Biodegradable Packaging from Agricultural Wastes: A Comprehensive Review of Processing Techniques, Material Properties, and Future Prospects

Abstract

1. Introduction

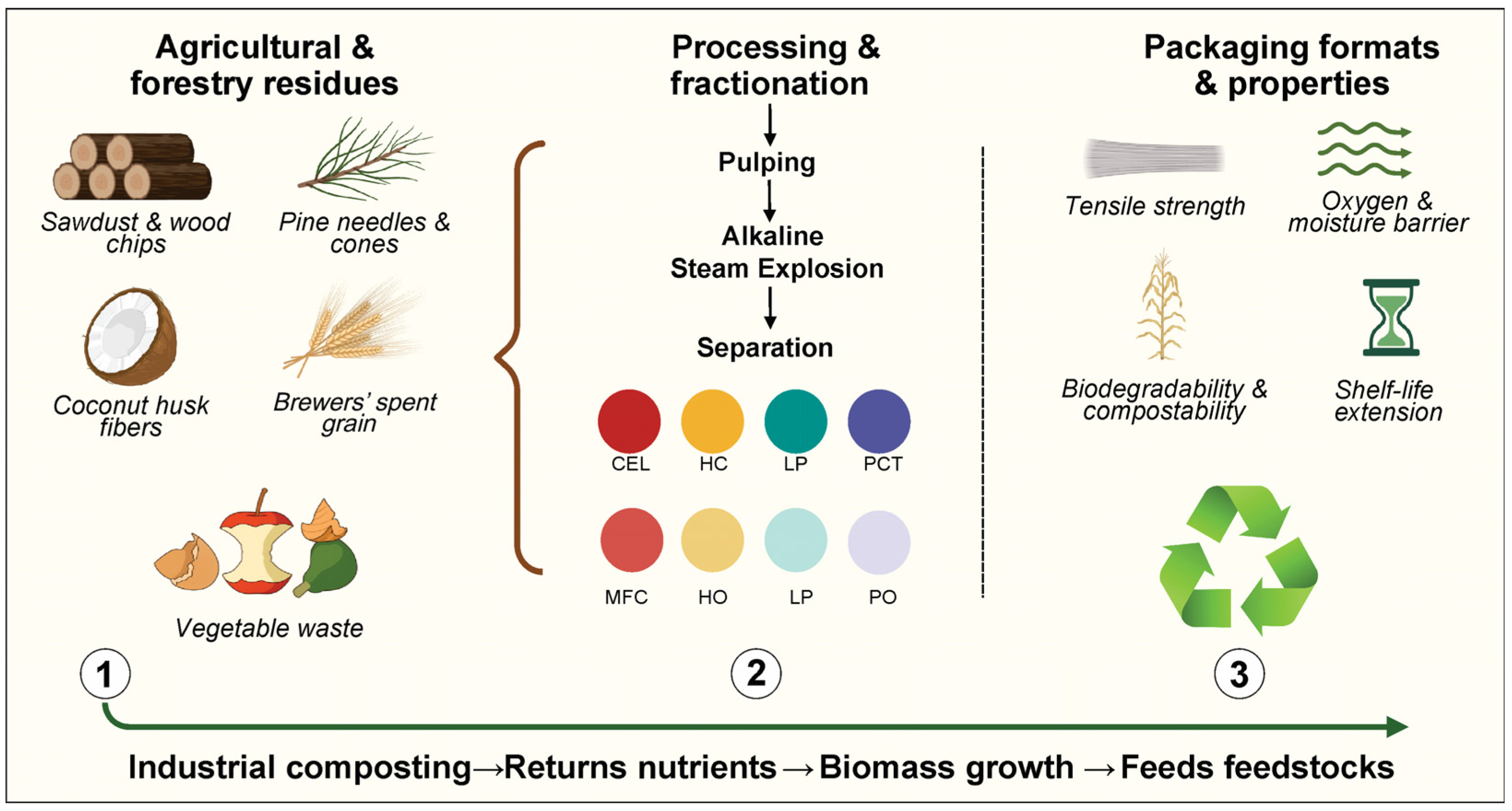

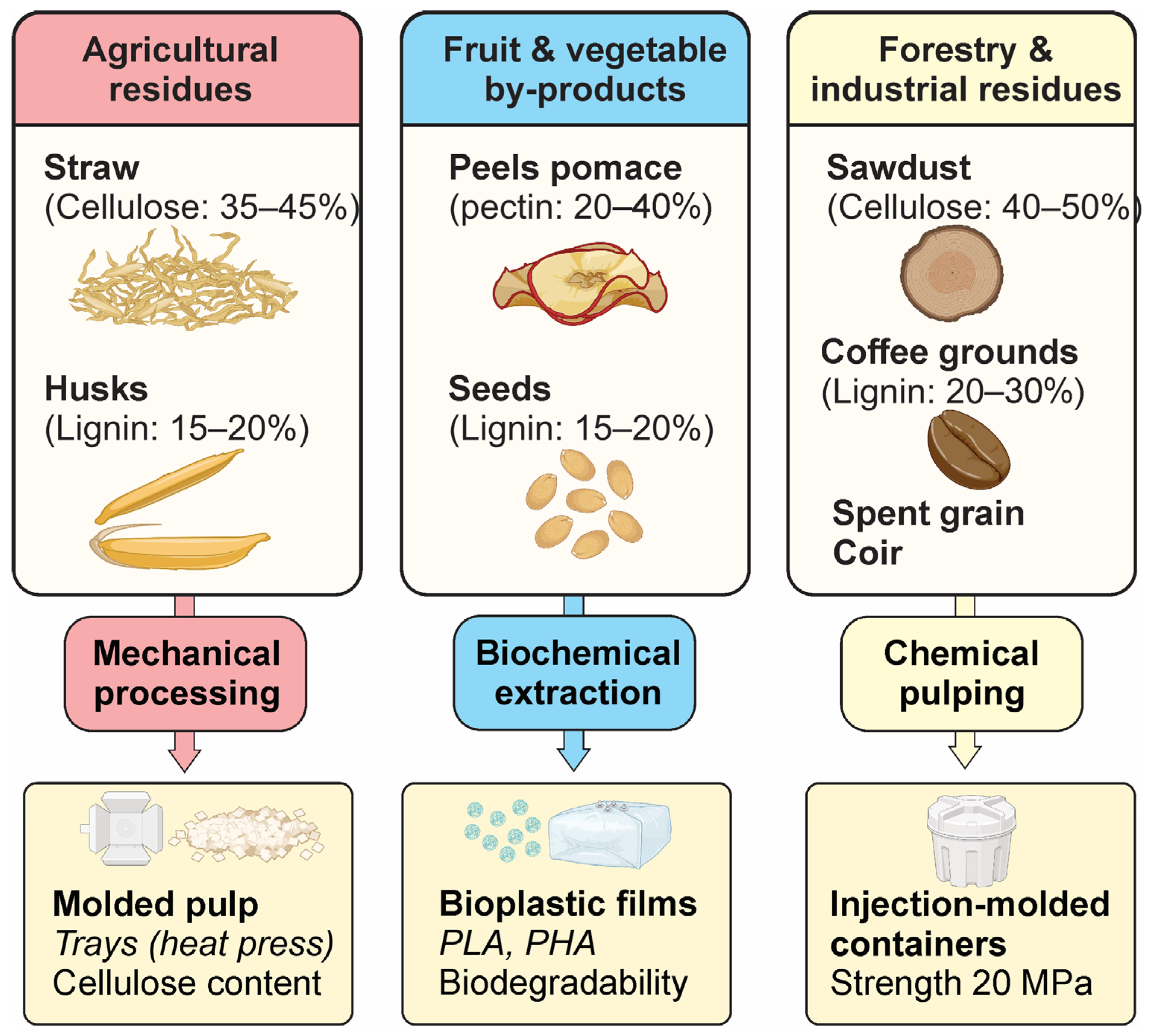

2. Sources of Plant Waste

2.1. Agricultural Residues

2.2. Fruit and Vegetable Processing By-Products

2.3. Forestry and Industrial Plant Residues

3. Chemical Composition of Lignocellulosic Materials

3.1. Main Components Bio-Waste Materials

3.2. Influence of Composition on Material Performance of Lignocellulosic Composition

3.3. Pre-Treatment Methods for Modifying the Properties of Sustainable Packaging Materials

4. Processing Methods for Packaging Materials

4.1. Mechanical Consolidation

4.2. Blends with Biopolymers

4.3. Recycling of PLA and PHA-Based Packaging

5. Future Outlook

Integration into Existing Value Chains

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BSG | Brewers’ spent grain |

| CEL | Cellulose |

| CNC | Cellulose nanocrystals |

| DES | Deep eutectic solvent |

| HC | Hemicellulose |

| HO | Hemi-oligosaccharides |

| LP | Lignin phenolics |

| MFC | Microfibrillated cellulose |

| PCT | Pectin |

| PHA | Polyhydroxyalkanoates |

| PLA | Polylactic acid |

| PO | Pectic oligosaccharides |

| PVA | Polyvinyl alcohol |

| PRO | Protein |

| STR | Starch |

References

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Rujnić-Sokele, M.; Pilipović, A. Challenges and opportunities of biodegradable plastics: A mini review. Waste Manag. Res. 2017, 35, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Balart, R.; Garcia-Garcia, D.; Fombuena, V.; Quiles-Carrillo, L.; Arrieta, M.P. Biopolymers from Natural Resources. Polymers 2021, 13, 2532. [Google Scholar] [CrossRef] [PubMed]

- Travalini, A.P.; Lamsal, B.; Magalhães, W.L.E.; Demiate, I.M. Cassava starch films reinforced with lignocellulose nanofibers from cassava bagasse. Int. J. Biol. Macromol. 2019, 139, 1151–1161. [Google Scholar] [CrossRef] [PubMed]

- Reddy, N.; Yang, Y. Citric acid cross-linking of starch films. Food Chem. 2010, 118, 702–711. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the Use of PLA-PHB Blends for Sustainable Food Packaging Applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef]

- Polipalli, K.; Suraboyina, S.; Kashimalla, M.; Polumati, A. A review on value addition of Agricultural Residues by Chemical and Bio-chemical Processes to abate environmental pollution. Green Technol. Sustain. 2025, 3, 100241. [Google Scholar] [CrossRef]

- Xu, R.; Chen, J.; Yan, N.; Xu, B.; Lou, Z.; Xu, L. High-value utilization of agricultural residues based on component characteristics: Potentiality and challenges. J. Bioresour. Bioprod. 2025, 10, 271–294. [Google Scholar] [CrossRef]

- Patidar, R.; Thakur, V.K.; Chaturvedi, R.; Khan, A.; Mallick, T.; Gupta, M.K.; Pappu, A. Production of Natural Straw-Derived Sustainable Polymer Composites for a Circular Agro-Economy. ACS Sustain. Resour. Manag. 2024, 1, 1729–1737. [Google Scholar] [CrossRef]

- Khan, M.S.; Islam, M.M.; Epaarachchi, J.; Shibata, S. Exploring the Prospects of Macadamia Nutshells for Bio-Synthetic Polymer Composites: A Review. Polymers 2023, 15, 4007. [Google Scholar] [CrossRef]

- Ural, Ç.; Aşkın, B. Potentials of Berry Fruits Pomaces for Bio-Based Films. Int. J. Innov. Approaches Agric. Res. 2023, 7, 558–568. [Google Scholar] [CrossRef]

- Mandala, R.; Hegde, G.; Kodali, D.; Kode, V.R. From Waste to Strength: Unveiling the Mechanical Properties of Peanut-Shell-Based Polymer Composites. J. Compos. Sci. 2023, 7, 307. [Google Scholar] [CrossRef]

- Maddirala, S.; Tadepalli, S.P.; Lakshiakanthan, E.; Ganesan, J.J.; Issac, R.; Basavegowda, N.; Baek, K.-H.; Haldar, D. Biodegradable composite films of barley fibers for food packaging applications: A review. Int. J. Biol. Macromol. 2025, 295, 139611. [Google Scholar] [CrossRef] [PubMed]

- Debnath, M.; Sarder, R.; Pal, L.; Hubbe, M.A. Molded pulp products for sustainable packaging: Production rate challenges and product opportunities. BioResources 2022, 17, 3810–3870. [Google Scholar] [CrossRef]

- Yan, J.; Liu, J.; Sun, Y.; Song, G.; Ding, D.; Fan, G.; Chai, B.; Wang, C.; Sun, L. Investigation on the Preparation of Rice Straw-Derived Cellulose Acetate and Its Spinnability for Electrospinning. Polymers 2021, 13, 3463. [Google Scholar] [CrossRef]

- Varghese, S.A.; Pulikkalparambil, H.; Promhuad, K.; Srisa, A.; Laorenza, Y.; Jarupan, L.; Nampitch, T.; Chonhenchob, V.; Harnkarnsujarit, N. Renovation of Agro-Waste for Sustainable Food Packaging: A Review. Polymers 2023, 15, 648. [Google Scholar] [CrossRef]

- Bartos, A.; Nagy, K.; Anggono, J.; Antoni; Purwaningsih, H.; Móczó, J.; Pukánszky, B. Biobased PLA/sugarcane bagasse fiber composites: Effect of fiber characteristics and interfacial adhesion on properties. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106273. [Google Scholar] [CrossRef]

- Stroescu, M.; Romina, A.; MureȘAn, C.C. A Comprehensive Review on Sugarcane Bagasse in Food Packaging: Properties, Applications, and Future Prospects. Hop Med. Plants 2024, 32, 169–184. [Google Scholar] [CrossRef]

- Laftah, W.A.; Wan Abdul Rahman, W.A. Rice waste–based polymer composites for packaging applications: A review. Polym. Polym. Compos. 2021, 29, S1621–S1629. [Google Scholar] [CrossRef]

- McCaffrey, Z.; Cal, A.; Torres, L.; Chiou, B.-S.; Wood, D.; Williams, T.; Orts, W. Polyhydroxybutyrate Rice Hull and Torrefied Rice Hull Biocomposites. Polymers 2022, 14, 3882. [Google Scholar] [CrossRef]

- Zhang, S.; Cheng, X.; Yang, W.; Fu, Q.; Su, F.; Wu, P.; Li, Y.; Wang, F.; Li, H.; Ai, S. Converting fruit peels into biodegradable, recyclable and antimicrobial eco-friendly bioplastics for perishable fruit preservation. Bioresour. Technol. 2024, 406, 131074. [Google Scholar] [CrossRef]

- Kharb, J.; Saharan, R. Development of biodegradable and eco-friendly fruit peel-derived bioplastic film with antibacterial potential for food packaging application. Biomass Convers. Biorefinery 2025, 15, 10839–10854. [Google Scholar] [CrossRef]

- Kasaai, M.R.; Moosavi, A. Treatment of Kraft paper with citrus wastes for food packaging applications: Water and oxygen barrier properties improvement. Food Packag. Shelf Life 2017, 12, 59–65. [Google Scholar] [CrossRef]

- Tsirigotis-Maniecka, M.; Górska, E.; Mazurek-Hołys, A.; Pawlaczyk-Graja, I. Unlocking the Potential of Food Waste: A Review of Multifunctional Pectins. Polymers 2024, 16, 2670. [Google Scholar] [CrossRef] [PubMed]

- Mileti, O.; Baldino, N.; Marchio, V.; Lupi, F.R.; Gabriele, D. Rheological and Textural Investigation to Design Film for Packaging from Potato Peel Waste. Gels 2024, 10, 681. [Google Scholar] [CrossRef]

- Cruz-Tirado, J.P.; Vejarano, R.; Tapia-Blácido, D.R.; Angelats-Silva, L.M.; Siche, R. The addition of sugarcane bagasse and asparagus peel enhances the properties of sweet potato starch foams. Packag. Technol. Sci. 2019, 32, 227–237. [Google Scholar] [CrossRef]

- Tran, T.N.; Lim, K.T.; Fiorentini, F.; Athanassiou, A. Antioxidant and Biocompatible CO2-Based Biocomposites from Vegetable Wastes for Active Food Packaging. Adv. Sustain. Syst. 2022, 6, 2100470. [Google Scholar] [CrossRef]

- Kumar, A.; Ramakanth, D.; Akhila, K.; Gaikwad, K.K. Influence of halloysite nanotubes/microfibrillated cellulose on pine leaves waste based ethylene scavenging composite paper for food packaging applications. Appl. Clay Sci. 2023, 231, 106726. [Google Scholar] [CrossRef]

- Vandna, V.; Yadav, V.L. Influence of alkali treatment on coir-reinforced polyvinyl alcohol/polyethylene glycol blends. J. Plast. Film Sheeting 2024, 40, 307–327. [Google Scholar] [CrossRef]

- Aradwad, P.; Raut, S.; Abdelfattah, A.; Rauh, C.; Sturm, B. Brewer’s spent grain: Unveiling innovative applications in the food and packaging industry. Compr. Rev. Food Sci. Food Saf. 2025, 24, e70150. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.; Hernandez-Hosaka, C.; Zhao, Y.; Park, B.-r. Researchers advance effort to turn spent coffee grounds into food packaging; Oregon State University. 26 March 2025. [Google Scholar]

- Nasri, K.; Loranger, É.; Toubal, L. Effect of cellulose and lignin content on the mechanical properties and drop-weight impact damage of injection-molded polypropylene-flax and -pine fiber composites. J. Compos. Mater. 2023, 57, 3347–3364. [Google Scholar] [CrossRef] [PubMed]

- Curling, S.F.; Laflin, N.; Davies, G.M.; Ormondroyd, G.A.; Elias, R.M. Feasibility of using straw in a strong, thin, pulp moulded packaging material. Ind. Crops Prod. 2017, 97, 395–400. [Google Scholar] [CrossRef]

- Srivastava, V.; Singh, S.; Das, D. Rice husk fiber-reinforced starch antimicrobial biocomposite film for active food packaging. J. Clean. Prod. 2023, 421, 138525. [Google Scholar] [CrossRef]

- Ali, M.Q.; Ahmad, N.; Azhar, M.A.; Munaim, M.S.A.; Hussain, A.; Mahdi, A.A. An overview: Exploring the potential of fruit and vegetable waste and by-products in food biodegradable packaging. Discov. Food 2024, 4, 130. [Google Scholar] [CrossRef]

- Cristofoli, N.L.; Lima, A.R.; Tchonkouang, R.D.N.; Quintino, A.C.; Vieira, M.C. Advances in the Food Packaging Production from Agri-Food Waste and By-Products: Market Trends for a Sustainable Development. Sustainability 2023, 15, 6153. [Google Scholar] [CrossRef]

- Durand, K.; Daassi, R.; Rodrigue, D.; Stevanovic, T. Study of Purified Cellulosic Pulp and Lignin Produced by Wheat Straw Biorefinery. Macromol 2024, 4, 650–679. [Google Scholar] [CrossRef]

- Mahmud, M.A.; Anannya, F.R. Sugarcane bagasse—A source of cellulosic fiber for diverse applications. Heliyon 2021, 7, e07771. [Google Scholar] [CrossRef]

- Islam, M.; Saini, P.; Das, R.; Shekhar, S.; Sinha, A.; Prasad, K. Rice straw as a source of nanocellulose for sustainable food packaging materials: A Review. BioResources 2023, 18, 2351–2385. [Google Scholar] [CrossRef]

- Zhang, S. Extrusion and Alkali Extrusion of Corn Stover to Improve Enzyme Saccharification. Master’s Thesis, University of Nebraska–Lincoln, Lincoln, NE, USA, 2011. [Google Scholar]

- Ragab, M.; Osman, M.F.; Khalil, M.E.; Gouda, M.S. Banana (Musa sp.) peels as a source of pectin and some food nutrients. J. Agric. Res. Kafr El-Sheikh Univ. 2016, 42, 88–102. [Google Scholar]

- Ichim, M.; Stelea, L.; Filip, I.; Lisa, G.; Muresan, E.I. Thermal and Mechanical Characterization of Coir Fibre–Reinforced Polypropylene Biocomposites. Crystals 2022, 12, 1249. [Google Scholar] [CrossRef]

- Gaba, E.W.; Asimeng, B.O.; Kaufmann, E.E.; Foster, E.J.; Tiburu, E.K. The Influence of Pineapple Leaf Fiber Orientation and Volume Fraction on Methyl Methacrylate-Based Polymer Matrix for Prosthetic Socket Application. Polymers 2021, 13, 3381. [Google Scholar] [CrossRef]

- Gaind, S. Exploitation of Orange Peel for Fungal Solubilization of Rock Phosphate by Solid State Fermentation. Waste Biomass Valorization 2017, 8, 1351–1360. [Google Scholar] [CrossRef]

- Sharma, A.; Thakur, M.; Bhattacharya, M.; Mandal, T.; Goswami, S. Commercial application of cellulose nano-composites—A review. Biotechnol. Rep. 2019, 21, e00316. [Google Scholar] [CrossRef] [PubMed]

- Madhu, R.; Periasamy, A.P.; Schlee, P.; Hérou, S.; Titirici, M.-M. Lignin: A sustainable precursor for nanostructured carbon materials for supercapacitors. Carbon 2023, 207, 172–197. [Google Scholar] [CrossRef]

- Szymańska-Chargot, M.; Chylińska, M.; Gdula, K.; Kozioł, A.; Zdunek, A. Isolation and Characterization of Cellulose from Different Fruit and Vegetable Pomaces. Polymers 2017, 9, 495. [Google Scholar] [CrossRef]

- Rojas-Lema, S.; Nilsson, K.; Langton, M.; Trifol, J.; Gomez-Caturla, J.; Balart, R.; Garcia-Garcia, D.; Moriana, R. The effect of pine cone lignin on mechanical, thermal and barrier properties of faba bean protein films for packaging applications. J. Food Eng. 2023, 339, 111282. [Google Scholar] [CrossRef]

- Rawat, S.; Pavithra, T.; Sunil, C.K. Citrus byproduct valorization: Pectin extraction, characterization, and research advances in biomaterial derivation for applications in active film packaging. Discov. Food 2024, 4, 149. [Google Scholar] [CrossRef]

- Dubowik, M.; Przybysz, K.; Dańczak, J.; Lipkiewicz, A.; Gajadhur, M.; Górska, B.; Pawłowska, E.; Drozd, R.; Przybysz, P. Micro- and Nanofibrillated Cellulose Coatings as Barriers Against Water and Oil in Food Packaging Paper: A Sustainable Alternative to Plastic Coatings. Coatings 2025, 15, 270. [Google Scholar] [CrossRef]

- Marques, C.S.; Arruda, T.R.; Silva, K.F.; de Oliveira, T.V. Lignin in Food Packaging. In Handbook of Lignin; Jawaid, M., Ahmad, A., Meraj, A., Eds.; Springer Nature: Singapore, 2025; pp. 1–35. [Google Scholar]

- Antony Jose, S.; Cowan, N.; Davidson, M.; Godina, G.; Smith, I.; Xin, J.; Menezes, P.L. A Comprehensive Review on Cellulose Nanofibers, Nanomaterials, and Composites: Manufacturing, Properties, and Applications. Nanomaterials 2025, 15, 356. [Google Scholar] [CrossRef]

- Bekele, A.E.; Lemu, H.G.; Jiru, M.G. Study of the Effects of Alkali Treatment and Fiber Orientation on Mechanical Properties of Enset/Sisal Polymer Hybrid Composite. J. Compos. Sci. 2023, 7, 37. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Effect of Mercerization/Alkali Surface Treatment of Natural Fibres and Their Utilization in Polymer Composites: Mechanical and Morphological Studies. J. Compos. Sci. 2021, 5, 175. [Google Scholar] [CrossRef]

- Bascón-Villegas, I.; Sánchez-Gutiérrez, M.; Pérez-Rodríguez, F.; Espinosa, E.; Rodríguez, A. Lignocellulose Nanofibre Obtained from Agricultural Wastes of Tomato, Pepper and Eggplants Improves the Performance of Films of Polyvinyl Alcohol (PVA) for Food Packaging. Foods 2021, 10, 3043. [Google Scholar] [CrossRef]

- Olawuyi, I.F.; Kim, S.R.; Lee, W.Y. Application of plant mucilage polysaccharides and their techno-functional properties’ modification for fresh produce preservation. Carbohydr. Polym. 2021, 272, 118371. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.M.; Tucker, N.; Le Guen, M.J. Thermal, mechanical and viscoelastic properties of citric acid-crosslinked starch/cellulose composite foams. Carbohydr. Polym. 2020, 230, 115675. [Google Scholar] [CrossRef] [PubMed]

- Ravindran, R.; Jaiswal, A.K. A comprehensive review on pre-treatment strategy for lignocellulosic food industry waste: Challenges and opportunities. Bioresour. Technol. 2016, 199, 92–102. [Google Scholar] [CrossRef]

- Hossam, Y.; Fahim, I.S. Towards a circular economy: Fabrication and characterization of biodegradable plates from sugarcane waste. Front. Sustain. Food Syst. 2023, 7, 1220324. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Preparation and characterization of cornhusk/sugar palm fiber reinforced Cornstarch-based hybrid composites. J. Mater. Res. Technol. 2020, 9, 200–211. [Google Scholar] [CrossRef]

- Ai, B.; Zheng, L.; Li, W.; Zheng, X.; Yang, Y.; Xiao, D.; Shi, J.; Sheng, Z. Biodegradable Cellulose Film Prepared from Banana Pseudo-Stem Using an Ionic Liquid for Mango Preservation. Front. Plant Sci. 2021, 12, 625878. [Google Scholar] [CrossRef]

- Sethupathi, M.; Khumalo, M.V.; Skosana, S.J.; Muniyasamy, S. Recent Developments of Pineapple Leaf Fiber (PALF) Utilization in the Polymer Composites—A Review. Separations 2024, 11, 245. [Google Scholar] [CrossRef]

- Othman, M.H.; Main, N.M.; Mon, S.Z.K.; Mohamad, Z. Development of Paper Using Coir Fibers as a Packaging Product. Asian J. Sci. Res. 2013, 6, 207–216. [Google Scholar] [CrossRef]

- Liu, Q.; Loxton, C.; Mohamed, A.A.; Jawaid, M.; Braganca, R.; Elias, R. Development of pulp moulded packaging samples from empty fruit bunch fibre. Pertanika J. Sci. Technol. 2021, 29, 2901–2912. [Google Scholar] [CrossRef]

- Sukyai, P.; Anongjanya, P.; Bunyahwuthakul, N.; Kongsin, K.; Harnkarnsujarit, N.; Sukatta, U.; Sothornvit, R.; Chollakup, R. Effect of cellulose nanocrystals from sugarcane bagasse on whey protein isolate-based films. Food Res. Int. 2018, 107, 528–535. [Google Scholar] [CrossRef]

- Lima, E.M.B.; Middea, A.; Neumann, R.; Thiré, R.M.d.S.M.; Pereira, J.F.; de Freitas, S.C.; Penteado, M.S.; Lima, A.M.; Minguita, A.P.d.S.; Mattos, M.d.C.; et al. Biocomposites of PLA and Mango Seed Waste: Potential Material for Food Packaging and a Technological Alternative to Reduce Environmental Impact. Starch—Stärke 2021, 73, 2000118. [Google Scholar] [CrossRef]

- Freitas, P.A.V.; González-Martínez, C.; Chiralt, A. Using rice straw fractions to develop reinforced, active PLA-starch bilayers for meat preservation. Food Chem. 2023, 405, 134990. [Google Scholar] [CrossRef] [PubMed]

- Alaghemandi, M. Sustainable Solutions Through Innovative Plastic Waste Recycling Technologies. Sustainability 2024, 16, 10401. [Google Scholar] [CrossRef]

- Muñoz-Gimena, P.F.; Oliver-Cuenca, V.; Peponi, L.; López, D. A Review on Reinforcements and Additives in Starch-Based Composites for Food Packaging. Polymers 2023, 15, 2972. [Google Scholar] [CrossRef]

- Berthet, M.A.; Angellier-Coussy, H.; Chea, V.; Guillard, V.; Gastaldi, E.; Gontard, N. Sustainable food packaging: Valorising wheat straw fibres for tuning PHBV-based composites properties. Compos. Part A Appl. Sci. Manuf. 2015, 72, 139–147. [Google Scholar] [CrossRef]

- Sánchez-Safont, E.L.; Aldureid, A.; Lagarón, J.M.; Gámez-Pérez, J.; Cabedo, L. Biocomposites of different lignocellulosic wastes for sustainable food packaging applications. Compos. Part B Eng. 2018, 145, 215–225. [Google Scholar] [CrossRef]

- Said, N.S.; Lee, W.Y. Pectin-Based Active and Smart Film Packaging: A Comprehensive Review of Recent Advancements in Antimicrobial, Antioxidant, and Smart Colorimetric Systems for Enhanced Food Preservation. Molecules 2025, 30, 1144. [Google Scholar] [CrossRef]

- Elhussieny, A.; Faisal, M.; D’Angelo, G.; Aboulkhair, N.T.; Everitt, N.M.; Fahim, I.S. Valorisation of shrimp and rice straw waste into food packaging applications. Ain Shams Eng. J. 2020, 11, 1219–1226. [Google Scholar] [CrossRef]

- Benito-González, I.; López-Rubio, A.; Martínez-Sanz, M. High-performance starch biocomposites with celullose from waste biomass: Film properties and retrogradation behaviour. Carbohydr. Polym. 2019, 216, 180–188. [Google Scholar] [CrossRef] [PubMed]

- Chatrath, S.; Alotaibi, M.; Barry, C.F. Performance of Recycled Polylactic Acid/Amorphous Polyhydroxyalkanoate Blends. Polymers 2024, 16, 1230. [Google Scholar] [CrossRef] [PubMed]

- Iñiguez-Franco, F.; Auras, R.; Dolan, K.; Selke, S.; Holmes, D.; Rubino, M.; Soto-Valdez, H. Chemical recycling of poly(lactic acid) by water-ethanol solutions. Polym. Degrad. Stab. 2018, 149, 28–38. [Google Scholar] [CrossRef]

- Akram, M.A.; Savitha, R.; Kinsella, G.K.; Nolan, K.; Ryan, B.J.; Henehan, G.T. Microbial and Enzymatic Biodegradation of Plastic Waste for a Circular Economy. Appl. Sci. 2024, 14, 11942. [Google Scholar] [CrossRef]

- Sourkouni, G.; Jeremić, S.; Kalogirou, C.; Höfft, O.; Nenadovic, M.; Jankovic, V.; Rajasekaran, D.; Pandis, P.; Padamati, R.; Nikodinovic-Runic, J.; et al. Study of PLA pre-treatment, enzymatic and model-compost degradation, and valorization of degradation products to bacterial nanocellulose. World J. Microbiol. Biotechnol. 2023, 39, 161. [Google Scholar] [CrossRef]

- Selvam, T.; Rahman, N.; Olivito, F.; Ilham, Z.; Ahmad, R.; Wan-Mohtar, W. Agricultural Waste-Derived Biopolymers for Sustainable Food Packaging: Challenges and Future Prospects. Polymers 2025, 17, 1897. [Google Scholar] [CrossRef]

- Eder, S.; Zueblin, P.; Diener, M.; Peydayesh, M.; Boulos, S.; Mezzenga, R.; Nyström, L. Effect of Polysaccharide Conformation on Ultrafiltration Separation Performance. Carbohydr. Polym. 2021, 260, 117830. [Google Scholar] [CrossRef]

- Aaliya, B.; Sunooj, K.V.; Lackner, M. Biopolymer composites: A review. Int. J. Biobased Plast. 2021, 3, 40–84. [Google Scholar] [CrossRef]

- D’Almeida, A.P.; de Albuquerque, T.L. Innovations in Food Packaging: From Bio-Based Materials to Smart Packaging Systems. Processes 2024, 12, 2085. [Google Scholar] [CrossRef]

- Raza, M.Y.; Lin, B. Analysis of Pakistan’s electricity generation and CO2 emissions: Based on decomposition and decoupling approach. J. Clean. Prod. 2022, 359, 132074. [Google Scholar] [CrossRef]

- Leal Filho, W.; Barbir, J.; Venkatesan, M.; Lange Salvia, A.; Dobri, A.; Bošković, N.; Eustachio, J.; Ingram, I.; Dinis, M.A.P. Policy Gaps and Opportunities in Bio-Based Plastics: Implications for Sustainable Food Packaging. Foods 2025, 14, 1955. [Google Scholar] [CrossRef] [PubMed]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Alaimo, G.; Morreale, M. Green Composites Based on PLA and Agricultural or Marine Waste Prepared by FDM. Polymers 2021, 13, 1361. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Wu, Z.; Li, A.; Chen, N.; Rao, J.; Zeng, Q. Nanocellulose Composite Films in Food Packaging Materials: A Review. Polymers 2024, 16, 423. [Google Scholar] [CrossRef]

- Jarzębski, M.; Smułek, W.; Baranowska, H.M.; Masewicz, Ł.; Kobus-Cisowska, J.; Ligaj, M.; Kaczorek, E. Characterization of St. John’s wort (Hypericum perforatum L.) and the impact of filtration process on bioactive extracts incorporated into carbohydrate-based hydrogels. Food Hydrocoll. 2020, 104, 105748. [Google Scholar] [CrossRef]

- Versino, F.; Ortega, F.; Monroy, Y.; Rivero, S.; López, O.V.; García, M.A. Sustainable and Bio-Based Food Packaging: A Review on Past and Current Design Innovations. Foods 2023, 12, 1057. [Google Scholar] [CrossRef]

- Zimmermann, L.; Dombrowski, A.; Völker, C.; Wagner, M. Are bioplastics and plant-based materials safer than conventional plastics? In vitro toxicity and chemical composition. Environ. Int. 2020, 145, 106066. [Google Scholar] [CrossRef]

- Weinstein, J.E.; Dekle, J.L.; Leads, R.R.; Hunter, R.A. Degradation of bio-based and biodegradable plastics in a salt marsh habitat: Another potential source of microplastics in coastal waters. Mar. Pollut. Bull. 2020, 160, 111518. [Google Scholar] [CrossRef]

- Castagna, A.; Aboudia, A.; Guendouz, A.; Scieuzo, C.; Falabella, P.; Matthes, J.; Schmid, M.; Drissner, D.; Allais, F.; Chadni, M.; et al. Transforming Agricultural Waste from Mediterranean Fruits into Renewable Materials and Products with a Circular and Digital Approach. Materials 2025, 18, 1464. [Google Scholar] [CrossRef]

- Arias, A.; Feijoo, G.; Moreira, M.T. Biorefineries as a driver for sustainability: Key aspects, actual development and future prospects. J. Clean. Prod. 2023, 418, 137925. [Google Scholar] [CrossRef]

- Rodríguez, A.; Eugenio Martin, M.E. Alternative Raw Materials for Pulp and Paper Production in the Concept of a Lignocellulosic Biorefinery. In Cellulose; Rodríguez, A., Eugenio Martin, M.E., Eds.; IntechOpen: Rijeka, Croatia, 2019. [Google Scholar]

- Porichha, G.K.; Hu, Y.; Rao, K.T.V.; Xu, C.C. Crop Residue Management in India: Stubble Burning vs. Other Utilizations including Bioenergy. Energies 2021, 14, 4281. [Google Scholar] [CrossRef]

- Peng, Y.; Lei, W.; Yu, W.; Chen, Y. Effect of Sugarcane Bagasse Content and Modification on the Properties of Sugarcane Bagasse/Poly(lactic Acid) Biocomposites. Molecules 2025, 30, 1583. [Google Scholar] [CrossRef] [PubMed]

- Gioia, C.; Giacobazzi, G.; Vannini, M.; Totaro, G.; Sisti, L.; Colonna, M.; Marchese, P.; Celli, A. End of Life of Biodegradable Plastics: Composting versus Re/Upcycling. ChemSusChem 2021, 14, 4167–4175. [Google Scholar] [CrossRef] [PubMed]

- Firoiu, D.; Ionescu, G.H.; Cismaș, C.M.; Costin, M.P.; Cismaș, L.M.; Ciobanu, Ș.C.F. Sustainable Production and Consumption in EU Member States: Achieving the 2030 Sustainable Development Goals (SDG 12). Sustainability 2025, 17, 1537. [Google Scholar] [CrossRef]

| Source | Composition | Packaging Application | Key properties and Benefits | Ref. |

|---|---|---|---|---|

| Wheat straw | Rich in cellulose (~40%), hemicellulose, lignin. | Molded pulp trays and packaging inserts | High strength comparable or superior to EPS foam (tensile modulus ~0.47 MPa for 80% straw vs. 0.16 MPa for EPS) and fully biodegradable. | [15,16] |

| Rice husks | High lignocellulosic fiber content (≈35–45% cellulose); also contain silica. | Reinforcement in bioplastic films | Enhanced tensile strength (~60% improvement with husk fiber addition) and reduced reliance on synthetic polymers. Often also imparts antimicrobial or antioxidant properties when treated | [17] |

| Sugarcane bagasse | Fibrous residue of sugar cane; ~40–50% cellulose, 25–35% hemicellulose, 20–25% lignin. | Biodegradable tableware; filler in biopolymer composites | Improves composite stiffness and lowers water permeability. Bagasse–fiber composites show reduced water vapor transmission and competitive mechanical strength, and are fully compostable in disposal. | [18,19] |

| Corn husks and stover | High cellulose fiber content | Pulp for paper and cardboard packaging; biodegradable paper products | Can replace wood pulp fibers in paper packaging up to ~80% without loss of strength. Corn husk fibers provide adequate mechanical integrity for paper and are renewable alternatives to wood. | [20,21] |

| Mixed fruit peels | Rich in pectin, starches, and polyphenolic antioxidants. | Bioplastic films and edible packaging | Intrinsically antimicrobial and antioxidant; helps extend shelf-life of fresh produce by inhibiting spoilage. For example, peel-derived films showed antimicrobial activity and prolonged fruit freshness. | [22,23] |

| Apple pomace and peel | High in pectin and polyphenols (antioxidants). | Active food packaging films | Provides antioxidant and antimicrobial functions. Apple peel polyphenol-infused films inhibit bacterial growth, suitable for meat or perishable foods. | [17,21] |

| Citrus peels | High pectin content; flavonoids and essential oils present. | Coatings and laminates for paper or bioplastic films. For instance, mandarin peel extract is used as a paper coating. | Improved barrier properties: coatings from citrus waste significantly reduced gas and water permeability and oxygen transmission of Kraft paper. Also adds antioxidant capacity to packaging. | [24] |

| Potato peels | Contain starch, dietary fiber, some protein, and phenolics. | Edible films and loose-fill foam packaging. Also used in biodegradable packing peanuts. | Potato peel-derived films exhibit an elastic modulus of 36 MPa, comparable to low-density polyethylene (LDPE, 25–80 MPa), demonstrating sufficient stiffness for flexible packaging. Native peel lipids and phenolic compounds reduce surface energy, yielding enhanced hydrophobicity (water contact angle > 80°). Foam articles molded from potato peel pulp cushion shocks as effectively as expanded polystyrene peanuts, yet are fully compostable under industrial conditions. | [25,26] |

| Sweet potato starch | Starch from sweet potato; reinforced with fibrous residues | Compostable foam trays for food packaging | Fiber reinforcement greatly improves both compressive strength and heat resistance of sweet potato starch foams. A formulation containing 5 wt% bagasse and asparagus fiber retained its cell structure up to higher temperatures, demonstrating enhanced dimensional and mechanical stability under heat, while also exhibiting lower water uptake than an unfilled starch foam. | [27] |

| Parsley and spinach stems | Dried herb, vegetable stems | Filler in bio-composite films | Acts as a natural filler and active additive. High loading (30–70 wt%) of micronized parsley and spinach stems in a biopolymer film provided antioxidant activity and added fiber reinforcement. | [28] |

| Sawdust and wood chips | Primarily cellulose (~50%) and lignin (~25%); fibrous wood pulp. | Molded fiber packaging (trays, plates, panels) as an alternative to Styrofoam. | Excellent strength-to-weight ratio and shock absorption. Pulp molded from wood, sawdust achieves comparable tensile strength to EPS foam, while being biodegradable. Often used in combination with other agro-fibers to improve sustainability and reduce cost. | [15,16] |

| Pine needles | Dried pine leaves; ~40% cellulose, high aromatic extractives. | Functional paper and fiber boards with active properties (e.g., ethylene-scavenging fruit packaging paper). | Pine-needle pulp provides a porous, renewable matrix for nano-zeolite impregnation. The zeolite adsorbs up to 62% of ethylene gas emitted by fruits at ambient temperature, slowing ripening and extending shelf-life. By valorizing forest residues, a wildfire fuel hazard, into a support for active ethylene scavengers, this approach creates high-value, compostable packaging. | [29] |

| Coconut coir fiber | High lignin (~41–45%) and moderate cellulose (~36–43%) content; very durable natural fiber. | Reinforcement in biopolymer composites (e.g., PLA or starch-based films, molded items). | Improves tensile strength and moisture resistance of composites. Coir-PLA biocomposites showed ~40% higher tensile properties than many other natural fiber composites. High lignin content imparts hydrophobicity, reducing water absorption in packaging. | [30] |

| Brewers’ spent grain | Mixture of fiber (cellulose ~17%, hemicellulose ~28%), protein (~20%), lignin (~12%), plus polyphenols. | Filler in biodegradable films and foils (starch, Polyvinyl alcohol (PVA), or PLA-based); also processed into paper sheets. | Films and coatings made from brewer’s spent grain (BSG) combine the grain’s residual proteins and phenolic compounds with its fibrous cellulose matrix. The protein–fiber network increases tensile strength and reduces gas permeability, while the bound phenolics provide antioxidant activity and UV-scavenging “active” functionality. This valorizes a high-volume brewery byproduct into fully compostable packaging with both barrier and active properties. | [31] |

| Residual coffee grounds | Lignocellulosic biomass with high lignin (~30%), cellulose (~15–20%), oils, and coffee polyphenols. | Pulped into paper sheets and molded packaging; also used as filler in bioplastics. | After solvent pre-treatment to remove oils, coffee grounds can yield cellulose-rich pulp for paper. The resulting packaging is biodegradable and can incorporate coffee’s bioactive compounds for antioxidant and antimicrobial effects. Diverts large amounts of coffee waste from landfills | [32] |

| Flax fiber residues | Very high cellulose content with some hemicellulose and lignin. | Reinforcement fiber in plastic composites | A 50:50 (w/w) flax-fiber/polypropylene composite, not a simple polymer blend, achieves up to 25% higher tensile strength and 15% greater flexural stiffness than neat PP under identical processing conditions. Under standardized Izod impact testing, this formulation also absorbs more energy before fracture. Such gains in impact performance require the selection of a relatively low molecular weight PP matrix and will vary with resin grade, fiber treatment, and test metric used. | [33] |

| Plant Waste | CEL, % | HO, % | LP, % | PCT, % | STR, % | PRO, % | Functional Components | Ref. |

|---|---|---|---|---|---|---|---|---|

| Wheat straw | 32–47 | 19–35 | 5–24 | 5 | - | 3–5 | 1% wax (cuticular lipid) | [38] |

| Rice straw | 30–38 | 19–32 | 7–13 | 2.8 | - | 3 | trace waxes present | [38] |

| Sugarcane bagasse | 40–50 | 25–35 | 20 | - | - | 1–3 | minor waxes/extractives (~5% total) | [39] |

| Rice husk | 35 | 25 | 20 | - | - | 3 | high silica ash (~17% inorganic) | [40] |

| Corn stover | 35–50 | 20–35 | 12–20 | 5 | - | 3 | - | [41] |

| Banana peel | 7.6–9.6 | 6.4–9.4 | 6–12 | 10–21 | 3 | 6–9 | 3.8–11% crude lipids; polyphenols 0.2–0.85% (tannic eq) | [42] |

| Coconut husk | 32–50 | 0.2–15 | 30–46 | 3–4 | - | - | - | [43] |

| Pineapple leaf fiber | 80 | 6–12 | 5–12 | - | - | - | - | [44] |

| Orange peel | 22 | 11 | 2 | 25 | - | 6 | - | [45] |

| Plant Waste | Main Processing Steps | Packaging Format | Ref. |

|---|---|---|---|

| Sugarcane bagasse | Cleaning and mechanically pulping to obtain fibrous pulp; pulp is molded into shape and heat-dried | Molded fiber products | [60] |

| Wheat straw | Chemical pulping to isolate straw fibers; fiber pulp molded under pressure into products | Molded pulp packaging | [60] |

| Rice husk | Mechanical grinding of rice husks into fine flour; melt-blended with biopolymer and thermo-compression molded | Bioplastic composite films | [17] |

| Corn husk | Alkaline pretreatment and fiber extraction from corn husks; fibers mixed with plasticized starch and solution cast into films | Hybrid starch-based films | [61] |

| Banana pseudo-stem fiber | Chemical delignification (acid and alkali) to extract cellulose from banana stem fibers; cellulose dissolved in ionic liquid and cast into films | Pure cellulose films | [62] |

| Pineapple leaf fiber | Acid hydrolysis to obtain cellulose nanocrystals (CNC) from pineapple leaf waste, CNC dispersed in polymer (PVA) solution, and cast into films | Bionanocomposite films | [63] |

| Coconut coir fiber | Alkaline treatment of coir (coconut husk) fibers for improved adhesion; fibers extruded or compounded with bio-polymers and molded | Fiber-reinforced biocomposites | [64] |

| Cocoa pod husk | Alkaline pulping of cocoa pod husks to extract cellulose; cellulose (with optional added fibers) solution cast into film form | Cellulose-based films | [17] |

| Oil palm EFB fiber | Mechanical refining of oil palm empty fruit bunch (EFB) fibers into pulp; vacuum-assisted molding of wet pulp into designed shapes | Molded pulp trays | [65] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kossalbayev, B.D.; Belkozhayev, A.M.; Abaildayev, A.; Kadirshe, D.K.; Tastambek, K.T.; Kurmanbek, A.; Toleutay, G. Biodegradable Packaging from Agricultural Wastes: A Comprehensive Review of Processing Techniques, Material Properties, and Future Prospects. Polymers 2025, 17, 2224. https://doi.org/10.3390/polym17162224

Kossalbayev BD, Belkozhayev AM, Abaildayev A, Kadirshe DK, Tastambek KT, Kurmanbek A, Toleutay G. Biodegradable Packaging from Agricultural Wastes: A Comprehensive Review of Processing Techniques, Material Properties, and Future Prospects. Polymers. 2025; 17(16):2224. https://doi.org/10.3390/polym17162224

Chicago/Turabian StyleKossalbayev, Bekzhan D., Ayaz M. Belkozhayev, Arman Abaildayev, Danara K. Kadirshe, Kuanysh T. Tastambek, Akaidar Kurmanbek, and Gaukhar Toleutay. 2025. "Biodegradable Packaging from Agricultural Wastes: A Comprehensive Review of Processing Techniques, Material Properties, and Future Prospects" Polymers 17, no. 16: 2224. https://doi.org/10.3390/polym17162224

APA StyleKossalbayev, B. D., Belkozhayev, A. M., Abaildayev, A., Kadirshe, D. K., Tastambek, K. T., Kurmanbek, A., & Toleutay, G. (2025). Biodegradable Packaging from Agricultural Wastes: A Comprehensive Review of Processing Techniques, Material Properties, and Future Prospects. Polymers, 17(16), 2224. https://doi.org/10.3390/polym17162224