Design of a Hybrid 3D-Printed Composite Material Based on Non-Woven Needle-Punched Fabrics with Radio-Absorbing Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. The Technology of Radio-Absorbing Hybrid Material Manufacturing

2.1.1. The Main Stages of the Technology

- (1)

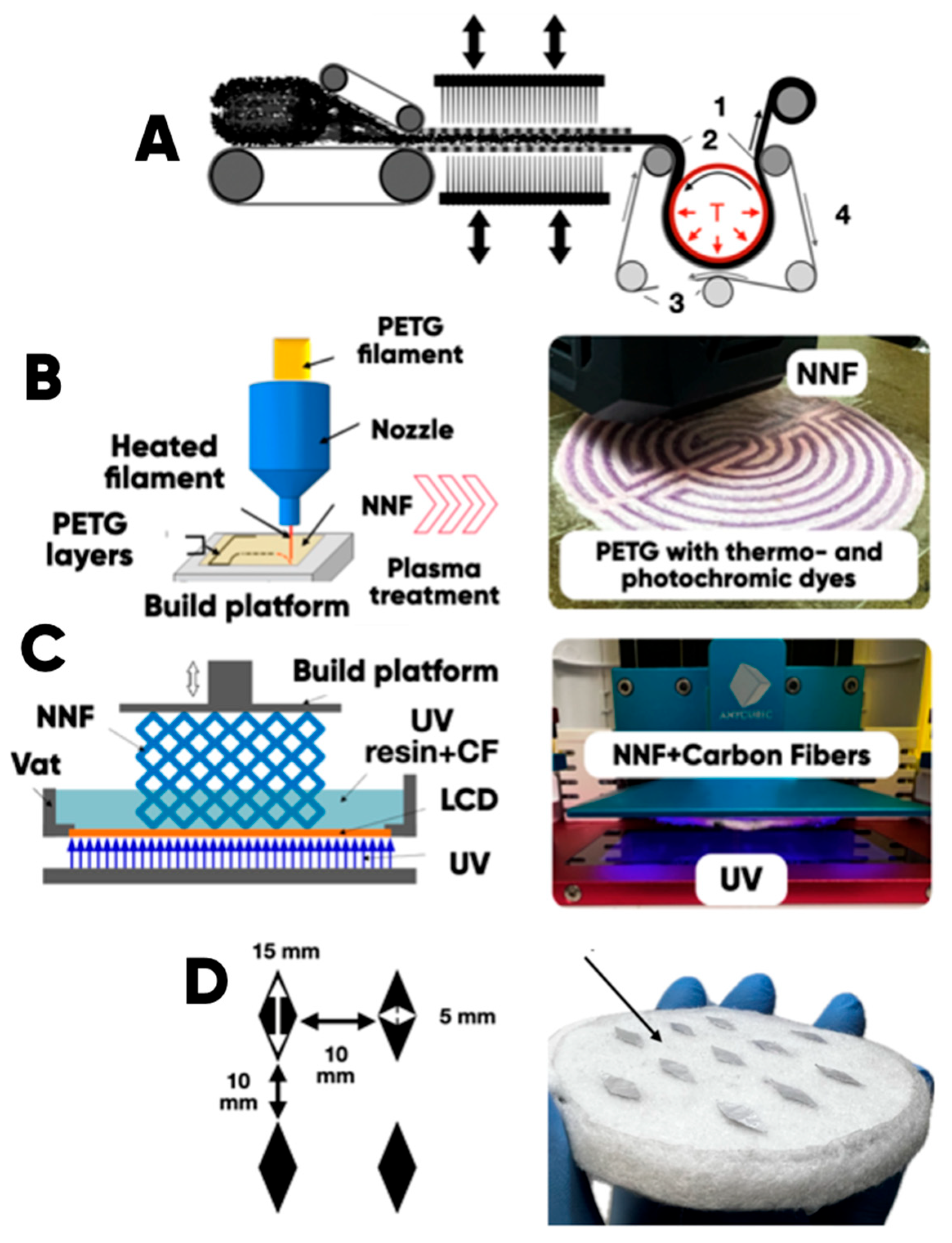

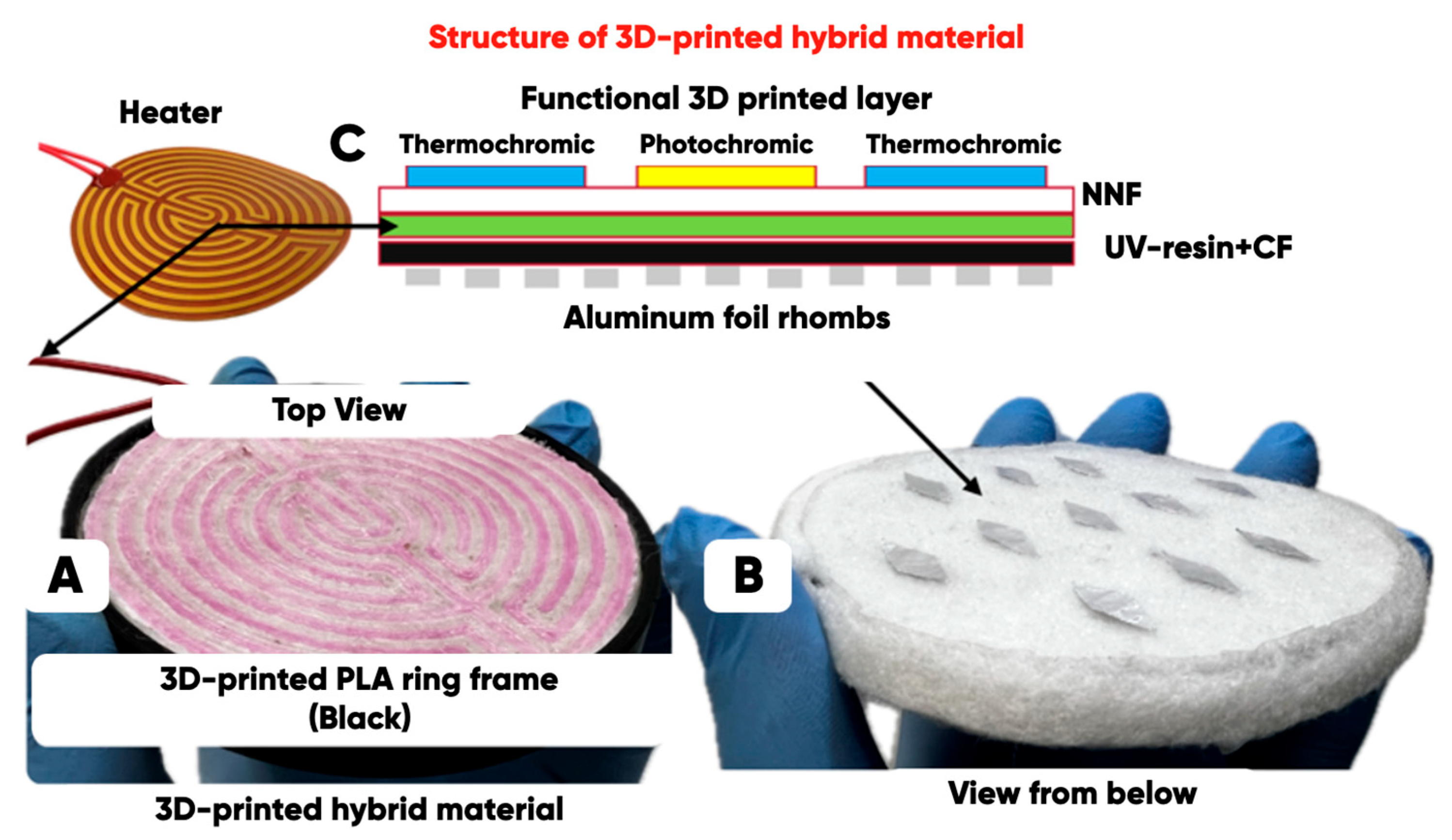

- The formation of NWF-base (determining mechanical properties of the hybrid material for radio-absorbing products manufacturing) by thermomechanical treatment of the polymer fibers (Figure 1A);

- (2)

- The FDM-prototyping of the 3D-printed pattern (simulating the heating element design) on the surface of the NWF-base (Figure 1B);

- (3)

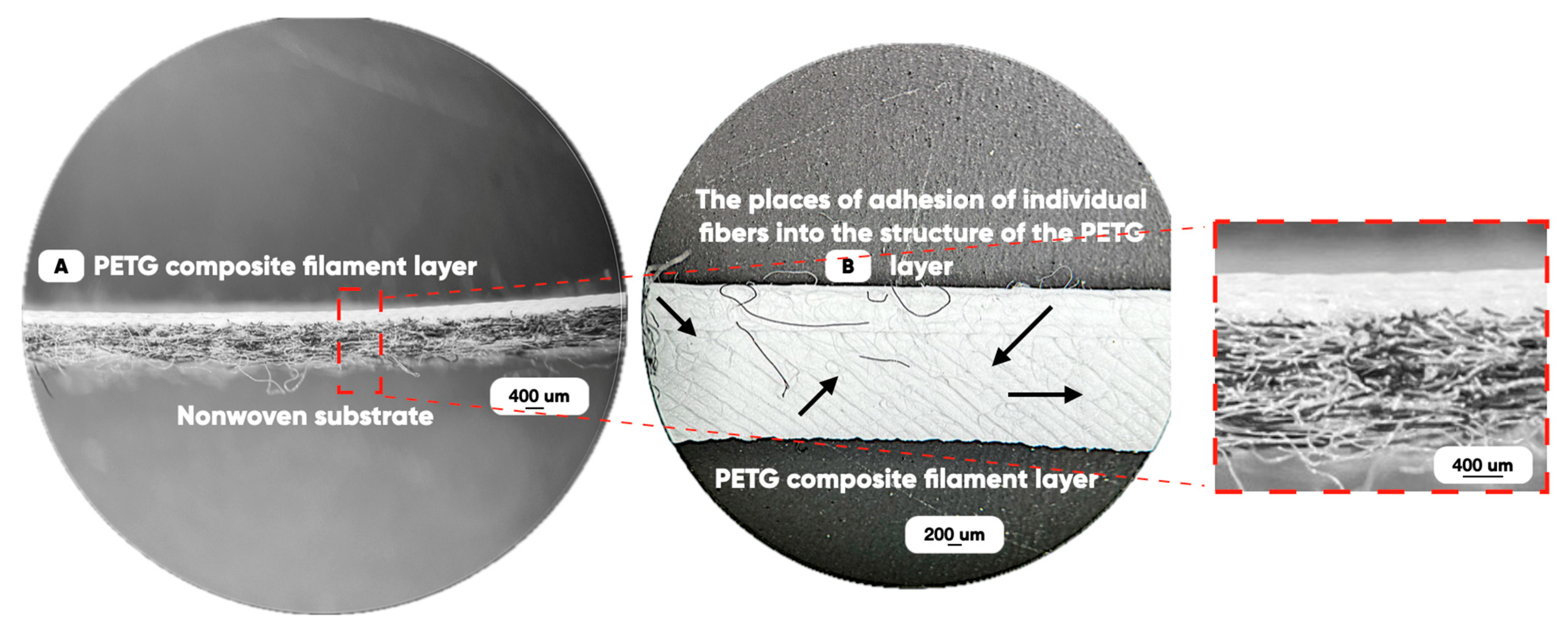

- The creation of a functional radio-absorbing layer of the carbon fibers (CFP-7-100, Yataida High Tech Co., Ltd., Shenzhen, China), bulk-modified UV-curable resin (ABS-live Resin Pro 2, Anycubic, Shenzhen, China) in the NWF-based near-surface layers with the photopolymerization 3D-printing technique (Figure 1C);

- (4)

- Applying the 2D-periodic system of aluminum foil rhombs onto the NWF-base surface provides an extension of the effective radio absorption range (Figure 1D).

2.1.2. The Hybrid Material NWF Basis

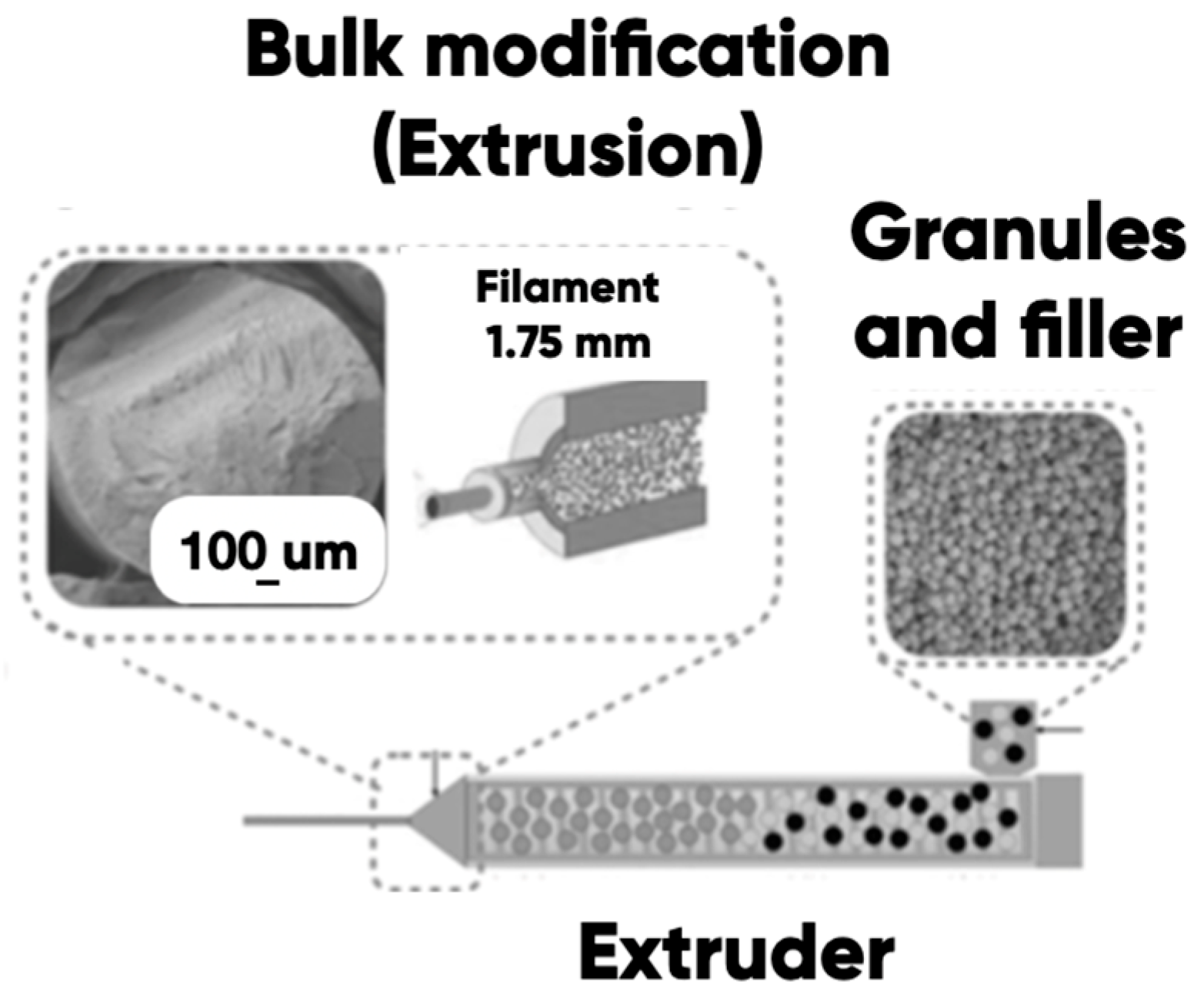

2.1.3. The PETG-Based Composite Filament

2.1.4. The Aluminum Foil 2D-Periodic Pattern

2.2. The Techniques of the Hybrid Material Components Structure and Properties Studying

3. Results and Discussion

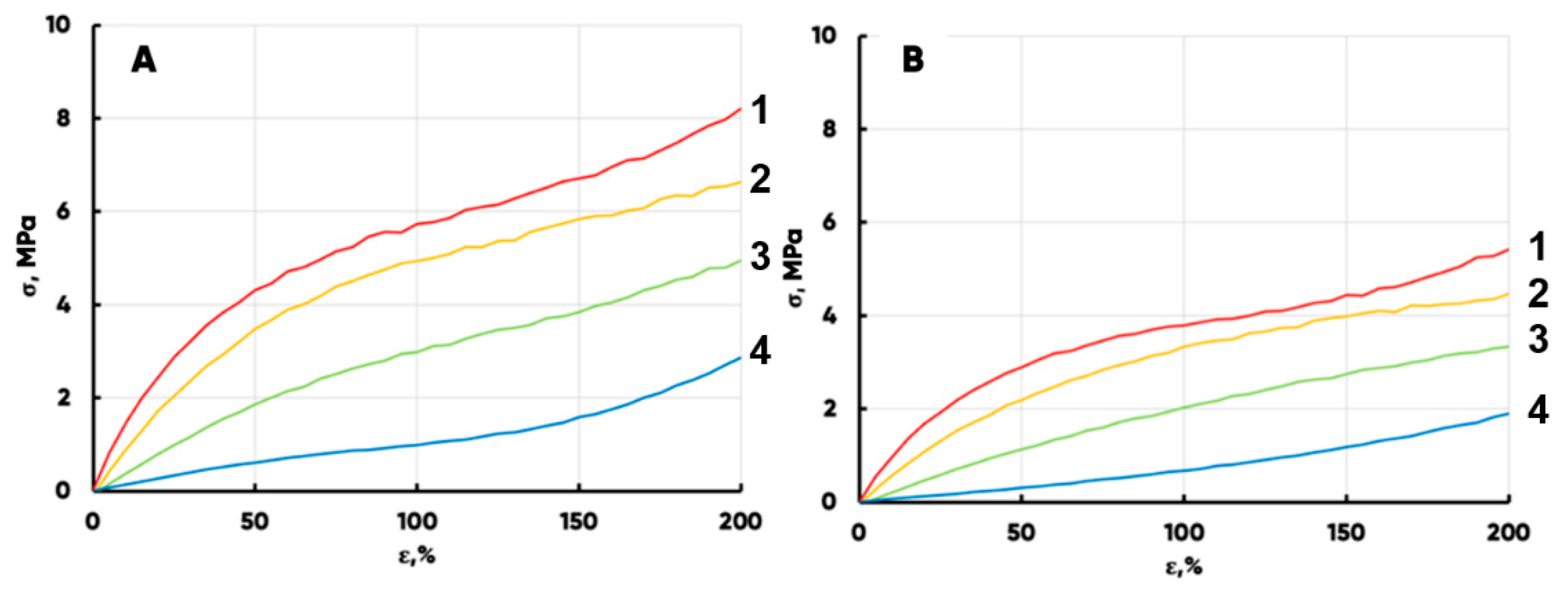

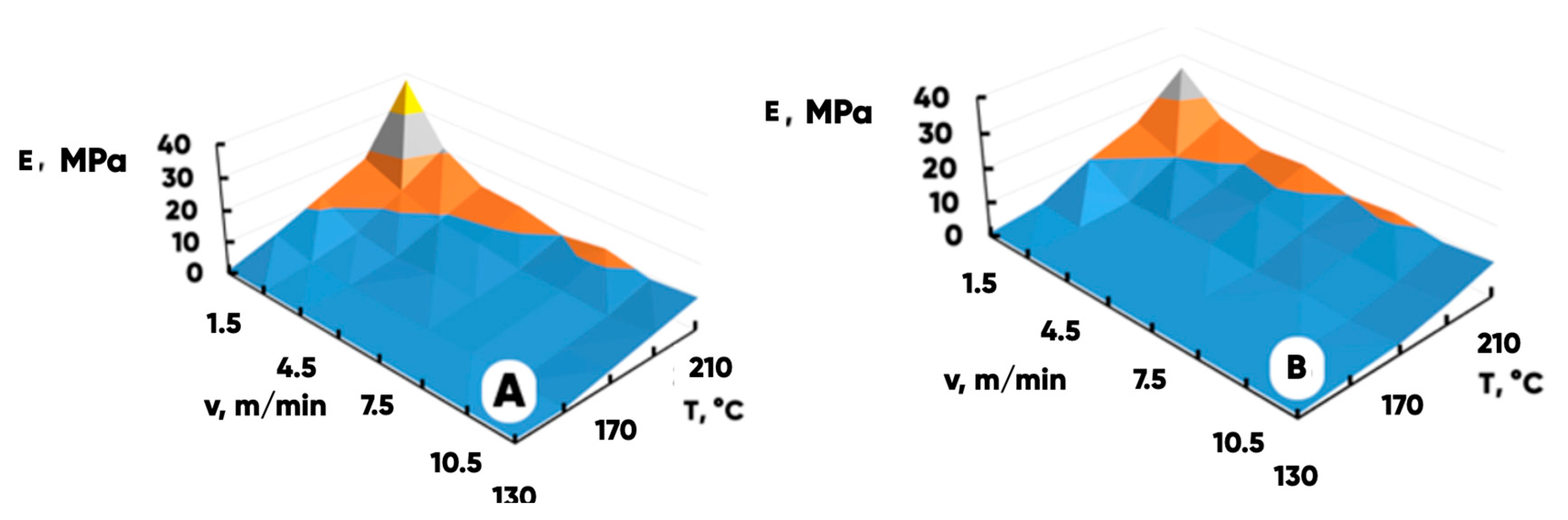

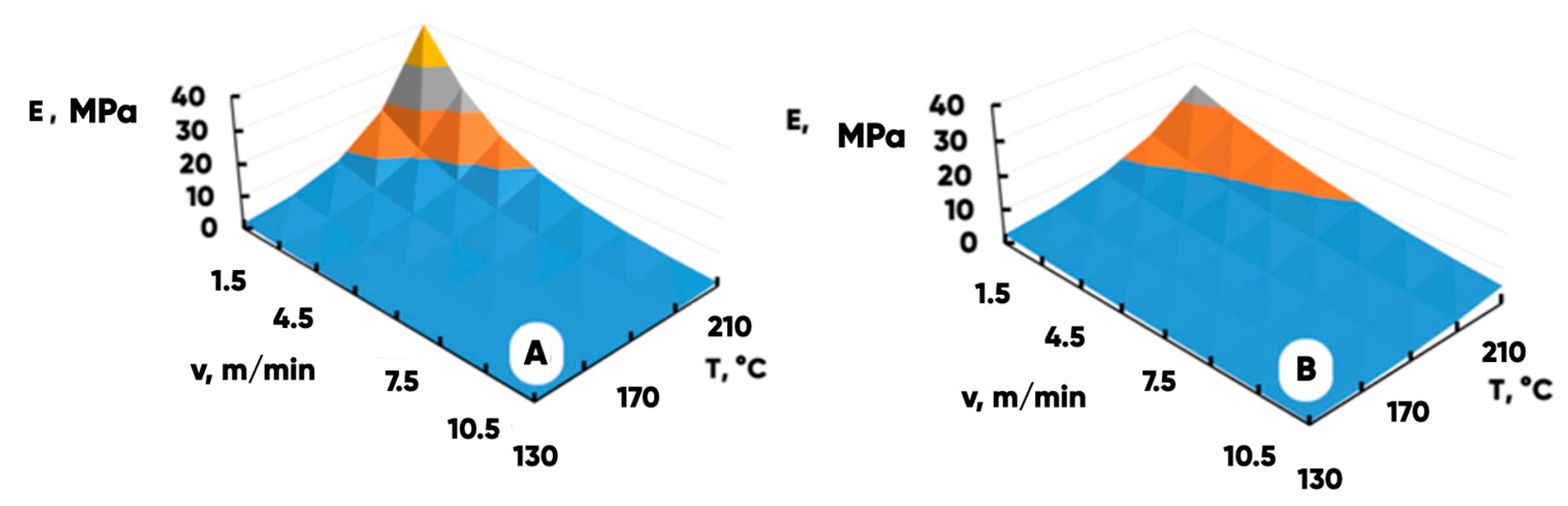

3.1. The Mechanical Properties of the Prototypes

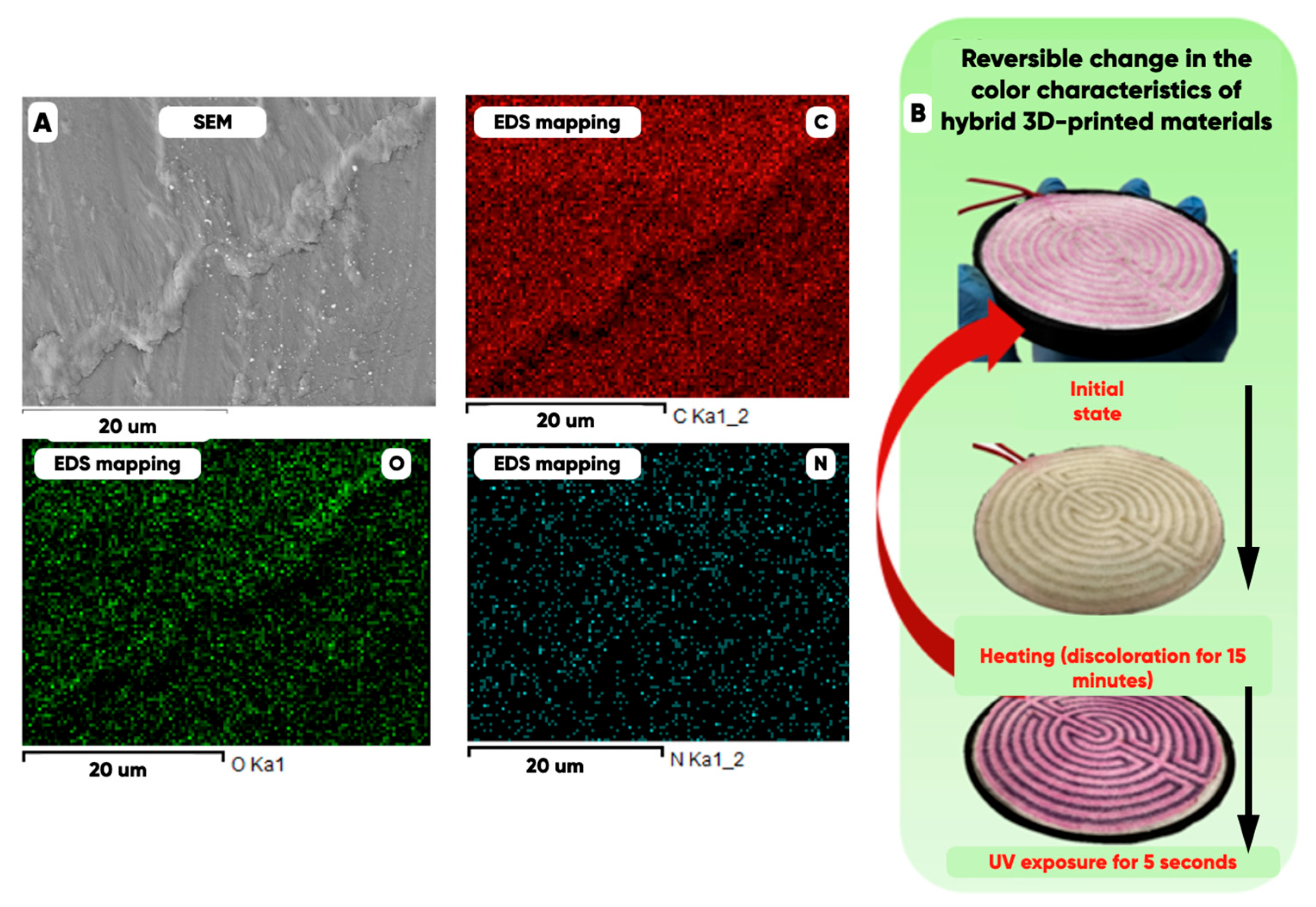

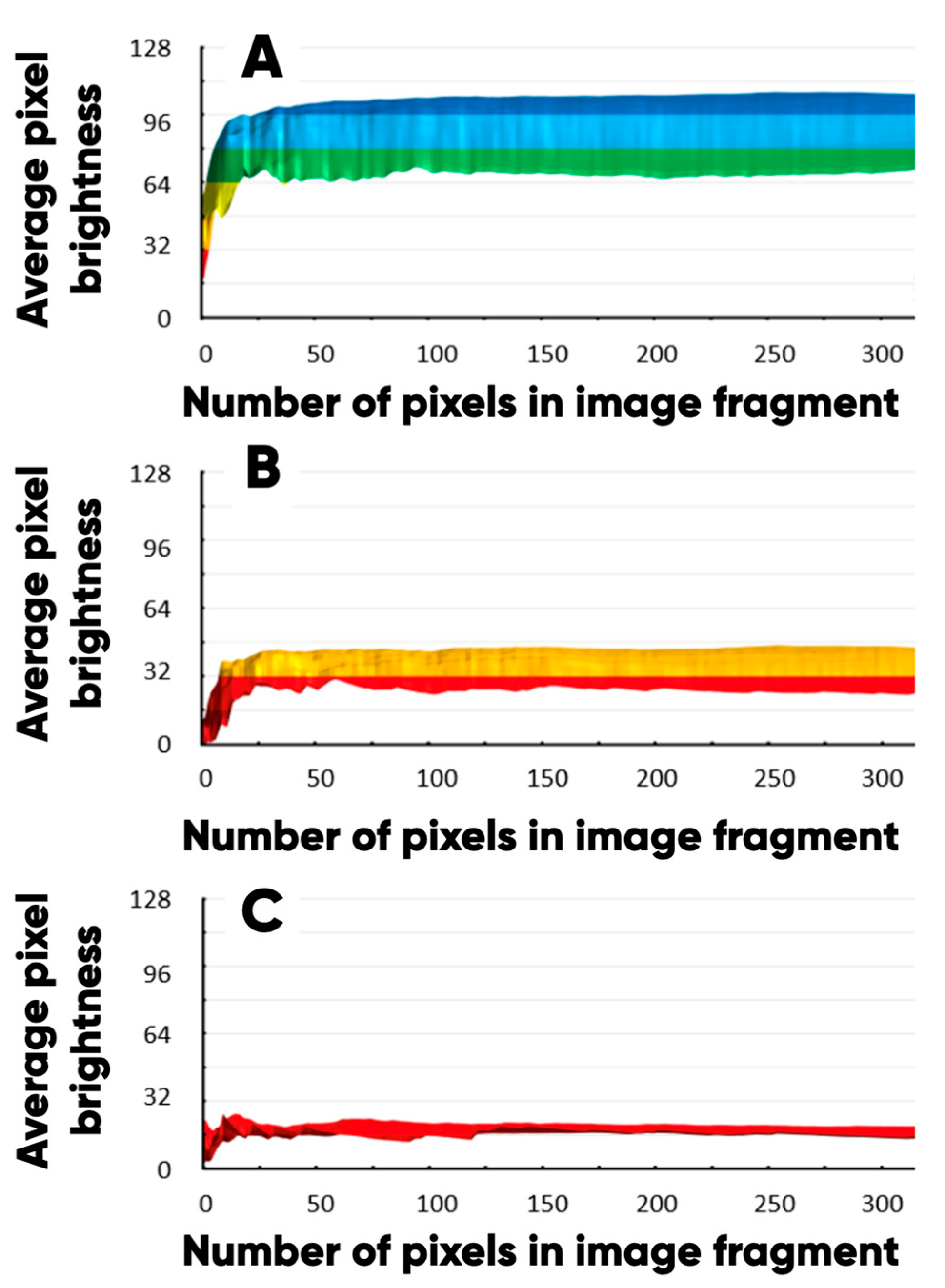

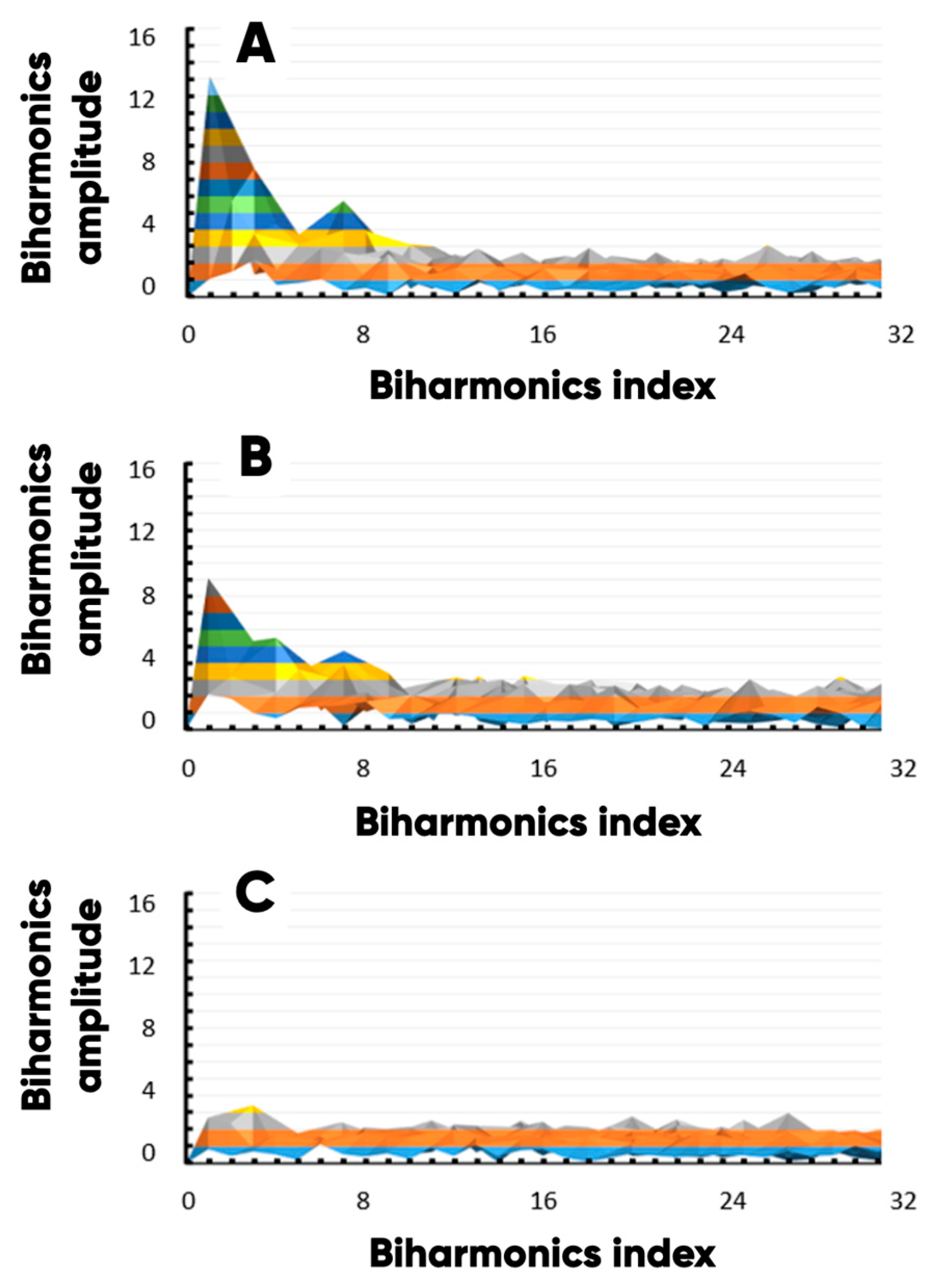

3.2. The Results of NWFs’ Structure and Optical Properties Determination

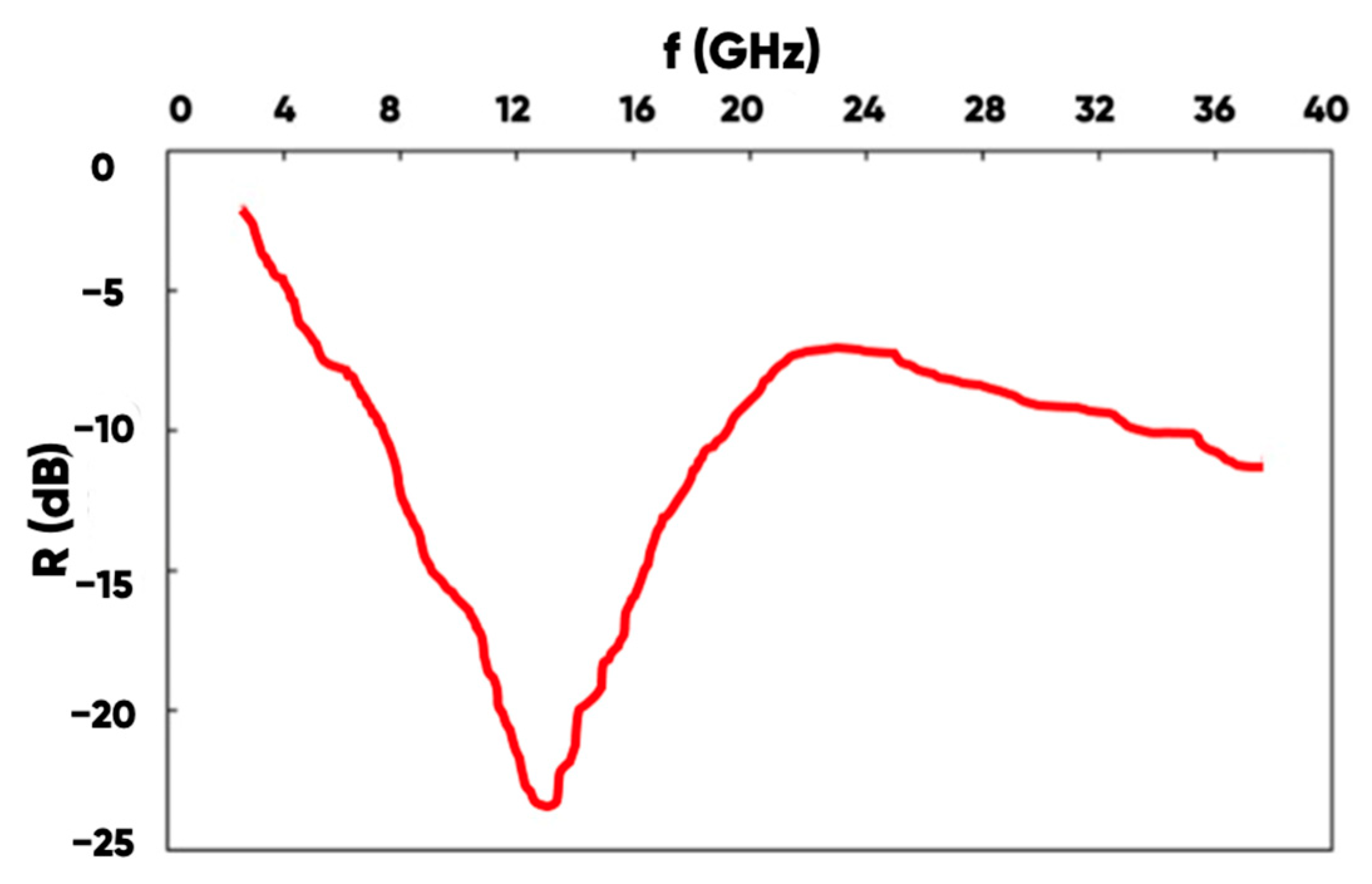

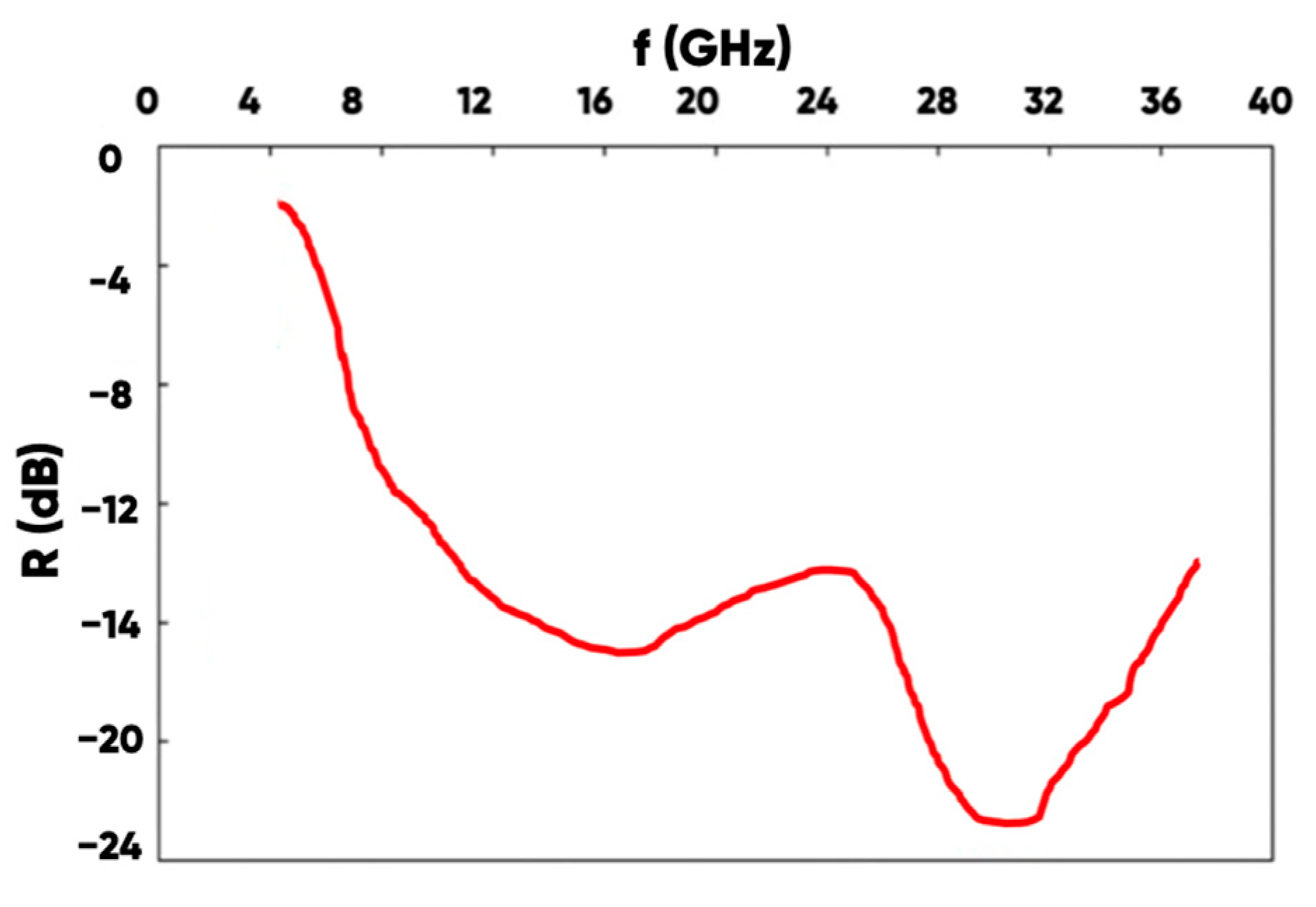

3.3. The Results of the NWF/PETG-Hybrid Material-Made Products Radio-Frequency Radiation Absorption Determining

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Shirota, Y. Organic materials for electronic and optoelectronic devices. J. Mater. Chem. 2000, 10, 1–25. [Google Scholar] [CrossRef]

- Anantram, M.P.; Léonard, F. Physics of carbon nanotube electronic devices. Rep. Prog. Phys. 2006, 69, 507–561. [Google Scholar] [CrossRef]

- Dolin, G.A.; Kudryashova, A.Y. Modified methods of circuit simulation of radio engineering devices in the time domain. Synchroinfo J. 2020, 6, 7–11. [Google Scholar] [CrossRef]

- Jia, Y.; Jiang, Q.; Sun, H.; Liu, P.; Hu, D.; Pei, Y.; Liu, W.; Crispin, X.; Fabiano, S.; Ma, Y.; et al. Wearable thermoelectric materials and devices for self-powered electronic systems. Adv. Mater. 2021, 33, 2102990. [Google Scholar] [CrossRef]

- Lv, H.; Yang, Z.; Ji, G.; Ong, S.J.H.; Wei, C.; Liao, H.; Xu, Z.J.; Xi, S.; Du, Y. A flexible microwave shield with tunable frequen-cy-transmission and electromagnetic compatibility. Adv. Funct. Mater. 2019, 29, 1900163. [Google Scholar] [CrossRef]

- Gizatullin, Z.M.; Gizatullin, R.M. Study of the electromagnetic compatibility of local area networks under the action of nanosecond electromagnetic disturbances. J. Commun. Technol. Electron. 2014, 59, 424–426. [Google Scholar] [CrossRef]

- Fionov, A.; Kraev, I.; Yurkov, G.; Solodilov, V.; Zhukov, A.; Surgay, A.; Kuznetsova, I.; Kolesov, V. Radio-absorbing materials based on polymer composites and their application to solving the problems of electromagnetic compatibility. Polymers 2022, 14, 3026. [Google Scholar] [CrossRef]

- Lopatin, A.V.; Kazantseva, N.E.; Kazantsev, Y.N.; D’yakonova, O.A.; Vilčáková, J.; Sáha, P. The efficiency of application of magnetic polymer composites as radio-absorbing materials. J. Commun. Technol. Electron. 2008, 53, 487–496. [Google Scholar] [CrossRef]

- Zakharychev, E.A.; Ryabov, S.A.; Zefirov, V.L.; Semchikov, Y.D.; Belov, M.S.; Kirpichev, D.V.; Zuev, A.A. Development of polymer radio-absorbing materials with carbon nanotubes for extremely high frequency range. Inorg. Mater. Appl. Res. 2013, 4, 405–409. [Google Scholar] [CrossRef]

- Vlasenko, E.A.; Bokova, E.S.; Dedov, A.V. A radio absorbing composite material based on compounded rubber and modified nonwoven fabric. Inorg. Mater. Appl. Res. 2016, 7, 590–592. [Google Scholar] [CrossRef]

- Bokova, E.S.; Devina, E.A.; Kovalenko, G.M. Development of multilayer radio-absorbing materials based on nonwoven dielectric matrixes and a polymeric binder. Fibre Chem. 2019, 50, 462–467. [Google Scholar] [CrossRef]

- Nazarov, V.G.; Dedov, A.V. Radio-absorbing nonwoven material with intermediate dispersed carbon-fiber layers. Fibre Chem. 2020, 52, 105–108. [Google Scholar] [CrossRef]

- Sharma, S.; Jones, A. Absorption and scattering of electromagnetic radiation by a large absorbing sphere with highly absorbing spherical inclusions. J. Quant. Spectrosc. Radiat. Transf. 2003, 79–80, 1051–1060. [Google Scholar] [CrossRef]

- Kim, B.R.; Lee, H.K.; Kim, E.; Lee, S.-H. Intrinsic electromagnetic radiation shielding/absorbing characteristics of polyani-line-coated transparent thin films. Synth. Met. 2010, 160, 1838–1842. [Google Scholar] [CrossRef]

- Sawant, K.K.; Satapathy, A.; Mahimkar, K.; Krishnamurthy, S.; Kaur, A.; Kandasubramanian, B.; Raj, A.A.B. Recent advances in MXENE nanocomposites as electromagnetic radiation absorbing materials. J. Electron. Mater. 2023, 52, 3576–3590. [Google Scholar] [CrossRef]

- Shalygina, T.A.; Simonov-Emelyanov, I.D. Composition, structures, and preparation of smart composite materials based on polyurethane and modified silicon carbide particles with controllable characteristics and kinetics of the shape memory effect. Russ. J. Appl. Chem. 2023, 96, 853–860. [Google Scholar] [CrossRef]

- Zhang, L.; Gou, H.; Zhuang, H.; Qin, Y.; Qiu, H.; Wu, W. Construction and characterization of intelligent, controlled drug release visualization systems: A new design and teaching practice of polymer experiments. Daxue Huaxue 2023, 38, 212–219. [Google Scholar] [CrossRef]

- Pawar, J.R.; Phatak, R.S.; Qureshi, N.M.; Singh, A.E.; Shinde, M.D.; Amalnerkar, D.P.; Doh, J. Contemporary trends in active and intelligent polymer nanocomposite based food packaging systems for food safety and sustainability in the modern aeon. Curr. Mater. Sci. 2024, 17, 358–385. [Google Scholar] [CrossRef]

- Udaipuria, N.; Bhattacharya, S. Novel carbohydrate polymer-based systems for precise drug delivery in colon cancer: Improving treatment effectiveness with intelligent biodegradable materials. Biopolymers 2024, 116, e23632. [Google Scholar] [CrossRef]

- Granqvist, C.G. Oxide-based chromogenic coatings and devices for energy efficient fenestration: Brief survey and update on thermochromics and electrochromics. J. Vac. Sci. Technol. B 2014, 32, 060801. [Google Scholar] [CrossRef]

- Ke, Y.; Chen, J.; Wang, S.; Zhou, Y.; Lee, P.S.; Long, Y.; Lin, G.; Yin, J. Smart windows: Electro-, thermo-, mechano-, photochromics, and beyond. Adv. Energy Mater. 2019, 9, 1902066. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, P.; Liu, L.; Li, Y.; Zhang, Y.; Wu, T.; Zhang, C.; Chen, J.; Xie, H.; Cui, J. Dual photochromics-contained pho-toswitchable multistate fluorescent polymers for advanced optical data storage, encryption, and photowritable pattern. Chem. Eng. J. 2021, 425, 131557. [Google Scholar] [CrossRef]

- Sheng, S.Z.; Wang, J.L.; Zhao, B.; He, Z.; Feng, X.F.; Shang, Q.G.; Chen, C.; Pei, G.; Zhou, J.; Liu, J.W.; et al. Nanowire-based smart windows combining electro- and thermochromics for dynamic regulation of solar radiation. Nat. Commun. 2023, 14, 3231. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Ning, J.; Hu, X.; Tu, J.; Zou, W.; Ruan, X.; Li, Y.; Xu, Y.; He, L. Adjustable electronic, optical and photocatalytic properties of black phosphorene by nonmetal doping. Appl. Surf. Sci. 2020, 505, 144488. [Google Scholar] [CrossRef]

- Kwak, Y.; Kang, Y.; Park, W.; Jo, E.; Kim, J. Fabrication of fine-pored polydimethylsiloxane using an isopropyl alcohol and water mixture for adjustable mechanical, optical, and thermal properties. RSC Adv. 2021, 11, 18061–18067. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Liang, Y.; Xia, C.; Ma, X.; Fei, B.; Wu, Y.; Ge, S.; Lu, J.; Li, J.; Xia, Z. Laminated transparent woods with adjustable optical and enhanced mechanical properties. Adv. Mater. Technol. 2023, 8, 2200704. [Google Scholar] [CrossRef]

- Roscoe, S.; Cousins, P.D.; Handfield, R. Transitioning additive manufacturing from rapid prototyping to high-volume production: A case study of complex final products. J. Prod. Innov. Manag. 2023, 40, 554–576. [Google Scholar] [CrossRef]

- Nys, N.; König, M.; Neugebauer, P.; Jones, M.J.; Gruber-Woelfler, H. Additive manufacturing as a rapid prototyping and fabrication tool for laboratory crystallizers─A proof-of-concept study. Org. Process. Res. Dev. 2023, 27, 1455–1462. [Google Scholar] [CrossRef]

- Chudpooti, N.; Savvides, G.; Duangrit, N.; Akkaraekthalin, P.; Robertson, I.D.; Somjit, N. Harmonized rapid prototyping of millimeter-wave components using additive and subtractive manufacturing. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 1241–1248. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Tejada-Ortigoza, V.; Barocio, E.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the me-chanical properties of FFF structures and materials: A review on the experimental, computational and theoretical approaches. Materials 2019, 12, 895. [Google Scholar] [CrossRef]

- Arif, M.F.; Alhashmi, H.; Kumar, S.; Varadarajan, K.M.; Koo, J.H.; Hart, A.J. Multifunctional performance of carbon nanotubes and graphene nanoplatelets reinforced peek composites enabled via FFF additive manufacturing. Compos. Part B Eng. 2020, 184, 107625. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; Casciaro, R.; Esposito Corcione, C. A review of polymer-based materials for fused filament fabrication (FFF): Focus on sustainability and recycled materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef]

- Hutmacher, D.W.; Sittinger, M.; Risbud, M.V. Scaffold-based tissue engineering: Rationale for computer-aided design and solid free-form fabrication systems. Trends Biotechnol. 2004, 22, 354–362. [Google Scholar] [CrossRef]

- Regassa Hunde, B.; Debebe Woldeyohannes, A. Future prospects of computer-aided design (CAD)—A review from the per-spective of artificial intelligence (AI), extended reality, and 3D printing. Results Eng. 2022, 14, 100478. [Google Scholar] [CrossRef]

- Serpe, M.J.; Jones, C.D.; Lyon, L.A. Layer-by-layer deposition of thermoresponsive microgel thin films. Langmuir 2003, 19, 8759–8764. [Google Scholar] [CrossRef]

- Flowers, P.F.; Reyes, C.; Ye, S.; Kim, M.J.; Wiley, B.J. 3D-printing electronic components and circuits with conductive thermo-plastic filament. Addit. Manuf. 2017, 18, 156–163. [Google Scholar]

- Mohan Pandey, P.; Venkata Reddy, N.; Dhande, S.G. Dhande Slicing procedures in layered manufacturing: A review. Rapid Prototyp. J. 2003, 9, 274–288. [Google Scholar]

- Piedra-Cascón, W.; Krishnamurthy, V.R.; Att, W.; Revilla-León, M. 3D printing parameters, supporting structures, slicing, and post-processing procedures of vat-polymerization additive manufacturing technologies: A narrative review. J. Dent. 2021, 109, 103630. [Google Scholar] [CrossRef]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D-printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D-printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Rodríguez, J.F.; Thomas, J.P.; Renaud, J.E. Renaud Mechanical behavior of acrylonitrile butadiene styrene (ABS) fused deposition materials. Experimental investigation. Rapid Prototyp. J. 2001, 7, 148–158. [Google Scholar]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Soleyman, E.; Aberoumand, M.; Rahmatabadi, D.; Soltanmohammadi, K.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. Assessment of controllable shape transformation, potential applications, and tensile shape memory properties of 3D-printed PETG. J. Mater. Res. Technol. 2022, 18, 4201–4215. [Google Scholar] [CrossRef]

- Shilov, S.Y.; Rozhkova, Y.A.; Markova, L.N.; Tashkinov, M.A.; Vindokurov, I.V.; Silberschmidt, V.V. Biocompatibility of 3D-printed PLA, PEEK and PETG: Adhesion of bone marrow and peritoneal lavage cells. Polymers 2022, 14, 3958. [Google Scholar] [CrossRef]

- Kopar, M.; Yildiz, A.R. Experimental investigation of mechanical properties of PLA, ABS and PETG 3D-printing materials using fused deposition modeling technique. Materialpruefung 2023, 65, 1795–1804. [Google Scholar]

- Yan, C.; Kleiner, C.; Tabigue, A.; Shah, V.; Sacks, G.; Shah, D.; DeStefano, V. PETG: Applications in modern medicine. Eng. Regen. 2024, 5, 45–55. [Google Scholar] [CrossRef]

- Gritskova, I.A.; Prokopov, N.I.; Ezhova, A.A.; Chalykh, A.E.; Gusev, S.A.; Levachev, S.M.; Zubov, V.P.; Gomzyak, V.I.; Skopintsev, I.V.; Stuzhuk, A.N.; et al. New approaches to the synthesis and stabilization of polymer microspheres with a narrow size distribution. Polymers 2023, 15, 2464. [Google Scholar] [CrossRef]

- Doronin, F.; Rudakova, A.; Rytikov, G.; Nazarov, V. Simple determination of the melt flow index of composite polymer filaments used in material extrusion additive manufacturing. Coatings 2023, 13, 1592. [Google Scholar] [CrossRef]

- Nazarov, V.; Dedov, A.; Doronin, F.; Savel’ev, M.; Evdokimov, A.; Rytikov, G. The air permeability and the porosity of polymer materials based on 3D-printed hybrid non-woven needle-punched fabrics. Polymers 2024, 16, 1424. [Google Scholar] [CrossRef] [PubMed]

- Doronin, F.; Savel’ev, M.; Rytikov, G.; Evdokimov, A.; Nazarov, V. A new approach to carbon nanotube filament nanostructuring for additive manufacturing. Polymers 2024, 16, 1423. [Google Scholar] [CrossRef] [PubMed]

- Hasib, A.G.; Niauzorau, S.; Xu, W.; Niverty, S.; Kublik, N.; Williams, J.; Chawla, N.; Song, K.; Azeredo, B. Rheology scaling of spherical metal powders dispersed in thermoplastics and its correlation to the extrudability of filaments for 3D printing. Addit. Manuf. 2021, 41, 101967. [Google Scholar] [CrossRef]

- Mancilla-De-la-Cruz, J.; Rodriguez-Salvador, M.; An, J.; Chua, C.K. Three-Dimensional Printing Technologies for Drug Delivery Applications: Processes, Materials, and Effects. Int. J. Bioprint. 2022, 8, 622. [Google Scholar] [CrossRef]

- Amiot, M.; Lewandowski, M.; Leite, P.; Thomas, M.; Perwuelz, A. An evaluation of fiber orientation and organization in nonwoven fabrics by tensile, air permeability and compression measurements. J. Mater. Sci. 2013, 49, 52–61. [Google Scholar] [CrossRef]

- Soltani, P.; Zarrebini, M.; Laghaei, R.; Hassanpour, A. Prediction of permeability of realistic and virtual layered nonwovens using combined application of X-ray μ CT and computer simulation. Chem. Eng. Res. Des. 2017, 124, 299–312. [Google Scholar] [CrossRef]

- Qiu, S.; Zhang, H.; Cheng, J.; Shi, S.; Lam, Y.; Li, W.; Li, H.; Wang, H.; Sun, F.; Jia, H. Pre-programmable pneumatic actuator: Leveraging mechanical anisotropy of nonwoven fabrics with an integrated tensile sensor. Mater. Horiz. 2024, 11, 3623–3632. [Google Scholar] [CrossRef]

- Atakok, G.; Kam, M.; Koc, H.B. Tensile, three-point bending and impact strength of 3d printed parts using PLA and recycled PLA filaments: A statistical investigation. J. Mater. Res. Technol. 2022, 18, 1542–1554. [Google Scholar] [CrossRef]

- Tian, J.; Cao, Z.; Qian, S.; Xia, Y.; Zhang, J.; Kong, Y.; Sheng, K.; Zhang, Y.; Wan, Y.; Takahashi, J. Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose. Nanotechnol. Rev. 2022, 11, 2469–2482. [Google Scholar] [CrossRef]

- Boopathy, G.; Vanitha, V.; Karthiga, K.; Gugulothu, B.; Pradeep, A.; Pydi, H.P.; Vijayakumar, S.; Acierno, D. Optimization of tensile and impact strength for injection moulded nylon 66/SIC/B4C composites. J. Nanomater. 2022, 2022, 4920774. [Google Scholar] [CrossRef]

- Wang, P.H.; Liu, H.T. Voltage-dependent modulation of effective Young’s modulus and shape in piezoelectric composite metamaterials. Compos. Struct. 2023, 306, 116583. [Google Scholar] [CrossRef]

- Li, G.; Chen, Y.; Wei, G. Continuous fiber reinforced meta-composites with tailorable Poisson’s ratio and effective elastic modulus: Design and experiment. Compos. Struct. 2024, 329, 117768. [Google Scholar] [CrossRef]

- Hao, T.; Mustafa, J.; Gray, G.; Hossain, Z. Effective modulus of 3d-printable curvi-linear fiber reinforced composites. Compos. Struct. 2024, 330, 117811. [Google Scholar] [CrossRef]

- Chicco, D.; Warrens, M.J.; Jurman, G. The coefficient of determination R-squared is more informative than SMAPE, MAE, MAPE, MSE and RMSE in regression analysis evaluation. PeerJ Comput. Sci. 2021, 7, e623. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Shao, H.; Cheng, J.; Kang, D. Preparation of non-woven fabric reinforced poly(vinylidene fluoride) composite mem-branes for water treatment. Fibers Polym. 2022, 23, 1378–1386. [Google Scholar] [CrossRef]

- Javed, M.A.; Akram, R.; Nazeer, M.; Ghaffari, A. Heat transfer analysis of the non-Newtonian polymer in the calendering process with slip effects. Int. J. Mod. Phys. B 2023, 38, 2450105. [Google Scholar] [CrossRef]

- Mitsoulis, E.; Polychronopoulos, N.D.; Hatzikiriakos, S.G. Calendering of thermo-plastics: Models and computations. Int. Polym. Process. 2022, 37, 341–356. [Google Scholar] [CrossRef]

- Tran, T.Q.; Ng, F.L.; Kai, J.T.Y.; Feih, S.; Nai, M.L.S. Tensile strength enhancement of fused filament fabrication printed parts: A review of process improvement approaches and respective impact. Addit. Manuf. 2022, 54, 102724. [Google Scholar] [CrossRef]

- Ishizuka, F.; Kim, H.J.; Kuchel, R.P.; Yao, Y.; Chatani, S.; Niino, H.; Zetterlund, P.B. Polymeric nanocomposites based on high aspect ratio polymer fillers: Simultaneous improvement in tensile strength and stretchability. Eur. Polym. J. 2022, 169, 111134. [Google Scholar] [CrossRef]

- Alekhin, A.K.; Lyusova, L.R.; Naumova, Y.A.; Kotova, S.V.; Monakhova, T.V. Improving the adhesive properties of adhesives based on a mixture of nitrile butadiene and chlorinated rubbers with metal chelates. Polym. Sci. Ser. D 2020, 13, 26–30. [Google Scholar] [CrossRef]

- Nayyeri, P.; Zareinia, K.; Bougherara, H. Planar and nonplanar slicing algorithms for fused deposition modeling technology: A critical review. Int. J. Adv. Manuf. Technol. 2022, 119, 2785–2810. [Google Scholar] [CrossRef]

- Xie, F.; Jing, X.; Zhang, C.; Chen, S.; Bi, D.; Li, Z.; He, D.; Tang, K. Volume decomposition for multi-axis support-free and gouging-free printing based on ellipsoidal slicing. Comput. Aided Des. 2022, 143, 103135. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, J.; Yee Leung, K.M.; Wu, F. Color: An important but overlooked factor for plastic photoaging and microplastic formation. Environ. Sci. Technol. 2022, 56, 9161–9163. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhang, H.; Chen, Z.; Zhao, Y.; Gu, Z.; Shang, L. Polymer-based responsive structural color materials. Prog. Mater. Sci. 2023, 135, 101091. [Google Scholar] [CrossRef]

- Zienko, S.I.; Zhbanova, V.L. Ultra-wideband properties of the spectral sensitivity of a human eye. Russ. Phys. J. 2022, 65, 847–855. [Google Scholar] [CrossRef]

- Li, Z.; Liu, X.; Wang, G.; Li, B.; Chen, H.; Li, H.; Zhao, Y. Photoresponsive supra-molecular coordination polyelectrolyte as smart anticounterfeiting inks. Nat. Commun. 2021, 12, 1363. [Google Scholar] [CrossRef]

- Xu, G.; Xia, H.; Chen, P.; Zhang, H.; Ma, J.; Ruan, Q.; Zhang, W.; Sun, Z.; She, W. Thermochromic hydrogels with dynamic solar modulation and regulatable critical response temperature for energy-saving smart windows. Adv. Funct. Mater. 2022, 32, 2109597. [Google Scholar] [CrossRef]

- Olaosebikan, T.E.; Egbon, F.O.; Olayemi, K.S. Mathematical methods applied to economy and sustainable development goals. Open J. Model. Simul. 2022, 10, 283–291. [Google Scholar] [CrossRef]

- Yaman, O.; Yetiş, H.; Karaköse, M. Image processing and machine learning-based classification method for hyperspectral images. J. Eng. 2021, 2021, 85–96. [Google Scholar] [CrossRef]

- Liu, Y.; Li, W. Error bounds for augmented truncation approximations of Markov chains via the perturbation method. Adv. Appl. Probab. 2018, 50, 645–669. [Google Scholar] [CrossRef]

- Masuyama, H. Error bounds for last-column-block-augmented truncations of block-structured Markov chains. J. Oper. Res. Soc. Jpn. 2017, 60, 271–320. [Google Scholar] [CrossRef]

- Drozdov, S.; Nazarov, V.; Nozdrachev, S.; Rudyak, Y.; Rytikov, G. The polymer composites’ morphological structure simulation. Nanosyst. Phys. Chem. Math. 2017, 8, 137–145. [Google Scholar] [CrossRef]

- Doronin, F.; Evdokimov, A.; Rudyak, Y.; Rytikov, G.; Taranets, I.; Nazarov, V. A new approach to function-structure modeling of the surface modified polymers. Nanosyst. Phys. Chem. Math. 2022, 13, 115–127. [Google Scholar] [CrossRef]

- Taranets, I.P.; Rytikov, G.O.; Doronin, F.A.; Saveliev, M.A.; Nazarov, V.G. Structural-functional mathematical modeling of ad-ditive manufacturing polymers. Russ. J. Gen. Chem. 2024, 94, 1558–1563. [Google Scholar] [CrossRef]

- Yang, H.; Qi, M.; Yang, Z.; Xie, W.; Zhang, J.; Feng, N. Digitalization of visual discrimination threshold and acceptable tolerance of color depth by psychophysical experiments. Color Res. Appl. 2022, 47, 1155–1162. [Google Scholar] [CrossRef]

- Chae, Y.; Moon, S. Color discrimination threshold of human vision for textiles under different illumination conditions. Text. Res. J. 2023, 93, 3158–3170. [Google Scholar] [CrossRef]

- Devi, G.; Priya, R.; Tapas Bapu, B.R.; Thandaiah Prabu, R.; Sathish Kumar, P.J.; Anusha, N. Role of carbonaceous fillers in elec-tromagnetic interference shielding behavior of pol-ymeric composites: A review. Polym. Compos. 2022, 43, 7701–7723. [Google Scholar] [CrossRef]

| , MPa | Parameters of Approximating Model (1) | ||||

|---|---|---|---|---|---|

| Longitudinal | 58 ± 6 | 480 ± 50 | 25 ± 3 | 3.0 ± 0.3 | 0.89 ± 0.09 |

| Transverse | 47 ± 5 | 500 ± 50 | 37 ± 4 | 7.0 ± 0.7 | 0.89 ± 0.09 |

| Sample Type | Ultimate Tensile Strength σ, MPa | ||||||

|---|---|---|---|---|---|---|---|

| Calendar Rolling Temperature, °C | |||||||

| 20 | 110 | 130 | 150 | 170 | 190 | 210 | |

| NWF | 6.0 ± 0.6 | 5.7 ± 0.6 | 2.9 ± 0.3 | 3.1 ± 0.3 | 4.4 ± 0.5 | 5.7 ± 0.6 | 4.8 ± 0.5 |

| NWF/PETG | 8.1 ± 0.8 | 18 ± 2 | 11 ± 1 | 8.1 ± 0.8 | 8.3 ± 0.8 | 12 ± 1 | 6.1 ± 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazarov, V.; Doronin, F.; Dedov, A.; Evdokimov, A.; Rytikov, G.; Savel’ev, M. Design of a Hybrid 3D-Printed Composite Material Based on Non-Woven Needle-Punched Fabrics with Radio-Absorbing Properties. Polymers 2025, 17, 2324. https://doi.org/10.3390/polym17172324

Nazarov V, Doronin F, Dedov A, Evdokimov A, Rytikov G, Savel’ev M. Design of a Hybrid 3D-Printed Composite Material Based on Non-Woven Needle-Punched Fabrics with Radio-Absorbing Properties. Polymers. 2025; 17(17):2324. https://doi.org/10.3390/polym17172324

Chicago/Turabian StyleNazarov, Victor, Fedor Doronin, Alexander Dedov, Andrey Evdokimov, Georgy Rytikov, and Mikhail Savel’ev. 2025. "Design of a Hybrid 3D-Printed Composite Material Based on Non-Woven Needle-Punched Fabrics with Radio-Absorbing Properties" Polymers 17, no. 17: 2324. https://doi.org/10.3390/polym17172324

APA StyleNazarov, V., Doronin, F., Dedov, A., Evdokimov, A., Rytikov, G., & Savel’ev, M. (2025). Design of a Hybrid 3D-Printed Composite Material Based on Non-Woven Needle-Punched Fabrics with Radio-Absorbing Properties. Polymers, 17(17), 2324. https://doi.org/10.3390/polym17172324