2D to 3D Modification of Chang–Chang Criterion Considering Multiaxial Coupling Effects in Fiber and Inter-Fiber Directions for Continuous Fiber-Reinforced Composites

Abstract

1. Introduction

2. An Overview of the Chang–Chang Criterion

- Fiber tensile failure or fiber–matrix shear failure:

- Fiber compression failure:

- Matrix tensile failure:

- Matrix compression failure:

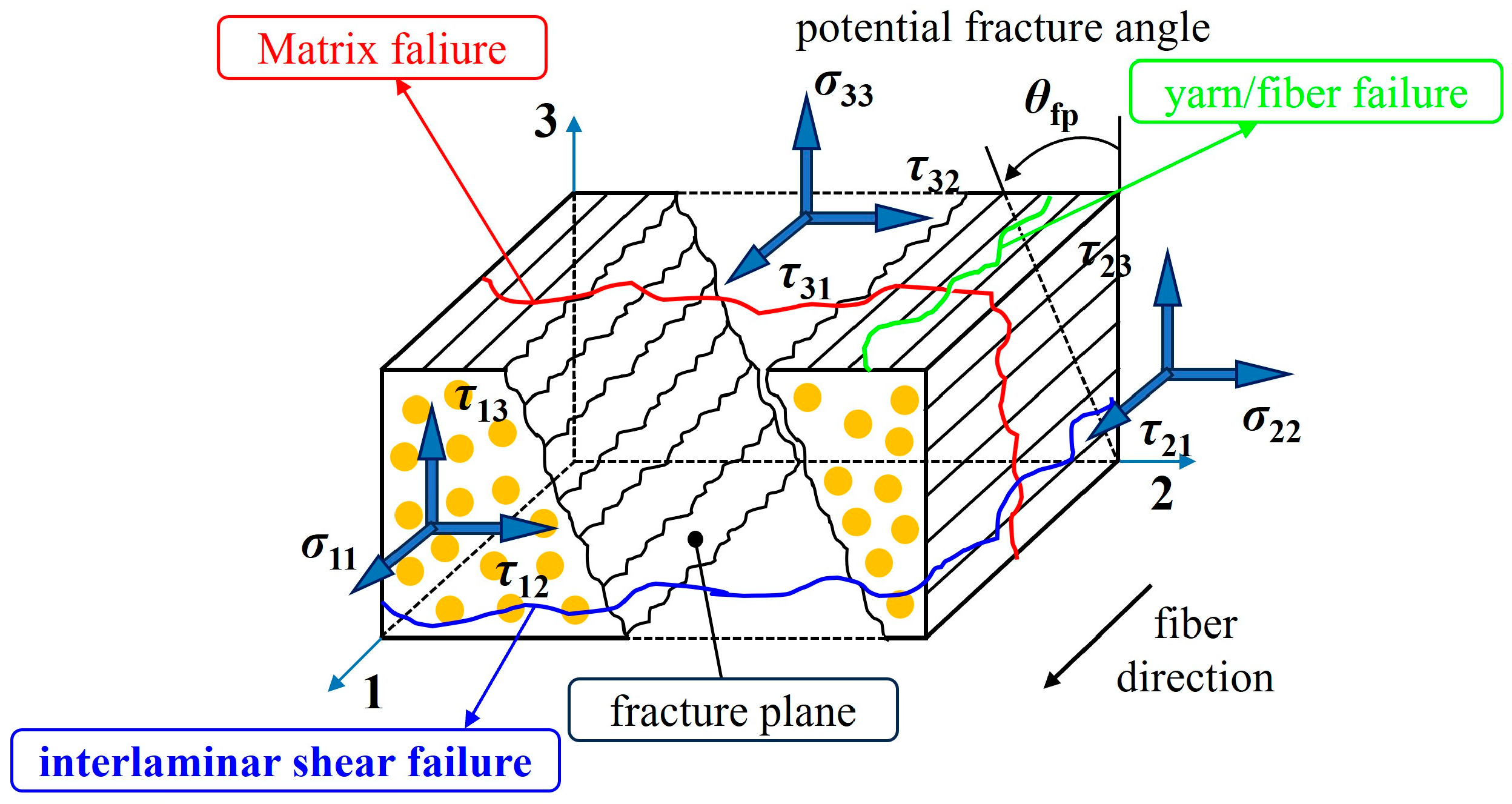

3. Construction of 3D Chang–Chang Criterion

3.1. Construction of 3D Failure Criterion for Matrix

- Matrix compression:

- 2.

- Matrix tension:

3.2. Construction of 3D Failure Criterion for Fiber

4. Construction of 3D Failure Criterion Coupling for Transverse and Longitudinal Failure

4.1. Determination of Coefficients Under the Conditions of (σ11 < 0, σ22 + σ33 < 0)

- 1.

- When , transverse hydrostatic compression failure occurs firstly, so that there is the following:

- 2.

- When , longitudinal compression failure occurs firstly, so that there is the following:

4.2. Determination of Coefficients Under the Conditions of (σ11 ≥ 0, σ22 + σ33 < 0)

- When , transverse hydrostatic compression failure occurs firstly, so that there is the following:

- 2.

- When , longitudinal tensile failure occurs preferentially, so that there is the following:

4.3. Determination of Coefficients Under the Conditions of (σ11 < 0, σ22 + σ33 ≥ 0)

- When , transverse tensile failure occurs preferentially, so that there is the following:

- 2.

- When , longitudinal compression failure occurs preferentially, so that there is the following:

4.4. Determination of Coefficients Under the Conditions of (σ11 ≥ 0, σ22 + σ33 ≥ 0)

- 1.

- When , transverse stretch failure occurs preferentially, so that there is the following:

- 2.

- When , longitudinal tensile failure occurs preferentially, so that there is the following:

4.5. Theoretical Justification of Stress-State-Coupled Transition at Failure Boundaries

4.6. Summary of the Modified Chang–Chang Criterion

- 1.

- In the case of σ11 < 0 and σ22 + σ33 < 0

- 2.

- In the case of σ11 ≥ 0 and σ22 + σ33 < 0

- 3.

- In the case of σ11 ≥ 0 and σ22 + σ33 ≥ 0

- 4.

- In the case of σ11 ≥ 0 and σ22 + σ33 ≥ 0

5. Results and Discussions

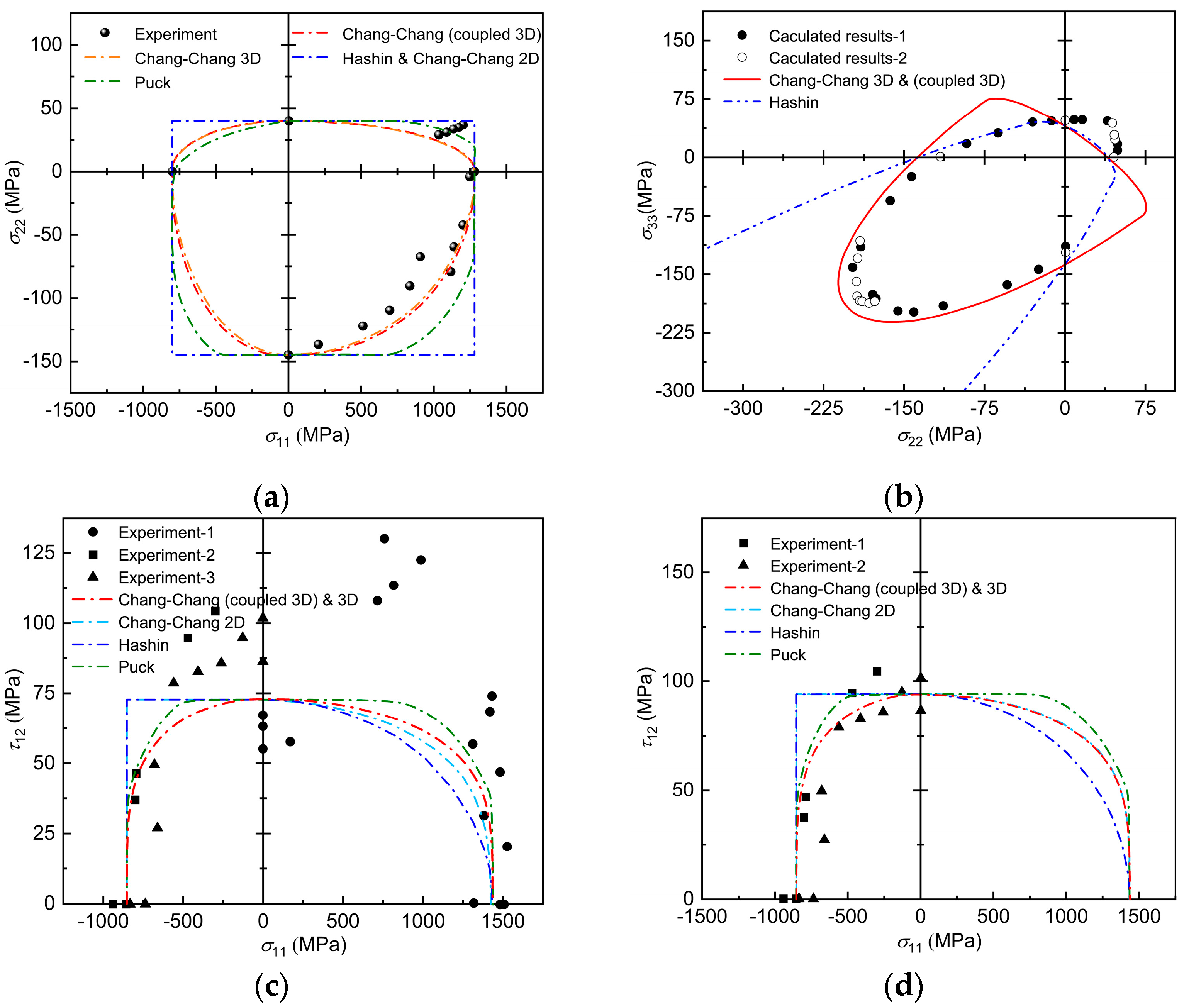

5.1. Experimental Evaluation of the Modified Chang–Chang Criterion

5.1.1. Performance Under Biaxial Stress States

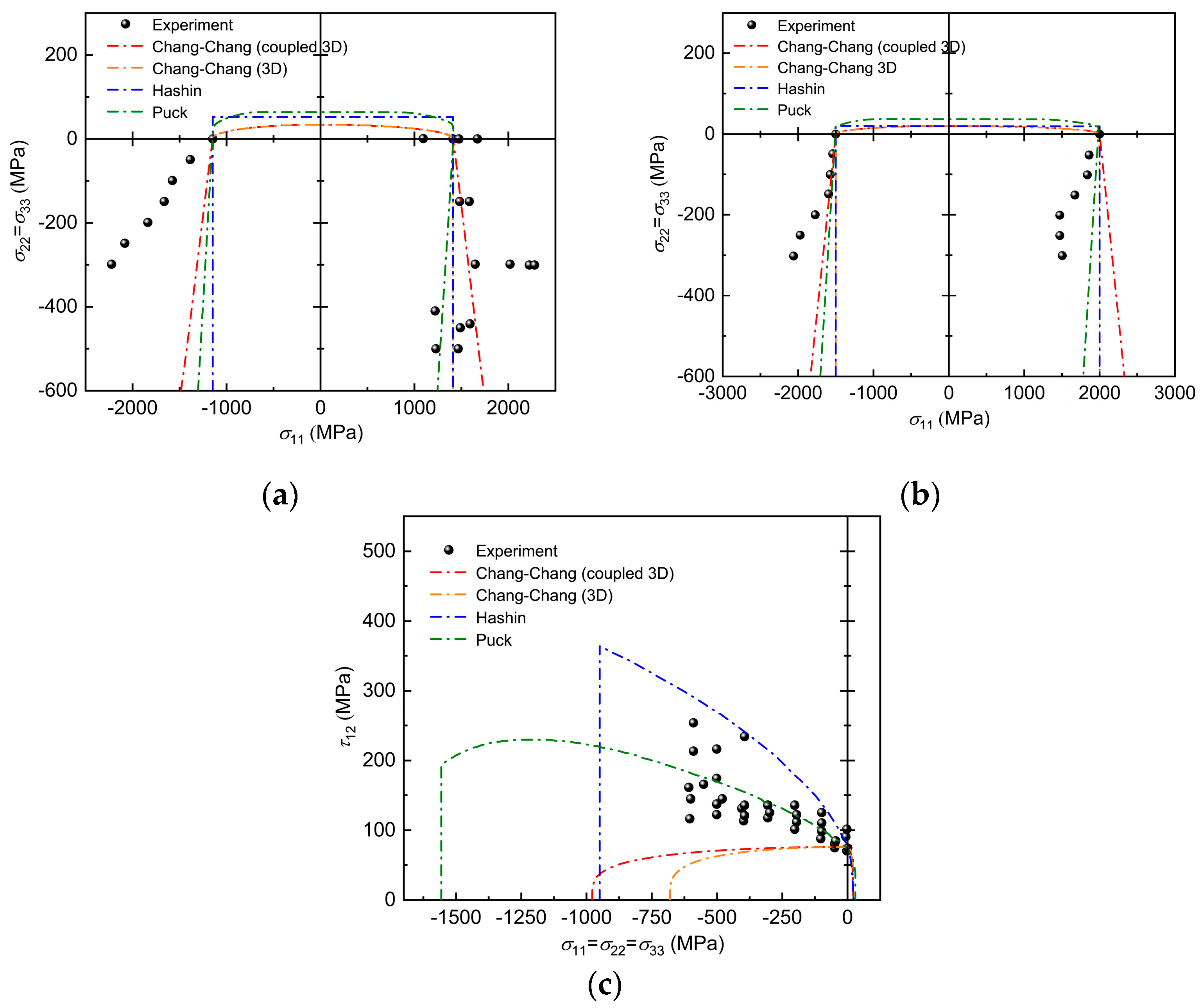

5.1.2. Performance Under Triaxial Stress States

5.2. The Effect of Mechanical Parameters on the Failure Envelope Curve

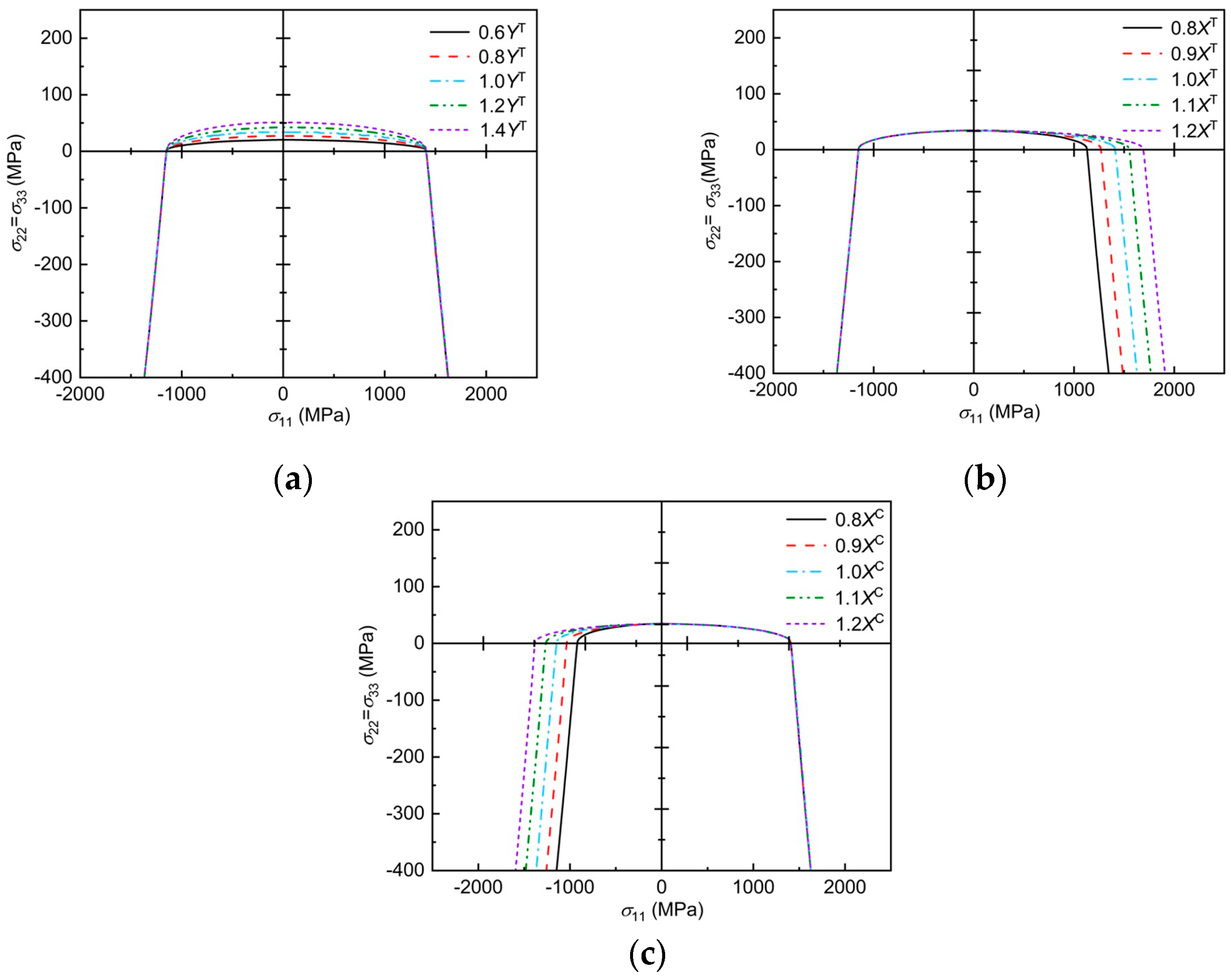

5.2.1. Effect of Mechanical Parameters on Failure Envelopes at σ11-σ22 Stress States

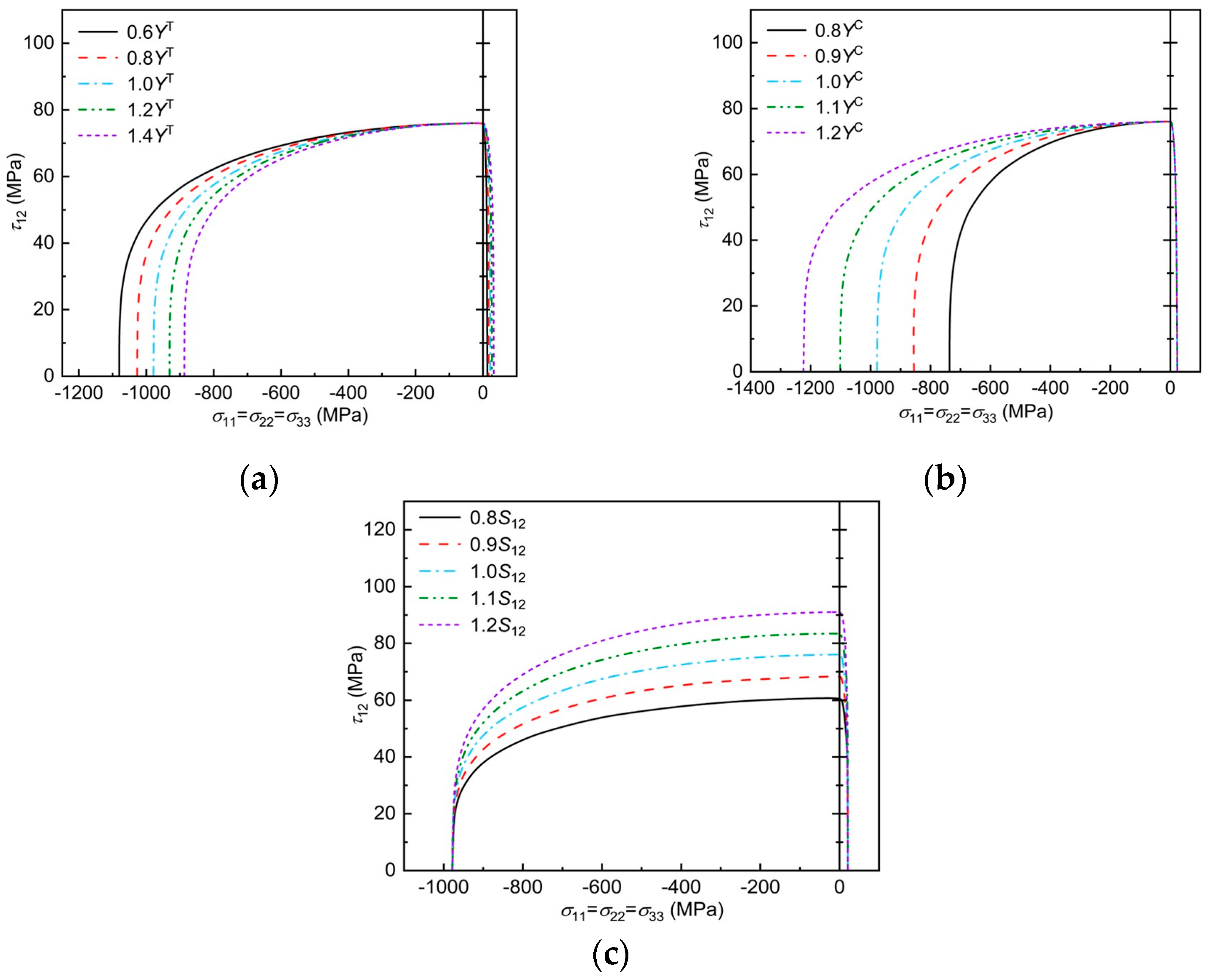

5.2.2. Effect of Mechanical Parameters on Failure Envelopes at σ11-τ12 Stress States

5.2.3. Effect of Mechanical Parameters on Failure Envelopes at σ22-σ33 Stress States

5.2.4. Effect of Mechanical Parameters on the Failure Envelope at σ11-σ22 = σ33 Stress States

5.2.5. Effect of Mechanical Parameters on the Failure Envelope at the σ11 = σ22 = σ33-τ12 Stress State

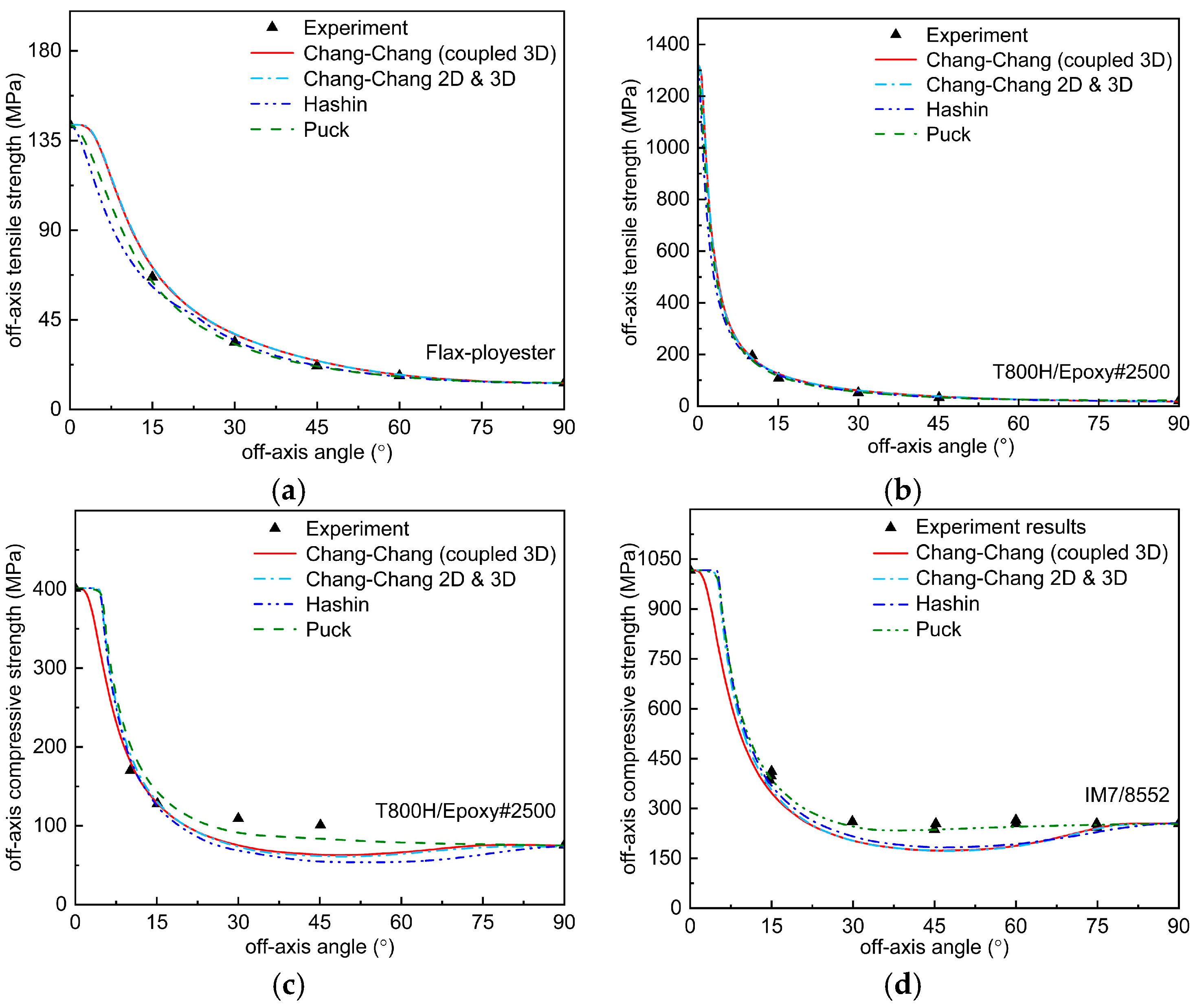

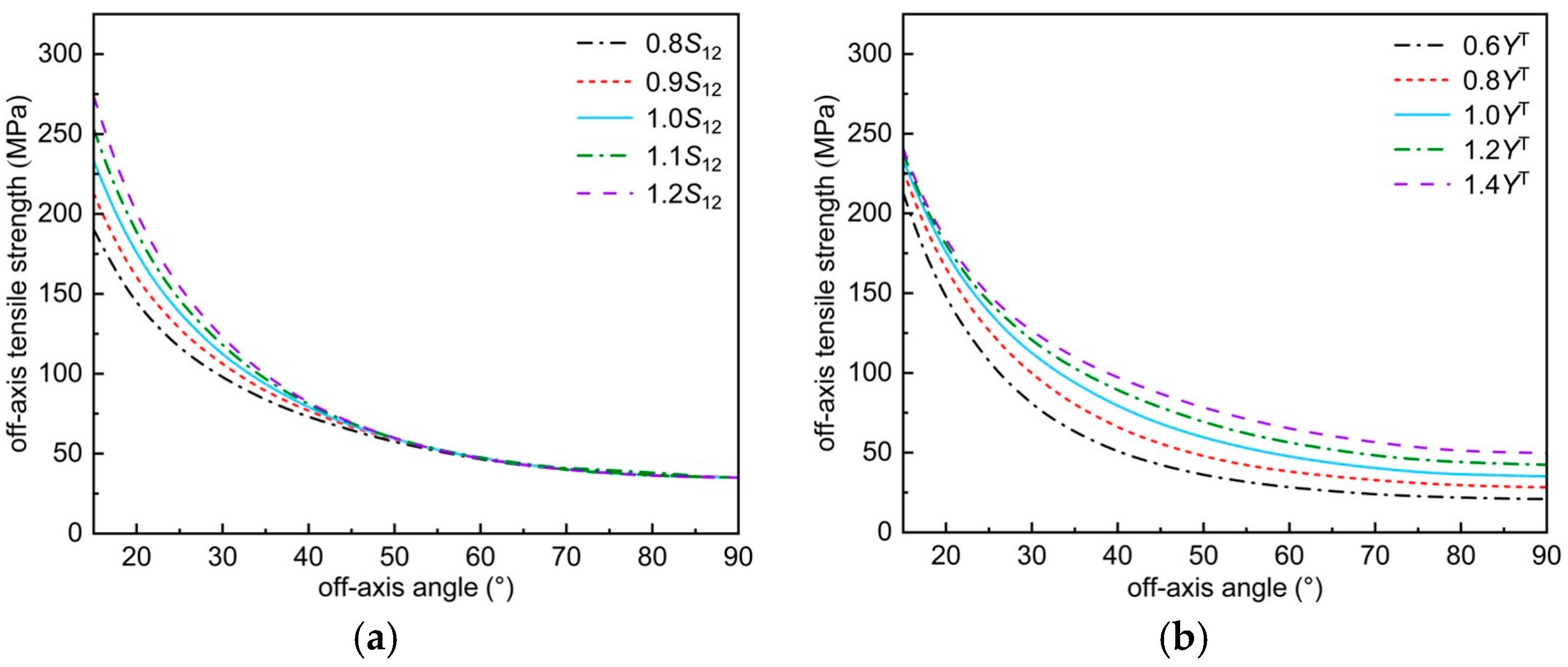

5.3. The Effect of Mechanical Parameters on the Prediction of Off-Axis Tensile Strength

5.4. The Effect of Mechanical Parameters on the Prediction of Off-Axis Compression Strength

6. Conclusions and Future Work Prospects

- By incorporating the coupling effects between transverse and longitudinal failure modes, the improved Chang–Chang criterion significantly enhances the accuracy of failure prediction for composite materials under complex stress conditions, such as transverse compression, longitudinal tension, and triaxial compression in three-dimensional stress states. Compared to traditional Chang–Chang, Hashin, and Puck criteria, the proposed criterion demonstrates superior performance. Its applicability is particularly evident in multiaxial stress environments, exhibiting strong potential for application in aerospace composite structures such as wing root attachments and spar joints, where accurate failure prediction under multidimensional loading is critical.

- By considering the coupling between transverse and longitudinal failure mechanisms, the improved guideline significantly enhances the predictive accuracy of composite materials’ out-of-plane tensile strength, particularly in accurately capturing the transition behavior of failure modes within small out-of-plane angles. Compared to other established standards, it more effectively captures mode-of-failure transitions and demonstrates better consistency with experimental data. These improvements offer practical value for the design and evaluation of automotive composite components, such as chassis elements and battery enclosures, which frequently encounter out-of-plane loading conditions.

- The improved criterion improves the rationality of failure prediction under biaxial stress conditions by introducing the problem that the traditional criterion of finite biaxial transverse compressive strength () does not close the failure envelope under biaxial compressive stress, which provides a more accurate failure assessment tool for the safe design of composites in complex engineering environments. For example, in wind turbine blade root connections, accurate failure prediction under biaxial compression is critical for structural integrity and safety.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Guo, J.; Wen, H.; Cui, H.; Zhang, H.; Wen, W.; Guo, C.; Zhang, Y.; Guo, W. A parametric modeling method for 2.5D warp-reinforced woven composites considering the extruded distortion of yarns. Compos. Sci. Technol. 2024, 257, 110807. [Google Scholar] [CrossRef]

- Liu, B.; Wang, W.; Sutherland, L. Experimental and numerical response and failure of laterally impacted carbon/glass fibre-reinforced hybrid composite laminates. Int. J. Impact Eng. 2023, 179, 104654. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Han, C.; Huang, S.; Sun, B.; Gu, B. Electrical resistance changes of 3D carbon fiber/epoxy woven composites under short beam shear loading along different orientations. Compos. Struct. 2021, 276, 114549. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Li, F.; Huang, Z.; Chen, H. Failure analysis and experimental study on bolted composite joints based on continuum damage mechanics. Compos. Struct. 2023, 303, 116274. [Google Scholar] [CrossRef]

- Mertgenç Yoldaş, D. Investigation of Diffusion Induced Fiber–Matrix Interface Damages in Adhesively Bonded Polymer Composites. Polymers 2025, 17, 1672. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, Z.; Li, Q.; Qi, Z.; Chen, W.; Liu, P. Comparative analysis of dynamic progressive failure of CFRPs using the scale-span and macroscopic modeling method in drilling. Eng. Fract. Mech. 2022, 268, 108434. [Google Scholar] [CrossRef]

- Li, N.; Ju, C.; Yang, P.; Zhuang, F. Stress invariant-based failure criteria for predicting matrix failure of transversely isotropic composites: Theoretical assessment and rationalized improvement. Thin-Walled Struct. 2022, 181, 110110. [Google Scholar] [CrossRef]

- Hinton, M.J.; Kaddour, A.S.; Soden, P.D. Failure Criteria in Fibre Reinforced Polymer Composites: The World-Wide Failure Exercise; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Hinton, M.; Kaddour, A. The background to the Second World-Wide Failure Exercise. J. Compos. Mater. 2012, 46, 2283–2294. [Google Scholar] [CrossRef]

- Kaddour, A.; Hinton, M.; Smith, P.; Li, S. The background to the third world-wide failure exercise. J. Compos. Mater. 2013, 47, 2417–2426. [Google Scholar] [CrossRef]

- Schulte, K. World wide failure exercise on failure prediction in composites. Compos. Sci. Technol. 2002, 62, 1479. [Google Scholar] [CrossRef]

- Hoffman, O. The Brittle Strength of Orthotropic Materials. J. Compos. Mater. 1967, 1, 200–206. [Google Scholar] [CrossRef]

- Franklin, H.G. Classic theories of failure of anisotropic materials. Fibre Sci. Technol. 1968, 1, 137–150. [Google Scholar] [CrossRef]

- Tsai, S.W.; Wu, E.M. A general theory of strength for anisotropic materials. J. Compos. Mater. 1971, 5, 58–80. [Google Scholar] [CrossRef]

- Chang, F.-K.; Chang, K.-Y. A Progressive Damage Model for Laminated Composites Containing Stress Concentrations. J. Compos. Mater. 1987, 21, 834–855. [Google Scholar] [CrossRef]

- Chang, K.-Y.; Llu, S.; Chang, F.-K. Damage Tolerance of Laminated Composites Containing an Open Hole and Subjected to Tensile Loadings. J. Compos. Mater. 1991, 25, 274–301. [Google Scholar] [CrossRef]

- Chang, F.K.; Lessard, L.B. Damage tolerance of laminated composites containing an open hole and subjected to compressive loadings: Part I—Analysis. J. Compos. Mater. 1991, 25, 2–43. [Google Scholar] [CrossRef]

- Christensen, R.M. Stress based yield/failure criteria for fiber composites. Int. J. Solids Struct. 1997, 34, 529–543. [Google Scholar] [CrossRef]

- Puck, A.; Schürmann, H. Failure analysis of FRP laminates by means of physically based phenomenological models. Compos. Sci. Technol. 1998, 58, 1045–1067. [Google Scholar] [CrossRef]

- Puck, A.; Kopp, J.; Knops, M. Guidelines for the determination of the parameters in Puck’s action plane strength criterion. Compos. Sci. Technol. 2002, 62, 371–378. [Google Scholar] [CrossRef]

- Daniel, I.M. Failure of composite materials. Strain 2007, 43, 4–12. [Google Scholar] [CrossRef]

- Daniel, I.M.; Luo, J.-J.; Schubel, P.M. Three-dimensional characterization of textile composites. Compos. Part. B Eng. 2008, 39, 13–19. [Google Scholar] [CrossRef]

- Daniel, I.M.; Luo, J.-J.; Schubel, P.M.; Werner, B.T. Interfiber/interlaminar failure of composites under multi-axial states of stress. Compos. Sci. Technol. 2009, 69, 764–771. [Google Scholar] [CrossRef]

- Daniel, I.M.; Werner, B.T.; Fenner, J.S. Strain-rate-dependent failure criteria for composites. Compos. Sci. Technol. 2011, 71, 357–364. [Google Scholar] [CrossRef]

- Hahn, H.T.; Tsai, S.W. Nonlinear Elastic Behavior of Unidirectional Composite Laminae. J. Compos. Mater. 1973, 7, 102–118. [Google Scholar] [CrossRef]

- Soden, P.D.; Hinton, M.J.; Kaddour, A.S. Biaxial test results for strength and deformation of a range of E-glass and carbon fibre reinforced composite laminates: Failure exercise benchmark data. Compos Sci Technol 2002, 62, 1489–1514. [Google Scholar] [CrossRef]

- Li, N.; Gu, J.F.; Chen, P.H. Fracture plane based failure criteria for fibre-reinforced composites under three-dimensional stress state. Compos. Struct. 2018, 204, 466–474. [Google Scholar] [CrossRef]

- Shen, J.; Liu, Z.; Guo, J. From Several Puck-like Inter-Fiber Failure Criteria to Longitudinal Compressive Failure: An Extension and Application for UD Composites. Polymers 2025, 17, 1613. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Zhang, Y.; Zhou, G.; Wen, H.; Wen, W.; Zhang, H.; Cui, H.; Zhang, Y. A transverse failure criterion for unidirectional composites based on the Puck failure surface theory. Compos. Sci. Technol. 2023, 242, 110192. [Google Scholar] [CrossRef]

- Li, S. Stress or Strain? Proc. R. Soc. A 2024, 480, 20240269. [Google Scholar] [CrossRef]

- Pincus, H.J. Closed-form/least-squares failure envelopes for rock strength. Int. J. Rock. Mech. Min. Sci. 2000, 37, 763–785. [Google Scholar] [CrossRef]

- Zambrano-Mendoza, O.; Valkó, P.P.; Russell, J.E. Error-in-variables for rock failure envelope. Int. J. Rock. Mech. Min. Sci. 2003, 40, 137–143. [Google Scholar] [CrossRef]

- Gu, J.; Chen, P. A Failure Criterion for Isotropic Materials Based on Mohr’s Failure Plane Theory. Mech. Res. Commun. 2017, 87, 1–6. [Google Scholar] [CrossRef]

- Donadon, M.V.; Iannucci, L.; Falzon, B.G.; Hodgkinson, J.M.; de Almeida, S.F.M. A Progressive Failure Model for Composite Laminates Subjected to Low Velocity Impact Damage. Comput. Struct. 2008, 86, 1232–1252. [Google Scholar] [CrossRef]

- Soden, P.D.; Hinton, M.J.; Kaddour, A.S. Lamina properties, lay-up configurations and loading conditions for a range of fibre reinforced composite laminates. In Failure Criteria in Fibre-Reinforced-Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2004; pp. 30–51. [Google Scholar]

- Hinton, M.; Kaddour, A. Triaxial test results for fibre-reinforced composites: The Second World-Wide Failure Exercise benchmark data. J. Compos. Mater. 2013, 47, 653–678. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J.; Licence, P. The tensile behavior of off-axis loaded plant fiber composites: An insight on the nonlinear stress–strain response. Polym. Compos. 2012, 33, 1494–1504. [Google Scholar] [CrossRef]

- Kawai, M.; Saito, S. Off-axis strength differential effects in unidirectional carbon/epoxy laminates at different strain rates and predictions of associated failure envelopes. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1632–1649. [Google Scholar] [CrossRef]

- Koerber, H.; Xavier, J.; Camanho, P.P. High strain rate characterisation of unidirectional carbon-epoxy IM7-8552 in transverse compression and in-plane shear using digital image correlation. Mech. Mater. 2010, 42, 1004–1019. [Google Scholar] [CrossRef]

- Parvizi, A.; Garrett, K.W.; Bailey, J.E. Constrained cracking in glass fibre-reinforced epoxy cross-ply laminates. J. Mater. Sci. 1978, 13, 195–201. [Google Scholar] [CrossRef]

- Camanho, P.P.; Arteiro, A.; Melro, A.R.; Catalanotti, G.; Vogler, M. Three-dimensional invariant-based failure criteria for fibre-reinforced composites. Int. J. Solids Struct. 2015, 55, 92–107. [Google Scholar] [CrossRef]

- Camanho, P.P.; Dávila, C.G.; Pinho, S.T.; Iannucci, L.; Robinson, P. Prediction of in situ strengths and matrix cracking in composites under transverse tension and in-plane shear. Compos. Part A Appl. Sci. Manuf. 2006, 37, 165–176. [Google Scholar] [CrossRef]

- Catalanotti, G.; Camanho, P.P.; Marques, A.T. Three-dimensional failure criteria for fiber-reinforced laminates. Compos. Struct. 2013, 95, 63–79. [Google Scholar] [CrossRef]

- Kaddour, A.S.; Hinton, M.J.; Soden, P.D. A comparison of the predictive capabilities of current failure theories for composite laminates: Additional contributions. Compos. Sci. Technol. 2002, 58, 1225–1254. [Google Scholar] [CrossRef]

- Gu, J. Research on Failure Criteria for Aircraft Structural Materials. Jiangsu; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2018. [Google Scholar]

| Material | Modulus/GPa | Poisson’s Ratio | Strength/MPa | |||||

|---|---|---|---|---|---|---|---|---|

| E1 | E1f | v12 | Xt | Xc | Yt | Yc | S12 | |

| E-glass/MY750 [37] | 45.6 | 74 | 0.278 | 1280 | 800 | 40 | 145 | 73 |

| T300/BSL914C [28] | 138 | 230 | 0.28 | 1433.6 | 853 | 27 | 200 | 73 |

| E-glass/LY556 [28] | 53.48 | 80 | 0.291 | 1140 | 570 | 40 | 137.4 | 61.2 |

| S-glass/epoxy [38] | 52 | 87 | 0.3 | 1410 | 1147 | 63 | 180 | 72 |

| A-S carbon/epoxy [38] | 140 | 231 | 0.3 | 2000 | 1500 | 38 | 150 | 72 |

| T300/PR319 [38] | 129 | 231 | 0.318 | 1378 | 950 | 40 | 125 | 60 |

| Flax-polyester [39] | 15.3 | 4.1 | 0.269 | 143 | - | 13.3 | - | 20 |

| T800H/Epoxy#2500 [40] | - | - | - | 1319.5 | 1045 | 51.7 | 244 | 95.1 |

| IM7/8552 [41] | 171 | 9.1 | 0.32 | 2323 | 1017 | 160 | 255 | 89.6 |

| AS4/3501-6 [25] | 126 | 11 | 0.49 | 2300 | 1725 | 60.2 | 285 | 73.4 |

| Material | Chang–Chang (Coupled 3D) | Chang–Chang 2D and 3D | Hashin | Puck |

|---|---|---|---|---|

| Flax-ployester | 4.71% | 6.07% | 2.36% | 2.54% |

| T800H/Epoxy#2500 | 7.36% | 8.84% | 7.16% | 6.16% |

| Material | Chang–Chang (Coupled 3D) | Chang–Chang 2D and 3D | Hashin | Puck |

|---|---|---|---|---|

| T800H/Epoxy#2500 | 12.14% | 13.90% | 15.28% | 10.36% |

| IM7/8552 | 15.01% | 14.75% | 13.05% | 3.48% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Guo, J.; Guo, W. 2D to 3D Modification of Chang–Chang Criterion Considering Multiaxial Coupling Effects in Fiber and Inter-Fiber Directions for Continuous Fiber-Reinforced Composites. Polymers 2025, 17, 2416. https://doi.org/10.3390/polym17172416

Chen Y, Guo J, Guo W. 2D to 3D Modification of Chang–Chang Criterion Considering Multiaxial Coupling Effects in Fiber and Inter-Fiber Directions for Continuous Fiber-Reinforced Composites. Polymers. 2025; 17(17):2416. https://doi.org/10.3390/polym17172416

Chicago/Turabian StyleChen, Yingchi, Junhua Guo, and Wantao Guo. 2025. "2D to 3D Modification of Chang–Chang Criterion Considering Multiaxial Coupling Effects in Fiber and Inter-Fiber Directions for Continuous Fiber-Reinforced Composites" Polymers 17, no. 17: 2416. https://doi.org/10.3390/polym17172416

APA StyleChen, Y., Guo, J., & Guo, W. (2025). 2D to 3D Modification of Chang–Chang Criterion Considering Multiaxial Coupling Effects in Fiber and Inter-Fiber Directions for Continuous Fiber-Reinforced Composites. Polymers, 17(17), 2416. https://doi.org/10.3390/polym17172416