Experimental Study on the Bending Behaviour of GFRP Laminates Repaired with Stainless-Steel Wire Mesh

Abstract

1. Introduction

2. Experimental Details

2.1. Materials

2.2. Fabrication of the Parent Laminate

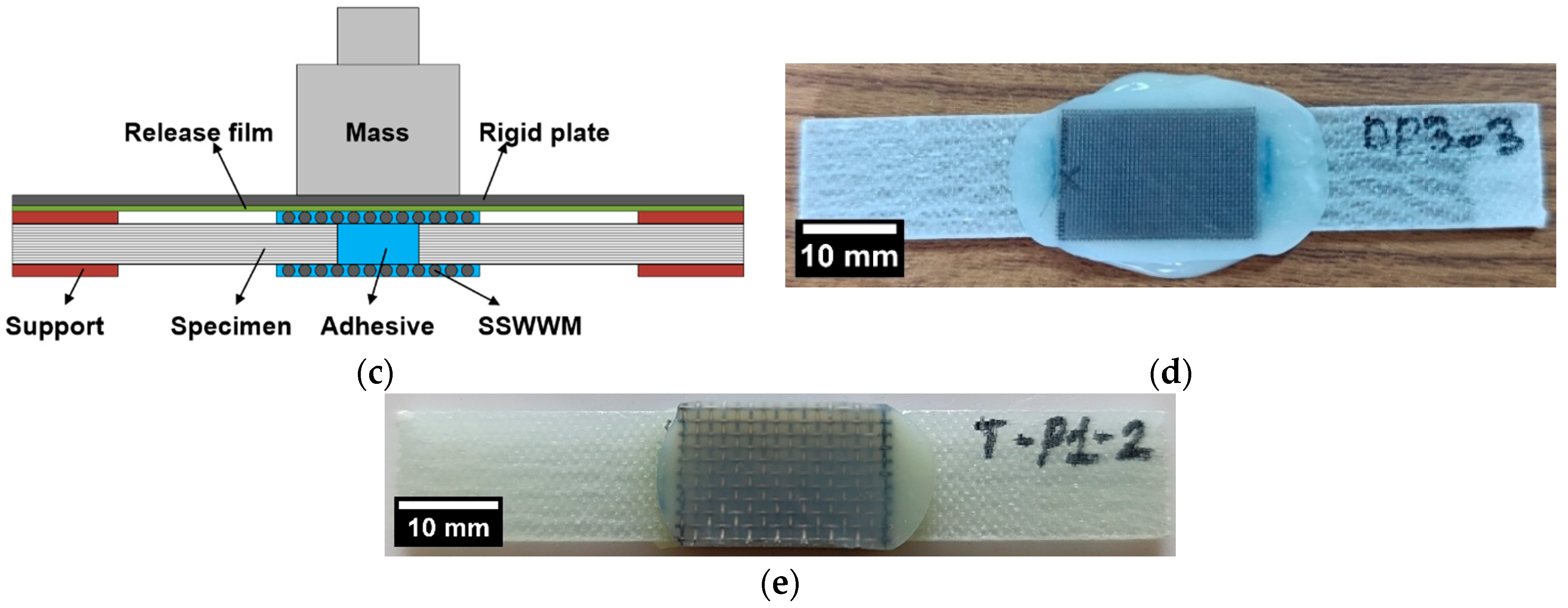

2.3. Repair of the Parent Laminate

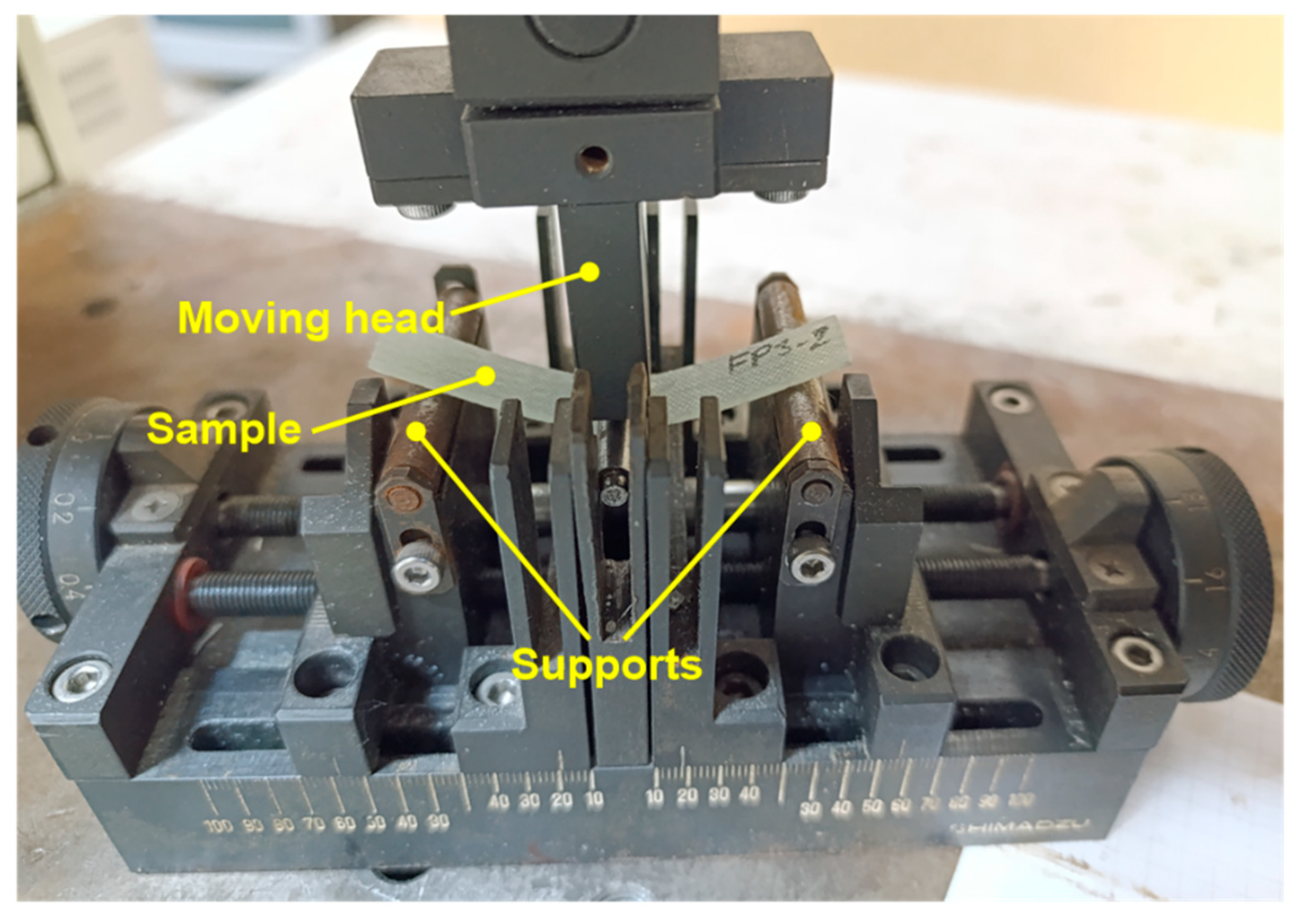

2.4. Three-Point Bending Tests

3. Results and Discussion

3.1. Statistical Analysis of the Test Results

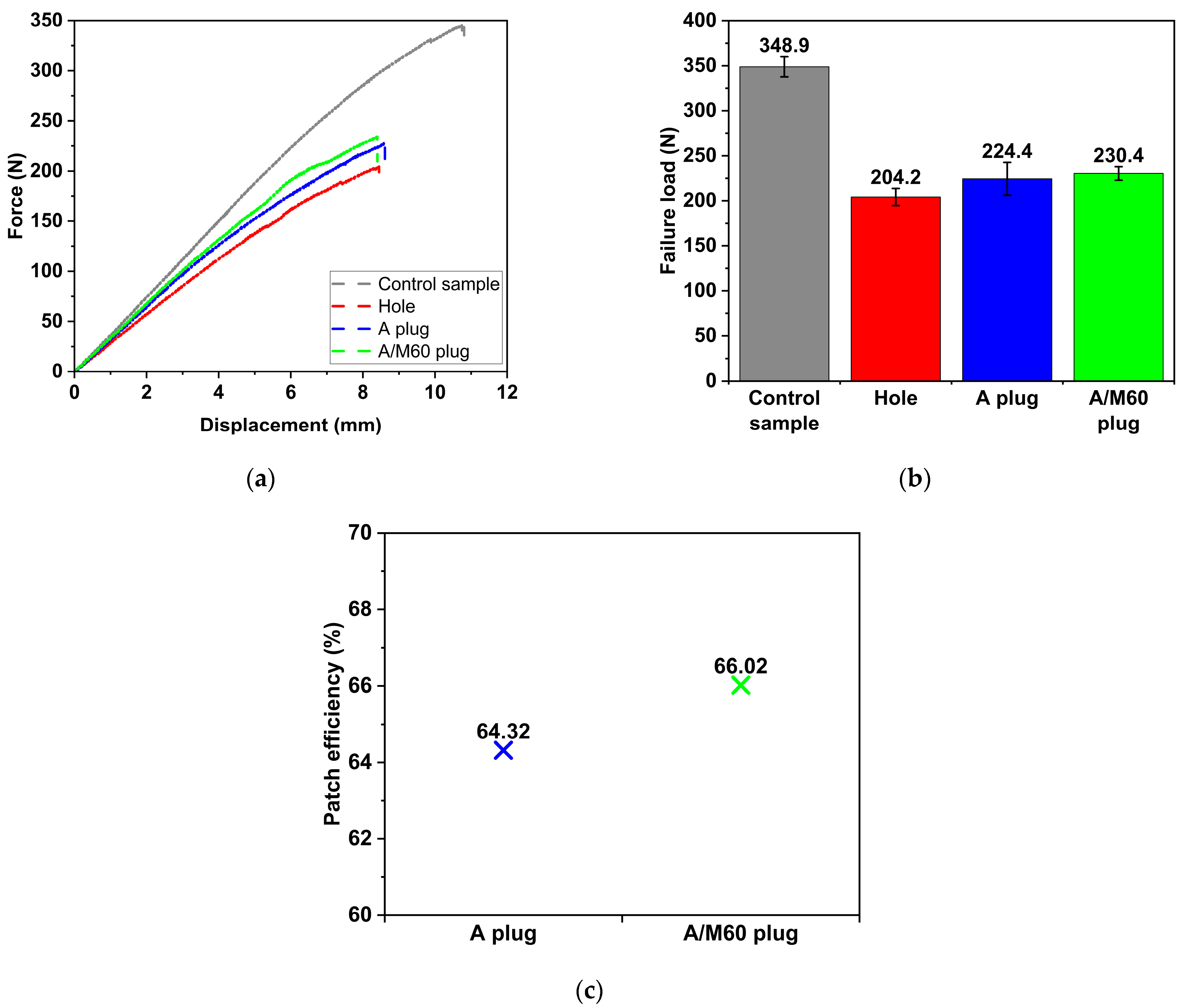

3.2. Influence of Plugging the Open Hole

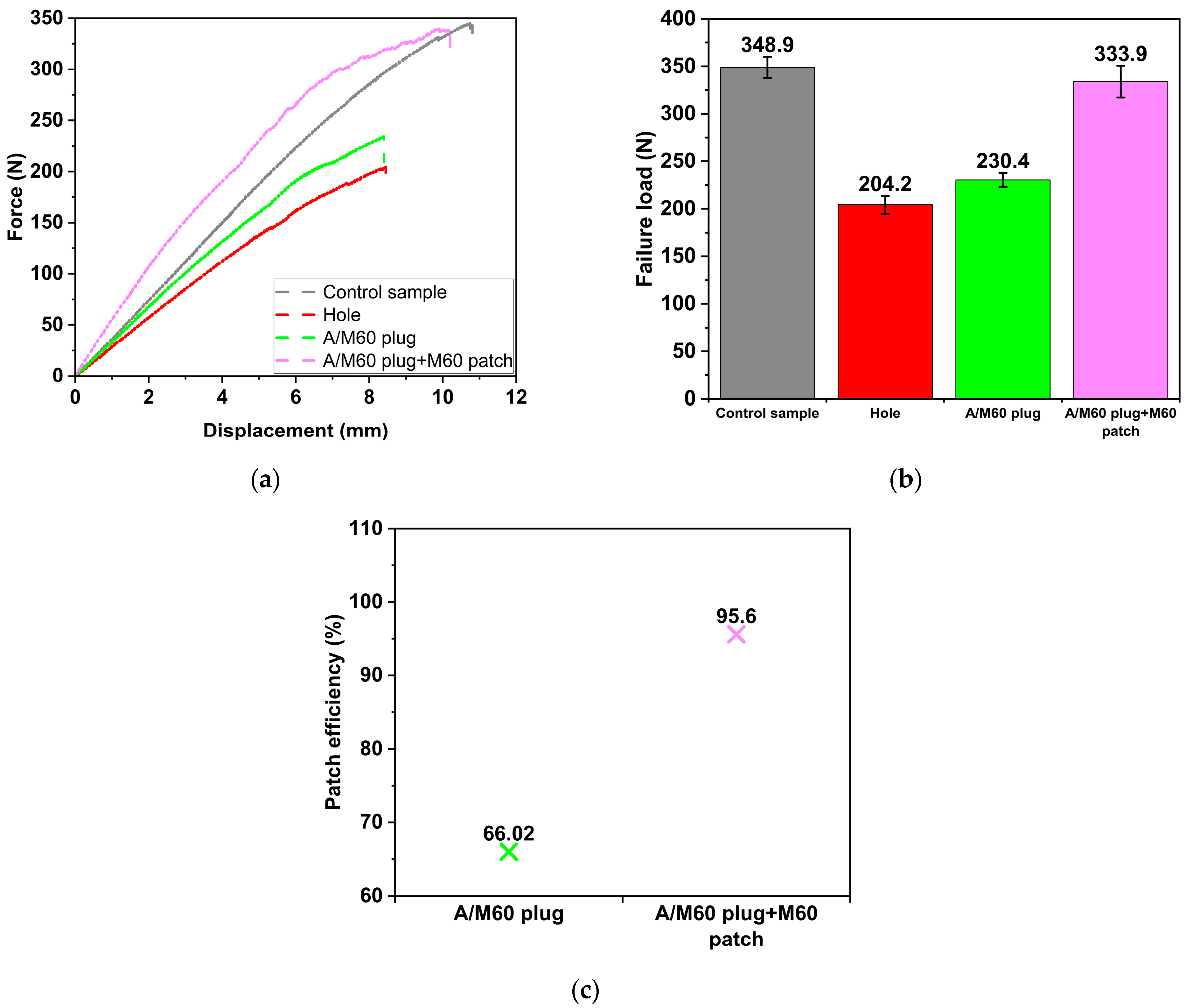

3.3. Influence of the External Patch Repair

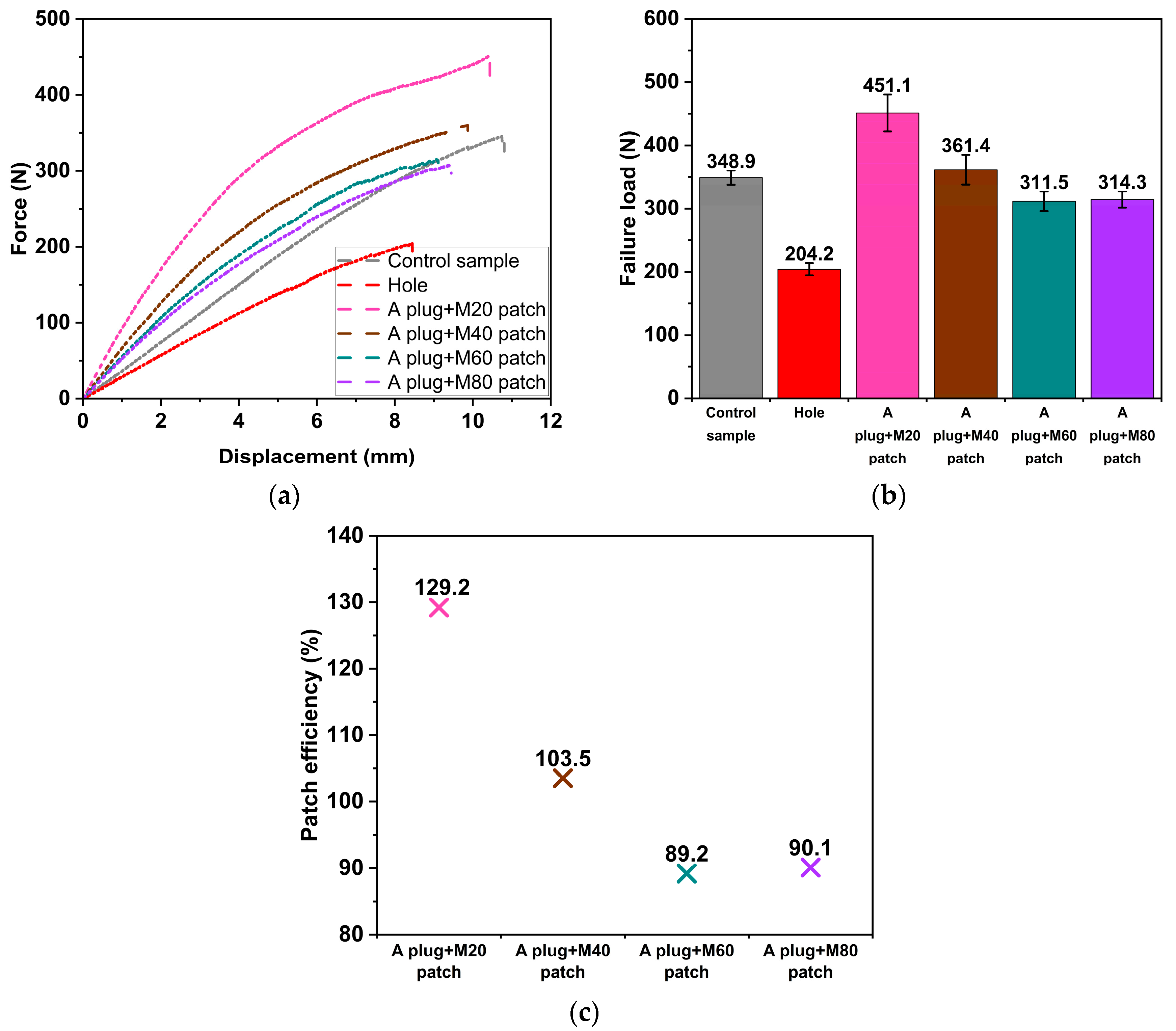

3.4. Influence of the SSWWM Count

3.5. Influence of the Number of SSWWM Layers

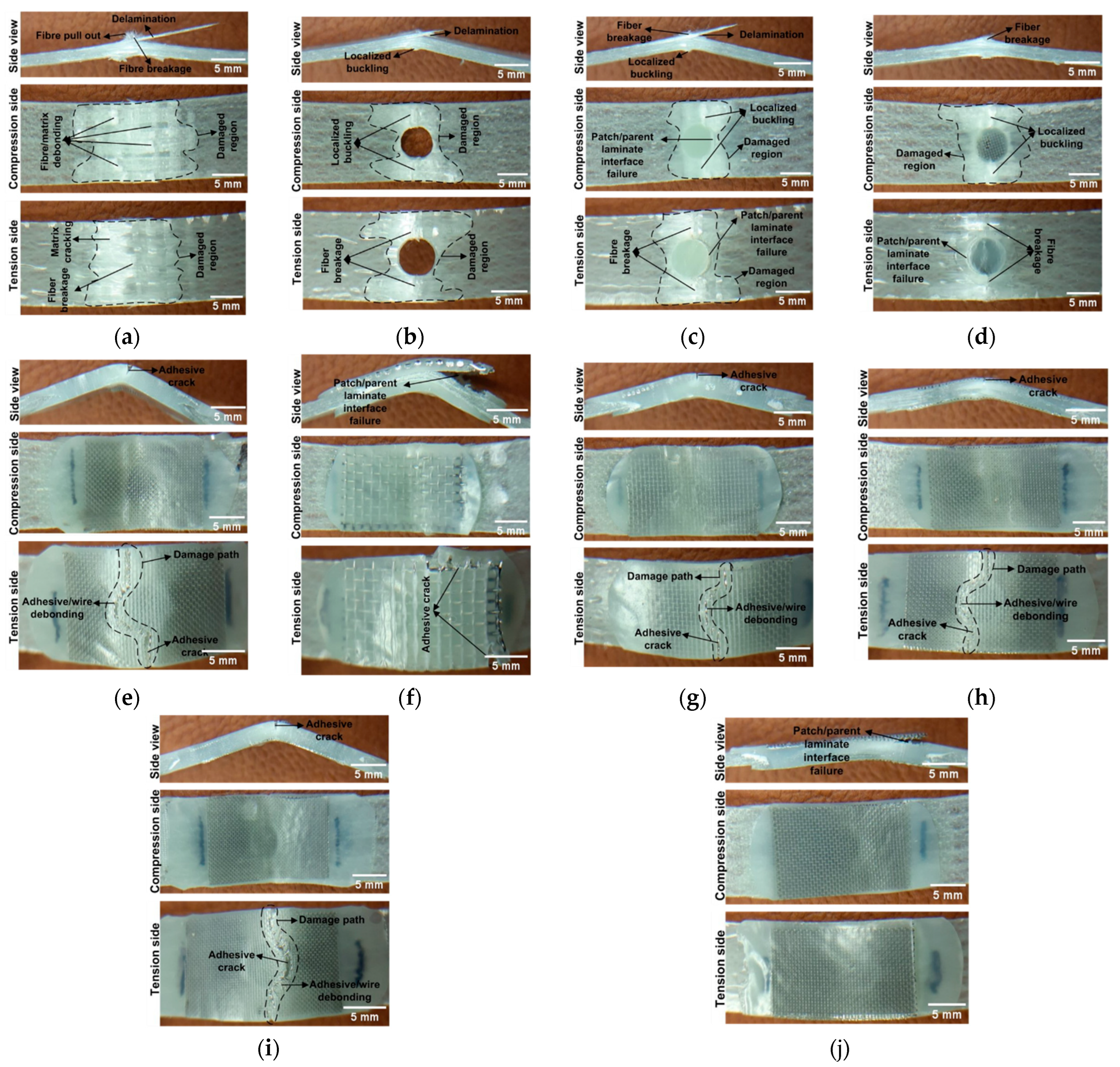

3.6. Damage Modes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SSWWM | Stainless-steel woven wire mesh. |

| GFR | Glass fibre-reinforced. |

| 3PB | Three-point bending. |

| a | Depth. |

| t | Thickness. |

| SLJ | Single-lap joint |

| OSB | Oriented Strand Board. |

| UD | Unidirectional. |

| VARI | Vacuum-assisted resin infusion. |

References

- Harussani, M.M.; Sapuan, S.M.; Nadeem, G.; Rafin, T.; Kirubaanand, W. Recent applications of carbon-based composites in defence industry: A review. Def. Technol. 2022, 18, 1281–1300. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Kumar, S.; Lee, K.-M.; Kim, S.-Y.; Yoon, S.-W.; Bae, S.-Y.; Shin, D.-H. Advancing carbon fiber and its composites technology: Korea’s strategic growth and innovation. Compos. Part B Eng. 2025, 296, 112266. [Google Scholar] [CrossRef]

- Parvizi, P.; Jalilian, M.; Dearn, K.D. Epoxy composites reinforced with nanomaterials and fibres: Manufacturing, properties, and applications. Polym. Test. 2025, 146, 108761. [Google Scholar] [CrossRef]

- Yu, Y.; Pan, Y.; Zhou, R.; Miao, X. Effects of Water and Alkaline Solution on Durability of Carbon-Glass Hybrid Fiber Reinforced Polymer Bars. Polymers 2021, 13, 3844. [Google Scholar] [CrossRef]

- Öztürk, R.; Taş, H.; Soykok, I.F. Determinating optimum combination of ageing and manufacturing parameters for laminated composites using response surface methodology. J. Reinf. Plast. Compos. 2025, 44, 259–279. [Google Scholar] [CrossRef]

- Ghabezi, P.; Harrison, N. Mechanical behavior and long-term life prediction of carbon/epoxy and glass/epoxy composite laminates under artificial seawater environment. Mater. Lett. 2020, 261, 127091. [Google Scholar] [CrossRef]

- Tazi, M.A.; de Araujo Alves Lima, R.; Pires da Silva, E.H.; Jebli, M.; Teixeira De Freitas, S.; Casari, P.; de Barros, S. Experimental evaluation of interface adhesion of a flax fiber composite patch with epoxy and polyurethane adhesives for the reinforcement of steel structures. Int. J. Adhes. Adhes. 2024, 129, 103559. [Google Scholar] [CrossRef]

- Sahu, B.; Sahoo, C.K.; Chennamsetti, R.; Arockiarajan, A. Effect of graphene nanoparticles (GNP) on adhesively bonded patch repaired composite under tensile static and fatigue loading. Int. J. Adhes. Adhes. 2025, 142, 104072. [Google Scholar] [CrossRef]

- Errahmane, M.A.; Benyettou, M.; Madani, K.; Rezgani, L.; Amin, H.; Djebbar, S.C.; Belhouari, M.; Campliho, R.D.S.G.; Feaugas, X. Numerical and experimental analysis of the performance of the metal patch compared to the composite patch under aging conditions in water immersion. Int. J. Adhes. Adhes. 2025, 138, 103943. [Google Scholar] [CrossRef]

- Rajendran, B.; Vellayaraj, A. Improving low cycle fatigue performance of cracked aluminum plate with carbon fiber composite patches reinforced with B4C nanoparticles. Eng. Fail. Anal. 2025, 169, 109139. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Z.; Jia, C.; Li, Z.; Qiu, Y.; Yan, C. Effects of I-lap patch layout on mechanical properties of the repaired composite. Constr. Build. Mater. 2025, 458, 139689. [Google Scholar] [CrossRef]

- Sahoo, C.K.; Bhatia, G.S.; Arockiarajan, A. Effect of patch-parent stacking sequence and patch stiffness on the tensile behaviour of the patch repaired carbon-glass hybrid composite. Thin-Walled Struct. 2022, 179, 109551. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Hall, Z.E.C.; Brooks, R.A.; Crocker, J.W.M.; Joesbury, A.M.; Harper, L.T.; Blackman, B.R.K.; Kinloch, A.J.; Dear, J.P. Modelling the effects of patch-plug configuration on the impact performance of patch-repaired composite laminates. Compos. Sci. Technol. 2023, 233, 109917. [Google Scholar] [CrossRef]

- Messaoud, Z.; Meriem-Benziane, M. Experimental study of natural fiber Jute reinforced by metal wires and its using as patch on semi-elliptical defected of the API X52 pipelines corroded according to ratio a/t. Int. J. Press. Vessel. Pip. 2024, 212 Pt B, 105346. [Google Scholar] [CrossRef]

- Taş, H. Effects of stainless steel woven wire mesh reinforcement on the load-bearing capacity of adhesively bonded aluminium alloy single-lap joints. Arab. J. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- Khoramishad, H.; Razavi, N. Metallic fiber-reinforced adhesively bonded joints. Int. J. Adhes. Adhes. 2014, 55, 114–122. [Google Scholar] [CrossRef]

- Çalık, A.; Akpınar, S.; Demiral, M. The effects of using intermittent metal part reinforcement and countersink on the strength of adhesively bonded joints. Int. J. Adhes. Adhes. 2024, 130, 103613. [Google Scholar] [CrossRef]

- Bayramoglu, S.; Demir, K.; Akpinar, S. Investigation of internal step and metal part reinforcement on joint strength in the adhesively bonded joint: Experimental and numerical analysis. Theor. Appl. Fract. Mech. 2020, 108, 102613. [Google Scholar] [CrossRef]

- Kanani, A.Y.; Hou, X.; Ye, J. A novel dissimilar single-lap joint with interfacial stiffness improvement. Compos. Struct. 2020, 252, 112741. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, C. Failure analysis of CFRP/Al single lap adhesive joint with enhancing porous metal foam insert. Eng. Fail. Anal. 2024, 165, 108792. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wang, C.H.; Mouritz, A.P. Design considerations in the strengthening of composite lap joints using metal z-pins. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107031. [Google Scholar] [CrossRef]

- Rezvaninasab, M.; Farhadinia, M.; Mirzaei, A.; Ramzaninezhad, M.; Khamseh, F.; Alaei, M.H. Experimental evaluation of reinforcing the single lap joint in both longitudinal and transverse direction under tensile and bending condition. Int. J. Adhes. Adhes. 2019, 88, 19–25. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Shankar, K.; Morozov, E.V.; Hazell, P.J. On the mechanical behaviour of steel wire mesh subjected to low-velocity impact. Thin-Walled Struct. 2021, 159, 107281. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Li, C.; Dong, W.; Su, Y.; Li, J.; Cui, N.; Zeng, F.; Dai, L.; Meng, Q.; et al. Blast testing of high performance geopolymer composite walls reinforced with steel wire mesh and aluminium foam. Constr. Build. Mater. 2019, 197, 533–547. [Google Scholar] [CrossRef]

- Xu, G.; Liu, Y.; Luo, X.; Ma, J.; Li, H. Experimental investigation of transpiration cooling for sintered woven wire mesh structures. Int. J. Heat Mass Transf. 2015, 91, 898–907. [Google Scholar] [CrossRef]

- Karunagaran, N.; Bharathiraja, G.; Muniappan, A.; Yoganandam, K. Energy absorption and damage behaviour of surface treated glass fibre/stainless steel wire mesh reinforced hybrid composites. Mater. Today Proc. 2020, 22 Pt 3, 1078–1084. [Google Scholar] [CrossRef]

- Wan, Y.; Diao, C.; Yang, B.; Zhang, L.; Chen, S. GF/epoxy laminates embedded with wire nets: A way to improve the low-velocity impact resistance and energy absorption ability. Compos. Struct. 2018, 202, 818–835. [Google Scholar] [CrossRef]

- Hasselbruch, H.; von Hehl, A.; Zoch, H.-W. Properties and failure behavior of hybrid wire mesh/carbon fiber reinforced thermoplastic composites under quasi-static tensile load. Mater. Des. 2015, 66 Pt B, 429–436. [Google Scholar] [CrossRef]

- Truong, G.T.; Tran, H.V.; Choi, K.-K. Tensile behavior of on- and off-axis carbon fiber reinforced polymer composites incorporating steel wire mesh. Mech. Mater. 2019, 137, 103131. [Google Scholar] [CrossRef]

- Meng, Q.; Chen, W.; Hao, H. Numerical and experimental study of steel wire mesh and basalt fibre mesh strengthened structural insulated panel against projectile impact. Adv. Struct. Eng. 2017, 21, 1183–1196. [Google Scholar] [CrossRef]

- Kashfuddoja, M. Experimental and Numerical Study of Composite Patch Repair on Open Hole Carbon Fiber Reinforced Polymer Panel under Tensile Loading. Ph.D. Thesis, Indian Institute of Technology Hyderabad, Kandi, India, May 2014. [Google Scholar]

- Technical Information Epoxy and Phenolic Resins Division Epoxy Resins. Available online: https://www.dostkimya.com/Documents/mgs-laminasyon-epoksi-re%C3%A7ine-l160.pdf (accessed on 31 August 2025).

- Zheng, C.; Yu, W. Effect of low-temperature on mechanical behavior for an AISI 304 austenitic stainless steel. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2018, 710, 359–365. [Google Scholar] [CrossRef]

- Lingadurai, K.; Nagasivamuni, B.; Muthu Kamatchi, M.; Palavesam, J. Selection of Wire Electrical Discharge Machining Process Parameters on Stainless Steel AISI Grade-304 using Design of Experiments Approach. J. Inst. Eng. India Ser. C 2012, 93, 163–170. [Google Scholar] [CrossRef]

- Loctite EA 9466-Technical Data Sheet. Available online: https://datasheets.tdx.henkel.com/LOCTITE-EA-9466-en_GL.pdf (accessed on 28 February 2025).

- Rahmani, A.; Choupani, N. Experimental and numerical analysis of fracture parameters of adhesively bonded joints at low temperatures. Eng. Fract. Mech. 2019, 207, 222–236. [Google Scholar] [CrossRef]

- Soutis, C.; Duan, D.M.; Goutas, P. Compressive behaviour of CFRP laminates repaired with adhesively bonded external patches. Compos. Struct. 1999, 45, 289–301. [Google Scholar] [CrossRef]

- ASTM D7264/D7264M-15; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- Karunagaran, N.; Rajadurai, A. Effect of surface treatment on mechanical properties of glass fiber/stainless steel wire mesh reinforced epoxy hybrid composites. J. Mech. Sci. Technol. 2016, 30, 2475–2482. [Google Scholar] [CrossRef]

- Abdulla, M.; Hrairi, M.; Shaikh, A.A.; Abdullah, N.A. Effect of temperature and adhesive defect on repaired structure using composite patch. Fract. Struct. Integr. 2025, 19, 124–150. [Google Scholar] [CrossRef]

- Rezvani, M.B.; Atai, M.; Hamze, F. Effect of fiber diameter on flexural properties of fiber-reinforced composites. Indian J. Dent. Res. 2013, 24, 237–241. [Google Scholar] [CrossRef] [PubMed]

- Aabid, A.; Rosli, M.N.S.B.; Hrairi, M.; Baig, M. Enhancing repair of cracked plate using fiber-reinforced composite patch: Experimental and simulation analysis. Forces Mech. 2025, 18, 100302. [Google Scholar] [CrossRef]

- Droździel-Jurkiewicz, M.; Bieniaś, J. Evaluation of Surface Treatment for Enhancing Adhesion at the Metal–Composite Interface in Fibre Metal-Laminates. Materials 2022, 15, 6118. [Google Scholar] [CrossRef]

- Li, X.; Sun, M.; Song, J.; Zhang, T.; Zhao, Y.; Wang, K. Enhanced adhesion between PEEK and stainless-steel mesh in resistance welding of CF/PEEK composites by various surface treatments. High Perform. Polym. 2021, 33, 892–904. [Google Scholar] [CrossRef]

| Properties | Unit | Value |

|---|---|---|

| Tensile strength | MPa | 515 |

| Yield strength | MPa | 205 |

| Young’s modulus | GPa | 193 |

| Poisson’s ratio | - | 0.27–0.30 |

| Properties | Unit | Value |

|---|---|---|

| Young’s modulus | GPa | 1.91 |

| Yield strength | MPa | 41.33 |

| Ultimate tensile strength | MPa | 44.38 |

| Poisson’s ratio | - | 0.35 |

| Fracture strain | % | 3.8582 |

| Critical strain energy release rate in mode I | J/m2 | 313.76 |

| Critical strain energy release rate in mode II | J/m2 | 155.88 |

| Sample Code | Description |

|---|---|

| Control sample | Sample with no damage |

| Hole | Sample with a 5 mm diameter hole at its centre |

| A plug | The sample was repaired by filling the hole with adhesive. |

| A/M60 plug | The sample was repaired by filling the hole with SSWWM-reinforced adhesive. Here, three layers of SSWWM, with a mesh count of 60, were applied. |

| A/M60 plug + M60 patch | SSWWMs with a mesh count of 60 were bonded to both sides of the specimen “A/M60 plug”. |

| A plug + M20 patch | The sample was repaired by bonding the SSWWM with a mesh count of 20 to both sides of the sample. Here, the hole was filled solely with adhesive. |

| A plug + M40 patch | The sample was repaired by bonding the SSWWM with a mesh count of 40 to both sides of the sample. Here, the hole was filled solely with adhesive. |

| A plug + M60 patch | The sample was repaired by bonding the SSWWM with a mesh count of 60 to both sides of the sample. Here, the hole was filled solely with adhesive. |

| A plug + M80 patch | The sample was repaired by bonding the SSWWM with a mesh count of 80 to both sides of the sample. Here, the hole was filled solely with adhesive. |

| A plug + 2L-M60 patch | The sample was repaired by bonding the two layers of SSWWM, each with a mesh count of 60, to both sides of the sample. Here, the hole was filled solely with adhesive. |

| Specimen | Weight (g) | Change (%) |

|---|---|---|

| Control sample | 2.93 ± 0.02 | --- |

| Hole | 2.84 ± 0.02 | −2.94 |

| A plug | 2.96 ± 0.03 | 1.03 |

| A/M60 plug | 2.96 ± 0.03 | 1.23 |

| A/M60 plug + M60 patch | 3.60 ± 0.08 | 22.97 |

| A plug + M20 patch | 4.38 ± 0.10 | 49.56 |

| A plug + M40 patch | 3.94 ± 0.04 | 34.52 |

| A plug + M60 patch | 3.59 ± 0.08 | 22.62 |

| A plug + M80 patch | 3.57 ± 0.04 | 21.87 |

| A plug + 2L-M60 patch | 3.99 ± 0.04 | 36.50 |

| Sample | Mean | Std. Dev | p-Value |

|---|---|---|---|

| Control sample | 348.9 | 11.2 | --- |

| Hole | 204.2 | 9.5 | <0.001 |

| A plug | 224.4 | 18.3 | <0.001 |

| A/M60 plug | 230.4 | 7.5 | <0.001 |

| A/M60 plug + M60 patch | 333.9 | 16.7 | 0.19 |

| A plug + M20 patch | 451.1 | 29.2 | <0.001 |

| A plug + M40 patch | 361.4 | 23.4 | 0.43 |

| A plug + M60 patch | 311.5 | 15.2 | 0.02 |

| A plug + M80 patch | 314.3 | 12.6 | 0.006 |

| A plug + 2L-M60 patch | 353.2 | 12.9 | 0.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taş, H.; Ünal, H.Y. Experimental Study on the Bending Behaviour of GFRP Laminates Repaired with Stainless-Steel Wire Mesh. Polymers 2025, 17, 2417. https://doi.org/10.3390/polym17172417

Taş H, Ünal HY. Experimental Study on the Bending Behaviour of GFRP Laminates Repaired with Stainless-Steel Wire Mesh. Polymers. 2025; 17(17):2417. https://doi.org/10.3390/polym17172417

Chicago/Turabian StyleTaş, Hamza, and Hasan Yavuz Ünal. 2025. "Experimental Study on the Bending Behaviour of GFRP Laminates Repaired with Stainless-Steel Wire Mesh" Polymers 17, no. 17: 2417. https://doi.org/10.3390/polym17172417

APA StyleTaş, H., & Ünal, H. Y. (2025). Experimental Study on the Bending Behaviour of GFRP Laminates Repaired with Stainless-Steel Wire Mesh. Polymers, 17(17), 2417. https://doi.org/10.3390/polym17172417