Bio-Based Alginate Films Incorporating Bacterial Nanocellulose and Grape Seed Extract for Enhanced Food Packaging

Abstract

1. Introduction

- To fabricate composite films of Na-alginate reinforced with BNC and enriched with different concentrations of GSE.

- To evaluate the physicochemical, mechanical, and barrier properties of the prepared films.

- To assess the antioxidant and antimicrobial activities imparted by GSE within the film matrices.

- To investigate the effectiveness of the developed films in extending the shelf life, maintaining quality, and reducing spoilage of fresh blueberries during storage.

- To explore the potential of utilizing agro-industrial byproducts (grape seeds) and microbial biopolymers (BNC) in sustainable and circular economy-oriented food packaging solutions.

2. Materials and Methods

2.1. Materials

2.2. Film Preparation

2.3. Film Analysis and Characterization

2.3.1. Film Thickness and Porosity of the Films

2.3.2. Mechanical Properties

2.3.3. Water Vapor Permeability (WVP)

2.3.4. Antioxidant Activity

2.3.5. Total Phenolic Content (TPC)

2.3.6. Antimicrobial Activity

2.3.7. Statistical Analysis

2.4. Blueberry Packaging and Storage

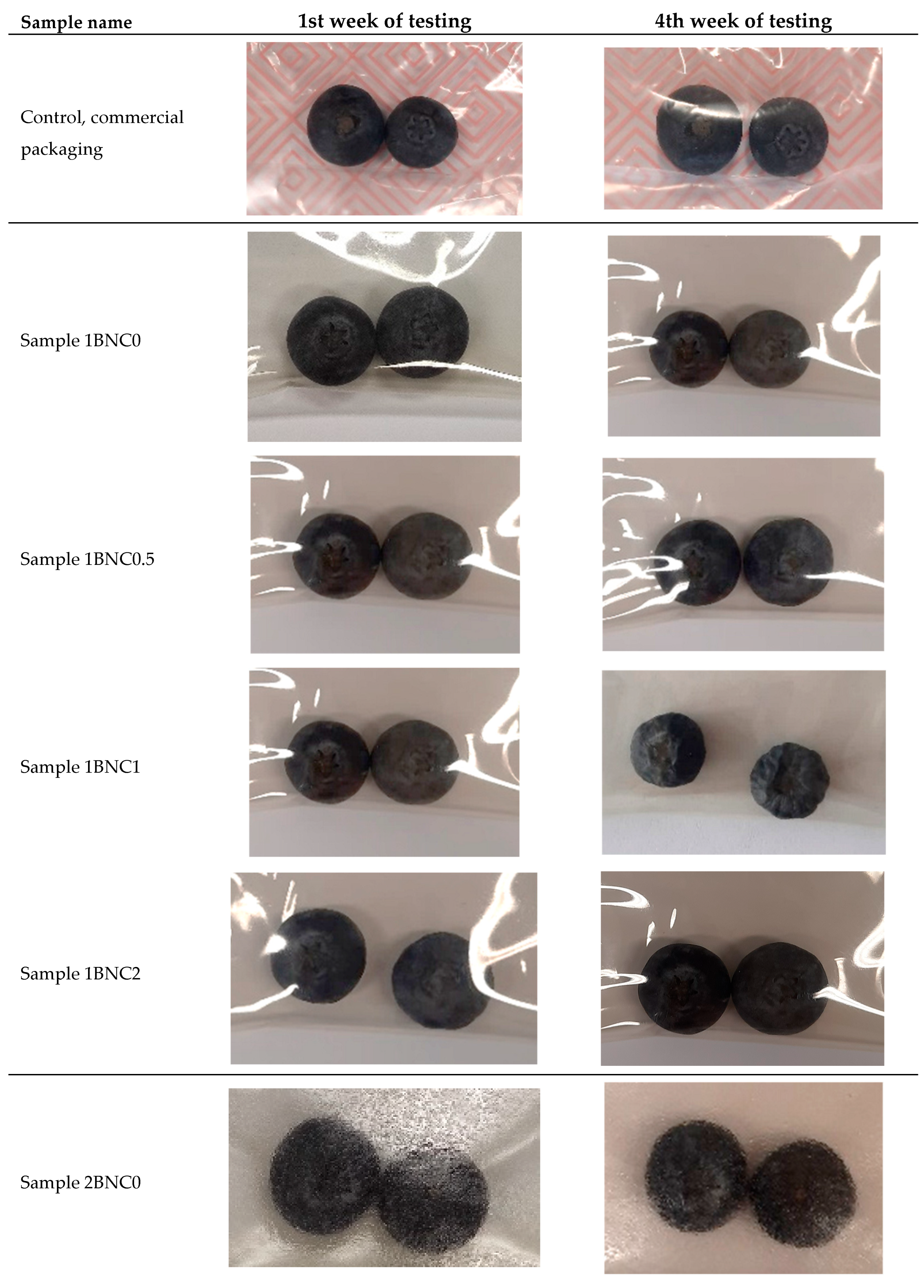

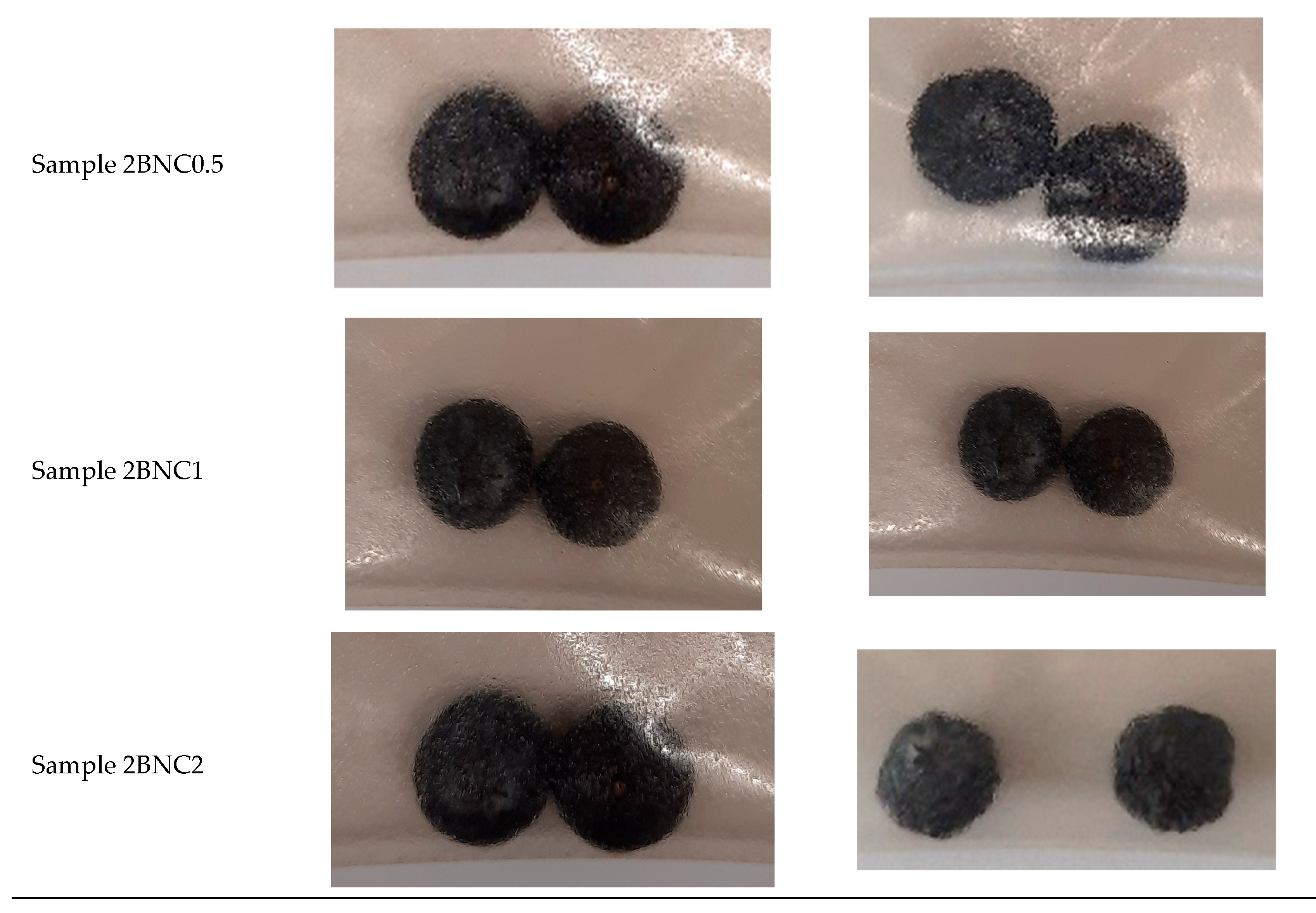

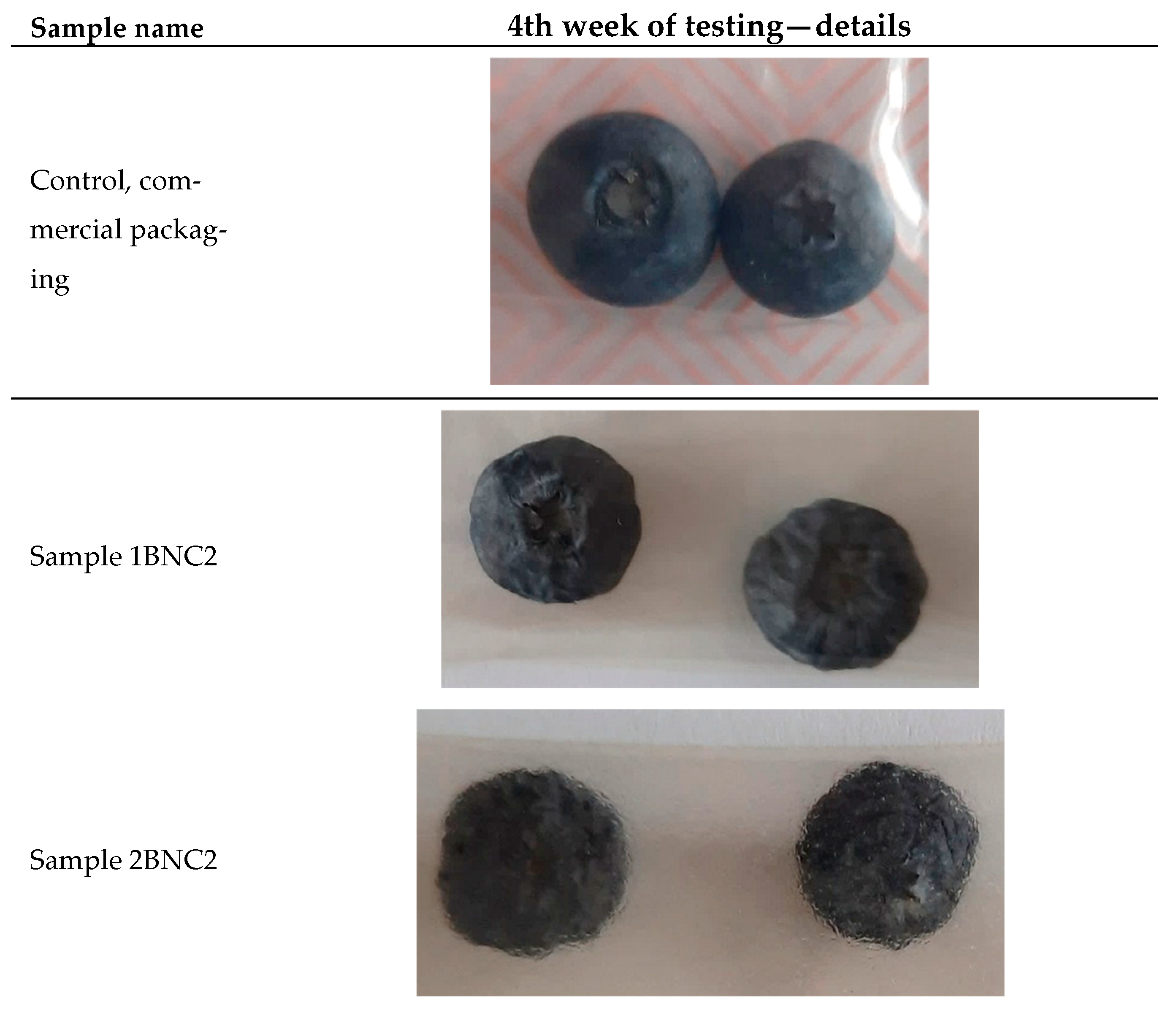

- Visual Quality Assessment: Inspection for color changes, mold growth, and other visual spoilage indicators.

- Weight Loss: Weighed before and after storage; expressed as a percentage of initial weight.

3. Results and Discussion

3.1. Film Thickness and Mechanical Properties

3.2. Results of Water Vapor Permeability (WVP)

3.3. Antioxidant Activity and Total Phenolic Content

3.4. Results of Antimicrobial Activities of Prepared Samples

3.5. Blueberry Packaging and Storage Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Vrabič-Brodnjak, U.; Vidmar, A. Sustainable Adhesive Formulation and Performance Evaluation of Bacterial Nanocellulose and Aloe Vera for Packaging Applications. Molecules 2025, 30, 3136. [Google Scholar] [CrossRef]

- Torkelis, A.; Dvarionienė, J.; Denafas, G. The factors influencing the recycling of plastic and composite packaging waste. Sustainability 2024, 16, 9515. [Google Scholar] [CrossRef]

- Arias, L.V.A.; Silva, V.D.S.; Vieira, J.M.M.; Fakhouri, F.M.; de Oliveira, R.A. Plant-based films for food packaging as a plastic waste management alternative: Potato and cassava starch case. Polymers 2024, 16, 2390. [Google Scholar] [CrossRef]

- Shams, M. Polymers from renewable resources: Sustainable adsorbents. Polym. Renew. Resour. 2024, 15, 503–516. [Google Scholar] [CrossRef]

- Patra, N.; Ramesh, P.; Donthu, V.; Ahmad, A. Biopolymer-based composites for sustainable energy storage: Recent developments and future outlook. J. Mater. Sci. Mater. Electron. Eng. 2024, 19, 34. [Google Scholar] [CrossRef]

- Polunin, Y.; Domnich, B.; Setien, K.P.; Voronov, A. Bioplastics from natural renewable polymeric resources: A review. Polym. Int. 2025, 19, 91–107. [Google Scholar] [CrossRef]

- Latif, S.; Imran, M.; Ahmad, M.N.; Franco, M. Biopolymer-based nanomaterials for the removal of environmental pollutants. In Advances in Chemical Pollution, Environmental Management and Protection, 12th ed.; Elsevier: Amsterdam, The Netherlands, 2025; pp. 665–687. [Google Scholar]

- Akinsemolu, A.A.; Idowu, A.M.; Onyeaka, H.N. Recycling technologies for biopolymers: Current challenges and future directions. Polymers 2024, 16, 2770. [Google Scholar] [CrossRef] [PubMed]

- Abdul Khalil, H.P.S.; Nurul Fazita, M.R.; Mohd Nurazzi, N. Biopolymers and Biopolymer Blends: Fundamentals, Processes, and Emerging Applications; CRC Press: Boca Raton, FL, USA, 2024. [Google Scholar]

- Singh, A.; Maheshwari, S.; Verma, A.; Ansari, V.A.; Prajapati, B.G.; Singh, S. Biopolymer composites for sustainable and green technology. In Advances in Sustainable Biomaterials; CRC Press: Boca Raton, FL, USA, 2024; pp. 1–16. [Google Scholar]

- Chadorshabi, S.; Mohammadi, M.; Shamloo, E.; Mahmoudzadeh, M. Marine algae-derived bioactives: A sustainable resource for the food and agriculture industries. Food Front. 2025, 1–28. [Google Scholar] [CrossRef]

- Cebrián-Lloret, V.; Metz, M.; Martínez-Abad, A.; Knutsen, S.H.; Ballance, S.; López-Rubio, A.; Martínez-Sanz, M. Valorization of alginate-extracted seaweed biomass for the development of cellulose-based packaging films. Algal Res. 2022, 61, 102576. [Google Scholar] [CrossRef]

- Hasanin, M.S.; Hassan, Y.R.; Youssef, A.M. Active packaging films based on the nanoform of chitin, alginate, and layered double hydroxides: Characterization, mechanical properties, permeability, and bioactive properties. RSC Adv. 2024, 14, 37380–37391. [Google Scholar] [CrossRef]

- Azadi, E.; Dinari, M.; Derakhshani, M.; Reid, K.R.; Karimi, B. Sources and extraction of biopolymers and manufacturing of bio-based nanocomposites for different applications. Molecules 2024, 29, 4406. [Google Scholar] [CrossRef]

- Makaremi, M.; Yousefi, H.; Cavallaro, G.; Lazzara, G.; Goh, C.B.S.; Lee, S.M.; Solouk, A.; Pasbakhsh, P. Safely dissolvable and healable active packaging films based on alginate and pectin. Polymers 2019, 11, 1594. [Google Scholar] [CrossRef]

- Hernández-Arriaga, A.M.; Campano, C.; Rivero-Buceta, V.; Prieto, M.A. When microbial biotechnology meets material engineering. Microb. Biotechnol. 2022, 15, 149–163. [Google Scholar] [CrossRef]

- Ramakrishnan, R.K.; Wacławek, S.; Černík, M.; Padil, V.V. Biomacromolecule assembly based on gum kondagogu-sodium alginate composites and their expediency in flexible packaging films. Int. J. Biol. Macromol. 2021, 177, 526–534. [Google Scholar] [CrossRef]

- Permatasari, A.A.A.P.; Rosiana, I.W.; Wiradana, P.A.; Lestari, M.D.; Widiastuti, N.K.; Kurniawan, S.B.; Widhiantara, I.G. Extraction and characterization of sodium alginate from three brown algae collected from Sanur Coastal Waters, Bali as biopolymer agent. Biodiversitas J. Biol. Divers. 2022, 23, 3. [Google Scholar] [CrossRef]

- Metha, C.; Pawar, S.; Suvarna, V. Recent advancements in alginate-based films for active food packaging applications. Sustain. Food Technol. 2024, 2, 1246–1265. [Google Scholar] [CrossRef]

- Jayakody, M.M.; Vanniarachchy, M.P.G.; Wijesekara, I. Seaweed derived alginate, agar, and carrageenan based edible coatings and films for the food industry: A review. J. Food Meas. Charact. 2022, 16, 1195–1227. [Google Scholar] [CrossRef]

- Waseem, M.; Khan, M.U.; Majeed, Y.; Ntsefong, G.N.; Kirichenko, I.; Klopova, A.; Trushov, P.; Lodygin, A. Seaweed-based films for sustainable food packaging: Properties, incorporation of essential oils, applications, and future directions. Potravinarstvo/Slov. J. Food Sci. 2023, 17, 1. [Google Scholar] [CrossRef] [PubMed]

- Aman Mohammadi, M.; Mirza Alizadeh, A.; Dakhili, S.; Kooki, S.; Hosseini, S.M. Bacterial nanocellulose: A sustainable revolution in food science. eFood 2025, 6, e70080. [Google Scholar] [CrossRef]

- Acharyya, P.P.; Sarma, M.; Kashyap, A. Recent advances in synthesis and bioengineering of bacterial nanocellulose composite films for green, active and intelligent food packaging. Cellulose 2024, 31, 7163–7187. [Google Scholar] [CrossRef]

- Guo, J.; Ding, K.; Li, S.; Li, S.; Jin, P.; Zheng, Y.; Wu, Z. Polysaccharide-based high barrier food packaging film: Design and application. Crit. Rev. Food Sci. Nutr. 2025, online ahead of print, 1–20. [Google Scholar] [CrossRef]

- Yudishter, S.; Shams, R.; Dash, K.K. Polysaccharide nanoparticles as building blocks for food processing applications: A comprehensive review. Food Sci. Biotechnol. 2025, 34, 527–546. [Google Scholar] [CrossRef] [PubMed]

- Soares da Silva, F.A.G.; Matos, M.; Dourado, F.; Reis, M.A.M.; Branco, P.C.; Poças, F.; Gama, M. Development of a layered bacterial nanocellulose-PHBV composite for food packaging. J. Sci. Food Agric. 2023, 103, 1077–1087. [Google Scholar] [CrossRef] [PubMed]

- Kishore, A.; Mithul Aravind, S.; Singh, A. Bionanocomposites for active and smart food packaging: A review on its application, safety, and health aspects. J. Food Process Eng. 2023, 46, e14320. [Google Scholar] [CrossRef]

- Pathak, B.; Saikia, S.; Kashyap, A.; Sarma, R.; Sarma, M.; Choudhury, S. Bacterial nanocellulose as a green material for food packaging application. In Cellulose-Biobased Solutions for Society; IntechOpen: London, UK, 2025. [Google Scholar]

- Mahović Poljaček, S.; Tomašegović, T.; Strižić Jakovljević, M.; Jamnicki Hanzer, S.; Murković Steinberg, I.; Žuvić, I.; Leskovać, M.; Lavrič, G.; Kavčič, U.; Karlovits, I. Starch-based functional films enhanced with bacterial nanocellulose for smart packaging: Physicochemical properties, pH sensitivity and colorimetric response. Polymers 2024, 16, 2259. [Google Scholar] [CrossRef]

- Goswami, S.; Kishore, A.; Singh, A.; Kumari, P.; Mane, S. Organic-based nanomaterials and their use in food packaging. In Organic-Based Nanomaterials in Food Packaging; Springer Nature: Cham, Switzerland, 2024; pp. 63–90. [Google Scholar]

- Amara, C.; El Mahdi, A.; Medimagh, R.; Khwaldia, K. Nanocellulose-based composites for packaging applications. Curr. Opin. Green Sustain. Chem. 2021, 31, 100512. [Google Scholar] [CrossRef]

- Tang, L.; Jin, Y.; He, X.; Huang, R. Biodegradable poly (ethylene glycol-glycerol-itaconate-sebacate) copolyester elastomer with significantly reinforced mechanical properties by in-situ construction of bacterial cellulose interpenetrating network. Sci. Rep. 2024, 14, 7172. [Google Scholar] [CrossRef]

- Weslie, T.; Felixius, V.; Amala, Z.; Shofinita, D. Pediocin and grape seed extract as antimicrobial agents in nanocellulose biobased food packaging: A review. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bandung, Indonesia, 16–17 November 2020; IOP Publishing: Bristol, UK, 2021; Volume 1143, p. 012037. [Google Scholar]

- Singh, N.; Garg, M.; Chopra, R. Active biodegradable composites for packaging applications. In Biodegradable Composites for Packaging Applications; CRC Press: Boca Raton, FL, USA, 2022; pp. 257–279. [Google Scholar]

- Zhang, Y.Q.; Li, J.; Huang, X.J.; Yang, C.X.; Wu, C.; Yang, Z.L.; Li, D.Q. Performance-enhanced regenerated cellulose film by adding grape seed extract. Int. J. Biol. Macromol. 2023, 232, 123290. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Zhang, W.; Biswas, D.; Ramakrishnan, R.; Rhim, J.W. Grapefruit seed extract-added functional films and coating for active packaging applications: A review. Molecules 2023, 28, 730. [Google Scholar] [CrossRef]

- Akbar, S.A.; Mustari, A. Food packaging based on biodegradable polymers from seaweeds: A systematic review. In Proceedings of the BIO Web of Conferences, Tanjungpinang, Indonesia, 28–29 November 2024; EDP Sciences: Les Ulis, France, 2024; Volume 87, p. 01005. [Google Scholar]

- Wongphan, P.; Promhuad, K.; Srisa, A.; Laorenza, Y.; Oushapjalaunchai, C.; Harnkarnsujarit, N. Unveiling the future of meat packaging: Functional biodegradable packaging preserving meat quality and safety. Polymers 2024, 16, 1232. [Google Scholar] [CrossRef]

- He, X.; Tang, L.; Li, C.; Hao, J.; Huang, R. Eco-friendly poly(butylene adipate-co-butylene terephthalate)/poly(lactic acid) packaging films with grape seed extract for extending the shelf life of strawberries and broccoli. LWT 2025, 227, 117990. [Google Scholar] [CrossRef]

- Sant’anna Andrade, L.; da Silva, E.O. Nanohybrids with potential barrier property and antimicrobial activity for application in sustainable polymer food packaging: A mini-review. Polym. Adv. Technol. 2024, 35, e6455. [Google Scholar] [CrossRef]

- Kim, U.; Oh, S.W. Antimicrobial resistance induction potential of grapefruit seed extract on multi-species biofilm of E. coli in food industry. Int. J. Food Microbiol. 2024, 424, 110849. [Google Scholar] [CrossRef] [PubMed]

- ASTM D882-12; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM E96-16; Standard Test Methods for Water Vapor Transmission of Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Dhaundiyal, A.; Jamwal, V.; Mittal, A.; Pal, K.; Jeevitha, G.C.; Tripathi, R.; Paul, N.; Rameshpathy, M.; Guimarães Junior, M. Harnessing pomegranate rind waste to develop novel bioactive packaging films using citric acid crosslinked polyvinyl alcohol (PVA)/starch-based polymer matrix. Biomass Convers. Biorefin. 2024, 1–20. [Google Scholar] [CrossRef]

| Sample Name | % of BNC (w/w) | % of GSE (w/w) | % of Glycerol (w/w) |

|---|---|---|---|

| Sample 1BNC0 | 1 | 0 | 15 |

| Sample 1BNC0.5 | 0.5 | 15 | |

| Sample 1BNC1 | 1 | 15 | |

| Sample 1BNC2 | 2 | 15 | |

| Sample 2BNC0 | 2 | 0 | 15 |

| Sample 2BNC0.5 | 0.5 | 15 | |

| Sample 2BNC1 | 1 | 15 | |

| Sample 2BNC2 | 2 | 15 |

| Sample Name | Thickness [mm] | Tensile Strength [MPa] | Elongation at Break [%] | Porosity [mL/min] |

|---|---|---|---|---|

| Sample 1BNC0 | 0.085 ± 0.003 | 25.2 ± 1.4 | 15.8 ± 0.9 | 0 |

| Sample 1BNC0.5 | 0.087 ± 0.002 | 28.5 ± 1.2 | 14.2 ± 0.4 | 0 |

| Sample 1BNC1 | 0.089 ± 0.003 | 30.1 ± 1.5 | 14.0 ± 1.0 | 0 |

| Sample 1BNC2 | 0.092 ± 0.004 | 31.7 ± 1.5 | 12.4 ± 0.5 | 0 |

| Sample 2BNC0 | 0.090 ± 0.001 | 26.8 ± 1.2 | 14.7 ± 0.2 | 0 |

| Sample 2BNC0.5 | 0.092 ± 0.002 | 28.9 ± 1.3 | 13.9 ± 0.1 | 0 |

| Sample 2BNC1 | 0.097 ± 0.001 | 33.4 ± 1.6 | 12.7 ± 0.5 | 0 |

| Sample 2BNC2 | 0.099 ± 0.003 | 39. 7 ± 1.0 | 12.1 ± 0.2 | 0 |

| Sample Name | Water Vapor Permeability [g·mm/m2·h·kPa] |

|---|---|

| Sample 1BNC0 | 4.3 ± 0.1 |

| Sample 1BNC0.5 | 3.7 ± 0.1 |

| Sample 1BNC1 | 3.1 ± 0.2 |

| Sample 1BNC2 | 2.8 ± 0.4 |

| Sample 2BNC0 | 4.3 ± 0.2 |

| Sample 2BNC0.5 | 3.6 ± 0.1 |

| Sample 2BNC1 | 3.2 ± 0.2 |

| Sample 2BNC2 | 2.9 ± 0.3 |

| Sample Name | Diameter of Bacteriostatic Circle [mm] | |

|---|---|---|

| Escherichia coli | Staphylococcus aureus | |

| Sample 1BNC0 | 5.8 ± 0.0 | 6.0 ± 0.0 |

| Sample 1BNC0.5 | 8.4 ± 0.2 | 9.2 ± 0.1 |

| Sample 1BNC1 | 12.8 ± 0.6 | 14.4 ± 0.1 |

| Sample 1BNC2 | 19.3 ± 0.3 | 20.7 ± 0.4 |

| Sample 2BNC0 | 6.0 ± 0.0 | 6.1 ± 0.0 |

| Sample 2BNC0.5 | 8.0 ± 0.4 | 9.0 ± 0.6 |

| Sample 2BNC1 | 12.4 ± 0.1 | 13.6 ± 1.1 |

| Sample 2BNC2 | 18.1 ± 0.5 | 19.7 ± 0.2 |

| Sample Name | 1st Week | 2nd Week | 3rd Week | 4th Week |

|---|---|---|---|---|

| Weight Loss of Packed Blueberries [%] | ||||

| Control—no film | 6.8 | 9.4 | 10.5 | 11.3 |

| Sample 1BNC0 | 1.2 | 3.8 | 3.9 | 4.6 |

| Sample 1BNC0.5 | 1.0 | 3.2 | 3.8 | 4.3 |

| Sample 1BNC1 | 0.9 | 2.8 | 3.8 | 4.0 |

| Sample 1BNC2 | 0.8 | 2.5 | 3.2 | 3.9 |

| Sample 2BNC0 | 1.3 | 4.0 | 4.4 | 4.4 |

| Sample 2BNC0.5 | 1.1 | 3.4 | 3.5 | 4.0 |

| Sample 2BNC1 | 1.1 | 3.1 | 3.8 | 4.0 |

| Sample 2BNC2 | 1.0 | 2.8 | 3.3 | 3.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vrabič-Brodnjak, U.; Ružič, T. Bio-Based Alginate Films Incorporating Bacterial Nanocellulose and Grape Seed Extract for Enhanced Food Packaging. Polymers 2025, 17, 2564. https://doi.org/10.3390/polym17192564

Vrabič-Brodnjak U, Ružič T. Bio-Based Alginate Films Incorporating Bacterial Nanocellulose and Grape Seed Extract for Enhanced Food Packaging. Polymers. 2025; 17(19):2564. https://doi.org/10.3390/polym17192564

Chicago/Turabian StyleVrabič-Brodnjak, Urška, and Tina Ružič. 2025. "Bio-Based Alginate Films Incorporating Bacterial Nanocellulose and Grape Seed Extract for Enhanced Food Packaging" Polymers 17, no. 19: 2564. https://doi.org/10.3390/polym17192564

APA StyleVrabič-Brodnjak, U., & Ružič, T. (2025). Bio-Based Alginate Films Incorporating Bacterial Nanocellulose and Grape Seed Extract for Enhanced Food Packaging. Polymers, 17(19), 2564. https://doi.org/10.3390/polym17192564