Production Technologies and Application of Polymer Composites in Engineering: A Review

Abstract

1. Introduction

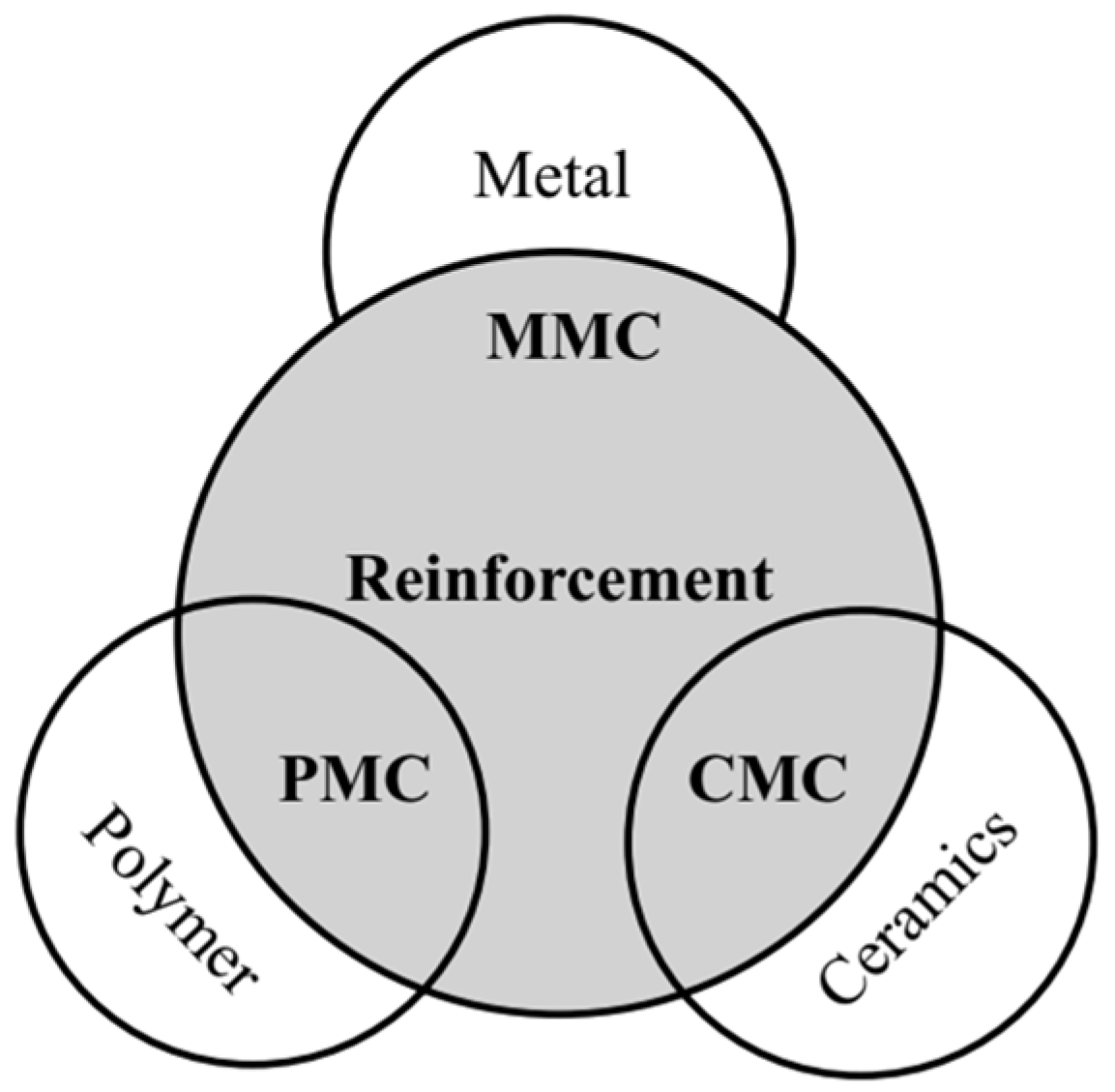

2. Polymer Composites: Characteristics and Manufacturing

2.1. Conventional Manufacturing Technologies

- Extrusion molding;

- Injection molding;

- Calendaring;

- Hot pressing;

- Resin transfer molding;

- Filament;

- Winding;

- Pultrusion;

- Vacuum bagging.

2.2. Advanced Manufacturing Technologies

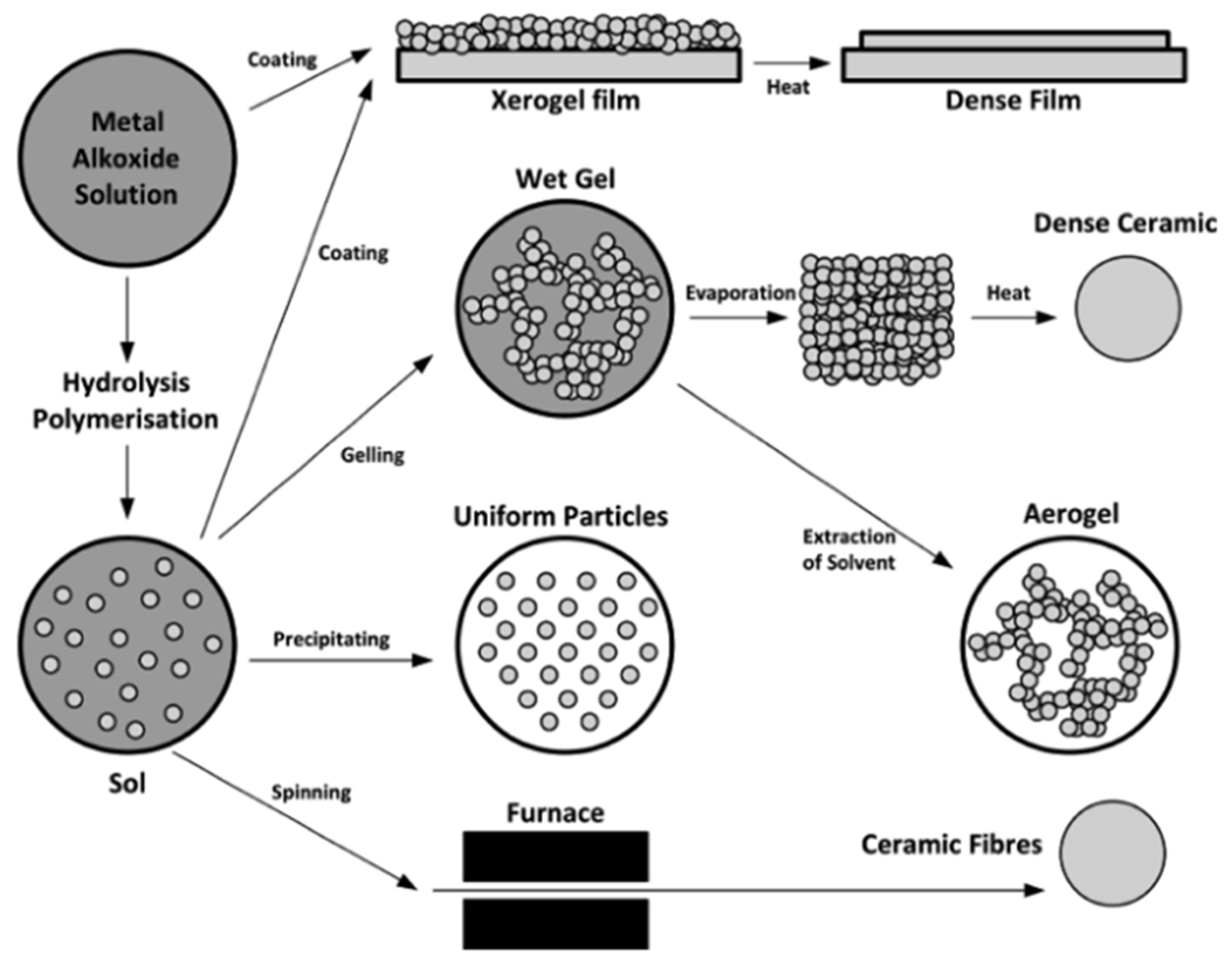

- Surface Coating Technology: This method involves applying a thin film onto a prepared substrate surface. Its key advantages include applicability to a wide range of materials, adaptability to various operating conditions, and low cost of raw materials and process execution. However, controlling coating thickness and the need for post-processing are common drawbacks. Applications include corrosion protection, pipeline construction, antibacterial coatings, and drug handling systems [28,29];

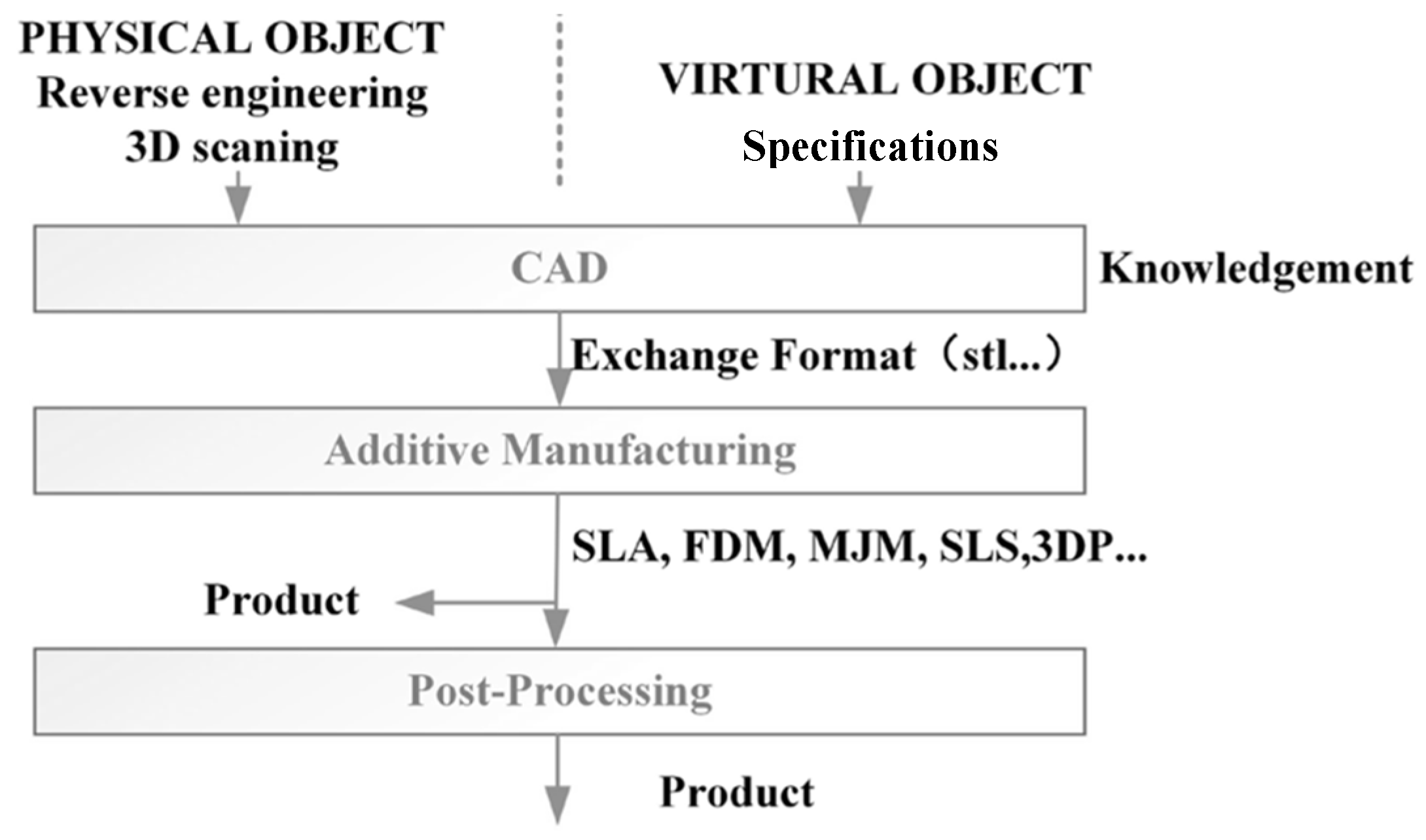

- Additive Manufacturing: Additive manufacturing operates on a bottom-up layering principle, allowing for high precision and the formation of stable internal structures [30,31]. The major advantages are design flexibility and ease of automation. However, limitations include the restricted volume of processed material and relatively slow production speeds [32,33]. Additive manufacturing is widely used in biomedicine [34,35], electronics, and aerospace applications [36,37];

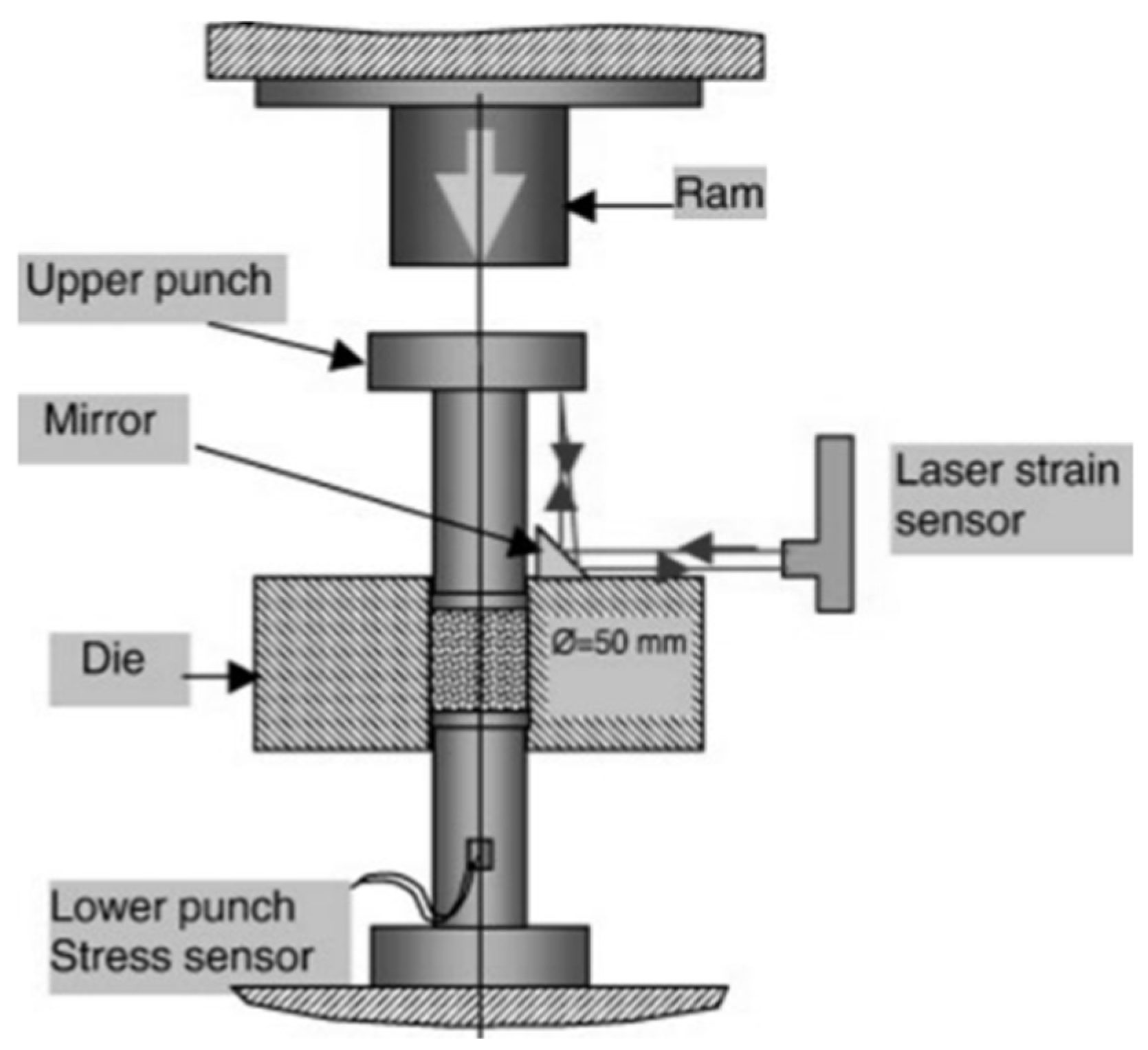

- Magnetic Pulse Powder Compaction Technology: This technique consolidates powders using pulse-modulated electromagnetic field pressure. It is advantageous due to low cost, fast processing, and simplicity of use, but suffers from low overall efficiency. Its applications span medicine [38], ceramic composite manufacturing [39], and packaging materials [40].

2.3. Influence of Manufacturing Processes

- The type and characteristics of the matrix;

- The form and geometry of raw materials;

- The desired final shape of the composite;

- The targeted application, whether for macro or micro use environments [41].

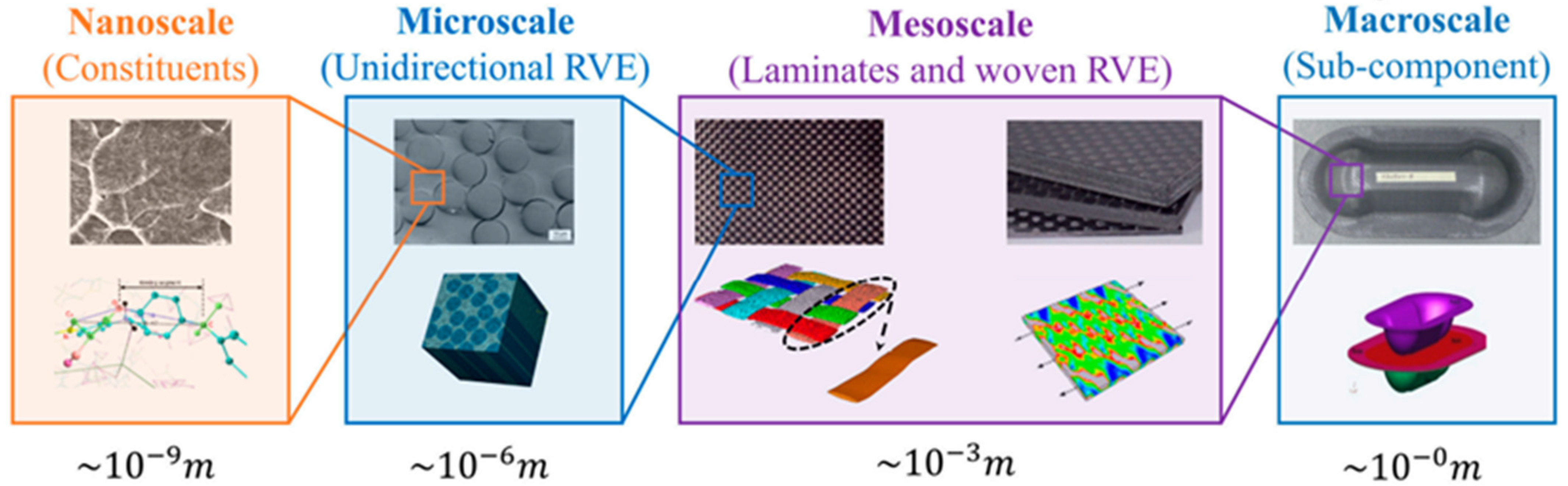

2.4. Macro-, Micro-, and Mesoscale Considerations

3. Polymer Surface Treatment Technologies

3.1. Surface Coating

3.2. Additive Production Technology

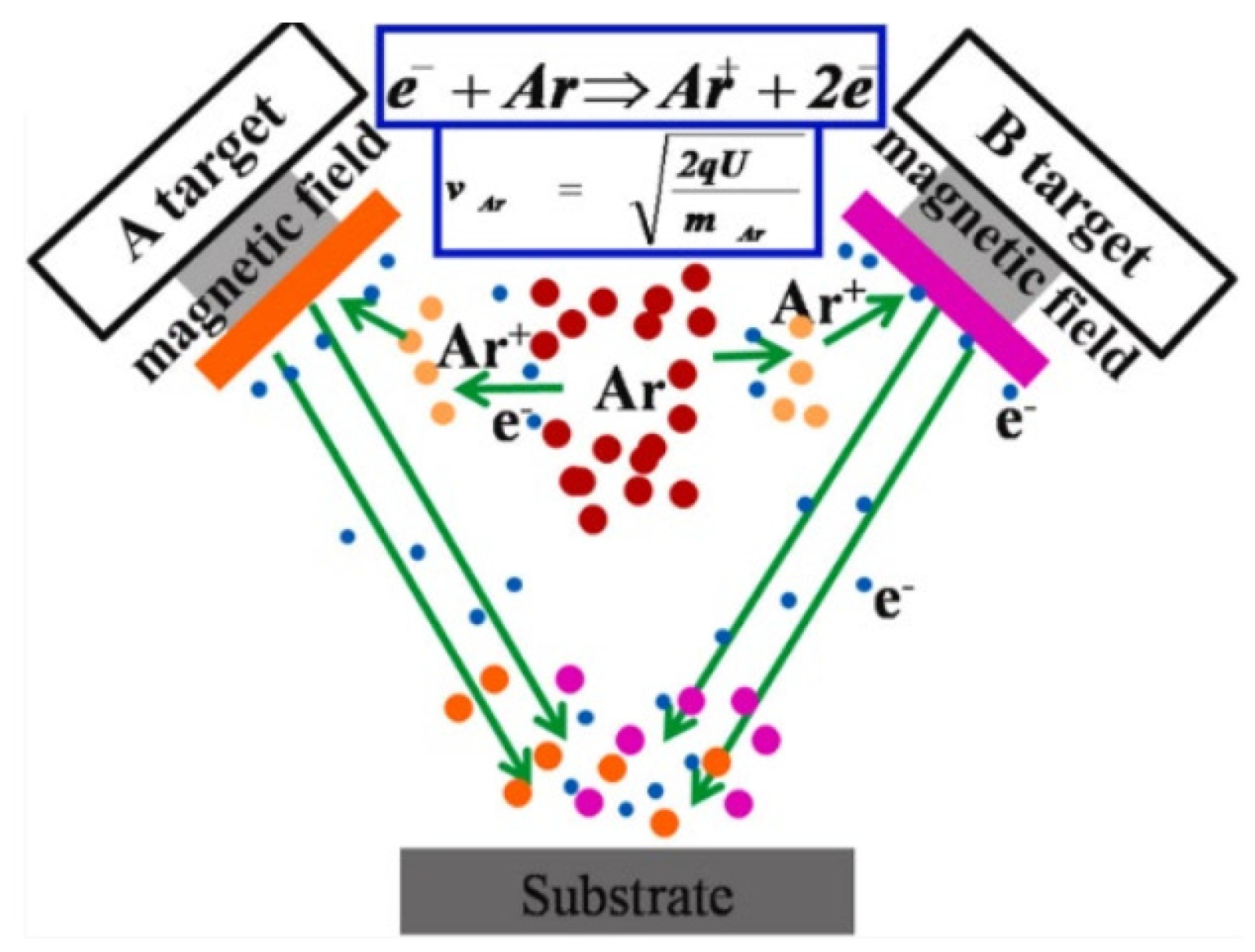

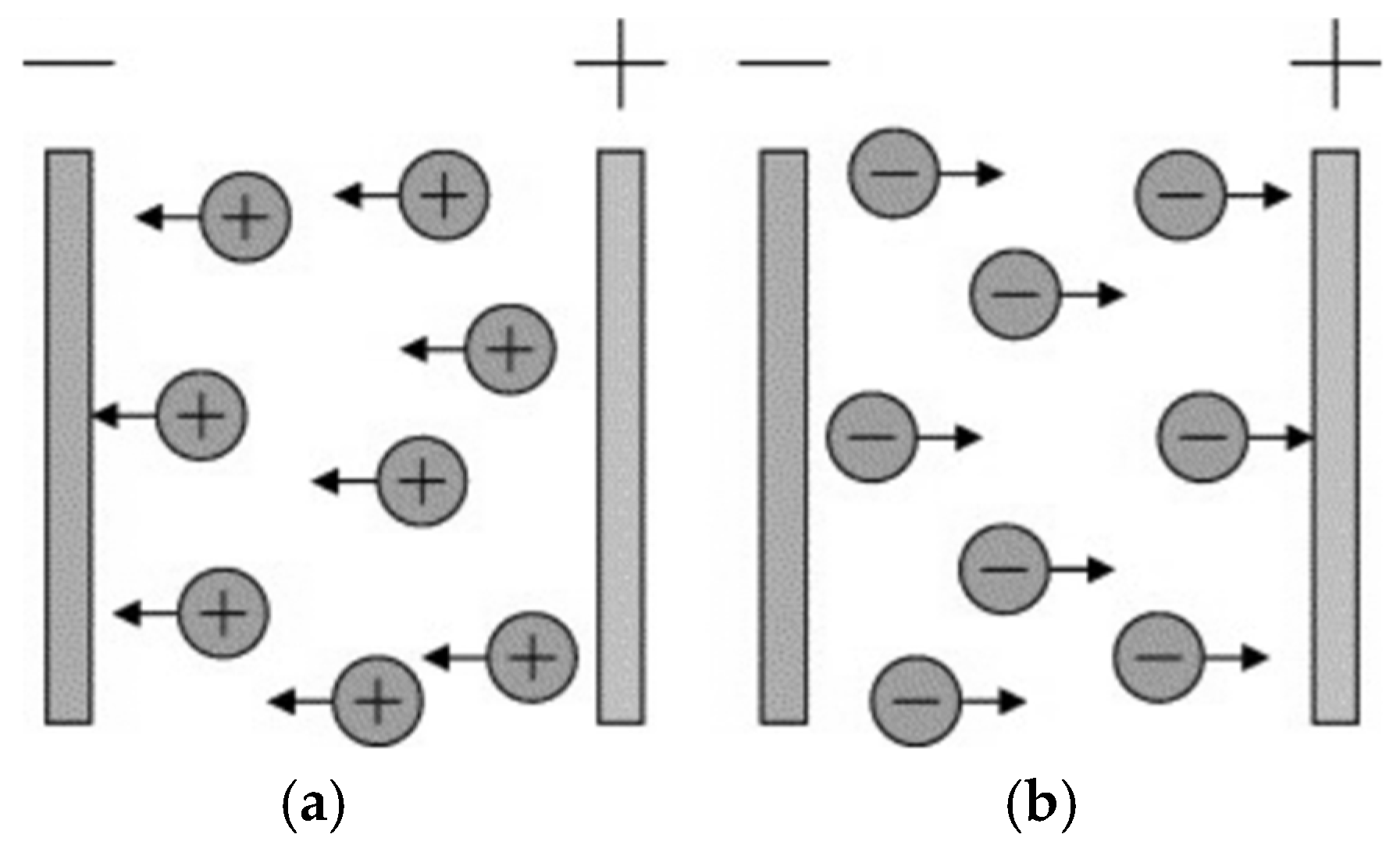

3.3. Magnetic Technology

4. Applications of Polymer Composite Materials

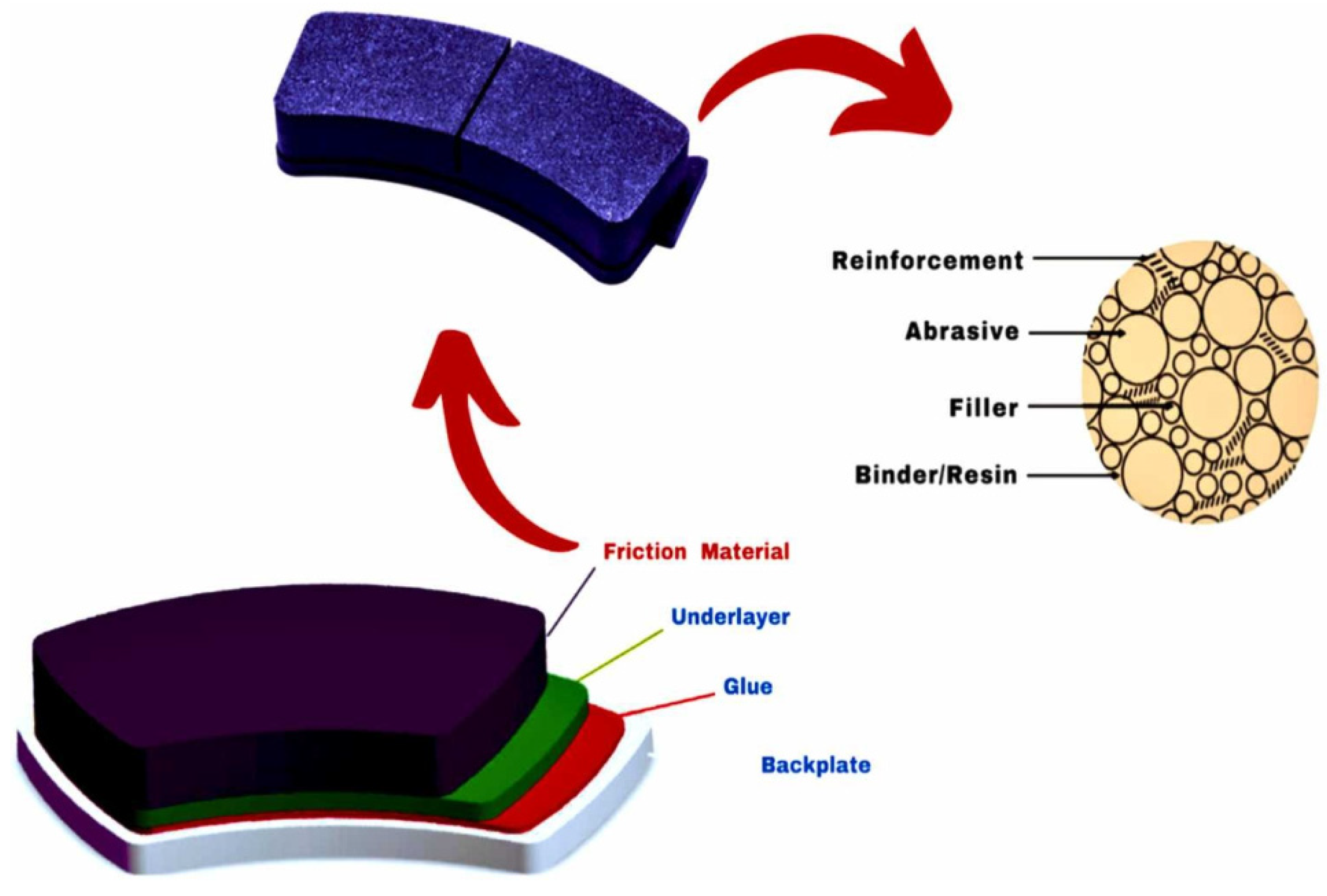

4.1. Application of Polymer Composites in the Automotive Industry

4.2. Application of Polymer Composites in Medicine

4.3. Application of Polymer Composites in the Military Industry

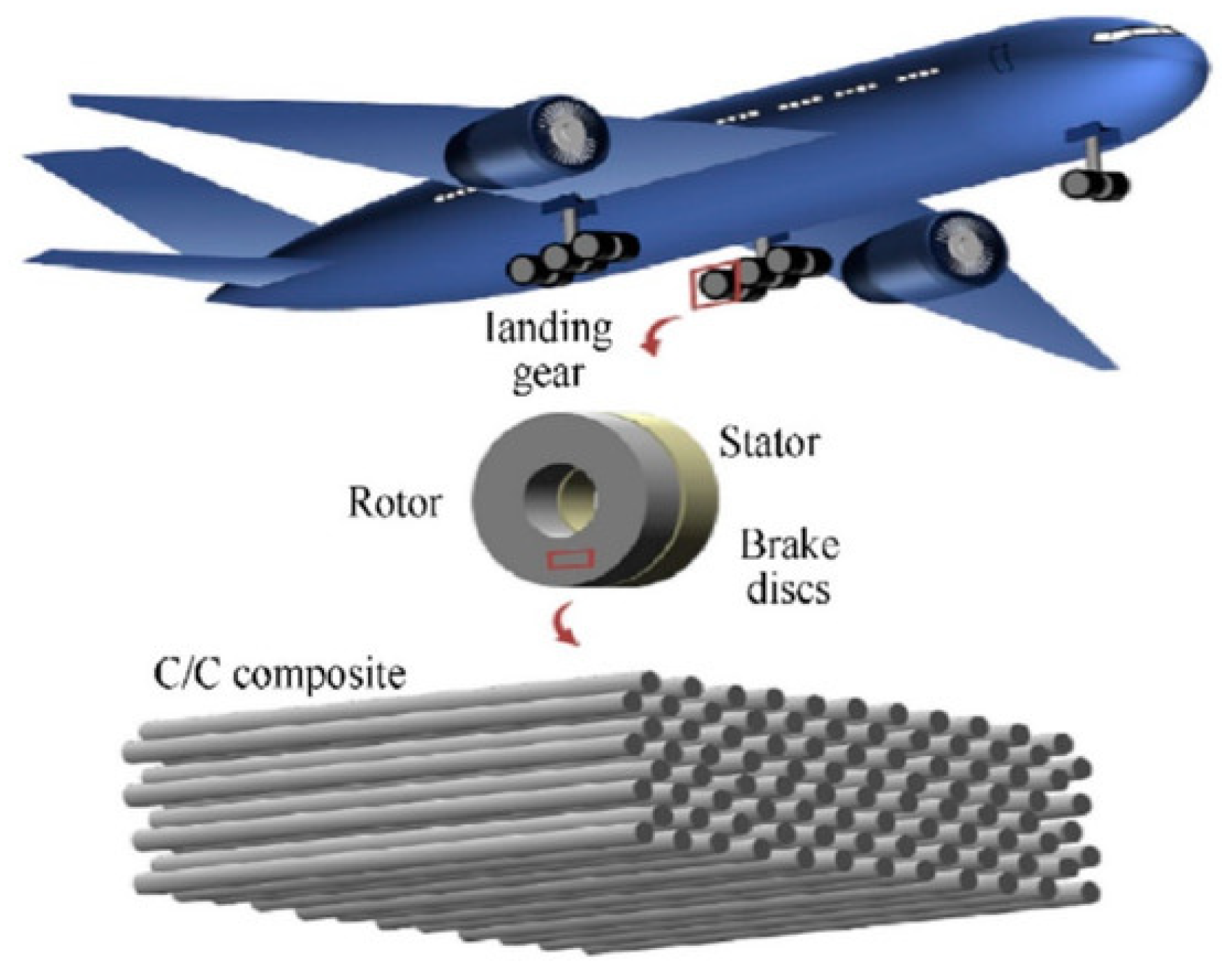

4.4. Application of Polymer Composites in the Aviation Industry

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ngo, T. Introduction to composite materials. In IntechOpen eBooks; Intechopen: London, UK, 2020. [Google Scholar] [CrossRef]

- Abramovich, H. Introduction to composite materials. In Stability and Vibrations of Thin-Walled Composite Structures; Woodhead Publishing: Cambridge, UK, 2017; pp. 1–47. [Google Scholar] [CrossRef]

- Baley, C.; Bourmaud, A.; Davies, P. Eighty years of composites reinforced by flax fibres: A historical review. Compos. Part A Appl. Sci. Manuf. 2021, 144, 106333. [Google Scholar] [CrossRef]

- Kurihara, Y. Polymer matrix composite materials in automobile industries. Adv. Compos. Mater. 1995, 4, 209–219. [Google Scholar] [CrossRef]

- Seydibeyoğlu, M.Ö.; Doğru, A.; Kandemir, M.B.; Aksoy, Ö. Lightweight composite materials in transport structures. In Lightweight Polymer Composite Structures; CRC Press: Boca Raton, FL, USA, 2020; pp. 103–130. [Google Scholar] [CrossRef]

- Kurien, R.A.; Selvaraj, D.P.; Sekar, M.; Koshy, C.P. Green composite materials for green technology in the automotive industry. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, England, 2020; Volume 872, p. 012064. [Google Scholar] [CrossRef]

- Kaymaz, I.C.; Dogru, A.; Seydibeyoglu, M.O. Hybrid composites for railway and transportation uses—A review. Appl. Sci. Eng. Prog. 2022, 15, 5801. [Google Scholar] [CrossRef]

- Wazeer, A.; Das, A.; Abeykoon, C.; Sinha, A.; Karmakar, A. Composites for electric vehicles and automotive sector: A review. Green Energy Intell. Transp. 2023, 2, 100043. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Kandakodeeswaran, K.; Maheswaran, K.; Geetha, M. Investigation on mechanical properties of automobile strut made by GFRP composites. Mater. Today Proc. 2021, 45, 1338–1347. [Google Scholar] [CrossRef]

- Khan, L.; Mehmood, A. Cost-effective composites manufacturing processes for automotive applications. In Lightweight Composite Structures in Transport; Woodhead Publishing: Cambridge, UK, 2015; pp. 93–119. [Google Scholar] [CrossRef]

- Bogoeva-Gaceva, G.; Avella, M.; Malinconico, M.; Bužarovska, A.; Grozdanov, A.; Gentile, G.; Errico, M.E. Natural fiber eco-composites. Polym. Compos. 2007, 28, 98–107. [Google Scholar] [CrossRef]

- Zhang, D.; Xiao, L.; Wang, Y.; Huang, G. Study on vehicle fire safety: Statistic, investigation methods and experimental analysis. Saf. Sci. 2019, 117, 194–204. [Google Scholar] [CrossRef]

- Amran, Y.M.; Alyousef, R.; Rashid, R.S.; Alabduljabbar, H.; Hung, C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Arya, A.; Ahamad, A.; Kumar, P.; Chandra, A. A review on lignin-based nanocomposites: Fabrication, characterisation and application. Mater. Today Proc. 2023, 78, A10–A15. [Google Scholar] [CrossRef]

- Shah, D.U.; Porter, D.; Vollrath, F. Can silk become an effective reinforcing fibre? Compos. Sci. Technol. 2014, 101, 173–183. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2000, 10, 19–26. [Google Scholar] [CrossRef]

- Yang, H.S.; Wolcott, M.P.; Kim, H.S.; Kim, H.J.; Kim, S. Thermal properties of lignocellulosic filler–thermoplastic polymer bio-composites. Compos. Interfaces 2020, 27, 539–553. [Google Scholar] [CrossRef]

- Campbell, F.C. Structural Composite Materials; ASM International: Almere, The Netherlands, 2010; ISBN 978-1615030378. [Google Scholar]

- Thomson, R.S.; Orifici, A.C.; Degenhardt, R. Composite Structures in Aerospace Engineering; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Gibson, A.G.; Mizen, D.W.; Wang, W. Impact performance of nanocomposite-modified aerospace laminates. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106512. [Google Scholar]

- Kalita, S.J.; Bhardwaj, A.; Bhatt, H.A. Nanocrystalline calcium phosphate ceramics in biomedical engineering. Mater. Sci. Eng. C 2007, 27, 441–449. [Google Scholar] [CrossRef]

- Ferracane, J.L. Resin composite—State of the art. Dent. Mater. 2011, 27, 29–38. [Google Scholar] [CrossRef]

- Ilie, N.; Hickel, R. Resin composite restorative materials. Aust. Dent. J. 2015, 60, 59–66. [Google Scholar] [CrossRef]

- Stojanovic, B.; Babic, M.; Mitrovic, S.; Vencl, A.; Miloradović, N.; Pantić, M. Tribological characteristics of aluminium hybrid composites reinforced with silicon carbide and graphite. J. Balk. Tribol. Assoc. 2013, 19, 83–96. [Google Scholar]

- Li, Z.J.; Zhang, Y.S.; Zhou, X.M. Short fiber reinforced geopolymer composites manufactured by extrusion. J. Mater. Civ. Eng. 2005, 17, 624–631. [Google Scholar] [CrossRef]

- Liu, S.J. Injection molding in polymer matrix composites. In Manufacturing Technology of Polymer Matrix Composites (PMCs); Woodhead Publishing: Cambridge, UK, 2012; pp. 15–46. [Google Scholar] [CrossRef]

- Alizadeh-Osgouei, M.; Li, Y.; Wen, C. A comprehensive review of biodegradable synthetic polymer-ceramic composites and their manufacture for biomedical applications. Bioact. Mater. 2019, 4, 22–36. [Google Scholar] [CrossRef] [PubMed]

- Oladapo, B.I.; Zahedi, S.A.; Ismail, S.O.; Omigbodun, F.T. 3D printing of PEEK and its composite to increase biointerfaces as a biomedical material—A review. Colloids Surf. B Biointerfaces 2021, 203, 111726. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric composites for powder-based additive manufacturing: Materials and applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- Thiruchitrambalam, M.; Kumar, D.B.; Shanmugam, D.; Jawaid, M. A review on PEEK composites–Manufacturing methods, properties and applications. Mater. Today Proc. 2020, 33, 1085–1092. [Google Scholar] [CrossRef]

- Alshahrani, H.A. Review of 4D printing materials and reinforced composites: Behaviors, applications and challenges. J. Sci. Adv. Mater. Devices 2021, 6, 167–185. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, D.; Pei, X.; Wu, X.; Xu, F.; Wang, H.; Cao, M.; Chen, H. Investigation of electromagnetic pulse compaction on conducting graphene/PEKK composite powder. Materials 2021, 14, 636. [Google Scholar] [CrossRef] [PubMed]

- Inamuddin; Boddula, R.; Ahamed, M.I.; Asiri, A.M. Polymers Coatings: Technology and Applications; CRC Press: Boca Raton, FL, USA, 2020; ISBN 978-1-119-65514-5. [Google Scholar]

- Zhao, L.; Lee, V.K.; Yoo, S.S.; Dai, G.; Intes, X. The integration of 3-D cell printing and mesoscopic fluorescence molecular tomography of vascular constructs within thick hydrogel scaffolds. Biomaterials 2012, 33, 5325–5332. [Google Scholar] [CrossRef] [PubMed]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A simple, low-cost conductive composite material for 3D printing of electronic sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef]

- Invernizzi, M.; Natale, G.; Levi, M.; Turri, S.; Griffini, G. UV-assisted 3D printing of glass and carbon fiber-reinforced dual-cure polymer composites. Materials 2016, 9, 583. [Google Scholar] [CrossRef]

- Li, M. Microstructure and Properties of TI6AL4V Alloy Prepared by Magnetic Pulse Compaction and Sintering of Hydrogenated Powder. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2011. [Google Scholar]

- Shi, J. Study on Simulation and Research on Forming Mechanism in Low-voltage Electromagnetic Compaction of Function Ceramics. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2006. [Google Scholar]

- Liu, Y.Z. Study on Densifying Behavior of Electromagnetic Compaction of High Indium and Tin Silver Based Brazing Filler Metal. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2018. [Google Scholar]

- Olowokere, J.A.; Akpan, U.G.; Okafor, J.O.; Auta, S.M. Advances and development in hybrid polymer composite: The way forward. J. Eng. Res. Rep. 2022, 23, 281–295. [Google Scholar] [CrossRef]

- Müzel, D.; Bonhin, E.P.; Guimarães, N.M.; Guidi, E.S. Application of the finite element method in the analysis of composite materials: A review. Polymers 2020, 12, 818. [Google Scholar] [CrossRef]

- Bostanabad, R.; Liang, B.; Gao, J.; Liu, W.K.; Cao, J.; Zeng, D.; Su, X.; Xu, H.; Li, Y.; Chen, W. Uncertainty quantification in multiscale simulation of woven fiber composites. Comput. Methods Appl. Mech. Eng. 2018, 338, 506–532. [Google Scholar] [CrossRef]

- Dai, D.; Fan, M. Wood fibres as reinforcements in natural fibre composites: Structure, properties, processing and applications. In Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2014; pp. 3–65. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Naveen, J.; Satheeshkumar, S. Hybrid fibre reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 454–471. [Google Scholar] [CrossRef]

- Umer, R.; Bickerton, S.; Fernyhough, A. Modelling the application of wood fibre reinforcements within liquid composite moulding processes. Compos. Part A Appl. Sci. Manuf. 2008, 39, 624–639. [Google Scholar] [CrossRef]

- Ulven, C.A.; Vaidya, U.K. Impact response of fibre damaged polymer-based composite materials. Compos. Part B Eng. 2008, 39, 92–107. [Google Scholar] [CrossRef]

- Wienhold, P.D.; Lennon, A.M.; Roberts, J.C.; Rooney, M.; Kercher, A.K.; Nagle, D.C.; Sorathia, U. Characterisation of carbonised wood core for use in FRP sandwich ship structures. Mater. Des. 2000, 45, II. [Google Scholar] [CrossRef]

- Oksman, K.; Wallstrom, L.; Berglund, L.A.; Toledo, R.D. Morphology and mechanical properties of unidirectional sisal–epoxy composites. J. Appl. Polym. Sci. 2002, 84, 2358–2365. [Google Scholar] [CrossRef]

- Mehta, G.; Mohanty, A.K.; Drzal, L.T.; Kamdem, D.P.; Misra, M. Effect of accelerated weathering on biocomposites processed by SMC and compression molding. J. Polym. Environ. 2006, 14, 359–368. [Google Scholar] [CrossRef]

- Heimann, R.B. Thermal spraying of biomaterials. Surf. Coat. Technol. 2006, 201, 2012–2019. [Google Scholar] [CrossRef]

- Jinho, S.; Kwangmin, L.; Jeongtae, K.; Hyeju, S.; Hyunseung, K.; Hyun-Pil, L.; Kwidug, Y.; Gyejeong, O.; Seokwoo, L.; Heekyun, O.; et al. Hydroxyapatite coatings on nanotubular titanium dioxide thin films prepared by radio frequency magnetron sputtering. J. Nanosci. Nanotechnol. 2013, 13, 5807–5810. [Google Scholar] [CrossRef] [PubMed]

- Boccaccini, A.R.; Keim, S.; Ma, R.; Li, Y.; Zhitomirsky, I. Electrophoretic deposition of biomaterials. J. R. Soc. Interface 2010, 7, 581–613. [Google Scholar] [CrossRef]

- Layrolle, P.; Ito, A.; Tateishi, T. Sol–gel synthesis of amorphous calcium phosphate and sintering into microporous hydroxyapatite bioceramics. J. Am. Ceram. Soc. 1998, 81, 1421–1428. [Google Scholar] [CrossRef]

- Ratha, I.; Datta, P.; Balla, V.K.; Nandi, S.K.; Kundu, B. Effect of doping in hydroxyapatite as coating material on biomedical implants by plasma spraying method: A review. Ceram. Int. 2021, 47, 4426–4445. [Google Scholar] [CrossRef]

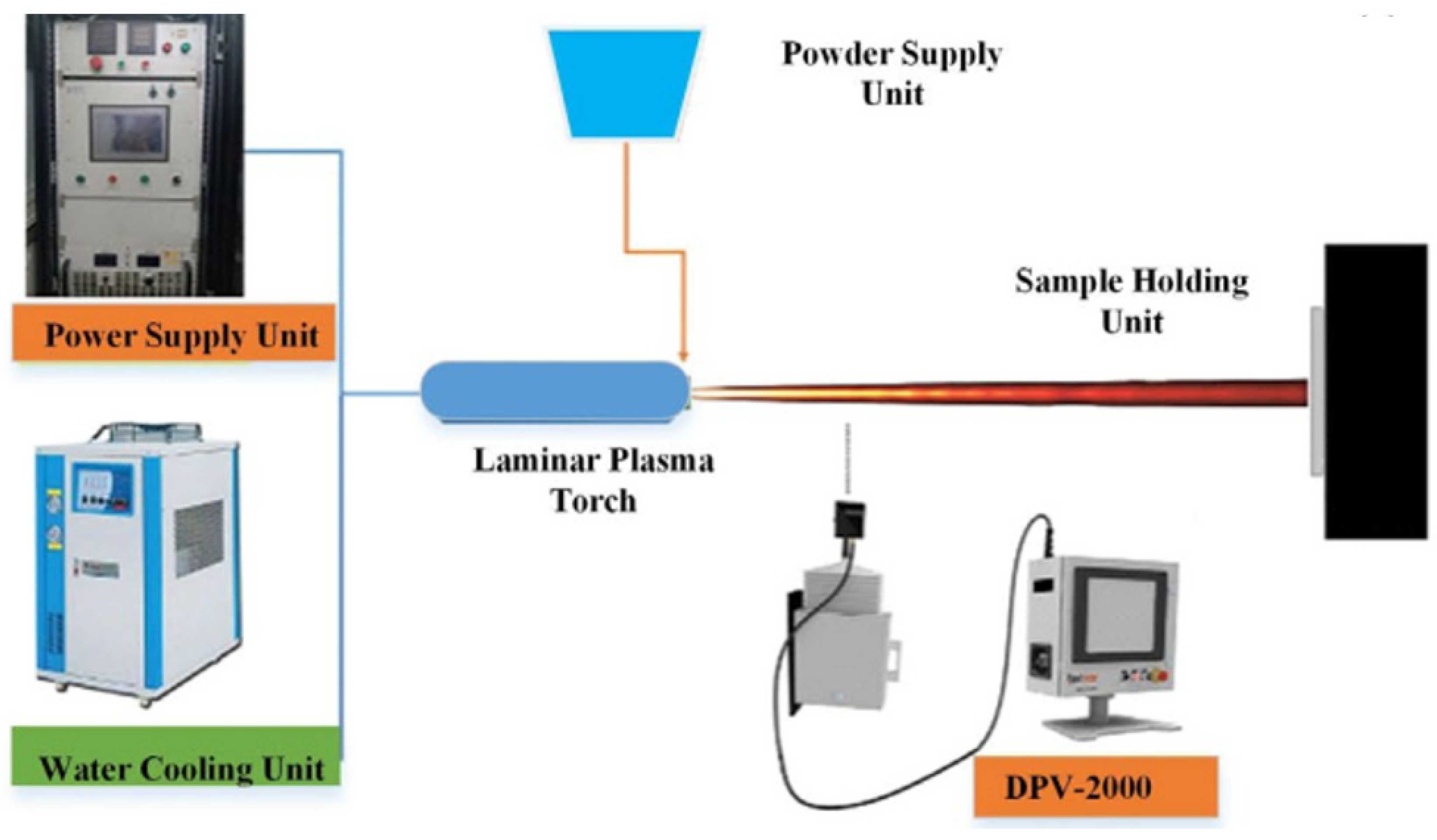

- Liu, S.H.; Zhang, H.Y.; Wang, Y.P.; Ji, G.; Li, L.; Xu, P.; Huang, J.H.; Zhang, S.L.; Li, C.X.; Li, C.J. Microstructural evolution of alumina coatings by a novel long laminar plasma spraying method. Surf. Coat. Technol. 2019, 363, 210–220. [Google Scholar] [CrossRef]

- Ruzbarsky, J.; Panda, A. Plasma and Thermal Spraying. In SpringerBriefs in Applied Sciences and Technology; Springer: Berlin/Heidelberg, Germany, 2017; pp. 13–23. [Google Scholar] [CrossRef]

- Yang, Y.; Kim, K.H.; Ong, J.L. A review on calcium phosphate coatings produced using a sputtering process—An alternative to plasma spraying. Biomaterials 2005, 26, 327–337. [Google Scholar] [CrossRef] [PubMed]

- Palka, V.; Postrkova, E.; Koerten, H.K. Some characteristics of hydroxylapatite powder particles after plasma spraying. Biomaterials 1998, 19, 1763–1772. [Google Scholar] [CrossRef] [PubMed]

- Baolong, G.; Deyi, L.; Jiajun, Z.; Wulin, Y.; Licai, F.; Lingping, Z. Construction of magnetron sputtering non-equilibrium Miedema’s model for application in Ag–Mo thin films. Phys. B Condens. Matter 2021, 602, 412541. [Google Scholar] [CrossRef]

- Wu, C.; Xu, F.; Wang, H.; Liu, H.; Yan, F.; Ma, C. Manufacturing technologies of polymer composites—A review. Polymers 2023, 15, 712. [Google Scholar] [CrossRef]

- Rtimi, S.; Konstantinidis, S.; Britun, N.; Bensimon, M.; Khmel, I.; Nadtochenko, V. Extracellular bacterial inactivation proceeding without Cu-ion release: Drastic effects of the applied plasma energy on the performance of the Cu-polyester (PES) samples. Appl. Catal. B Environ. 2018, 239, 245–253. [Google Scholar] [CrossRef]

- Twu, M.J.; Chiou, A.H.; Hu, C.C.; Hsu, C.Y.; Kuo, G.G. Properties of TiO2 films deposited on flexible substrates using direct current magnetron sputtering and high power impulse magnetron sputtering. Polym. Degrad. Stab. 2015, 117, 1–7. [Google Scholar] [CrossRef]

- Ganesan, R.; Akhavan, B.; Hiob, M.A.; McKenzie, D.R.; Weiss, A.S.; Bilek, M.M.M. HiPIMS carbon coatings show covalent protein binding that imparts enhanced hemocompatibility. Carbon 2018, 139, 118–128. [Google Scholar] [CrossRef]

- Mohandesnezhad, S.; Etminanfar, M.; Mahdavi, S.; Safavi, M.S. Enhanced bioactivity of 316L stainless steel with deposition of polypyrrole/hydroxyapatite layered hybrid coating: Orthopedic applications. Surf. Interfaces 2022, 28, 101604. [Google Scholar] [CrossRef]

- Zhitomirsky, I. Electrophoretic deposition of organic-inorganic nanocomposites. J. Mater. Sci. 2006, 41, 8186–8195. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Cho, J.; Subhani, T.; Kaya, C.; Kaya, F. Electrophoretic deposition of carbon nanotube–ceramic nanocomposites. J. Eur. Ceram. Soc. 2010, 30, 1115–1129. [Google Scholar] [CrossRef]

- Besra, L.; Liu, M. A review on fundamentals and applications of electrophoretic deposition (EPD). Prog. Mater. Sci. 2007, 52, 1–61. [Google Scholar] [CrossRef]

- Wang, Y.; Pang, X.; Zhitomirsky, I. Electrophoretic deposition of chiral polymers and composites. Colloids Surf. B Biointerfaces 2011, 87, 505–509. [Google Scholar] [CrossRef]

- Chen, C.Y.; Wang, S.C.; Tien, Y.H.; Tasi, W.T.; Lin, C.K. Hybrid manganese oxide films for supercapacitor application prepared by sol–gel technique. Thin Solid Film. 2009, 518, 1557–1560. [Google Scholar] [CrossRef]

- Camara, R.M.; Portela, R.; Gutierrez-Martin, F.; Sanchez, B. Photocatalytic activity of TiO2 films prepared by surfactant-mediated sol–gel methods over commercial polymer substrates. Chem. Eng. J. 2016, 283, 535–543. [Google Scholar] [CrossRef]

- Camara, R.M.; Crespo, E.; Portela, R.; Suarez, S.; Bautista, L.; Gutierrez-Martin, F.; Sanchez, B. Enhanced photocatalytic activity of TiO2 thin films on plasma-pretreated organic polymers. Catal. Today 2014, 230, 145–151. [Google Scholar] [CrossRef]

- Liu, W.; Sun, L.; Luo, Y.; Wu, R.; Jiang, H.; Chen, Y.; Zeng, G.; Liu, Y. Facile transition from hydrophilicity to superhydrophilicity and superhydrophobicity on aluminum alloy surface by simple acid etching and polymer coating. Appl. Surf. Sci. 2013, 280, 193–200. [Google Scholar] [CrossRef]

- Monia, T. Sustainable natural biopolymers for biomedical applications. J. Thermoplast. Compos. Mater. 2024, 37, 2505–2524. [Google Scholar] [CrossRef]

- Gardan, J. Additive manufacturing technologies for polymer composites: State-of-the-art and future trends. In Structure and Properties of Additive Manufactured Polymer Components; Woodhead Publishing: Soston, UK, 2020; pp. 3–15. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Mustapha, K.B.; Metwalli, K.M. A review of fused deposition modelling for 3D printing of innovative polymeric materials and composites. Eur. Polym. J. 2021, 156, 110591. [Google Scholar] [CrossRef]

- Kenzari, S.; Bonina, D.; Dubois, J.M.; Fournee, V. Quasicrystal–polymer composites for selective laser sintering technology. Mater. Des. 2012, 35, 691–695. [Google Scholar] [CrossRef]

- Graf, D.; Bermejo, A.; Martinez, L.; Gleissner, U.; Megnin, C.; Eiselt, T.; Mauck, M.; Hanemann, T. Polymer–ceramic–composites for 3D inkjet printing. In Proceedings of the Mikro System Technik 2017 Congress, München, Germany, 23–25 October 2017; pp. 1–4. [Google Scholar]

- Nagarajan, B.; Mertiny, P.; Qureshi, A.J. Magnetically loaded polymer composites using stereolithography—Material processing and characterisation. Mater. Today Commun. 2020, 25, 101520. [Google Scholar] [CrossRef]

- Majid, F.; Zekeriti, N.; Lahlou, M.; Rhanim, R.; Lahlou, M.; Rhanim, H.; Mrani, B. Mechanical behavior and crack propagation of ABS 3D printed specimens. Procedia Struct. Integr. 2020, 28, 1719–1726. [Google Scholar] [CrossRef]

- Roy, R.; Mukhopadhyay, A. Tribological studies of 3D printed ABS and PLA plastic parts. Mater. Today Proc. 2021, 41, 856–862. [Google Scholar] [CrossRef]

- Caulfield, B.; McHugh, P.E.; Lohfeld, S. Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J. Mater. Process. Technol. 2007, 182, 477–488. [Google Scholar] [CrossRef]

- Dermanaki Farahani, R.; Dubé, M. Printing polymer nanocomposites and composites in three dimensions. Adv. Eng. Mater. 2018, 20, 1700539. [Google Scholar] [CrossRef]

- Azhdar, B.; Stenberg, B.; Kari, L. Development of a high-velocity compaction process for polymer powders. Polym. Test. 2005, 24, 909–919. [Google Scholar] [CrossRef]

- Azhdar, B.; Stenberg, B.; Kari, L. Determination of dynamic and sliding friction, and observation of stick-slip phenomenon on compacted polymer powders during high-velocity compaction. Polym. Test. 2006, 25, 1069–1080. [Google Scholar] [CrossRef]

- Azhdar, B.; Stenberg, B.; Kari, L. Polymer–nanofiller prepared by high-energy ball milling and high velocity cold compaction. Polym. Compos. 2008, 29, 252–261. [Google Scholar] [CrossRef]

- Souriou, D.; Goeuriot, P.; Bonnefoy, O.; Thomas, G.; Dore, F. Influence of the formulation of an alumina powder on compaction. Powder Technol. 2009, 190, 152–159. [Google Scholar] [CrossRef][Green Version]

- Bai, Y.; Li, L.; Fu, L.; Wang, Q. A review on high velocity compaction mechanism of powder metallurgy. Sci. Prog. 2021, 104, 00368504211016945. [Google Scholar] [CrossRef]

- Cui, J.; Huang, X.; Dong, D.; Li, G. Effect of discharge energy of magnetic pulse compaction on the powder compaction characteristics and spring back behavior of copper compacts. Met. Mater. Int. 2021, 27, 3385–3397. [Google Scholar] [CrossRef]

- Dong, D.; Fu, S.; Jiang, H.; Li, G.; Cui, J. Study on the compaction characteristics of CNTs/TC4 composites based on electromagnetic warm compaction. J. Alloys Compd. 2021, 857, 158046. [Google Scholar] [CrossRef]

- Dong, D.; Huang, X.; Cui, J.; Li, G.; Jiang, H. Effect of aspect ratio on the compaction characteristics and micromorphology of copper powders by magnetic pulse compaction. Adv. Powder Technol. 2020, 31, 4354–4364. [Google Scholar] [CrossRef]

- Li, M.; Yu, H.P.; Li, C.F. Microstructure and mechanical properties of Ti6Al4V powder compacts prepared by magnetic pulse compaction. Trans. Nonferrous Met. Soc. China 2010, 20, 553–558. [Google Scholar] [CrossRef]

- Eremina, M.A.; Lomaeva, S.F.; Paranin, S.N.; Demakov, S.L.; Elsukov, E.P. Effect of compaction method on the structure and properties of bulk Cu + Cr3C2 composites. Phys. Met. Metallogr. 2016, 117, 510–517. [Google Scholar] [CrossRef]

- Choi, S.H.; Ali, B.; Kim, S.Y.; Hyun, S.K.; Park, K.T.; Kim, B.S.; Kim, T.S.; Park, J.S. Fabrication of Ag–SnO2 contact materials from gas-atomized Ag–Sn powder using combined oxidation and ball-milling process. Int. J. Appl. Ceram. Technol. 2016, 13, 258–264. [Google Scholar] [CrossRef]

- Lee, J.G.; Hong, S.J.; Park, J.J.; Lee, M.K.; Ivanov, V.V.; Rhee, C.K. Fabrication of a yttria thin-wall tube by radial magnetic pulsed compaction of powder-based tapes. Mater. Trans. 2010, 51, 1689–1693. [Google Scholar] [CrossRef]

- Ivanov, V.V.; Ivanov, S.N.; Kaigorodov, A.S.; Taranov, A.V.; Khazanov, E.N.; Khrustov, V.R. Transparent Y2O3:Nd3+ ceramics produced from nanopowders by magnetic pulse compaction and sintering. Inorg. Mater. 2007, 43, 1365–1370. [Google Scholar] [CrossRef]

- Elmarakbi, A. Advanced Composite Materials for Automotive Applications: Structural Integrity and Crashworthiness; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Kainer, K.U. Metal Matrix Composites; Wiley-VCH: Weinheim, Germany, 2006. [Google Scholar] [CrossRef]

- Walters, B.; Stegemann, J.P. Strategies for directing the structure and function of three-dimensional collagen biomaterials across length scales. Acta Biomater. 2014, 10, 1488–1501. [Google Scholar] [CrossRef]

- Crăciun, A.M.; Pinca-Bretotean, C.; Birtok-Băneasă, C.; Josan, A. Composites materials for friction and braking application. IOP Conf. Ser. Mater. Sci. Eng. 2017, 200, 012009. [Google Scholar] [CrossRef]

- Praveenkumar, B.; Gnanaraj, S.D. Case Studies on the Applications of Phenolic Resin-Based Composite Materials for Developing Eco-Friendly Brake Pads. J. Inst. Eng. India Ser. D 2020, 101, 327–334. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Behera, A.; Menezes, P.L. Role of composite materials in the automotive sector: Potential applications. In Energy, Environment, and Sustainability; Springer: Cham, Switzerland, 2021; pp. 193–217. [Google Scholar] [CrossRef]

- Khan, F.; Hossain, N.; Mim, J.J.; Rahman, S.M.; Iqbal, M.J.; Billah, M.; Chowdhury, M.A. Advances of composite materials in automobile applications—A review. J. Eng. Res. 2024, in press. [Google Scholar] [CrossRef]

- Thornton, P.H.; Jeryan, R.A. Crash energy management in composite automotive structures. Int. J. Impact Eng. 1988, 7, 167–180. [Google Scholar] [CrossRef]

- Nturanabo, F.; Masu, L.; Govender, G. Automotive Light-Weighting using aluminum metal matrix composites. Mater. Sci. Forum 2015, 828–829, 485–491. [Google Scholar] [CrossRef]

- Kim, D.; Jung, K.; Kim, D.; Park, S.; Kim, D.; Lim, J.; Nam, B.; Kim, H. Improving pedestrian safety via the optimisation of composite hood structures for automobiles based on the equivalent static load method. Compos. Struct. 2017, 176, 780–789. [Google Scholar] [CrossRef]

- Cole, G.S.; Sherman, A.M. Lightweight materials for automotive applications. Mater. Charact. 1995, 35, 3–9. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fibre-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Rao, M. Recent applications of viscoelastic damping for noise control in automobiles and commercial airplanes. J. Sound Vib. 2003, 262, 457–474. [Google Scholar] [CrossRef]

- Li, V.C. On Engineered cementitious composites (ECC). J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Eurenius, C.A.; Danielsson, N.; Khokar, A.; Krane, E.; Olofsson, M.; Wass, J. Analysis of Composite Chassis. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2013. [Google Scholar]

- Teixeira, A.R.P. Design of a Composite Chassis Car. Master’s Thesis, University of Porto, Porto, Portugal, 2014. [Google Scholar]

- Power Plant Instrumentation and Control Handbook; Elsevier: Amsterdam, The Netherlands, 2015. [CrossRef]

- Pruez, J.; Shoukry, S.N.; Williams, G.; Shoukry, M. Lightweight Composite Materials for Heavy Duty Vehicles; U.S. Department of Energy: Washington, DC, USA, 2013. [Google Scholar] [CrossRef]

- Sajan, S.S.P.S.; Selvaraj, D.P. A review on polymer matrix composite materials and their applications. Mater. Today Proc. 2021, 47, 5493–5498. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; Van Heerden, D.; Kuiper, P.J.C.; De Wit, H. Recycling of composite materials. Chem. Eng. Process. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Patel, S.; Vusa, V.R.; Soares, C.G. Crashworthiness analysis of polymer composites under axial and oblique impact loading. Int. J. Mech. Sci. 2019, 156, 221–234. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Yogesha, B. Study on Mechanical Properties of Natural–Glass Fibre Reinforced Polymer Hybrid Composites: A review. Mater. Today Proc. 2015, 2, 2959–2967. [Google Scholar] [CrossRef]

- Belingardi, G.; Beyene, A.T.; Koricho, E.G. Geometrical optimisation of bumper beam profile made of pultruded composite by numerical simulation. Compos. Struct. 2013, 102, 217–225. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fibre-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Benedyk, J. Aluminum alloys for lightweight automotive structures. In Elsevier eBooks; Elsevier: Amsterdam, The Netherlands, 2010; pp. 79–113. [Google Scholar] [CrossRef]

- Arenas, J.P. Applications of Acoustic Textiles in Automotive/Transportation. In Textile Science and Clothing Technology; Springer: Singapore, 2016; pp. 143–163. [Google Scholar] [CrossRef]

- Veeraswamy, K.; Babu, V.V.S. Design and analysis of a composite beam for side impact protection of a car door. Int. Res. J. Eng. Technol. 2016, 3, 464–469. [Google Scholar]

- Ahmad, F.; Choi, H.J.; Park, M.S. A review: Natural fibre composites selection given mechanical, lightweight, and economic properties. Macromol. Mater. Eng. 2014, 300, 10–24. [Google Scholar] [CrossRef]

- Stewart, R. Rebounding automotive industry welcome news for FRP. Reinf. Plast. 2011, 55, 38–44. [Google Scholar] [CrossRef]

- Chauhan, V.; Kärki, T.; Varis, J. Review of natural fibre-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J. Thermoplast. Compos. Mater. 2019, 35, 1169–1209. [Google Scholar] [CrossRef]

- Kim, J.; Kim, K.-D.; Kim, S.; Shin, D.; Kim, D. Development of carbon continuous-fiber composite frame for automotive sunroof assembly. Trans. Korean Soc. Automot. Eng. 2017, 25, 350–357. [Google Scholar] [CrossRef]

- Park, H.; Dang, X.; Roderburg, A.; Nau, B. Development of plastic front side panels for green cars. CIRP J. Manuf. Sci. Technol. 2013, 6, 44–52. [Google Scholar] [CrossRef]

- Huang, Y.; Xiao, X.; Kang, H.; Lv, J.; Zeng, R.; Shen, J. Thermal management of polymer electrolyte membrane fuel cells: A critical review of heat transfer mechanisms, cooling approaches, and advanced cooling techniques analysis. Energy Convers. Manag. 2022, 254, 115221. [Google Scholar] [CrossRef]

- Sharma, A.K.; Bhandari, R.; Sharma, C.; Dhakad, S.K.; Pinca-Bretotean, C. Polymer matrix composites: A state of art review. Mater. Today Proc. 2022, 57, 2330–2333. [Google Scholar] [CrossRef]

- Tao, W.; Liu, Z.; Zhu, P.; Zhu, C.; Chen, W. Multi-scale design of three dimensional woven composite automobile fender using modified particle swarm optimisation algorithm. Compos. Struct. 2017, 181, 73–83. [Google Scholar] [CrossRef]

- Mohammed, L.J.; Ansari, M.A.; Pua, G.; Sapuan, S.; Islam, M.S. A review on natural fibre reinforced polymer composite and its applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Sherwani, S.; Sapuan, S.; Leman, Z.; Zainuddin, E.; Ilyas, R. Application of polymer composite materials in motorcycles: A comprehensive review. In Elsevier eBooks; Elsevier: Amsterdam, The Netherlands, 2021; pp. 401–426. [Google Scholar] [CrossRef]

- Fan, W.; Guo, W.; Sun, Y.; Chen, B.; Shao, X. Experimental and numerical investigations of a novel steel-UHPFRC composite fender for bridge protection in vessel collisions. Ocean Eng. 2018, 165, 1–21. [Google Scholar] [CrossRef]

- Feraboli, P.; Masini, A. Development of carbon/epoxy structural components for a high performance vehicle. Compos. Part B Eng. 2004, 35, 323–330. [Google Scholar] [CrossRef]

- Tang, L.; Hu, Q.; Li, L.; Jiang, J.; Chen, D.; Zhou, P.; Liu, X. Properties of poly (p-phenylene benzobisoxazole) fiber, and advances in its surface modification to enhance fiber–matrix adhesion: A review. Polym. Compos. 2025, 46, 6793–6812. [Google Scholar] [CrossRef]

- Scholz, M.-S.; Blanchfield, J.P.; Bloom, L.D.; Coburn, B.H.; Elkington, M.; Fuller, J.D.; Bond, I.P. The use of composite materials in modern orthopaedic medicine and prosthetic devices: A review. Compos. Sci. Technol. 2011, 71, 1791–1803. [Google Scholar] [CrossRef]

- Kowsari, E.; Haddadi-Asl, V.; Ajdari, F.B.; Hemmat, J. Aramid fibers composites to innovative sustainable materials for biomedical applications. In Materials for Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 73–204. [Google Scholar] [CrossRef]

- Teo, A.J.T.; Mishra, A.; Park, I.; Kim, Y.-J.; Park, W.-T.; Yoon, Y.-J. Polymeric biomaterials for medical implants and devices. ACS Biomater. Sci. Eng. 2016, 2, 454–472. [Google Scholar] [CrossRef]

- Kim, S.S.; Lee, J. Antimicrobial polyacrylonitrile/m-aramid hybrid composite. Ind. Eng. Chem. Res. 2013, 52, 10297–10304. [Google Scholar] [CrossRef]

- Kim, S.S.; Lee, J. Miscibility and antimicrobial properties of m-aramid/chitosan hybrid composite. Ind. Eng. Chem. Res. 2013, 52, 12703–12709. [Google Scholar] [CrossRef]

- Vallittu, P.K.; Närhi, T.O.; Hupa, L. Fiber glass–bioactive glass composite for bone replacing and bone anchoring implants. Dent. Mater. 2015, 31, 371–381. [Google Scholar] [CrossRef]

- Jaganathan, S.K.; Mani, M.P. Enriched mechanical, thermal, and blood compatibility of single stage electrospun polyurethane nickel oxide nanocomposite for cardiac tissue engineering. Polym. Compos. 2018, 40, 2381–2390. [Google Scholar] [CrossRef]

- Kim, O.V.; Litvinov, R.I.; Chen, J.; Chen, D.Z.; Weisel, J.W.; Alber, M.S. Compression-induced structural and mechanical changes of fibrin-collagen composites. Matrix Biol. 2017, 60, 141–156. [Google Scholar] [CrossRef]

- Bensaıd, W.; Triffitt, J.; Blanchat, C.; Oudina, K.; Sedel, L.; Petite, H. A biodegradable fibrin scaffold for mesenchymal stem cell transplantation. Biomaterials 2003, 24, 2497–2502. [Google Scholar] [CrossRef] [PubMed]

- Shevchenko, R.V.; James, S.L.; James, S.E. A review of tissue-engineered skin bioconstructs available for skin reconstruction. J. R. Soc. Interface 2010, 7, 229–258. [Google Scholar] [CrossRef] [PubMed]

- Oladele, I.O.; Omotosho, T.F.; Adediran, A.A. Polymer-based composites: An indispensable material for present and future applications. Int. J. Polym. Sci. 2020, 2020, 8834518. [Google Scholar] [CrossRef]

- Agbabiaka, O.G.; Oladele, I.O.; Akinwekomi, A.D.; Adediran, A.A.; Balogun, A.O.; Olasunkanmi, O.G.; Olayanju, T.M.A. Effect of calcination temperature on hydroxyapatite developed from waste poultry eggshell. Sci. Afr. 2020, 8, e00452. [Google Scholar] [CrossRef]

- Gunatillake, P.; Adhikari, R. Biodegradable synthetic polymers for tissue engineering. Eur. Cells Mater. 2003, 5, 1–16. [Google Scholar] [CrossRef]

- Campbell, A.I.; Sexton, S.; Schaschke, C.J.; Kinsman, H.; McLaughlin, B.; Boyle, M. Prosthetic limb sockets from plant-based composite materials. Prosthet. Orthot. Int. 2012, 36, 181–189. [Google Scholar] [CrossRef]

- Zagho, M.M.; Hussein, E.A.; Elzatahry, A.A. Recent overviews in functional polymer composites for biomedical applications. Polymers 2018, 10, 739. [Google Scholar] [CrossRef] [PubMed]

- Agbeboh, N.I.; Oladele, I.O.; Daramola, O.O.; Adediran, A.A.; Olasukanmi, O.O.; Tanimola, M.O. Environmentally sustainable processes for the synthesis of hydroxyapatite. Heliyon 2020, 6, e03765. [Google Scholar] [CrossRef]

- Oladele, I.O.; Agbabiaka, O.G.; Olasunkanmi, O.G.; Balogun, A.O.; Popoola, M.O. Non-synthetic sources for the development of hydroxyapatite. J. Appl. Biotechnol. Bioeng. 2018, 5, 88–95. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.; Ghazali, S.; Heim, H.P.; Feldmann, M. Effects of surface modification on dispersion, mechanical, thermal and dynamic mechanical properties of injection molded PLA-hydroxyapatite composites. Compos. Part A Appl. Sci. Manuf. 2017, 103, 96–105. [Google Scholar] [CrossRef]

- Sadiku, E.R.; Agboola, O.; Mochane, M.J.; Fasiku, V.O.; Owonubi, S.J.; Ibrahim, I.D.; Ndamase, A.S. The use of polymer nanocomposites in the aerospace and the military/defence industries. In Polymer Nanocomposites for Advanced Engineering and Military Applications; IGI Global: Hershey, PA, USA, 2019; pp. 316–349. [Google Scholar] [CrossRef]

- Edwards, E.; Brantley, C.; Ruffin, P.B. Overview of nanotechnology in military and aerospace applications. In Nanotechnology Commercialization: Manufacturing Processes and Products; Wiley: Hoboken, NJ, USA, 2017; pp. 133–176. [Google Scholar] [CrossRef]

- Kurahatti, R.V.; Surendranathan, A.O.; Kori, S.A.; Singh, N.; Kumar, A.V.; Srivastava, S. Defence applications of polymer nanocomposites. Def. Sci. J. 2010, 60, 551–563. [Google Scholar] [CrossRef]

- Koniuszewska, A.G.; Kaczmar, J.W. Application of polymer based composite materials in transportation. Prog. Rubber Plast. Recycl. Technol. 2016, 32, 1–24. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Sultan, M.T.; Yahaya, R.B. Selection of natural fiber for hybrid kevlar/natural fiber reinforced polymer composites for personal body armor by using analytical hierarchy process. Front. Mater. 2018, 5, 52. [Google Scholar] [CrossRef]

- Naveen, J.; Jayakrishna, K.; Hameed Sultan, M.T.B.; Amir, S.M.M. Ballistic performance of natural fiber based soft and hard body armour—A mini review. Front. Mater. 2020, 7, 608139. [Google Scholar] [CrossRef]

- Itapu, B.; Jayatissa, A. A review in graphene/polymer composites. Chem. Sci. Int. J. 2018, 23, 1–16. [Google Scholar] [CrossRef]

- Galpaya, D. Synthesis, Characterisation and Applications of Graphene Oxide-Polymer Nanocomposites. Ph.D. Thesis, Queensland University of Technology, Brisbane, Australia, 2015. [Google Scholar]

- Khan, D.M.; Kausar, A.; Salman, S.M. Exploitation of nanobifiller in polymer/graphene oxide–carbon nanotube, polymer/graphene oxide–nanodiamond, and polymer/graphene oxide–montmorillonite composite: A review. Polym.-Plast. Technol. Eng. 2016, 55, 744–768. [Google Scholar] [CrossRef]

- Chawla, K.K. Polymer matrix composites. In Composite Materials: Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2019; pp. 139–198. [Google Scholar] [CrossRef]

- Matthews, F.L.; Rawlings, R.D. Polymer-matrix composites. In Composite Materials; Woodhead Publishing: Cambridge, UK, 1999; pp. 168–205. [Google Scholar] [CrossRef]

- Nambiar, S.; Yeow, J.T.W. Polymer-composite materials for radiation protection. ACS Appl. Mater. Interfaces 2012, 4, 5717–5726. [Google Scholar] [CrossRef]

- Yadav, R.; Tirumali, M.; Wang, X.; Naebe, M.; Kandasubramanian, B. Polymer composite for antistatic application in aerospace. Def. Technol. 2020, 16, 107–118. [Google Scholar] [CrossRef]

- Irving, P.E.; Soutis, C. Polymer Composites in the Aerospace Industry; Woodhead Publishing: Cambridge, UK, 2019; pp. 3–22. [Google Scholar] [CrossRef]

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Kuram, E. Hybrid Biocomposites: Utilisation in Aerospace Engineering. In Advanced Composites in Aerospace Engineering Applications; Springer: Cham, Switzerland, 2022; pp. 281–310. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D.; Wambua, P.; Chapple, S.A.; Klems, T.; Doecker, M.; Erasmus, L.D. Bio-based structural composite materials for aerospace applications. In Proceedings of the South African International Aerospace Symposium, Stellenbosch, South Africa, 14–16 September 2008. [Google Scholar]

- Boegler, O.; Kling, U.; Empl, D.; Isikveren, A.T. Potential of Sustainable Materials in Wing Structural Design; Deutsche Gesellschaft für Luft-und Raumfahrt-Lilienthal-Oberth e.V.: Bonn, Germany, 2015; pp. 16–18. [Google Scholar]

- Parveez, B.; Kittur, M.I.; Badruddin, I.A.; Kamangar, S.; Hussien, M.; Umarfarooq, M.A. Scientific advancements in composite materials for aircraft applications: A review. Polymers 2022, 14, 5007. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bukvić, M.; Milojević, S.; Gajević, S.; Đorđević, M.; Stojanović, B. Production Technologies and Application of Polymer Composites in Engineering: A Review. Polymers 2025, 17, 2187. https://doi.org/10.3390/polym17162187

Bukvić M, Milojević S, Gajević S, Đorđević M, Stojanović B. Production Technologies and Application of Polymer Composites in Engineering: A Review. Polymers. 2025; 17(16):2187. https://doi.org/10.3390/polym17162187

Chicago/Turabian StyleBukvić, Milan, Saša Milojević, Sandra Gajević, Momčilo Đorđević, and Blaža Stojanović. 2025. "Production Technologies and Application of Polymer Composites in Engineering: A Review" Polymers 17, no. 16: 2187. https://doi.org/10.3390/polym17162187

APA StyleBukvić, M., Milojević, S., Gajević, S., Đorđević, M., & Stojanović, B. (2025). Production Technologies and Application of Polymer Composites in Engineering: A Review. Polymers, 17(16), 2187. https://doi.org/10.3390/polym17162187