Valorization of Tomato Stem Waste: Biochar as a Filler in Three-Dimensional Printed PLA Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Production of Biochar from Tomato Stem Waste

2.2.1. Grinding of Tomato Stem Waste

2.2.2. Biochar Production via Slow Pyrolysis of Tomato Stem Powder

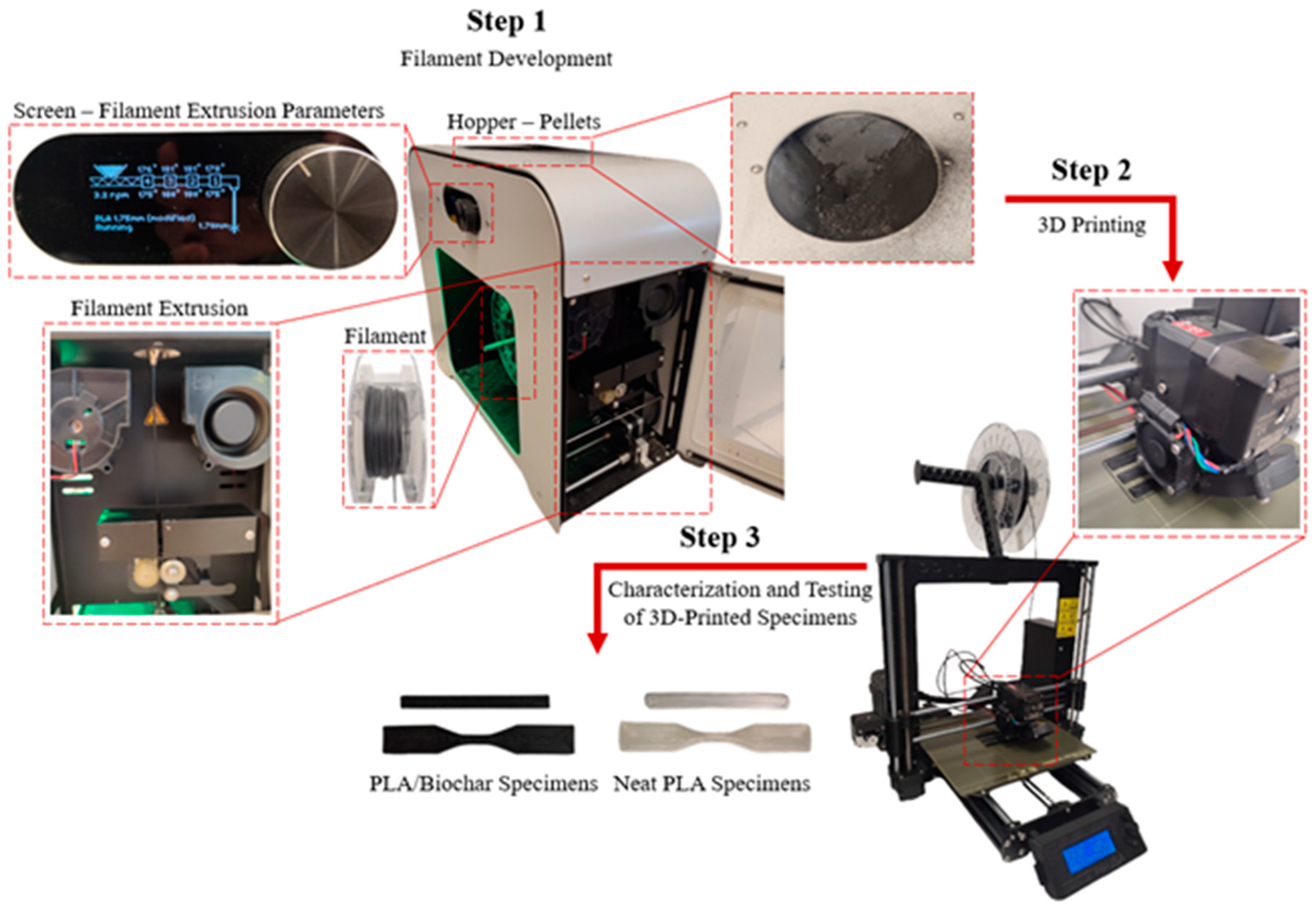

2.3. Production of PLA/Biochar Composite Filaments

2.4. Additive Manufacturing Process (Specimens with Rectilinear and Concentric Patterns)

2.5. Characterization and Testing

2.5.1. Elemental Analysis

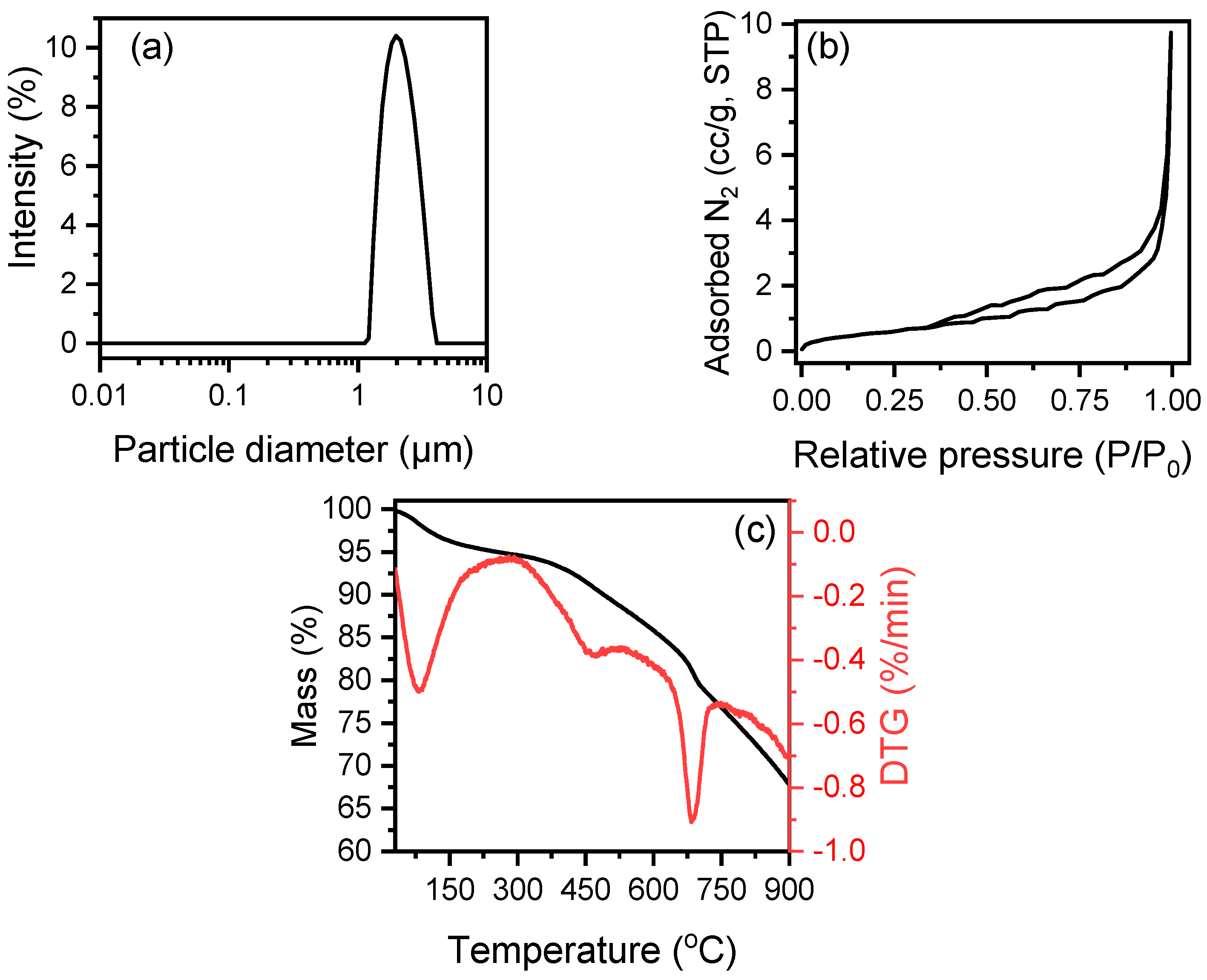

2.5.2. Dynamic Light Scattering (DLS)

2.5.3. N2 Physisorption

2.5.4. Thermal Gravimetric Analysis (TGA)

2.5.5. FTIR Spectroscopy

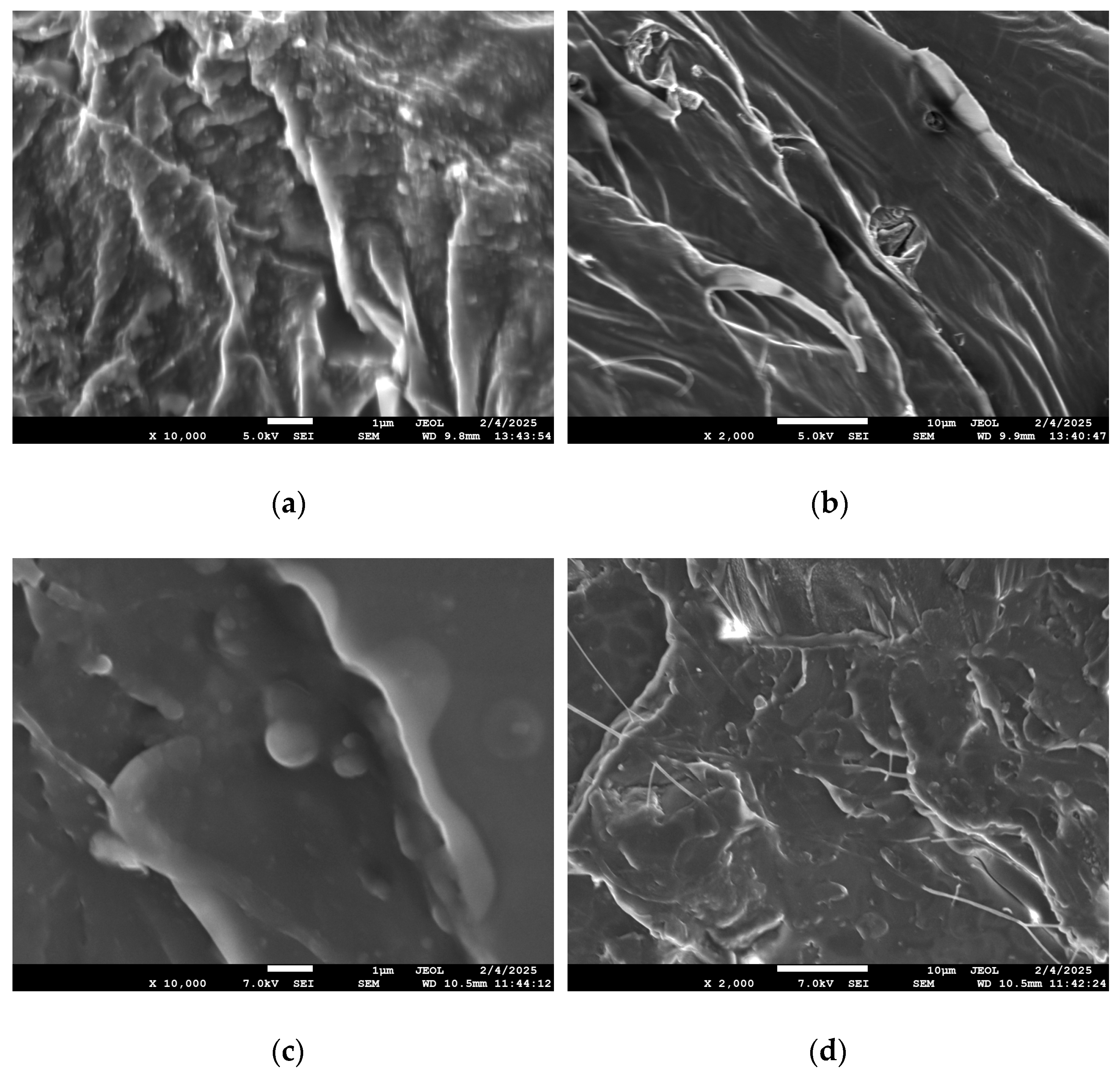

2.5.6. Scanning Electron Microscopy (SEM)

2.5.7. Differential Scanning Calorimetry (DSC)

2.5.8. Mechanical Properties

2.5.9. Dynamic Mechanical Analysis (DMA)

3. Results

3.1. Biochar Characterization

3.2. PLA/Biochar Composites Properties

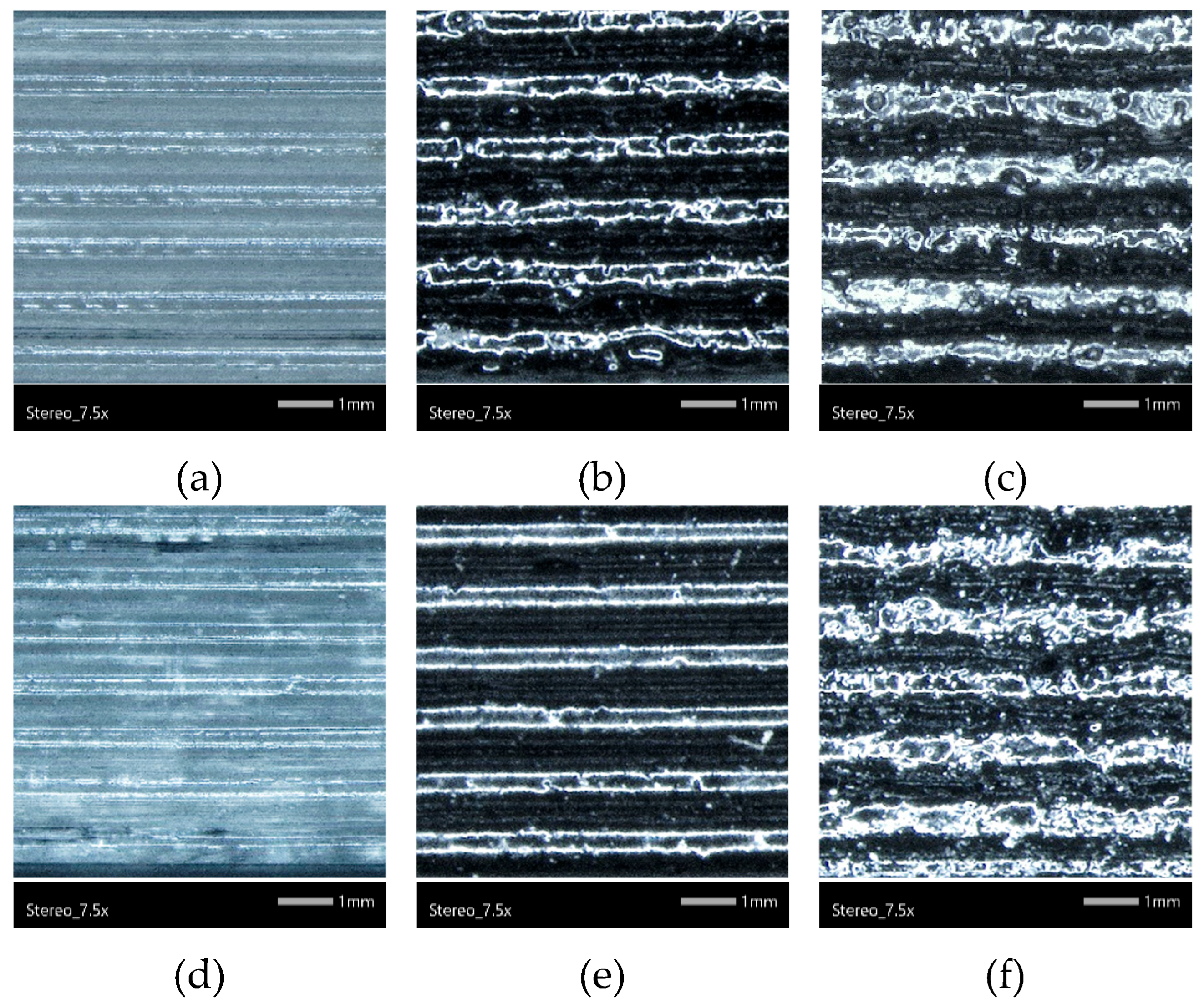

3.2.1. Morphological and Structural Characterization

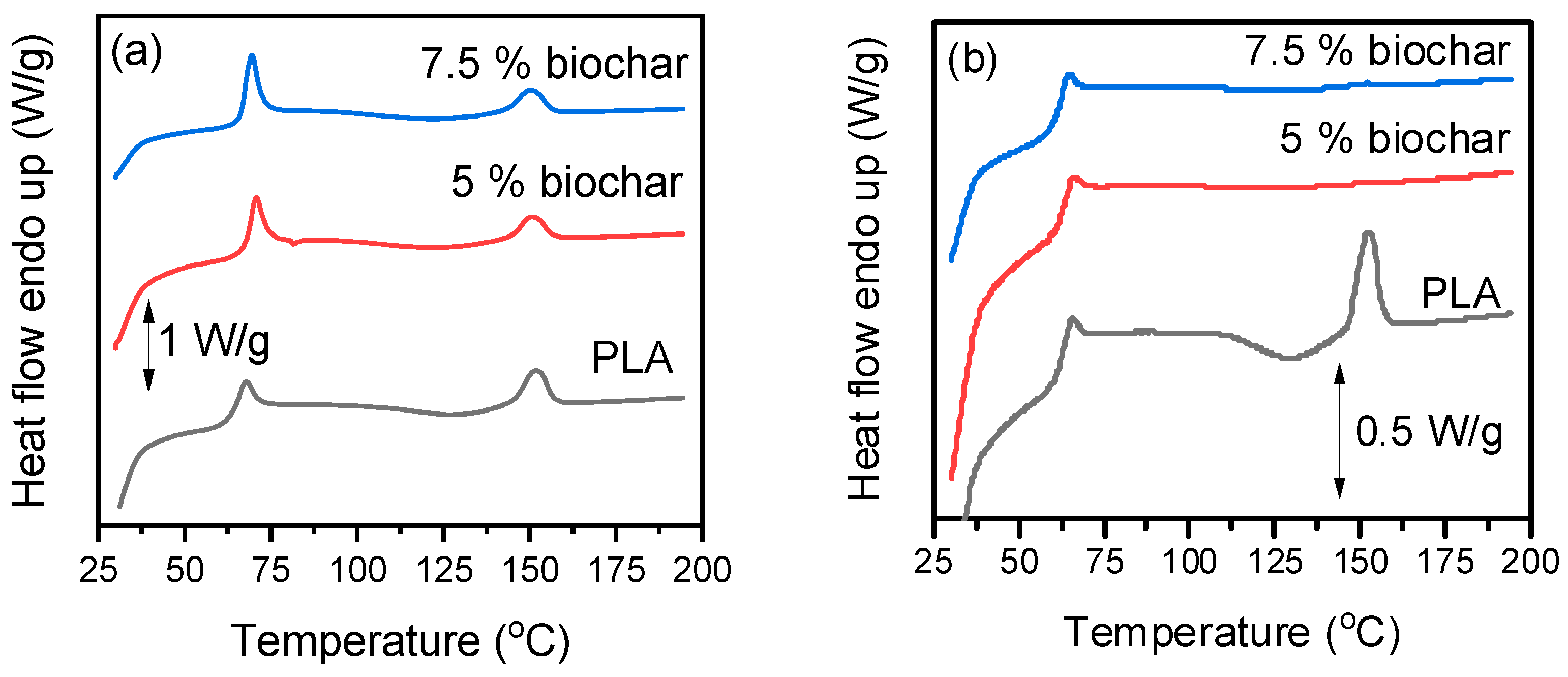

3.2.2. Thermal Transitions

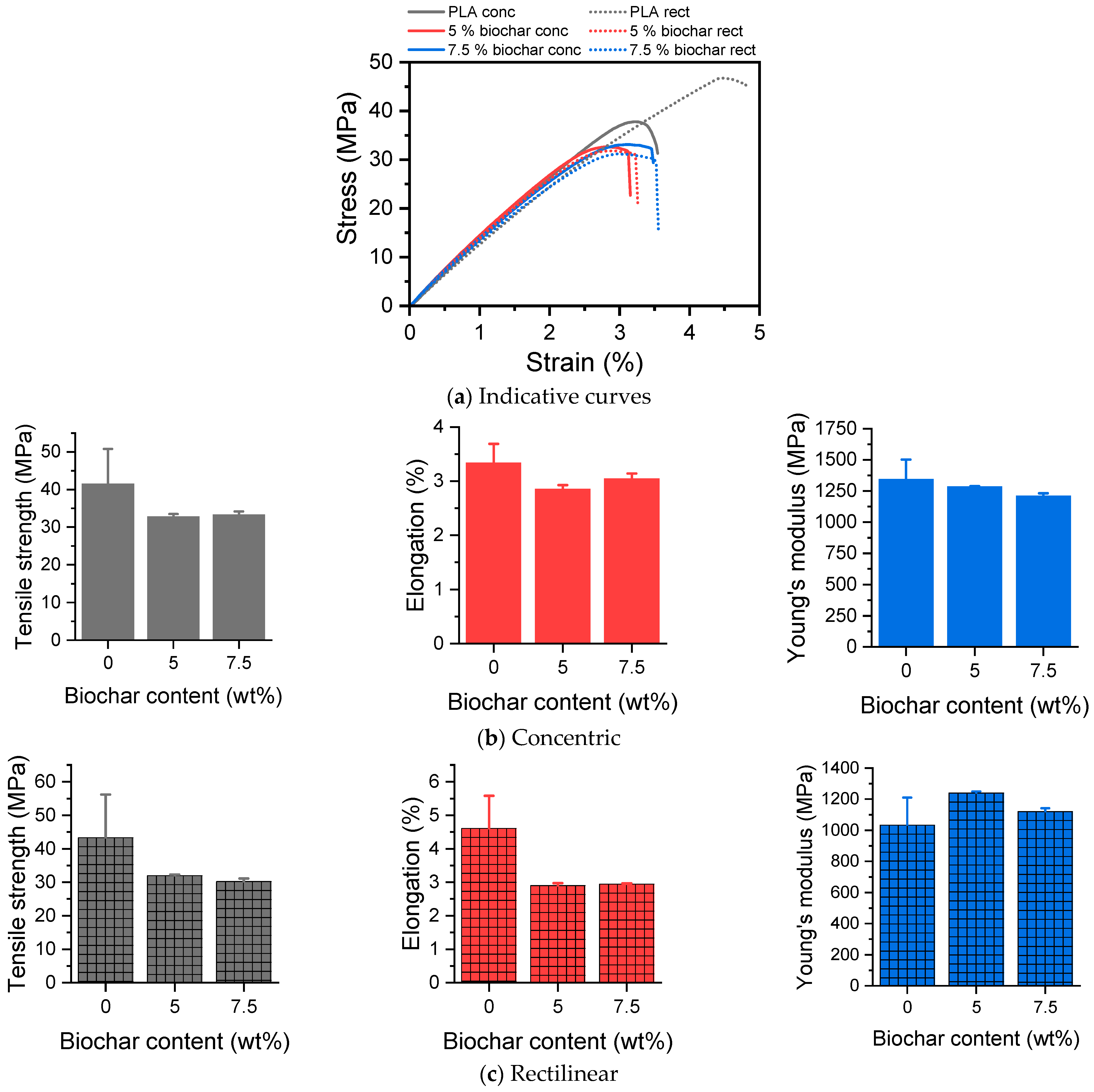

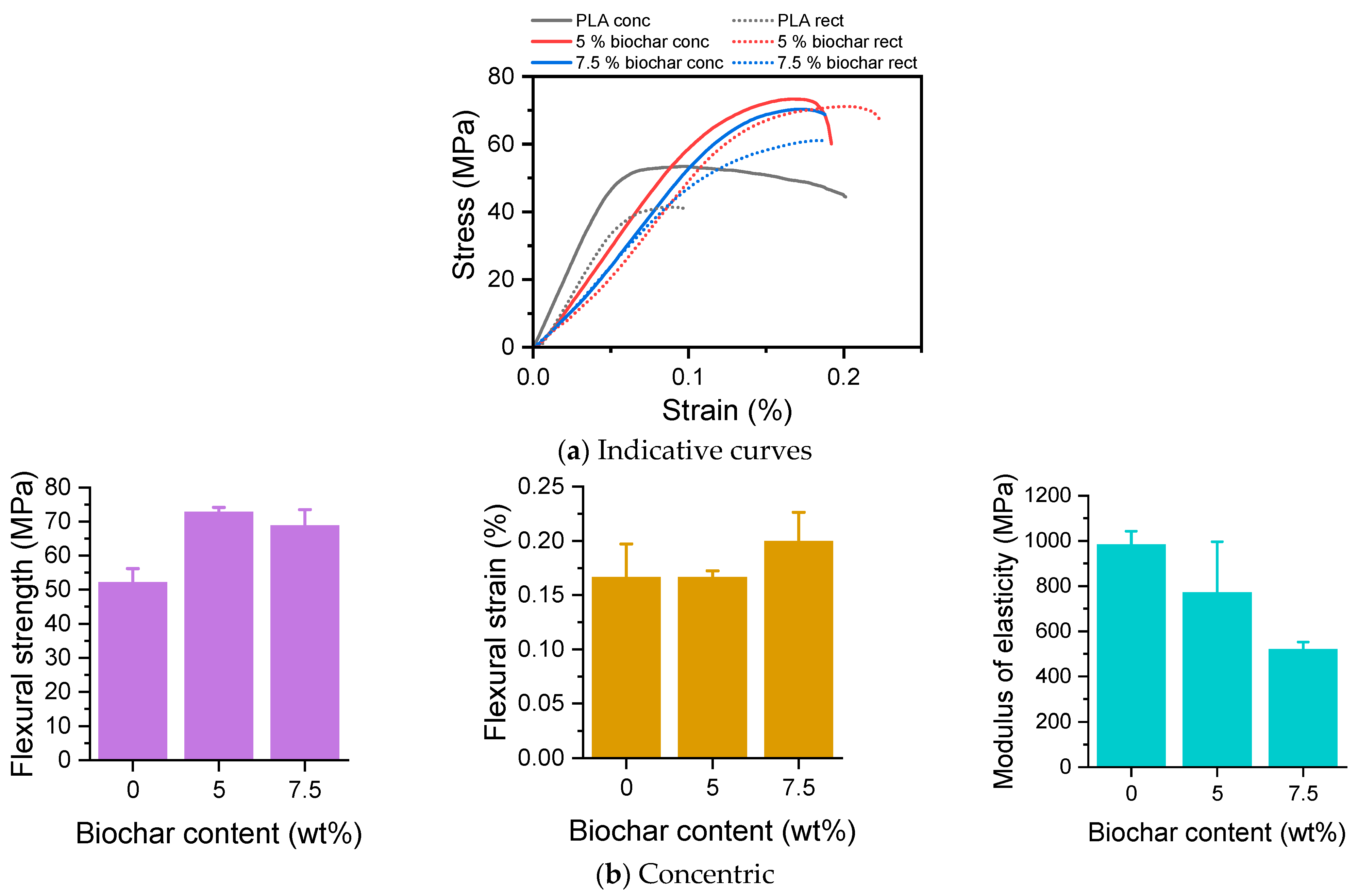

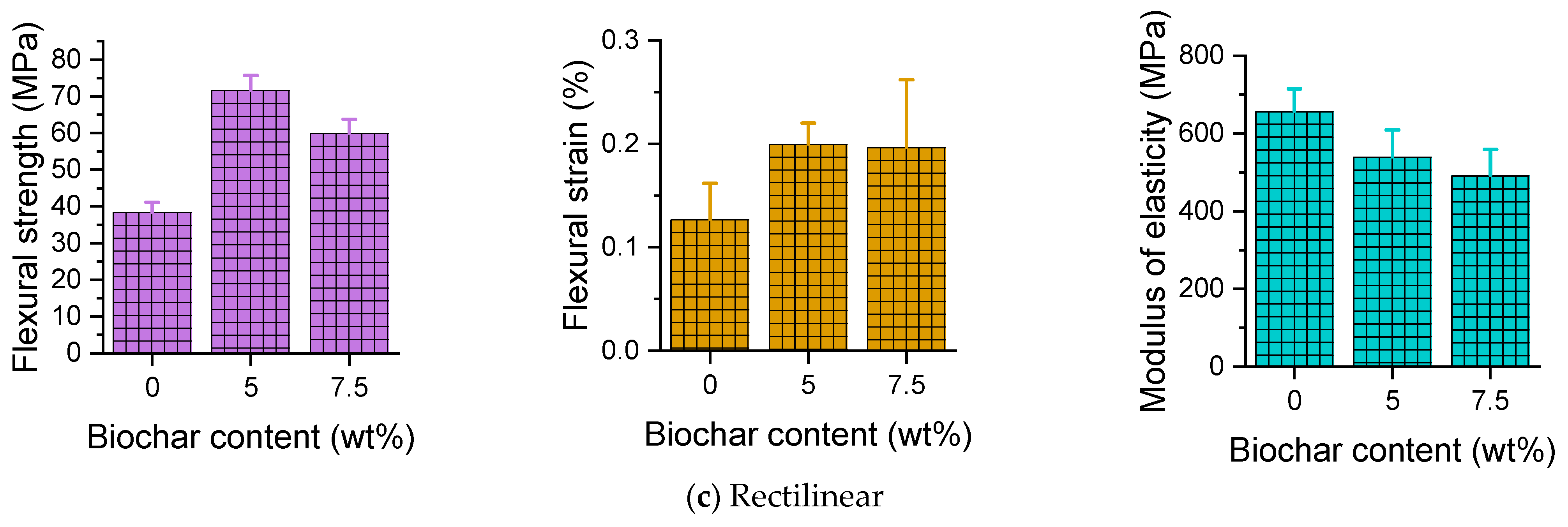

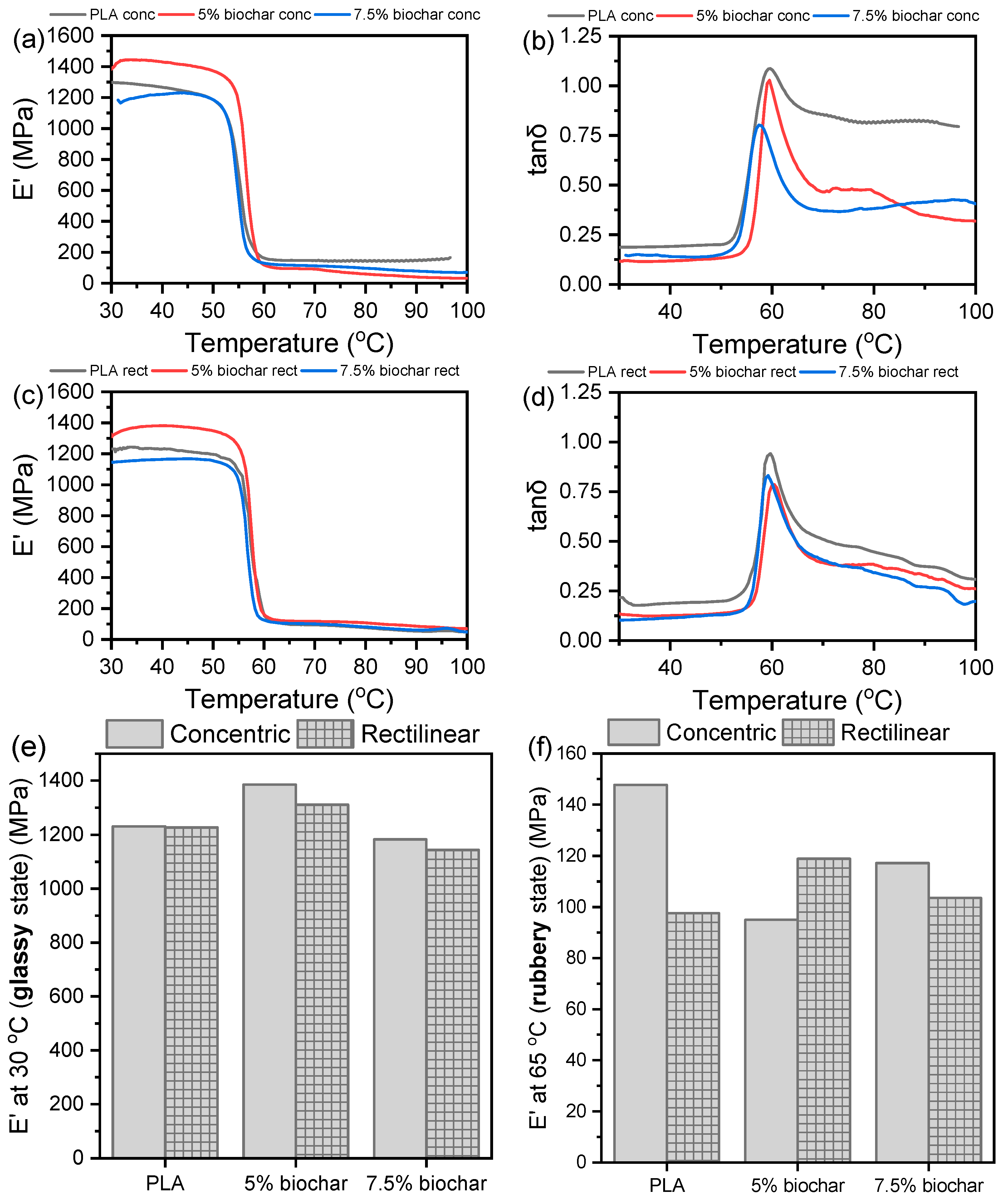

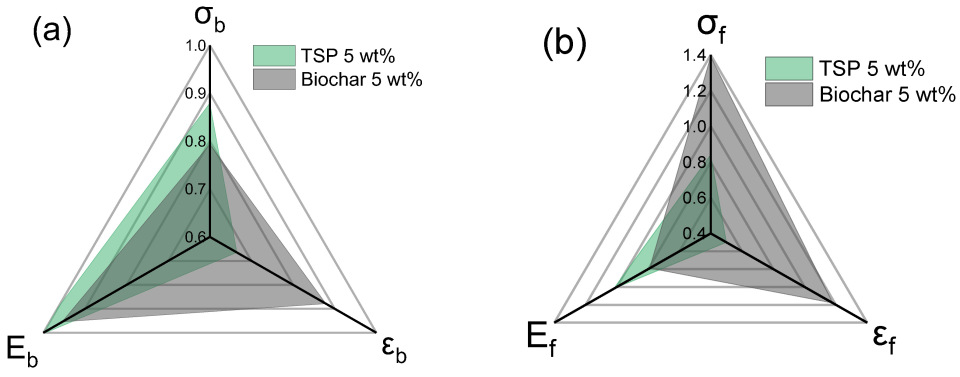

3.2.3. Mechanical and Thermomechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three dimensional |

| AM | Additive Manufacturing |

| ANOVA | Analysis of Variance |

| ASTM | American Society for Testing and Materials |

| BET | Brunauer–Emmett–Teller |

| DLS | Dynamic Light Scattering |

| DMA | Dynamic Mechanical Analysis |

| DSC | Differential Scanning Calorimetry |

| FDM | Fused Deposition Modeling |

| FFF | Fused Filament Fabrication |

| PBS | Poly(Butylene Succinate) |

| PLA | Poly(Lactic Acid) |

| PSD | Particle Size Distribution |

| SEM | Scanning Electron Microscopy |

| SLS | Selective Laser Sintering |

| TGA | Thermal Gravimetric Analysis |

| TSP | Tomato Stem Powder |

| UV | Ultraviolet |

References

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef]

- Zimmerman, J.B.; Anastas, P.T.; Erythropel, H.C.; Leitner, W. Designing for a green chemistry future. Science 2020, 367, 397–400. [Google Scholar] [CrossRef]

- Liu, Z.-H.; Liu, H.; Xu, T.; Zhao, Z.-M.; Ragauskas, A.J.; Li, B.-Z.; Yuan, J.S.; Yuan, Y.-J. Lignin valorization reshapes sustainable biomass refining. Renew. Sustain. Energy Rev. 2025, 211, 115296. [Google Scholar] [CrossRef]

- Wang, F.; Harindintwali, J.D.; Yuan, Z.; Wang, M.; Wang, F.; Li, S.; Yin, Z.; Huang, L.; Fu, Y.; Li, L.; et al. Technologies and perspectives for achieving carbon neutrality. Innovation 2021, 2, 100180. [Google Scholar] [CrossRef]

- Rex, P.; Mohammed Ismail, K.R.; Meenakshisundaram, N.; Barmavatu, P.; Sai Bharadwaj, A.V.S.L. Agricultural Biomass Waste to Biochar: A Review on Biochar Applications Using Machine Learning Approach and Circular Economy. ChemEngineering 2023, 7, 50. [Google Scholar] [CrossRef]

- Veksha, A.; McLaughlin, H.; Layzell, D.B.; Hill, J.M. Pyrolysis of wood to biochar: Increasing yield while maintaining microporosity. Bioresour. Technol. 2014, 153, 173–179. [Google Scholar] [CrossRef] [PubMed]

- Saravanan, A.; Kumar, P.S. Biochar derived carbonaceous material for various environmental applications: Systematic review. Environ. Res. 2022, 214, 113857. [Google Scholar] [CrossRef] [PubMed]

- Grutzmacher, P.; Puga, A.P.; Bibar, M.P.S.; Coscione, A.R.; Packer, A.P.; de Andrade, C.A. Carbon stability and mitigation of fertilizer induced N2O emissions in soil amended with biochar. Sci. Total Environ. 2018, 625, 1459–1466. [Google Scholar] [CrossRef] [PubMed]

- Man, K.Y.; Chow, K.L.; Man, Y.B.; Mo, W.Y.; Wong, M.H. Use of biochar as feed supplements for animal farming. Crit. Rev. Environ. Sci. Technol. 2021, 51, 187–217. [Google Scholar] [CrossRef]

- Lyu, H.; Zhang, Q.; Shen, B. Application of biochar and its composites in catalysis. Chemosphere 2020, 240, 124842. [Google Scholar] [CrossRef]

- Legan, M.; Gotvajn, A.Ž.; Zupan, K. Potential of biochar use in building materials. J. Environ. Manag. 2022, 309, 114704. [Google Scholar] [CrossRef]

- Qureshi, S.S.; Premchand; Javed, M.; Saeed, S.; Abro, R.; Mazari, S.A.; Mubarak, N.M.; Siddiqui, M.T.H.; Baloch, H.A.; Nizamuddin, S. Hydrothermal carbonization of oil palm trunk via taguchi method. Korean J. Chem. Eng. 2021, 38, 797–806. [Google Scholar] [CrossRef]

- Chen, W.; Meng, J.; Han, X.; Lan, Y.; Zhang, W. Past, present, and future of biochar. Biochar 2019, 1, 75–87. [Google Scholar] [CrossRef]

- Ye, L.; Peng, Z.; Wang, L.; Anzulevich, A.; Bychkov, I.; Kalganov, D.; Tang, H.; Rao, M.; Li, G.; Jiang, T. Use of Biochar for Sustainable Ferrous Metallurgy. JOM 2019, 71, 3931–3940. [Google Scholar] [CrossRef]

- Mekha, K.B.; Abu Talip Yusof, N.; Sudhakar, K.; Zainol, N.; Hasan, N.; Abdul Karim, M.S. Development of sustainable polymer-based dielectric composites from agricultural waste: A review. Heliyon 2024, 10, e39118. [Google Scholar] [CrossRef] [PubMed]

- Udayakumar, G.P.; Muthusamy, S.; Selvaganesh, B.; Sivarajasekar, N.; Rambabu, K.; Sivamani, S.; Sivakumar, N.; Maran, J.P.; Hosseini-Bandegharaei, A. Ecofriendly biopolymers and composites: Preparation and their applications in water-treatment. Biotechnol. Adv. 2021, 52, 107815. [Google Scholar] [CrossRef]

- Siryk, O.; Tomczyk, A.; Nosalewicz, A.; Szewczuk-Karpisz, K. Novel biochar-filled hydrogel composites: Assessment of multifunctionality and potential in environmental applications. J. Environ. Manag. 2024, 371, 123345. [Google Scholar] [CrossRef]

- Chavhan, M.P.; Khandelwal, M.; Arya, S.; Das, T.; Singh, A.; Ghodbane, O. A review of nanocomposites/hybrids made from biomass-derived carbons for electrochemical capacitors. Chem. Eng. J. 2024, 500, 157267. [Google Scholar] [CrossRef]

- Zhang, Y.; He, M.; Wang, L.; Yan, J.; Ma, B.; Zhu, X.; Ok, Y.S.; Mechtcherine, V.; Tsang, D.C.W. Biochar as construction materials for achieving carbon neutrality. Biochar 2022, 4, 59. [Google Scholar] [CrossRef]

- Vidakis, N.; Kalderis, D.; Petousis, M.; Maravelakis, E.; Mountakis, N.; Bolanakis, N.; Papadakis, V. Biochar filler in MEX and VPP additive manufacturing: Characterization and reinforcement effects in polylactic acid and standard grade resin matrices. Biochar 2023, 5, 39. [Google Scholar] [CrossRef]

- Petousis, M.; Maravelakis, E.; Kalderis, D.; Saltas, V.; Mountakis, N.; Spiridaki, M.; Bolanakis, N.; Argyros, A.; Papadakis, V.; Michailidis, N.; et al. Biochar for sustainable additive manufacturing: Thermal, mechanical, electrical, and rheological responses of polypropylene-biochar composites. Biomass Bioenergy 2024, 186, 107272. [Google Scholar] [CrossRef]

- Mohammed, Z.; Jeelani, S.; Rangari, V.K. Effect of Low-Temperature Plasma Treatment on Starch-Based Biochar and Its Reinforcement for Three-Dimensional Printed Polypropylene Biocomposites. ACS Omega 2022, 7, 39636–39647. [Google Scholar] [CrossRef]

- Baniasadi, H.; Chatzikosmidou, D.; Seppälä, J. Innovative integration of pyrolyzed biomass into polyamide 11: Sustainable advancements through in situ polymerization for enhanced mechanical, thermal, and additive manufacturing properties. Addit. Manuf. 2023, 78, 103869. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kalderis, D.; Michailidis, N.; Maravelakis, E.; Saltas, V.; Bolanakis, N.; Papadakis, V.; Spiridaki, M.; Argyros, A. Reinforced HDPE with optimized biochar content for material extrusion additive manufacturing: Morphological, rheological, electrical, and thermomechanical insights. Biochar 2024, 6, 37. [Google Scholar] [CrossRef]

- Pemas, S.; Baliakas, D.; Pechlivani, E.M.; Stefanidou, M. Mechanical Properties of Bio-Printed Mortars with Bio-Additives for Green and Sustainable Construction. Materials 2025, 18, 3375. [Google Scholar] [CrossRef]

- Pechlivani, E.M.; Melidis, L.; Pemas, S.; Katakalos, K.; Tzovaras, D.; Konstantinidis, A.A. On the Effect of Volumetric Energy Density on the Characteristics of 3D-Printed Metals and Alloys. Metals 2023, 13, 1776. [Google Scholar] [CrossRef]

- Pemas, S.; Kladovasilakis, N.; Pechlivani, E.M.; Natsios, I.; Melidis, L.; Chortis, A.; Konstantinidis, A.A.; Katakalos, K.; Tzetzis, D.; Tzovaras, D.; et al. Utilizing LDPE as a Second Life of Waste Plastic Through Pellet Extruder 3D Printing. In Supply Chains; Springer: Cham, Switzerland, 2025; pp. 26–38. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Forcael, E.; Medina, M.; Opazo-Vega, A.; Moreno, F.; Pincheira, G. Additive manufacturing in the construction industry. Autom. Constr. 2025, 169, 105888. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Pemas, S.; Sougioultzi, K.; Kouroutzidou, C.; Stefanidou, M.; Konstantinidis, A.A.; Pechlivani, E.M. Enhancing Clay-Based 3D-Printed Mortars with Polymeric Mesh Reinforcement Techniques. Polymers 2024, 16, 2182. [Google Scholar] [CrossRef]

- Pechlivani, E.M.; Papadimitriou, A.; Pemas, S.; Ntinas, G.; Tzovaras, D. IoT-Based Agro-Toolbox for Soil Analysis and Environmental Monitoring. Micromachines 2023, 14, 1698. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Truby, R.L.; Lewis, J.A. Printing soft matter in three dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Papadopoulou, K.; Ainali, N.M.; Mašek, O.; Bikiaris, D.N. Biochar as a UV Stabilizer: Its Impact on the Photostability of Poly(butylene succinate) Biocomposites. Polymers 2024, 16, 3080. [Google Scholar] [CrossRef]

- Papadopoulou, K.; Klonos, P.A.; Kyritsis, A.; Mašek, O.; Wurzer, C.; Tsachouridis, K.; Anastasiou, A.D.; Bikiaris, D.N. Synthesis and Study of Fully Biodegradable Composites Based on Poly(butylene succinate) and Biochar. Polymers 2023, 15, 1049. [Google Scholar] [CrossRef]

- Papadopoulou, K.; Klonos, P.A.; Kyritsis, A.; Tarani, E.; Chrissafis, K.; Mašek, O.; Tsachouridis, K.; Anastasiou, A.D.; Bikiaris, D.N. Synthesis and Characterization of PLA/Biochar Bio-Composites Containing Different Biochar Types and Content. Polymers 2025, 17, 263. [Google Scholar] [CrossRef]

- Papadopoulou, K.; Tarani, E.; Ainali, N.M.; Chrissafis, K.; Wurzer, C.; Mašek, O.; Bikiaris, D.N. The Effect of Biochar Addition on Thermal Stability and Decomposition Mechanism of Poly(butylene succinate) Bionanocomposites. Molecules 2023, 28, 5330. [Google Scholar] [CrossRef]

- Papadopoulou, K.; Tarani, E.; Chrissafis, K.; Mašek, O.; Bikiaris, D.N. Non-Isothermal Crystallization Kinetics of PBSu/Biochar Composites Studied by Isoconversional and Model Fitting Methods. Polymers 2023, 15, 1603. [Google Scholar] [CrossRef]

- Pemas, S.; Gkiliopoulos, D.; Samiotaki, C.; Bikiaris, D.N.; Terzopoulou, Z.; Pechlivani, E.M. Valorization of Tomato Agricultural Waste for 3D-Printed Polymer Composites Based on Poly(lactic acid). Polymers 2024, 16, 1536. [Google Scholar] [CrossRef]

- Stylianou, M.; Laifi, T.; Bennici, S.; Dutournie, P.; Limousy, L.; Agapiou, A.; Papamichael, I.; Khiari, B.; Jeguirim, M.; Zorpas, A.A. Tomato waste biochar in the framework of circular economy. Sci. Total Environ. 2023, 871, 161959. [Google Scholar] [CrossRef]

- Pemas, S.; Xanthopoulou, E.; Terzopoulou, Z.; Konstantopoulos, G.; Bikiaris, D.N.; Kottaridi, C.; Tzovaras, D.; Pechlivani, E.M. Exploration of Methodologies for Developing Antimicrobial Fused Filament Fabrication Parts. Materials 2023, 16, 6937. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2022.

- Fernandez-Vicente, M.; Calle, W.; Ferrandiz, S.; Conejero, A. Effect of Infill Parameters on Tensile Mechanical Behavior in Desktop 3D Printing. 3D Print. Addit. Manuf. 2016, 3, 183–192. [Google Scholar] [CrossRef]

- Yeoh, C.K.; Cheah, C.S.; Pushpanathan, R.; Song, C.C.; Tan, M.A.; Teh, P.L. Effect of infill pattern on mechanical properties of 3D printed PLA and cPLA. IOP Conf. Ser. Mater. Sci. Eng. 2020, 957, 012064. [Google Scholar] [CrossRef]

- Szymańska, J.; Doczekalska, B.; Strzemiecka, B.; Bednarek, W.H.; Woźniak, M.; Paukszta, D. Polypropylene Composites with Biochars from Miscanthus and Tomato Biomass—Part I: Thermal and Structural Properties. J. Nat. Fibers 2023, 20, 2282047. [Google Scholar] [CrossRef]

- Ayala-Cortés, A.; Arancibia-Bulnes, C.A.; Villafán-Vidales, H.I.; Lobato-Peralta, D.R.; Martínez-Casillas, D.C.; Cuentas-Gallegos, A.K. Solar pyrolysis of agave and tomato pruning wastes: Insights of the effect of pyrolysis operation parameters on the physicochemical properties of biochar. AIP Conf. Proc. 2019, 2126, 180001. [Google Scholar] [CrossRef]

- Di Blasi, C. Heat, momentum and mass transport through a shrinking biomass particle exposed to thermal radiation. Chem. Eng. Sci. 1996, 51, 1121–1132. [Google Scholar] [CrossRef]

- Barr, M.R.; Jervis, R.; Zhang, Y.; Bodey, A.J.; Rau, C.; Shearing, P.R.; Brett, D.J.L.; Titirici, M.M.; Volpe, R. Towards a mechanistic understanding of particle shrinkage during biomass pyrolysis via synchrotron X-ray microtomography and in-situ radiography. Sci. Rep. 2021, 11, 2656. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Skic, K.; Adamczuk, A.; Gryta, A.; Boguta, P.; Tóth, T.; Jozefaciuk, G. Surface areas and adsorption energies of biochars estimated from nitrogen and water vapour adsorption isotherms. Sci. Rep. 2024, 14, 30362. [Google Scholar] [CrossRef]

- McCall, M.A.; Watson, J.S.; Tan, J.S.W.; Sephton, M.A. Biochar Stability Revealed by FTIR and Machine Learning. ACS Sustain. Resour. Manag. 2025, 2, 842–852. [Google Scholar] [CrossRef]

- George, J.; Jung, D.; Bhattacharyya, D. Improvement of Electrical and Mechanical Properties of PLA/PBAT Composites Using Coconut Shell Biochar for Antistatic Applications. Appl. Sci. 2023, 13, 902. [Google Scholar] [CrossRef]

- Kane, S.; Ryan, C. Biochar from food waste as a sustainable replacement for carbon black in upcycled or compostable composites. Compos. Part C Open Access 2022, 8, 100274. [Google Scholar] [CrossRef]

- Wei, M.; Li, Q.; Chen, F.; Zhang, Y. Improving mechanical properties of PLA with pinus sylvestris char: Exploring thermal stability, interfacial strengthening mechanisms, and applications in 3D printing. Sustain. Chem. Pharm. 2024, 42, 101759. [Google Scholar] [CrossRef]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly(lactic Acid)–Biochar Biocomposites: Effect of Processing and Filler Content on Rheological, Thermal, and Mechanical Properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef]

- Khan, S.F.; Zakaria, H.; Chong, Y.L.; Saad, M.A.M.; Basaruddin, K. Effect of infill on tensile and flexural strength of 3D printed PLA parts. IOP Conf. Ser. Mater. Sci. Eng. 2018, 429, 012101. [Google Scholar] [CrossRef]

- Xia, Y.; Qian, S.; Zhang, X.; Zhang, Z.; Zhu, C. Biochar as an efficient reinforcing agent for poly(lactic acid)/poly(ε-caprolactone) biodegradable composites with high robustness and thermo-resistance. Ind. Crops Prod. 2024, 219, 119049. [Google Scholar] [CrossRef]

- Botta, C.; Grottola, C.M.; Amato, D.; Acocella, M.R. Biochar as Sustainable Filler of Recycled Polylactic Acid (PLA): A New Generation of Processable Biocomposites. Polymers 2024, 16, 3347. [Google Scholar] [CrossRef]

- Aup-Ngoen, K.; Noipitak, M. Effect of carbon-rich biochar on mechanical properties of PLA-biochar composites. Sustain. Chem. Pharm. 2020, 15, 100204. [Google Scholar] [CrossRef]

- Mandala, R.; Prasad, B.A.; Akella, S. Development and characterization of groundnut shell-derived biocarbon-reinforced polylactic acid composite filaments for FDM. J. Appl. Polym. Sci. 2024, 141, e55689. [Google Scholar] [CrossRef]

- Arora, N.; Dua, S.; Choudhary, V.; Singh, S.K.; Senthilkumar, T. Mechanical properties of novel PLA composite infused with betel nut waste biocarbon for sustainable 3D printing. Compos. Commun. 2025, 53, 102188. [Google Scholar] [CrossRef]

- Pudełko, A.; Postawa, P.; Stachowiak, T.; Malińska, K.; Dróżdż, D. Waste derived biochar as an alternative filler in biocomposites—Mechanical, thermal and morphological properties of biochar added biocomposites. J. Clean. Prod. 2021, 278, 123850. [Google Scholar] [CrossRef]

- Baniasadi, H.; Lizundia, E.; Paganelli, Z.; Dammann, N.; Välinen, L.; Seppälä, J.; Niskanen, J. Structure-property correlations study in biochar-enhanced polyamide composites for sustainable materials development. Compos. Part B Eng. 2024, 286, 111809. [Google Scholar] [CrossRef]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3D Printing PLA Waste to Produce Ceramic Based Particulate Reinforced Composite Using Abundant Silica-Sand: Mechanical Properties Characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef] [PubMed]

- Al Abir, A.; Chakrabarti, D.; Trindade, B. Fused Filament Fabricated Poly(lactic acid) Parts Reinforced with Short Carbon Fiber and Graphene Nanoparticles with Improved Tribological Properties. Polymers 2023, 15, 2451. [Google Scholar] [CrossRef]

- Anerao, P.; Kulkarni, A.; Munde, Y.; Shinde, A.; Das, O. Biochar reinforced PLA composite for fused deposition modelling (FDM): A parametric study on mechanical performance. Compos. Part C Open Access 2023, 12, 100406. [Google Scholar] [CrossRef]

- Bolanakis, N.; Vidakis, N.; Petousis, M.; Kalderis, D.; Galanakis, D.; Mountakis, N.; Maravelakis, E. Enhancing 3D Printing Materials with Biochar: A Literature Review. In Proceedings of the 2024 5th International Conference in Electronic Engineering, Information Technology & Education (EEITE), Chania, Greece, 29–31 May 2024; pp. 1–8. [Google Scholar]

- Bortoli, L.S.D.; Farias, R.d.; Mezalira, D.Z.; Schabbach, L.M.; Fredel, M.C. Functionalized carbon nanotubes for 3D-printed PLA-nanocomposites: Effects on thermal and mechanical properties. Mater. Today Commun. 2022, 31, 103402. [Google Scholar] [CrossRef]

- Camargo, J.C.; Machado, Á.R.; Almeida, E.C.; Silva, E.F.M.S. Mechanical properties of PLA-graphene filament for FDM 3D printing. Int. J. Adv. Manuf. Technol. 2019, 103, 2423–2443. [Google Scholar] [CrossRef]

- Chen, K.; Yu, L.; Cui, Y.; Jia, M.; Pan, K. Optimization of printing parameters of 3D-printed continuous glass fiber reinforced polylactic acid composites. Thin-Walled Struct. 2021, 164, 107717. [Google Scholar] [CrossRef]

- Chicos, L.-A.; Pop, M.A.; Zaharia, S.-M.; Lancea, C.; Buican, G.R.; Pascariu, I.S.; Stamate, V.-M. Fused Filament Fabrication of Short Glass Fiber-Reinforced Polylactic Acid Composites: Infill Density Influence on Mechanical and Thermal Properties. Polymers 2022, 14, 4988. [Google Scholar] [CrossRef]

- Chong, W.J.; Shen, S.; Li, Y.; Trinchi, A.; Pejak, D.; Kyratzis, I.; Sola, A.; Wen, C. Additive manufacturing of antibacterial PLA-ZnO nanocomposites: Benefits, limitations and open challenges. J. Mater. Sci. Technol. 2022, 111, 120–151. [Google Scholar] [CrossRef]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef]

- Dou, H.; Cheng, Y.; Ye, W.; Zhang, D.; Li, J.; Miao, Z.; Rudykh, S. Effect of Process Parameters on Tensile Mechanical Properties of 3D Printing Continuous Carbon Fiber-Reinforced PLA Composites. Materials 2020, 13, 3850. [Google Scholar] [CrossRef]

- Ismail, K.I.; Pang, R.; Ahmed, R.; Yap, T.C. Tensile Properties of In Situ 3D Printed Glass Fiber-Reinforced PLA. Polymers 2023, 15, 3436. [Google Scholar] [CrossRef]

- Le Duigou, A.; Correa, D.; Ueda, M.; Matsuzaki, R.; Castro, M. A review of 3D and 4D printing of natural fibre biocomposites. Mater. Des. 2020, 194, 108911. [Google Scholar] [CrossRef]

- Lee, D.; Wu, G.-Y. Parameters Affecting the Mechanical Properties of Three-Dimensional (3D) Printed Carbon Fiber-Reinforced Polylactide Composites. Polymers 2020, 12, 2456. [Google Scholar] [CrossRef]

- Liu, W.; Wu, N.; Pochiraju, K. Shape recovery characteristics of SiC/C/PLA composite filaments and 3D printed parts. Compos. Part A Appl. Sci. Manuf. 2018, 108, 1–11. [Google Scholar] [CrossRef]

- Luo, X.; Cheng, H.; Wu, X. Nanomaterials Reinforced Polymer Filament for Fused Deposition Modeling: A State-of-the-Art Review. Polymers 2023, 15, 2980. [Google Scholar] [CrossRef] [PubMed]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef]

- Öteyaka, M.Ö.; Aybar, K.; Öteyaka, H.C. Effect of Infill Ratio on the Tensile and Flexural Properties of Unreinforced and Carbon Fiber-Reinforced Polylactic Acid Manufactured by Fused Deposition Modeling. J. Mater. Eng. Perform. 2021, 30, 5203–5215. [Google Scholar] [CrossRef]

- Podsiadły, B.; Matuszewski, P.; Skalski, A.; Słoma, M. Carbon Nanotube-Based Composite Filaments for 3D Printing of Structural and Conductive Elements. Appl. Sci. 2021, 11, 1272. [Google Scholar] [CrossRef]

- Qian, Y.; Li, C.; Qi, Y.; Zhong, J. 3D printing of graphene oxide composites with well controlled alignment. Carbon 2021, 171, 777–784. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Arvindh Seshadri, S.; Devnani, G.L.; Sanjay, M.R.; Siengchin, S.; Prakash Maran, J.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites—A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Subramaniyan, M.; Karuppan, S. Mechanical properties of sandwich products obtained by 3D printing from PLA-PLA/Al2O3. Polimery 2024, 68, 646–651. [Google Scholar] [CrossRef]

- Suvanjumrat, C.; Chansoda, K.; Chookaew, W. Additive manufacturing advancement through large-scale screw-extrusion 3D printing for precision parawood powder/PLA furniture production. Clean. Eng. Technol. 2024, 20, 100753. [Google Scholar] [CrossRef]

- Valvez, S.; Santos, P.; Parente, J.M.; Silva, M.P.; Reis, P.N.B. 3D printed continuous carbon fiber reinforced PLA composites: A short review. Procedia Struct. Integr. 2020, 25, 394–399. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Sagris, D.; David, C.; Mountakis, N.; Spiridaki, M.; Maravelakis, E.; Charitidis, C.; Stratakis, E. Enhancing biocomposite critical quality indicators (CQIs): The impact of biochar content in additive manufacturing. Biochar 2025, 7, 22. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, D.; Wan, G.; Li, B.; Zhao, G. Glass fiber reinforced PLA composite with enhanced mechanical properties, thermal behavior, and foaming ability. Polymer 2019, 181, 121803. [Google Scholar] [CrossRef]

- Yang, L.; Li, S.; Zhou, X.; Liu, J.; Li, Y.; Yang, M.; Yuan, Q.; Zhang, W. Effects of carbon nanotube on the thermal, mechanical, and electrical properties of PLA/CNT printed parts in the FDM process. Synth. Met. 2019, 253, 122–130. [Google Scholar] [CrossRef]

- Yu, F.; Liu, T.; Zhao, X.; Yu, X.; Lu, A.; Wang, J. Effects of talc on the mechanical and thermal properties of polylactide. J. Appl. Polym. Sci. 2012, 125, E99–E109. [Google Scholar] [CrossRef]

- Zárybnická, L.; Ševčík, R.; Pokorný, J.; Machová, D.; Stránská, E.; Šál, J. CaCO3 Polymorphs Used as Additives in Filament Production for 3D Printing. Polymers 2022, 14, 199. [Google Scholar] [CrossRef] [PubMed]

- Patil, S.; Sathish, T.; Othman, N.A.; Tarawneh, B.; Saidani, T. Optimization of Compressive Strength Properties in Fused Deposition Modeling 3D Printed PLA/HA Composites for Bone Tissue Engineering Applications. Eng. Rep. 2025, 7, e70133. [Google Scholar] [CrossRef]

| Filament Type | Components | ||

|---|---|---|---|

| PLA | Biochar | Joncryl | |

| (wt.%) | (wt.%) | (wt.%) | |

| Neat PLA | 98 | - | 2 |

| PLA-5% Biochar | 93 | 5 | 2 |

| PLA-7.5% Biochar | 90.5 | 7.5 | 2 |

| Type of Test | Specimen Morphology | Infill Pattern | Number of Specimens | ||

|---|---|---|---|---|---|

| Neat PLA | PLA-5% Biochar | PLA-7.5% Biochar | |||

| Tensile Strength | ASTM D638 Standard, Type V | Concentric/ Rectilinear | 5/5 | 5/5 | 5/5 |

| Flexural Strength | rectangular parallelepiped 50 × 5 × 2 mm | Concentric/ Rectilinear | 5/5 | 5/5 | 5/5 |

| Dynamic Mechanical Analysis | rectangular parallelepiped 50 × 5 × 2 mm | Concentric/ Rectilinear | 5/5 | 5/5 | 5/5 |

| Elemental Analysis | DLS | N2 Physisorption | |||

|---|---|---|---|---|---|

| C (wt.%) | 61.93 | Particle diameter (μm) | 2.2 | BET surface area, SBET (m2/g) | 2.048 |

| H (wt.%) | 2.38 | Hydrodynamic diameter (μm) | 2.0 | ||

| N (wt.%) | 2.21 | Pore volume, VP (cc/g) | 0.015 | ||

| O (wt.%) | 33.48 | ||||

| Temperature Range | Tonset | TDTO max | Tend | Mass Loss |

|---|---|---|---|---|

| (°C) | (°C) | (°C) | (°C) | (%) |

| 24–220 | 24.3 | 81.6 | 132.4 | 4.65 |

| 220–520 | 403.6 | 472.8 | 514.3 | 9.18 |

| 520–760 | 637.0 | 684.0 | 752.8 | 9.86 |

| Sample | 1st Heating | 2nd Heating | ||||||

|---|---|---|---|---|---|---|---|---|

| Tc | Tcc | Tm | Xc | Tc | Tcc | Tm | Xc | |

| (°C) | (°C) | (°C) | (%) | (°C) | (°C) | (°C) | (%) | |

| Neat PLA | 63 | 127 | 152 | 0.16 | 61.7 | 128 | 152.3 | 0 |

| PLA-5% Biochar | 66.7 | 121.7 | 150.7 | 0 | 62.7 | 125.7 | 151.4 | 0 |

| PLA-7.5% Biochar | 65.6 | 118.74 | 150.4 | 0 | 61.6 | 123.7 | 151.1 | 0 |

| Property | Neat PLA | PLA-5% Biochar | PLA-7.5% Biochar | |||

|---|---|---|---|---|---|---|

| Concentric | Rectilinear | Concentric | Rectilinear | Concentric | Rectilinear | |

| Tensile Testing | ||||||

| Tensile strength, σb (MPa) | 41.5 ± 9.2 | 46.8 ± 12.8 | 32.9 ± 0.6 | 32.0 ± 0.2 | 33.4 ± 0.8 | 30.3 ± 0.8 |

| Elongation at break, εb (%) | 3.3 ± 0.3 | 4.6 ± 1.0 | 2.9 ± 0.1 | 2.9 ± 0.1 | 3.3 ± 0.1 | 3.0 ± 0.0 |

| Young’s modulus, Eb (MPa) | 1347 ± 155 | 1149 ± 175 | 1286 ± 2 | 1242 ± 8 | 1212 ± 19 | 1123 ± 19 |

| Flexural Testing | ||||||

| Flexural strength, σf (MPa) | 52.3 ± 3.9 | 38.5 ± 2.6 | 72.9 ± 1.3 | 71.7 ± 4.0 | 68.9 ± 4.7 | 60.0 ± 3.7 |

| Flexural strain at break, εf (%) | 0.17 ± 0.03 | 0.13 ± 0.04 | 0.17 ± 0.01 | 0.20 ± 0.02 | 0.20 ± 0.03 | 0.20 ± 0.07 |

| Modulus of elasticity, Ef (MPa) | 984.0 ± 59.3 | 657.8 ± 56.7 | 772.2 ± 223.3 | 540.1 ± 69.7 | 520.7 ± 31.4 | 492.2 ± 66.4 |

| Dynamic Mechanical Analysis | ||||||

| Storage modulus, E’, at 30 °C (MPa) | 1298 | 1228 | 1385 | 1310 | 1183 | 1145 |

| Storage modulus, E’, at 65 °C (MPa) | 147 | 148 | 95 | 119 | 117 | 104 |

| Glass transition temperature, Tg (°C) | 59.3 | 59.8 | 59.5 | 60.4 | 57.4 | 59.2 |

| Additive Type | Typical Additives | Mechanical Impact | Thermal Stability | Printability |

|---|---|---|---|---|

| Biochar [21,61,69,70,91] | Biochar from different sources at 5–40 wt.% loadings | Mechanical reinforcement at low (5–10 wt.%) loadings; mechanical properties decrease in higher (>10 wt.%) loadings | Minor changes in thermal stability, glass transition temperature, and degree of crystallinity | Potential increase in agglomeration, extrusion torque, and nozzle abrasion; moisture sensitivity |

| Natural fibers [42,76,79,83,87,89] | Wood powder, natural fibers, etc. | Moderate increase in stiffness; reduced tensile strength | Minor improvement in heat deflection | Increased nozzle wear; moisture sensitivity |

| Synthetic fibers [73,74,77,78,80,84,90,92] | Carbon fibers, glass fibers, Kevlar, etc. | Significant gain in tensile strength and stiffness | Substantial increase in glass transition | Higher extrusion torque; nozzle clogging risk |

| Inorganic particles [67,75,81,82,88,94,95,96] | Calcium carbonate, talc, metal oxides, etc. | Improved dimensional stability; slight stiffness gain | Enhanced dimensional accuracy | Better melt flow; reduced shrinkage |

| Nanomaterials [68,71,72,85,86,93] | Graphene, carbon nanotubes, etc. | Exceptional rise in strength and modulus | Considerable increase in thermal stability | Requires controlled dispersion; potential nozzle abrasion |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gkiliopoulos, D.; Pemas, S.; Torofias, S.; Triantafyllidis, K.; Bikiaris, D.N.; Terzopoulou, Z.; Pechlivani, E.M. Valorization of Tomato Stem Waste: Biochar as a Filler in Three-Dimensional Printed PLA Composites. Polymers 2025, 17, 2565. https://doi.org/10.3390/polym17192565

Gkiliopoulos D, Pemas S, Torofias S, Triantafyllidis K, Bikiaris DN, Terzopoulou Z, Pechlivani EM. Valorization of Tomato Stem Waste: Biochar as a Filler in Three-Dimensional Printed PLA Composites. Polymers. 2025; 17(19):2565. https://doi.org/10.3390/polym17192565

Chicago/Turabian StyleGkiliopoulos, Dimitrios, Sotirios Pemas, Stylianos Torofias, Konstantinos Triantafyllidis, Dimitrios N. Bikiaris, Zoi Terzopoulou, and Eleftheria Maria Pechlivani. 2025. "Valorization of Tomato Stem Waste: Biochar as a Filler in Three-Dimensional Printed PLA Composites" Polymers 17, no. 19: 2565. https://doi.org/10.3390/polym17192565

APA StyleGkiliopoulos, D., Pemas, S., Torofias, S., Triantafyllidis, K., Bikiaris, D. N., Terzopoulou, Z., & Pechlivani, E. M. (2025). Valorization of Tomato Stem Waste: Biochar as a Filler in Three-Dimensional Printed PLA Composites. Polymers, 17(19), 2565. https://doi.org/10.3390/polym17192565