Evaluation and Optimization of Thermoplastic Extrusion Parameters Influencing the Impact Resistance of Additively Manufactured Samples from PETG and Recycled PETG

Abstract

1. Introduction

2. Materials and Experimental Procedure

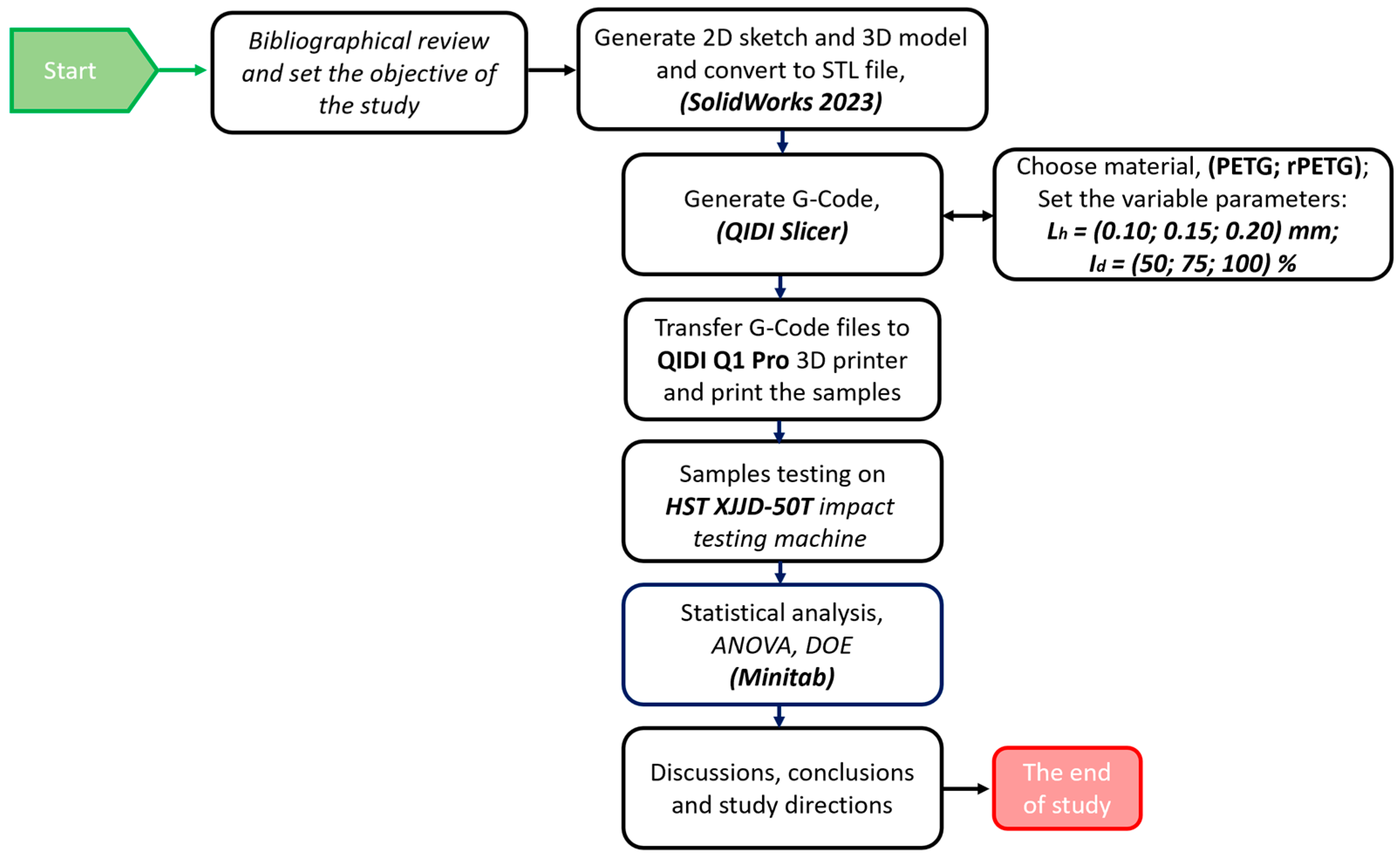

2.1. Research Methodology

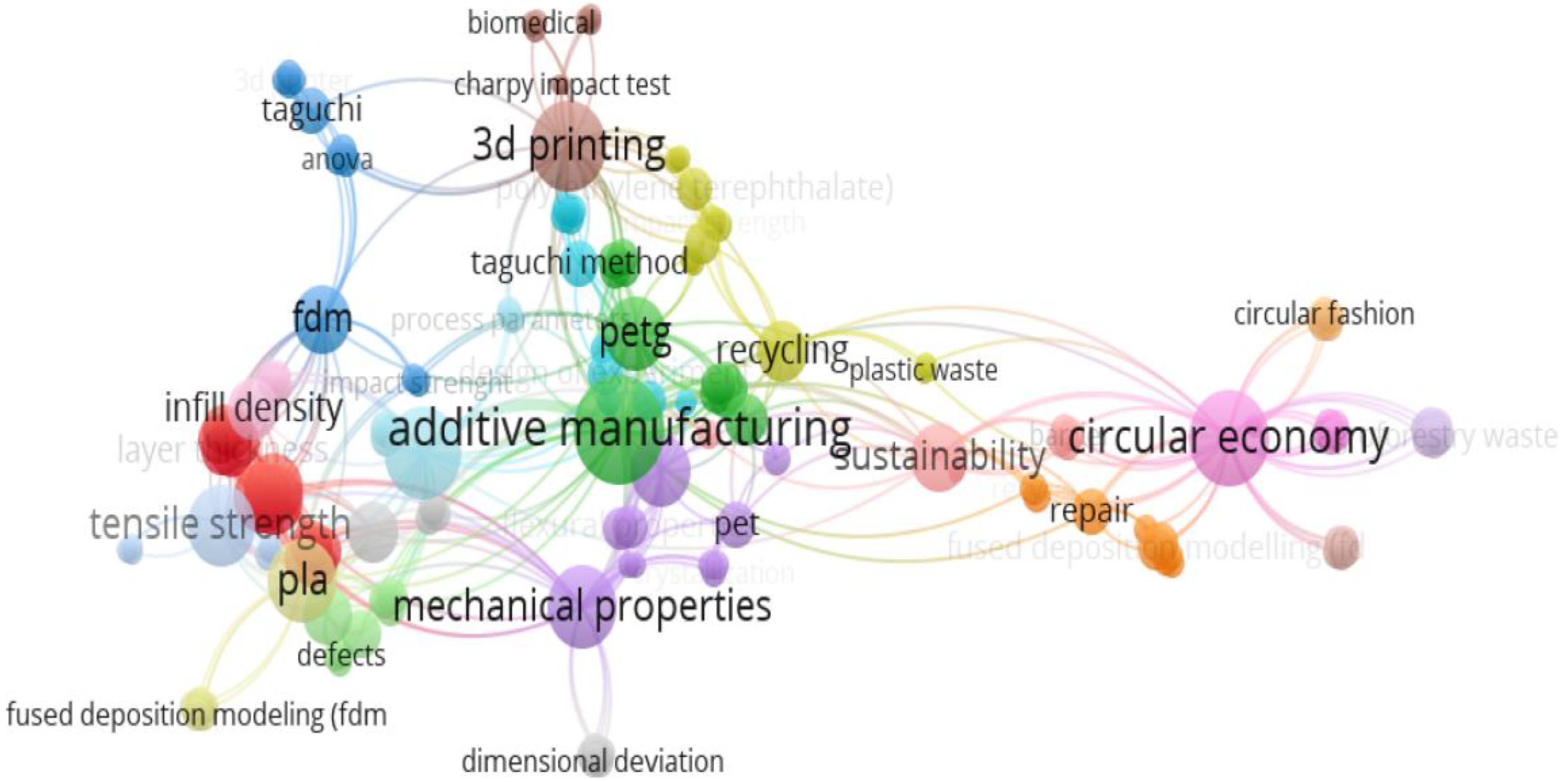

2.2. Bibliographical Study

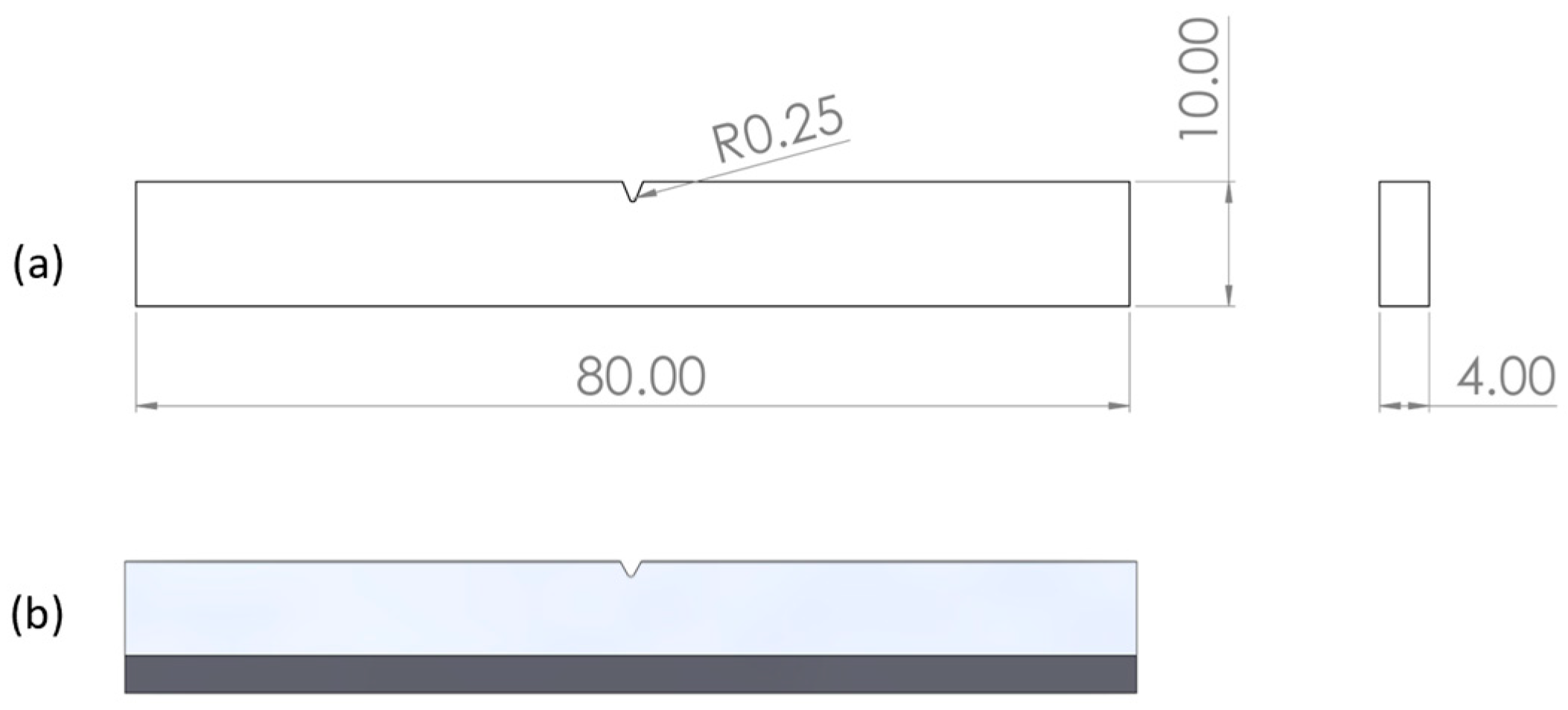

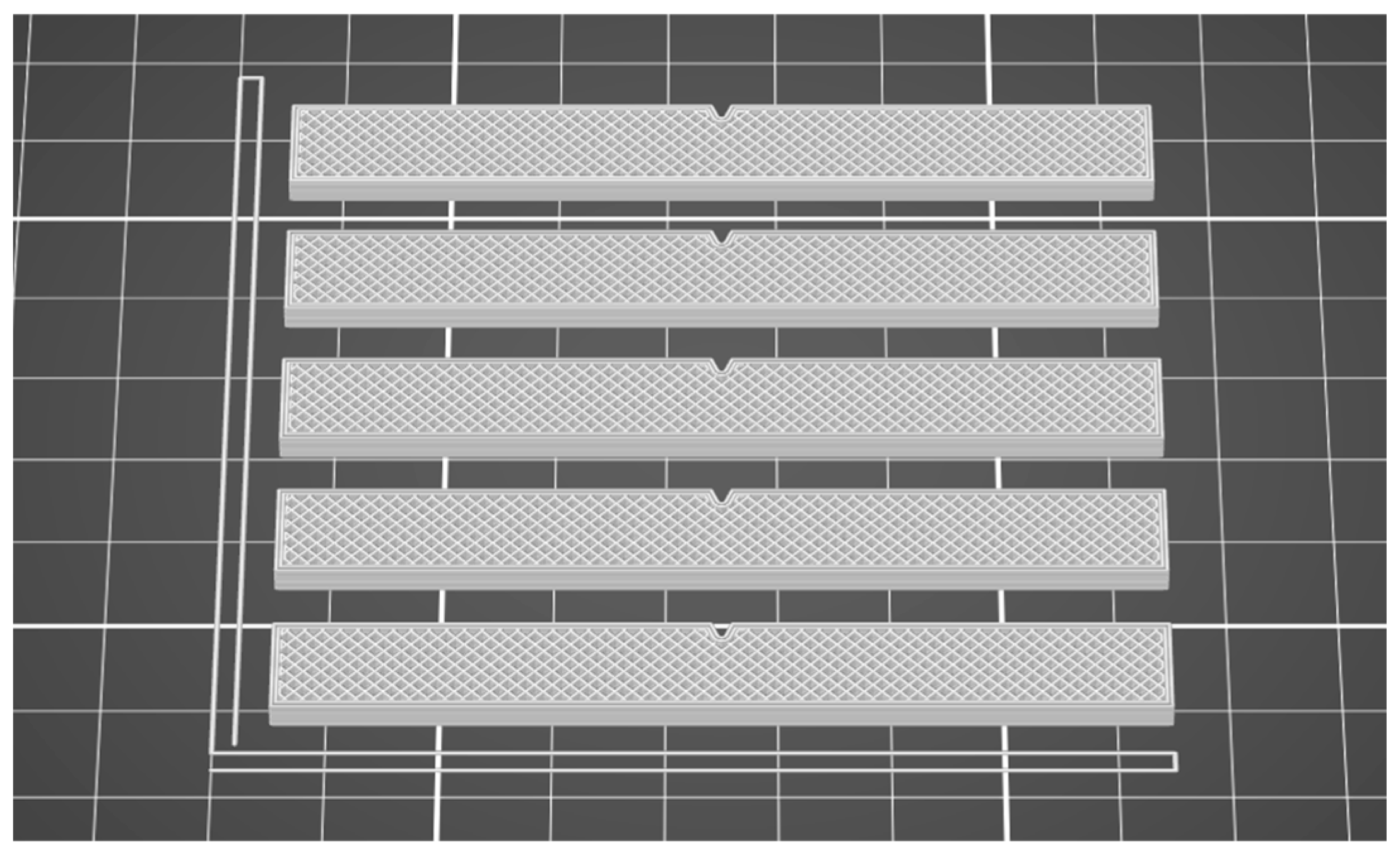

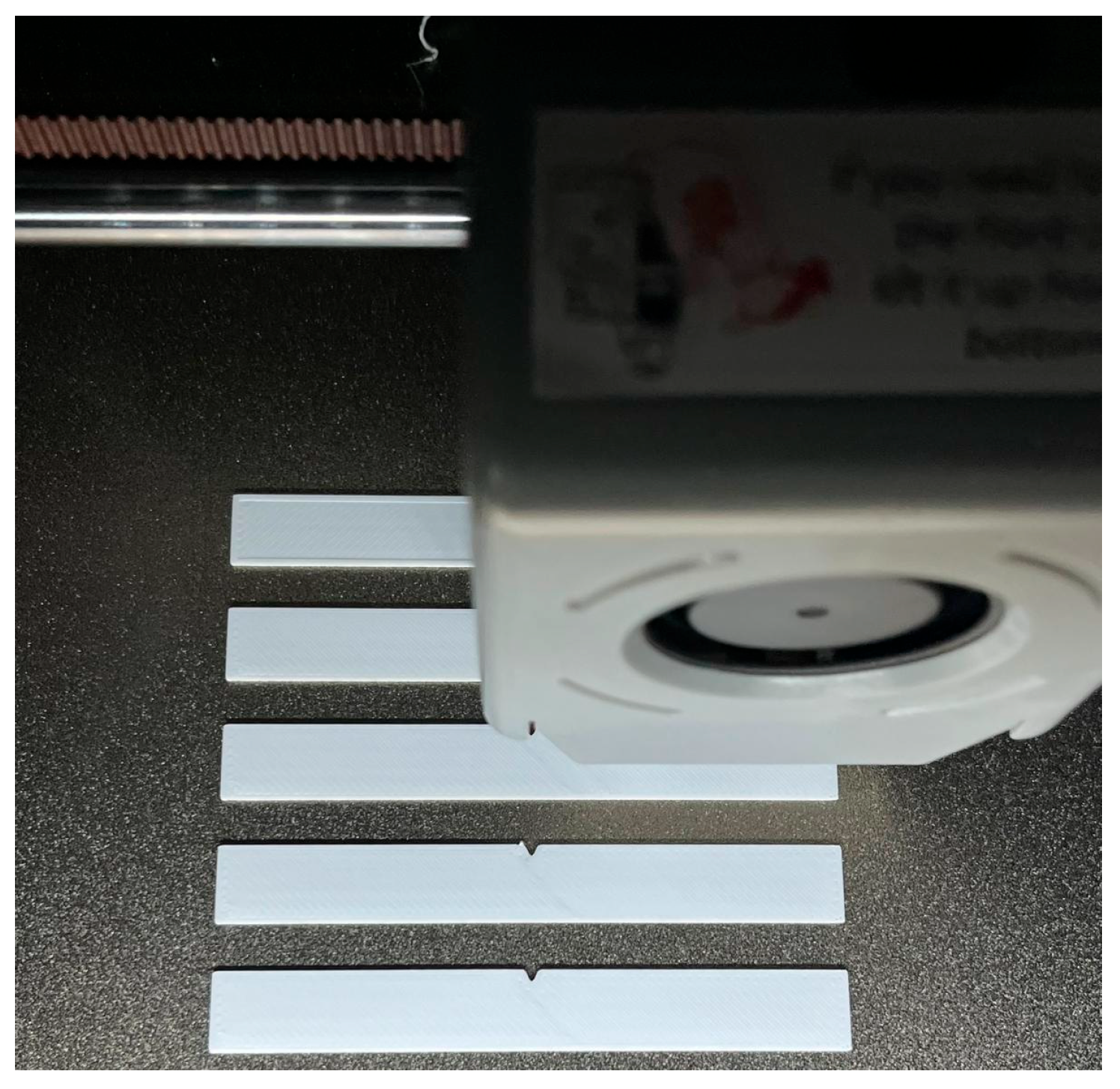

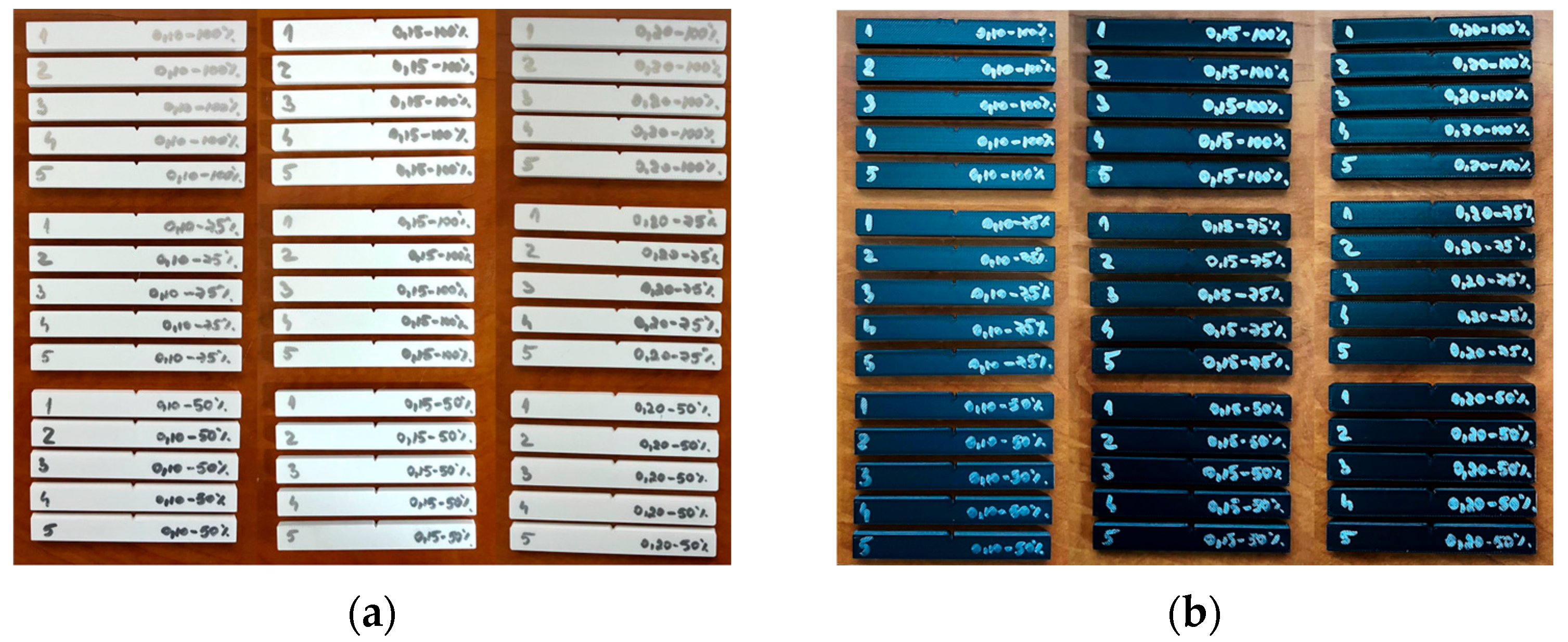

2.3. Manufacturing of Samples for Charpy Impact Testing

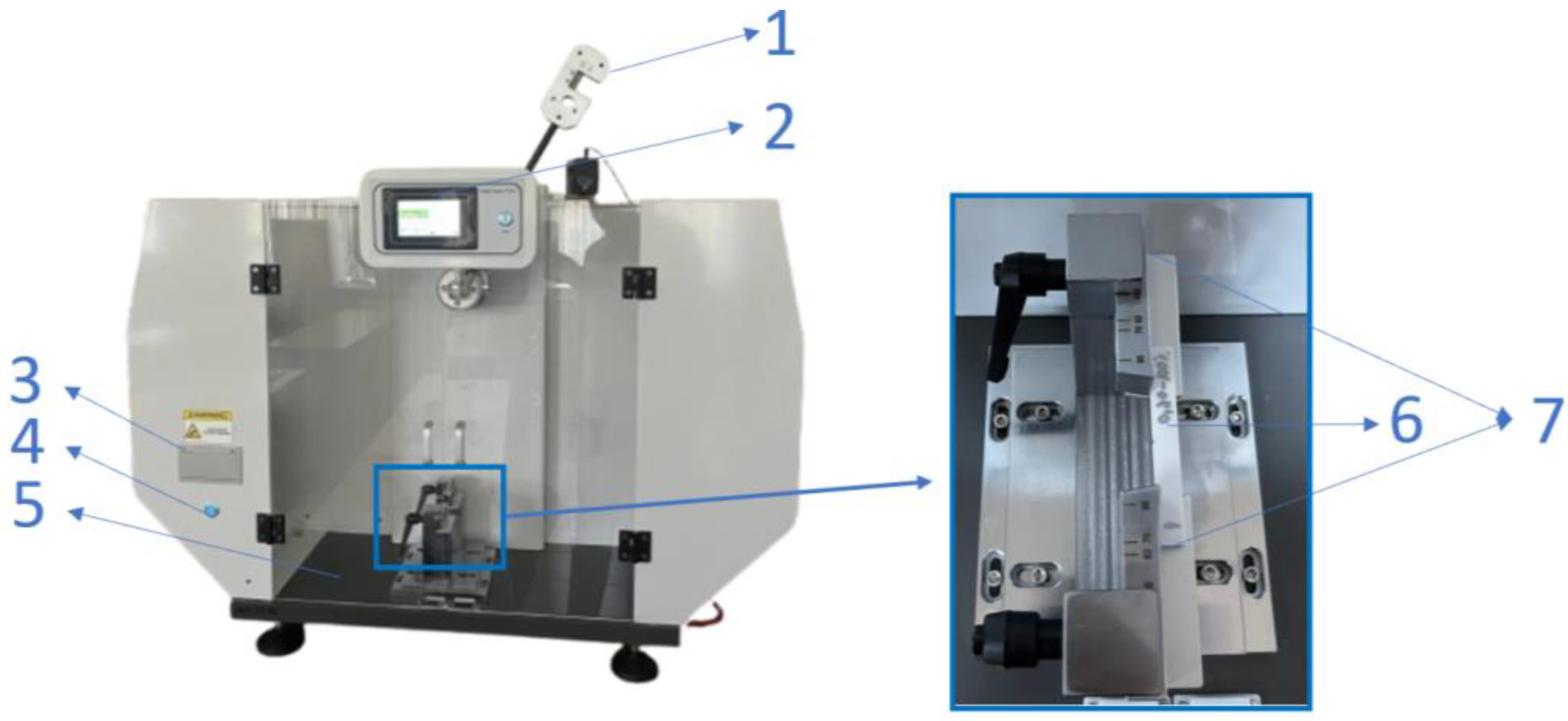

2.4. Charpy Impact Testing of Samples Manufactured by Additively Thermoplastic Extrusion of PETG and rPETG Filaments

2.5. Experimental Design and Statistical Analysis

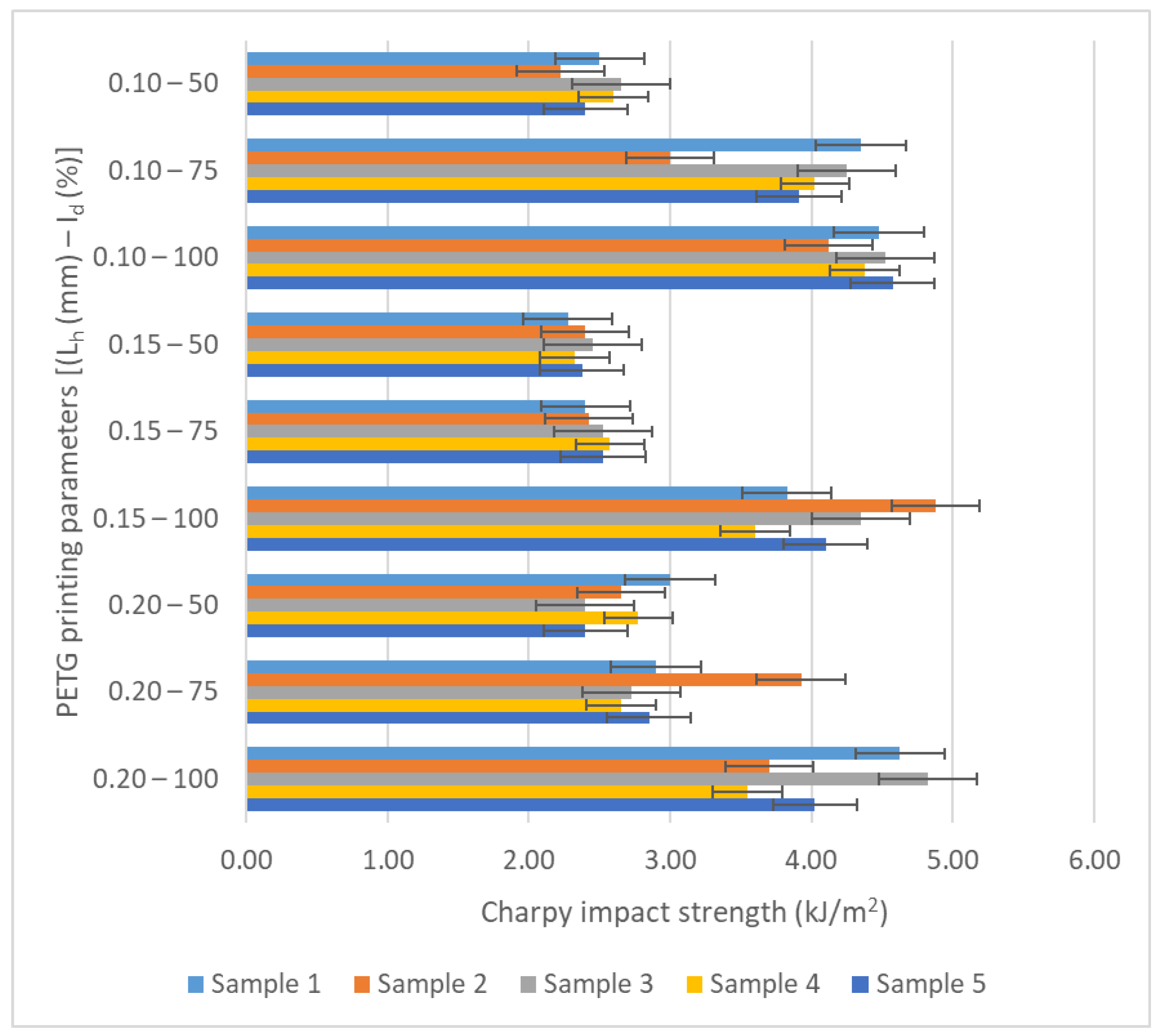

3. Results and Discussion

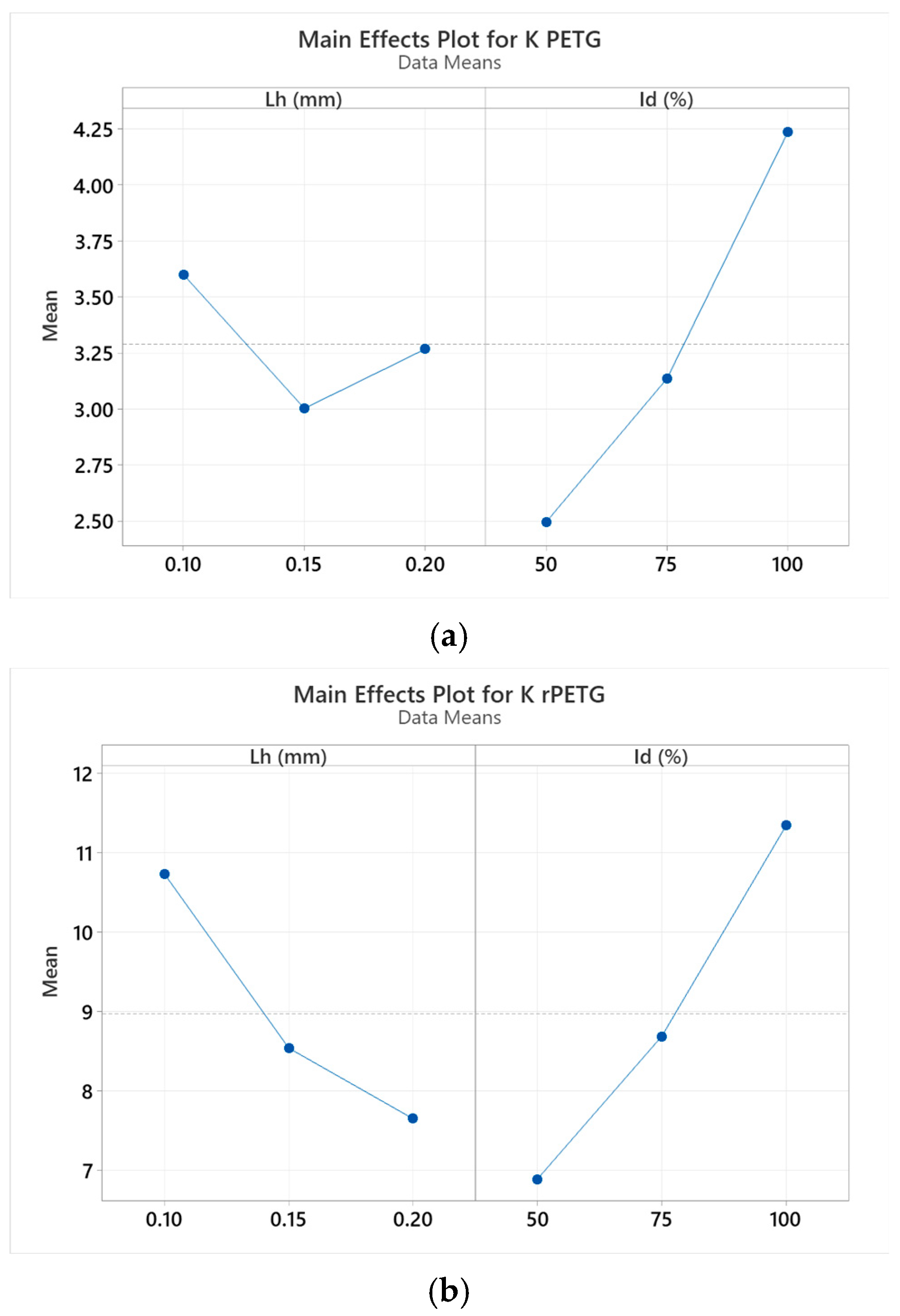

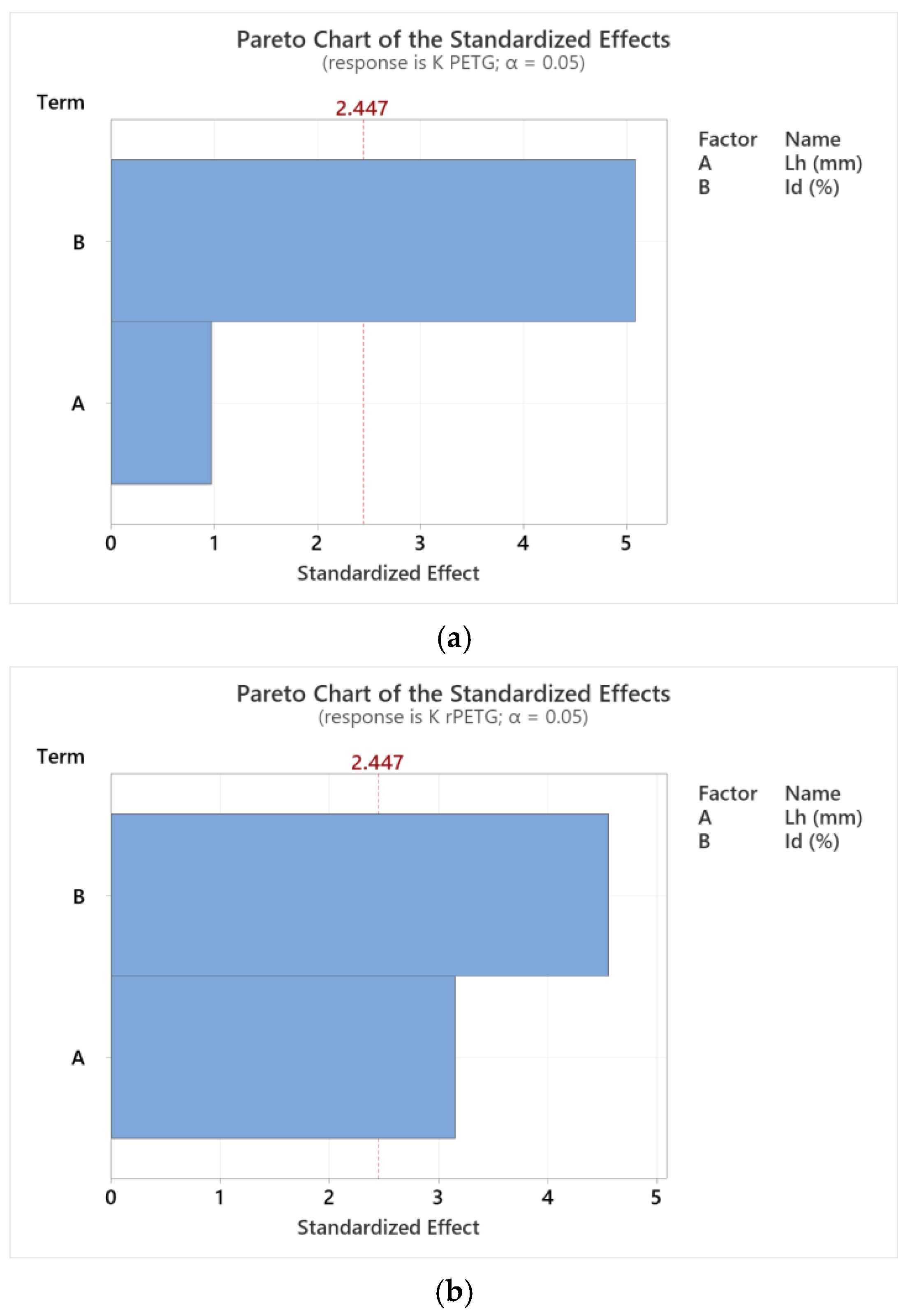

4. Statistical Evaluation of the Influence of FDM Parameters on Impact Resistance and Their Optimization

5. Conclusions

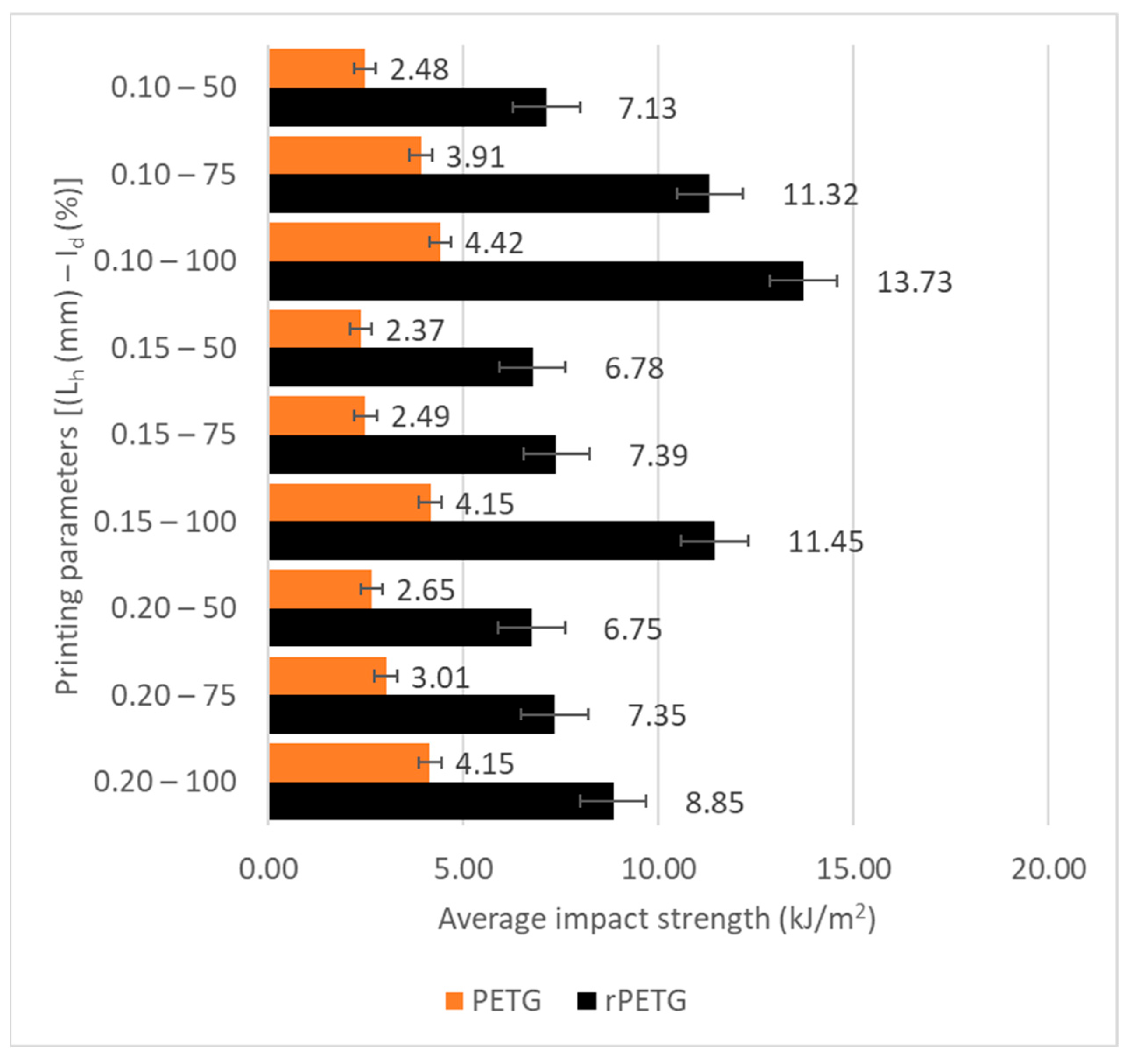

- The general average of the impact strengths corresponding to the samples manufactured from rPETG is higher by 172.64% compared with the general average of the impact strengths corresponding to the samples manufactured from PETG;

- The filling percentage (Id) is the variable parameter that significantly affects the impact strengths (K);

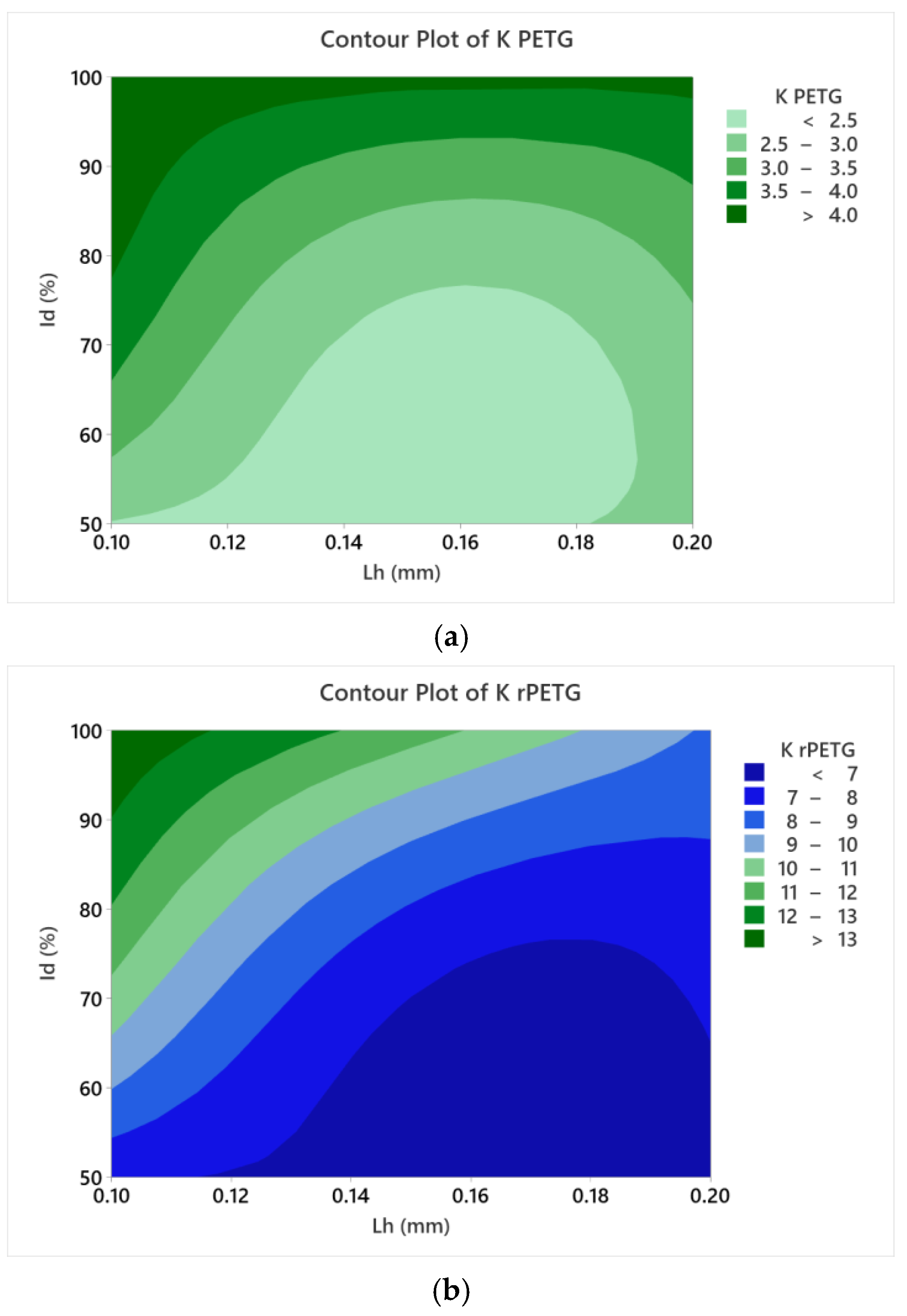

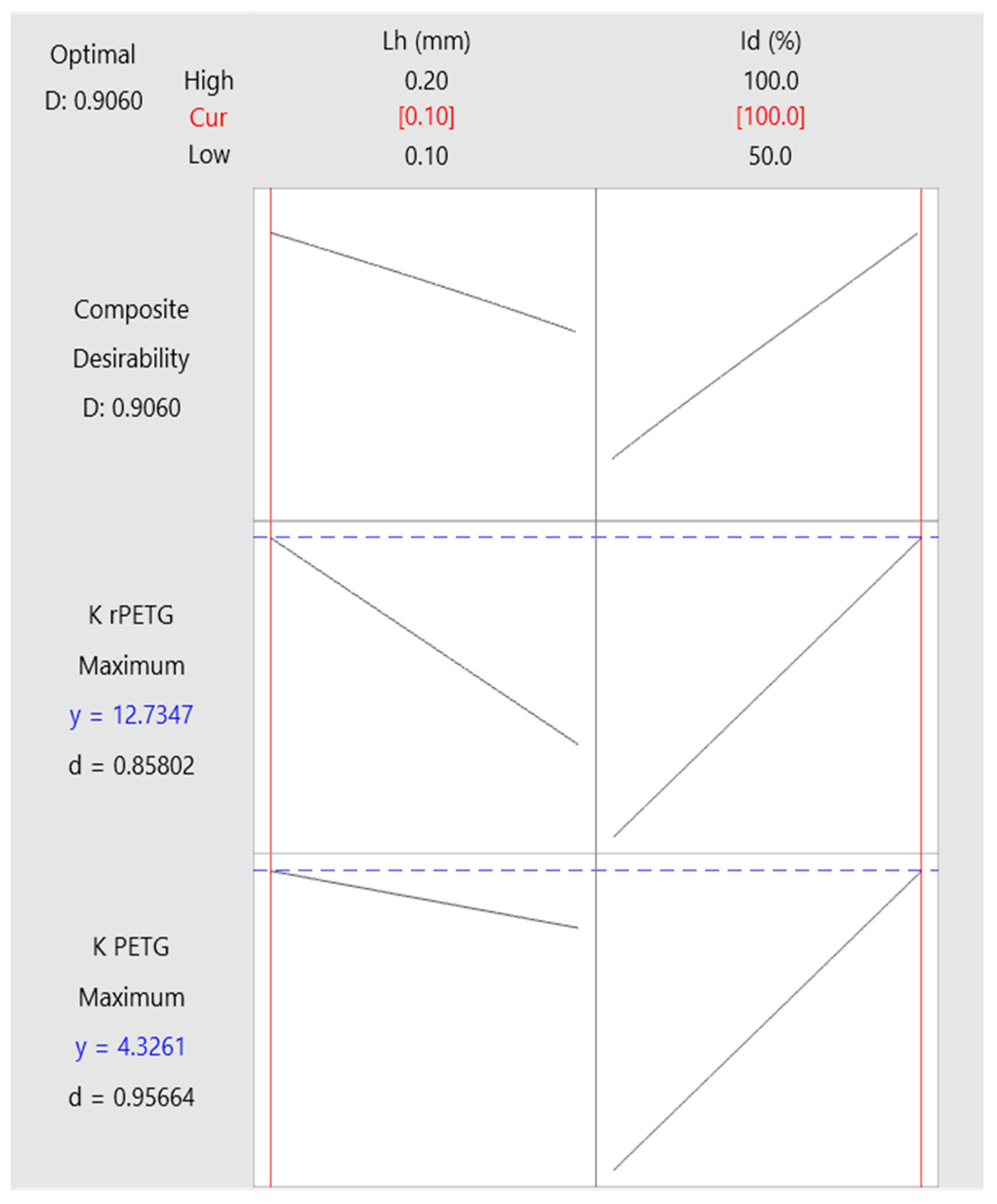

- The optimal parameters for additive manufacturing by thermoplastic extrusion of PETG and rPETG impact samples are Lh = 0.10 mm and Id = 100% (see Figure 15);

- For Lh = 0.10 mm and Id = 100%, the impact strengths of the samples manufactured additively by thermoplastic extrusion of rPETG are 210.87% higher than the impact strengths of samples manufactured additively by thermoplastic extrusion of PETG.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ferreira, J.C., Jr.; Triki, E.; Doutres, O.; Demarquette, N.R.; Hof, L.A. Recyclable Polyester Textile Waste-Based Composites for Building Applications in a Circular Economy Framework. J. Clean. Prod. 2025, 515, 145759. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.-J. Plastics in the Context of the Circular Economy and Sustainable Plastics Recycling: Comprehensive Review on Research Development, Standardization and Market. Compos. Part C Open Access 2021, 6, 100168. [Google Scholar] [CrossRef]

- Moradi, M.; Meiabadi, M.S.S.; Siddique, U.; Salimi, N.; Farahani, S. Circular Economy-Driven Repair of 3D Printed Polylactic Acid (PLA) by Fused Deposition Modelling (FDM) through Statistical Approach. Mater. Today Commun. 2025, 42, 111264. [Google Scholar] [CrossRef]

- Espinach, F.X.; Monzon, M.; Paz, R.; Ortega, R.; Fullana, P.; Bala, A.; Campos, C.; Delgado-Aguilar, M.; Tarrés, Q. Composites Made of a Blend of Plastics Recovered from Bottle Caps Reinforced with Fibers from Banana Rachis Waste. A Circular Economy Strategy in the Canary Islands. J. Clean. Prod. 2024, 483, 144244. [Google Scholar] [CrossRef]

- Naveed, N.; Anwar, M.N.; Armstrong, M.; Ahmad, F.; Haq, M.I.U.; Ridley, G. Enhancing Sustainability and Functionality with Recycled Materials in Multi-Material Additive Manufacturing. Sustainability 2025, 17, 6105. [Google Scholar] [CrossRef]

- Rashid, K.H.O.; Aziz, R.A.; Karmaker, C.L.; Bari, A.B.M.M.; Raihan, A. Evaluating the Challenges to Circular Economy Implementation in the Apparel Accessories Industry: Implications for Sustainable Development. Green Technol. Sustain. 2025, 3, 100140. [Google Scholar] [CrossRef]

- Yin, S.; Jia, F.; Chen, L.; Wang, Q. Circular Economy Practices and Sustainable Performance: A Meta-Analysis. Resour. Conserv. Recycl. 2023, 190, 106838. [Google Scholar] [CrossRef]

- Repp, L.; Hekkert, M.; Kirchherr, J. Circular Economy-Induced Global Employment Shifts in Apparel Value Chains: Job Reduction in Apparel Production Activities, Job Growth in Reuse and Recycling Activities. Resour. Conserv. Recycl. 2021, 171, 105621. [Google Scholar] [CrossRef]

- Pintos, P.B.; Sanz de León, A.; Molina, S.I. Large Format Additive Manufacturing of Polyethylene Terephthalate (PET) by Material Extrusion. Addit. Manuf. 2024, 79, 103908. [Google Scholar] [CrossRef]

- Mishbak, H.; Hassan, M.H.; Daskalakis, E.; Omar, A.M.; Freitas, D.M.; Mirihanage, W.; Mativenga, P.; Potluri, P.; Bartolo, P. Accelerated Degradation of 3D-Printed PETG Bone–Tissue Scaffolds via Geometrical Control. CIRP Ann. 2025, 74, 327–331. [Google Scholar] [CrossRef]

- Patel, K.S.; Shah, D.B.; Joshi, S.J.; Aldawood, F.K.; Kchaou, M. Effect of Process Parameters on the Mechanical Performance of FDM Printed Carbon Fiber Reinforced PETG. J. Mater. Res. Technol. 2024, 30, 8006–8018. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, Y.; Kobir, M.H.; Faludi, J.; Zhao, F. Driving Additive Manufacturing towards Circular Economy: State-of-the-Art and Future Research Directions. J. Manuf. Process. 2024, 124, 621–637. [Google Scholar] [CrossRef]

- Kumar, R.; Sharma, H.; Saran, C.; Tripathy, T.S.; Sangwan, K.S.; Herrmann, C. A Comparative Study on the Life Cycle Assessment of a 3D Printed Product with PLA, ABS & PETG Materials. Procedia CIRP 2022, 107, 15–20. [Google Scholar] [CrossRef]

- Tura, N.; Hanski, J.; Ahola, T.; Ståhle, M.; Piiparinen, S.; Valkokari, P. Unlocking Circular Business: A Framework of Barriers and Drivers. J. Clean. Prod. 2019, 212, 90–98. [Google Scholar] [CrossRef]

- Petousis, M.; Michailidis, N.; Kulas, V.; Papadakis, V.; Spiridaki, M.; Mountakis, N.; Argyros, A.; Valsamos, J.; Stratakis, E.; Vidakis, N. Valorization of Recycled Fine Powder Glass (RFPG) in Additive Manufacturing: Optimization of the RFPG Content in Polyethylene Terephthalate Glycol (PETG) and Multi-Response Analysis. Clean. Mater. 2024, 14, 100271. [Google Scholar] [CrossRef]

- Galațanu, S.-V.; Serralha, F.N.; Mărghitaș, M.-P.; Șoșdean, C.; Popa, C.-F.; Emanoil, L.; Marșavina, L. Mechanical Behavior of Recycled FDM Printed Parts from PETG in the Circular Economy. Procedia Struct. Integr. 2024, 56, 138–143. [Google Scholar] [CrossRef]

- Kumaresan, R.; Kadirgama, K.; Samykano, M.; Harun, W.S.W.; Thirugnanasambandam, A.; Kanny, K. In-Depth Study and Optimization of Process Parameters to Enhance Tensile and Compressive Strengths of PETG in FDM Technology. J. Mater. Res. Technol. 2025, 37, 397–416. [Google Scholar] [CrossRef]

- Raja, S.; Jayalakshmi, M.; Rusho, M.A.; Selvaraj, V.K.; Subramanian, J.; Yishak, S.; Kumar, T.A. Fused Deposition Modeling Process Parameter Optimization on the Development of Graphene Enhanced Polyethylene Terephthalate Glycol. Sci. Rep. 2024, 14, 30744. [Google Scholar] [CrossRef] [PubMed]

- Zhai, C.; Wang, J.; Tu, Y.; Chang, G.; Ren, X.; Ding, C. Robust optimization of 3D printing process parameters considering process stability and production efficiency. Addit. Manuf. 2023, 71, 103588. [Google Scholar] [CrossRef]

- Wei, H.; Tang, L.; Qin, H.; Wang, H.; Chen, C.; Li, Y.; Wang, C. Optimizing FDM 3D printing parameters for improved tensile strength using the Takagi–Sugeno fuzzy neural network. Mater. Today Commun. 2024, 38, 108268. [Google Scholar] [CrossRef]

- Valvez, S.; Silva, A.P.; Reis, P.N.B. Compressive Behaviour of 3D-Printed PETG Composites. Aerospace 2022, 9, 124. [Google Scholar] [CrossRef]

- Fountas, N.A.; Zaoutsos, S.; Chaidas, D.; Kechagias, J.D.; Vaxevanidis, N.M. Statistical modelling and optimization of mechanical properties for PLA and PLA/Wood FDM materials. Mater. Today Proc. 2023, 93, 824–830. [Google Scholar] [CrossRef]

- Nyabadza, A.; Mc Donough, L.M.; Manikandan, A.; Ray, A.B.; Plouze, A.; Muilwijk, C.; Freeland, B.; Vazquez, M.; Brabazon, D. Mechanical and antibacterial properties of FDM additively manufactured PLA parts. Results Eng. 2024, 21, 101744. [Google Scholar] [CrossRef]

- Nikam, M.; Pawar, P.; Patil, A.; Patil, A.; Mokal, K.; Jadhav, S. Sustainable Fabrication of 3D Printing Filament from Recycled PET Plastic. Mater. Today Proc. 2023, 103, 115–125. [Google Scholar] [CrossRef]

- Kothandaraman, L.; Balasubramanian, N.K. Optimization of FDM Printing Parameters for Square Lattice Structures: Improving Mechanical Characteristics. Mater. Today Proc. 2024; in Press. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Tensile Behavior of Specimens Manufactured by FDM from Recycled PETG in the Context of the Circular Economy Transition. Eng. Technol. Appl. Sci. Res. 2024, 14, 18681–18687. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study of the Optimization of FDM Parameters for the Manufacture of Compression Specimens from Recycled PETG in the Context of the Transition to the Circular Economy. Eng. Technol. Appl. Sci. Res. 2024, 14, 18774–18779. [Google Scholar] [CrossRef]

- Jabłońska, M. Experimental Study on Hybrid Additive and Subtractive Manufacturing Processes for Improving Surface Quality. Materials 2025, 18, 3136. [Google Scholar] [CrossRef]

- Li, Y.; Molazem, A.; Kuo, H.-I.; Ahmadi, V.; Shastri, V.P. Comparative Analysis of Dimensional Accuracy in PLA-Based 3D Printing: Effects of Key Printing Parameters and Related Variables. Polymers 2025, 17, 1698. [Google Scholar] [CrossRef]

- Saber, A.; Güler, M.A.; Acar, E.; ElSayed, O.S.; Aldallal, H.; Alsadi, A.; Aldousari, Y. Crash Performance of Additively Manufactured Tapered Tube Crash Boxes: Influence of Material and Geometric Parameters. Designs 2025, 9, 72. [Google Scholar] [CrossRef]

- Ishfaq, K.; Jawad, M.; Sana, M.; Mahmood, M.A.; Anwar, S.; Alfaify, A. Understanding the Circular Economy and Mechanical Performance of Additively Manufactured Recycled PET for Sustainable Process Optimization. Rapid Prototyp. J. 2025, 31, 1393–1411. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kazancoglu, Y.; Sezer, M.D.; Top, N.; Sahin, I. Optimizing Fused Deposition Modelling Parameters Based on the Design for Additive Manufacturing to Enhance Product Sustainability. Comput. Ind. 2023, 145, 103833. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Ferretti, P.; Leon-Cardenas, C.; Santi, G.M.; Sali, M.; Ciotti, E.; Frizziero, L.; Donnici, G.; Liverani, A. Relationship between FDM 3D Printing Parameters Study: Parameter Optimization for Lower Defects. Polymers 2021, 13, 2190. [Google Scholar] [CrossRef]

- Khan, S.; Joshi, K.; Deshmukh, S. A Comprehensive Review on Effect of Printing Parameters on Mechanical Properties of FDM Printed Parts. Mater. Today Proc. 2022, 50, 2119–2127. [Google Scholar] [CrossRef]

- Doshi, M.; Mahale, A.; Kumar Singh, S.; Deshmukh, S. Printing Parameters and Materials Affecting Mechanical Properties of FDM-3D Printed Parts: Perspective and Prospects. Mater. Today Proc. 2022, 50, 2269–2275. [Google Scholar] [CrossRef]

- Almuflih, A.S.; Abas, M.; Khan, I.; Noor, S. Parametric Optimization of FDM Process for PA12-CF Parts Using Integrated Response Surface Methodology, Grey Relational Analysis, and Grey Wolf Optimization. Polymers 2024, 16, 1508. [Google Scholar] [CrossRef] [PubMed]

- Palanisamy, S.; Karuppiah, G.; Kumar, P.; Dharmalingam, S.; Mubarak, S.; Santulli, C.; Ayrilmis, N.; Karumuri, S. Effect of Process Parameters and Material Selection on the Quality of 3D Printed Products by Fused Deposition Modeling (FDM): A Review. Adv. Polym. Technol. 2024, 2024, 3480281. [Google Scholar] [CrossRef]

- Khusheef, A.S.; Hashemi, R.; Shahbazi, M. Optimizing FDM Process Parameters: Predictive Insights through Taguchi, Regression, and Neural Networks. Phys. Scr. 2024, 99, 066005. [Google Scholar] [CrossRef]

- Hartomacıoğlu, S.; Oksuz, M.; Ekinci, A.; Ates, M. Optimization of Produced Parameters for PA6/PA6GF30 Composite Produced by 3D Printing with Novel Knitting Method. Polymers 2025, 17, 1590. [Google Scholar] [CrossRef] [PubMed]

- Alzahrani, M.; Alhumade, H.; Simon, L.; Yetilmezsoy, K.; Madhuranthakam, C.M.R.; Elkamel, A. Additive Manufacture of Recycled Poly(Ethylene Terephthalate) Using Pyromellitic Dianhydride Targeted for FDM 3D-Printing Applications. Sustainability 2023, 15, 5004. [Google Scholar] [CrossRef]

- Vaucher, J.; Demongeot, A.; Michaud, V.; Leterrier, Y. Recycling of Bottle Grade PET: Influence of HDPE Contamination on the Microstructure and Mechanical Performance of 3D Printed Parts. Polymers 2022, 14, 5507. [Google Scholar] [CrossRef] [PubMed]

- Iacob, D.V.; Zisopol, D.G.; Minescu, M. Study on the Optimization of FDM Parameters for the Manufacture of Three-Point Bending Specimens from PETG and Recycled PETG in the Context of the Transition to the Circular Economy. Polymers 2025, 17, 1645. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Grammatikos, S.A.; Porfyrakis, E.; Maniadi, A.; Mountakis, N. Sustainable Additive Manufacturing: Mechanical Response of Polyethylene Terephthalate Glycol over Multiple Recycling Processes. Materials 2021, 14, 1162. [Google Scholar] [CrossRef] [PubMed]

- Trossaert, L.; Ohnmacht, H.; Fiorillo, C.; Cardon, L.; D’hooge, D.R.; Edeleva, M. The Potential of Virgin Polyethylene Terephthalate Glycol (PETG) Grades and Their Blends with Waste PET(G) for Filament-Based Material Extrusion Applications. Addit. Manuf. 2025, 97, 104602. [Google Scholar] [CrossRef]

- VOSviewer. Available online: https://www.vosviewer.com/ (accessed on 10 June 2025).

- ISO 179-1:2023; Plastics—Determination of Charpy Impact Properties. International Organization for Standardization: Geneva, Switzerland, 2023.

- QIDI Studio. Available online: https://qidi3d.com/pages/software-firmware (accessed on 7 March 2025).

- Filament Everfil PETG S10 Diam/1.75mm, Colour/Burgundy, Weight/1.00kg Net. Available online: https://3dkordo.eu/en/product/filament-everfil-petg-s10-diam-175mm-color-burgundy-weight-100kg-netto (accessed on 28 May 2025).

- ASTM D792-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: Montgomery County, PA, USA, 2020.

- ISO 527-1:2019; Plastics—Determination of Tensile Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 178:2019; Plastics—Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- ASTM D3418-21; Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. ASTM International: Montgomery County, PA, USA, 2021.

- Available online: https://www.minitab.com/en-us/ (accessed on 14 June 2025).

- Zisopol, D.G. Ingineria Valorii (Value Engineering); UPG Ploieşti Publishing House: Ploiesti, Romania, 2004. [Google Scholar]

- Zisopol, D.G.; Dumitrescu, A. Ecotehnologie: Studii de Caz; Universitatii Petrol-Gaze din Ploiesti: Ploiesti, Romania, 2020. [Google Scholar]

| Thermoplastic Extrusion 3D Printing Parameters | QIDI Q1 PRO |

|---|---|

| Materials, Mat | PETG; rPETG |

| Part orientation, Po | XY |

| Extruder temperature, Et Platform temperature, Pt Printing speed, Ps First layer speed, Fls | 250 °C 70 °C 120 mm/s 50 mm/s |

| Plate adhesion, Pa | Brim |

| Layer height, Lh | 0.10; 0.15; 0.20 mm |

| First layer height, Flh | 0.30 mm |

| Top layers, Tl | 5 |

| Bottom layers, Bl | 3 |

| Infill percentage, Id | 50; 75; 100% |

| Infill structure, Is | Rectilinear |

| Infill angle, Ia | 45° |

| Top fill pattern, Tf | Monotonic lines |

| Bottom fill pattern, Bf | Monotonic lines |

| Nozzle diameter, Nd | 0.40 mm |

| Layer Height, Lh | Infill Percentage, Id | Charpy Impact Strength, K (kJ/m2) | Average | ||||

|---|---|---|---|---|---|---|---|

| (mm) | (%) | Sample Number | (kJ/m2) | ||||

| 1 | 2 | 3 | 4 | 5 | |||

| 0.10 | 50 | 2.50 | 2.23 | 2.65 | 2.60 | 2.40 | 2.48 |

| 75 | 4.35 | 3.00 | 4.25 | 4.03 | 3.91 | 3.91 | |

| 100 | 4.48 | 4.13 | 4.53 | 4.38 | 4.58 | 4.42 | |

| 0.15 | 50 | 2.28 | 2.40 | 2.45 | 2.33 | 2.38 | 2.37 |

| 75 | 2.40 | 2.43 | 2.53 | 2.58 | 2.53 | 2.49 | |

| 100 | 3.83 | 4.88 | 4.35 | 3.60 | 4.10 | 4.15 | |

| 0.20 | 50 | 3.00 | 2.65 | 2.40 | 2.78 | 2.40 | 2.65 |

| 75 | 2.90 | 3.93 | 2.73 | 2.65 | 2.85 | 3.01 | |

| 100 | 4.63 | 3.70 | 4.83 | 3.55 | 4.03 | 4.15 | |

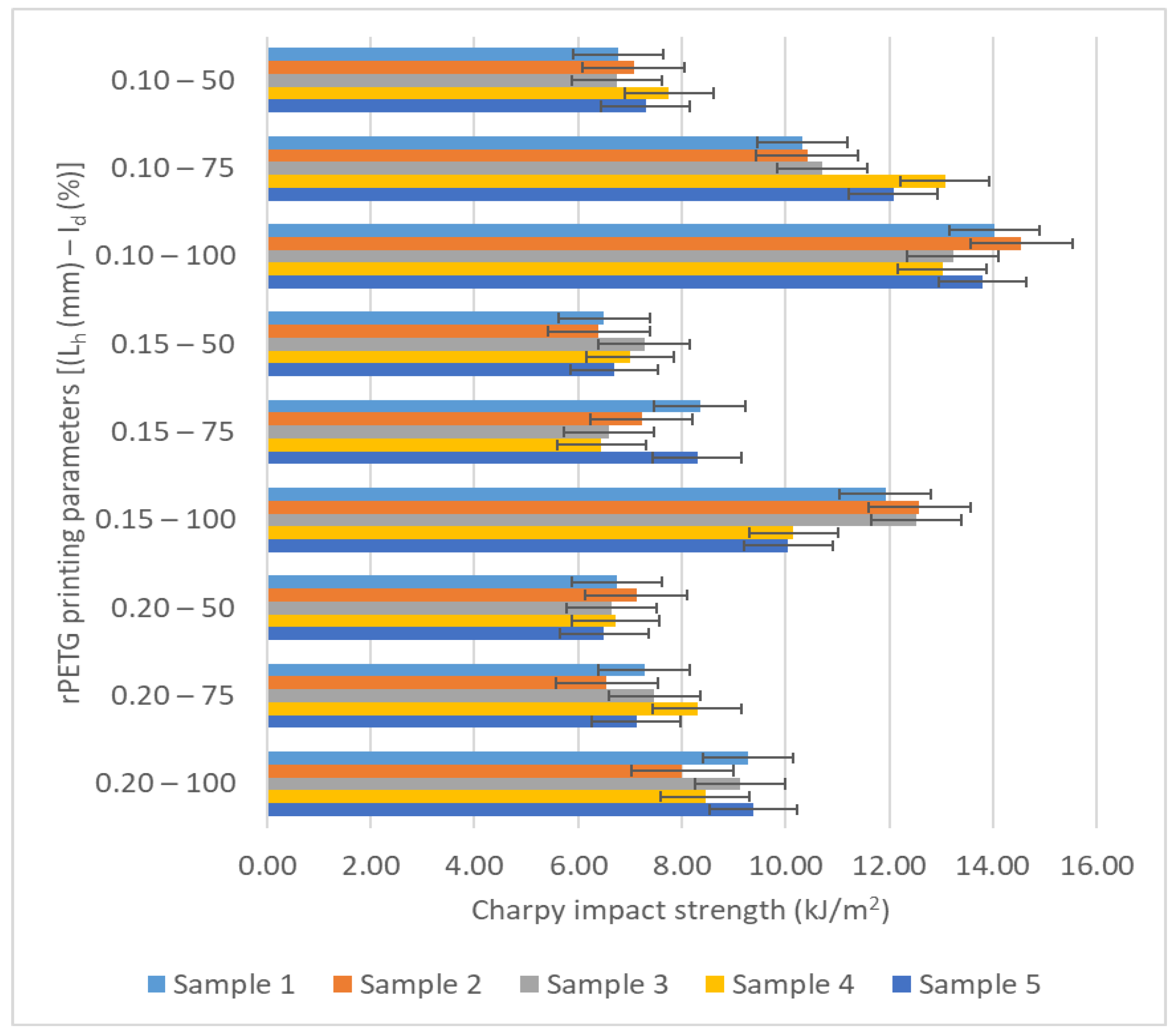

| Layer Height, Lh | Infill Percentage, Id | Charpy Impact Strength, K (kJ/m2) | Average | ||||

|---|---|---|---|---|---|---|---|

| (mm) | (%) | Sample Number | (kJ/m2) | ||||

| 1 | 2 | 3 | 4 | 5 | |||

| 0.10 | 50 | 6.78 | 7.08 | 6.75 | 7.75 | 7.30 | 7.13 |

| 75 | 10.33 | 10.43 | 10.70 | 13.08 | 12.08 | 11.32 | |

| 100 | 14.03 | 14.55 | 13.23 | 13.03 | 13.80 | 13.73 | |

| 0.15 | 50 | 6.50 | 6.40 | 7.28 | 7.00 | 6.70 | 6.78 |

| 75 | 8.35 | 7.23 | 6.60 | 6.45 | 8.30 | 7.39 | |

| 100 | 11.93 | 12.58 | 12.53 | 10.15 | 10.05 | 11.45 | |

| 0.20 | 50 | 6.75 | 7.13 | 6.65 | 6.73 | 6.50 | 6.75 |

| 75 | 7.28 | 6.55 | 7.48 | 8.30 | 7.13 | 7.35 | |

| 100 | 9.28 | 8.00 | 9.13 | 8.45 | 9.38 | 8.85 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zisopol, D.G.; Minescu, M.; Iacob, D.V. Evaluation and Optimization of Thermoplastic Extrusion Parameters Influencing the Impact Resistance of Additively Manufactured Samples from PETG and Recycled PETG. Polymers 2025, 17, 2533. https://doi.org/10.3390/polym17182533

Zisopol DG, Minescu M, Iacob DV. Evaluation and Optimization of Thermoplastic Extrusion Parameters Influencing the Impact Resistance of Additively Manufactured Samples from PETG and Recycled PETG. Polymers. 2025; 17(18):2533. https://doi.org/10.3390/polym17182533

Chicago/Turabian StyleZisopol, Dragos Gabriel, Mihail Minescu, and Dragos Valentin Iacob. 2025. "Evaluation and Optimization of Thermoplastic Extrusion Parameters Influencing the Impact Resistance of Additively Manufactured Samples from PETG and Recycled PETG" Polymers 17, no. 18: 2533. https://doi.org/10.3390/polym17182533

APA StyleZisopol, D. G., Minescu, M., & Iacob, D. V. (2025). Evaluation and Optimization of Thermoplastic Extrusion Parameters Influencing the Impact Resistance of Additively Manufactured Samples from PETG and Recycled PETG. Polymers, 17(18), 2533. https://doi.org/10.3390/polym17182533