Biomimetic Functional Fluorinated Oxygen-Containing Coatings on 3D-Printing Composite Polymer Items

Abstract

1. Introduction

2. Materials and Methods

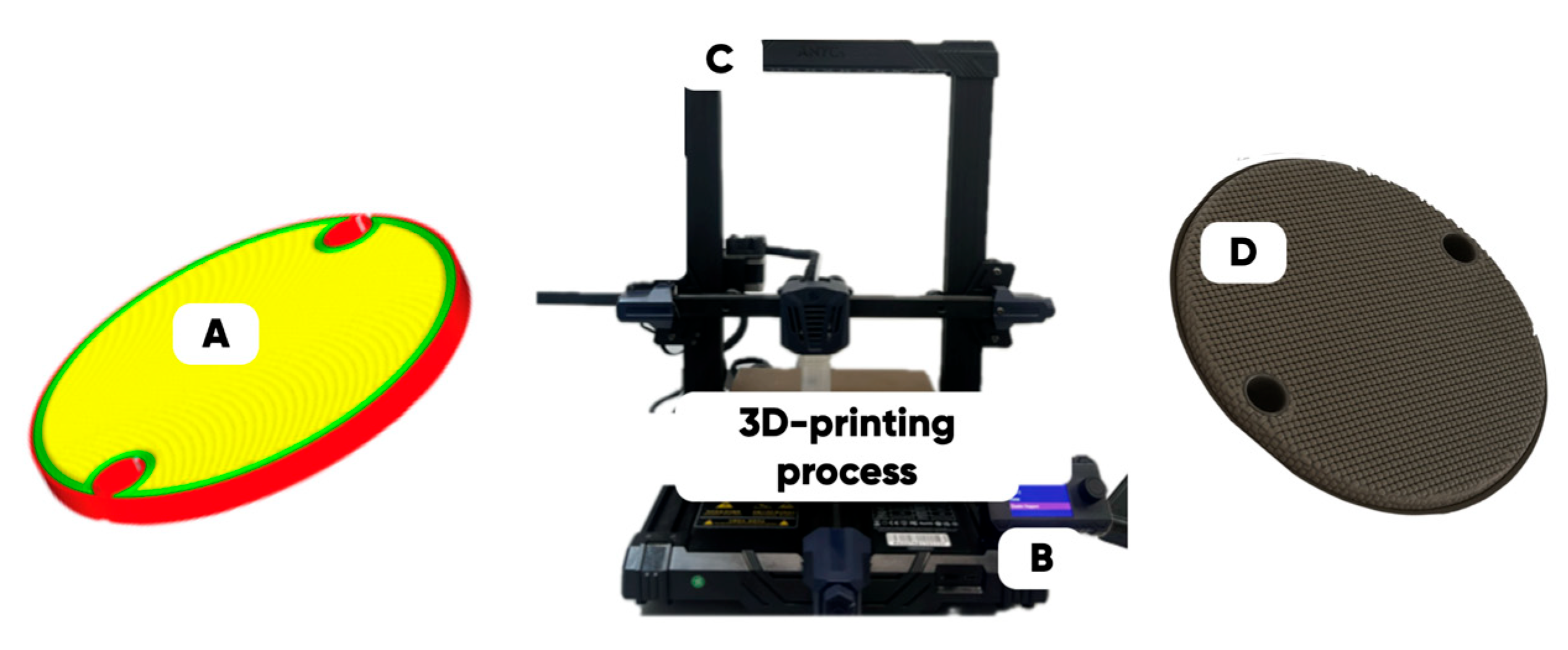

2.1. The Experimental Samples’ Surface Design

- (1)

- The formation of the shark skin’s surface digital twin (using the original jpg2xls converter);

- (2)

- (3)

- The digital construction of the 3D-printing products structure (based on the obtained model and using Paint3D and Cura slicer software).

2.2. The Experimental Samples’ Creation

- (1)

- The initial polymer matrix and the bulk modifies the materials’ rational choice;

- (2)

- The polymer matrix dispersed filling with the reinforcing ingredients;

- (3)

- The FFF-technology using prototypes production;

- (4)

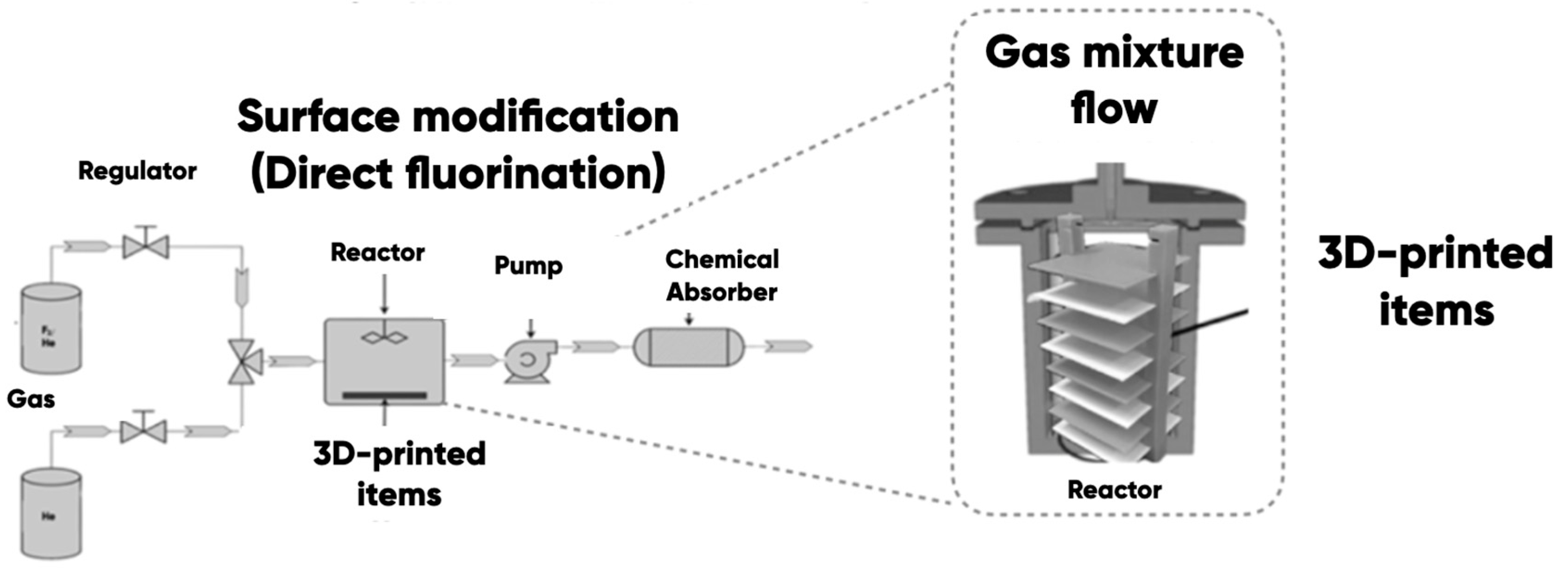

- The direct regulation of the sample’s surface functional properties (by the original technique of the fluorine-containing gas mixture modification) [62].

2.3. Identifying the Properties and Structure of the Experimental Samples

- (1)

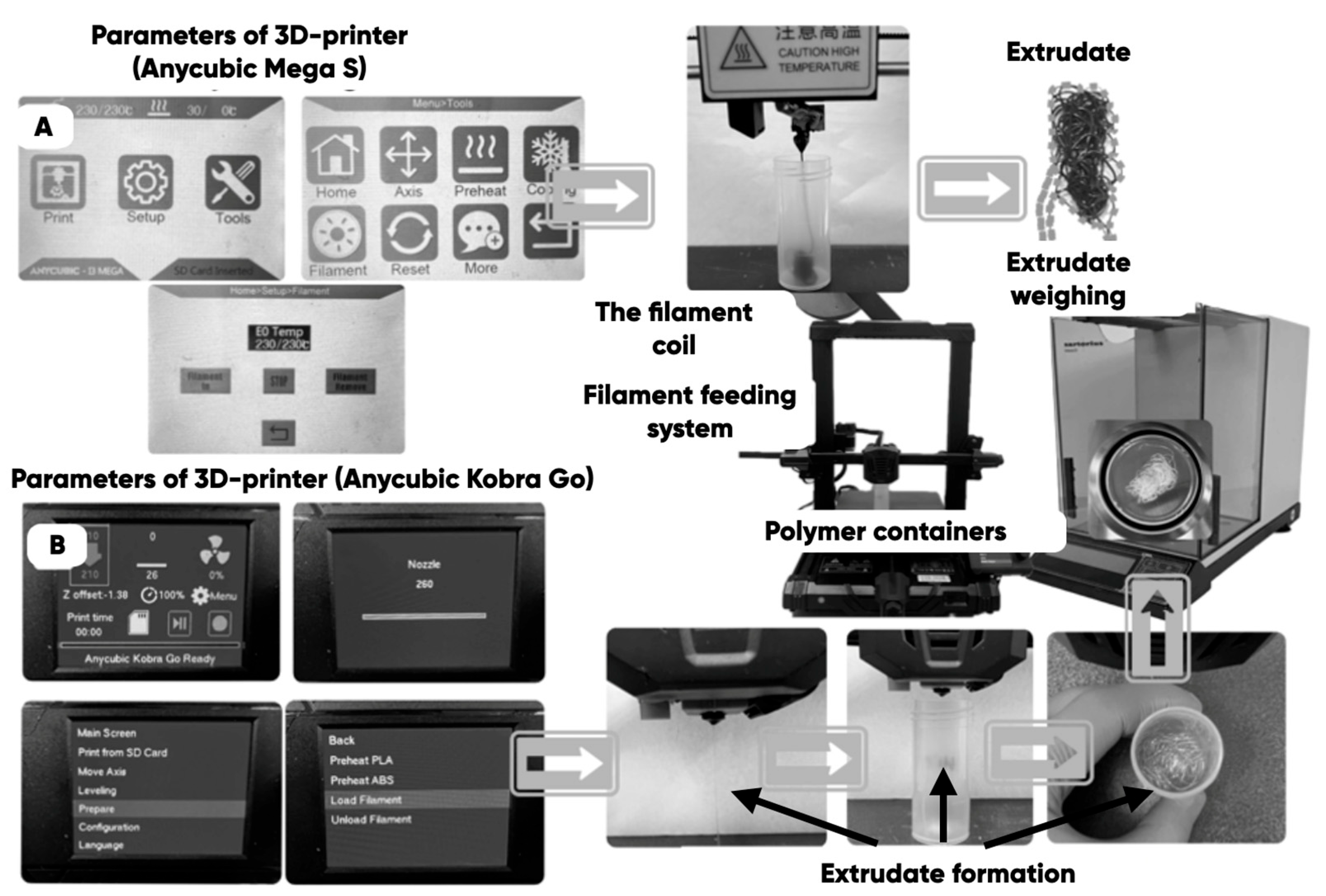

- The determination of 3D-printing and technological properties of the composite filaments (using the original melt flow index measurement (MFI) technique [62]);

- (2)

- The empirical characterization of the elemental composition and the physical structure of the experimental sample’s surface with scanning electron microscopy (SEM);

- (3)

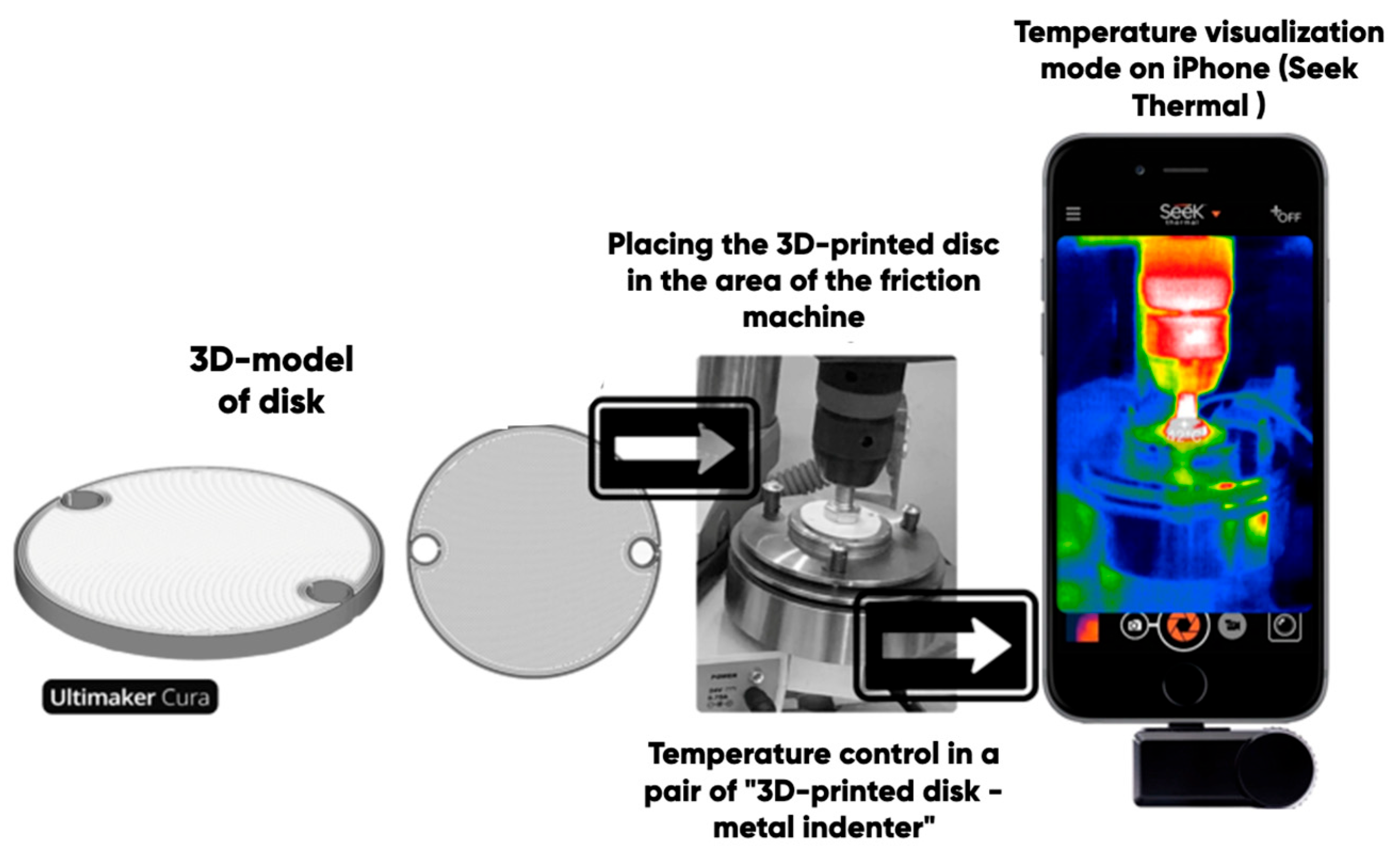

- The study of tribotechnical properties (the coefficient of friction, the temperature in the tribological contact zone, the wear resistance) of the manufactured products.

3. Results and Discussion

3.1. The Results of 3D-Printing Products’ Surface Biomimetic Design

3.2. The Results of the Determined and Developed Composite Filaments’ 3D-Printing Properties

3.3. The Results of the Formed Integrated Fluorine-Containing Layers’ Tribological Properties’ Determination

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lubineau, G.; Rahaman, A. A review of strategies for improving the degradation properties of laminated continuous-fiber/epoxy composites with carbon-based nanoreinforcements. Carbon 2012, 50, 2377–2395. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Chen, Y.B.; Zhou, K.G.; Liu, C.H.; Zeng, J.; Zhang, H.L.; Peng, Y. Improving gas sensing properties of graphene by introducing dopants and defects: A first-principles study. Nanotechnology 2009, 20, 185504. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Ruan, W.H. Surface modification of nanoscale fillers for improving properties of polymer nanocomposites: A review. Mater. Sci. Technol. 2006, 22, 787–796. [Google Scholar] [CrossRef]

- Gliozzi, A.; Relini, A.; Chong, P.L.G. Structure and permeability properties of biomimetic membranes of bolaform archaeal tetraether lipids. J. Membr. Sci. 2002, 206, 131–147. [Google Scholar] [CrossRef]

- Zhao, N.; Xu, J.; Xie, Q.; Weng, L.; Guo, X.; Zhang, X.; Shi, L. Fabrication of biomimetic superhydrophobic coating with a micro-nano-binary structure. Macromol. Rapid Commun. 2005, 26, 1075–1080. [Google Scholar] [CrossRef]

- Xu, Y.; Han, Y.; Li, Y.; Li, J.; Li, J.; Gao, Q. Preparation of a strong, mildew-resistant, and flame-retardant biomimetic multifunctional soy protein adhesive via the construction of an organic-inorganic hybrid multiple-bonding structure. Chem. Eng. J. 2022, 437, 135437. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, D.; Gu, J.; Li, W.; Jiang, H.; Zhou, G.; Chen, Z. A simple and effective approach towards biomimetic replication of photonic structures from butterfly wings. Nanotechnology 2009, 20, 315303. [Google Scholar] [CrossRef]

- Bixler, G.D.; Bhushan, B.; Theiss, A.; Lee, S.C. Anti-fouling properties of microstructured surfaces bio-inspired by rice leaves and butterfly wings. J. Colloid Interface Sci. 2014, 419, 114–133. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Zhu, M.; Zhang, Y.; Dong, S.; Wang, X. Magnetic-responsive superhydrophobic surface of magnetorheological elastomers mimicking from lotus leaves to rose petals. Langmuir 2021, 37, 2312–2321. [Google Scholar] [CrossRef]

- Bixler, G.D.; Bhushan, B. Bioinspired rice leaf and butterfly wing surface structures combining shark skin and lotus effects. Soft Matter 2012, 8, 11271–11284. [Google Scholar] [CrossRef]

- Naresh, M.D.; Arumugam, V.; Sanjeevi, R. Mechanical behaviour of shark skin. J. Biosci. 1997, 22, 431–437. [Google Scholar] [CrossRef]

- Bandyopadhyay, P.R.; Hellum, A.M. Modeling how shark and dolphin skin patterns control transitional wall-turbulence vorticity patterns using spatiotemporal phase reset mechanisms. Sci. Rep. 2014, 4, 6650. [Google Scholar] [CrossRef] [PubMed]

- Jo, W.; Choi, J.; Jung, J.; Hyun, J.; Kwon, J.; Kim, I.; Kim, H.-T.; Kang, H.S.; Lee, H. Light-designed shark skin-mimetic surfaces. Nano Lett. 2021, 21, 5500–5507. [Google Scholar] [CrossRef]

- Gabler-Smith, M.K.; Lauder, G.V. Ridges and riblets: Shark skin surfaces versus biomimetic models. Front. Mar. Sci. 2022, 9, 975062. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, M.; Liu, G.; Zheng, Y.; Xue, C.; Shen, C. Relationship between skin scales and the main flow field around the shortfin mako shark Isurus oxyrinchus. Front. Bioeng. Biotechnol. 2022, 10, 742437. [Google Scholar] [CrossRef]

- Ghimire, A.; Dahl, R.B.; Shen, S.F.; Chen, P.Y. Shark skin denticles: From morphological diversity to multi-functional adaptations and applications. Adv. Funct. Mater. 2024, 34, 2307121. [Google Scholar] [CrossRef]

- Avramescu, R.E.; Ghica, M.V.; Dinu-Pîrvu, C.; Prisada, R.; Popa, L. Superhydrophobic natural and artificial surfaces-a structural approach. Materials 2018, 11, 866. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Q.; Yin, Y.; Song, H.; Tang, J. Effects and optimization of bionic texture parameters on the tribological behavior of line contacts under starved lubrication conditions. Ind. Lubr. Tribol. 2024, 76, 241–251. [Google Scholar] [CrossRef]

- Sun, N.; Hou, Z.; Jiang, Z.; Geng, J.; Xia, L. Facile modification of sepiolite and its application in wear-resistant and superhydrophobic epoxy coatings by mimicking the structure of shark skin. Appl. Clay Sci. 2025, 264, 107642. [Google Scholar] [CrossRef]

- Jiang, L.; Fan, Z. Design of advanced porous graphene materials: From graphene nanomesh to 3d architectures. Nanoscale 2014, 6, 1922–1945. [Google Scholar] [CrossRef] [PubMed]

- Herzberger, J.; Sirrine, J.M.; Long, T.E.; Williams, C.B. Polymer design for 3d printing elastomers: Recent advances in structure, properties, and printing. Prog. Polym. Sci. 2019, 97, 101144. [Google Scholar] [CrossRef]

- Li, J.; Gelinsky, M.; Chu, P.K.; Wu, C. 3d printing of hydrogels: Rational design strategies and emerging biomedical applications. Mater. Sci. Eng. R Rep. 2020, 140, 100543. [Google Scholar] [CrossRef]

- Wernick, M.N.; Wirjadi, O.; Galatsanos, N.P.; Yang, Y.; Brankov, J.G.; Chapman, D.; Oltulu, O.; Zhong, Z.; Anastasio, M.A.; Muehleman, C. Multiple-image radiography. Phys. Med. Biol. 2003, 48, 3875–3895. [Google Scholar] [CrossRef]

- Ku, G.; Jin, X.; Xu, M.; Wang, L.V.; Fornage, B.D.; Hunt, K.K. Thermoacoustic and photoacoustic tomography of thick biological tissues toward breast imaging. Technol. Cancer Res. Treat. 2005, 4, 559–565. [Google Scholar] [CrossRef]

- Li, J.; Xu, W.; Deng, L.; Xiao, Y.; Han, Z.; Zheng, H. Deep learning for visual recognition and detection of aquatic animals: A review. Rev. Aquac. 2023, 15, 409–433. [Google Scholar] [CrossRef]

- Huang, T.Q.; Qu, X.; Liu, J.; Chen, S. 3d printing of biomimetic microstructures for cancer cell migration. Biomed. Microdevices 2014, 16, 127–132. [Google Scholar] [CrossRef] [PubMed]

- Budharaju, H.; Suresh Sh Sekar, M.P.; De Vega, B.; Sethuraman, S.; Sundaramurthi, D.; Kalaskar, D.M. Ceramic materials for 3d printing of biomimetic bone scaffolds—Current state-of-the-art & future perspectives. Mater. Des. 2023, 231, 112064. [Google Scholar]

- Kumar, A.S.; Akoumeh, R.; Ramanathan, A.; Park, J.; Thippanna, V.; Patil, D.; Zhu, Y.; Ravichandran, D.; Thummalapalli, S.V.; Sobczak, M.T.; et al. Biomimetic 3d prototyping of hierarchically porous multilayered membranes for enhanced oil–water filtration. ACS Appl. Mater. Interfaces 2025, 17, 8285–8298. [Google Scholar] [CrossRef]

- Askadskii, A.A.; Todadze, T.V.; Slonimskii, G.L. Forecasting the relaxation properties of representatives of some classes of polymers. Polym. Sci. USSR 1980, 22, 716–725. [Google Scholar] [CrossRef]

- Eremin, E.N.; Yurov, V.M.; Guchenko, S.A.; Ch Laurynas, V. Nanocrystalline coatings properties forecasting. J. Phys. Conf. Ser. 2017, 858, 012011. [Google Scholar] [CrossRef]

- Emad, W.; Salih, A.; Kurda, R. Forecasting the mechanical properties of soilcrete using various simulation approaches. Structures 2021, 34, 653–665. [Google Scholar] [CrossRef]

- Nafees, A.; Khan, S.; Javed, M.F.; Alrowais, R.; Mohamed, A.M.; Vatin, N.I. Forecasting the mechanical properties of plastic concrete employing experimental data using machine learning algorithms: DT, MLPNN, SVM, and RF. Polymers 2022, 14, 1583. [Google Scholar] [CrossRef]

- Limami, H.; Guettioui, D.; Dahi, O.; Boustani, E.M.E.; Manssouri, I.; El Alami, A.; Khaldoun, A. Machine learning forecasting of thermal, mechanical and physicochemical properties of unfired clay bricks with plastic waste additives. Mater. Today Proc. 2023, 72, 3509–3513. [Google Scholar] [CrossRef]

- Yang, T.; Du, Z.; Qiu, H.; Gao, P.; Zhao, X.; Wang, H.; Tu, Q.; Xiong, K.; Huang, N.; Yang, Z. From surface to bulk modification: Plasma polymerization of amine-bearing coating by synergic strategy of biomolecule grafting and nitric oxide loading. Bioact. Mater. 2020, 5, 17–25. [Google Scholar] [CrossRef]

- Wang, D.; Chen, Y.; Fan, L.; Xiao, T.; Meng, T.; Xing, Z.; Yang, X. Bulk and surface dual modification of nickel-cobalt spinel with ruthenium toward highly efficient overall water splitting. Appl. Catal. B Environ. 2022, 305, 121081. [Google Scholar]

- Chamatete, K.; Yalçınkaya, Ç. Numerical evaluation on thermal performance of 3d printed concrete walls: The effects of lattice type, filament width and granular filling material. Buildings 2024, 14, 926. [Google Scholar] [CrossRef]

- Zainol, N.; Noor, N.M.; Zaidel, D.N.A.; Mat Taher, Z.; Mohamed, M.; Sadek, N. Breadfruit (Artocarpus altilis) studies: Rheological stability, incorporation of gluten free, and bioactive compound as an intermediate ingredient in health-related products. ECS Trans. 2022, 107, 14455–14463. [Google Scholar] [CrossRef]

- Shi, L.; Liu, J.; Ma, L.; Wang, Y. The dual-band emission with long-lived thermally activated delayed fluorescence and room temperature phosphorescence by trace ingredient incorporation. Chem. Eng. J. 2024, 493, 152492. [Google Scholar]

- Thepwatee, S.; Pinket, A.; Rangauthok, S. Strategic development of nanoemulsion bases for versatile active ingredient incorporation. Mater. Sci. Forum 2024, 1143, 9–16. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, F.; Niu, J.; Jiang, Y.; Wang, Z. Superhydrophobic surfaces: From structural control to functional application. J. Mater. Chem. 2008, 18, 621–633. [Google Scholar] [CrossRef]

- Zhang, Y.-L.; Xia, H.; Sun, H.-B.; Kim, E. Recent developments in superhydrophobic surfaces with unique structural and functional properties. Soft Matter 2012, 8, 11217–11231. [Google Scholar] [CrossRef]

- Saparov, B.; Mitzi, D.B. Organic-inorganic perovskites: Structural versatility for functional materials design. Chem. Rev. 2016, 116, 4558–4596. [Google Scholar] [CrossRef]

- Maksimkin, A.V.; Danilov, V.D.; Senatov, F.S.; Olifirov, L.K.; Kaloshkin, S.D. Wear performance of bulk oriented nanocomposites uhmwpe/fmwcnt and metal-polymer composite sliding bearings. Wear 2017, 392–393, 167–173. [Google Scholar] [CrossRef]

- Janahmadov, A.; Volchenko, D.A.; Javadov, M.Y.; Volchenko, N.A.; Skrypnyk, V.S.; Zhuravlev, D.; Vozniy, A. Effects of electrothermal contact resistance in metal-polymer friction pairs of brakes. Her. Azerbaijan Eng. Acad. 2024, 16, 18–31. [Google Scholar] [CrossRef]

- Krasnyy, V.A.; Osminko, D.A. Improving the wear resistance of bushings through polymer coatings. Key Eng. Mater. 2020, 836, 136–141. [Google Scholar] [CrossRef]

- Kalin, M.; Kupec, A. The dominant effect of temperature on the fatigue behaviour of polymer gears. Wear 2017, 376–377, 1339–1346. [Google Scholar] [CrossRef]

- Skowrońska, J.; Kosucki, A.; Stawiński, Ł. Overview of materials used for the basic elements of hydraulic actuators and sealing systems and their surfaces modification methods. Materials 2021, 14, 1422. [Google Scholar] [CrossRef]

- An, V.; Irtegov, Y.; De Izarra, C. Study of tribological properties of nanolamellar WS2 and MoS2 as additives to lubricants. J. Nanomater. 2014, 2014, 865839. [Google Scholar] [CrossRef]

- Kontsevoi, Y.V.; Meilakh, A.G.; Shubin, A.B.; Pastukhov, E.A.; Sipatov, I.S. Designing of laminated structure of antifriction powder composite. Int. J. Eng. Appl. Sci. 2017, 12, 6045–6049. [Google Scholar]

- Zlotnikov, I.I.; Shapovalov, V.M. Improving the antifriction properties of ceramic coatings obtained by the method of Mao on aluminum alloys. J. Frict. Wear 2019, 40, 360–363. [Google Scholar] [CrossRef]

- Huang, T.; Xin, Y.; Li, T.; Su, C.; Chen, H.; Liu, P.; Lai, Z.; Nutt, S. Modified graphene/polyimide nanocomposites: Reinforcing and tribological effects. ACS Appl. Mater. Interfaces 2013, 5, 4878–4891. [Google Scholar] [CrossRef]

- Zhao, Y.; Qi, X.; Ma, J.; Zhang, Q.; Yang, Y.; Song, L.; Yang, Q.; Dong, Y. Mechanical, thermal and tribological properties of polyimide/nano-SiO2 composites synthesized using an in-situ polymerization. Tribol. Int. 2016, 103, 599–608. [Google Scholar] [CrossRef]

- Yumashev, A.; Mikhaylov, A. Development of polymer film coatings with high adhesion to steel alloys and high wear resistance. Polym. Compos. 2020, 41, 2875–2880. [Google Scholar] [CrossRef]

- Qu, J.; Blau, P.J.; Watkins, T.R.; Cavin, O.B.; Kulkarni, N.S. Friction and wear of titanium alloys sliding against metal, polymer, and ceramic counterfaces. Wear 2005, 258, 1348–1356. [Google Scholar] [CrossRef]

- Sun, J.; Du, S. Application of graphene derivatives and their nanocomposites in tribology and lubrication: A review. RSC Adv. 2019, 9, 40642–40661. [Google Scholar] [CrossRef]

- Jozwik, J.; Dziedzic, K.; Barszcz, M.; Pashechko, M. Analysis and comparative assessment of basic tribological properties of selected polymer composites. Materials 2020, 13, 75. [Google Scholar] [CrossRef]

- Spoerk, M.; Raguž, I.; Holzer, C.; Gonzalez-Gutierrez, J.; Arbeiter, F. Mechanical recyclability of polypropylene composites produced by material extrusion-based additive manufacturing. Polymers 2019, 11, 1318. [Google Scholar] [CrossRef]

- Bulanda, K.; Oleksy, M.; Oliwa, R. Polymer composites based on glycol-modified poly(ethylene terephthalate) applied to additive manufacturing using melted and extruded manufacturing technology. Polymers 2022, 14, 1605. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Esposito Corcione, C. Sustainable polymer composites manufacturing through 3d printing technologies by using recycled polymer and filler. Polymers 2022, 14, 3756. [Google Scholar] [CrossRef]

- Doronin, F.; Rudakova, A.; Rytikov, G.; Nazarov, V. Simple determination of the melt flow index of composite polymer filaments used in material extrusion additive manufacturing. Coatings 2023, 13, 1592. [Google Scholar] [CrossRef]

- Babbi, G.; Minak, G. Design strategy for the prototyping of 3d-printed continuous fiber-reinforced components for solar-powered vehicle. Acta Polytech. CTU Proc. 2024, 48, 1–8. [Google Scholar] [CrossRef]

- Doronin, F.; Rudakova, A.; Rytikov, G.; Nazarov, V. A novel determination of the melt flow index of composite filaments used in extrusion additive manufacturing. Polym. Test. 2024, 133, 108376. [Google Scholar] [CrossRef]

- Doronin, F.A.; Saveliev, M.A.; Taranets, I.P.; Rytikov, G.O.; Nazarov, V.G. Direct structuring of polymers used in additive manufacturing. Russ. J. Gen. Chem. 2024, 94, 1550–1557. [Google Scholar] [CrossRef]

- Doronin, F.; Savel’ev, M.; Rytikov, G.; Evdokimov, A.; Nazarov, V. A new approach to carbon nanotube filament nanostructuring for additive manufacturing. Polymers 2024, 16, 1423. [Google Scholar] [CrossRef]

- Aslamazova, T.R.; Vysotskii, V.V.; Zolotarevskii, V.I.; Kotenev, V.A.; Lomovskoi, V.A.; Tsivadze, A.Y. Modifying latex polymers by using highly dispersed iron powder as a filler. Prot. Met. Phys. Chem. Surf. 2019, 55, 1091–1096. [Google Scholar] [CrossRef]

- Hosseini, S.F.; Ghaderi, J.; Gómez-Guillén, M.C. Tailoring physico-mechanical and antimicrobial/antioxidant properties of biopolymeric films by cinnamaldehyde-loaded chitosan nanoparticles and their application in packaging of fresh rainbow trout fillets. Food Hydrocoll. 2022, 124, 107249. [Google Scholar] [CrossRef]

- Lin, Y.; Deng, W.; Rui, Y.; Liu, Y.; Lu, G.; Liu, J. Enhanced thermal conductivity of epoxy acrylate/h-bn and aln composites by photo-curing 3d printing technology. J. Appl. Polym. Sci. 2022, 139, e52629. [Google Scholar] [CrossRef]

- Jaggessar, A.; Shahali, H.; Yarlagadda, P.K.D.V.; Mathew, A. Bio-mimicking nano and micro-structured surface fabrication for antibacterial properties in medical implants. J. Nanobiotechnol. 2017, 15, 64. [Google Scholar] [CrossRef]

- Qian, H.; Xu, D.; Du, C.; Zhang, D.; Li, X.; Huang, L.; Deng, L.; Tu, Y.; Mol, J.M.C.; Terryn, H.A. Dual-action smart coatings with a self-healing superhydrophobic surface and anti-corrosion properties. J. Mater. Chem. A 2017, 5, 2355–2364. [Google Scholar] [CrossRef]

- Luo, H.; Zhao, Y.; Li, Y.; Xiang, Y.; He, D.; Pan, X. Aging of microplastics affects their surface properties, thermal decomposition, additives leaching and interactions in simulated fluids. Sci. Total Environ. 2020, 714, 136862. [Google Scholar] [CrossRef]

- Doronin, F.; Rytikov, G.; Evdokimov, A.; Rudyak, Y.; Taranets, I.; Nazarov, V. The effect of electro-induced multi-gas modification on polymer substrates’ surface structure for additive manufacturing. Processes 2023, 11, 774. [Google Scholar]

- Belov, N.A.; Alentiev, A.Y.; Bogdanova, Y.G.; Vdovichenko, A.Y.; Pashkevich, D.S. Direct Fluorination as Method of Improvement of Operational Properties of Polymeric Materials. Polymers 2020, 12, 2836. [Google Scholar] [CrossRef]

- Rudyak, Y.V.; Doronin, F.A.; Rytikov, G.O.; Filyugina, E.K.; Nazarov, V.G. Nanotexture effect of the fiber surface on the sorption capacity of nonwoven fabrics. Nanosyst. Phys. Chem. Math. 2020, 11, 553–564. [Google Scholar]

- Doronin, F.; Rytikov, G.; Evdokimov, A.; Rudyak, Y.; Savel’ev, M.; Nazarov, V. Biostable fluorine-containing coatings on the surface of polymers. Coatings 2023, 13, 424. [Google Scholar] [CrossRef]

- Nazarov, V.G.; Stolyarov, V.P.; Doronin, F.A.; Evdokimov, A.G.; Rytikov, G.O.; Brevnov, P.N.; Zabolotnov, A.S.; Novokshonova, L.A.; Berlin, A.A. Comparison of the effects of some modification methods on the characteristics of ultrahigh-molecular-weight polyethylene and composites on its basis. Polym. Sci. Ser. A 2019, 61, 325–333. [Google Scholar]

- Nazarov, V.G.; Doronin, F.A.; Evdokimov, A.G.; Rytikov, G.O.; Stolyarov, V.P. Oxyfluorination-controlled variations in the wettability of polymer film surfaces. Colloid J. 2019, 81, 146–157. [Google Scholar] [CrossRef]

- Isaev, E.A.; Doronin, F.A.; Evdokimov, A.G.; Pervukhin, D.V.; Rudyak, Y.V.; Rytikov, G.O.; Kornilov, V.V.; Nazarov, V.G. Quantitative Assessment of the Development of Micromycete Colony on the Surfaces of Polymers and Polymer Composites. Mat. Biol. Bioinformatika 2021, 16, 367–379. [Google Scholar]

- Wen, L.; Weaver, J.C.; Lauder, G.V. Biomimetic shark skin: Design, fabrication and hydrodynamic function. J. Exp. Biol. 2014, 217, 1656–1666. [Google Scholar] [CrossRef]

- Drozdov, S.A.; Nazarov, V.G.; Nozdrachev, S.A.; Rudyak, Y.V.; Rytikov, G.O. The polymer composites’ morphological structure simulation. Nanosyst. Phys. Chem. Math. 2017, 8, 137–145. [Google Scholar] [CrossRef]

- Taranets, I.P.; Rytikov, G.O.; Doronin, F.A.; Saveliev, M.A.; Nazarov, V.G. Structural-functional mathematical modeling of additive manufacturing polymers. Russ. J. Gen. Chem. 2024, 94, 1558–1563. [Google Scholar] [CrossRef]

- Grigoriev, A.A.; Isaev, E.A.; Pervukhin, D.V.; Petrushin, V.N.; Doronin, F.A.; Rudyak, Y.u.V.; Rytikov, G.O.; Nazarov, V.G. A Biomimetic Approach to the Creation of Polymer Materials with Improved Tribological Properties. Mat. Biol. Bioinformatika 2024, 19, 1–14. [Google Scholar] [CrossRef]

- Doronin, F.A.; Evdokimov, A.G.; Rudyak, Y.V.; Rytikov, G.O.; Taranets, I.P.; Nazarov, V.G. A new approach to function-structure modeling of the surface modified polymers. Nanosyst. Phys. Chem. Math. 2022, 13, 115–127. [Google Scholar] [CrossRef]

- Erdaş, M.U.; Yıldız, B.S.; Yıldız, A.R. Experimental analysis of the effects of different production directions on the mechanical characteristics of ABS, PLA and PETG materials produced by FDM. Materialpruefung 2024, 66, 198–206. [Google Scholar] [CrossRef]

- Rahatuzzaman; Mahmud, M.; Rahman, S.; Hoque, M.D.E. Design, fabrication, and characterization of 3D-printed ABS and PLA scaffolds potentially for tissue engineering. Results Eng. 2024, 21, 101685. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soltanmohammadi, K.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. 4D printing of porous PLA-TPU structures: Effect of applied deformation, loading mode and infill pattern on the shape memory performance. Phys. Scr. 2024, 99, 025013. [Google Scholar] [CrossRef]

- Yan, C.; Kleiner, C.; Tabigue, A.; Shah, V.; Sacks, G.; Shah, D.; DeStefano, V. PETG: Applications in modern medicine. Eng. Regen. 2024, 5, 45–55. [Google Scholar] [CrossRef]

- Tian, Y.; Huang, M.; Wang, Y.; Zheng, Y.; Yin, R.; Liu, H.; Liu, C.; Shen, C. Ultra-stretchable, sensitive and breathable electronic skin based on tpu electrospinning fibrous membrane with microcrack structure for human motion monitoring and self-powered application. Chem. Eng. J. 2024, 480, 147899. [Google Scholar] [CrossRef]

- Nazarov, V.; Doronin, F.; Dedov, A.; Evdokimov, A.; Rytikov, G.; Savel’ev, M. Design of a Hybrid 3D-Printed Composite Material Based on Non-Woven Needle-Punched Fabrics with Radio-Absorbing Properties. Polymers 2025, 17, 2324. [Google Scholar] [CrossRef]

- Mancilla-De-la-Cruz, J.; Rodriguez-Salvador, M.; An, J.; Chua, C.K. Three-Dimensional Printing Technologies for Drug Delivery Applications: Processes, Materials, and Effects. Int. J. Bioprint. 2022, 8, 622. [Google Scholar] [CrossRef]

- Doronin, F.A.; Rytikov, G.O.; Evdokimov, A.G.; Ruduak, Y.V.; Nazarov, V.G. The synergistic effect of bulk-surface modification onto the wear resistance of the ultrahigh molecular weight polyethylene. Polym. Polym. Compos. 2023, 31. [Google Scholar] [CrossRef]

- Cong, H.-P.; Chen, J.-F.; Yu, S.-H. Graphene-based macroscopic assemblies and architectures: An emerging material system. Chem. Soc. Rev. 2014, 43, 7295–7325. [Google Scholar] [CrossRef]

- Tian, Y.; Su, B.; Jiang, L. Interfacial material system exhibiting superwettability. Adv. Mater. 2014, 26, 6872–6897. [Google Scholar] [CrossRef]

- Bondareva, N.S.; Sheremet, M.A.; Buonomo, B.; Manca, O. Heat transfer performance of the finned nano-enhanced phase change material system under the inclination influence. Int. J. Heat Mass Transf. 2019, 135, 1063–1072. [Google Scholar] [CrossRef]

- Rytikov, G.O.; Pervoukhin, D.V.; Nazarov, V.G. A new approach to quantitative characterization of the material’s surface morphological heterogeneity. Lect. Notes Civ. Eng. 2022, 210, 301–307. [Google Scholar]

- Rytikov, G.O.; Doronin, F.A.; Evdokimov, A.G.; Nazarov, V.G.; Savel’ev, M.A. An approach to structural and functional modeling of the surface morphology of materials based on fluorinated polymers. Russ. J. Gen. Chem. 2021, 91, 2667–2672. [Google Scholar] [CrossRef]

- Doronin, F.A.; Rudyak, Y.V.; Rytikov, G.O.; Evdokimov, A.G.; Nazarov, V.G. 3D-printed planar microfluidic device on oxyfluorinated PET-substrate. Polym. Test. 2021, 99, 107209. [Google Scholar] [CrossRef]

- Subramanian, K.; Ramasubramanian, S.; Selvam, B.; Rajaram, P. Investigations on effectiveness of transfer layer on specific wear rate and coefficient of friction during dry sliding of hybrid polymer matrix composites. Polym. Compos. 2021, 43, 250–266. [Google Scholar] [CrossRef]

- Mukhanov, V.A.; Kurakevych, O.O.; Solozhenko, V.L. Hardness of materials at high temperature and high pressure. Philos. Mag. 2009, 89, 2117–2127. Available online: https://api.semanticscholar.org/CorpusID:137268587 (accessed on 13 July 2025). [CrossRef]

- Mukhanov, V.A.; Kurakevych, O.O.; Solozhenko, V.L. Thermodynamic model of hardness: Particular case of boron-rich solids. J. Superhard Mater. 2010, 32, 167–176. Available online: https://api.semanticscholar.org/CorpusID:100590573 (accessed on 13 July 2025). [CrossRef]

- Zhang, T.; Jiang, F.; Yan, L.; Xu, X. FEM Modeling of the Relationship between the High-Temperature Hardness and High-Temperature, Quasi-Static Compression Experiment. Materials 2017, 11, 34. Available online: https://api.semanticscholar.org/CorpusID:46828498 (accessed on 13 July 2025). [CrossRef]

- Chen, H.; Hou, J.-P.; Lee, S.-Y.; Lin, Y.-M. Effects of postpolymerization time and temperature on the flexural properties and hardness profile of three-dimensional printed provisional resin. J. Dent. Sci. 2024, 19, 455–460. [Google Scholar] [CrossRef] [PubMed]

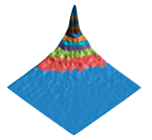

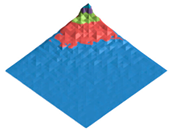

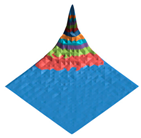

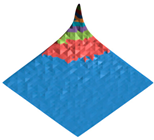

| Parameter/Materials | Shark Skin | PETG | PETG + F2 | PETG + MoS2 + F2 |

|---|---|---|---|---|

| The digital twin of the surface |  |  |  |  |

| - | 0.06 ± 0.01 | 0.011 ± 0.006 | 0.011 ± 0.009 | |

| The profile projections of the averaged surface morphological spectra |  |  |  |  |

| - | 0.915 ± 0.005 | 0.928 ± 0.005 | 0.935 ± 0.005 |

| Filler Content in the PETG Filament mass.% | MFI3D printer (g/min) | ||

|---|---|---|---|

| 0.5 | 1.0 | 1.5 | |

| GNP | 0.884 ± 0.009 | 0.882 ± 0.009 | 0.549 ± 0.005 |

| Taunite | 0.810 ± 0.008 | 0.443 ± 0.005 | 0.065 ± 0.007 |

| PETG | PETG + F2 | PETG + MoS2 | PETG + MoS2 + F2 | PETG + MMT | PETG + MMT + F2 | PETG + Shungite | PETG + Shungite + F2 | PETG + NPG | PETG + NPG + F2 | PETG + Taunite | PETG + Taunite + F2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.5 ± 0.4 | 3.5 ± 0.3 | 0.15 ± 0.05 | 0.37 ± 0.08 | 0.6 ± 0.1 | 0.13 ± 0.04 | 2.1 ± 0.2 | 0.70 ± 0.09 | 1.1 ± 0.1 | 0.33 ± 0.05 | 0.36 ± 0.08 | 0.20 ± 0.05 | |

| 340 ± 30 | 270 ± 20 | 11 ± 3 | 28 ± 5 | 48 ± 6 | 10 ± 3 | 160 ± 10 | 53 ± 9 | 78 ± 10 | 25 ± 5 | 27 ± 6 | 15 ± 4 |

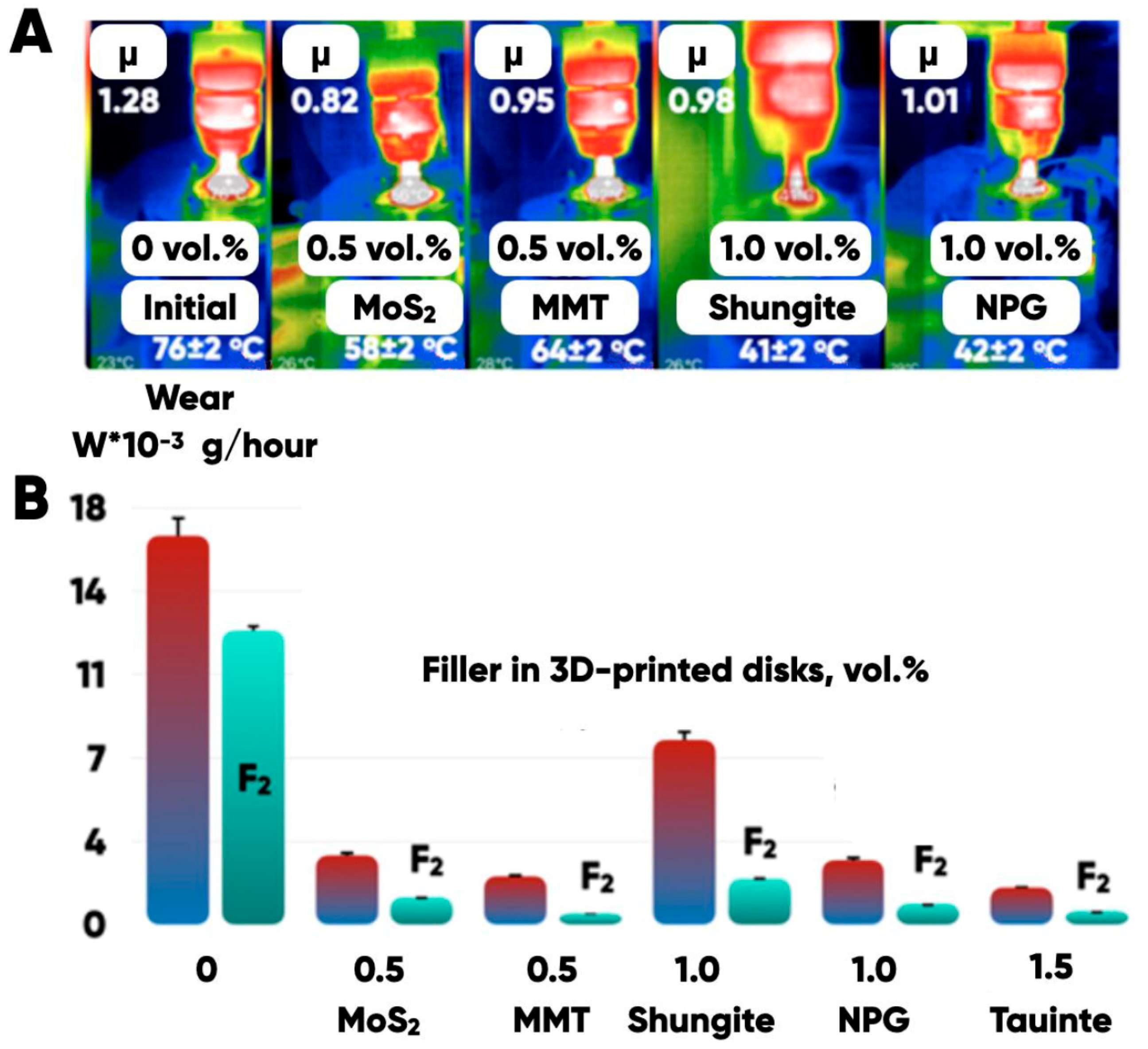

| Rest Friction Coefficient | PETG | PETG + F2 | PETG + MoS2 | PETG + MoS2 + F2 | PETG + MMT | PETG + MMT + F2 | PETG + Snungite | PETG + Snungite + F2 | PETG + NPG | PETG + NPG + F2 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1.28 | 1.13 | 0.82 | 0.27 | 0.95 | 0.24 | 0.98 | 0.9 | 1.0 | 0.51 | |

| 0.15 | 0.15 | 0.09 | 0.06 | 0.09 | 0.06 | 0.09 | 0.1 | 0.1 | 0.08 |

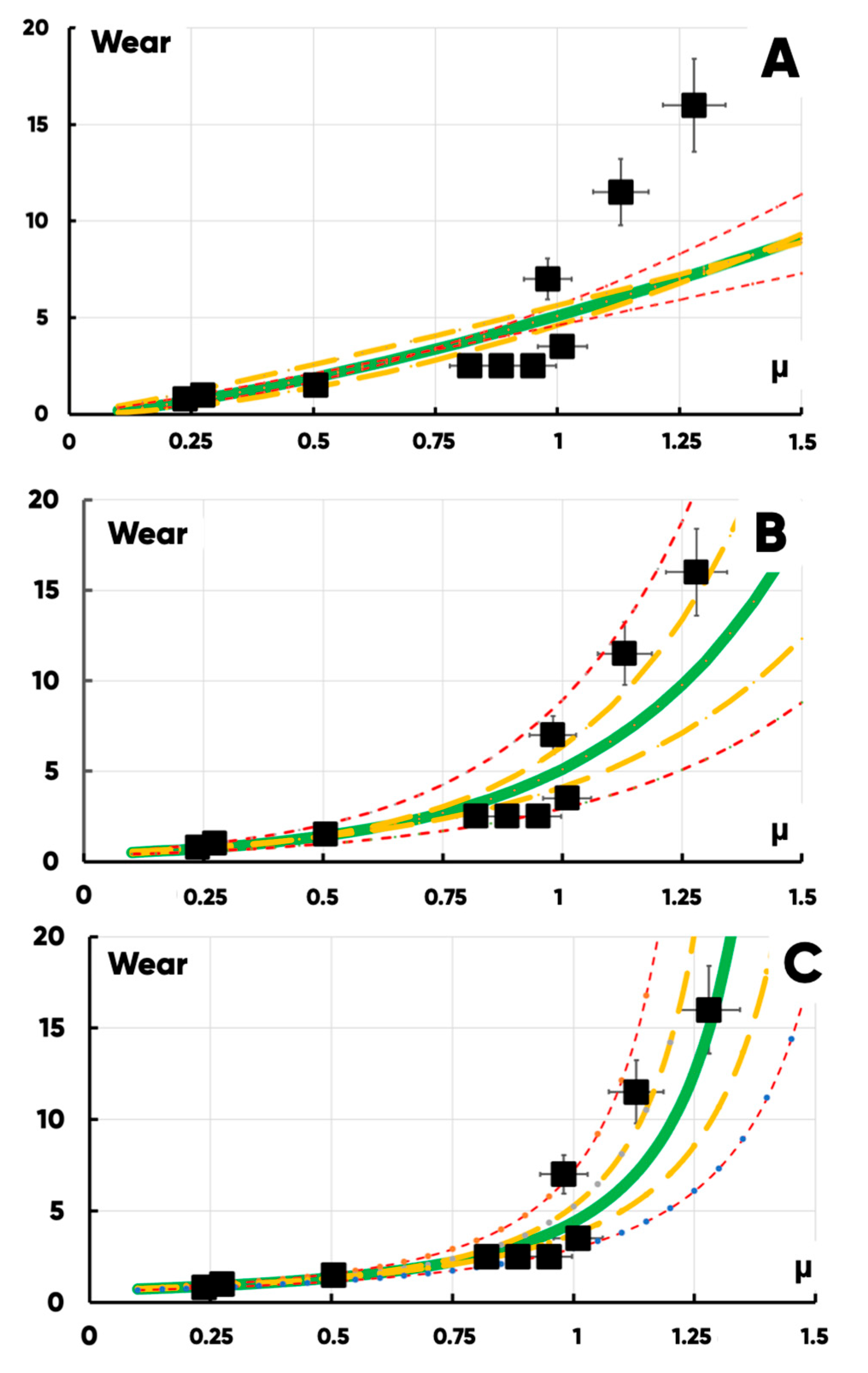

| MODEL | ||||

|---|---|---|---|---|

| Power-law | ||||

| Exponential | ||||

| Superhyperbolic |

| Wear | Fluorination | PETG | +F2 | Composition | |

|---|---|---|---|---|---|

| Filling | Synergy | ||||

| PETG | 16 ± 2 | 13 ± 1 | −19% | PETG/F2 | |

| +Shungite | 7.5 ± 0.8 | 2.0 ± 0.5 | −73% | PETG/Shungite/F2 | |

| −53% | −85% | −88% | |||

| +NPG | 3.0 ± 0.5 | 1.5 ± 0.5 | −50% | PETG/NPG/F2 | |

| −81% | −88% | −91% | |||

| +MoS2 | 3.0 ± 0.5 | 1.0 ± 0.5 | −67% | PETG/MoS2/F2 | |

| −81% | −92% | −94% | |||

| +Taunite | 1.5 ± 0.5 | 0.5 ± 0.5 | −67% | PETG/Taunite/F2 | |

| −91% | −88% | −97% | |||

| +MMT | 2.0 ± 0.5 | 0.5 ± 0.5 | −75% | PETG/MMT/F2 | |

| −88% | −96% | −97% | |||

| Standardized Three-Dimensional Surface Parameters | PETG | PETG + F2 | PETG + MMT + F2 |

|---|---|---|---|

| , µm | 0.46 ± 0.01 | 0.47 ± 0.01 | 0.48 ± 0.02 |

| , un. | 14.5 ± 0.3 | 14.9 ± 0.4 | 15.2 ± 0.7 |

| , un. | 1.63 ± 0.03 | 1.61 ± 0.02 | 1.58 ± 0.07 |

| , un. | 3.2 ± 0.2 | 3.1 ± 0.1 | 3.0 ± 0.3 |

| , µm | 0.24 ± 0.04 | 0.16 ± 0.02 | 0.7 ± 0.1 |

| , un. | 0.7 ± 0.2 | 0.6 ± 0.3 | 0.5 ± 0.2 |

| Molybdenum Disulfide Content, vol.% | The Morphological Spectra for the Optical Images of the PETG-Based Composite 3D-Disks’ Surface | |

|---|---|---|

| Initial | 86.5%He + 13.5%F2 | |

| 0.5 |  MSV ~ 0.025 |  MSV ~ 0.055 |

| 1.0 |  MSV ~ 0.023 |  MSV ~ 0.037 |

| 1.5 |  MSV ~ 0.047 |  MSV ~ 0.033 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rytikov, G.; Doronin, F.; Evdokimov, A.; Savel’ev, M.; Rudyak, Y.; Nazarov, V. Biomimetic Functional Fluorinated Oxygen-Containing Coatings on 3D-Printing Composite Polymer Items. Polymers 2025, 17, 2490. https://doi.org/10.3390/polym17182490

Rytikov G, Doronin F, Evdokimov A, Savel’ev M, Rudyak Y, Nazarov V. Biomimetic Functional Fluorinated Oxygen-Containing Coatings on 3D-Printing Composite Polymer Items. Polymers. 2025; 17(18):2490. https://doi.org/10.3390/polym17182490

Chicago/Turabian StyleRytikov, Georgy, Fedor Doronin, Andrey Evdokimov, Mikhail Savel’ev, Yuriy Rudyak, and Victor Nazarov. 2025. "Biomimetic Functional Fluorinated Oxygen-Containing Coatings on 3D-Printing Composite Polymer Items" Polymers 17, no. 18: 2490. https://doi.org/10.3390/polym17182490

APA StyleRytikov, G., Doronin, F., Evdokimov, A., Savel’ev, M., Rudyak, Y., & Nazarov, V. (2025). Biomimetic Functional Fluorinated Oxygen-Containing Coatings on 3D-Printing Composite Polymer Items. Polymers, 17(18), 2490. https://doi.org/10.3390/polym17182490