polym. Compos. 2024, 45, 10632–10644. [Google Scholar] [CrossRef]

- Vinay, D.L.; Keshavamurthy, R.; Tambrallimath, V. Enhanced Mechanical Properties of Metal Filled 3D Printed Polymer Composites. J. Inst. Eng. Ser. D 2023, 104, 181–195. [Google Scholar] [CrossRef]

- Kim, K.; Ong, J.; Okuno, O. The Effect of Filler Loading and Morphology on the Mechanical Properties of contemporary Composites. Prosthet. Dent. 2002, 87, 6. [Google Scholar] [CrossRef]

- Bhavith, K.; Prashanth Pai, M.; Sudheer, M.; Ramachandra, C.G.; Maruthi Prashanth, B.H.; Kiran Kumar, B. The Effect of Metal Filler on the Mechanical Performance of Epoxy Resin Composites. Eng. Proc. 2023, 59, 200. [Google Scholar] [CrossRef]

- Tagliavia, G.; Porfiri, M.; Gupta, N. Analysis of Flexural Properties of Hollow-Particle Filled Composites. Compos. B Eng. 2010, 41, 86–93. [Google Scholar] [CrossRef]

- Badyankal, P.V.; Gouda, P.S.S.; Manjunatha, T.S.; Maruthi Prashanth, B.H.; Shivayogi, B.H. Realization of Mechanical and Tribological Properties of Hybrid Banana, Sisal, and Pineapple Fiber Epoxy Composites Using Naturally Available Fillers. Eng. Res. Express 2023, 5, 015070. [Google Scholar] [CrossRef]

- Fong, S.W.Z.; Tey, J.Y.; Yeo, W.H.; Tee, S.F. Direct Ink Writing of 17–4PH Stainless Steel Using Green Binder: Rheological Sensitivity and Performance Assessment. J. Manuf. Process 2024, 132, 519–531. [Google Scholar] [CrossRef]

- Kim, H.J.; Park, H.K.; Lee, C.W.; Yoo, B.G.; Jung, H.Y. Baking Effect on Desorption of Diffusible Hydrogen and Hydrogen Embrittlement on Hot-Stamped Boron Martensitic Steel. Metals 2019, 9, 636. [Google Scholar] [CrossRef]

- Wagner, M.A.; Engel, J.; Hadian, A.; Clemens, F.; Rodriguez-Arbaizar, M.; Carreño-Morelli, E.; Wheeler, J.M.; Spolenak, R. Filament Extrusion-Based Additive Manufacturing of 316L Stainless Steel: Effects of Sintering Conditions on the Microstructure and Mechanical Properties. Addit. Manuf. 2022, 59, 103147. [Google Scholar] [CrossRef]

- Mao, Y.; Cai, C.; Zhang, J.; Heng, Y.; Feng, K.; Cai, D.; Wei, Q. Effect of Sintering Temperature on Binder Jetting Additively Manufactured Stainless Steel 316L: Densification, Microstructure Evolution and Mechanical Properties. J. Mater. Res. Technol. 2023, 22, 2720–2735. [Google Scholar] [CrossRef]

- Rishmawi, I.; Salarian, M.; Vlasea, M. Tailoring Green and Sintered Density of Pure Iron Parts Using Binder Jetting Additive Manufacturing. Addit. Manuf. 2018, 24, 508–520. [Google Scholar] [CrossRef]

- Di Pompeo, V.; Santecchia, E.; Santoni, A.; Sleem, K.; Cabibbo, M.; Spigarelli, S. Microstructure and Defect Analysis of 17-4PH Stainless Steel Fabricated by the Bound Metal Deposition Additive Manufacturing Technology. Crystals 2023, 13. [Google Scholar] [CrossRef]

- Zhang, Y.; Roch, A. Fused Filament Fabrication and Sintering of 17-4PH Stainless Steel. Manuf. Lett. 2022, 33, 29–32. [Google Scholar] [CrossRef]

- Yu, H.; Díaz, A.; Lu, X.; Sun, B.; Ding, Y.; Koyama, M.; He, J.; Zhou, X.; Oudriss, A.; Feaugas, X.; et al. Hydrogen Embrittlement as a Conspicuous Material Challenge─Comprehensive Review and Future Directions. Chem. Rev. 2024, 124, 6271–6392. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Arbeiter, F.; Schlauf, T.; Kukla, C.; Holzer, C. Tensile Properties of Sintered 17-4PH Stainless Steel Fabricated by Material Extrusion Additive Manufacturing. Mater. Lett. 2019, 248, 165–168. [Google Scholar] [CrossRef]

- Cleveland-Cliffs Inc. ARMCO® 17-4 PH® Stainless Steel—Product Data Bulletin (PDB-EURO-10/2022-89); Cleveland-Cliffs Inc.: Cleveland, OH, USA, 2022; Available online: https://www.aksteel.nl/files/downloads/clf_datasheet_armco_17-4_ph_pdb_euro_102022_89.pdf (accessed on 16 September 2025).

- EOS GmbH, Electro Optical Systems. EOS StainlessSteel 17-4PH—IndustryLine (M290), Status 07/2022; EOS GmbH, Electro Optical Systems: Krailling, Germany, 2022; Available online: https://www.eos.info/var/assets/03_system-related-assets/material-related-contents/metal-materials-and-examples/metal-material-datasheet/stainlesssteel/material_datasheet_industryline_17-4ph_m290_en_screen.pdf (accessed on 16 September 2025).

- Pellegrini, A.; Lavecchia, F.; Guerra, M.G.; Galantucci, L.M. Influence of Aging Treatments on 17–4 PH Stainless Steel Parts Realized Using Material Extrusion Additive Manufacturing Technologies. Int. J. Adv. Manuf. Technol. 2023, 126, 163–178. [Google Scholar] [CrossRef]

- Parenti, P.; Puccio, D.; Semeraro, Q.; Colosimo, B.M. A Techno-Economic Approach for Decision-Making in Metal Additive Manufacturing: Metal Extrusion versus Single and Multiple Laser Powder Bed Fusion. Prog. Addit. Manuf. 2024, 9, 185–210. [Google Scholar] [CrossRef]

- Kong, X.; Wang, Y.; Wu, J.; Wu, D.; Zhang, S.; Rong, L. Effects of Different Binder Systems on the Characteristics of Metal-Based Diamond Composites Fabricated via Fused Deposition Modeling and Sintering Technology. Int. J. Refract. Met. Hard Mater. 2024, 123, 106775. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Tensile, Fracture, and Fatigue Crack Growth Properties of a 3D Printed Maraging Steel through Selective Laser Melting. J. Alloys Compd. 2017, 725, 355–364. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Santamaria, R.; Salasi, M.; Bakhtiari, S.; Leadbeater, G.; Iannuzzi, M.; Quadir, M.Z. Microstructure and Mechanical Behaviour of 316L Stainless Steel Produced Using Sinter-Based Extrusion Additive Manufacturing. J. Mater. Sci. 2022, 57, 9646–9662. [Google Scholar] [CrossRef]

- Shibata, A.; Takeda, Y.; Kimura, Y.; Tsuji, N. Hydrogen-Related Fracture Behavior under Constant Loading Tensile Test in As-Quenched Low-Carbon Martensitic Steel. Metals 2022, 12, 440. [Google Scholar] [CrossRef]

- Bris, J.; Mateo, A.; Calero, J.A.; Bris, J.; Benítez, F.; Calero, J.; Anglada, M.; Llanes, L. Fracture Toughness of High Density Sintered Steels. An. De Mecánica De La Fract. 2006, 2, 397–401. [Google Scholar]

- Mil’man, Y.V.; Ivashchenko, R.K.; Zakharova, N.P. Mechanical Properties of Sintered Materials. II. Effect of Porosity on the Ductility of Sintered Alloys. Sov. Powder Metall. Met. Ceram. 1991, 30, 250–256, Translated from Poroshkovaya Metall. 1991, 93–100 (Mar. 1991). Plenum Publishing Corporation. [Google Scholar]

- Huang, X.; Mei, S.; Li, Y.; Li, M.; Zhou, S.; Shang, H. Effect of TiC Content on Microstructure and Wear Performance of 17-4PH Stainless Steel Composites Manufactured by Indirect Metal 3D Printing. Materials 2023, 16, 6449. [Google Scholar] [CrossRef] [PubMed]

| Fe | Cr | Ni | Mn | Si | C | Cu | Nb + Ta |

|---|---|---|---|---|---|---|---|

| Bal. | 16–17 | 4–5 | ≤1.0 | ≤1.0 | ≤0.07 | 4 | 0.3 |

| Sample | Metal Powder (wt.%) | PW (wt.%) | SA (wt.%) |

|---|---|---|---|

| F1 | 93.0 | 5.0 | 2.0 |

| F2 | 94.0 | 4.3 | 1.7 |

| F3 | 94.5 | 3.9 | 1.6 |

| F4 | 95.0 | 3.6 | 1.4 |

| F5 | 95.5 | 3.2 | 1.3 |

| F6 | 96.0 | 2.9 | 1.1 |

| Temperature (°C) | Printing Speed (mm·s−1) | Flow Rate (mm3·s−1) |

|---|---|---|

| 80 | 10 | 5 |

| 80 | 7 | 10 |

| 80 | 5 | 15 |

| 90 | 5 | 15 |

| 90 | 7 | 10 |

| 90 | 10 | 5 |

| 95 | 5 | 15 |

| 95 | 7 | 5 |

| 95 | 10 | 10 |

| Sample | Nozzle Size (mm) | Layer Height (mm) | Temperature (°C) | Printing Speed (mm·s−1) | Flow Rate (mm3·s−1) |

|---|---|---|---|---|---|

| F1 | 1.2 | 1 | 80 | 10 | 5 |

| F2 | 1.2 | 1 | 90 | 10 | 5 |

| F3 | 1.2 | 1 | 90 | 7 | 10 |

| F4 | 1.2 | 1 | 90 | 7 | 10 |

| F5 | 1.2 | 1 | 95 | 5 | 15 |

| Sample | UTS (MPa) | YS (MPa) | Elongation at Break (%) |

|---|---|---|---|

| F4 | 618 ± 36 | 531 ± 25 | 1.5 ± 0.08 |

| F5 | 758 ± 32 | 622 ± 25 | 5.2 ± 0.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khazaee, S.; Bitar-Nehme, E.; Boukhili, R.; Kostenov, J.; Regnaud, W.; Martin, E. A Low-Viscosity, Recyclable Polymer-Based Binder Strategy for Metal FDM: Toward High Powder Loading, Sustainable Processing, and Comprehensive Characterization of 17-4PH Stainless Steel Parts. Polymers 2025, 17, 2575. https://doi.org/10.3390/polym17192575

Khazaee S, Bitar-Nehme E, Boukhili R, Kostenov J, Regnaud W, Martin E. A Low-Viscosity, Recyclable Polymer-Based Binder Strategy for Metal FDM: Toward High Powder Loading, Sustainable Processing, and Comprehensive Characterization of 17-4PH Stainless Steel Parts. Polymers. 2025; 17(19):2575. https://doi.org/10.3390/polym17192575

Chicago/Turabian StyleKhazaee, Sheyda, Elie Bitar-Nehme, Rachid Boukhili, Jovan Kostenov, William Regnaud, and Etienne Martin. 2025. "A Low-Viscosity, Recyclable Polymer-Based Binder Strategy for Metal FDM: Toward High Powder Loading, Sustainable Processing, and Comprehensive Characterization of 17-4PH Stainless Steel Parts" Polymers 17, no. 19: 2575. https://doi.org/10.3390/polym17192575

APA StyleKhazaee, S., Bitar-Nehme, E., Boukhili, R., Kostenov, J., Regnaud, W., & Martin, E. (2025). A Low-Viscosity, Recyclable Polymer-Based Binder Strategy for Metal FDM: Toward High Powder Loading, Sustainable Processing, and Comprehensive Characterization of 17-4PH Stainless Steel Parts. Polymers, 17(19), 2575. https://doi.org/10.3390/polym17192575