Highly-Oriented Polylactic Acid Fiber Reinforced Polycaprolactone Composite Produced by Infused Fiber Mat Process for 3D Printed Tissue Engineering Technology

Abstract

1. Introduction

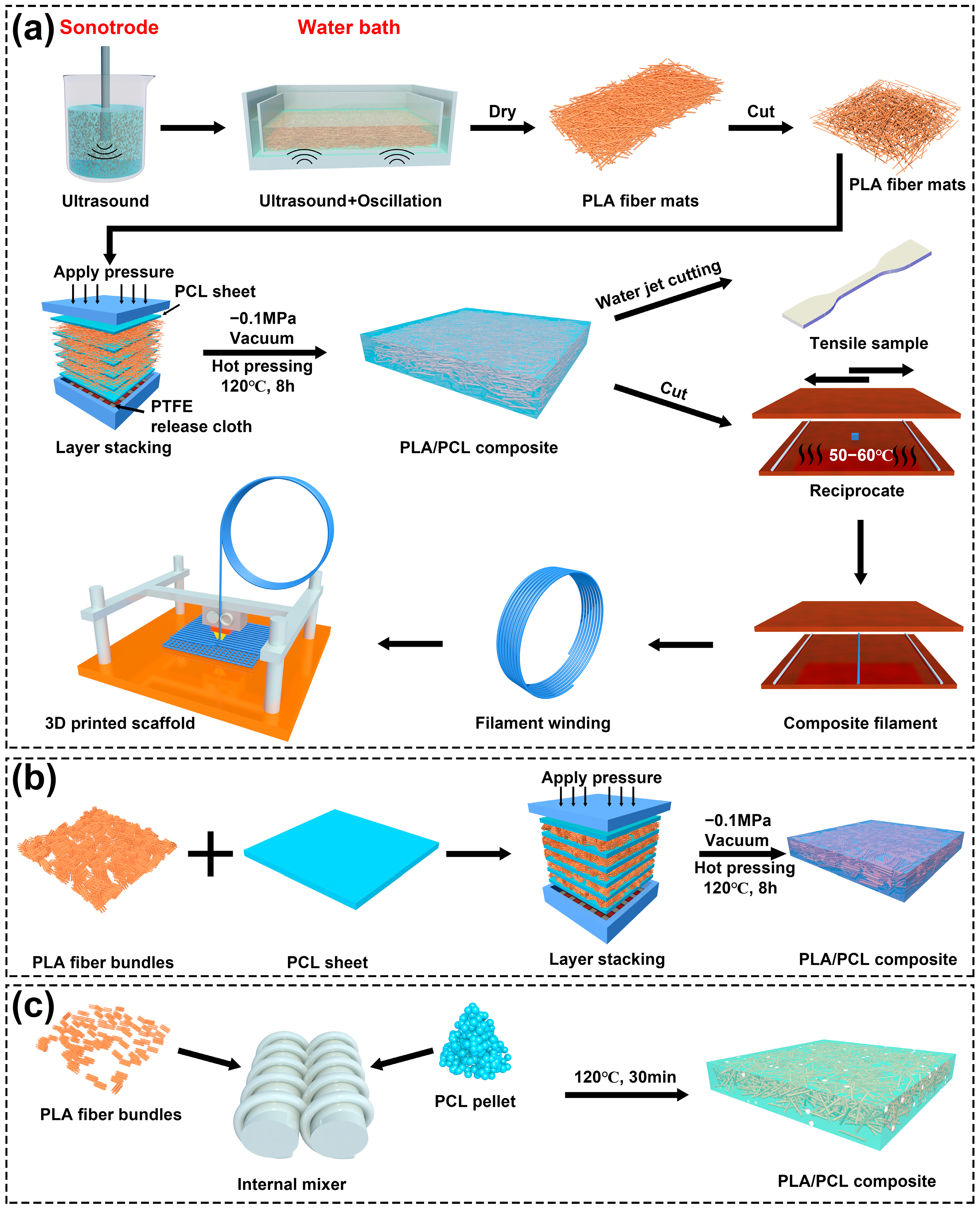

2. Materials and Methods

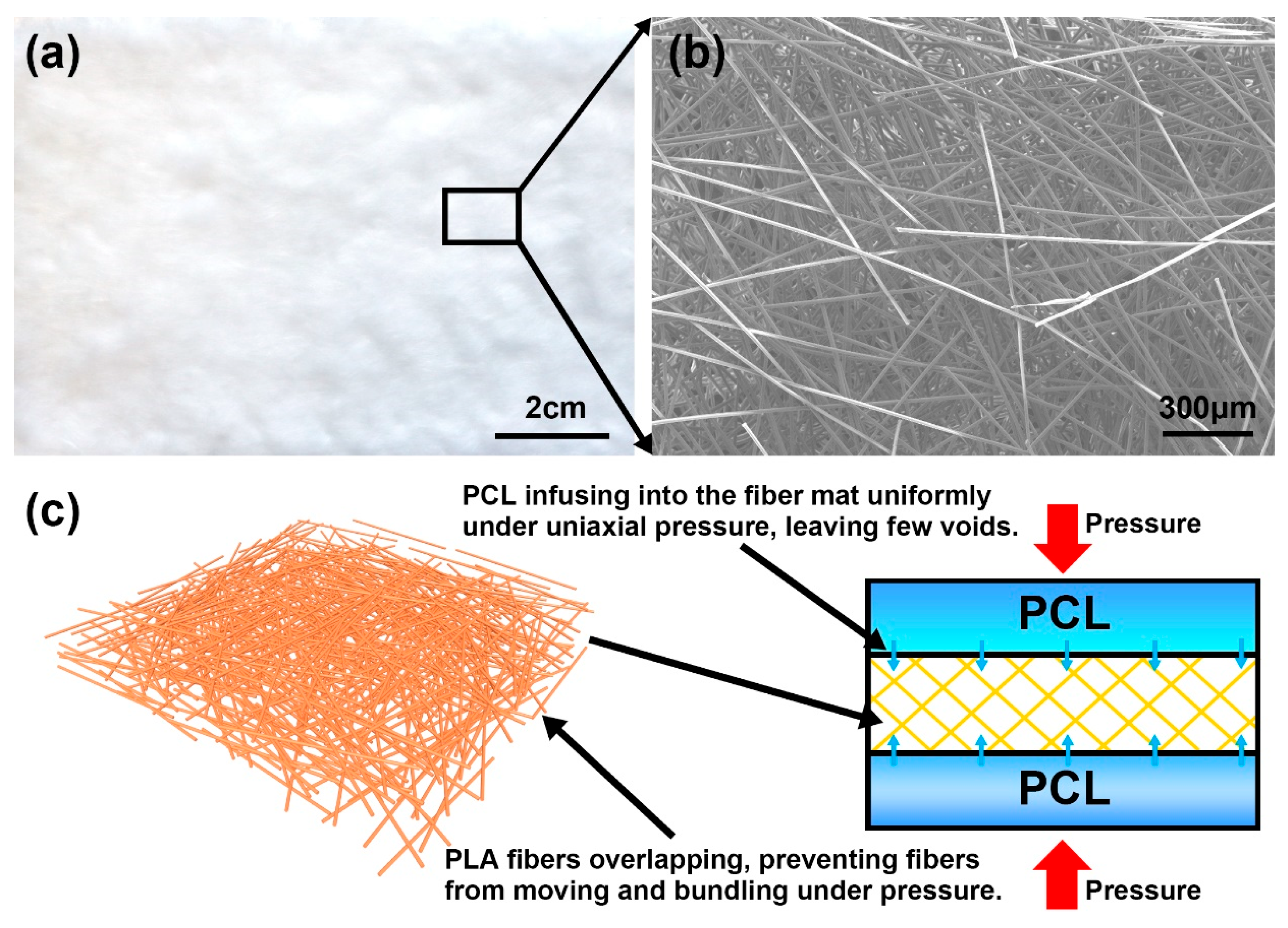

2.1. Material Preparation

2.2. Composites and 3D Printed Component Characterization

3. Results and Discussion

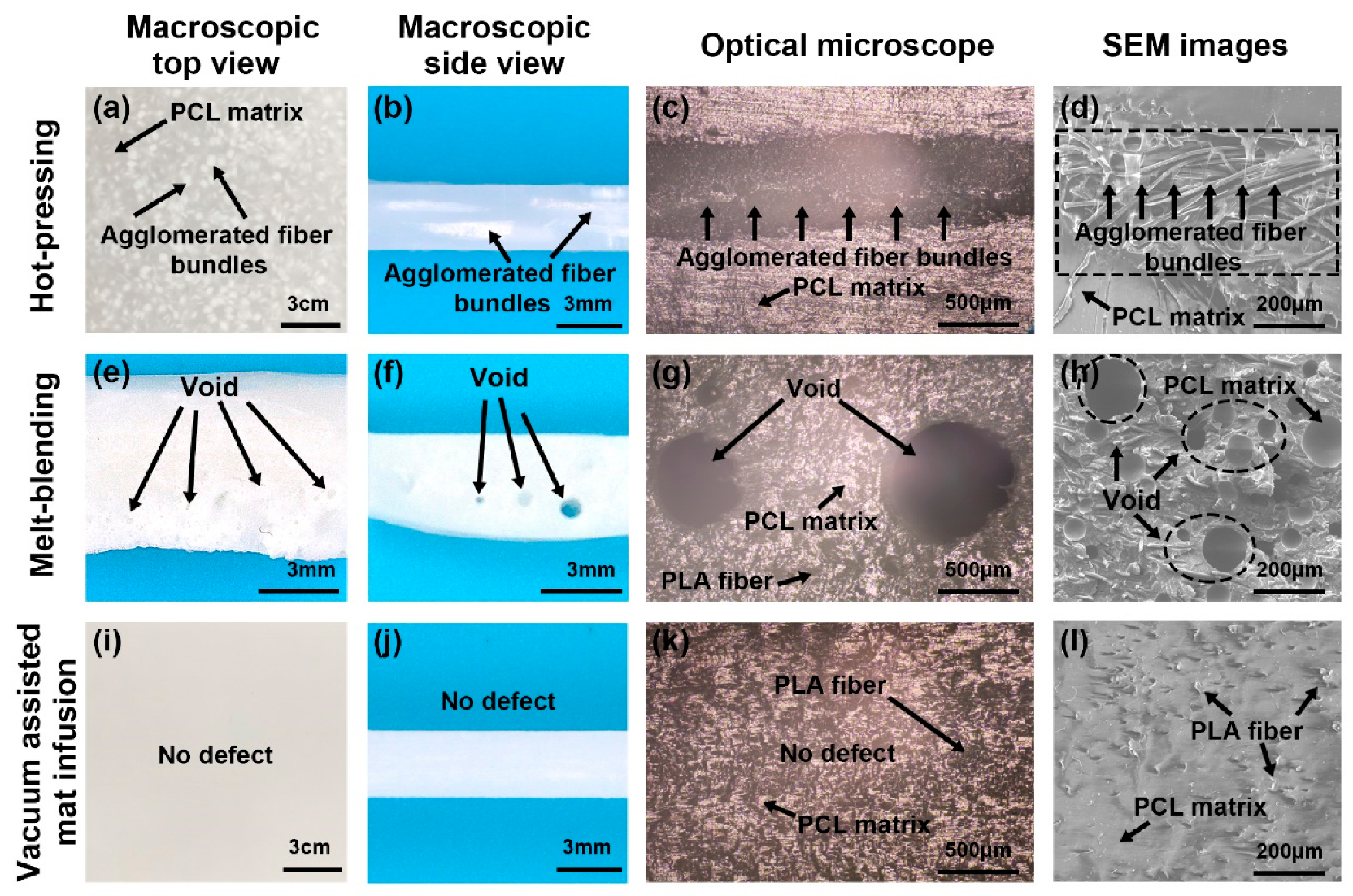

3.1. Defect Inspection

3.2. Mechanical Performance of PLA/PCL Composites

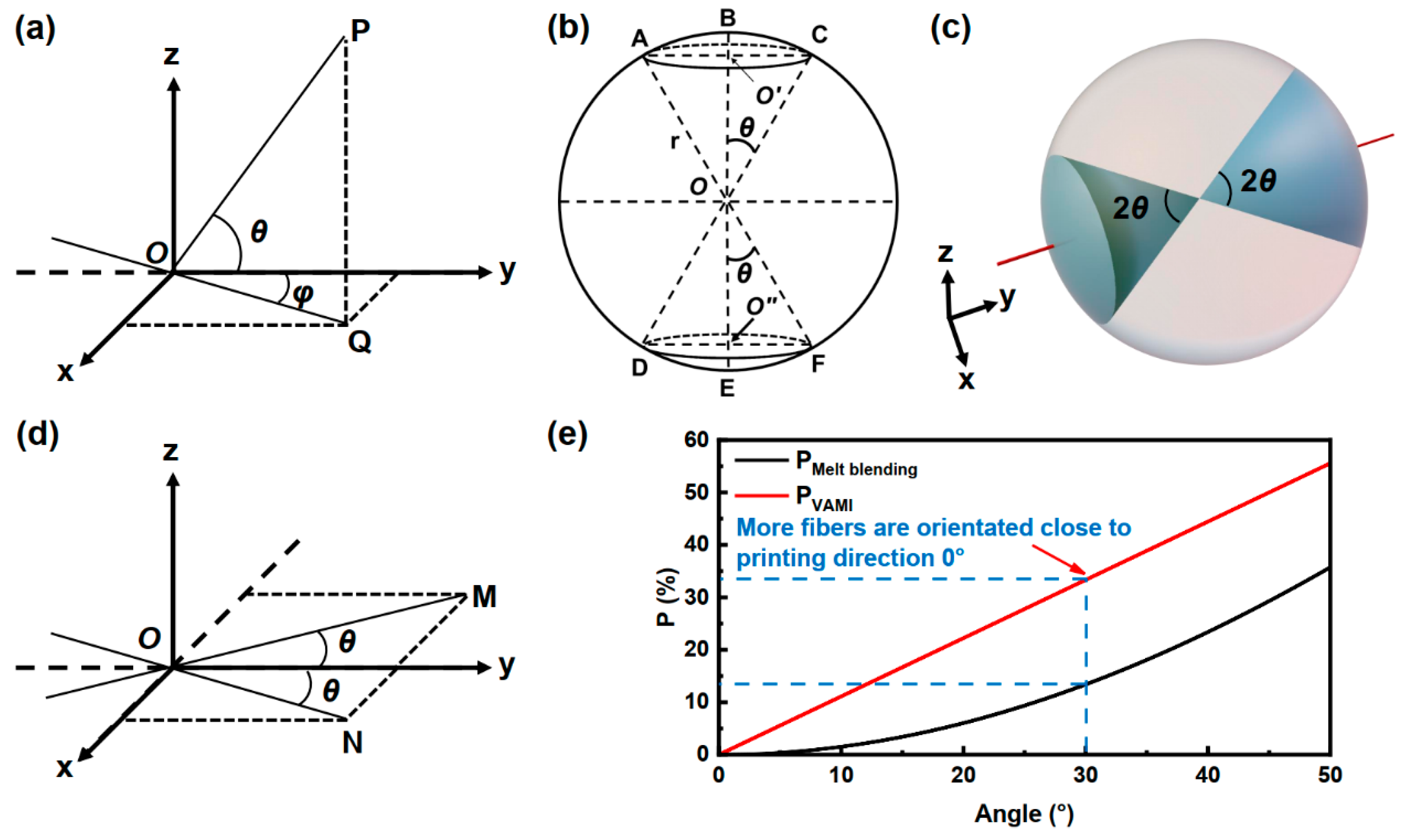

3.3. Morphology and Mechanical Performance of the Printed Strands

3.4. Morphology and Mechanical Performance of 3D Printed Tissue Engineering Scaffolds

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- O’Brien, F.J. Biomaterials & scaffolds for tissue engineering. Mater. Today 2011, 14, 88–95. [Google Scholar] [CrossRef]

- Woodruff, M.A.; Hutmacher, D.W. The return of a forgotten polymer—Polycaprolactone in the 21st century. Prog. Polym. Sci. 2010, 35, 1217–1256. [Google Scholar] [CrossRef]

- Yao, H.; Zhu, W.; Zhu, X.; Yi, X.; Yao, J.; Yuan, X.; Chen, F.; Han, X. Development of Hydroxyapatite/Polycaprolactone Composite Biomaterials for Laser Powder Bed Fusion: Evaluation of Powder Characteristics, Mechanical Properties and Biocompatibility. Polymers 2024, 16, 731. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Raveendran, N.T.; Fournier, B.; Ivanovski, S. Fabrication of biocompatible and bioabsorbable polycaprolactone/ magnesium hydroxide 3D printed scaffolds: Degradation and in vitro osteoblasts interactions. Compos. Part B Eng. 2020, 197, 108158. [Google Scholar] [CrossRef]

- Cho, Y.S.; Quan, M.; Lee, S.-H.; Hong, M.W.; Kim, Y.Y.; Cho, Y.-S. Assessment of osteogenesis for 3D-printed polycaprolactone/hydroxyapatite composite scaffold with enhanced exposure of hydroxyapatite using rat calvarial defect model. Compos. Sci. Technol. 2019, 184, 107844. [Google Scholar] [CrossRef]

- Han, J.; Wu, J.; Xiang, X.; Xie, L.; Chen, R.; Li, L.; Ma, K.; Sun, Q.; Yang, R.; Huang, T.; et al. Biodegradable BBG/PCL composite scaffolds fabricated by selective laser sintering for directed regeneration of critical-sized bone defects. Mater. Des. 2023, 225, 111543. [Google Scholar] [CrossRef]

- Pei, M.; Hwangbo, H.; Kim, G. Hierarchical fibrous collagen/poly(ε-caprolactone) structure fabricated with a 3D-printing process for tissue engineering applications. Compos. Part B Eng. 2023, 259, 110730. [Google Scholar] [CrossRef]

- Zou, L.; Hu, L.; Pan, P.; Tarafder, S.; Du, M.; Geng, Y.; Xu, G.; Chen, L.; Chen, J.; Lee, C.H. Icariin-releasing 3D printed scaffold for bone regeneration. Compos. Part B Eng. 2022, 232, 109625. [Google Scholar] [CrossRef]

- Kim, S.E.; Yun, Y.-P.; Shim, K.-S.; Kim, H.-J.; Park, K.; Song, H.-R. 3D printed alendronate-releasing poly(caprolactone) porous scaffolds enhance osteogenic differentiation and bone formation in rat tibial defects. Biomed. Mater. 2016, 11, 055005. [Google Scholar] [CrossRef]

- Kelnar, I.; Fortelný, I.; Kaprálková, L.; Kratochvíl, J.; Angelov, B.; Nevoralová, M. Effect of layered silicates on fibril formation and properties of PCL/PLA microfibrillar composites. J. Appl. Polym. Sci. 2016, 133, 43061. [Google Scholar] [CrossRef]

- Ghosh, R.; Gupta, S.; Mehrotra, S.; Kumar, A. Surface-modified diopside-reinforced PCL biopolymer composites with enhanced interfacial strength and mechanical properties for orthopedic applications. ACS Appl. Mater. Interfaces 2024, 16, 7670–7685. [Google Scholar] [CrossRef]

- Huang, H.; Qiang, L.; Fan, M.; Liu, Y.; Yang, A.; Chang, D.; Li, J.; Sun, T.; Wang, Y.; Guo, R.; et al. 3D-printed tri-element-doped hydroxyapatite/ polycaprolactone composite scaffolds with antibacterial potential for osteosarcoma therapy and bone regeneration. Bioact. Mater. 2024, 31, 18–37. [Google Scholar] [CrossRef]

- Yahay, Z.; Moein Farsani, N.; Mirhadi, M.; Tavangarian, F. Fabrication of highly ordered willemite/PCL bone scaffolds by 3D printing: Nanostructure effects on compressive strength and in vitro behavior. J. Mech. Behav. Biomed. Mater. 2023, 144, 105996. [Google Scholar] [CrossRef] [PubMed]

- Zhu, B.; Bai, T.; Wang, P.; Wang, Y.; Liu, J. Mech. Behav. Biomed. Mater. C.; Shen, C. Selective dispersion of carbon nanotubes and nanoclay in biodegradable poly(ε-caprolactone)/poly(lactic acid) blends with improved toughness, strength and thermal stability. Int. J. Biol. Macromol. 2020, 153, 1272–1280. [Google Scholar] [CrossRef]

- Botlhoko, O.J.; Ramontja, J.; Ray, S.S. A new insight into morphological, thermal, and mechanical properties of melt-processed polylactide/poly(ε-caprolactone) blends. Polym. Degrad. Stab. 2018, 154, 84–95. [Google Scholar] [CrossRef]

- da Silva, W.A.; Luna, C.B.B.; de Melo, J.B.d.C.A.; Araújo, E.M.; Filho, E.A.d.S.; Duarte, R.N.C. Feasibility of Manufacturing Disposable Cups using PLA/PCL Composites Reinforced with Wood Powder. J. Polym. Environ. 2021, 29, 2932–2951. [Google Scholar] [CrossRef]

- Dodda, J.M.; Azar, M.G.; Bělský, P.; Šlouf, M.; Gajdošová, V.; Kasi, P.B.; Anerillas, L.O.; Kovářík, T. Bioresorbable films of polycaprolactone blended with poly(lactic acid) or poly(lactic-co-glycolic acid). Int. J. Biol. Macromol. 2023, 248, 126654. [Google Scholar] [CrossRef]

- Finotti, P.F.M.; Costa, L.C.; Capote, T.S.O.; Scarel-Caminaga, R.M.; Chinelatto, M.A. Immiscible poly(lactic acid)/poly(ε-caprolactone) for temporary implants: Compatibility and cytotoxicity. J. Mech. Behav. Biomed. Mater. 2017, 68, 155–162. [Google Scholar] [CrossRef]

- Han, L.; Xu, H.; Wang, B.; Sui, X.; Zhang, L.; Zhong, Y.; Mao, Z. Preparation and characterization of biodegradable poly(ϵ-caprolactone) self-reinforced composites and their crystallization behavior. Polym. Int. 2017, 66, 1555–1563. [Google Scholar] [CrossRef]

- Jakus, A.E.; Rutz, A.L.; Jordan, S.W.; Kannan, A.; Mitchell, S.M.; Yun, C.; Koube, K.D.; Yoo, S.C.; Whiteley, H.E.; Richter, C.P.; et al. Hyperelastic “bone”: A highly versatile, growth factor-free, osteoregenerative, scalable, and surgically friendly biomaterial. Sci. Transl. Med. 2016, 8, 358ra127. [Google Scholar] [CrossRef]

- Navarro-Baena, I.; Sessini, V.; Dominici, F.; Torre, L.; Kenny, J.M.; Peponi, L. Design of biodegradable blends based on PLA and PCL: From morphological, thermal and mechanical studies to shape memory behavior. Polym. Degrad. Stab. 2016, 132, 97–108. [Google Scholar] [CrossRef]

- Ju, D.; Han, L.; Li, F.; Chen, S.; Dong, L. Crystallization, mechanical properties, and enzymatic degradation of biodegradable poly(ε-caprolactone) composites with poly(lactic acid) fibers. Polym. Compos. 2013, 34, 1745–1752. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Kazemi, Y.; Rodrigue, D.; Park, C.B. Facile production of biodegradable PCL/PLA in situ nanofibrillar composites with unprecedented compatibility between the blend components. Chem. Eng. J. 2018, 351, 976–984. [Google Scholar] [CrossRef]

- Qiao, Y.; Li, Q.; Jalali, A.; Yang, J.; Wang, X.; Zhao, N.; Jiang, Y.; Wang, S.; Hou, J.; Jiang, J. In-situ microfibrillated Poly(ε-caprolactone)/Poly(lactic acid) composites with enhanced rheological properties, crystallization kinetics and foaming ability. Compos. Part B Eng. 2021, 208, 108594. [Google Scholar] [CrossRef]

- Guarino, V.; Causa, F.; Taddei, P.; di Foggia, M.; Ciapetti, G.; Martini, D.; Fagnano, C.; Baldini, N.; Ambrosio, L. Polylactic acid fibre-reinforced polycaprolactone scaffolds for bone tissue engineering. Biomaterials 2008, 29, 3662–3670. [Google Scholar] [CrossRef]

- Chen, J.; Lu, L.; Wu, D.; Yuan, L.; Zhang, M.; Hua, J.; Xu, J. Green Poly(ε-caprolactone) Composites Reinforced with Electrospun Polylactide/Poly(ε-caprolactone) Blend Fiber Mats. ACS Sustain. Chem. Eng. 2014, 2, 2102–2110. [Google Scholar] [CrossRef]

- Tumbic, J.; Romo-Uribe, A.; Boden, M.; Mather, P.T. Hot-compacted interwoven webs of biodegradable polymers. Polymer 2016, 101, 127–138. [Google Scholar] [CrossRef]

- Deng, S.; Ma, J.; Guo, Y.; Chen, F.; Fu, Q. One-step modification and nanofibrillation of microfibrillated cellulose for simultaneously reinforcing and toughening of poly(ε-caprolactone). Compos. Sci. Technol. 2018, 157, 168–177. [Google Scholar] [CrossRef]

- Fan, Y.; Miao, X.; Hou, C.; Wang, J.; Lin, J.; Bian, F. High tensile performance of PLA fiber-reinforced PCL composite via a synergistic process of strain and crystallization. Polymer 2023, 270, 125778. [Google Scholar] [CrossRef]

- Han, L.; Wang, B.; Dai, Y.; Zhang, Y.; Xu, H.; Sui, X.; Zhang, L.; Zhong, Y.; Mao, Z. Dually self-reinforced Poly(ε-caprolactone) composites based on unidirectionally arranged fibers. Compos. Sci. Technol. 2018, 165, 331–338. [Google Scholar] [CrossRef]

- Hashim, H.b.; Emran, N.A.A.b.; Isono, T.; Katsuhara, S.; Ninoyu, H.; Matsushima, T.; Yamamoto, T.; Borsali, R.; Satoh, T.; Tajima, K. Improving the mechanical properties of polycaprolactone using functionalized nanofibrillated bacterial cellulose with high dispersibility and long fiber length as a reinforcement material. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106978. [Google Scholar] [CrossRef]

- Urquijo, J.; Guerrica-Echevarría, G.; Eguiazábal, J.I. Melt processed PLA/PCL blends: Effect of processing method on phase structure, morphology, and mechanical properties. J. Appl. Polym. Sci. 2015, 132, 1745–1752. [Google Scholar] [CrossRef]

- Li, R.; Feng, Y.; Zhang, S.; Soutis, C.; Gong, R.H. Controllable porous structure polylactide self-reinforced composites with a large processing temperature window. Compos B 2025, 291, 111996. [Google Scholar] [CrossRef]

- Meng, C.; Tang, D.; Liu, X.; Meng, J.; Wei, W.; Gong, R.H.; Li, J. Heterogeneous porous PLLA/PCL fibrous scaffold for bone tissue regeneration. Int. J. Biol. Macromol. 2023, 235, 123781. [Google Scholar] [CrossRef]

- Scaffaro, R.; Lopresti, F.; Botta, L. Preparation, characterization and hydrolytic degradation of PLA/PCL co-mingled nanofibrous mats prepared via dual-jet electrospinning. Eur. Polym. J. 2017, 96, 266–277. [Google Scholar] [CrossRef]

- Pereira-Lobato, C.; Echeverry-Rendón, M.; Fernández-Blázquez, J.P.; Llorca, J.; González, C. PLA/PCL composites manufactured from commingled yarns for biomedical applications. J. Mech. Behav. Biomed. Mater. 2025, 163, 106819. [Google Scholar] [CrossRef]

- Meng, C.; Liu, X.Z.; Li, R.Z.; Malekmohammadi, S.; Feng, Y.Y.; Song, J.; Gong, H.G.; Li, J.S. 3D Poly (L-lactic acid) fibrous sponge with interconnected porous structure for bone tissue scaffold. Int. J. Biol. Macromol. 2024, 268, 131688. [Google Scholar] [CrossRef]

- Oztemur, J.; Ozdemir, S.; Yalcin-Enis, I. Effect of blending ratio on morphological, chemical, and thermal characteristics of PLA/PCL and PLLA/PCL electrospun fibrous webs. Int. J. Polym. Mater. Polym. Biomater. 2023, 72, 793–803. [Google Scholar] [CrossRef]

- Liao, G.Y.; Chen, L.A.; Zeng, X.Y.; Zhou, X.P.; Xie, X.L.; Peng, E.J.; Ye, Z.Q.; Mai, Y.W. Electrospun Poly(L-lactide)/Poly(ε-caprolactone) Blend Fibers and Their Cellular Response to Adipose-Derived Stem Cells. J. Appl. Polym. Sci. 2011, 120, 2154–2165. [Google Scholar] [CrossRef]

- Sharma, D.; Saha, D.; Satapathy, B.K. Structurally optimized suture resistant polylactic acid (PLA)/poly (є-caprolactone) (PCL) blend based engineered nanofibrous mats. J. Mech. Behav. Biomed. Mater. 2021, 116, 104331. [Google Scholar] [CrossRef]

- Huang, S.; Lei, D.; Yang, Q.; Yang, Y.; Jiang, C.; Shi, H.; Qian, B.; Long, Q.; Chen, W.; Chen, Y.; et al. A perfusable, multifunctional epicardial device improves cardiac function and tissue repair. Nat. Med. 2021, 27, 480–490. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM international: West Conshohacken, PA, USA, 2022.

- Haque, A.N.M.A.; Naebe, M.; Mielewski, D.; Kiziltas, A. Waste wool/polycaprolactone filament towards sustainable use in 3D printing. J. Clean. Prod. 2023, 386, 135781. [Google Scholar] [CrossRef]

- Yang, M.; Li, W.; He, Y.; Zhang, X.; Li, Y.; Zhao, Z.; Dong, P.; Zheng, S.; Wang, L. Modeling the temperature dependent ultimate tensile strength of fiber/polymer composites considering fiber agglomeration. Compos. Sci. Technol. 2021, 213, 108905. [Google Scholar] [CrossRef]

- Murab, S.; Herold, S.; Hawk, T.; Snyder, A.; Espinal, E.; Whitlock, P. Advances in additive manufacturing of polycaprolactone based scaffolds for bone regeneration. J. Mater. Chem. B 2023, 11, 7250–7279. [Google Scholar] [CrossRef] [PubMed]

| Materials | Preparation Method | Solvent System | References |

|---|---|---|---|

| PLLA fiber reinforced PCL composite scaffold | Fiber winding | N,N-dimethylacetamide | [25] |

| PLA fiber reinforced PCL composites | Electrospinning with hot-pressing | Chloroform and dimethylformamide (4:1 w/w) | [26] |

| PLA fiber reinforced PCL composites | Electrospinning with hot-pressing | Chloroform and N,N-dimethylacetamide (4:1 v/v) | [27] |

| PLA fiber reinforced PCL composite membrane | Electrospinning with annealing | Methylene chloride and N,N-dimethylformamide (7:3 w/w) | [29] |

| PLLA/PCL fibrous membrane | Electrospinning | Dichloromethane and dimethyl formamide (19:1 w/w) | [37] |

| PLA/PCL fibrous membrane | Electrospinning | Chloroform and acetone (3:1 v/v) | [38] |

| PLA/PCL fibrous membrane | Electrospinning | Chloroform and methanol (3:1 v/v) | [39] |

| PLA/PCL fibrous membrane | Electrospinning | Chloroform and N,N-dimethylacetamide (90~70:10~30 v/v) | [40] |

| Designations | Composition by Weight (%) | |

|---|---|---|

| PCL | PLA | |

| PCL | 100 | 0 |

| PLA/PCL-6 | 94 | 6 |

| PLA/PCL-11 | 89 | 11 |

| PLA/PCL-16 | 84 | 16 |

| Designations | Yield Strength (MPa) | Percentage Increase (%) | Young’s Modulus (MPa) | Percentage Increase (%) | Elongation at Break (%) |

|---|---|---|---|---|---|

| PCL | 13.00 ± 0.30 | - | 281.25 ± 5.55 | - | 705.12 ± 12.67 |

| PLA/PCL-6 | 14.24 ± 0.84 | 9.54 | 390.24 ± 20.14 | 38.75 | 910.34 ± 16.87 |

| PLA/PCL-11 | 16.10 ± 0.32 | 23.85 | 553.22 ± 21.19 | 96.70 | 50.54 ± 2.65 |

| PLA/PCL-16 | 19.30 ± 1.17 | 48.46 | 676.76 ± 27.63 | 140.63 | 54.01 ± 3.98 |

| Designation | Yield Strength (MPa) | C.V. | Percentage Increase (%) | Young’s Modulus (MPa) | C.V. | Percentage Increase (%) |

|---|---|---|---|---|---|---|

| PLA0-S | 13.48 ± 0.10 | 0.74 | - | 279.15 ± 10.81 | 3.87 | - |

| PLA11M-S | 19.24 ± 0.92 | 4.78 | 42.73 | 693.56 ± 48.35 | 6.97 | 148.45 |

| PLA11B-S | 16.40 ± 0.53 | 3.23 | 21.66 | 461.18 ± 15.83 | 3.43 | 65.21 |

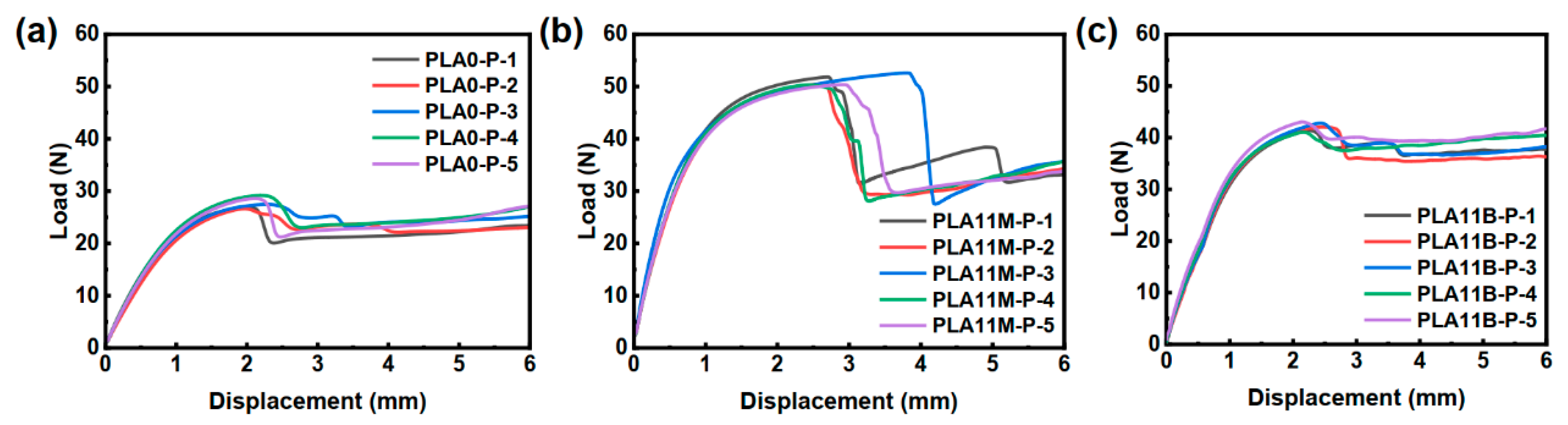

| Designation | Peak Load (N) | C.V. (%) | Percentage Increase (%) | Stiffness (N/m) | C.V. (%) | Percentage Increase (%) |

|---|---|---|---|---|---|---|

| PLA0-P | 27.75 ± 1.08 | 3.89 | - | 38.52 ± 1.04 | 2.70 | - |

| PLA11M-P | 51.12 ± 1.03 | 2.01 | 84.22 | 93.71 ± 2.05 | 2.19 | 143.28 |

| PLA11B-P | 42.16 ± 0.87 | 2.06 | 51.93 | 69.08 ± 3.93 | 5.69 | 79.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Z.; Rao, C.; Han, S.; Wei, Q.; Liang, Y.; Liu, J.; Jiang, D. Highly-Oriented Polylactic Acid Fiber Reinforced Polycaprolactone Composite Produced by Infused Fiber Mat Process for 3D Printed Tissue Engineering Technology. Polymers 2025, 17, 2138. https://doi.org/10.3390/polym17152138

Deng Z, Rao C, Han S, Wei Q, Liang Y, Liu J, Jiang D. Highly-Oriented Polylactic Acid Fiber Reinforced Polycaprolactone Composite Produced by Infused Fiber Mat Process for 3D Printed Tissue Engineering Technology. Polymers. 2025; 17(15):2138. https://doi.org/10.3390/polym17152138

Chicago/Turabian StyleDeng, Zhipeng, Chen Rao, Simin Han, Qungui Wei, Yichen Liang, Jialong Liu, and Dazhi Jiang. 2025. "Highly-Oriented Polylactic Acid Fiber Reinforced Polycaprolactone Composite Produced by Infused Fiber Mat Process for 3D Printed Tissue Engineering Technology" Polymers 17, no. 15: 2138. https://doi.org/10.3390/polym17152138

APA StyleDeng, Z., Rao, C., Han, S., Wei, Q., Liang, Y., Liu, J., & Jiang, D. (2025). Highly-Oriented Polylactic Acid Fiber Reinforced Polycaprolactone Composite Produced by Infused Fiber Mat Process for 3D Printed Tissue Engineering Technology. Polymers, 17(15), 2138. https://doi.org/10.3390/polym17152138