From Waste to Wires: PBAT/Lignin Biocomposites Functionalized by a CO2 Laser for Transient Electronics

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

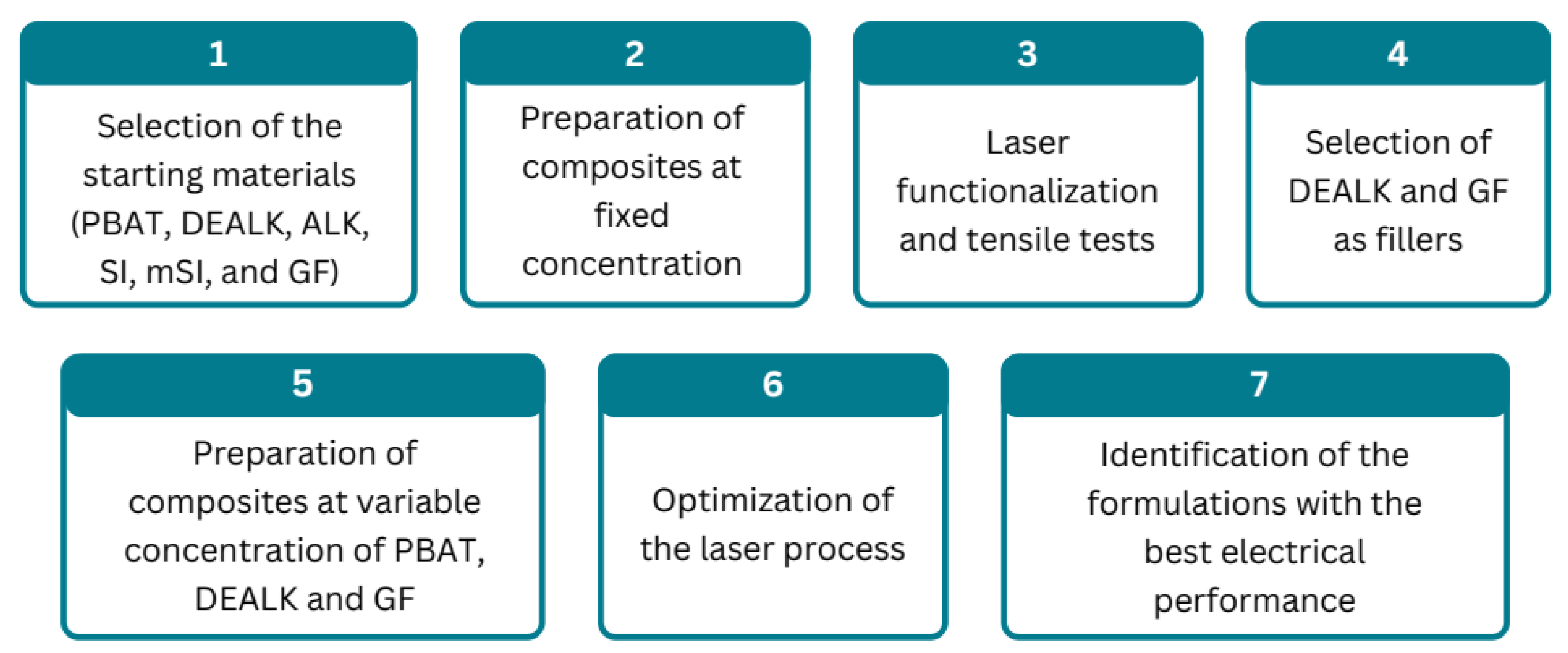

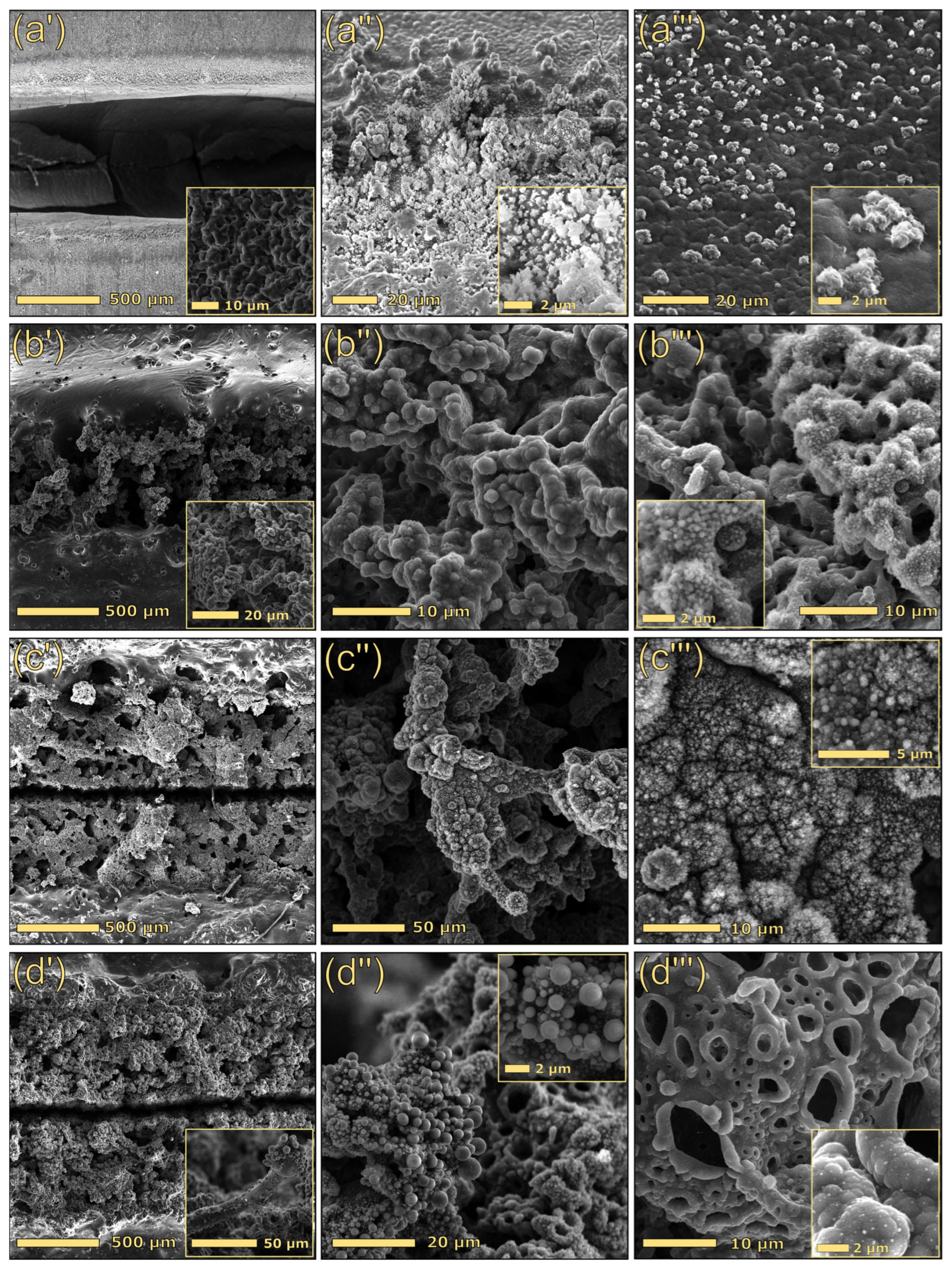

3.1. Preliminary Tests

3.1.1. Mechanical Properties

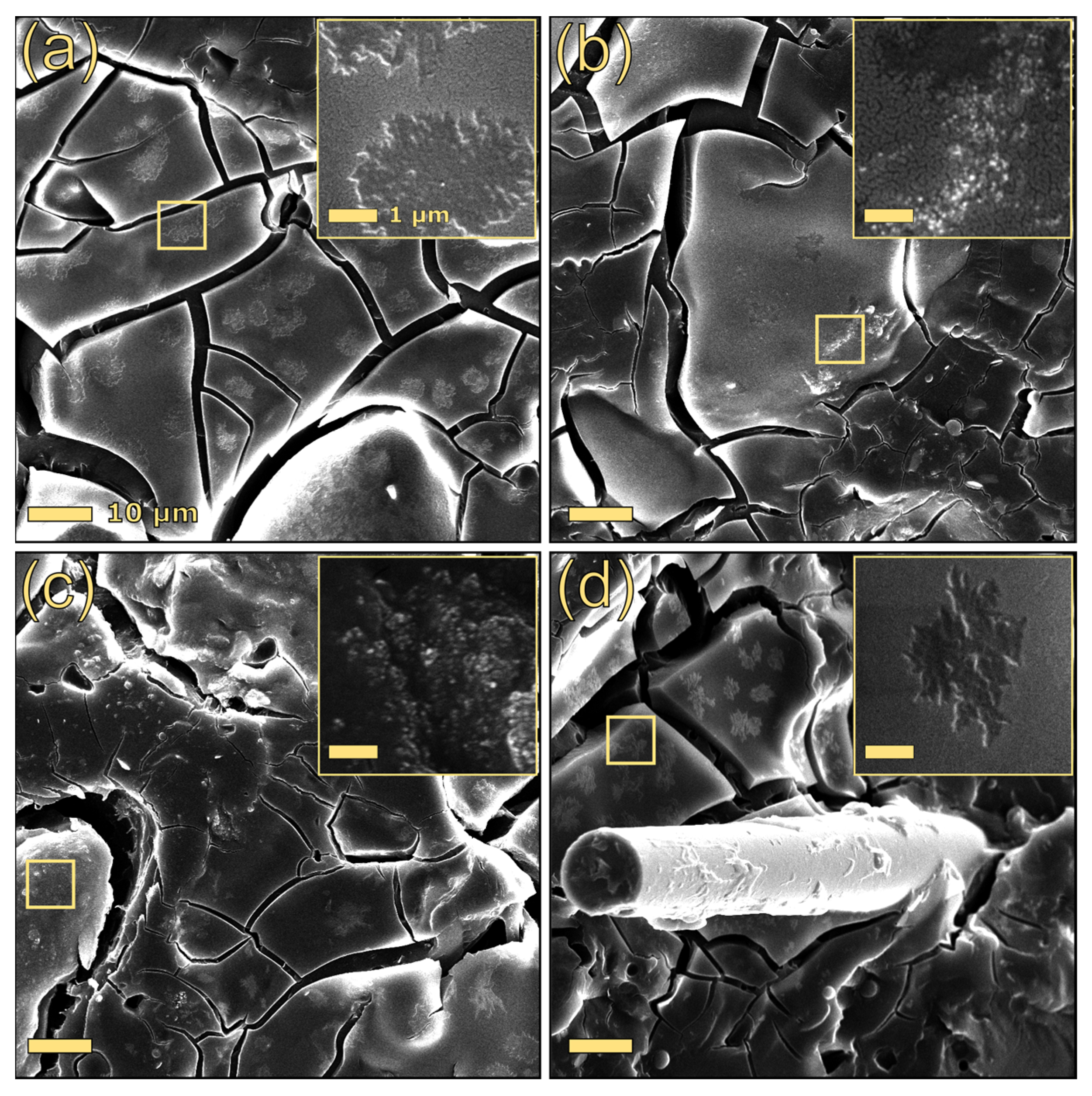

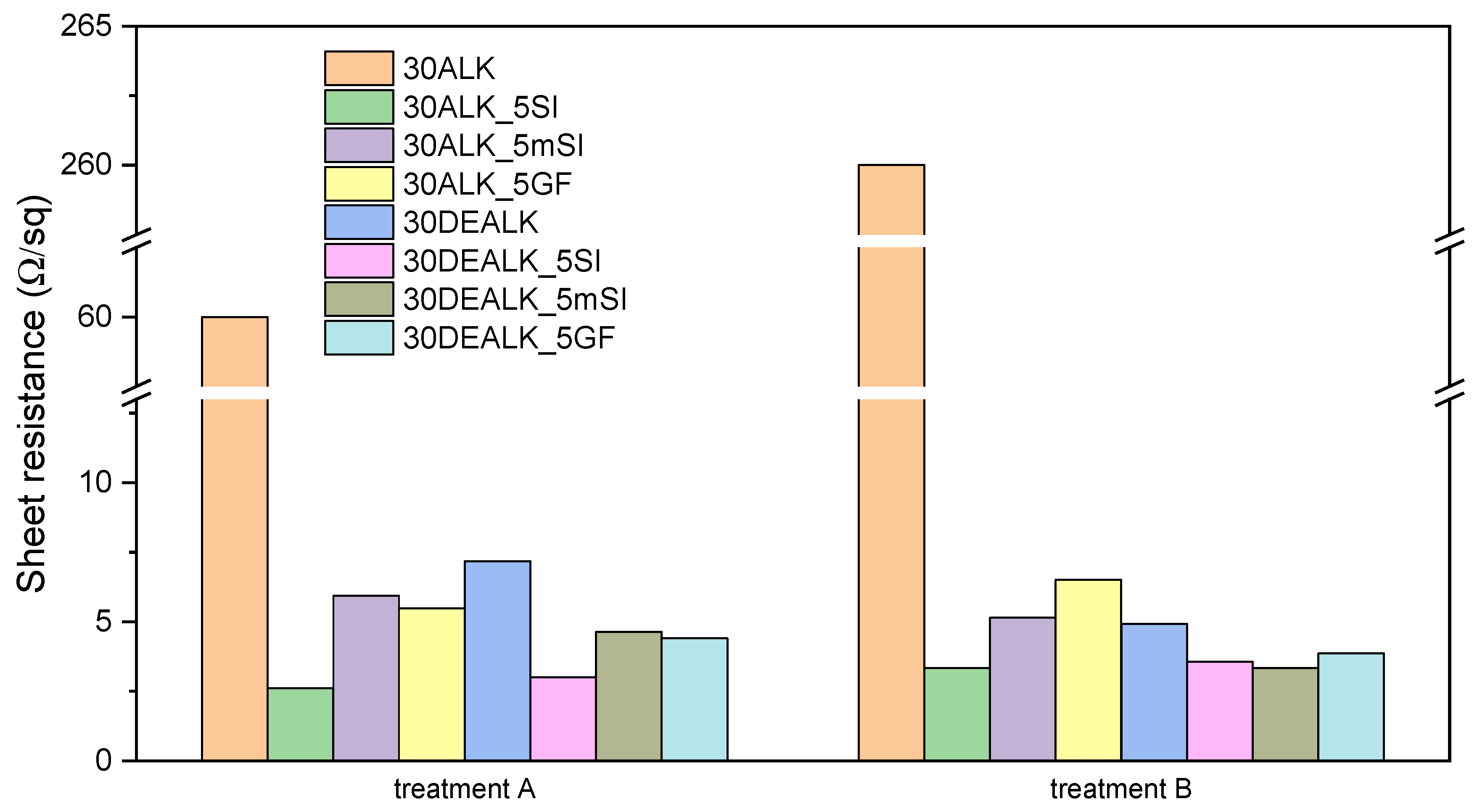

3.1.2. Electrical Properties

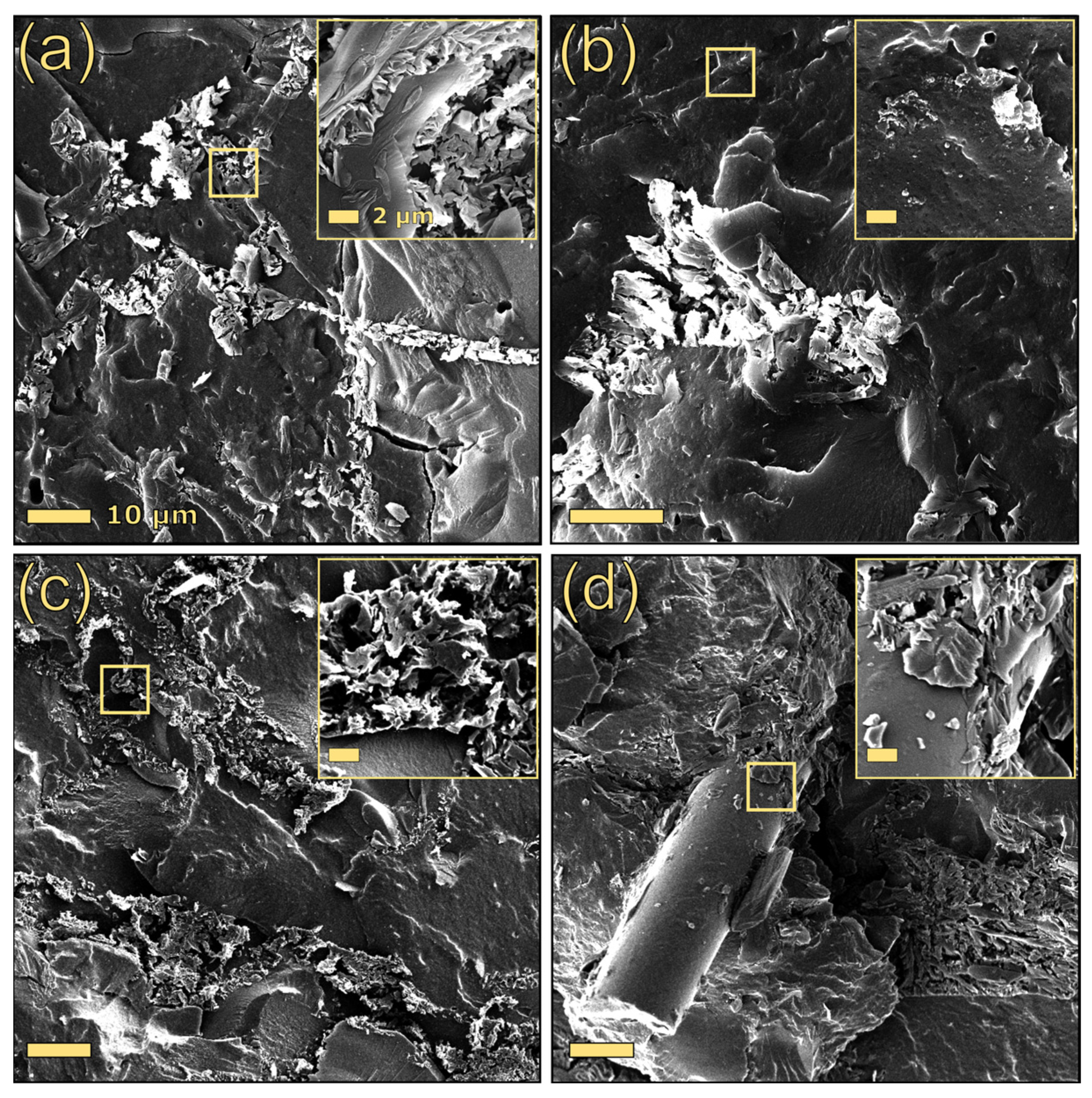

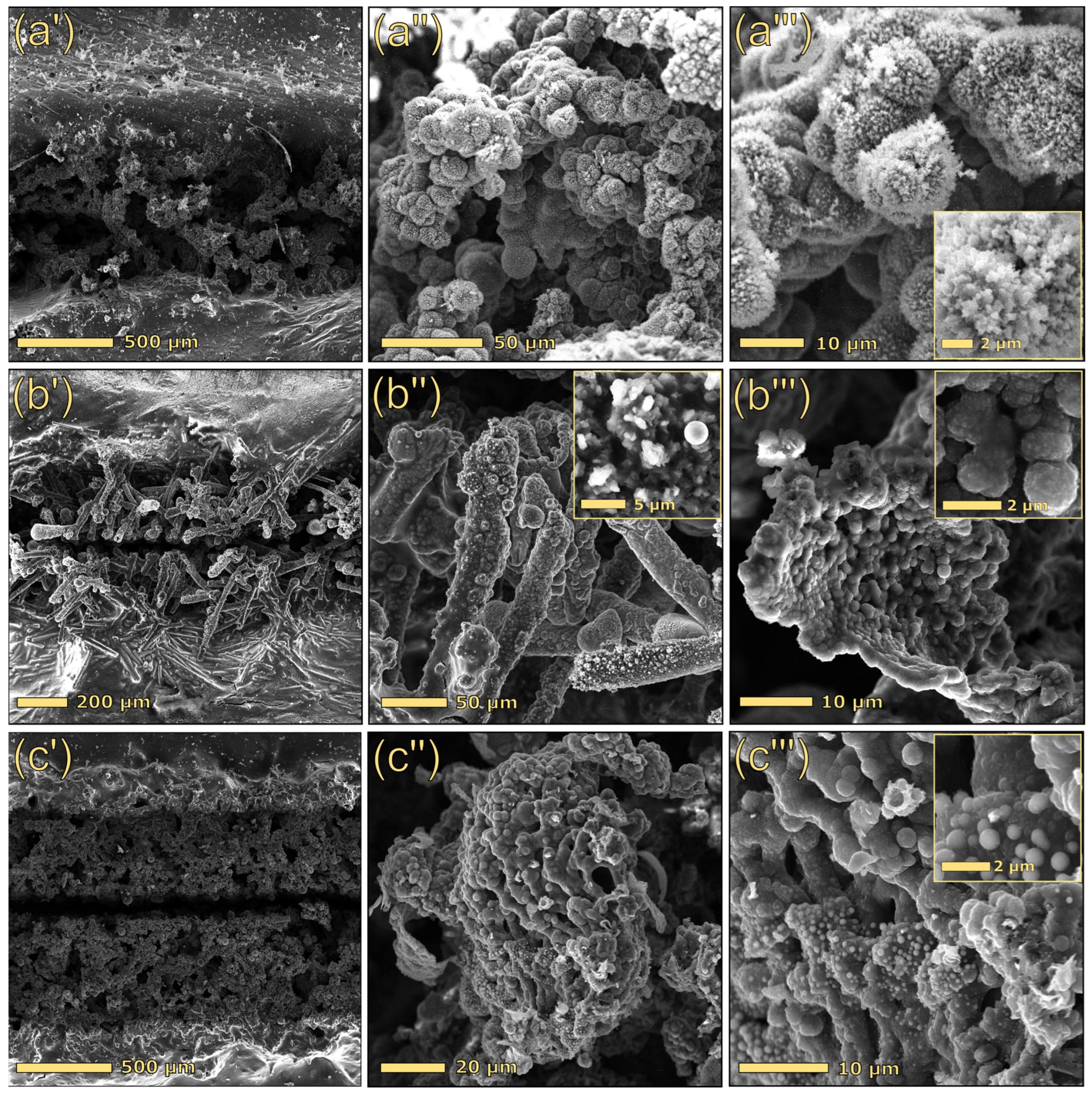

3.2. Study of Composites Containing PBAT, Dealkaline Lignin, and Glass Fibers

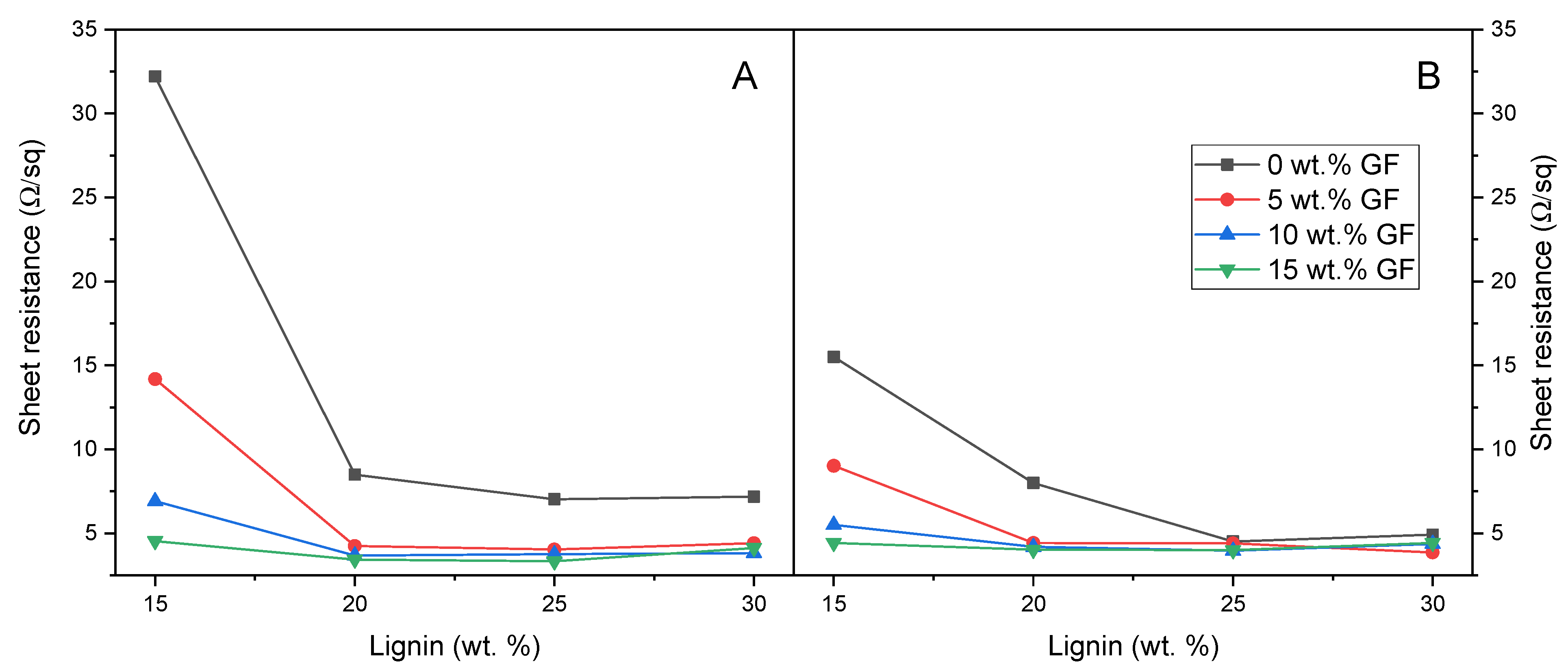

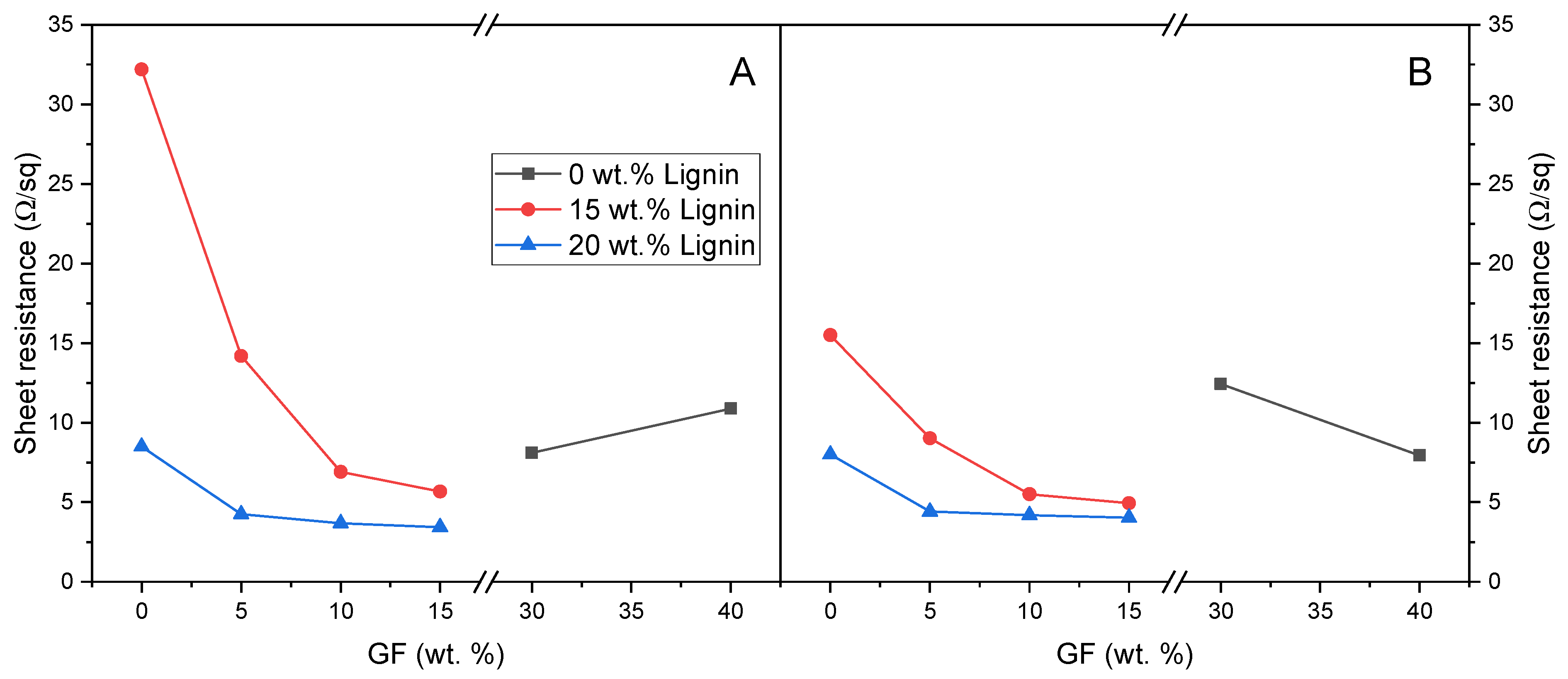

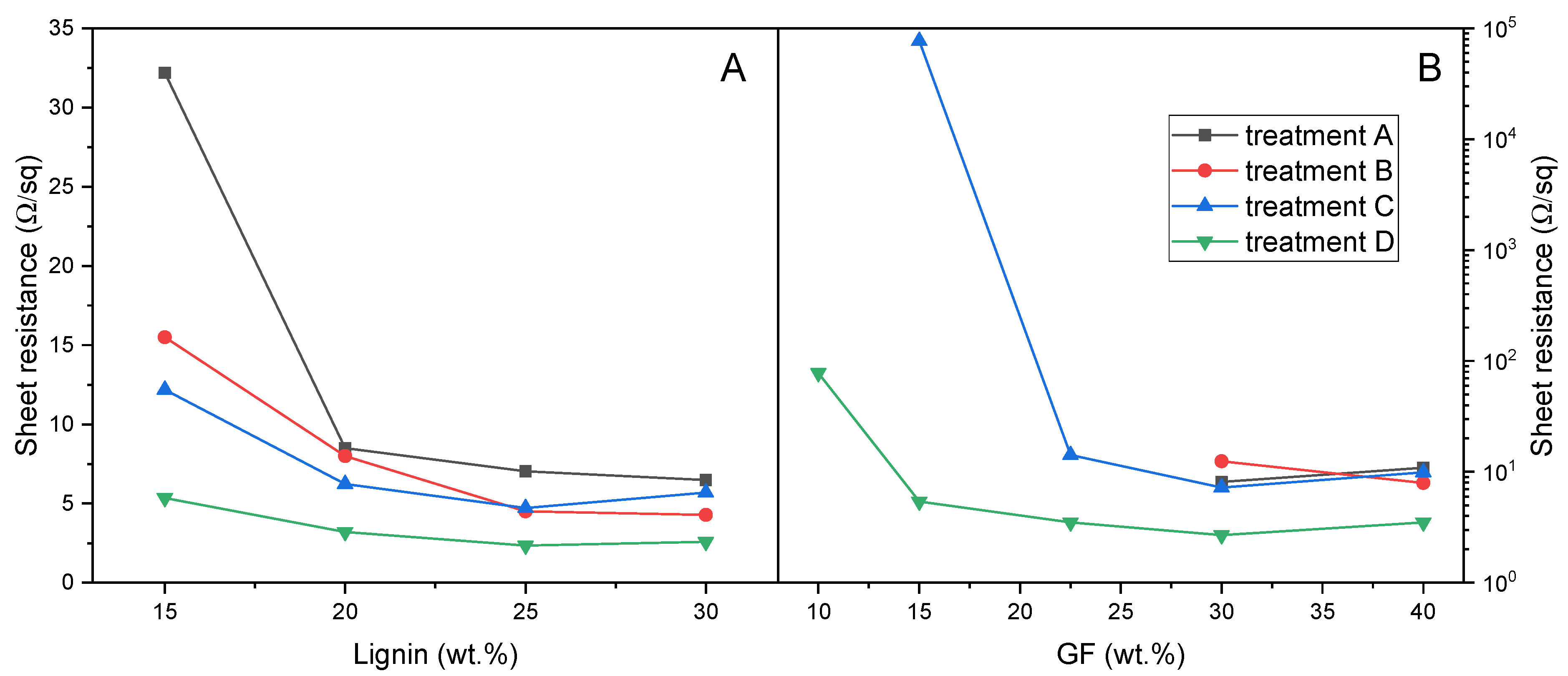

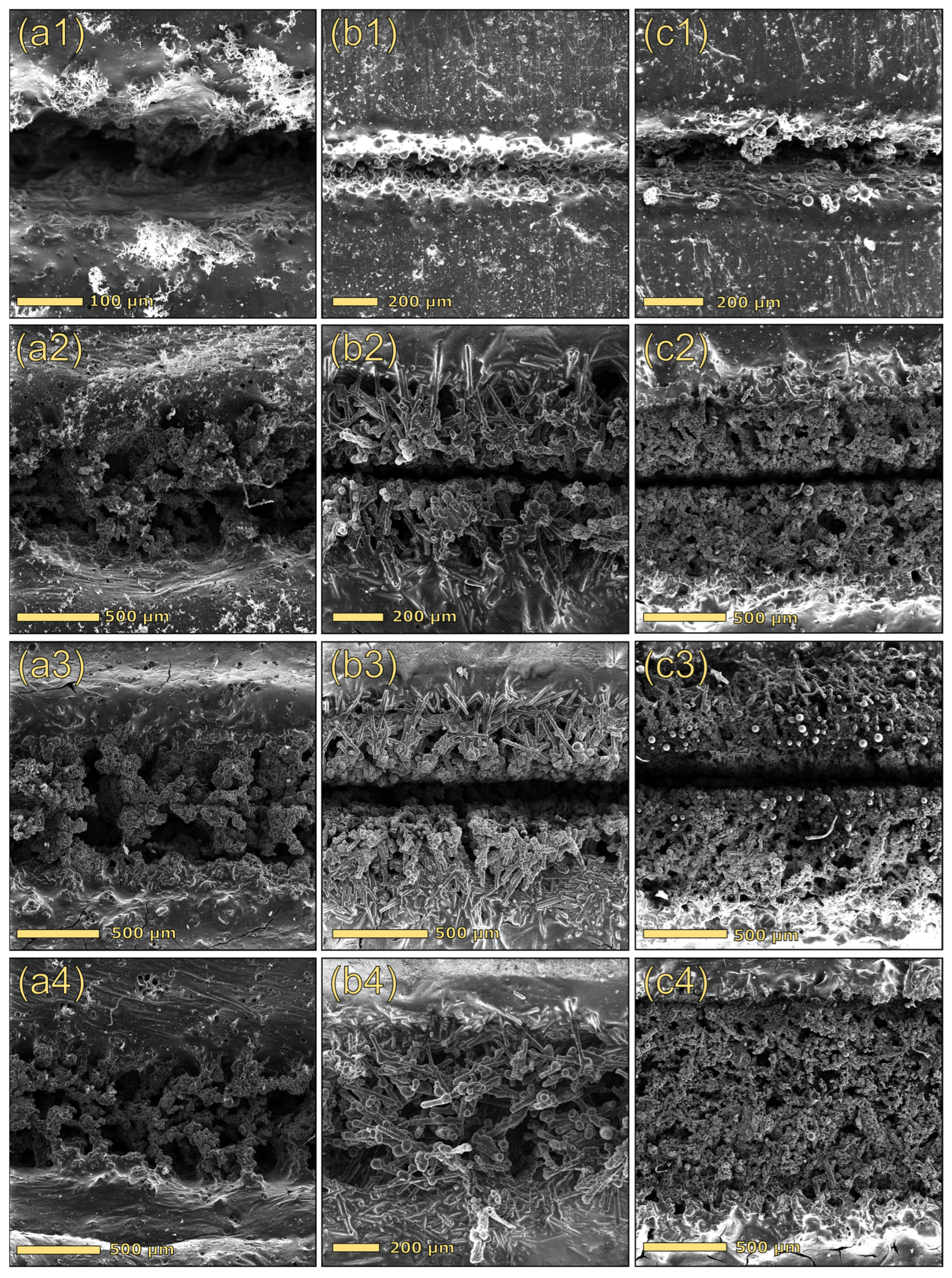

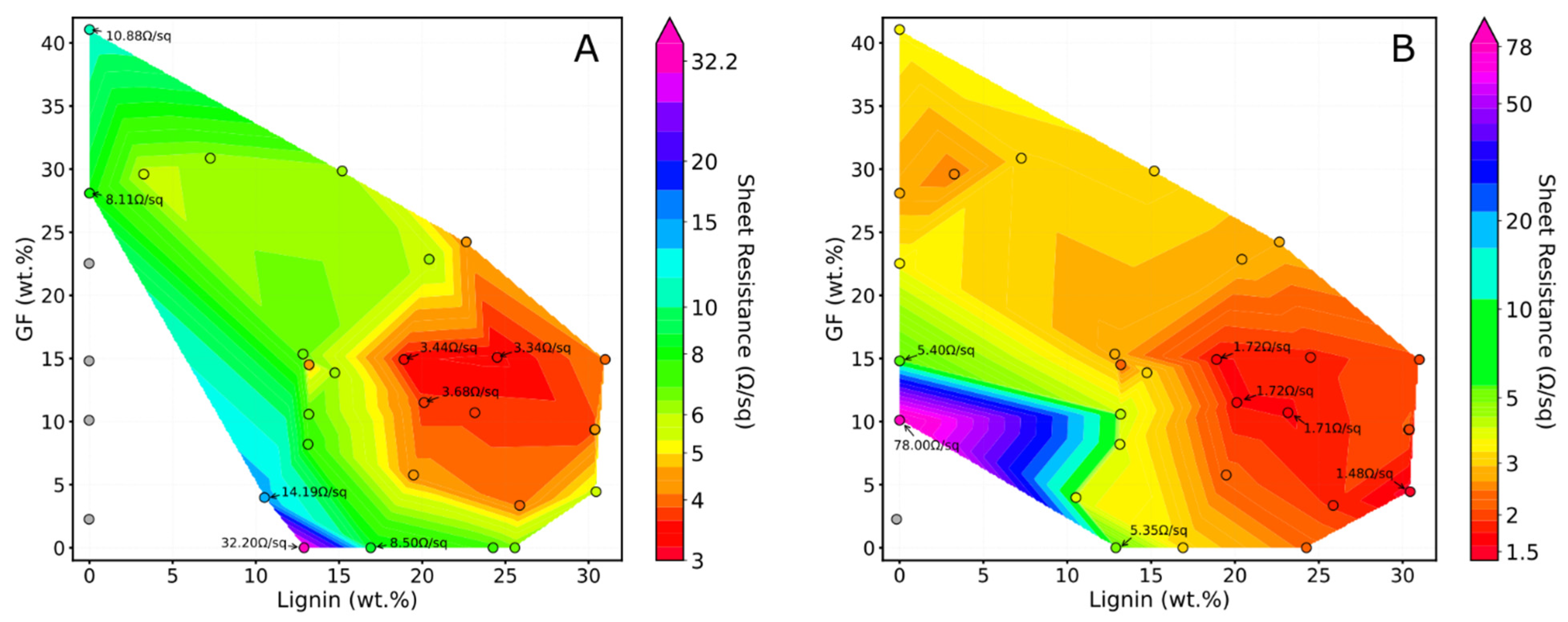

3.2.1. Optimization of the Electrical Properties

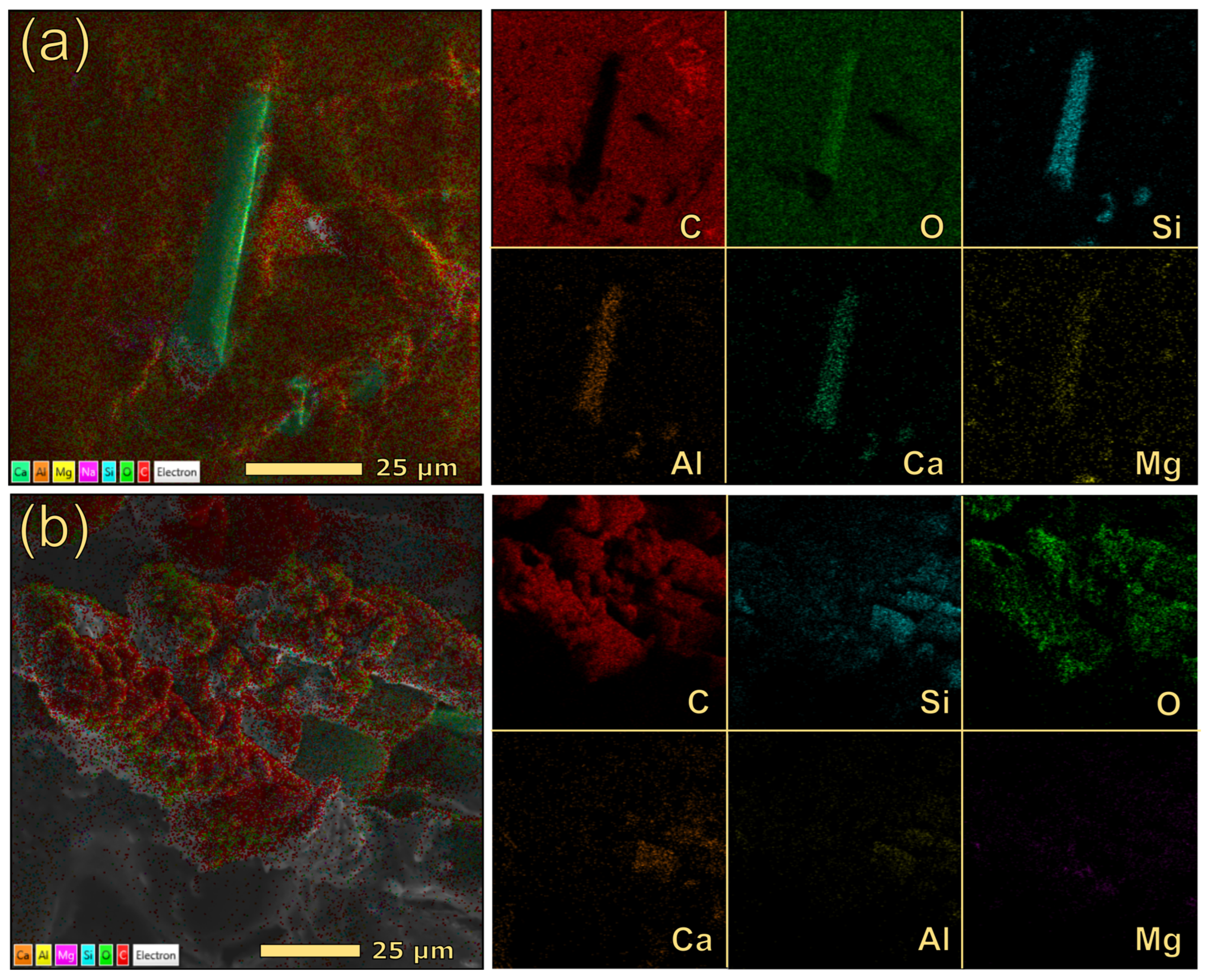

3.2.2. Correlation of the Actual Filler Content with the Electrical Performance

- -

- A and D indicate the pyrolysis and ash residues of PBAT, respectively.

- -

- B and E indicate the pyrolysis and ash residues of lignin, respectively.

- -

- C and F indicate the pyrolysis and ash residues of GF, respectively.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Institute for Training and Research Global E-Waste Monitor 2024: Electronic Waste Rising Five Times Faster than Documented E-Waste Recycling. Available online: https://unitar.org/about/news-stories/press/global-e-waste-monitor-2024-electronic-waste-rising-five-times-faster-documented-e-waste-recycling (accessed on 5 February 2025).

- Tan, M.J.; Owh, C.; Chee, P.L.; Kyaw, A.K.K.; Kai, D.; Loh, X.J. Biodegradable Electronics: Cornerstone for Sustainable Electronics and Transient Applications. J. Mater. Chem. C Mater. 2016, 4, 5531–5558. [Google Scholar] [CrossRef]

- Cao, Y.; Uhrich, K.E. Biodegradable and Biocompatible Polymers for Electronic Applications: A Review. J. Bioact. Compat. Polym. 2019, 34, 3–15. [Google Scholar] [CrossRef]

- Shim, J.-S.; Rogers, J.A.; Kang, S.-K. Physically Transient Electronic Materials and Devices. Mater. Sci. Eng. R Rep. 2021, 145, 100624. [Google Scholar] [CrossRef]

- Li, R.; Wang, L.; Kong, D.; Yin, L. Recent Progress on Biodegradable Materials and Transient Electronics. Bioact. Mater. 2018, 3, 322–333. [Google Scholar] [CrossRef]

- Peng, X.; Dong, K.; Wu, Z.; Wang, J.; Wang, Z.L. A Review on Emerging Biodegradable Polymers for Environmentally Benign Transient Electronic Skins. J. Mater. Sci. 2021, 56, 16765–16789. [Google Scholar] [CrossRef]

- Liu, H.; Jian, R.; Chen, H.; Tian, X.; Sun, C.; Zhu, J.; Yang, Z.; Sun, J.; Wang, C. Application of Biodegradable and Biocompatible Nanocomposites in Electronics: Current Status and Future Directions. Nanomaterials 2019, 9, 950. [Google Scholar] [CrossRef] [PubMed]

- Jamshidi, R.; Taghavimehr, M.; Chen, Y.; Hashemi, N.; Montazami, R. Transient Electronics as Sustainable Systems: From Fundamentals to Applications. Adv. Sustain. Syst. 2022, 6, 2100057. [Google Scholar] [CrossRef]

- Song, Z.; Liu, Z.; Zhao, L.; Chang, C.; An, W.; Zheng, H.; Yu, S. Biodegradable and Flexible Capacitive Pressure Sensor for Electronic Skins. Org. Electron. 2022, 106, 106539. [Google Scholar] [CrossRef]

- Zhu, B.; Wang, H.; Leow, W.R.; Cai, Y.; Loh, X.J.; Han, M.; Chen, X. Silk Fibroin for Flexible Electronic Devices. Adv. Mater. 2016, 28, 4250–4265. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Zhang, H.; Liu, J.; Huang, W. Flexible Electronics from Intrinsically Soft Materials. Giant 2021, 6, 100051. [Google Scholar] [CrossRef]

- Brunella, V.; Rossatto, B.G.; Scarano, D.; Cesano, F. Thermal, Morphological, Electrical Properties and Touch-Sensor Application of Conductive Carbon Black-Filled Polyamide Composites. Nanomaterials 2021, 11, 3103. [Google Scholar] [CrossRef]

- Cesano, F.; Rattalino, I.; Demarchi, D.; Bardelli, F.; Sanginario, A.; Gianturco, A.; Veca, A.; Viazzi, C.; Castelli, P.; Scarano, D.; et al. Structure and Properties of Metal-Free Conductive Tracks on Polyethylene/Multiwalled Carbon Nanotube Composites as Obtained by Laser Stimulated Percolation. Carbon 2013, 61, 63–71. [Google Scholar] [CrossRef]

- Mastropasqua, C.; Veca, A.; Damin, A.; Brunella, V.; Cesano, F. Functional Piezoresistive Polymer Composites Based on CO2 Laser-Irradiated Graphene Oxide-Loaded Polyurethane: Morphology, Structure, Electrical and Piezoresistive Properties. Nanomaterials 2022, 13, 168. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, Q.; Peng, Y.; Cai, Z.; Wan, C. Upgrading Lignin into Graphene-Based Materials: State of the Art and Perspectives. Adv. Energy Sustain. Res. 2024, 5, 2300252. [Google Scholar] [CrossRef]

- Cesano, F.; Uddin, M.J.; Damin, A.; Scarano, D. Multifunctional Conductive Paths Obtained by Laser Processing of Non-Conductive Carbon Nanotube/Polypropylene Composites. Nanomaterials 2021, 11, 604. [Google Scholar] [CrossRef]

- Wang, M.; Yang, Y.; Gao, W. Laser-Engraved Graphene for Flexible and Wearable Electronics. Trends Chem. 2021, 3, 969–981. [Google Scholar] [CrossRef]

- Sarotto, E.; Brunella, V.; Cesano, F. Graphene-Loaded Recycled PET: Exploring and Enhancing Electrical Conductivity through Processing and Laser Treatments near the Electrical Percolation Threshold. Sustain. Mater. Technol. 2024, 40, e00986. [Google Scholar] [CrossRef]

- Aversa, C.; Barletta, M.; Cappiello, G.; Gisario, A. Compatibilization Strategies and Analysis of Morphological Features of Poly(Butylene Adipate-Co-Terephthalate) (PBAT)/Poly(Lactic Acid) PLA Blends: A State-of-Art Review. Eur. Polym. J. 2022, 173, 111304. [Google Scholar] [CrossRef]

- Itabana, B.E.; Mohanty, A.K.; Dick, P.; Sain, M.; Bali, A.; Tiessen, M.; Lim, L.; Misra, M. Poly (Butylene Adipate-Co-Terephthalate) (PBAT)—Based Biocomposites: A Comprehensive Review. Macromol. Mater. Eng. 2024, 309, 2400179. [Google Scholar] [CrossRef]

- Kim, K.S.; Yoo, J.; Shim, J.S.; Ryu, Y.I.; Choi, S.; Lee, J.Y.; Lee, H.M.; Koo, J.; Kang, S.K. Biodegradable Molybdenum/Polybutylene Adipate Terephthalate Conductive Paste for Flexible and Stretchable Transient Electronics. Adv. Mater. Technol. 2022, 7, 2001297. [Google Scholar] [CrossRef]

- Maciel, C.C.; de Barros, A.; Mazali, I.O.; Ferreira, M. Flexible Biodegradable Electrochemical Sensor of PBAT and CNDs Composite for the Detection of Emerging Pollutants. J. Electroanal. Chem. 2023, 940, 117491. [Google Scholar] [CrossRef]

- Wang, H.-M.; Wang, B.; Yuan, T.-Q.; Zheng, L.; Shi, Q.; Wang, S.-F.; Song, G.-Y.; Sun, R.-C. Tunable, UV-Shielding and Biodegradable Composites Based on Well-Characterized Lignins and Poly(Butylene Adipate-co-Terephthalate). Green Chem. 2020, 22, 8623–8632. [Google Scholar] [CrossRef]

- Farsi, M. Thermoplastic Matrix Reinforced with Natural Fibers: A Study on Interfacial Behavior. In Some Critical Issues for Injection Molding; InTechOpen: London, UK, 2012. [Google Scholar]

- Popescu, C.M. Wood as Bio-Based Building Material. In Performance of Bio-Based Building Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 21–96. [Google Scholar]

- Wang, H.-M.; Yuan, T.-Q.; Song, G.-Y.; Sun, R.-C. Advanced and Versatile Lignin-Derived Biodegradable Composite Film Materials toward a Sustainable World. Green Chem. 2021, 23, 3790–3817. [Google Scholar] [CrossRef]

- Leng, E.; Guo, Y.; Chen, J.; Liu, S.; Jiaqiang, E.; Xue, Y. A Comprehensive Review on Lignin Pyrolysis: Mechanism, Modeling and the Effects of Inherent Metals in Biomass. Fuel 2022, 309, 122102. [Google Scholar] [CrossRef]

- Li, Y.; Chen, M.; Shi, Q.-S.; Xie, X.; Guo, Y. Biomass Fractionation Techniques Impact on the Structure and Antioxidant Properties of Isolated Lignins. Sep. Purif. Technol. 2024, 330, 125499. [Google Scholar] [CrossRef]

- Zhang, M.; Tian, R.; Tang, S.; Wu, K.; Wang, B.; Liu, Y.; Zhu, Y.; Lu, H.; Liang, B. The Structure and Properties of Lignin Isolated from Various Lignocellulosic Biomass by Different Treatment Processes. Int. J. Biol. Macromol. 2023, 243, 125219. [Google Scholar] [CrossRef]

- Wang, S.; Ru, B.; Lin, H.; Sun, W.; Luo, Z. Pyrolysis Behaviors of Four Lignin Polymers Isolated from the Same Pine Wood. Bioresour. Technol. 2015, 182, 120–127. [Google Scholar] [CrossRef]

- Chen, W.; Tao, X.; Shi, X.; Guo, W.; Wang, Y.; Liu, B.; Yang, H. Insight into Catalytic Effects of Alkali Metal Salts Addition on Bamboo and Cellulose Pyrolysis. npj Mater. Sustain. 2024, 2, 25. [Google Scholar] [CrossRef]

- Gu, X.; Hou, J.; Ai, S. Effect of Silane Modified Nano-SiO2 on the Mechanical Properties and Compatibility of PBAT/Lignin Composite Films. J. Appl. Polym. Sci. 2022, 139, 52051. [Google Scholar] [CrossRef]

- Xiong, S.-J.; Pang, B.; Zhou, S.-J.; Li, M.-K.; Yang, S.; Wang, Y.-Y.; Shi, Q.; Wang, S.-F.; Yuan, T.-Q.; Sun, R.-C. Economically Competitive Biodegradable PBAT/Lignin Composites: Effect of Lignin Methylation and Compatibilizer. ACS Sustain. Chem. Eng. 2020, 8, 5338–5346. [Google Scholar] [CrossRef]

- Yang, X.; Zhong, S. Properties of Maleic Anhydride-modified Lignin Nanoparticles/Polybutylene Adipate-co-terephthalate Composites. J. Appl. Polym. Sci. 2020, 137, 49025. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, S.; Liu, Z.; Lei, Y.; Jiang, S.; Zhang, K.; Yan, W.; Qin, J.; He, M.; Qin, S.; et al. Enhanced Mechanical and Biodegradable Properties of PBAT/Lignin Composites via Silane Grafting and Reactive Extrusion. Compos. B Eng. 2021, 220, 108980. [Google Scholar] [CrossRef]

- Mai, V.-D.; Kwon, G.; Jang, Y.; Min, J.; Han, J.; Kim, S.-K. High-Performance and Economic Biodegradable Composites Based on Polybutylene Adipate Terephthalate and Modified Lignin. Polym. Test. 2024, 133, 108412. [Google Scholar] [CrossRef]

- Kim, J.; Bang, J.; Park, S.; Jung, M.; Jung, S.; Yun, H.; Kim, J.-H.; Choi, I.-G.; Kwak, H.W. Enhanced Barrier Properties of Biodegradable PBAT/Acetylated Lignin Films. Sustain. Mater. Technol. 2023, 37, e00686. [Google Scholar] [CrossRef]

- Xu, H.; Shaoyu, J.; Jin, J.; Li, M.; Ji, L.; Zhuang, W.; Tang, C.; Chang, Z.; Ying, H.; Zhu, C. Fabrication of PBAT/Lignin Composite Foam Materials with Excellent Foaming Performance and Mechanical Properties via Grafting Esterification and Twin-Screw Melting Free Radical Polymerization. Collagen Leather 2024, 6, 32. [Google Scholar] [CrossRef]

- Botta, L.; Titone, V.; Teresi, R.; Scarlata, M.C.; Lo Re, G.; La Mantia, F.P.; Lopresti, F. Biocomposite PBAT/Lignin Blown Films with Enhanced Photo-Stability. Int. J. Biol. Macromol. 2022, 217, 161–170. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Kobylińska, A.; Antos-Bielska, M.; Krzyżowska, M.; Gałęski, A. Exploring the Potential of Lignin Nanoparticles in Enhancing the Mechanical, Thermal, and Bioactive Properties of Poly (Butylene Adipate-Co-Terephthalate). Int. J. Biol. Macromol. 2024, 262, 129880. [Google Scholar] [CrossRef]

- Fang, W.; Yang, S.; Wang, X.-L.; Yuan, T.-Q.; Sun, R.-C. Manufacture and Application of Lignin-Based Carbon Fibers (LCFs) and Lignin-Based Carbon Nanofibers (LCNFs). Green Chem. 2017, 19, 1794–1827. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, J.; Wang, C.; Zhao, L.; Jian, W.; Lu, K.; Lin, H.; Qiu, X.; Alshareef, H.N. Lignin Derived Porous Carbons: Synthesis Methods and Supercapacitor Applications. Small Methods 2021, 5, 2100896. [Google Scholar] [CrossRef]

- Wen, A.; Wang, C.; Nong, J.; Hu, C. Rapid Construction of Robust and Hydrophilic Lignin-Derived Laser-Induced Graphene Electrodes Using PVA-Free Dopants. Carbon 2025, 232, 119767. [Google Scholar] [CrossRef]

- Funayama, R.; Hayashi, S.; Terakawa, M. Laser-Induced Graphitization of Lignin/PLLA Composite Sheets for Biodegradable Triboelectric Nanogenerators. ACS Sustain. Chem. Eng. 2023, 11, 3114–3122. [Google Scholar] [CrossRef]

- Lei, Y.; Alshareef, A.H.; Zhao, W.; Inal, S. Laser-Scribed Graphene Electrodes Derived from Lignin for Biochemical Sensing. ACS Appl. Nano Mater. 2020, 3, 1166–1174. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Q.; Hammond, K.D.; He, X.; Lin, J.; Wan, C. Probing Laser-Induced Structural Transformation of Lignin into Few-Layer Graphene. Green Chem. 2024, 26, 5921–5932. [Google Scholar] [CrossRef]

- Mallick, P.K. 2.18 Particulate Filled and Short Fiber Reinforced Polymer Composites. In Comprehensive Composite Materials II; Elsevier: Amsterdam, The Netherlands, 2018; pp. 360–400. [Google Scholar]

- Ghavipanjeh, A.; Sadeghzadeh, S. Simulation and Experimental Evaluation of Laser-Induced Graphene on the Cellulose and Lignin Substrates. Sci. Rep. 2024, 14, 4475. [Google Scholar] [CrossRef]

- Pinheiro, T.; Rosa, A.; Ornelas, C.; Coelho, J.; Fortunato, E.; Marques, A.C.; Martins, R. Influence of CO2 Laser Beam Modelling on Electronic and Electrochemical Properties of Paper-Based Laser-Induced Graphene for Disposable PH Electrochemical Sensors. Carbon. Trends 2023, 11, 100271. [Google Scholar] [CrossRef]

- Mao, X.; Wang, Y.; Li, H.; Zhao, P.; Zhao, N.; Xie, B.; Zhou, Y. Laser-Induced Graphene Based on the Controllable Angle between Two Irradiation Steps for the Fabrication of Flexible Sensor. J. Mater. Chem. C Mater. 2025, 13, 16577–16589. [Google Scholar] [CrossRef]

- Parkula, V.; Licata, A.; Valorosi, F.; Kovtun, A.; Scidà, A.; Ruani, G.; Liscio, F.; Zanardi, C.; Candini, A.; Bertocchi, F.; et al. Laser-Patterned Polyurethane Composites with Graphene, Graphene Oxide, and Aramid Fibers for the Production of Electric Circuits, Sensors, and Heaters. ACS Appl. Nano Mater. 2024, 7, 18077–18088. [Google Scholar] [CrossRef]

- Bressi, A.C.; Dallinger, A.; Steksova, Y.; Greco, F. Bioderived Laser-Induced Graphene for Sensors and Supercapacitors. ACS Appl. Mater. Interfaces 2023, 15, 35788–35814. [Google Scholar] [CrossRef]

- Mahmood, F.; Zhang, H.; Lin, J.; Wan, C. Laser-Induced Graphene Derived from Kraft Lignin for Flexible Supercapacitors. ACS Omega 2020, 5, 14611–14618. [Google Scholar] [CrossRef] [PubMed]

| pH | Methoxy Group (%) * | Ash (Sulfate) (%) * | |

|---|---|---|---|

| Alkaline lignin | 8.0–10.0 | 10.0–12.0 | 20.0–29.0 |

| Dealkaline lignin | 3.0–4.0 | 10.0–12.5 | 10.0–20.0 |

| Type of Silica | Properties |

|---|---|

| Hydrophilic silica | Fumed silica nanoparticles having a pH of 3.6–4.5. |

| Hydrophobic silica | Fumed silica nanoparticles having many trimethylsilyl groups in place of hydroxyl groups. |

| Glass fibers | Silica microfibers having a length of 160 µm and a nominal diameter of 13 µm. |

| Young’s Modulus (MPa) | Yield Stress (MPa) | Stress at Break (MPa) | Nominal Strain at Break (%) | |

|---|---|---|---|---|

| PBAT | 119 ± 1 | 7.9 ± 0.2 | 10.9 ± 0.2 | 320 ± 20 |

| 30DEALK | 292 ± 4 | 6.8 ± 0.1 | 6.2 ± 0.1 | 7.8 ± 0.7 |

| 30DEALK_5SI | 207 ± 5 | 6.2 ± 0.2 | 5.9 ± 0.1 | 13 ± 4 |

| 30DEALK_5mSI | 227 ± 9 | 6.1 ± 0.1 | 5.8 ± 0.2 | 12 ± 4 |

| 30DEALK_5GF | 251 ± 6 | 6.2 ± 0.1 | 5.7 ± 0.1 | 8.5 ± 0.9 |

| 30ALK | 260 ± 20 | 6.3 ± 0.1 | 5.7 ± 0.1 | 20 ± 3 |

| 30ALK_5SI | 240 ± 20 | 6.5 ± 0.2 | 6.0 ± 0.2 | 18 ± 3 |

| 30ALK_5mSI | 269 ± 2 | 6.9 ± 0.1 | 6.3 ± 0.1 | 13 ± 2 |

| 30ALK_5GF | 250 ± 20 | 5.7 ± 0.2 | 5.3 ± 0.1 | 11 ± 4 |

| Pyrolysis Residue | Ash | |

|---|---|---|

| PBAT | 5.1 ± 0.2 | 1.4 ± 0.1 |

| Dealkaline lignin | 55.8 ± 0.9 | 12.6 ± 0.5 |

| Glass fibers | 100 | 100 |

| PBAT/DEALK/GF Theoretical Ratio | PBAT (%) | DEALK (%) | GF (%) |

|---|---|---|---|

| 92.80/0/7.20 | 92.03 (−0.77) | 0.77 (0.77) | 7.20 (0) |

| 59.89/0/40.11 | 60.43 (0.54) | −0.41 (−0.41) | 39.98 (−0.13) |

| 90.44/9.56/0 | 91.01 (0.57) | 9.02 (−0.54) | −0.03 (−0.03) |

| 58.68/41.32/0 | 58.53 (−0.15) | 40.76 (−0.56) | 0.71 (0.71) |

| 0/44.63/55.37 | 0.13 (0.13) | 44.27 (−0.36) | 55.59 (0.22) |

| 58.34/19.85/21.81 | 58.30 (−0.04) | 20.04 (0.18) | 21.67 (−0.14) |

| PBAT (%) | DEALK (%) | GF (%) | |

|---|---|---|---|

| PBAT_5GF | 97.5 | 0.1 | 2.4 |

| PBAT_10GF | 90.7 | −0.8 | 10.1 |

| PBAT_15GF | 86.0 | −0.8 | 14.8 |

| PBAT_22.5GF | 77.9 | −0.4 | 22.5 |

| PBAT_30GF | 72.3 | −0.4 | 28.1 |

| PBAT_40GF | 59.7 | −0.8 | 41.1 |

| PBAT_5DEALK_30GF | 67.1 | 3.3 | 29.6 |

| PBAT_10DEALK_30GF | 61.8 | 7.3 | 30.9 |

| PBAT_15DEALK | 86.9 | 12.9 | 0.2 |

| PBAT_15DEALK_5GF | 85.5 | 10.5 | 4.0 |

| PBAT_15DEALK_7.5GF | 78.7 | 13.1 | 8.2 |

| PBAT_15DEALK_10GF | 76.2 | 13.2 | 10.6 |

| PBAT_15DEALK_15GF | 72.3 | 13.2 | 14.5 |

| PBAT_15DEALK_30GF | 54.9 | 15.2 | 29.9 |

| PBAT_20DEALK | 82.9 | 16.9 | 0.2 |

| PBAT_20DEALK_5GF | 74.7 | 19.5 | 5.8 |

| PBAT_20DEALK_10GF | 68.4 | 20.1 | 11.5 |

| PBAT_20DEALK_15GF | 66.2 | 18.9 | 14.9 |

| PBAT_20DEALK_25GF | 53.1 | 22.7 | 24.2 |

| PBAT_25DEALK | 75.8 | 24.3 | −0.1 |

| PBAT_25DEALK_5GF | 70.7 | 25.9 | 3.4 |

| PBAT_25DEALK_10GF | 66.1 | 23.2 | 10.7 |

| PBAT_25DEALK_15GF | 59.4 | 24.5 | 15.1 |

| PBAT_30DEALK | 75.1 | 24.3 | 0.6 |

| PBAT_30DEALK_5GF | 65.1 | 30.5 | 4.4 |

| PBAT_30DEALK_10GF | 60.1 | 30.4 | 9.4 |

| PBAT_30DEALK_15GF | 54.1 | 31.0 | 14.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moramarco, A.; Sarotto, E.; Otaegi, I.; Aranburu, N.; Cesano, F.; Brunella, V.; Zanetti, M.; Bracco, P. From Waste to Wires: PBAT/Lignin Biocomposites Functionalized by a CO2 Laser for Transient Electronics. Polymers 2025, 17, 3144. https://doi.org/10.3390/polym17233144

Moramarco A, Sarotto E, Otaegi I, Aranburu N, Cesano F, Brunella V, Zanetti M, Bracco P. From Waste to Wires: PBAT/Lignin Biocomposites Functionalized by a CO2 Laser for Transient Electronics. Polymers. 2025; 17(23):3144. https://doi.org/10.3390/polym17233144

Chicago/Turabian StyleMoramarco, Antonella, Elio Sarotto, Itziar Otaegi, Nora Aranburu, Federico Cesano, Valentina Brunella, Marco Zanetti, and Pierangiola Bracco. 2025. "From Waste to Wires: PBAT/Lignin Biocomposites Functionalized by a CO2 Laser for Transient Electronics" Polymers 17, no. 23: 3144. https://doi.org/10.3390/polym17233144

APA StyleMoramarco, A., Sarotto, E., Otaegi, I., Aranburu, N., Cesano, F., Brunella, V., Zanetti, M., & Bracco, P. (2025). From Waste to Wires: PBAT/Lignin Biocomposites Functionalized by a CO2 Laser for Transient Electronics. Polymers, 17(23), 3144. https://doi.org/10.3390/polym17233144