Processibility, Thermo-Mechanical Properties, and Radiation Hardness of Polyurethane and Silicone Resins

Abstract

1. Introduction

2. Materials and Methods

2.1. The Samples

2.1.1. SikaBiresin® RE 700-4

2.1.2. SikaBiresin® RE 820

2.1.3. Robnor ResinLab EL110H

2.1.4. SikaBiresin® UR350

2.1.5. Pad ShA75

2.1.6. Silastic RTV-4250-S

2.2. Viscosity Measurements

2.3. Irradiation

2.3.1. Gamma Irradiation

2.3.2. Proton Irradiation

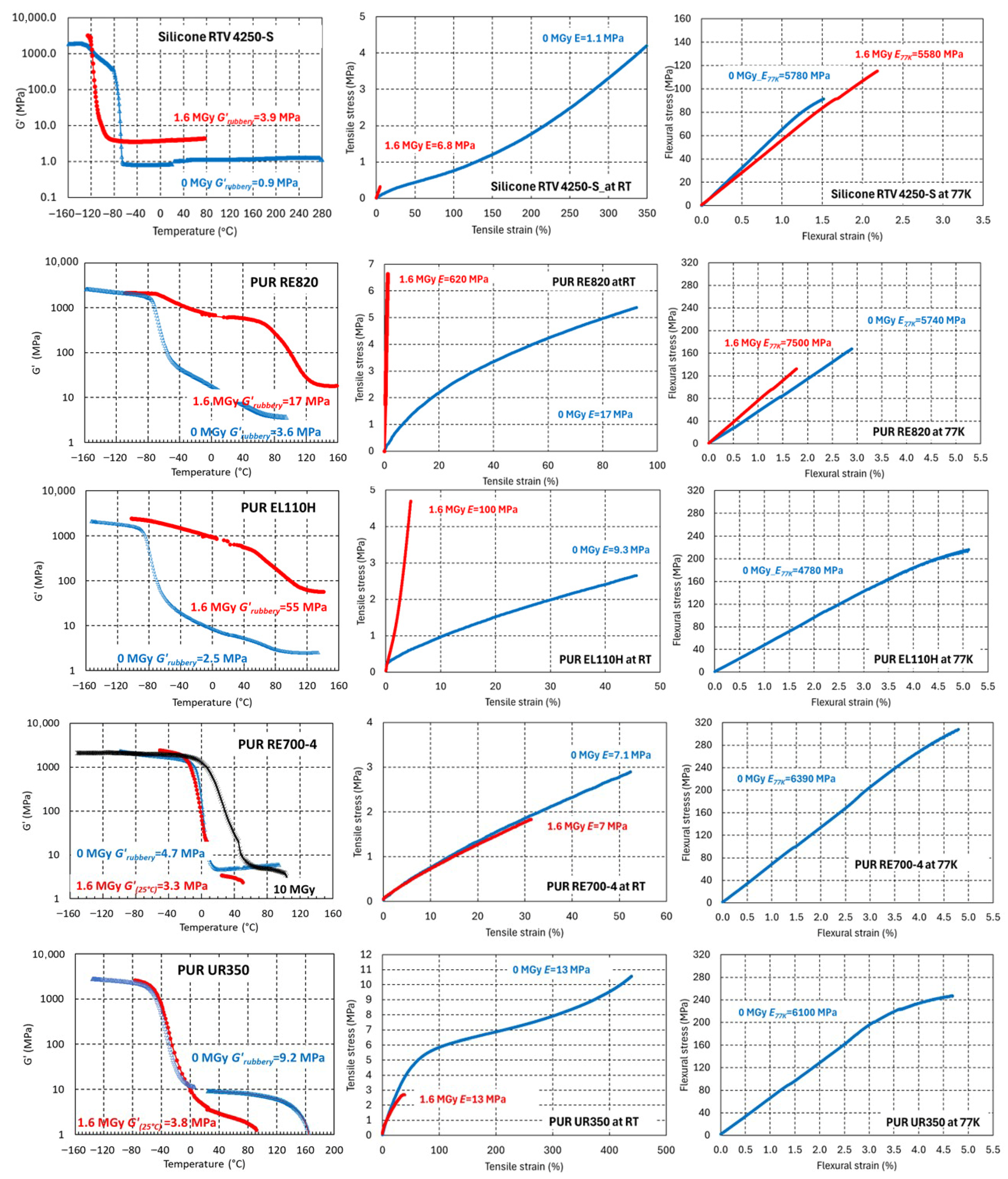

2.4. Dynamic Mechanical Analysis (DMA)

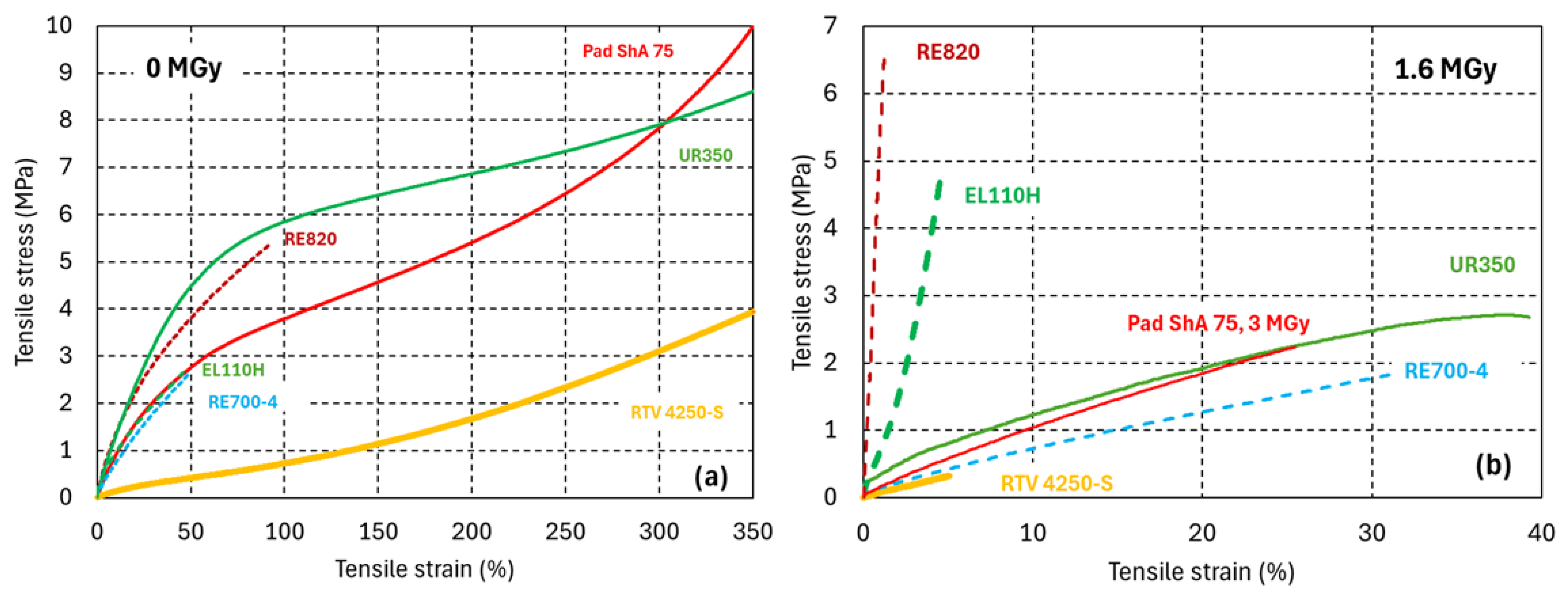

2.5. Tensile Stress–Strain Measurements

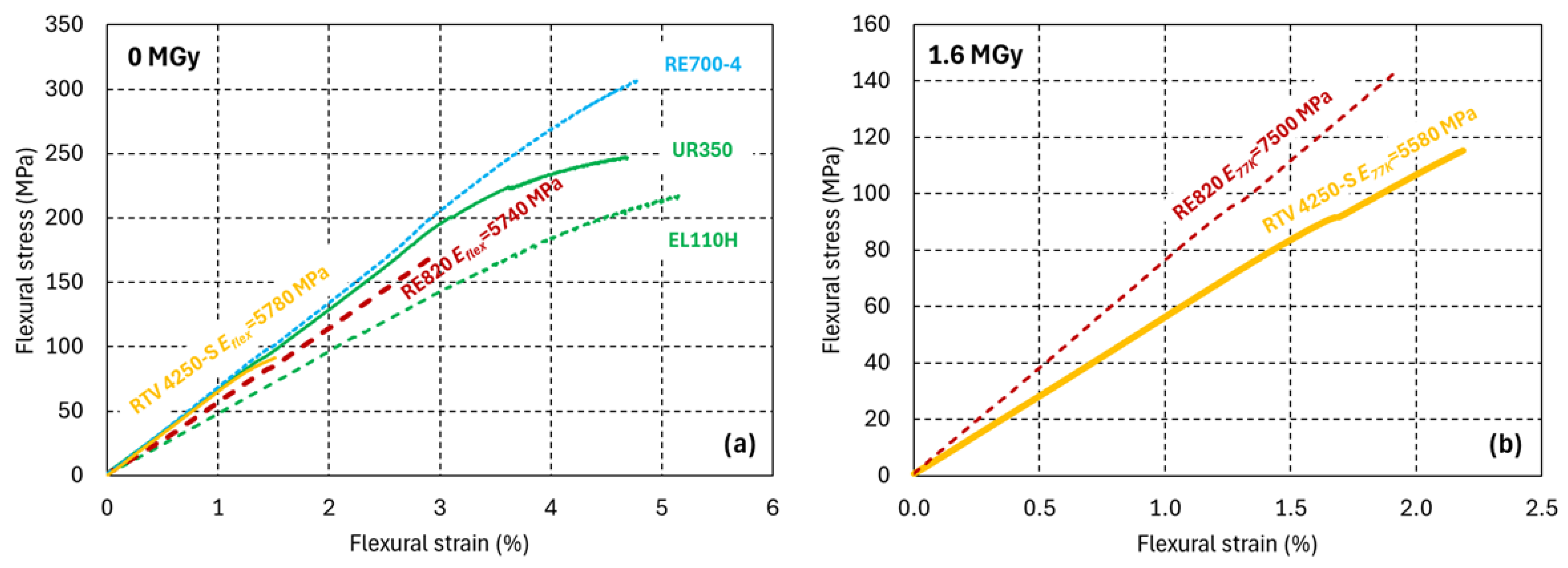

2.6. Flexural Tests

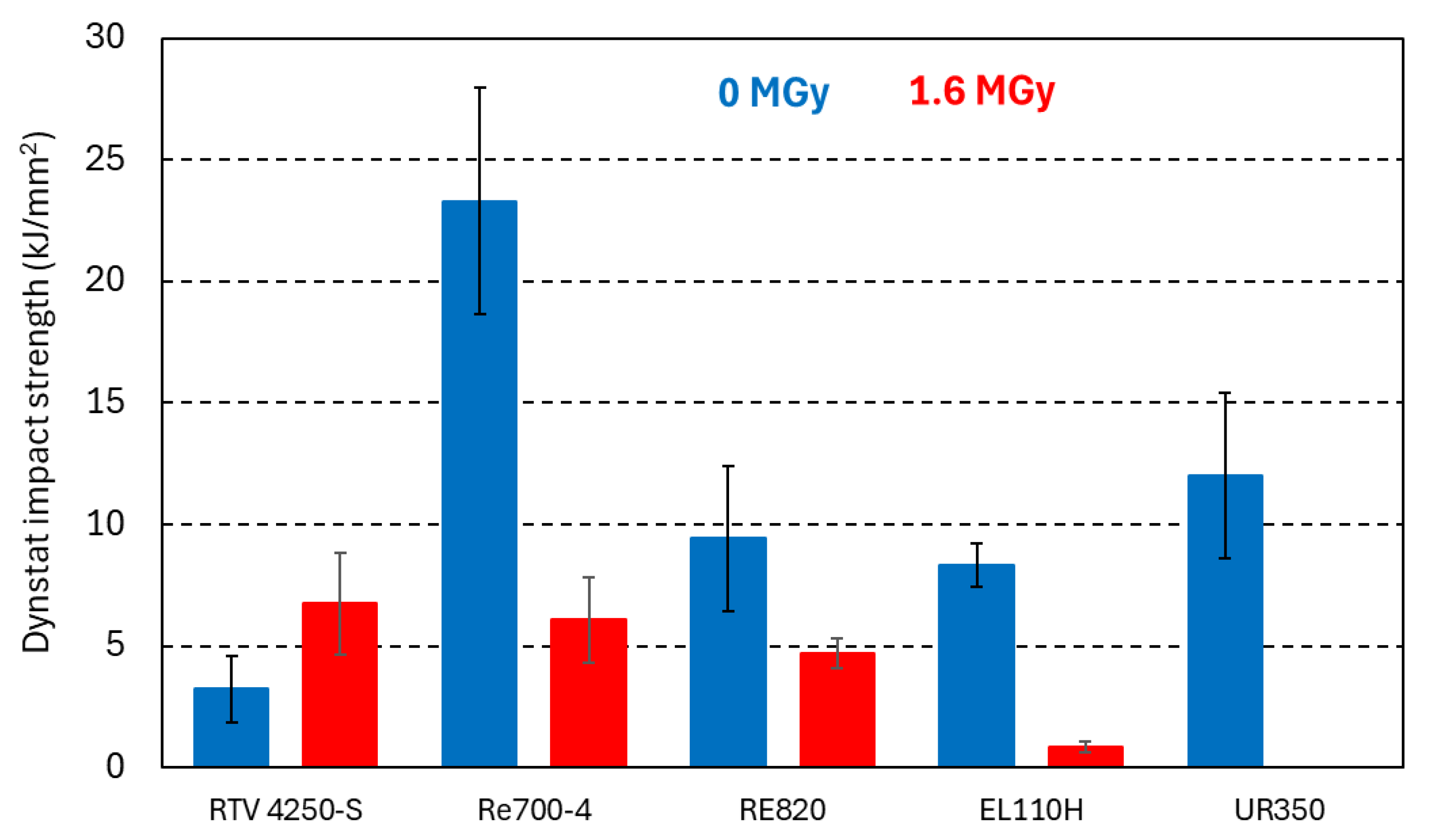

2.7. Impact Tests

2.8. Shore A Hardness

3. Results

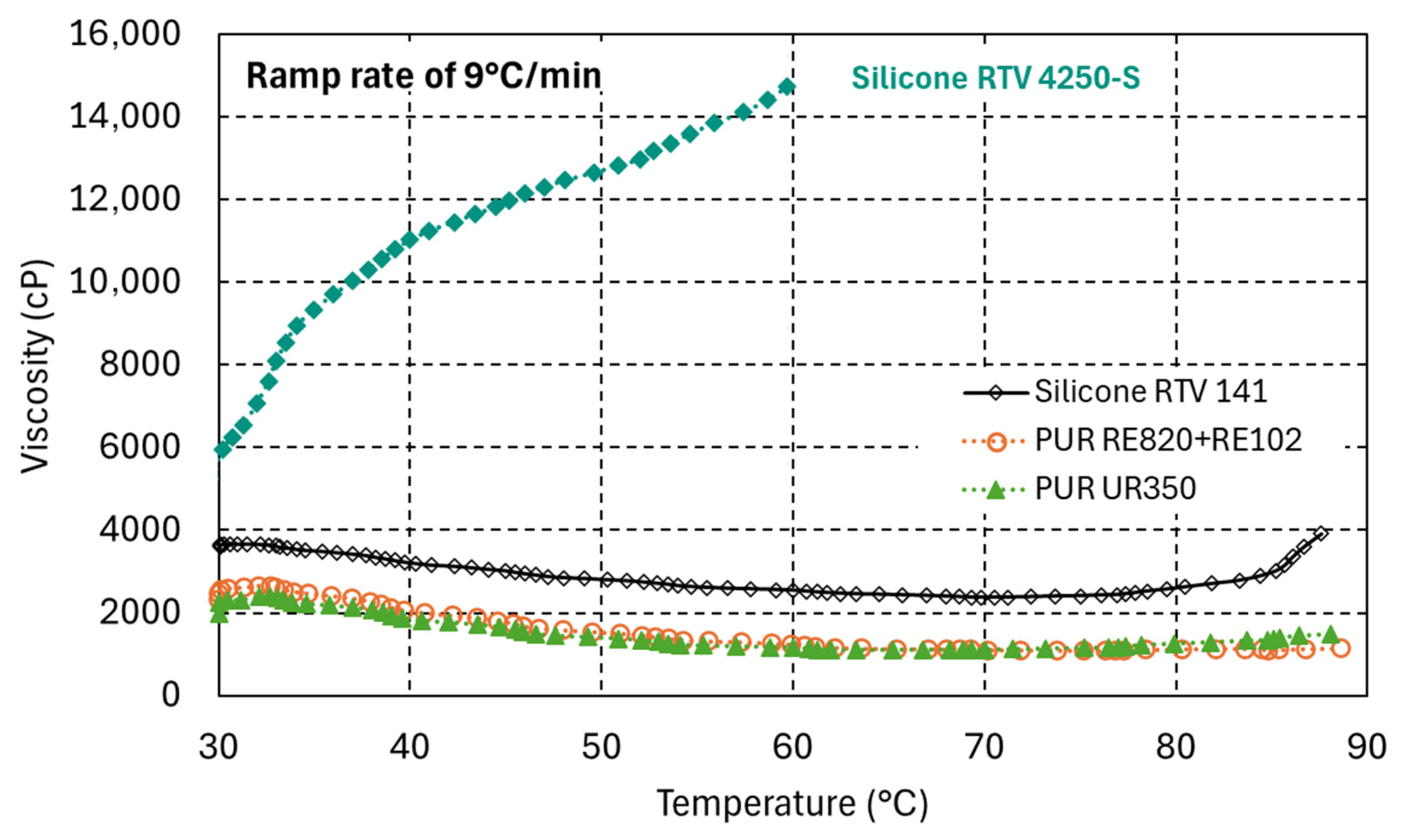

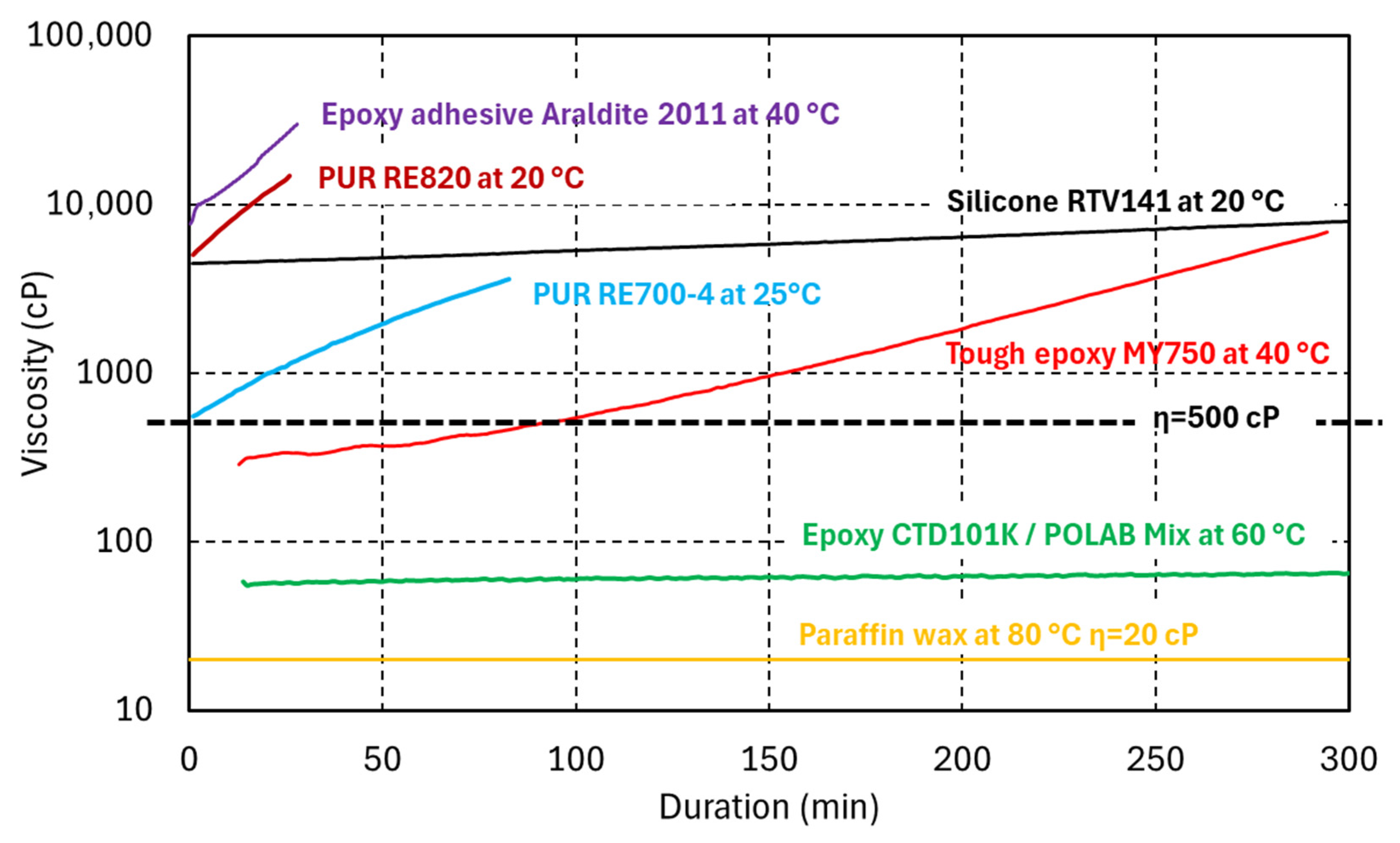

3.1. Viscosity of the Uncured Silicone and Polyurethanes

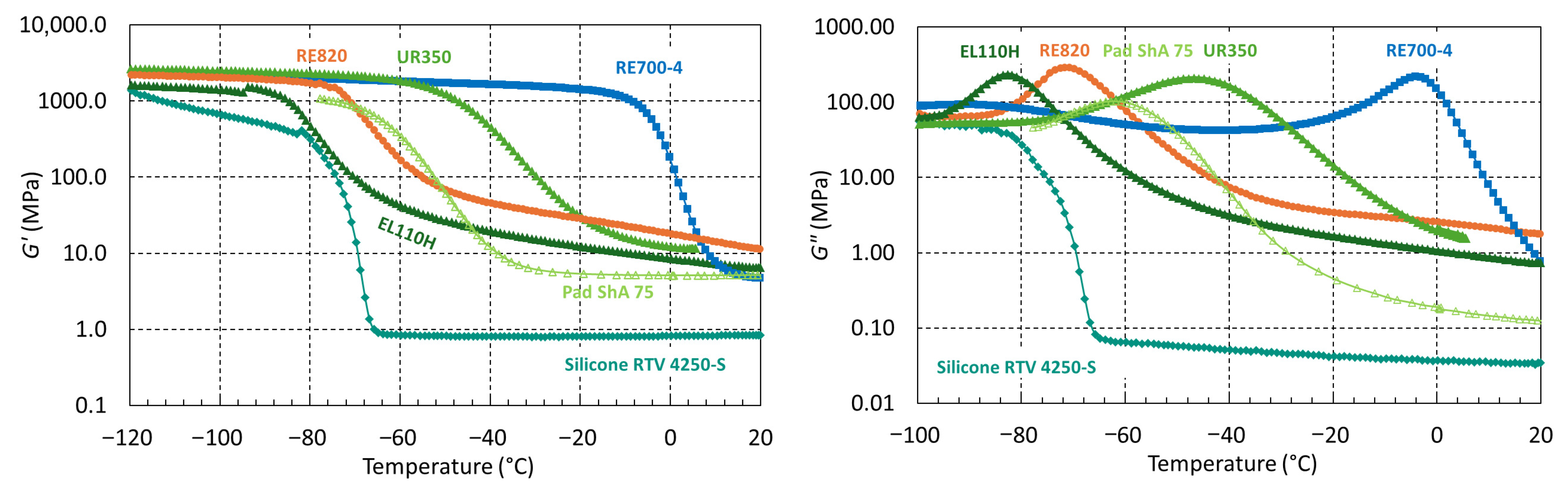

3.2. Viscoelastic Properties of the Cured Resins

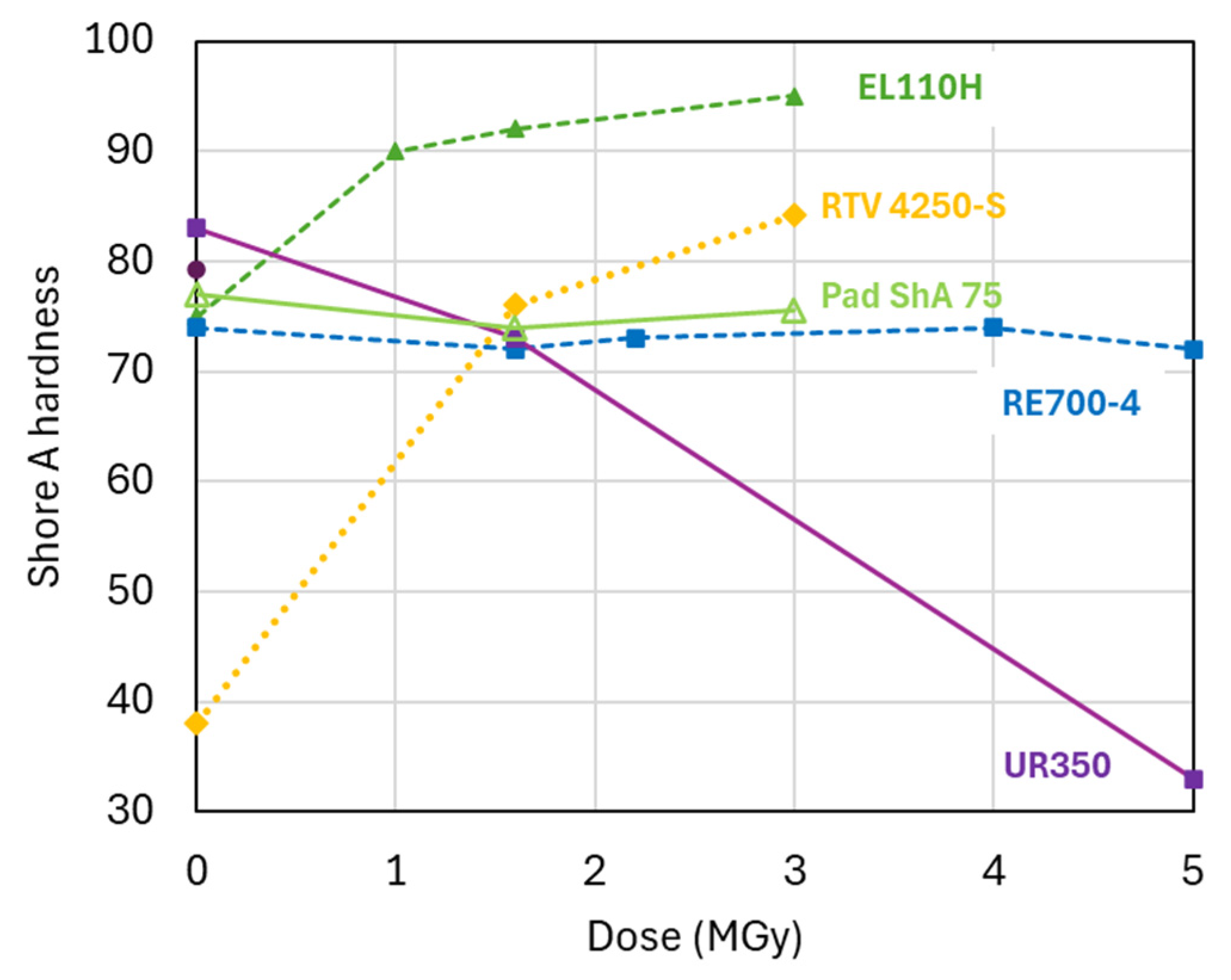

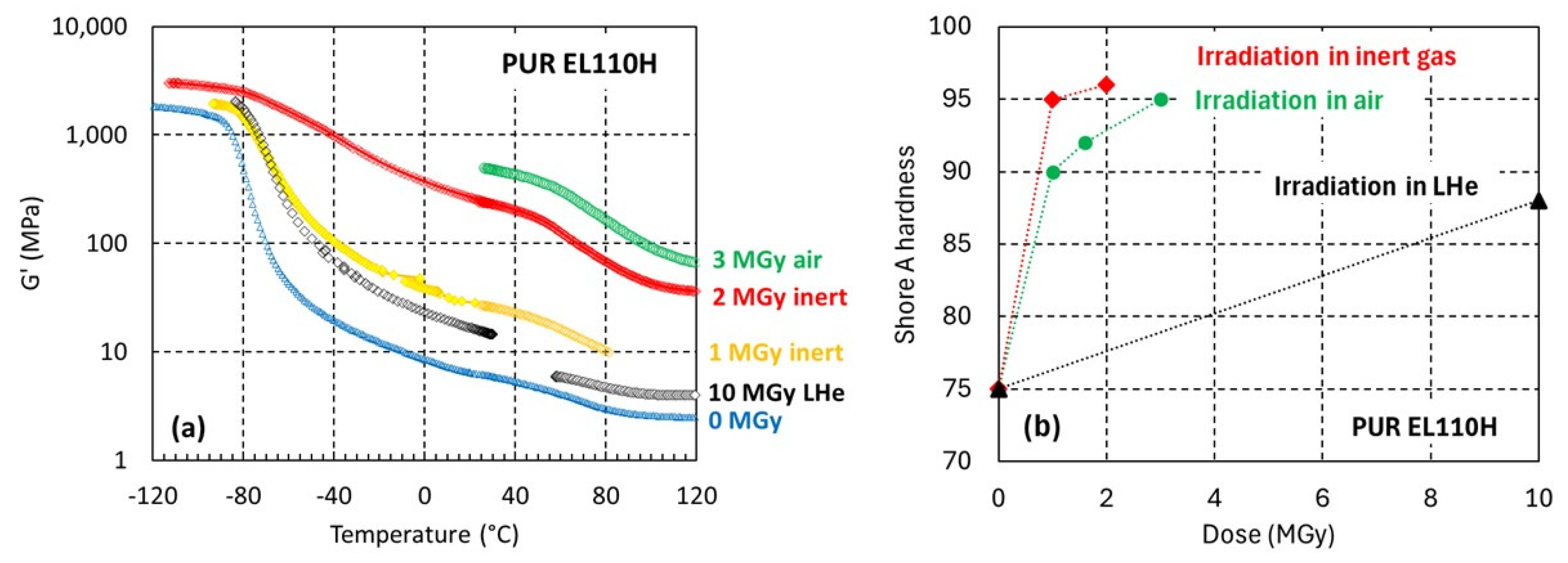

3.3. Irradiation-Induced Changes in Shore A Hardness

3.4. Irradiation-Induced Changes in Mechanical Properties

3.5. Irradiation-Induced Changes of 77 K Impact Strength

3.6. Effect of Irradiation Atmosphere and Temperature on Irradiation-Induced Cross-Linking

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van de Voorde, M.H. Effects of Radiation on Materials and Components; CERN: Meyrin, Switzerland, 1970; pp. 70–75. Available online: https://cds.cern.ch/record/274974/files/CERN-70-05.pdf (accessed on 18 June 2025).

- Guarino, F.; Tavlet, M.; Hauviller, C. Compilation of Readiation Damage Test Data, Part IV: Adhesives; CERN: Meyrin, Switzerland, 2001; Available online: https://cds.cern.ch/record/531818/files/CERN-2001-006.pdf (accessed on 18 June 2025).

- Tavlet, M.; Hominal, L. Shear tests on adhesives for magnet collars for the LHC. Cryogenics 1998, 38, 47–50. [Google Scholar] [CrossRef]

- Izquierdo, G.A.; Bacher, J.-P.; Hominal, L.; Dumitru Ilie, S.; Sgobba, S.; Podevin, C.; Quesnel, J.-P. The SPS Quadrupole Jacks; Technical note, EST-SU-ME/2003/002; CERN: Meyrin, Switzerland, 2003; Available online: https://edh.cern.ch/Document/SupplyChain/DAI/Attach/View/2242327/Tech_Note_EST-SU-ME-2003-002jp.pdf (accessed on 18 June 2025).

- Bestmann, P. Introduction to CERN & BE-GM. Available online: https://indico.cern.ch/event/1285164/contributions/5400492/attachments/2644536/4577182/Intro_GM_EMPA.pdf (accessed on 18 June 2025).

- Rossi, L.; Brüning, O. The High Luminosity Large Hadron Collider: The New Machine for Illuminating the Mysteries of Universe; Advanced Series on Directions in High Energy Physics; World Scientific: London, UK, 2015; Volume 31, p. 24. [Google Scholar]

- Bottura, L.; de Rijk, G.; Rossi, L.; Tedesco, E. Advanced Accelerator Magnets for Upgrading the LHC. IEEE Trans. Appl. Supercond. 2015, 25, 4002107. [Google Scholar] [CrossRef]

- Todesco, E.; Bajas, H.; Bajko, M.; Ballarino, A.; Bermudez, S.I.; Bordini, B.; Bottura, L.; De Rijk, G.; Devred, A.; Ramos, D.D.; et al. The High Luminosity LHC Interaction Region Magnets Towards Series Production. Supercond. Sci. Technol. 2021, 34, 053001. [Google Scholar] [CrossRef]

- Benedikt, M.; Blondel, A.; Janot, P.; Mangano, M.; Zimmermann, F. Future circular colliders succeeding the LHC. Nat. Phys. 2020, 16, 402–407. [Google Scholar] [CrossRef]

- Accettura, C.; Adams, D.; Agarwal, R.; Ahdida, C.; Aimè, C.; Amapane, N.; Amorim, D.; Andreetto, P.; Anulli, F.; Appleby, R.; et al. Towards a Muon Collider. Eur. Phys. J. C 2023, 83, 864. [Google Scholar] [CrossRef]

- Evans, D. Resins for superconducting magnet construction—An overview of requirements, processing and properties. IOP Conf. Ser. Mater. Sci. Eng. 2020, 756, 012003. [Google Scholar] [CrossRef]

- Gaarud, A.; Scheuerlein, C.; Parragh, D.M.; Clement, S.; Bertsch, J.; Urscheler, C.; Piccin, R.; Ravotti, F.; Pezzullo, G.; Lach, R. Fracture toughness, radiation hardness and processibility of polymers for superconducting magnets. Polymers 2024, 16, 1287. [Google Scholar] [CrossRef] [PubMed]

- Parragh, D.M.; Scheuerlein, C.; Martin, N.; Piccin, R.; Ravotti, F.; Pezzullo, G.; Koettig, T.; Lellinger, D. Effect of irradiation temperature and atmosphere on aging of epoxy resins for superconducting magnets. Polymers 2024, 16, 407. [Google Scholar] [CrossRef] [PubMed]

- Technical Data Sheet, SikaBiresin® RE 700-04 Polyol/SikaBiresin® RE 106 Isocyanate. Available online: https://fra.sika.com/dms/getdocument.get/131732bb-d6aa-4774-9ca5-fb4a3987e992/fr-np-ind-sikabiresin-re-700-04-sikabiresin-re-106.pdf (accessed on 11 May 2025).

- Technical Data Sheet, SikaBiresin® RE 820 (A) /SikaBiresin® RE 102 (B). Available online: https://fra.sika.com/dam/dms/fr01/i/fr-np-ind-sikabiresin-re-820-sikabiresin-re-102.pdf (accessed on 31 May 2025).

- Technical Data Sheet, EL110H. Available online: https://robnor-resinlab.com/wp-content/uploads/2021/11/TDS-EL110H.pdf (accessed on 31 May 2025).

- Technical Data Sheet, SikaBiresin® UR350 (UR 3450). Available online: https://www.acrczech.cz/images/TECHNICKELISTY/UR/SikaBiresin_UR350_UR_3450.pdf (accessed on 31 May 2025).

- Parragh, D.M.; Scheuerlein, C.; Piccin, R.; Ravotti, F.; Pezzullo, G.; Ternova, D.; Taborelli, M.; Lehner, M.; Eisterer, M. Irradiation induced aging of epoxy resins for impregnation of superconducting magnet coils. IEEE Trans. Appl. Supercond. 2024, 34, 7800107. [Google Scholar] [CrossRef]

- ASTM D4065; Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D7028-07; Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA). ASTM International: West Conshohocken, PA, USA, 2015.

- Flory, P.J. Molecular Theory of Rubber Elasticity. Polymer 1979, 20, 1317–1320. [Google Scholar] [CrossRef]

- Chen, T.T. Quantifying Polymer Crosslinking Density Using Rheology and DMA. TA Instruments. Available online: https://www.tainstruments.com/pdf/literature/RH102.pdf (accessed on 31 January 2024).

- Hill, L.W. Calculation of crosslink density in short chain networks. Prog. Org. Coat. 1997, 31, 235–243. [Google Scholar] [CrossRef]

- DIN_EN_ISO_527; Plastics—Determination of Tensile Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 178:2019; Plastics—Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- DIN 53435:2024-10; Testing of Plastics—Bending Test and Impact Test on Dynstat Test Specimens. German Institute for Standardisation: Berlin, Germany, 2024.

- IEC 60544-4:2003; Electrical Insulating Materials—Determination of the Effects of Ionizing Radiation—Part 4: Classification System for Service in Radiation Environments. International Electrotechnical Commission: Geneva, Switzerland, 2003.

- Brem, A.; Gold, B.J.; Auchmann, B.; Tommasini, D.; Tervoort, T.A. Elasticity, Plasticity and Fracture Toughness at Ambient and Cryogenic Temperatures of Epoxy Systems Used for the Impregnation of High-Field Superconducting Magnets. Cryogenics 2021, 115, 103260. [Google Scholar] [CrossRef]

- Ardebili, H.; Zhang, J.; Pecht, M.G. Encapsulation Technologies for Electronic Applications; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Axensalva, J.; Lackner, F.; Gauthier, R. Vacuum Pressure Impregnation Setup at CERN for Nb3Sn Coils. IEEE Trans. Appl. Supercond. 2020, 30, 4003204. [Google Scholar] [CrossRef]

- Drobny, J.G. Radiation Technology for Polymers; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

| Material | Dose (MGy) | Tg (°C) | G’rubbery at 25 °C (MPa) | Shore A Hardness | ||

|---|---|---|---|---|---|---|

| G’onset | G’’max | tan δmax | ||||

| Silicone RTV 4250-S | 0 | n.m. | −122 | −118 | 0.8 | 38 ± 0.4 |

| 1.6 | −119 | −120 | −114 | 3.9 | 76 ± 2 | |

| PUR RE700-4 | 0 | −5.1 | −4.2 | 5.8 | 4.7 | 74 ± 1 |

| 1.6 | n.m. | −12 | 5.1 | 3.3 | 72 ± 1 | |

| PUR RE820 | 0 | −75 | −72 | −63 | 3.6 (at 75 °C) | 80 ± 0.4 |

| 1.6 | n.m. | −53 | −40 | 17 (at 140 °C) | >100 | |

| PUR EL110H | 0 | −92 | −83 | −76 | 2.5 | 75 ± 0.5 |

| 1.6 | n.m. | −66 | −12 | 55 (at 125 °C) | 92 ± 4 | |

| PUR UR350 | 0 | −51 | −47 | −27 | 9.2 | 83 ± 1 |

| 1.6 | n.m. | −46 | −15 | 3.5 | 73 ± 1 | |

| PUR Pad ShA 75 | 0 | n.m. | −64 | −46 | 6.0 | 78 ± 0.5 |

| 1.6 | n.m. | −65 | −43 | 4.9 | 71 ± 4 | |

| Material | G’rubbery | ERT | Shore A | ɛmax at RT | ɛmax at 77 K |

|---|---|---|---|---|---|

| Silicone RTV 4250-S cross-linking dominated | +490% | +520% | +95% | −96% | +48% |

| RE700-4 [b] | −30% | <5% | <5% | −45% | n.m. |

| RE820 cross-linking dominated | +350% | +3500% | n.m. [c] | −99% | −38% |

| EL110H cross-linking dominated | +690% | +1000% | +23% | −90% | n.m. |

| UR350 [b] (polyester-based polyol) chain-scission dominated | −62% | +6% | −12% | −90% | n.m. [d] |

| Pad ShA 75 (polyether-based polyol) | −18% | <5% | <5% | n.m. | n.m. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scheuerlein, C.; Albeck, M.; Piccin, R.; Ravotti, F.; Pezzullo, G. Processibility, Thermo-Mechanical Properties, and Radiation Hardness of Polyurethane and Silicone Resins. Polymers 2025, 17, 2240. https://doi.org/10.3390/polym17162240

Scheuerlein C, Albeck M, Piccin R, Ravotti F, Pezzullo G. Processibility, Thermo-Mechanical Properties, and Radiation Hardness of Polyurethane and Silicone Resins. Polymers. 2025; 17(16):2240. https://doi.org/10.3390/polym17162240

Chicago/Turabian StyleScheuerlein, Christian, Melanie Albeck, Roland Piccin, Federico Ravotti, and Giuseppe Pezzullo. 2025. "Processibility, Thermo-Mechanical Properties, and Radiation Hardness of Polyurethane and Silicone Resins" Polymers 17, no. 16: 2240. https://doi.org/10.3390/polym17162240

APA StyleScheuerlein, C., Albeck, M., Piccin, R., Ravotti, F., & Pezzullo, G. (2025). Processibility, Thermo-Mechanical Properties, and Radiation Hardness of Polyurethane and Silicone Resins. Polymers, 17(16), 2240. https://doi.org/10.3390/polym17162240