Assessing the Influence of Inorganic Nanoparticles on the Mechanical and Tribological Performance of PPS-Based Composites: A Comparative Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of PPS Composites

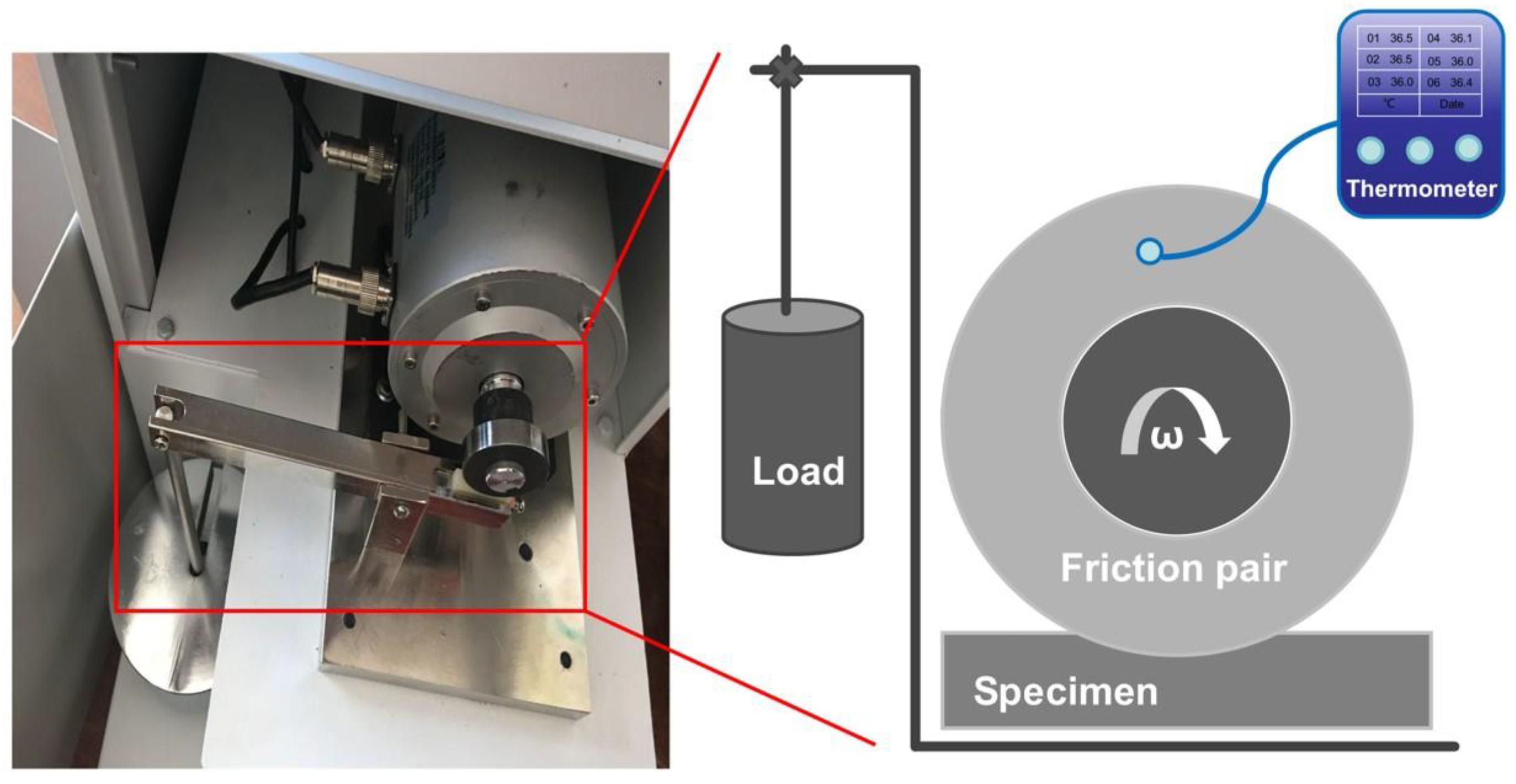

2.3. Characterizations

3. Results and Discussions

3.1. Morphology

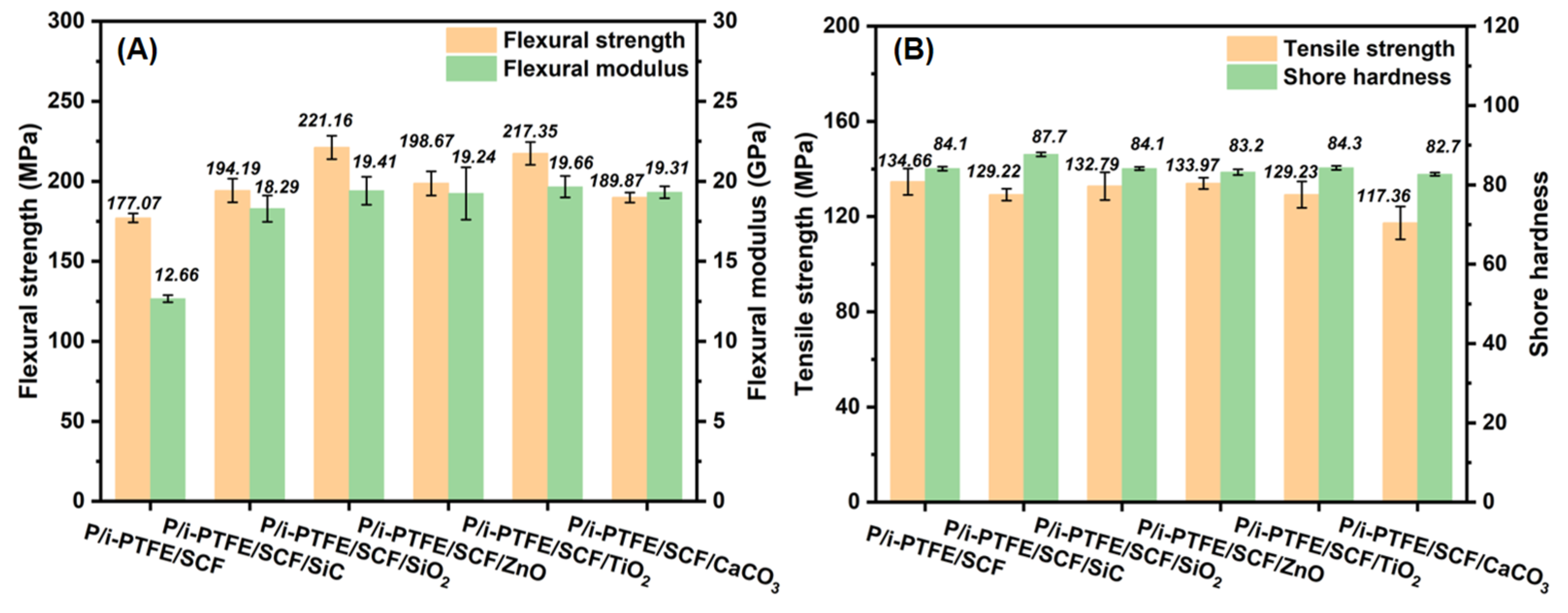

3.2. Mechanical Properties

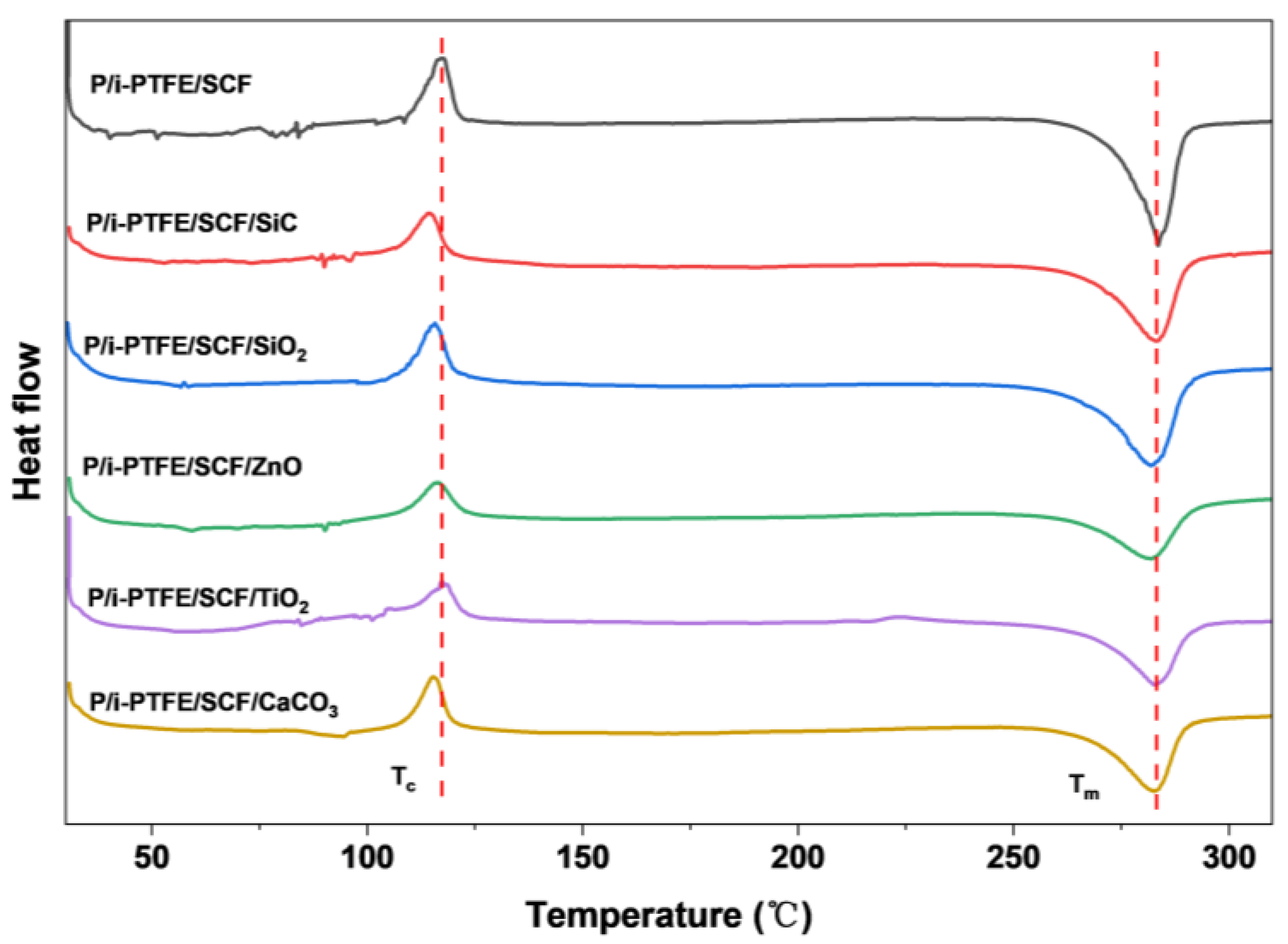

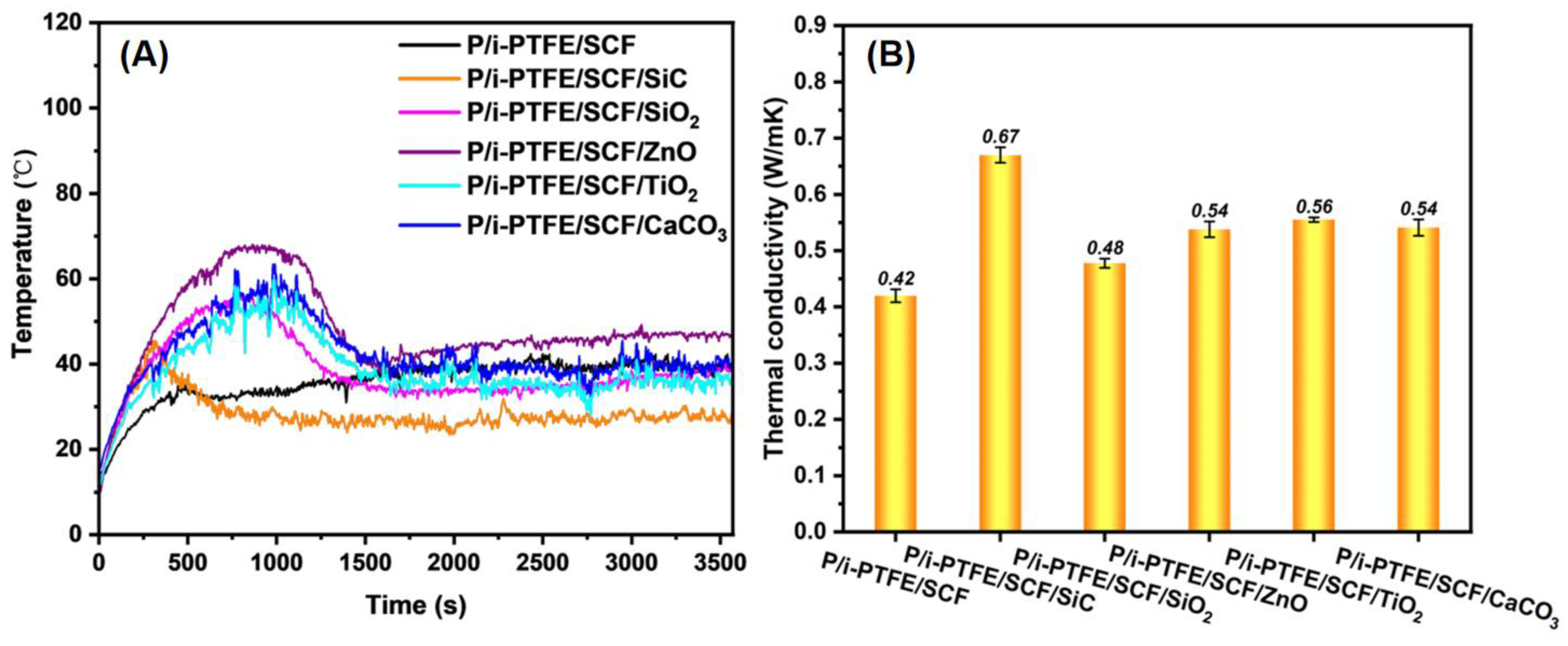

3.3. Thermal Properties

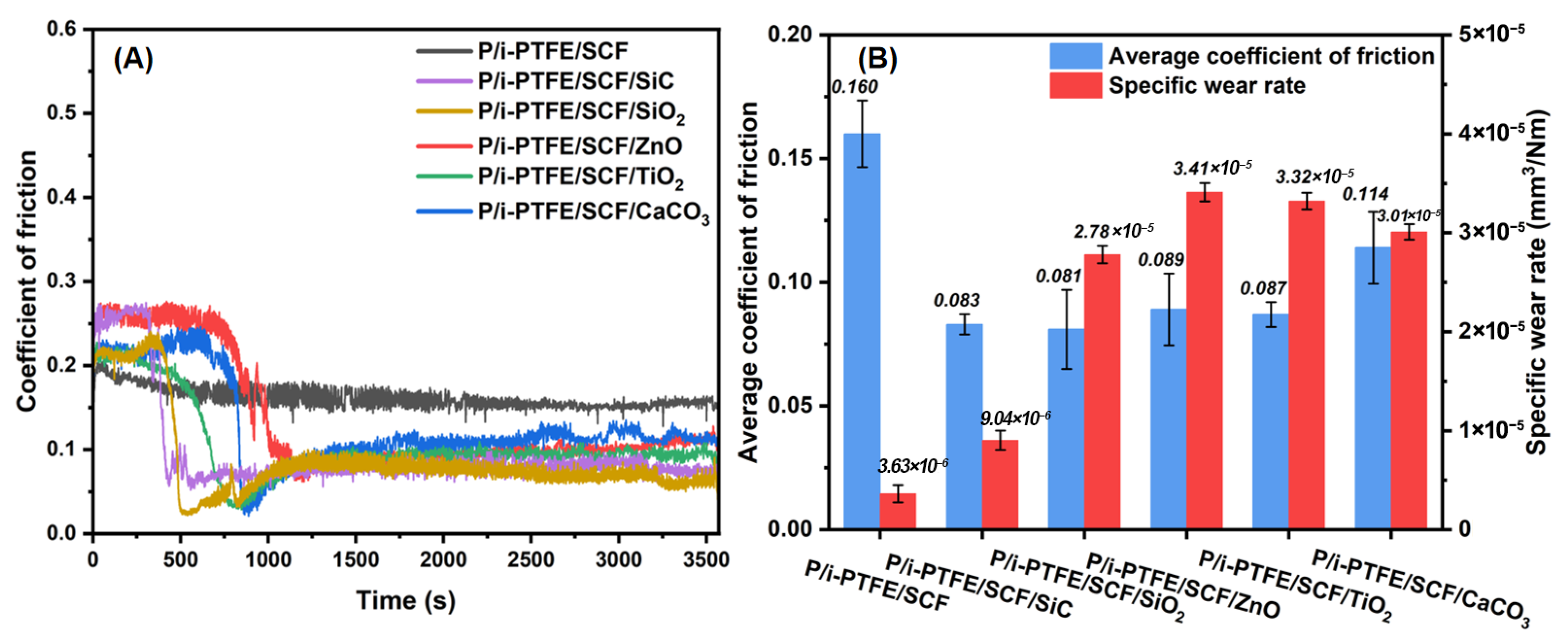

3.4. Tribological Properties

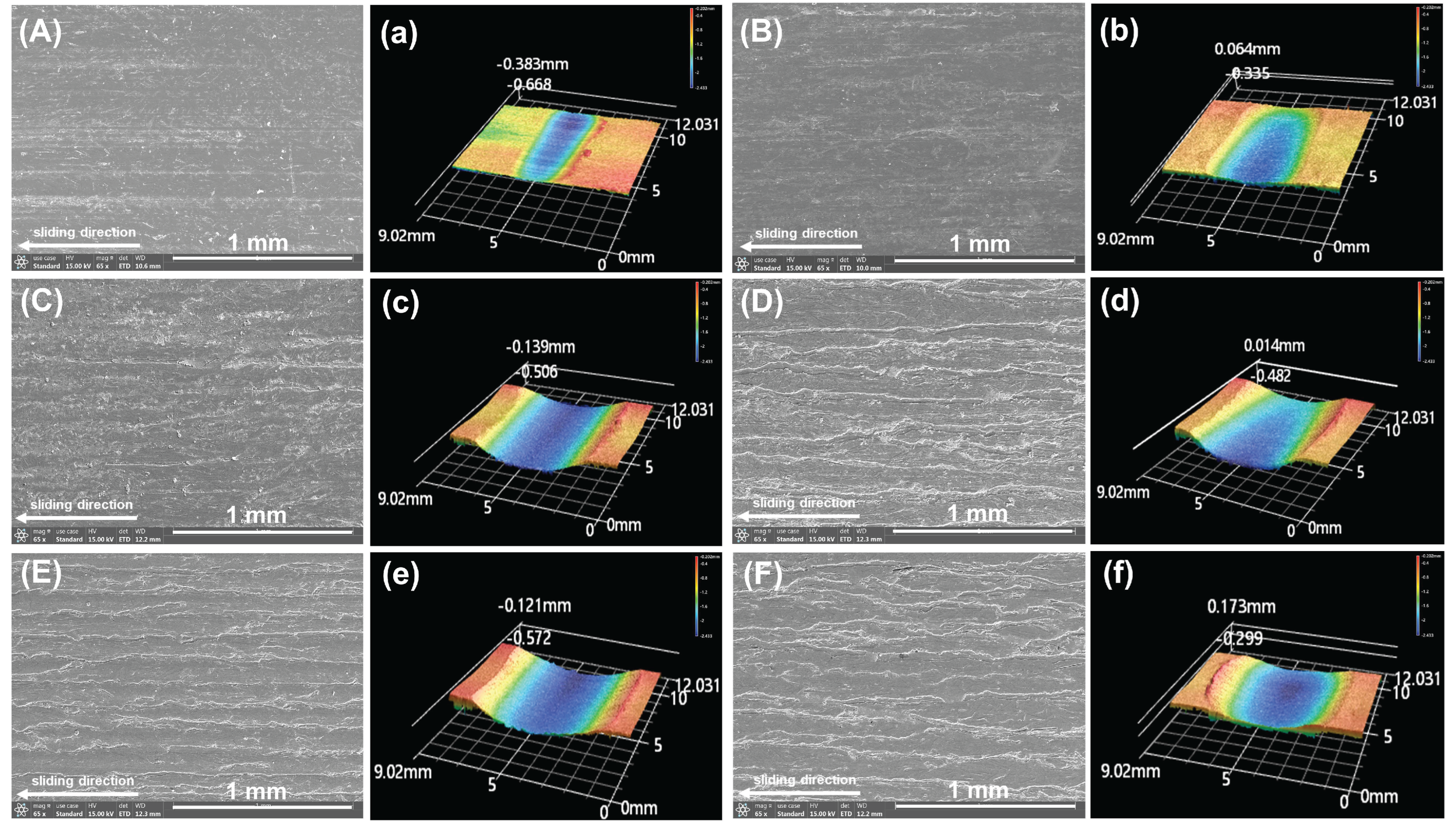

3.5. Wear Mechanism

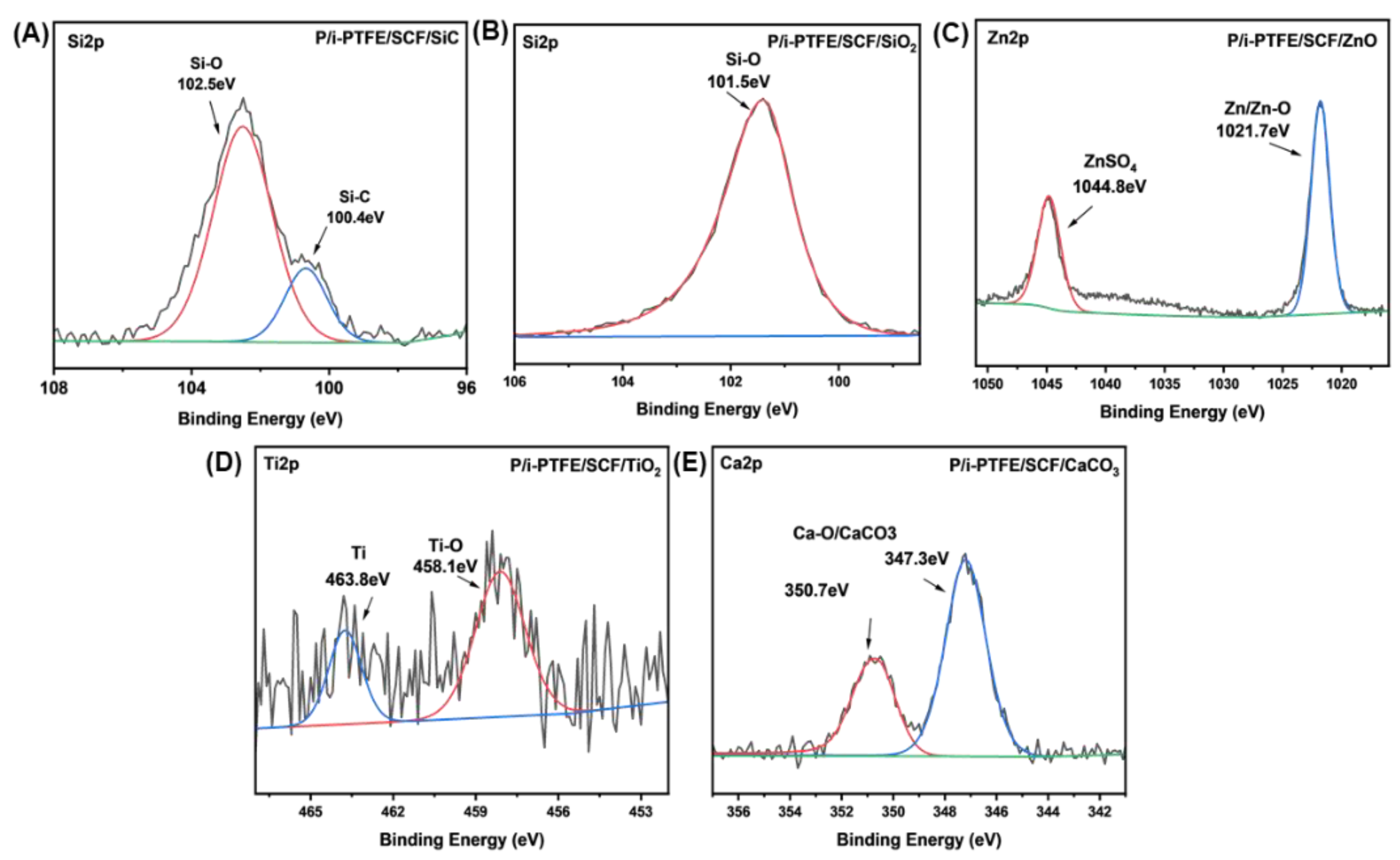

3.6. Friction-Induced Chemical Reactions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jost, H.P. Lubrication: Tribology; Education and Research; Report on the Present Position and Industry’s Needs; H.S. Office: London, UK, 1966; pp. 124–187. [Google Scholar]

- Ciulli, E. Tribology and industry: From the origins to 4.0. Front. Mech. Eng. 2019, 20, 5–55. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Ahalim, Z.A.; Ahmad, N.; Hanapi, M.F.; Zainal, M. Rapid surface treatment of grey cast iron for reduction of friction and wear by alumina coating using gas tunnel plasma spray. Mater. Chem. Phys. 2021, 260, 124134. [Google Scholar] [CrossRef]

- Dašić, P.; Franek, F.; Assenova, E.; Radovanović, M. International standardization and organizations in the field of tribology. Ind. Lubr. Tribol. 2003, 55, 287–291. [Google Scholar] [CrossRef]

- Jost, H.P. Tribology micro & macro economics: A road to economic savings. Tribol. Lubr. Technol. 2005, 61, 18. [Google Scholar]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Zirak, N.; Shirinbayan, M.; Deligant, M.; Tcharkhtchi, A. Toward polymeric and polymer composites impeller fabrication. Polymers 2021, 14, 97. [Google Scholar] [CrossRef]

- Kurdi, A.; Chang, L. Recent advances in high performance polymers-tribological aspects. Lubricants 2018, 7, 2. [Google Scholar] [CrossRef]

- Stoeffler, K.; Andjelic, S.; Legros, N.; Roberge, J.; Schougaard, S. Polyphenylene sulfide (PPS) composites reinforced with recycled carbon fiber. Compos. Sci. Technol. 2013, 84, 65–71. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, Q.; Wu, C.; Huang, J. Effect of carbon fiber reinforcement on the mechanical and tribological properties of polyamide 6/polyphenylene sulfide composites. Mater. Des. 2013, 44, 493–499. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J. Core-shell structured BN/PPS composite film for high thermal conductivity with low filler concentration. Compos. Sci. Technol. 2016, 134, 209–216. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Q.; Li, Y.; Zhou, S.; Zou, H.; Liang, M. Enhanced mechanical and tribological properties in polyphenylene sulfide/polytetrafluoroethylene composites reinforced by short carbon fiber. Compos. Part B Eng. 2016, 91, 579–588. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Xiang, J.; Gong, X.; Xie, P.; Chen, Y.; Zhou, S.; Zou, H.; Liang, M. Improving tribological performance of poly (phenylene sulfide) by incorporating PTFE fillers: The influence of filler type and concentrations. Polymers 2025, 17, 1222. [Google Scholar] [CrossRef]

- Kim, S.; Shin, M.; Jang, H. The wear mechanism of a polyphenylene sulfide (PPS) composite mixed with ethylene butyl acrylate (EBA). Tribol. Lett. 2012, 47, 165–173. [Google Scholar] [CrossRef]

- Yu, L.; Yang, S.; Liu, W.; Xue, Q. An investigation of the friction and wear behaviors of polyphenylene sulfide filled with solid lubricants. Polym. Eng. Sci. 2000, 40, 1825–1832. [Google Scholar] [CrossRef]

- Bahadur, S.; Sunkara, C. Effect of transfer film structure, composition and bonding on the tribological behavior of polyphenylene sulfide filled with nano particles of TiO2, ZnO, CuO and SiC. Wear 2005, 258, 1411–1421. [Google Scholar] [CrossRef]

- Manjunath, A.; Manjushree, H.; Nagaraja, K.C.; Pranesh, K.G. Role of E-glass fiber on mechanical, thermal and electrical properties of polyphenylene sulfide (PPS) composites. Mater. Today Proc. 2022, 62, 5439–5443. [Google Scholar] [CrossRef]

- Kato, A.; Nishioka, M.; Takahashi, Y.; Suda, T.; Sawabe, H.; Isoda, A.; Drozdova, O.; Hasegawa, T.; Izumi, T.; Nagata, K.; et al. Phase separation and mechanical properties of polyketone/polyamide polymer alloys. J. Appl. Polym. Sci. 2010, 116, 3056–3069. [Google Scholar] [CrossRef]

- Horiuchi, S.; Ishii, Y. Poly (phenylene sulfide) and low-density polyethylene reactive blends. Morphology, tribology, and moldability. Polym. J. 2000, 32, 339–347. [Google Scholar] [CrossRef]

- Menezes, P.; Rohatgi, P.; Omrani, E. Self-Lubricating Composites; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Hunke, H.; Soin, N.; Shah, T.; Kramer, E.; Witan, K.; Siores, E. Influence of plasma pre-treatment of polytetrafluoroethylene (PTFE) micropowders on the mechanical and tribological performance of Polyethersulfone (PESU)-PTFE composites. Wear 2015, 328–329, 480–487. [Google Scholar] [CrossRef]

- Shojaei, A.; Gholamalipour, S. Effect of chemical treatment of Teflon powder on the properties of polyamide 66/Teflon composites prepared by melt mixing. Macromol. Res. 2011, 19, 613–621. [Google Scholar] [CrossRef]

- Boittiaux, V.; Boucetta, F.; Combellas, C.; Kanoufi, F.; Thiébault, A.; Delamar, M.; Bertrand, P. Surface modification of halogenated polymers 3. Influence of additives such as alkali cations or nucleophiles on the magnesium reductive treatment of polytetrafluoroethylene. Polymer 1999, 40, 2011–2026. [Google Scholar] [CrossRef]

- Inagaki, N.; Tasaka, S.; Narushima, K.; Kanoufi, F.; Bertrand, P. Surface modification of poly(tetrafluoroethylene) with pulsed hydrogen plasma. J. Appl. Polym. Sci. 2002, 83, 340–348. [Google Scholar] [CrossRef]

- Khan, M.S.; Franke, R.; Gohs, U.; Lehmann, D.; Heinrich, G. Friction and wear behaviour of electron beam modified PTFE filled EPDM compounds. Wear 2009, 266, 175–183. [Google Scholar] [CrossRef]

- Chai, L.; Ning, K.; Qiao, L.; Wang, P.; Weng, L. Comparative study on microstructure, mechanical, and tribological property of gamma-irradiated polytetrafluoroethylene, polyetheretherketone, and polyimide polymers. Surf. Interface Anal. 2022, 54, 13–24. [Google Scholar] [CrossRef]

- Li, J.; Mei, J.; Peng, X.; Zou, H.; Zhou, S. Improving the tribological performance of polyphenylene sulfide by incorporating irradiation treated polytetrafluoroethylene powders. J. Appl. Polym. Sci. 2023, 140, e53998. [Google Scholar] [CrossRef]

- Zhao, Q.; Bahadur, S. A study of the modification of the friction and wear behavior of polyphenylene sulfide by particulate Ag2S and PbTe fillers. Wear 1998, 217, 62–72. [Google Scholar] [CrossRef]

- Yu, L.; Bahadur, S. An investigation of the transfer film characteristics and the tribological behaviors of polyphenylene sulfide composites in sliding against tool steel. Wear 1998, 214, 245–251. [Google Scholar] [CrossRef]

- Yu, L.; Bahadur, S.; Xue, Q. An investigation of the friction and wear behaviors of ceramic particle filled polyphenylene sulfide composites. Wear 1998, 214, 54–63. [Google Scholar] [CrossRef]

- Cho, M.; Bahadur, S. Study of the tribological synergistic effects in nano CuO-filled and fiber-reinforced polyphenylene sulfide composites. Wear 2005, 258, 835–845. [Google Scholar] [CrossRef]

- Aslan, C.; Karsli, N. Investigation of the synergetic effect of hybrid fillers of hexagonal boron nitride, graphene nanoplatelets and short basalt fibers for improved properties of polyphenylene sulfide composites. Polym. Bull. 2024, 81, 4969–4992. [Google Scholar] [CrossRef]

- GB/T 1040.2-2022; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. Standardization Administration of China: Beijing, China, 2022.

- GB/T 9341-2008; Plastics—Determination of Flexural Properties. Standardization Administration of China: Beijing, China, 2008.

- GB/T 2411-2008; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). Standardization Administration of China: Beijing, China, 2008.

- GB/T 3960-2016; Plastics—Test Method for Friction and Wear by Sliding. Standardization Administration of China: Beijing, China, 2016.

- Shi, Y.; Bai, Y.; Lei, Y.; Zhang, H.; Zhou, S.; Zou, H.; Liang, M.; Chen, Y. Simultaneously enhanced heat dissipation and tribological properties of polyphenylene sulfide-based composites via constructing segregated network structure. J. Mater. Sci. Technol. 2022, 99, 239–250. [Google Scholar] [CrossRef]

- Shi, Y.; Liang, M.; Zou, H.; Zhou, S.; Chen, Y. In Situ Microfibrillation of Polyamide 66 and Construction of Ordered Polytetrafluoroethylene Fibers to Significantly Reduce the Friction Coefficient of Polyphenylene Sulfide. Ind. Eng. Chem. Res. 2021, 60, 281–290. [Google Scholar] [CrossRef]

- GB/T 42919.1-2023; Plastics—Determination of Thermal Conductivity and Thermal Diffusivity—Part 4: Laser Flash Method. Standardization Administration of China: Beijing, China, 2023.

- Goyal, K.; Amol, R. Polyphenylene sulphide/graphite composites for EMI shielding applications. Adv. Mater. Lett. 2010, 1, 143–147. [Google Scholar] [CrossRef]

- Najim, A.S.; Ola, A.K. Enhancement of tribological and mechanical behavior of polyphenylene sulfide reinforced by titanium dioxide nanoparticles. Key. Eng. Mater. 2017, 724, 20–27. [Google Scholar] [CrossRef]

- Curtis, A.R.; Palin, W.M.; Fleming, G.J.; Shortall, A.C.; Marquis, P.M. The mechanical properties of nanofilled resin-based composites: Characterizing discrete filler particles and agglomerates using a micromanipulation technique. Dent. Mater. 2009, 25, 180–187. [Google Scholar] [CrossRef]

- Rajeshwari, P.; Dey, T. Novel HDPE nanocomposites containing aluminum nitride (nano) particles: Micro-structural and nano-mechanical properties correlation. Mater. Chem. Phys. Chem. Glass 2017, 190, 175–186. [Google Scholar] [CrossRef]

- Alexenko, V.; Hiep, L.; Buslovich, D.; Kornienko, L.; Panin, S. Effect of nanoparticles on mechanical and tribological properties of low-friction polyphenylene sulfide based composites. AIP. Conf. Proc. 2022, 2509, 56–78. [Google Scholar]

- Li, J.; Zhou, S.; Liang, M.; Zou, H. Fabrication of polyphenylene sulfide composites with integrated mechanical and tribological properties by synchronically adding irradiation-treated PTFE powders and short carbon fibers. Tribol. Int. 2023, 186, 108559. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, X.; Yamashita, S.; Kubota, M.; Kita, H. Effect of water temperature on tribological performance of B4C-SiC ceramics under water lubrication. Tribol. Lett. 2021, 69, 34. [Google Scholar] [CrossRef]

- Vyavhare, K.; Timmons, R.B.; Erdemir, A.; Edwards, B.L.; Aswath, P.B. Robust interfacial tribofilms by borate-and polymer-coated ZnO nanoparticles leading to improved wear protection under a boundary lubrication regime. Langmuir 2021, 37, 1743–1759. [Google Scholar] [CrossRef]

- Liu, D.; Zhao, G.; Wang, X. Tribological performance of lubricating greases based on calcium carbonate polymorphs under the boundary lubrication condition. Tribol. Lett. 2012, 47, 183–194. [Google Scholar] [CrossRef]

- Cao, W.; Gong, J.; Yang, D.; Gao, G.; Wang, H.; Ren, J.; Chen, S. Tribological behavior and energy dissipation characteristics of nano-Al2O3-reinforced PTFE-PPS composites in sliding system. J. Cent. South Univ. 2017, 24, 2001. [Google Scholar] [CrossRef]

- Shi, Y.; Liang, M.; Wu, H.; Chen, Y.; Zhou, S.; Zou, H.; Sun, T.; Zhang, H. Hybridization of Polytetrafluorethylene Fibers and Multiscale Short Carbon Fibers to Significantly Improve the Tribological Performance of Polyphenylene Sulfide. Adv. Eng. Mater. 2021, 23, 2000787. [Google Scholar] [CrossRef]

- Jain, A.; Somberg., J.; Emami, N. Development and Characterization of Multi-Scale Carbon Reinforced PPS Composites for Tribological Applications. Lubricants 2019, 7, 34. [Google Scholar] [CrossRef]

- Shi, Y.; Zhou, S.; Zou, H.; Liang, M.; Chen, Y. In situ micro-fibrillization and post annealing to significantly improve the tribological properties of polyphenylene sulfide/polyamide 66/polytetrafluoroethylene composites. Compos. Part B Eng. 2021, 216, 108841. [Google Scholar] [CrossRef]

- Kim, M.; Lee, J.; Cho, M.; Kim, J. Improvement of thermal and abrasion resistance performance of polyphenylene sulfide composite through 3-mercaptopropyl trimethoxysilane treatment of carbon fiber and graphene oxide fillers. Polym. Test. 2022, 108, 107517. [Google Scholar] [CrossRef]

- Qiu, X.; Gu, A.; Tang, W.; Tang, S.; Yu, Z. Effect of Perfluoropolymers on the Anti-Wear Properties of Carbon Fiber/Polyphenylene Sulfide Composites: A Comparative Study. ACS Omega 2022, 7, 40316. [Google Scholar] [CrossRef]

- Jiang, Z.; Gyurova, L.A.; Schlarb, A.K.; Friedrich, K.; Zhang, Z. Study on friction and wear behavior of polyphenylene sulfide composites reinforced by short carbon fibers and sub-micro TiO2 particles. Compos. Sci. Technol. 2008, 68, 734. [Google Scholar] [CrossRef]

| Sample ID | Composition (vol%) | |||||||

|---|---|---|---|---|---|---|---|---|

| PPS | i-PTFE | SCF | SiC | SiO2 | ZnO | TiO2 | CaCO3 | |

| P/i-PTFE/SCF | 62.81 | 16.53 | 20.66 | 0 | 0 | 0 | 0 | 0 |

| P/i-PTFE/SCF/SiC | 57.75 | 15.19 | 19.06 | 8 | 0 | 0 | 0 | 0 |

| P/i-PTFE/SCF/SiO2 | 57.75 | 15.19 | 19.06 | 0 | 8 | 0 | 0 | 0 |

| P/i-PTFE/SCF/ZnO | 57.75 | 15.19 | 19.06 | 0 | 0 | 8 | 0 | 0 |

| P/i-PTFE/SCF/TiO2 | 57.75 | 15.19 | 19.06 | 0 | 0 | 0 | 8 | 0 |

| P/i-PTFE/SCF/CaCO3 | 57.75 | 15.19 | 19.06 | 0 | 0 | 0 | 0 | 8 |

| Sample ID | Tc (°C) | Tm (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|

| P/i-PTFE/SCF | 117.34 | 284.19 | 20.58 | 29.11 |

| P/i-PTFE/SCF/SiC | 114.06 | 283.28 | 17.52 | 27.95 |

| P/i-PTFE/SCF/SiO2 | 115.52 | 282.38 | 20.30 | 28.60 |

| P/i-PTFE/SCF/ZnO | 116.23 | 282.23 | 14.98 | 23.12 |

| P/i-PTFE/SCF/TiO2 | 117.23 | 283.04 | 16.03 | 26.51 |

| P/i-PTFE/SCF/CaCO3 | 115.32 | 282.74 | 17.42 | 24.34 |

| Sample | Rw (μm) | Rd (μm) |

|---|---|---|

| P/i-PTFE/SCF | 2822.571 | 32.656 |

| P/i-PTFE/SCF/SiC | 5036.043 | 115.232 |

| P/i-PTFE/SCF/SiO2 | 6233.177 | 179.507 |

| P/i-PTFE/SCF/ZnO | 6832.973 | 225.694 |

| P/i-PTFE/SCF/TiO2 | 6950.581 | 266.067 |

| P/i-PTFE/SCF/CaCO3 | 6527.195 | 235.156 |

| Sample ID | μ | δ (×10−5 mm3/Nm) | Reference |

|---|---|---|---|

| PPS/i-PTFE/SCF/SiC | 0.083 | 0.904 | This work |

| PPS/CuO/CF | 0.221 | 4.36 | [32] |

| PPS/PTFE/Al2O3 | 0.255 | 1.14 | [50] |

| PPS/CNTs/SiC | 0.231 | 5.01 | [38] |

| PPS/PTFE/CF@GO | 0.165 | 3.12 | [51] |

| PPS/GR/CF | 0.342 | 1.52 | [52] |

| PPS/PTFE/PA | 0.174 | 1.34 | [53] |

| PPS/M-GO/M-CF | 0.176 | 3.23 | [54] |

| PPS/PFA/CF | 0.137 | 1.72 | [55] |

| PPS/TiO2/CF | 0.512 | 2.12 | [56] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Liang, M.; Zhao, X.; Zhou, S.; Zou, H. Assessing the Influence of Inorganic Nanoparticles on the Mechanical and Tribological Performance of PPS-Based Composites: A Comparative Study. Polymers 2025, 17, 2573. https://doi.org/10.3390/polym17192573

Li J, Liang M, Zhao X, Zhou S, Zou H. Assessing the Influence of Inorganic Nanoparticles on the Mechanical and Tribological Performance of PPS-Based Composites: A Comparative Study. Polymers. 2025; 17(19):2573. https://doi.org/10.3390/polym17192573

Chicago/Turabian StyleLi, Jixiang, Mei Liang, Xiaowen Zhao, Shengtai Zhou, and Huawei Zou. 2025. "Assessing the Influence of Inorganic Nanoparticles on the Mechanical and Tribological Performance of PPS-Based Composites: A Comparative Study" Polymers 17, no. 19: 2573. https://doi.org/10.3390/polym17192573

APA StyleLi, J., Liang, M., Zhao, X., Zhou, S., & Zou, H. (2025). Assessing the Influence of Inorganic Nanoparticles on the Mechanical and Tribological Performance of PPS-Based Composites: A Comparative Study. Polymers, 17(19), 2573. https://doi.org/10.3390/polym17192573