Mechanical Behavior Analysis of Polypropylene-Based Composites and a Photopolymer Resin via Tensile and Scratch Testing

Abstract

1. Introduction

2. Materials and Methods

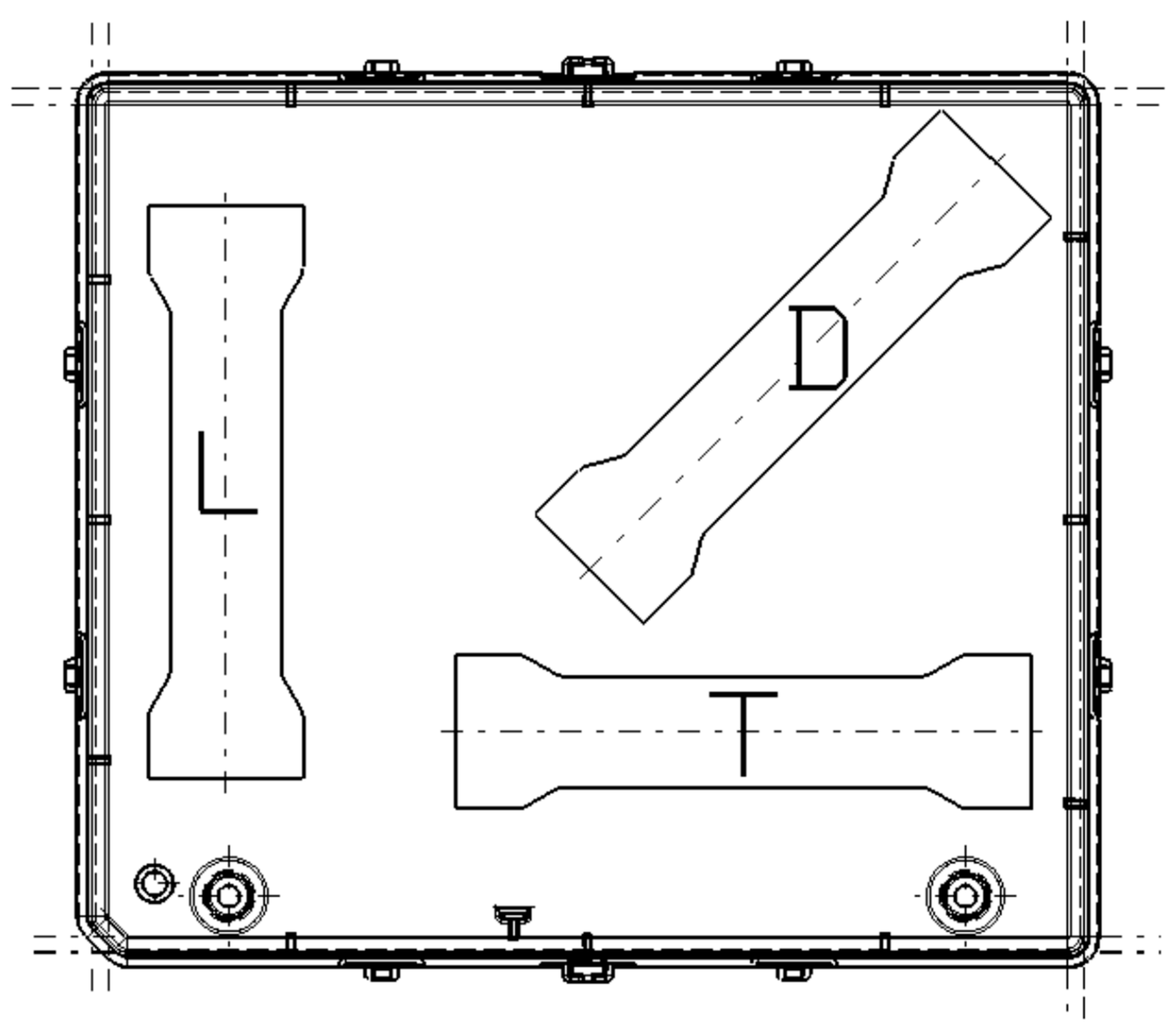

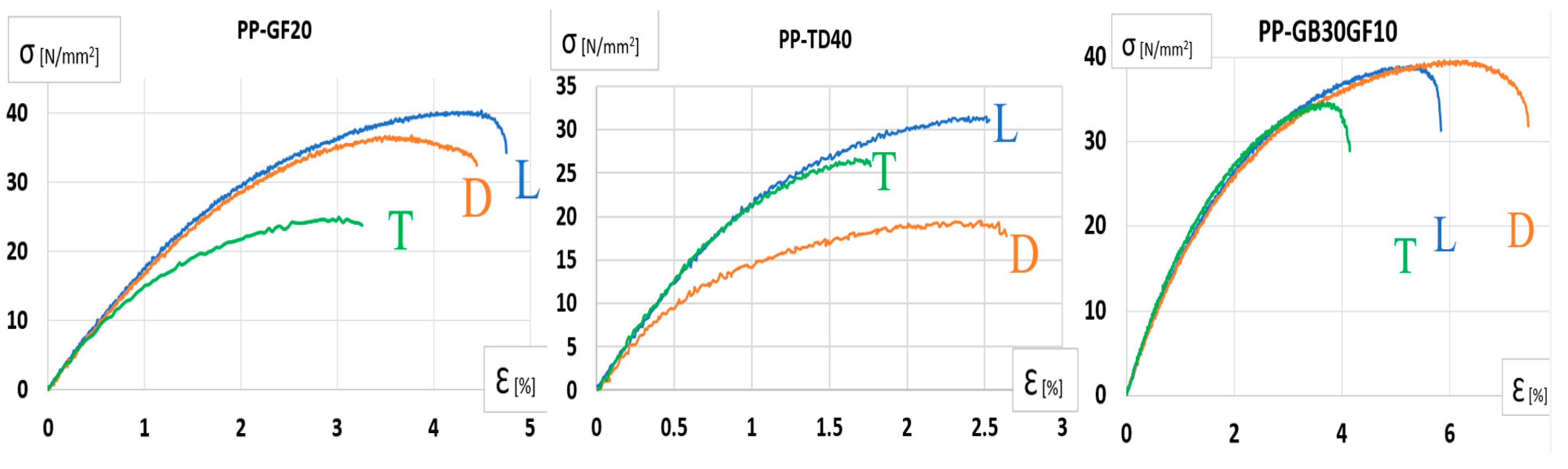

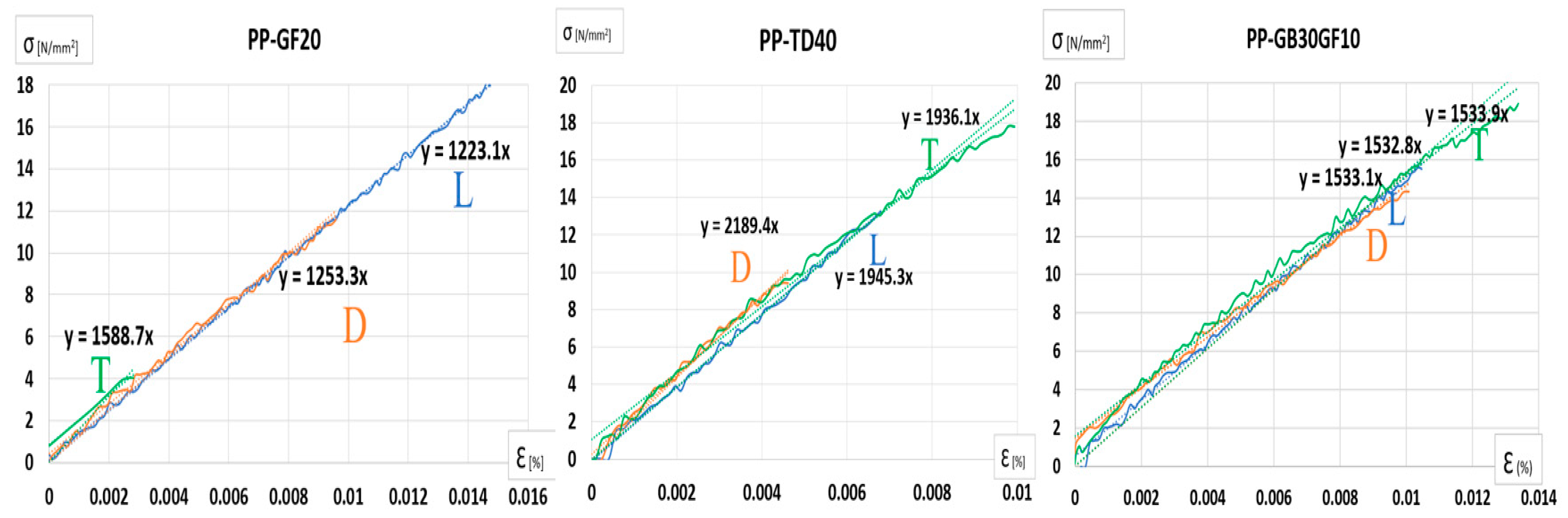

- Housing 1 (Figure 2a)—material PP-GB30GF10 (polypropylene, 30% glass beads + 10% glass fibers) with traction resistance of 44.1 MPa;

- Housing 2 (Figure 2b)—material PP-TD40 (polypropylene, 40% talc-filled) with traction resistance of 32 MPa;

- Housing 3 (Figure 2c)—material PP-GF20 (polypropylene, 20% glass-fiber-reinforced) with traction resistance of 80 MPa.

3. Results

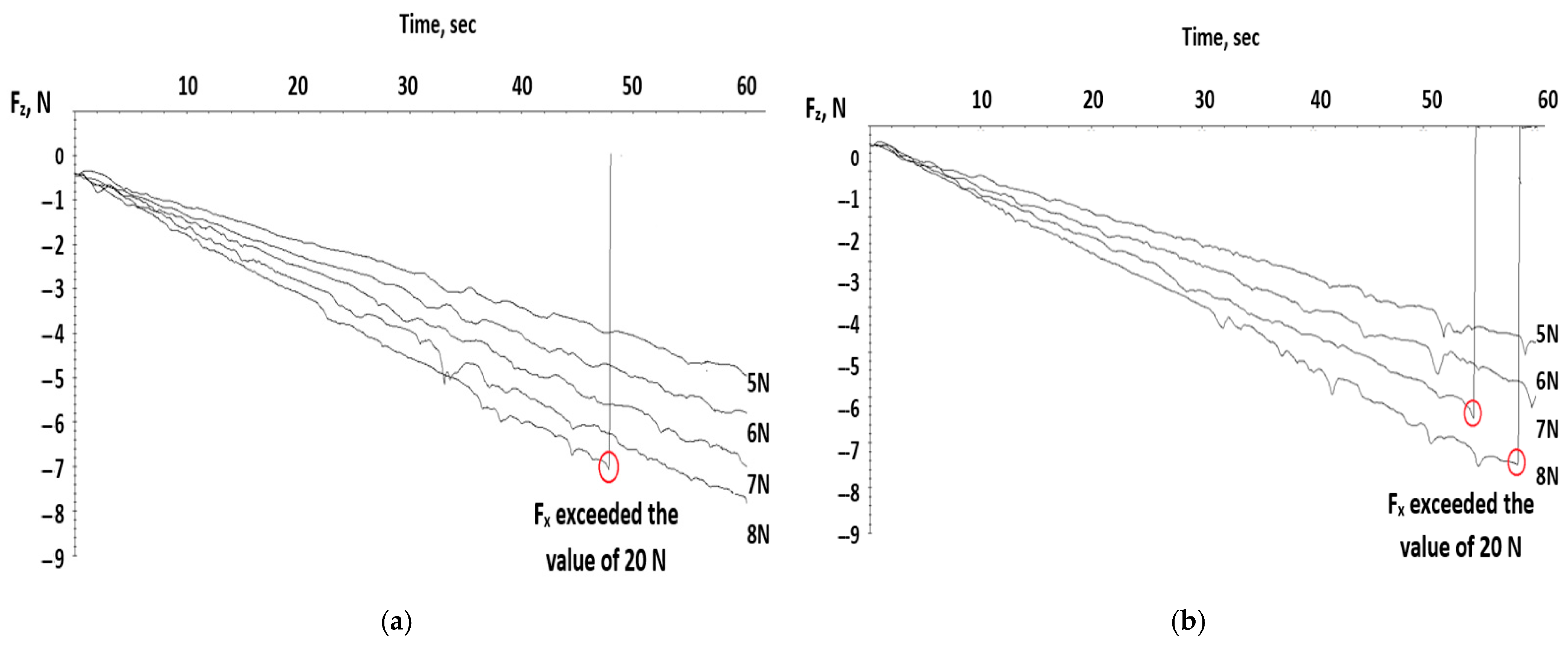

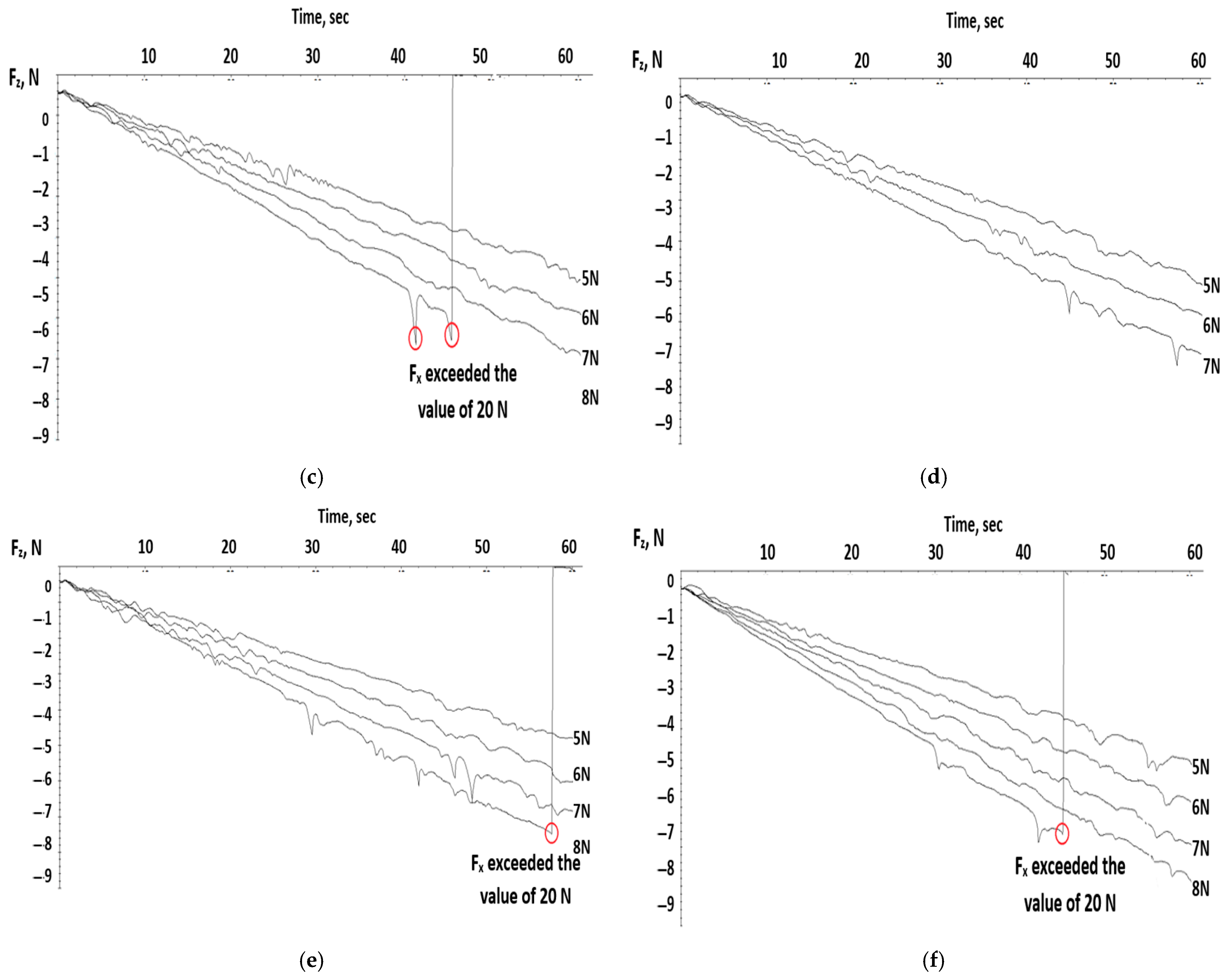

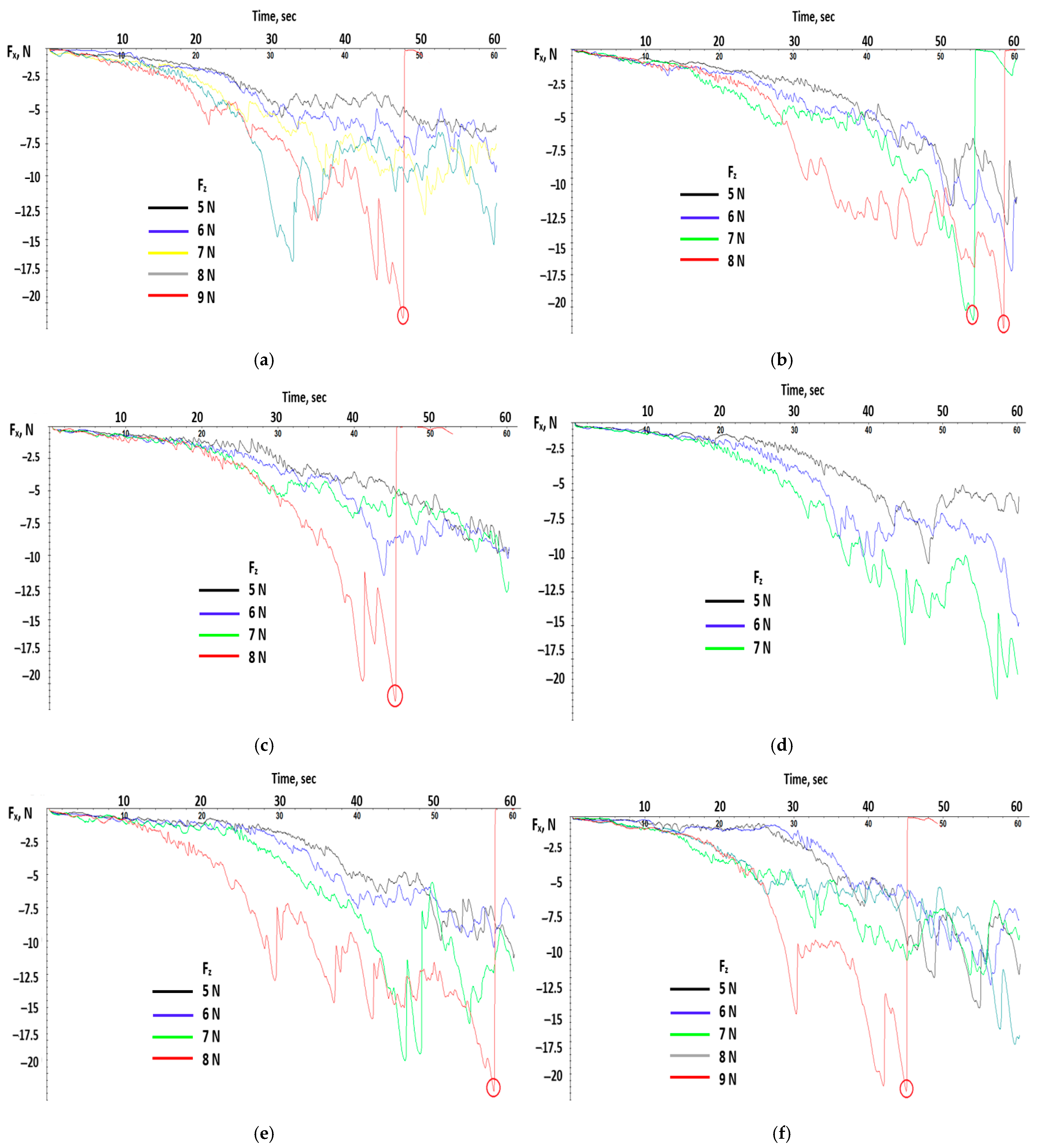

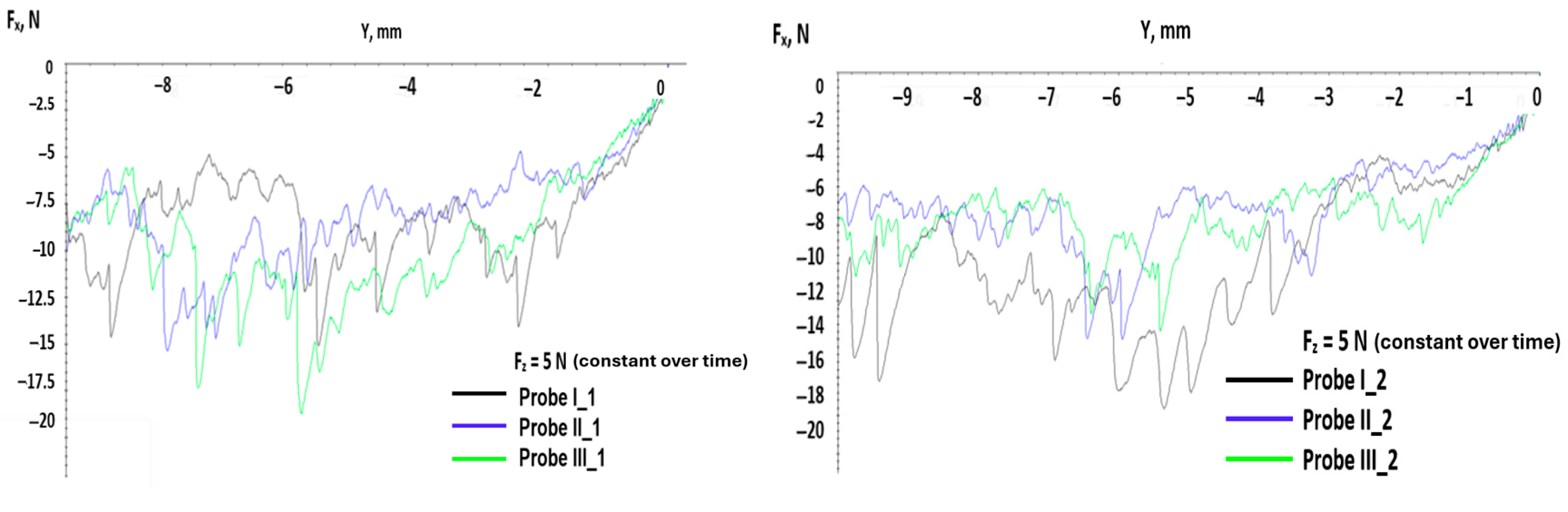

3.1. Scratch Test

- (a)

- Force that rose dependent on the time;

- (b)

- Constant force over time.

3.2. Tensile Test

4. Conclusions

4.1. Conclusions for Scratch Tests

4.2. Conclusions for Tensile Tests

4.3. Overall Conclusion

5. Limitations

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Xiang, Y.; Bousmina, M.; Utracki, L.A. Scratch Behavior of Polypropylene: Effect of Talc and Additives. Polym. Eng. Sci. 2004, 44, 1860–1871. [Google Scholar]

- Hadal, R.; Dean, D.; Strach, L.; Ougizawa, T.; Yasuda, H. Surface Damage of Filled Polypropylene under Scratch Test Conditions. J. Appl. Polym. Sci. 2004, 92, 1443–1450. [Google Scholar]

- Shelesh-Nezhad, K.; Movahed, M.; Akbari, B. Scratch Resistance of Talc-Filled Polypropylene Nanocomposites Under Progressive Load Conditions. Coatings 2020, 10, 1045. [Google Scholar]

- Soy, U.; Findik, F.; Yetgin, S.H.; Gokkurt, T.; Yıldırım, F. Mechanical and Morphological Properties of Recycled Polypropylene Reinforced with Glass Fiber, Talc, and CaCO3. Am. J. Appl. Sci. 2017, 14, 878–885. [Google Scholar] [CrossRef]

- Cuesta, E.; Barreiro, J.; Álvarez, B.J.; Núñez, P.J. Mechanical Characterization of 3D Printed Polymers Using Essential Work of Fracture. arXiv 2019, arXiv:1906.11512. [Google Scholar]

- Kherroubi, S.; Benkahla, Y.K.; Boutra, A.; Bensaci, A. Two- and three-dimensional comparative study of heat transfer and pressure drop characteristics of nanofluids flow through a ventilated cubic cavity (part II: Non-Newtonian nanofluids under the influence of a magnetic field). J. Therm. Anal. Calorim. 2022, 147, 1859–1886. [Google Scholar] [CrossRef]

- Chiou, A.-H.; Lin, C.-H. Mechanical Characterization of RPP Reinforced with Short Glass Fiber. Heliyon 2023, 9, e19403. [Google Scholar] [CrossRef]

- Chotiko, A.; Hamada, H. Properties of Composites Based on Recycled Polypropylene and Silico-Aluminous Industrial Waste. Polymers 2022, 15, 2545. [Google Scholar]

- Chu, J.; Rumao, L.; Coleman, B. Scratch and Mar Resistance of Filled Polypropylene Materials. Polym. Eng. Sci. 1998, 38, 1906–1914. [Google Scholar] [CrossRef]

- Chu, J.; Xiang, C.; Sue, H.-J.; Hollis, R.D. Scratch Resistance of Mineral-Filled Polypropylene Materials. Polym. Eng. Sci. 2000, 40, 944–955. [Google Scholar] [CrossRef]

- Arencón, D.; Velasco, J.I. Fracture Toughness of Polypropylene-Based Particulate Composites. Materials 2009, 2, 2046–2069. [Google Scholar] [CrossRef]

- Fidan, M.; Özsoy, M.İ.; Ürgün, S.; Bora, M.Ö. Scratch Resistance of Glass Basalt Fiber Reinforced Epoxy Hybrid Composites: A Comparative Study. Polym. Compos. 2024, 45, 11940–11959. [Google Scholar] [CrossRef]

- Várdai, R.; Schäffer, Á.; Ferdinánd, M.; Lummerstorfer, T.; Jerabek, M.; Gahleitner, M.; Faludi, G.; Móczó, J.; Pukánszky, B. Crystalline Structure and Reinforcement in Hybrid PP Composites. J. Therm. Anal. Calorim. 2022, 147, 145–154. [Google Scholar] [CrossRef]

- Mgbemena, C.O.; Okoye, O.A. Computational Approach to Modelling Fracture Behaviour of Polypropylene/Talc Composites. J. Mech. Mater. Contin. 2012, 3, 842–856. [Google Scholar] [CrossRef]

- Świetlicki, M.; Chocyk, D.; Klepka, T.; Prószyński, A.; Kwaśniewska, A.; Borc, J.; Gładyszewski, G. The Structure and Mechanical Properties of the Surface Layer of Polypropylene Polymers with Talc Additions. Materials 2020, 13, 698. [Google Scholar] [CrossRef] [PubMed]

- Xiang, C.; Sue, H.-J.; Chu, J.; Masuda, K. Roles of Additives in Scratch Resistance of High-Crystallinity Polypropylene Copolymers. Polym. Eng. Sci. 2001, 41, 23–31. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, S.H.; Han, D.H. A Study on Scratch Resistance by Additives of PDMS and Grain Pattern. J. Appl. Polym. Sci. 2008, 110, 222–227. [Google Scholar]

- Atmakuri, A. Mineral-Filled Polypropylene: Improvement of Scratch Resistance. Master’s Thesis, University of North Texas, Denton, TX, USA, 2001. [Google Scholar]

- Kocoglu, H.; Korkusuz, O.B.; Ozzaim, P.; Kodal, M.; Altan, M.C.; Sinmazcelik, T.; Ozcelik, B.; Ozkoc, G. Solid Particle Erosion and Scratch Behavior of CF/GF/PA6.6 Hybrid Composites. Polym. Compos. 2023, 44, 7197–7211. [Google Scholar] [CrossRef]

- Atta, M.; Srivastava, R.; Koutroumanis, N.; Semitekolos, D.; Chiavazzo, E.; Pappas, P.-N.; Galiotis, C.; Asinari, P.; Charitidis, C.A.; Fasano, M. Mesoscopic Modeling & Experimental Validation of PP Nanocomposites with Graphene-based Fillers. arXiv 2022, arXiv:2211.13148. [Google Scholar]

- Wypych, G. Improvement of Scratch and Wear Resistance of Polymers by Fillers Including Nanofillers; ChemTec Publishing: Toronto, ON, Canada, 2017. [Google Scholar]

- Harito, C.; Bavykin, D.V.; Yuliarto, B.; Dipojono, H.K.; Walsh, F.C. Polymer Nanocomposites Having a High Filler Content: Synthesis, Structures, Properties, and Applications. Nanoscale 2019, 11, 4653–4682. [Google Scholar] [CrossRef]

- Intapibool, D.; Jubsilp, C. Polypropylene Copolymer/Calcium Silicate Composites with Enhanced Mechanical Properties and Scratch Resistance. SWU Eng. J. 2019, 14, 35–45. [Google Scholar]

- Deniz, V. Polystyrene-Based Nanocomposites with Different Fillers. arXiv 2020, arXiv:2005.03360. [Google Scholar]

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019.

| Label | Material | Graph | Orientation | Sample Source | Notes |

|---|---|---|---|---|---|

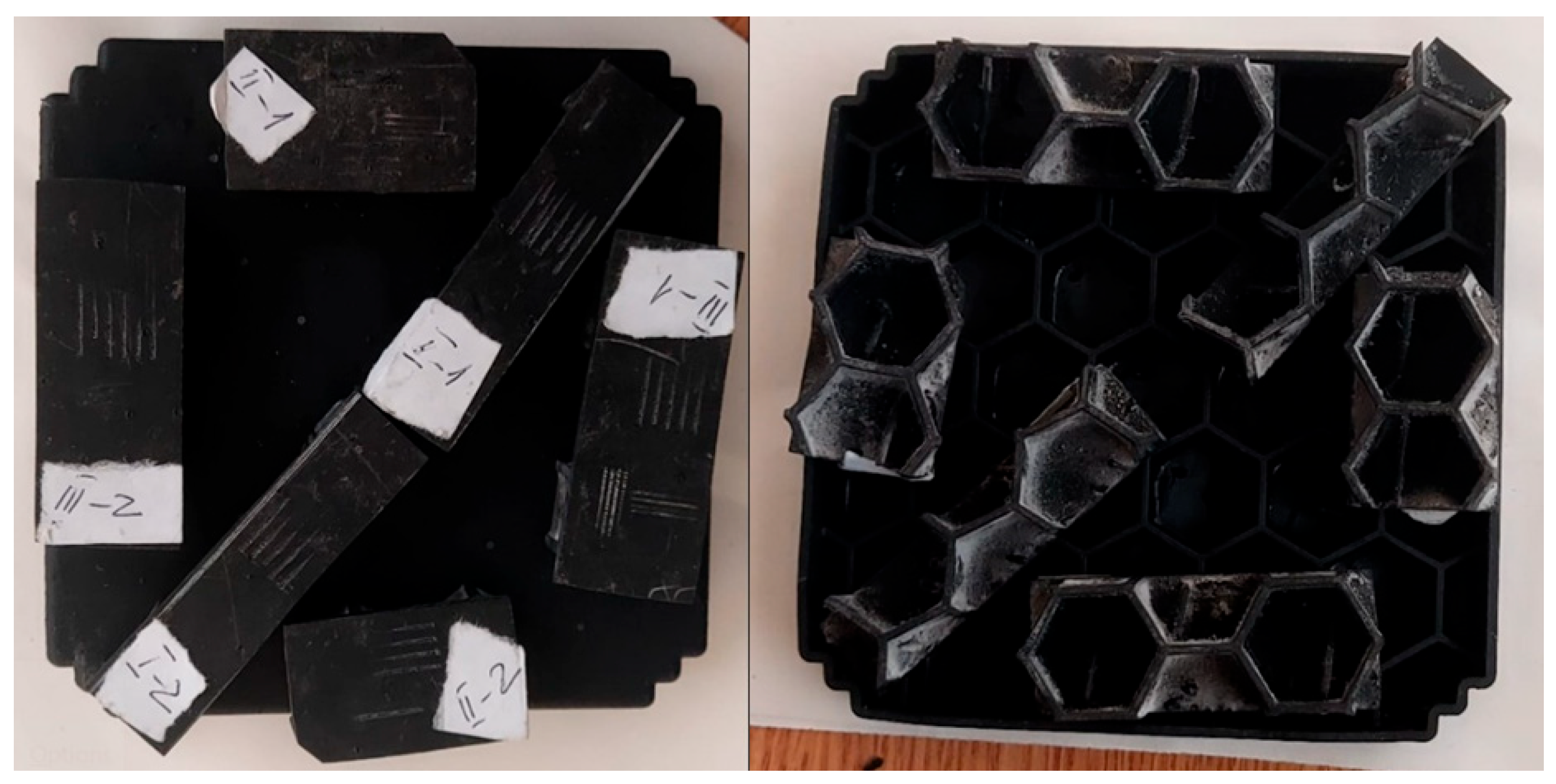

| I_1 | Black V4 resin | (a) | Diagonal | SLA-printed | From same housing, cut 1 |

| I_2 | Black V4 resin | (b) | Diagonal | SLA-printed | From same housing, cut 2 |

| II_1 | Black V4 resin | (c) | Horizontal | SLA-printed | From same housing, cut 1 |

| II_2 | Black V4 resin | (d) | Horizontal | SLA-printed | From same housing, cut 2 |

| III_1 | Black V4 resin | (e) | Vertical | SLA-printed | From same housing, cut 1 |

| III_2 | Black V4 resin | (f) | Vertical | SLA-printed | From same housing, cut 2 |

| L | PP-GB30GF10, PP-TD40, and PP-GF20 | Vertical | Injection-molded | ||

| T | PP-GB30GF10, PP-TD40, and PP-GF20 | Horizontal | Injection-molded | ||

| D | PP-GB30GF10, PP-TD40, and PP-GF20 | Diagonal | Injection-molded |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pal, S.G.; Goanta, V.; Moraras, C.I.; Carlescu, V. Mechanical Behavior Analysis of Polypropylene-Based Composites and a Photopolymer Resin via Tensile and Scratch Testing. Polymers 2025, 17, 2180. https://doi.org/10.3390/polym17162180

Pal SG, Goanta V, Moraras CI, Carlescu V. Mechanical Behavior Analysis of Polypropylene-Based Composites and a Photopolymer Resin via Tensile and Scratch Testing. Polymers. 2025; 17(16):2180. https://doi.org/10.3390/polym17162180

Chicago/Turabian StylePal, Sergiu Gabriel, Viorel Goanta, Ciprian Ionut Moraras, and Vlad Carlescu. 2025. "Mechanical Behavior Analysis of Polypropylene-Based Composites and a Photopolymer Resin via Tensile and Scratch Testing" Polymers 17, no. 16: 2180. https://doi.org/10.3390/polym17162180

APA StylePal, S. G., Goanta, V., Moraras, C. I., & Carlescu, V. (2025). Mechanical Behavior Analysis of Polypropylene-Based Composites and a Photopolymer Resin via Tensile and Scratch Testing. Polymers, 17(16), 2180. https://doi.org/10.3390/polym17162180