Tough Hydrogel Reinforced by Meta-Aramid Nanofibers for Flexible Sensors

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Meta-Aramid Nanofibers

2.3. Synthesis of Meta-Aramid (PMIA) Reinforced SA/CS Composite Hydrogel

2.4. Characterizations

3. Results

3.1. Morphologies of Meta-Aramid Nanofibers and Meta-Aramid Nanofiber-Reinforced Composite Hydrogel

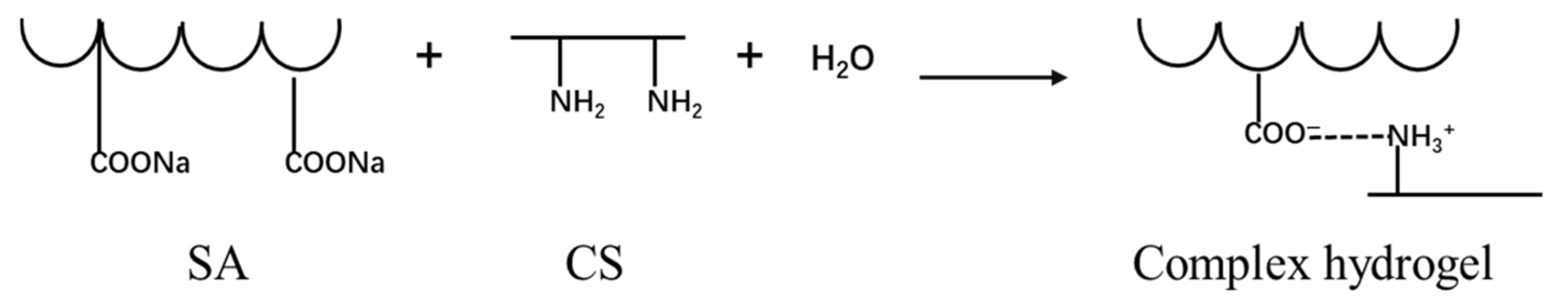

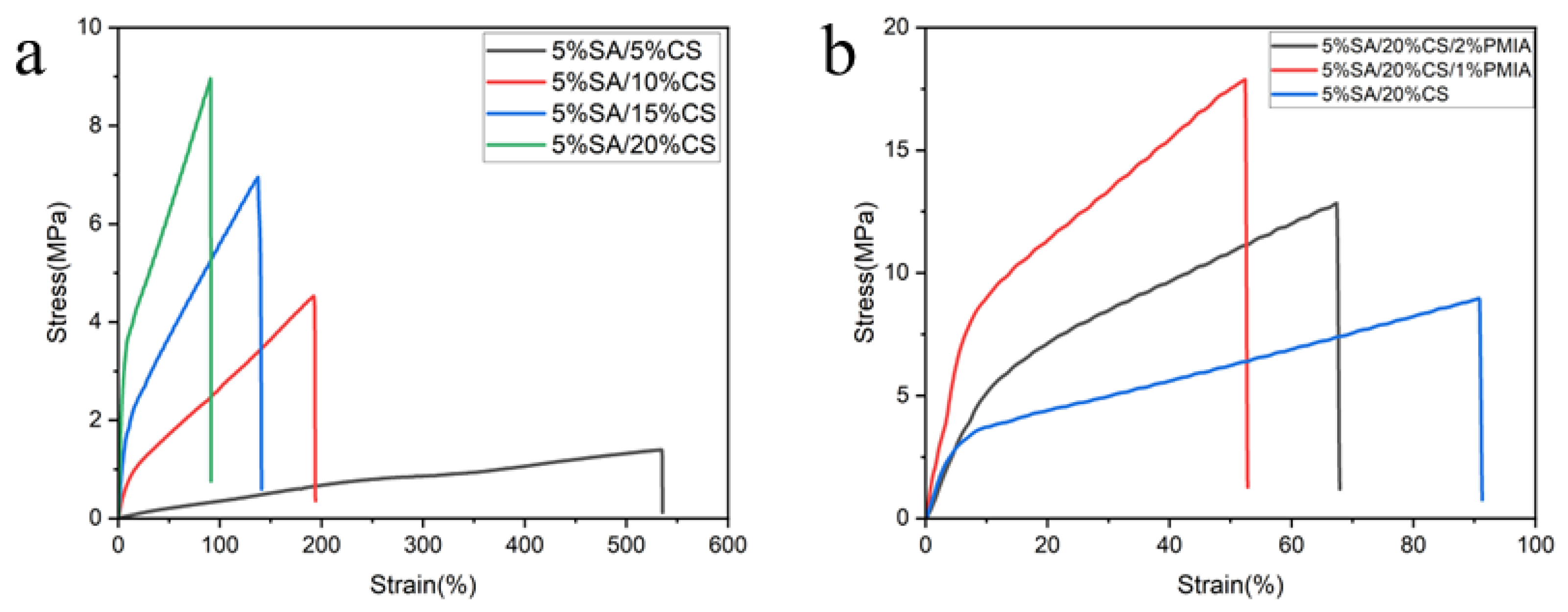

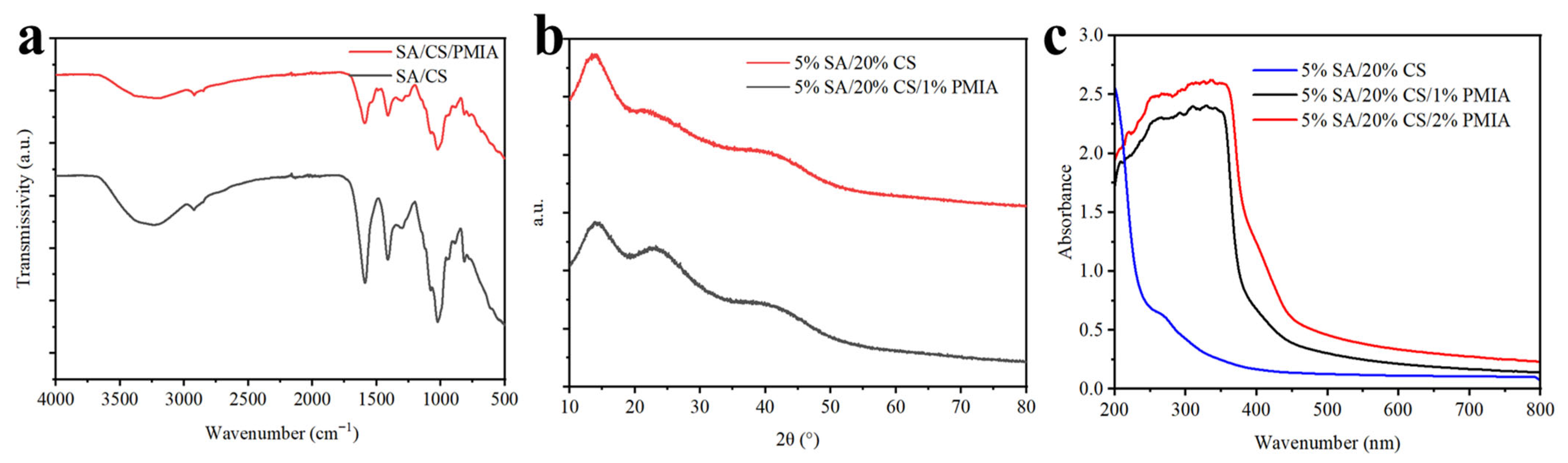

3.2. Mechanical Properties and Structure of Meta-Aramid Nanofiber-Reinforced Composite Hydrogel

| Sample | Young’s Modulus (MPa) | Max Tensile Strength (MPa) | Max Elongation at Break (%) |

|---|---|---|---|

| Hydrogel Reinforced by Meta-Aramid Nanofibers | 34.420 | 17.900 | 52 |

| optimized laminated hydrogel/fiber composite [26] | 2.180 | 0.129 | 5.9 |

| tough NC organo-hydrogels [27] | 0.050 | 0.178 | 356.17 |

| ANF Reinforced PVA Hydrogels [28] | 15.400 | 5.500 | 34 |

| Hydrogels Dual-Reinforced by Cellulose [29] | 0.002 | 0.056 | 3000 |

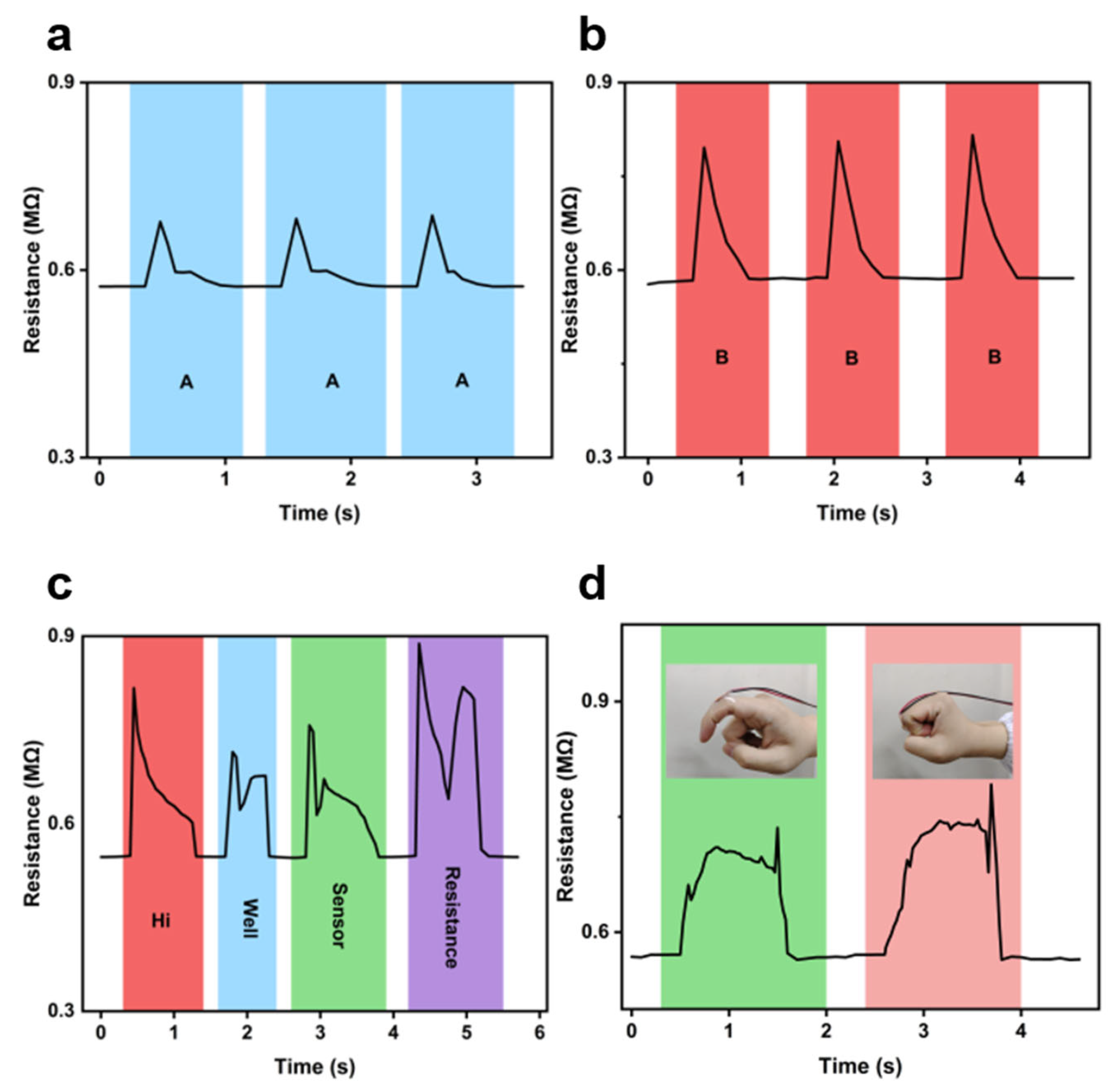

3.3. Sensing Performance of Hydrogel Sensor Reinforced by Meta-Aramid Nanofiber

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SA | Alginate |

| CS | Chitosan |

| DMAc | Dimethylacetamide |

| PMIA | meta-Aramid |

| XRD | X-Ray Diffraction |

| SEM | Scanning Electron Microscope |

| TEM | Transmission Electron Microscope |

References

- Li, X.; Gong, J.P. Design principles for strong and tough hydrogels. Nat. Rev. Mater. 2024, 9, 380–398. [Google Scholar] [CrossRef]

- Santiago, C.; Abigail, K.G.; Hector, L.H.; Doreen, C.; Anthony, C.Y.; Lyndsay, M.S.; Eric, A.A. Translational applications of hydrogels. Chem. Rev. 2021, 121, 11385–11457. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Song, S.; Ren, X.; Zhang, J.; Lin, Q.; Zhao, Y. Supramolecular adhesive hydrogels for tissue engineering applications. Chem. Rev. 2022, 122, 5604–5640. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Jin, Z.; Feng, W.; Sun, L.; Xu, H.; Wang, C. A hyperelastic hydrogel with an ultralarge reversible biaxial strain. Science 2024, 383, 1455–1461. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Yang, X.; Zhang, X. Ultrarobust subzero healable materials enabled by polyphenol nano-assemblies. Nat. Commun. 2023, 14, 814. [Google Scholar] [CrossRef]

- Yan, X.; Liu, Z.; Zhang, Q.; Jeffrey, L.; Wang, H.; Wu, H.; Niu, S.; Yan, H.; Wang, S.; Lei, T.; et al. Quadruple H-bonding cross-Linked supramolecular polymeric materials as substrates for stretchable, antitearing, and self-Healable thin film electrodes. J. Am. Chem. Soc. 2018, 140, 5280–5289. [Google Scholar] [CrossRef]

- Wang, H.; Du, M.; Jiang, H.; Zhou, R.; Wang, Y.; Sui, K.; Fan, W. Gradient p-polyanion/n-polycation heterojunction endows ionic diodes with vastly boosted output voltage, power density and sensitivity. Adv. Funct. Mater. 2024, 34, 2407639. [Google Scholar] [CrossRef]

- Li, Z.; Lu, J.; Ji, T.; Xue, Y.; Zhao, L.; Zhao, K.; Jia, B.; Wang, B.; Wang, J.; Zhang, S.; et al. Self-healing hydrogel bioelectronics. Adv. Mater. 2024, 21, 2306350. [Google Scholar] [CrossRef]

- Wu, L.; Kang, Y.; Shi, X.; Yue, B.; Qu, M.; Li, J.; Wu, Z. Natural-wood-inspired ultrastrong anisotropic hybrid hydrogels targeting artificial tendons or ligaments. ACS Nano 2023, 17, 13522–13532. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, R.; Cheng, D.; Yang, X.; Zhang, H.; Zheng, J.; Hu, R. Extremely ultrahigh stretchable starch-based hydrogels with continuous hydrogen bonding. Adv. Funct. Mater. 2025, 35, 2415530. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, Z.; Lai, B.; Wang, C.; Wu, H. Recent advances in marine-derived protein/polysaccharide hydrogels: Classification, fabrication, characterization, mechanism and food applications. Trends Food Sci. Technol. 2024, 151, 104637. [Google Scholar] [CrossRef]

- Sobia, N.; Andreas, B. Thiolated poly- and oligosaccharide-based hydrogels for tissue engineering and wound healing. Adv. Funct. Mater. 2024, 34, 2310129. [Google Scholar]

- Xia, M.; Pan, N.; Zhang, C.; Zhang, C.; Fan, W.; Xia, Y.; Wang, Z.; Sui, K. Self-powered multifunction ionic skins based on gradient polyelectrolyte hydrogels. ACS Nano 2022, 16, 4714–4725. [Google Scholar] [CrossRef]

- Cui, H.; Pan, N.; Fan, W.; Liu, C.; Li, Y.; Xia, Y.; Sui, K. Ultrafast fabrication of gradient nanoporous all-polysaccharide films as strong, superfast, and multiresponsive actuators. Adv. Funct. Mater. 2019, 29, 1807692. [Google Scholar] [CrossRef]

- Guo, R.; Li, J.; Chen, L.; Yu, Z.; Ma, S. SDC/OS-LDH composite for highly sensitive fluorescence detection of Fe3+ at much low concentration. Dalton Trans. 2020, 49, 10413–10420. [Google Scholar] [CrossRef]

- Liu, M.; Wang, K.; Wang, H.; Lu, J.; Xu, S.; Zhao, L.; Wang, X.; Du, J. Simple and sensitive colorimetric sensors for the selective detection of Cu(II). RSC Adv. 2021, 11, 11732–11738. [Google Scholar] [CrossRef]

- Marko, M.; Milos, M.; Patricia, Y.; Rosalinde, M.; Rint, P.S. Carbon nanotube reinforced supramolecular hydrogels for bioapplications. Macromol. Biosci. 2019, 1, 1800173. [Google Scholar]

- Lu, J.; Zeng, Y.; Ma, X.; Wang, H.; Meng, Q. Cobalt nanoparticles embedded into n-doped carbon from metal organic frameworks as highly active electrocatalyst for oxygen evolution reaction. Polymers 2019, 11, 828. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Zhou, X.; Liu, L.; Jiang, S.; Li, Y.; Guo, L.; Yan, S.; Tai, X. Heterogeneous bimetallic Cu–Ni nanoparticle-supported catalysts in the selective oxidation of benzyl alcohol to benzaldehyde. Catalysts 2019, 9, 538. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, H.; Li, S.; Guo, S.; Shen, L.; Zhou, T.; Zhong, H.; Wu, L. Oxygen-vacancy-enhanced peroxidase-like activity of reduced Co3O4 nanocomposites for the colorimetric detection of H2O2 and glucose. Inorg. Chem. 2020, 59, 3152–3159. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Gao, Q.; Sun, L.; Guo, H.; Sun, X. Facilitating active species by decorating CeO2 on Ni3S2 nanosheets for efficient water oxidation electrocatalysis. Chin. J. Catal. 2021, 42, 482–489. [Google Scholar] [CrossRef]

- Meng, X.; Qiao, Y.; Do, C.; Wim, B.; He, C.; Ke, Y.; Thomas, P.R.; Qiu, D. Hysteresis-free nanoparticle-reinforced hydrogels. Adv. Mater. 2022, 34, 2108243. [Google Scholar] [CrossRef] [PubMed]

- Chi, M.; Cai, C.; Liu, Y.; Zhang, S.; Nie, S. Aramid Triboelectric Materials: Opportunities for Self-Powered Wearable Personal Protective Electronics. Adv. Funct. Mater. 2024, 34, 2411020. [Google Scholar] [CrossRef]

- Santos, F.; Marto-Costa, C.; Branco, A.C.; Oliveira, A.S. Tribomechanical Properties of PVA/Nomex® Composite Hydrogels for Articular Cartilage Repair. Gels 2024, 10, 514. [Google Scholar] [CrossRef]

- Chen, X.; Sheng, D.; Xia, H.; Xu, W.; Deng, B.; Cao, G. Improved Dyeing of Meta-aramid Based on Particle Flow Dyeing Mechanism Using Hot-pressing Dyeing Method. Fibers Polym. 2020, 21, 2842–2847. [Google Scholar] [CrossRef]

- Zare, P.; Pezeshki-Modaress, M.; Hamid Rashedi, H.; Bagher, Z. Alginate sulfate-based hydrogel/nanofiber composite scaffold with controlled Kartogenin delivery for tissue engineering. Carbohydr. Polym. 2021, 266, 118123. [Google Scholar] [CrossRef]

- Zhou, Q.; Lyu, J.; Ye, C.; Zhu, M. Mechanically Strong and Multifunctional Hybrid Hydrogels with Ultrahigh Electrical Conductivity. Adv. Funct. Mater. 2021, 31, 2104536. [Google Scholar] [CrossRef]

- Zheng, H.; Huang, Q.; Lu, M.; Fu, J.; Liang, Z.; Zhang, T.; Wang, D. Anti-Freezing Nanocomposite Organohydrogels with HighStrength and Toughness. Polymers 2022, 14, 3721. [Google Scholar] [CrossRef]

- Zhong, Y.; Seidi, F.; Li, C.; Wan, Z.; Jin, Y.; Song, J.; Xiao, H. Antimicrobial/Biocompatible Hydrogels Dual-Reinforced by Cellulose as Ultrastretchable and Rapid Self-Healing Wound Dressing. Biomacromolecules 2021, 22, 1654–1663. [Google Scholar] [CrossRef] [PubMed]

| Sample | SA | CS | PMIA |

|---|---|---|---|

| 5% SA + 5%CS | 5% | 5% | |

| 5% SA + 10% CS | 5% | 10% | |

| 5% SA + 15% CS | 5% | 15% | |

| 5% SA + 20% CS | 5% | 20% | |

| 6% SA + 20% CS | 6% | 20% | |

| 5% SA + 20% CS + 1% PMIA | 5% | 20% | 1% |

| 5% SA + 20% CS + 2% PMIA | 5% | 20% | 2% |

| 6% SA + 20% CS + 1% PMIA | 6% | 20% | 1% |

| Sample | Young’s Modulus (MPa) | Max Tensile Strength (MPa) | Max Elongation at Break (%) | Toughness (J/m3) |

|---|---|---|---|---|

| 5% SA + 5% CS | 0.243 | 1.91 | 786 | 412.7 |

| 5% SA + 10% CS | 2.34 | 4.51 | 193 | 502.3 |

| 5% SA + 15% CS | 5.02 | 6.94 | 138 | 613.0 |

| 5% SA + 20% CS | 7.40 | 8.96 | 121 | 536.7 |

| 5% SA + 20% CS + 1% PMIA | 34.42 | 17.9 | 52 | 637.4 |

| 5% SA + 20% CS + 2% PMIA | 19.10 | 12.8 | 67 | 571.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Z.; Li, Y.; Zhang, D.; Peng, C.; Wang, Y.; Sui, K. Tough Hydrogel Reinforced by Meta-Aramid Nanofibers for Flexible Sensors. Polymers 2025, 17, 2179. https://doi.org/10.3390/polym17162179

Hou Z, Li Y, Zhang D, Peng C, Wang Y, Sui K. Tough Hydrogel Reinforced by Meta-Aramid Nanofibers for Flexible Sensors. Polymers. 2025; 17(16):2179. https://doi.org/10.3390/polym17162179

Chicago/Turabian StyleHou, Zhiwen, Yongzheng Li, Donghao Zhang, Cun Peng, Yan Wang, and Kunyan Sui. 2025. "Tough Hydrogel Reinforced by Meta-Aramid Nanofibers for Flexible Sensors" Polymers 17, no. 16: 2179. https://doi.org/10.3390/polym17162179

APA StyleHou, Z., Li, Y., Zhang, D., Peng, C., Wang, Y., & Sui, K. (2025). Tough Hydrogel Reinforced by Meta-Aramid Nanofibers for Flexible Sensors. Polymers, 17(16), 2179. https://doi.org/10.3390/polym17162179