Strain-Rate-Dependent Tensile Behaviour and Viscoelastic Modelling of Kevlar® 29 Plain-Woven Fabric for Ballistic Applications

Abstract

1. Introduction

2. Experimental Protocol

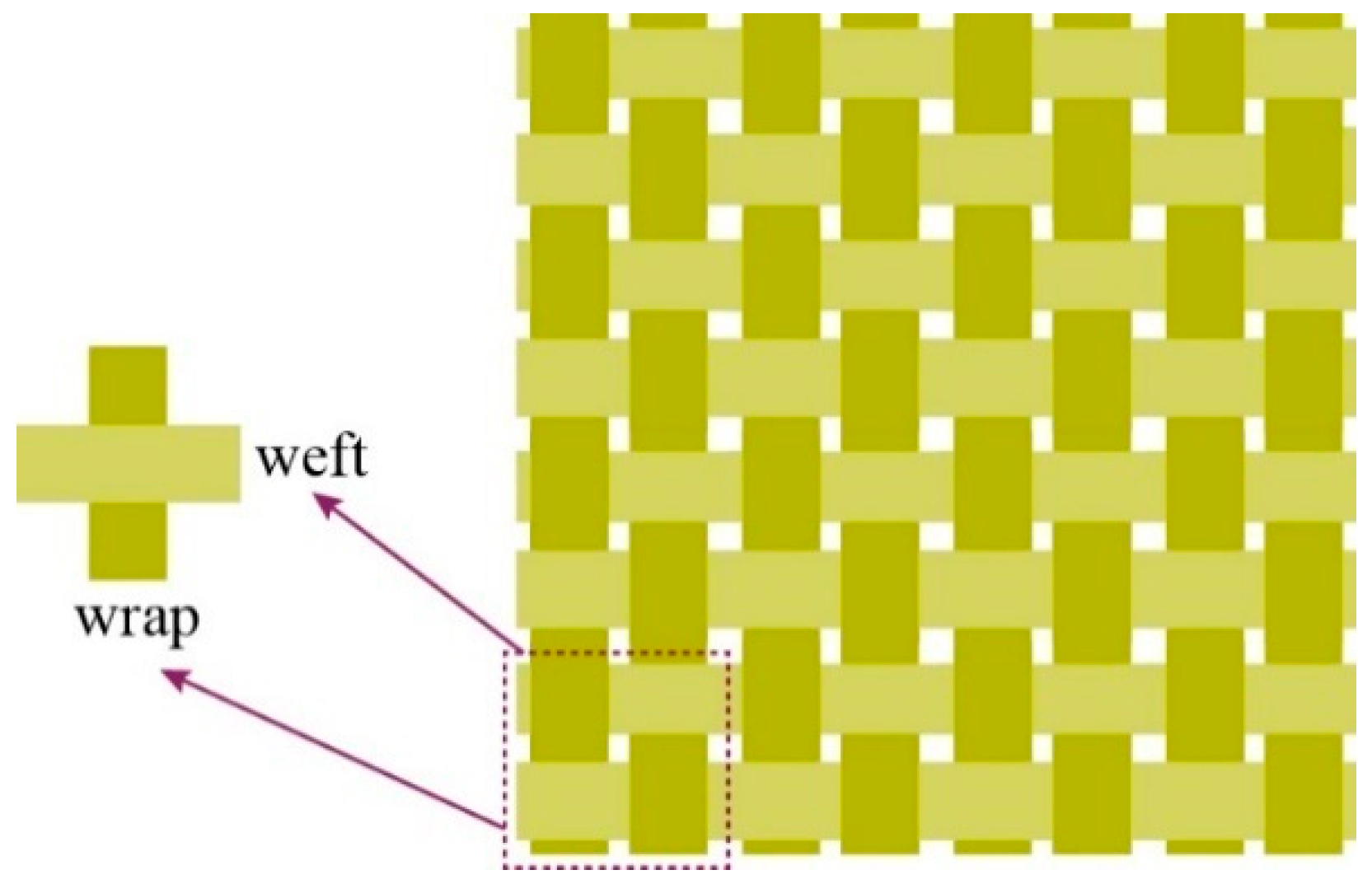

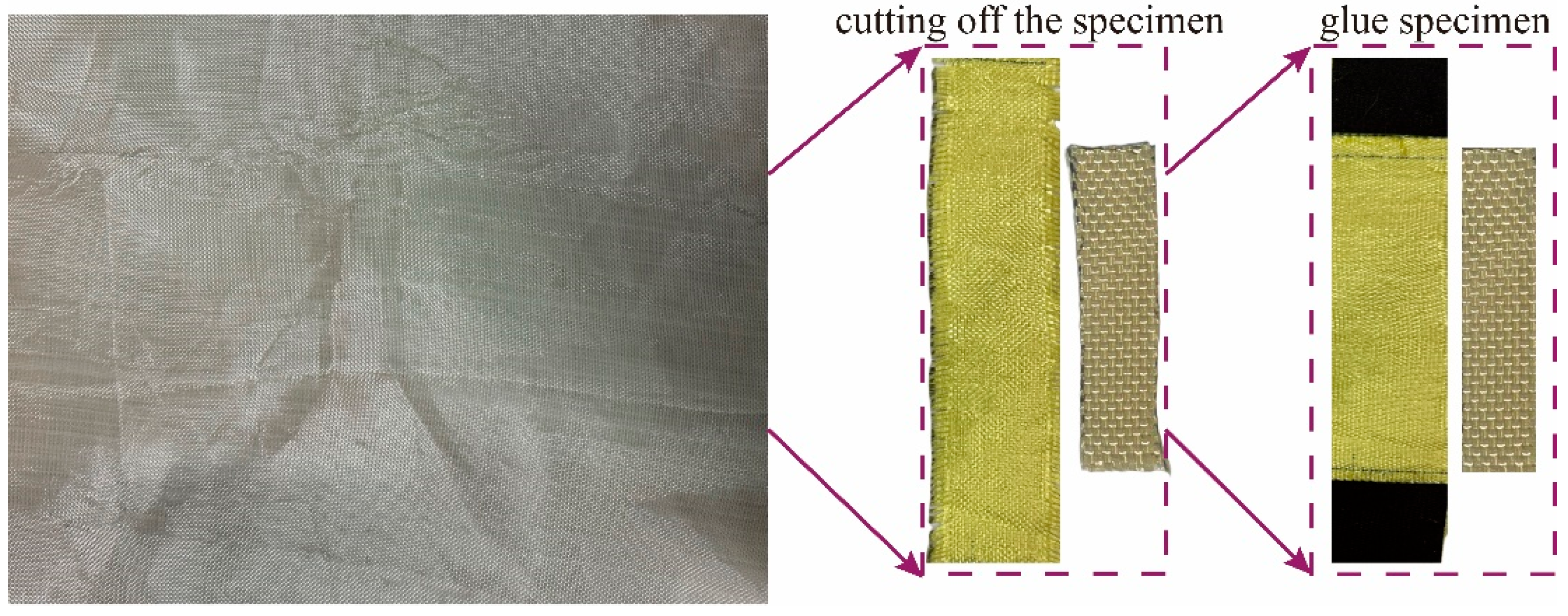

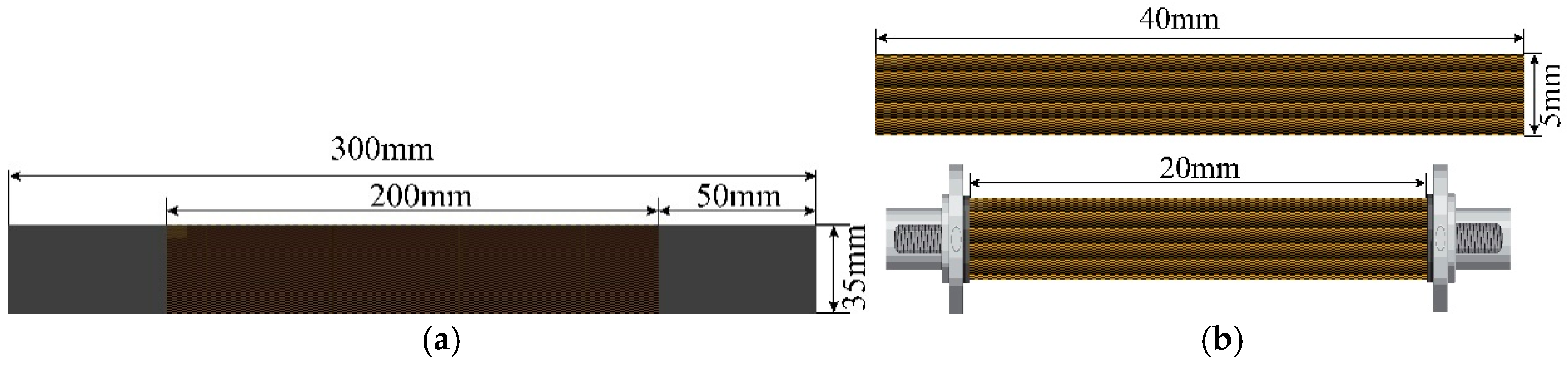

2.1. Specimen Preparation

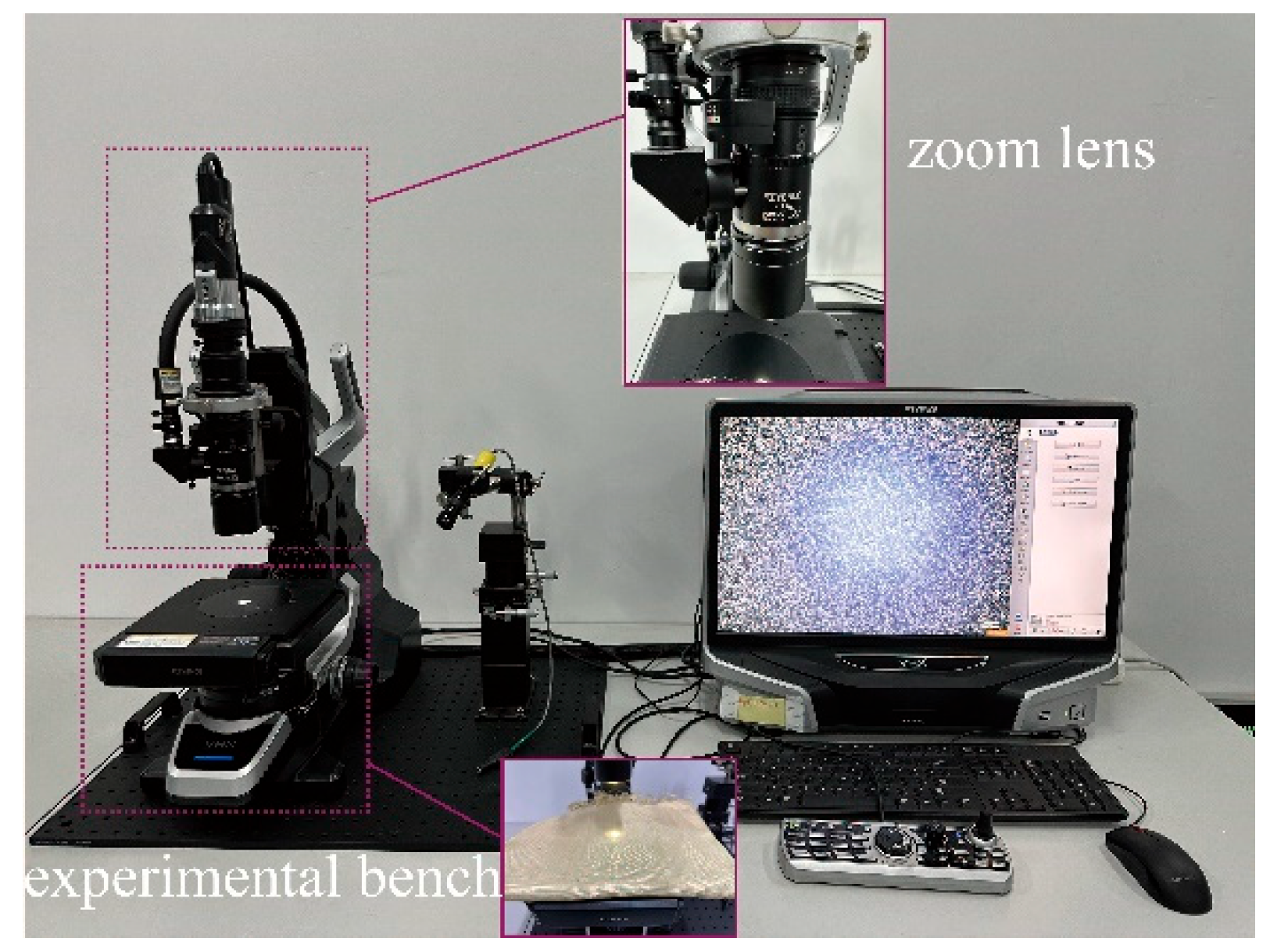

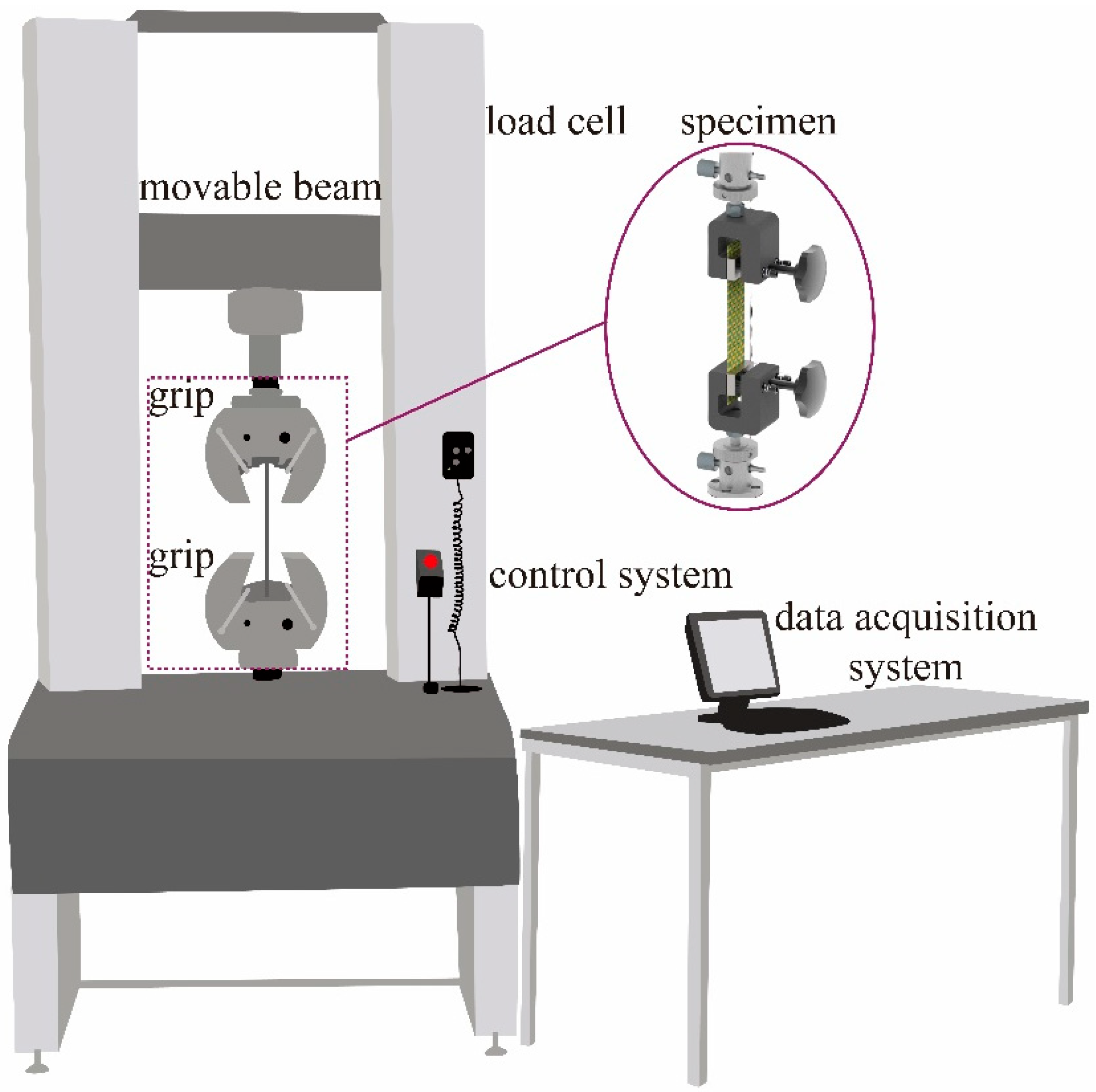

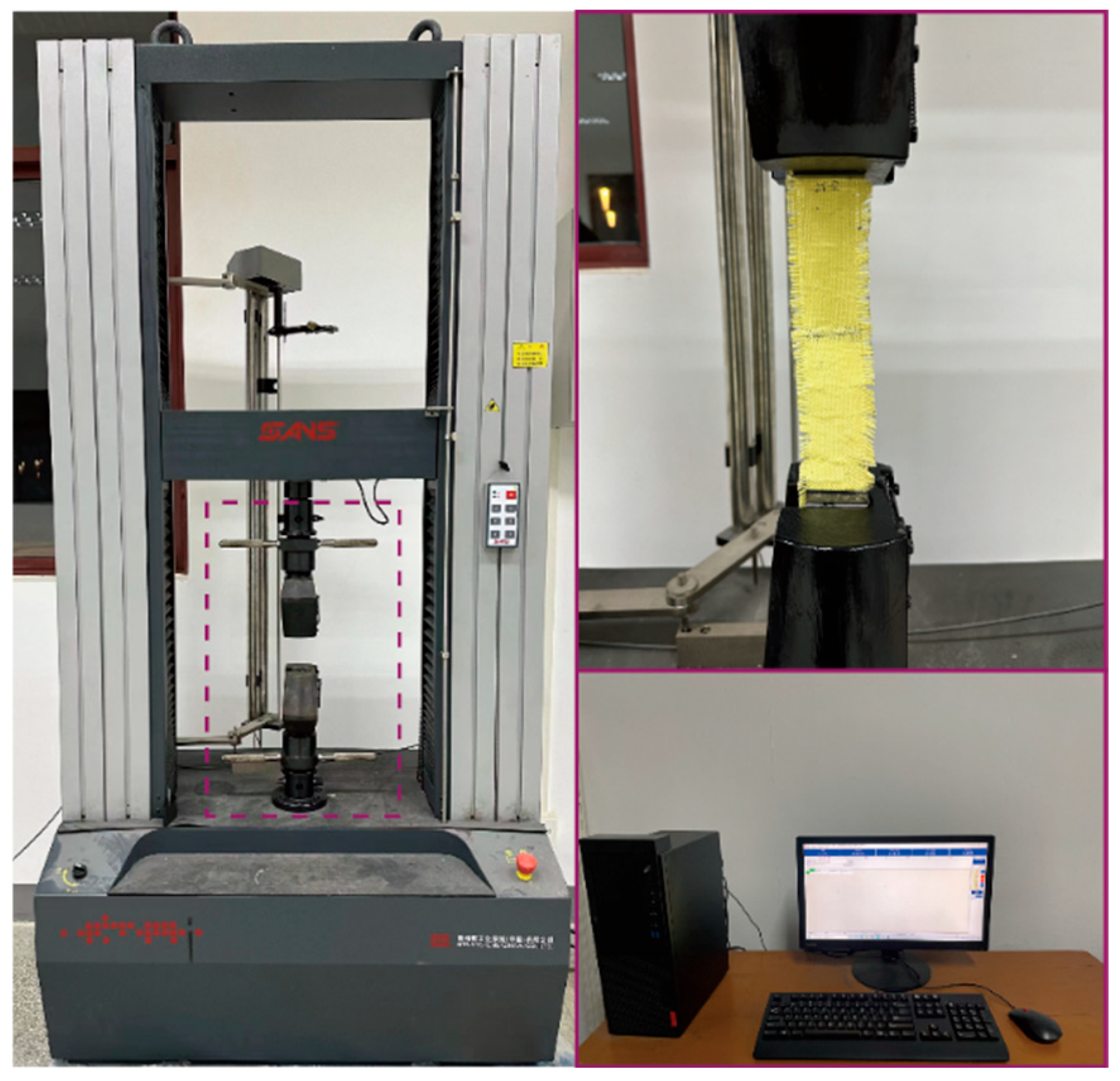

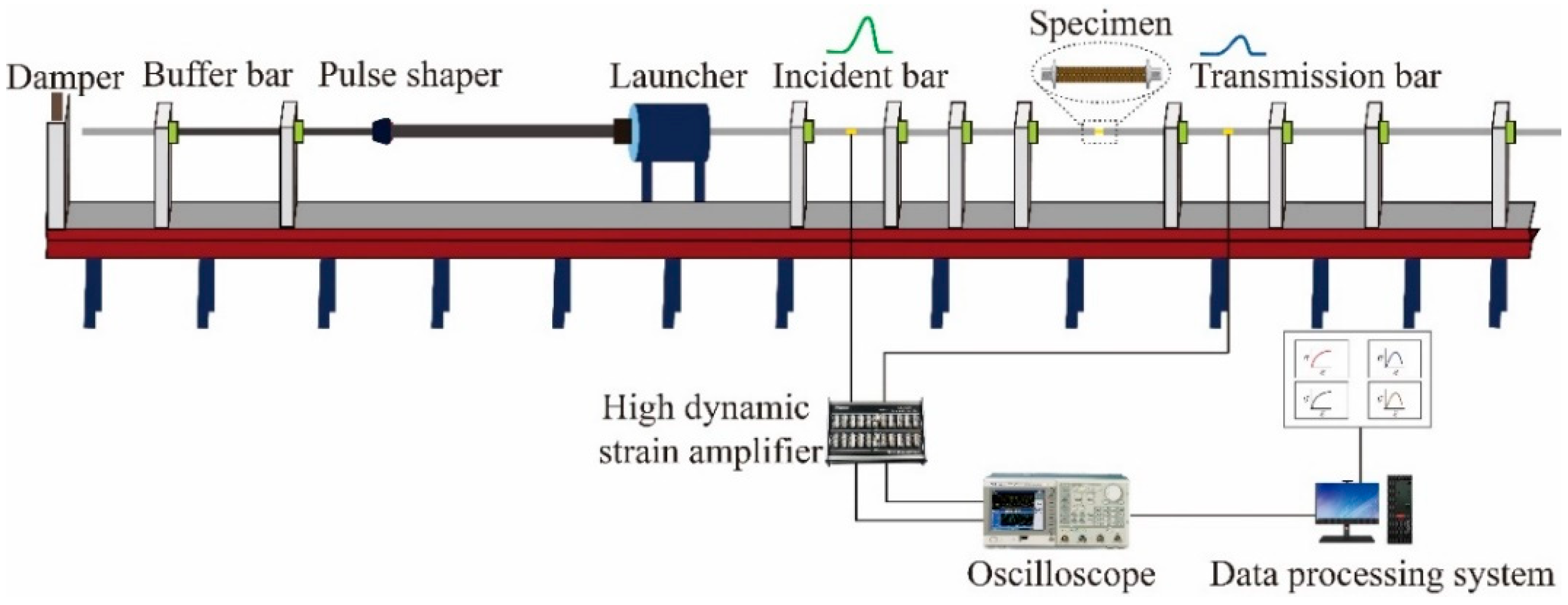

2.2. Experimental Methodology and Procedures

2.2.1. Quasi-Static Tensile Testing

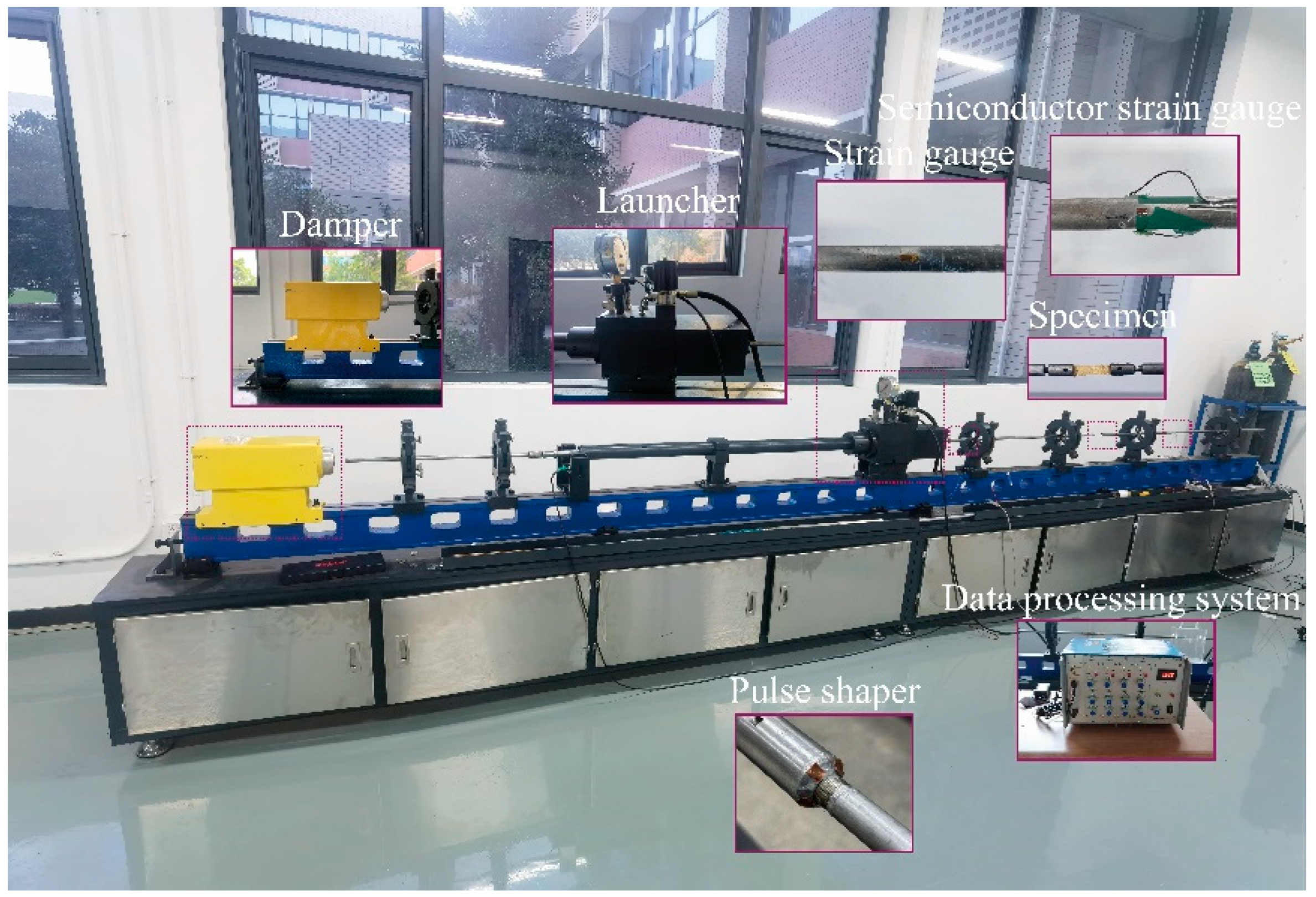

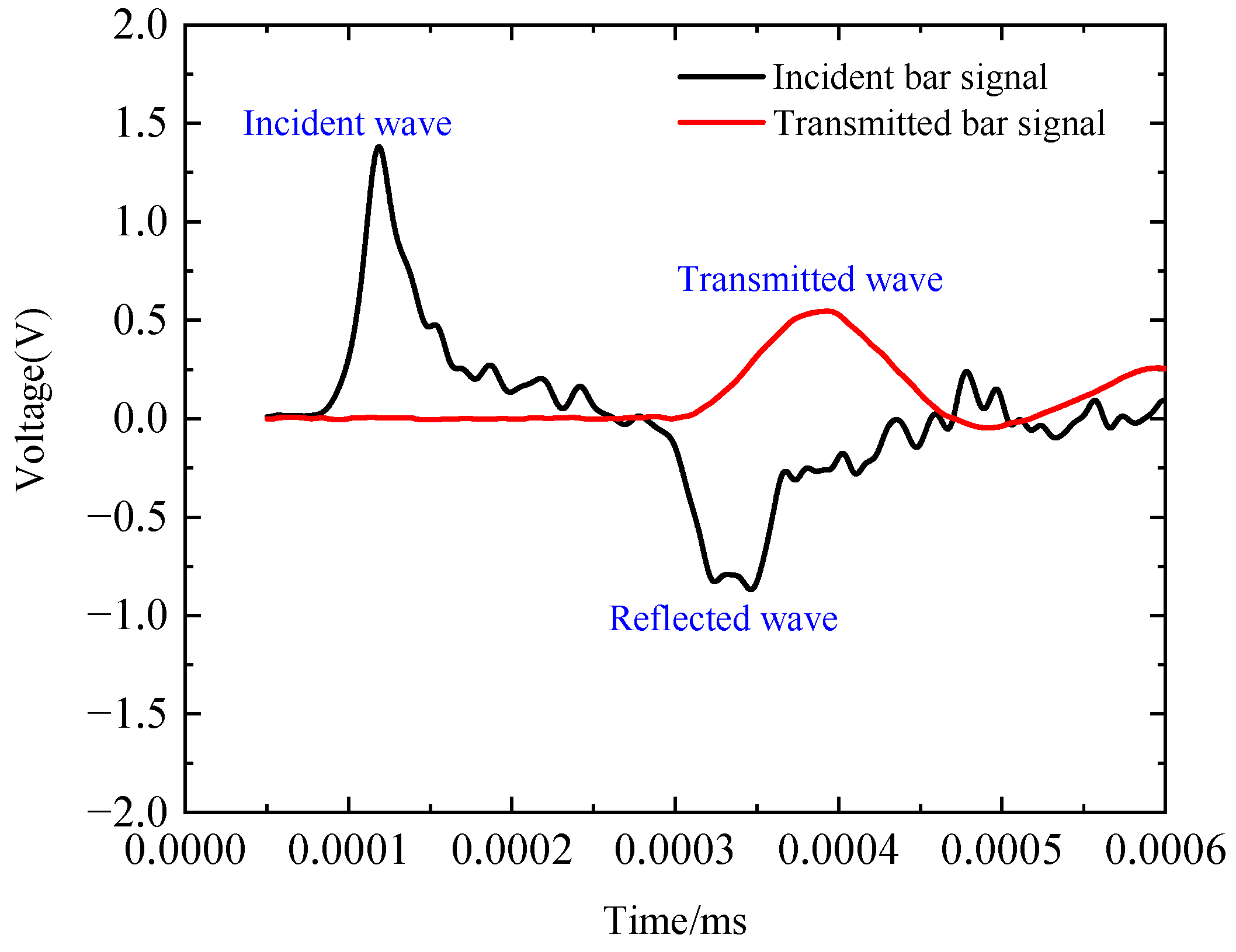

2.2.2. Dynamic Tensile Testing

3. Experimental Results and Analysis

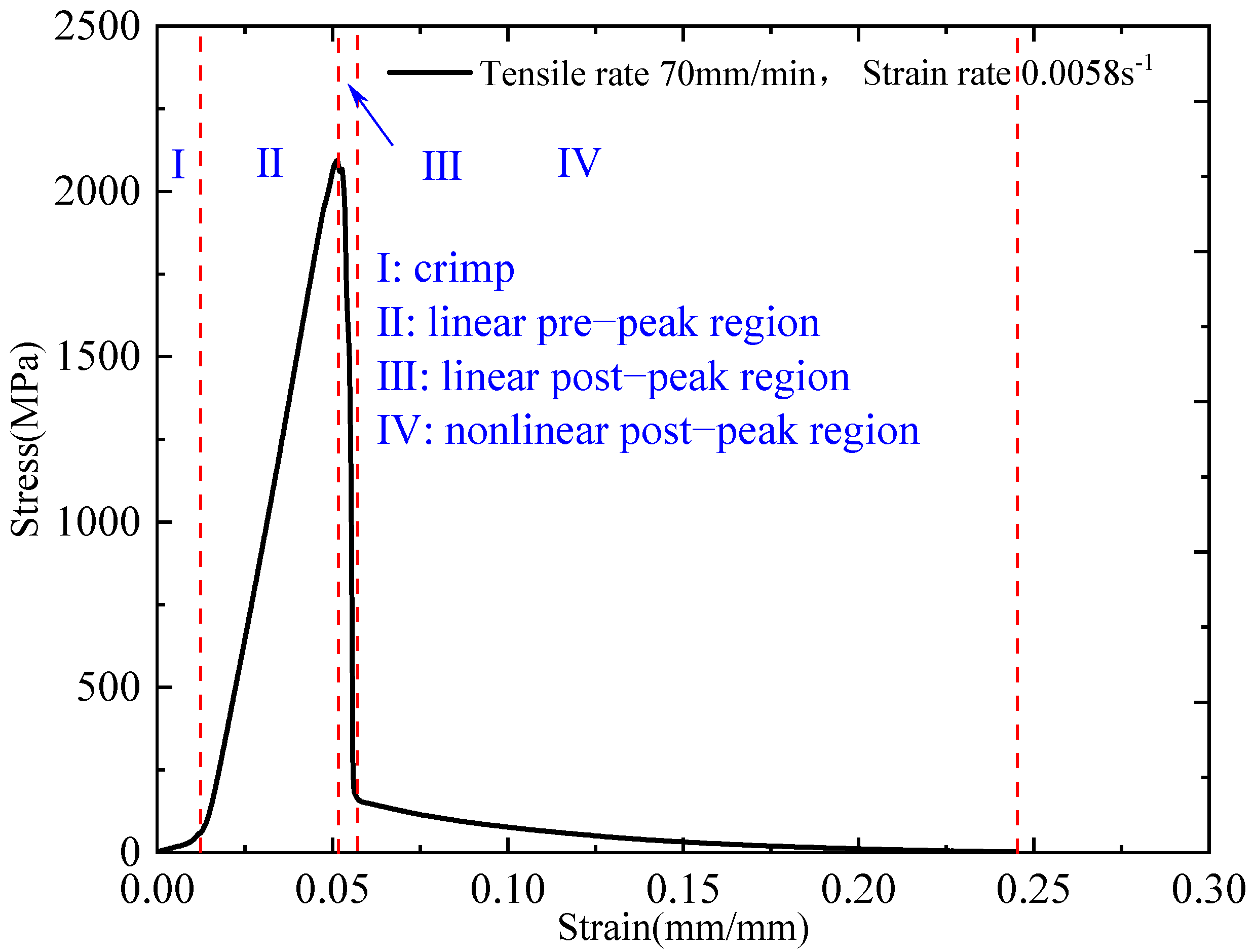

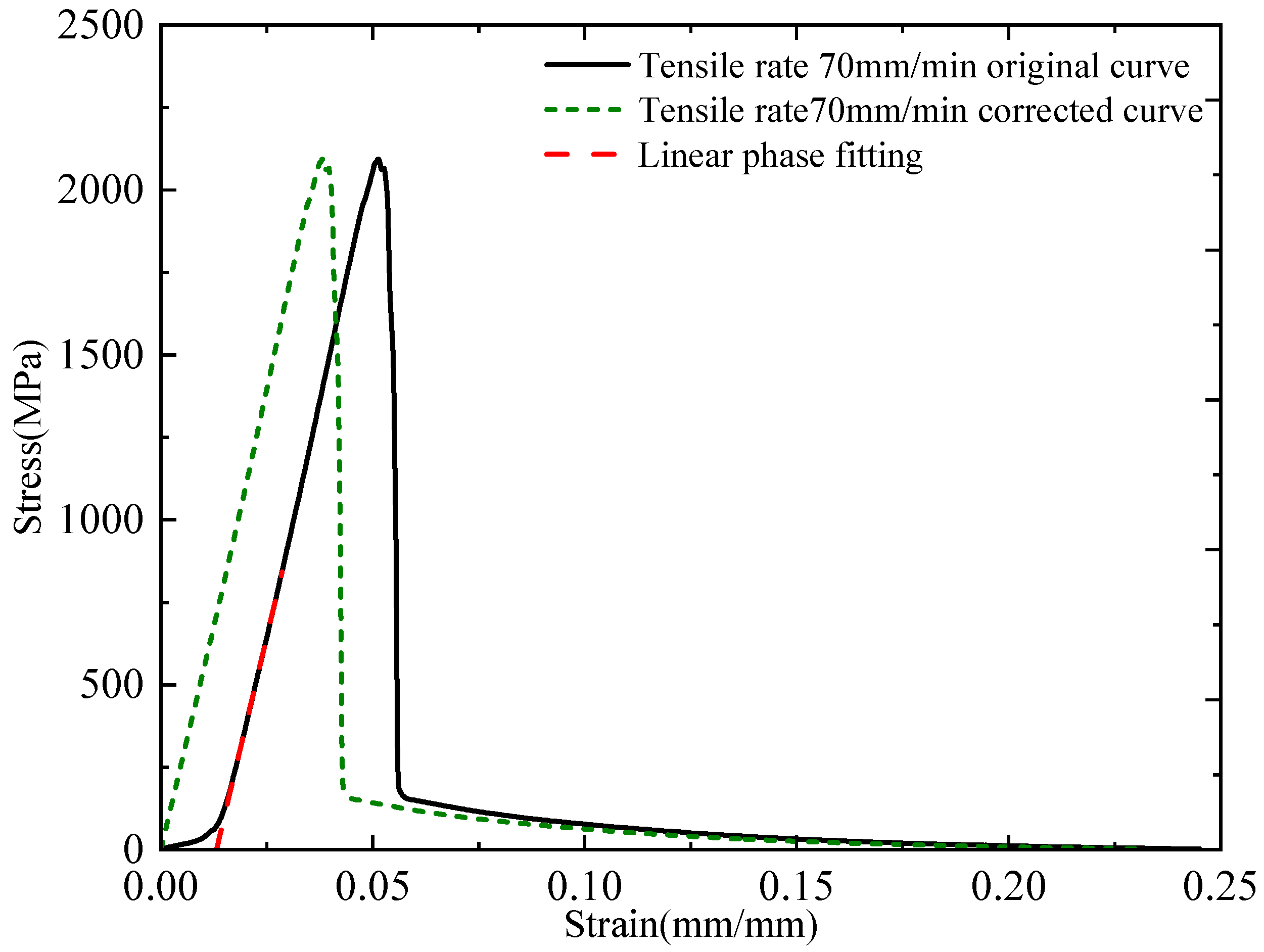

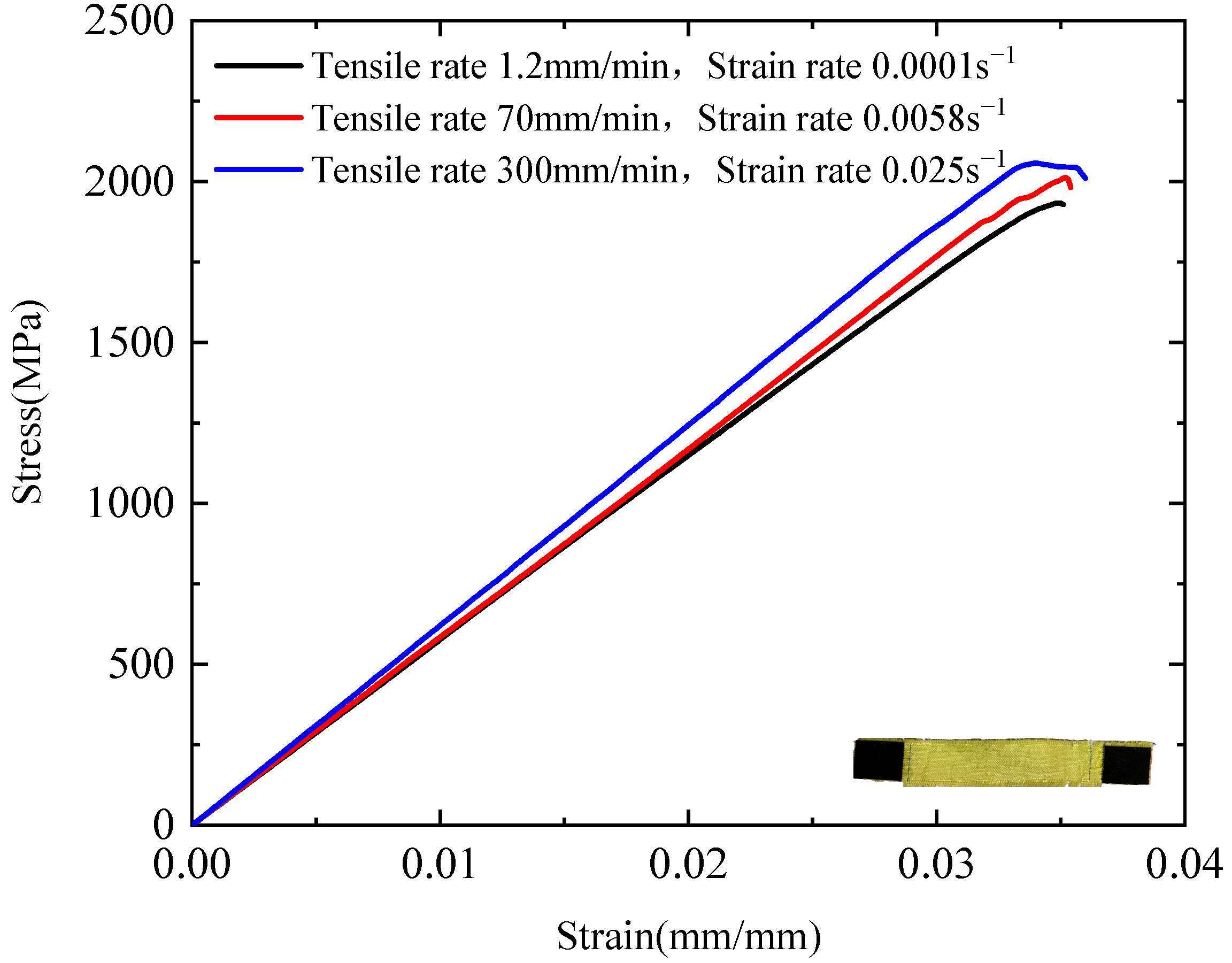

3.1. Quasi-Static Tensile Test Results

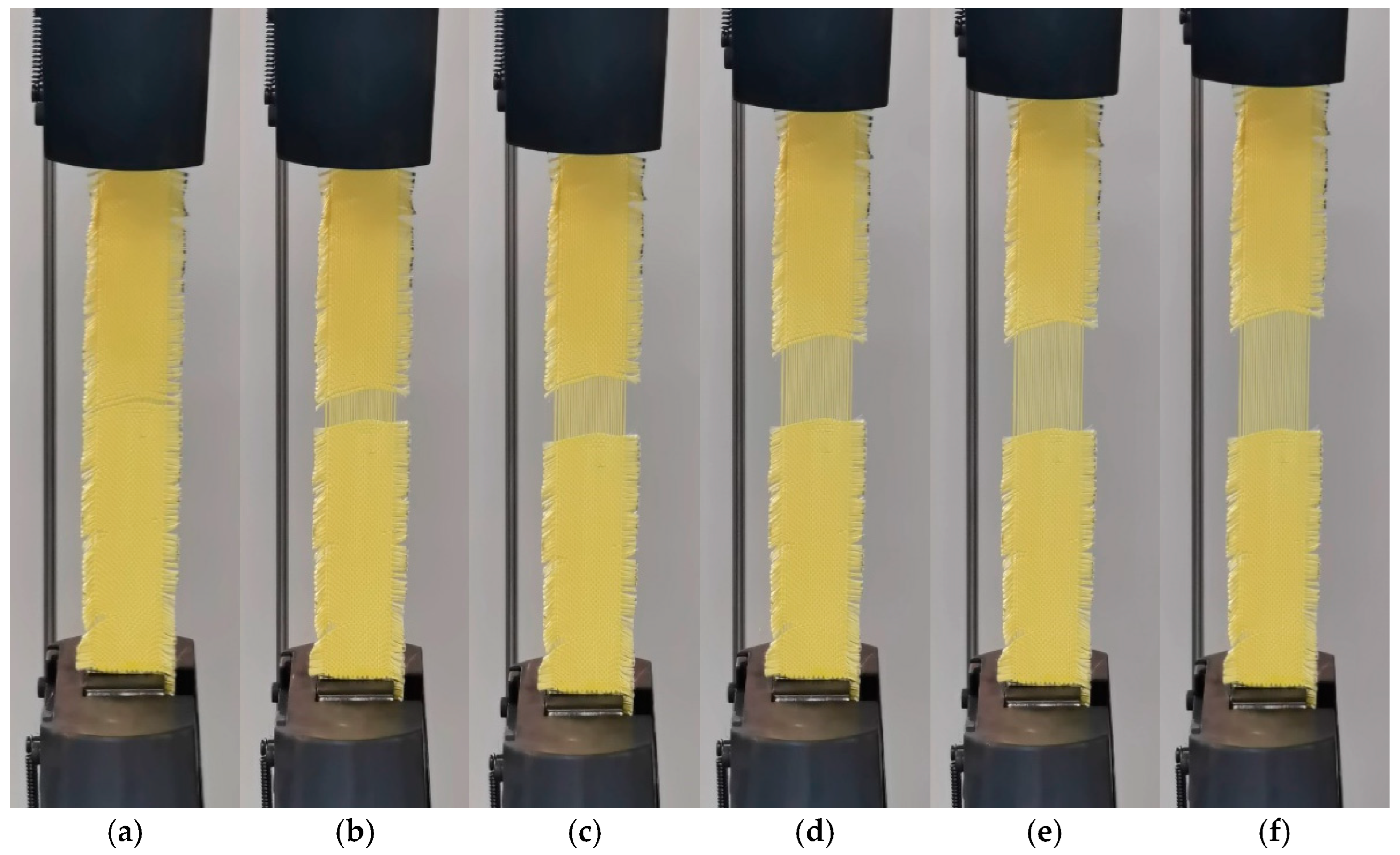

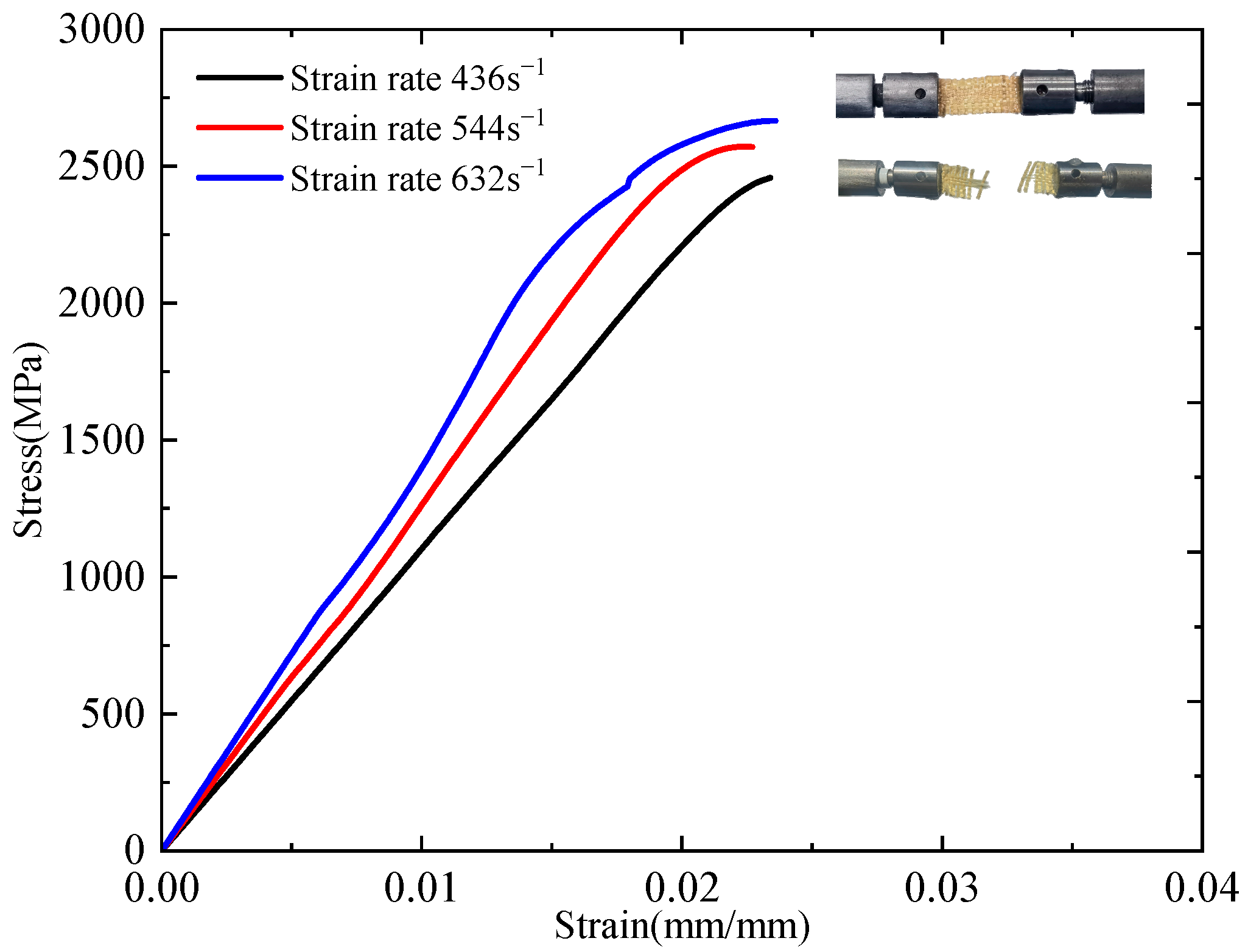

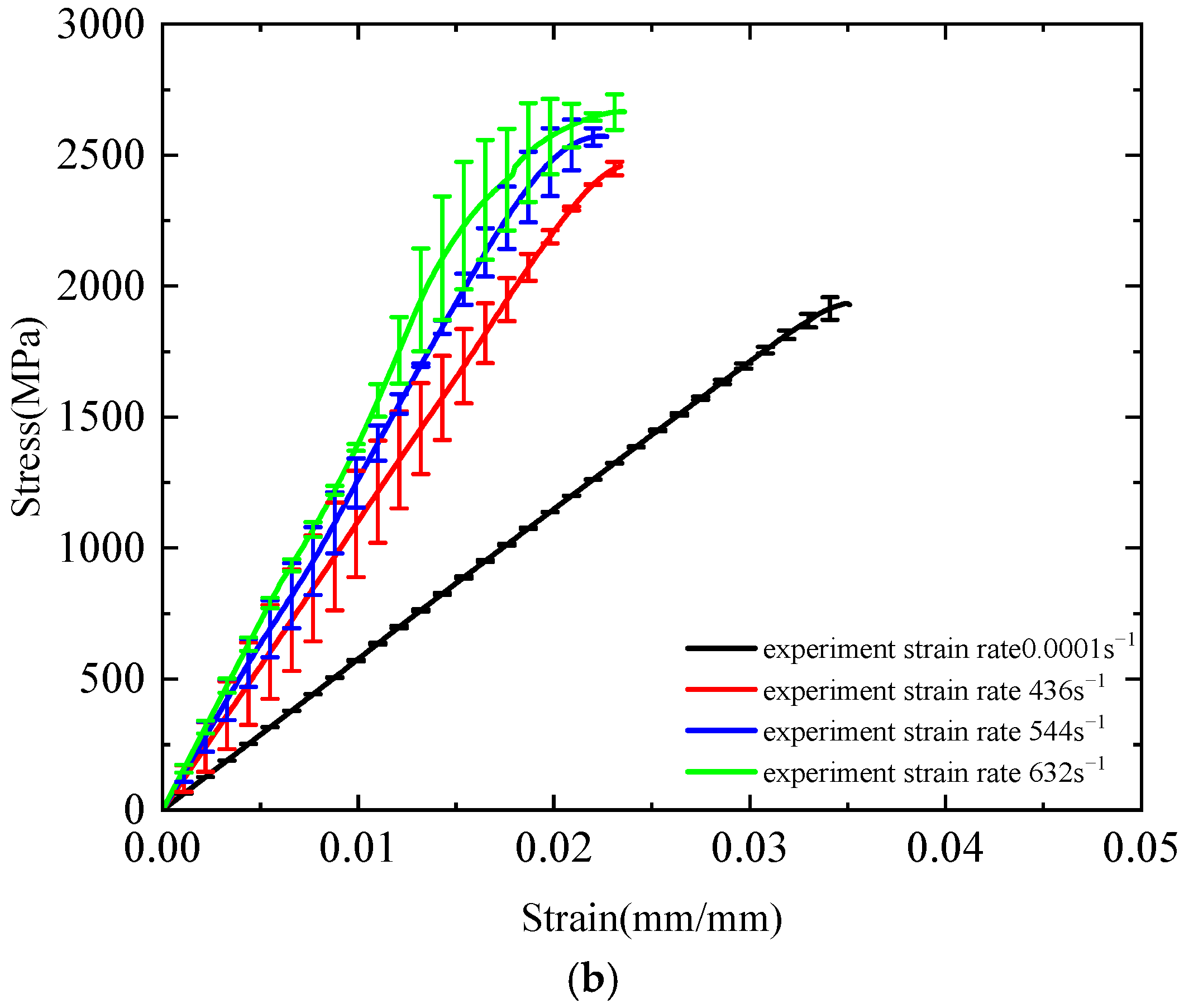

3.2. Dynamic Tensile Test Results

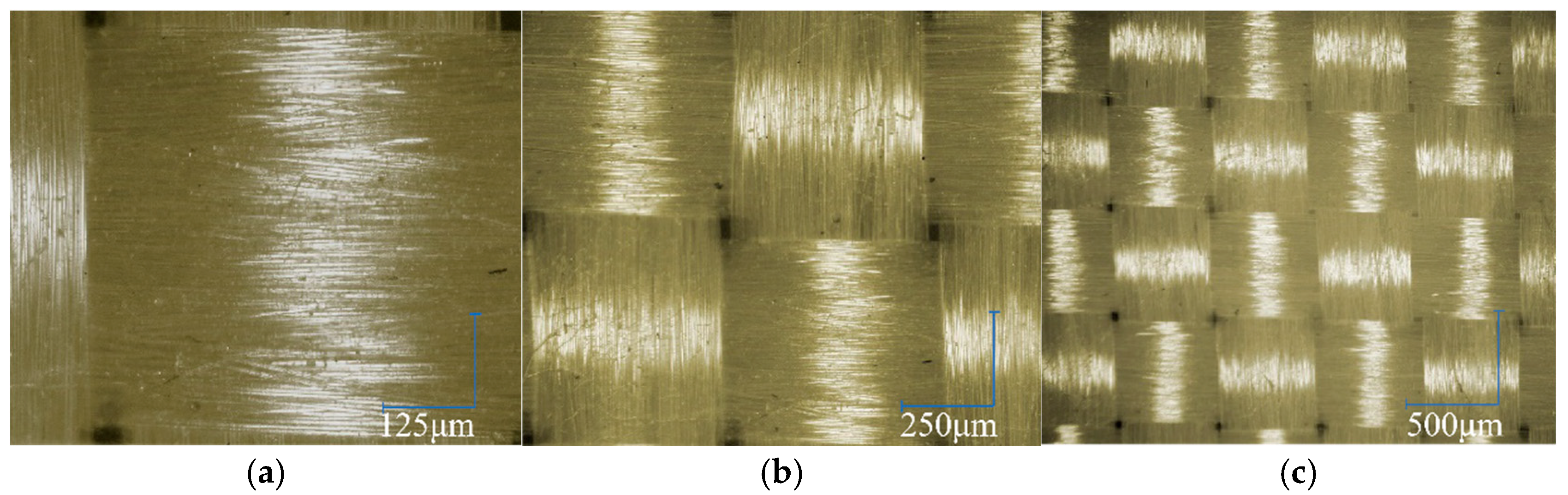

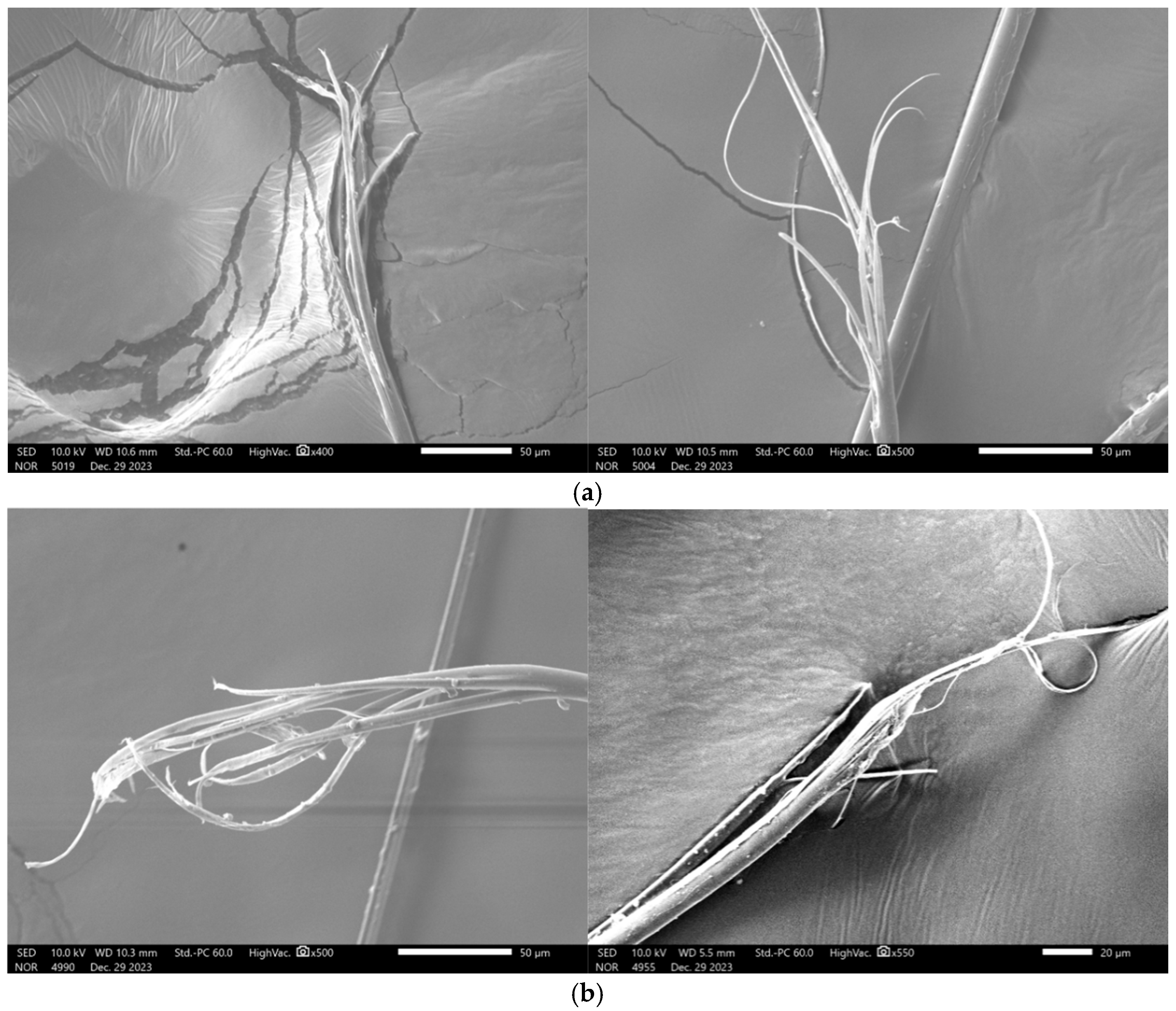

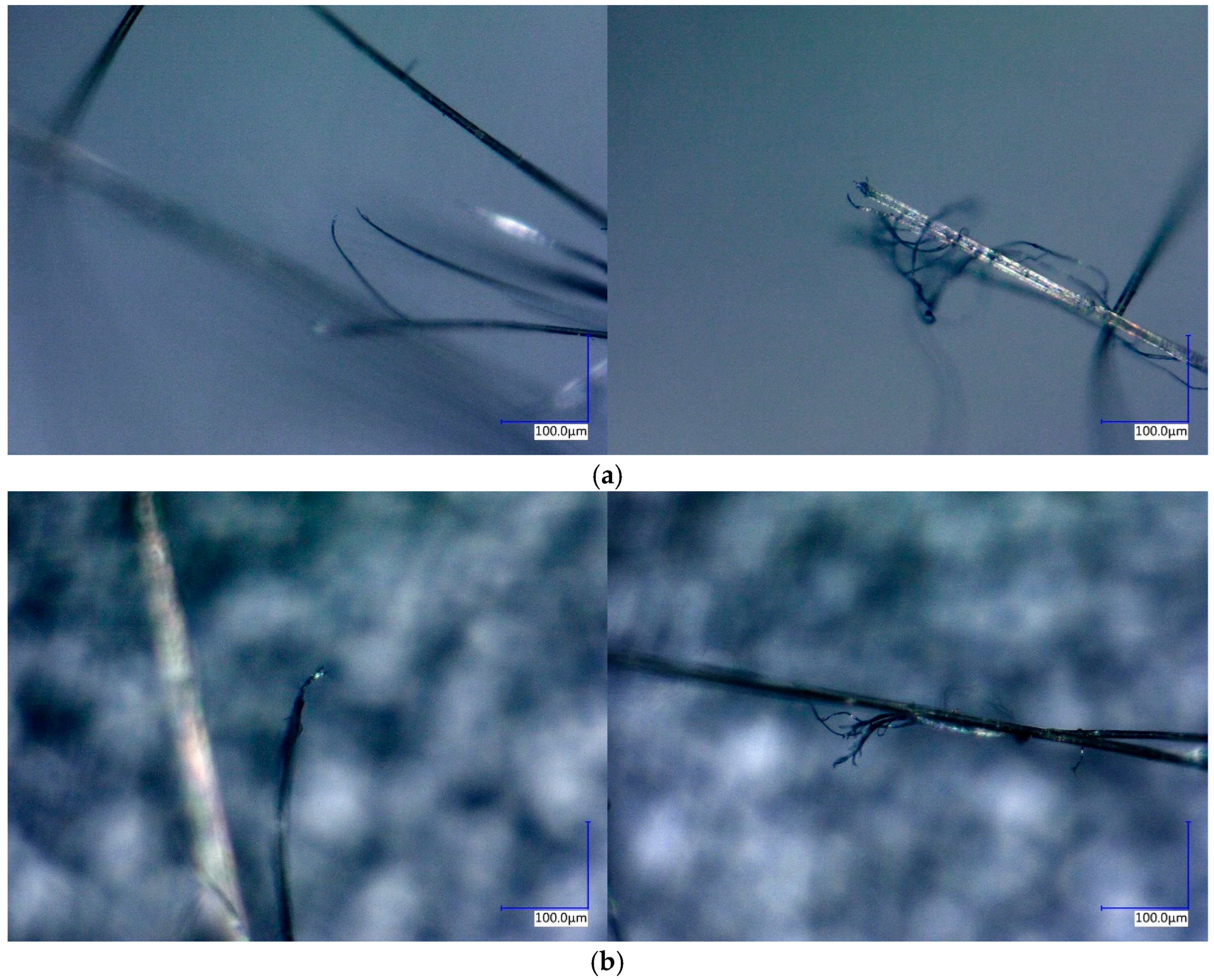

3.3. Microstructural Damage Characterisation

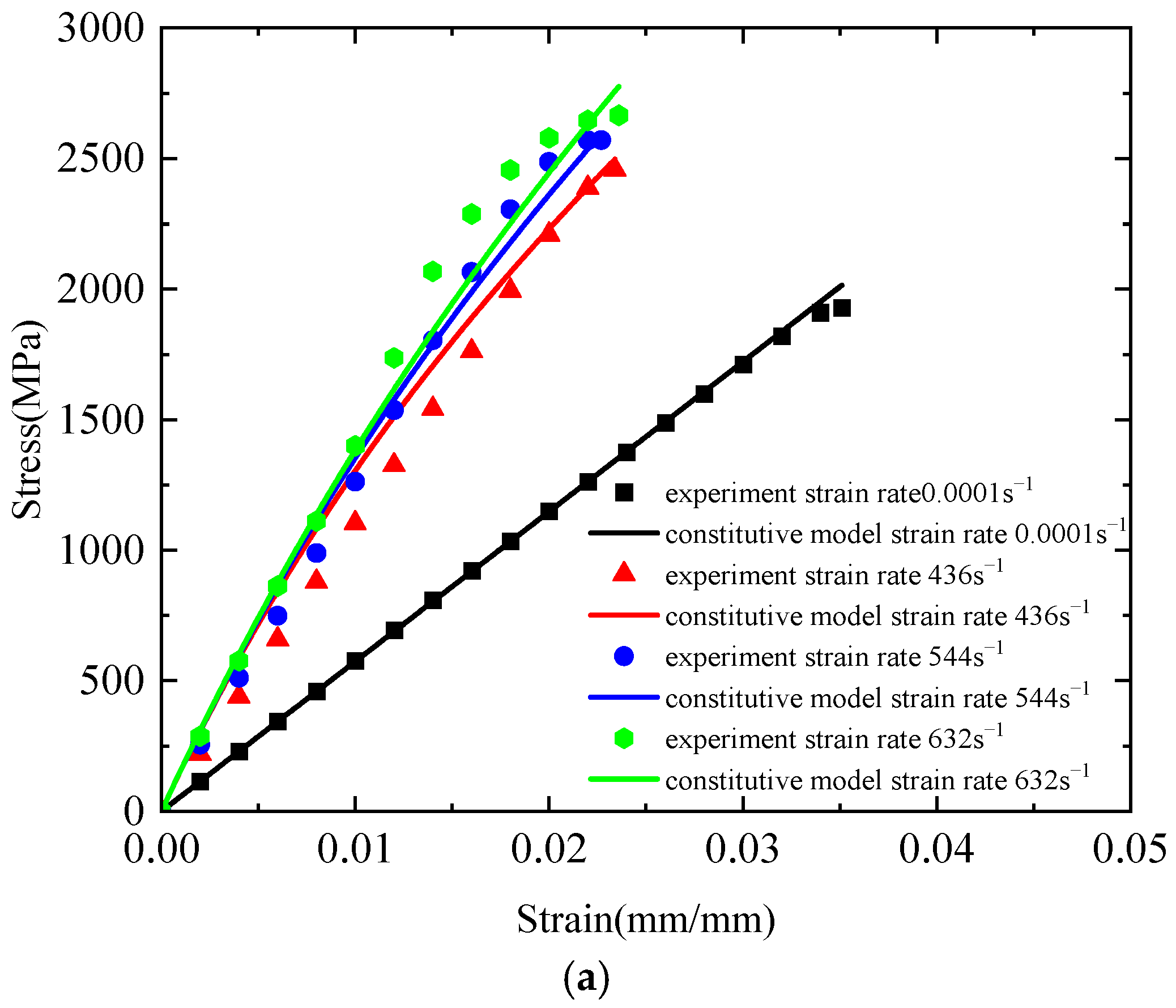

4. Constitutive Model

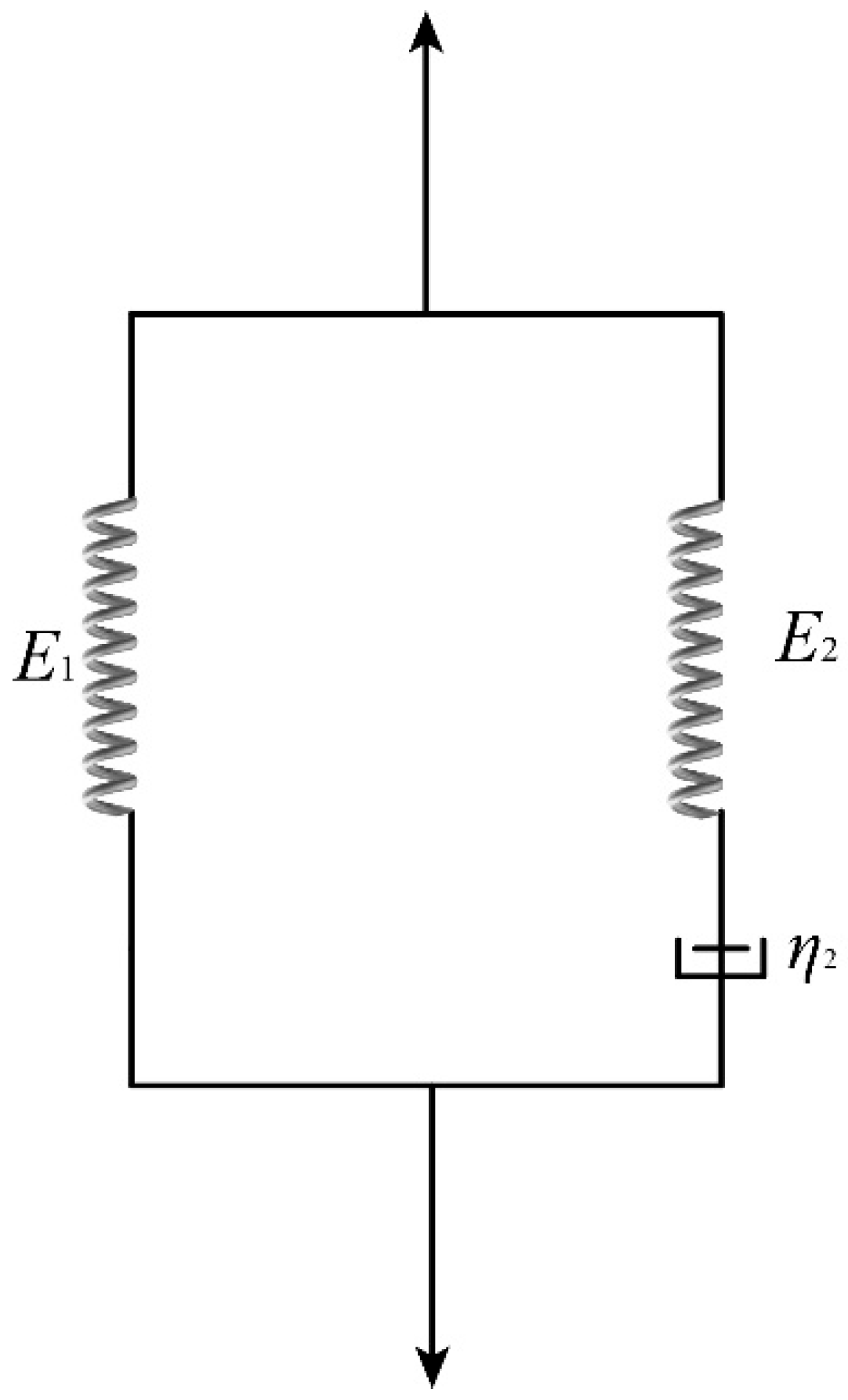

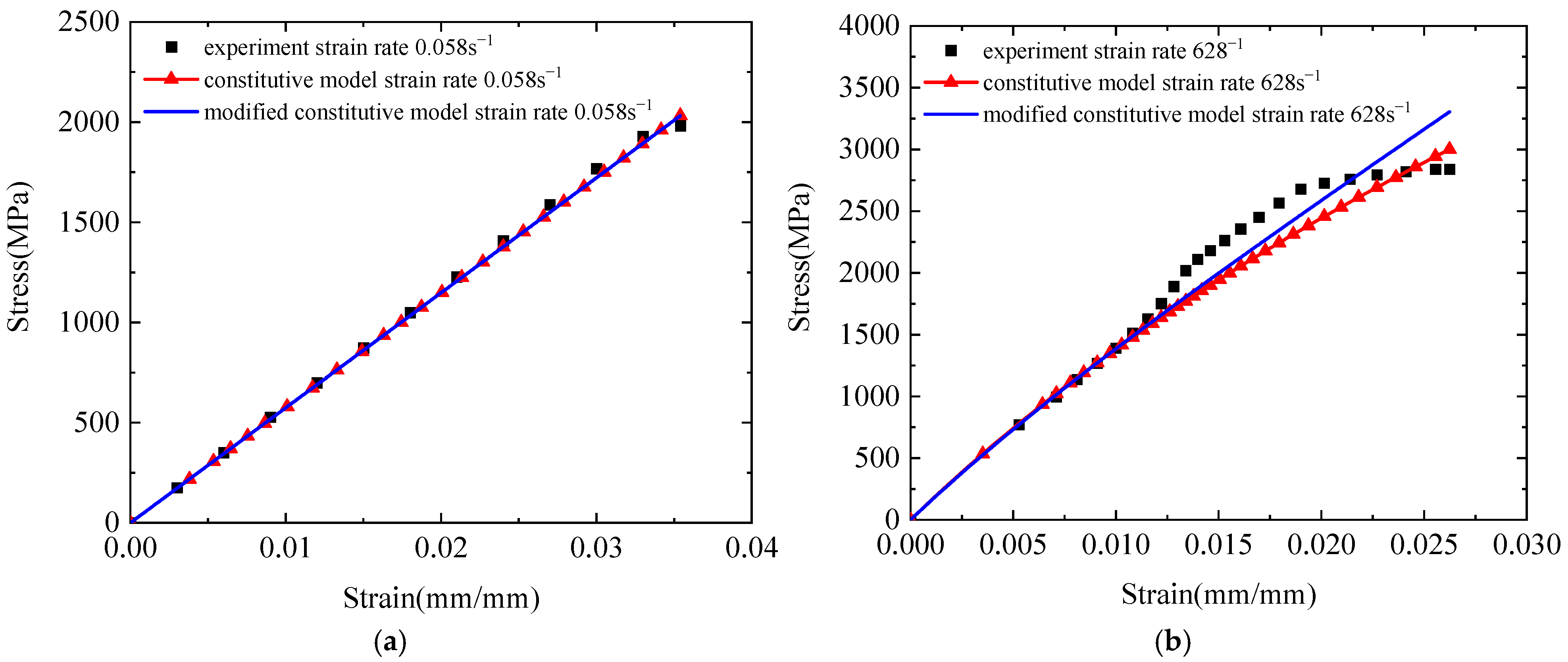

4.1. Three-Element Viscoelastic Constitutive Model

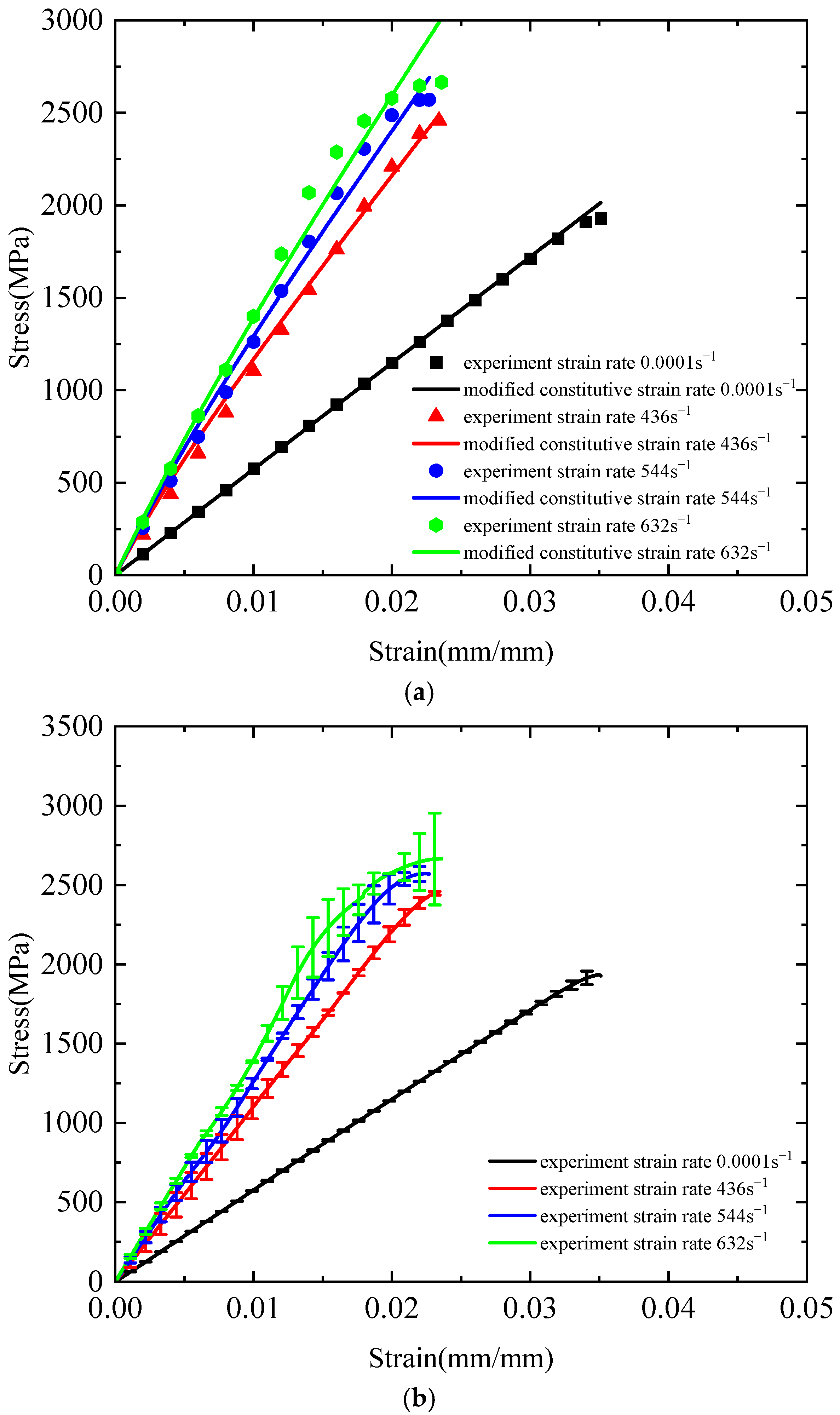

4.2. Modified Three-Element Viscoelastic Constitutive Model

5. Conclusions

- Under quasi-static tensile loading, the stress–strain response of the fabric can be divided into four distinct stages: the fibre crimp region, linear pre-peak region, linear post-peak region, and nonlinear post-peak region. The fabric exhibits clear strain-rate sensitivity, with tensile strength, Young’s modulus, and toughness increasing as the strain rate increases, whereas fracture strain and elongation at break decrease accordingly.

- Under dynamic tensile loading, the plain-woven fabric demonstrates pronounced strain-rate dependence. As the strain rate increases, tensile strength, elastic modulus, and toughness increase, whereas fracture strain decreases. Compared to quasi-static conditions, the fabric exhibits brittle fracture behaviour, resulting in complete specimen failure.

- Under quasi-static loading, fracture surfaces display evidence of plastic flow, with slight axial splitting and tapered fibre ends, features characteristic of ductile fracture. The ductile fracture behavior is associated with a necking mechanism, wherein localised plastic flow is achieved through dynamic hydrogen bond reorganization and fibrillar slippage of molecular chains, thereby retarding crack propagation. In contrast, dynamic loading produces sharply tapered fracture ends. At higher strain rates, significant axial splitting occurs with reduced splitting depth. Some fibres exhibit simultaneous rupture of both the surface and core layers, accompanied by fibrillation phenomena, indicating brittle fracture behaviour. Following the tensile failure, numerous microfibrils are observed along the fibre axis, along with localised temperature rise, resulting in charring or carbonisation. The brittle fracture behavior follows a crazing mechanism, wherein the hydrogen bond network and molecular chains cannot reorganize under rapid loading, leading to rapid nucleation and propagation of microcracks at stress concentration sites (e.g., grain boundaries or defects).

- The modified three-element viscoelastic constitutive model effectively captures the strain-rate-dependent mechanical behaviour of plain-woven Kevlar® fabrics and accurately describes their tensile response across a range of strain rates. These findings provide valuable data for advancing ballistic protection research and optimising the performance of protective materials.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Leiva Palomera, D.F.; Fernández Abreu, M.E.; Valín Rivera, J.L.; Valin Fernández, M.; Ferreira de Amorim Júnior, W.; Valenzuela Diaz, F.R.; Alcaino Molina, D.A.; Mendez Jofre, P.E.; Ketterer, C.I.G. Analysis of the ballistic effectiveness of the hybrid composite of polyurethane and kevlar 29 with different grammages. Polymers 2025, 17, 372. [Google Scholar] [CrossRef]

- Yang, D.; Liu, S.; Zhang, W.; Liu, Q.; Yao, G.; Zhu, K. High-velocity impact performance of ballistic fabric using core-spun compound yarns. Polymers 2024, 16, 2973. [Google Scholar] [CrossRef]

- Lu, Z.Q.; Yuan, Z.S.; Chen, X.G.; Qiu, J. Evaluation of ballistic performance of STF impregnated fabrics under high velocity impact. Compos. Struct. 2019, 227, 111208. [Google Scholar] [CrossRef]

- Shim, V.P.W.; Lim, C.T.; Foo, K.J. Dynamic mechanical properties of fabric armour. Int. J. Impact Eng. 2001, 25, 1–15. [Google Scholar] [CrossRef]

- Naik, D.; Sankaran, S.; Mobasher, B.; Rajan, S.D.; Pereira, J.M. Development of reliable modeling methodologies for fan blade out containment analysis—Part I: Experimental studies. Int. J. Impact Eng. 2009, 36, 1–11. [Google Scholar] [CrossRef]

- Stahlecker, Z.; Mobasher, B.; Rajan, S.D.; Pereira, J.M. Development of reliable modeling methodologies for engine fan blade out containment analysis—Part II: Finite element analysis. Int. J. Impact Eng. 2009, 36, 447–459. [Google Scholar] [CrossRef]

- Cheng, M.; Chen, W.N.; Weerasooriya, T. Experimental investigation of the transverse mechanical properties of a single Kevlar® KM2 fiber. Int. J. Solids Struct. 2004, 41, 6215–6232. [Google Scholar] [CrossRef]

- Sanborn, B.; Gunnarsson, C.A.; Moy, P.; Zheng, J.Q.; Weerasooriya, T. Effect of strain rate and pre-twist on strength of single Kevlar® KM2 fiber. Dyn. Behav. Mater. 2013, 1, 445–447. [Google Scholar] [CrossRef]

- Tapie, E.; Shim, V.P.W.; Guo, Y.B. Influence of weaving on the mechanical response of aramid yarns subjected to high-speed loading. Int. J. Impact Eng. 2015, 80, 1–12. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, Y.M. The effects of strain rate on the mechanical behaviour of Kevlar fibre bundles: An experimental and theoretical study. Compos. Part A Appl. Sci. Manuf. 1998, 29, 1411–1415. [Google Scholar] [CrossRef]

- Zhu, L.T.; Sun, B.Z. Fracture mechanism of basalt filament and Twaron filament under high strain rate tensile. J. Donghua Univ. (Nat. Sci. Ed.) 2011, 37, 565–569. [Google Scholar] [CrossRef]

- Liu, L.L.; Chen, W.; Shi, Q.Z.; Zhao, Z.H.; Guan, Y.P. Investigation on the high speed impact numerical simulation method of Kevlar fabrics based on its unit cell model. Aeronaut. Sci. Technol. 2015, 26, 119–125. [Google Scholar] [CrossRef]

- Liu, L.L.; Yang, Z.Z.; Liu, X.; Chen, W.; Zhao, Z.; Luo, G. Yarn dynamic tensile behavior and meso-scale numerical simulation method for STF-Kevlar fabrics. Thin Walled Struct. 2021, 159, 107319. [Google Scholar] [CrossRef]

- Zhu, D.J.; Ou, Y.F.; Zhang, X.T.; Huang, M.Y. Experiment study and finite element modeling of the multi-scale mechanical behavior of Kevlar® 29 fibers. Eng. Mech. 2016, 33, 242–249. [Google Scholar] [CrossRef]

- Zhu, D.J.; Ou, Y.F.; Zhang, X.T.; Huang, M.Y. Probabilistic failure and finite element simulation of Kevlar 49 single filament and single yarn. Acta Mater. Compos. Sin. 2016, 33, 213–223. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, L.Z.; Ren, W.K.; Gao, G.F. Dynamic tensile mechanical properties and constitutive equation of Kevlar 29 yarn. Explos. Shock Waves 2024, 44, 013101. [Google Scholar] [CrossRef]

- Lei, J.F.; Xuan, Y.; Liu, T.; Jiang, X.Q.; Duan, F.Y.; Wei, Z. Experiments of dynamic tensile properties of a polyvinyl chloride elastomer. Chin. J. High Press. Phys. 2021, 35, 034101. [Google Scholar] [CrossRef]

- Wang, A.Q.; Liu, Y.; Yan, R.; Wang, Y.Y.; Luo, P.J.; Li, Y.B. Enhanced dynamic impact resistance of 3d-printed continuous optical fiber-reinforced helicoidal polylactic acid composites. Polymers 2023, 15, 4599. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, F.X.; Yang, B.; Li, L.; Gao, L.; Guo, F.Z. Mechanical response and failure mechanisms of natural bamboo fiber reinforced poly-benzoxazine composite subjected to Split-Hopkinson Tensile Bar loading. Polymers 2022, 14, 1450. [Google Scholar] [CrossRef]

- Liu, G.K.; Bai, Z.X.; Liu, W.; He, Y.J. Research on compression failure characteristics and damage constitutive model of steel fiber-reinforced concrete with 2% copper-coated fibers under impact load. Materials 2024, 17, 5724. [Google Scholar] [CrossRef]

- Hu, F.Q.; Liu, X.; Wang, B.S.; Xiang, Y. Investigations on the Johnson-Cook constitutive and damage-fracture model parameters of a Q345C steel. Metals 2024, 14, 509. [Google Scholar] [CrossRef]

- Li, F.; Sun, R.C.; Zhang, Y.; Wang, G.H.; Xiang, G.Y. Dynamic response characteristics and damage evolution of multi-layer combined coal and rock mass under impact loading. Sustainability 2022, 14, 9175. [Google Scholar] [CrossRef]

- Vangheluwe, L. Influence of strain rate and yarn number on tensile test results. Text. Res. J. 1992, 62, 586–589. [Google Scholar] [CrossRef]

- Wang, L.L. Foundation of Stress Waves; National Defense Industry Press: Beijing, China, 2010. [Google Scholar]

| Areal Density | Cross-Sectional Area | Linear Density | Yarn Count | Volumetric Density | Fibre Type | Manufacturer |

|---|---|---|---|---|---|---|

| /(g·m−2) | /(cm2) | /(g·m−1) | /D | /(g·cm−3) | ||

| 200 | 7.7 × 10−4 | 0.11 | 1000 | 1.44 | Kevlar® 29 | DuPontTM |

| Wave Impedance | Wave Velocity | Poisson’s Ratio | Elastic Modulus | Density | Material |

|---|---|---|---|---|---|

| /(kg·m−2·s−1) | /(m·s−1) | /(GPa) | /(g·cm−3) | ||

| 4.07 × 107 | 5.18 × 103 | 0.3 | 1.44 | 7.85 | 60Si2MnA Spring steel (Huoxin, Luoyang, China) |

| η2/(MPa·s) | E2/(GPa) | E1/(GPa) |

|---|---|---|

| 3.23 | 103.11 | 57.4 |

| η2/(MPa·s) | E3/(MPa) | E2/(GPa) | E1/(GPa) |

|---|---|---|---|

| 0.59 | 87.5 | 45.6 | 57.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Feng, Y.; Kang, B.; Song, J.; Li, Z.; Wu, Z.; Zhang, W. Strain-Rate-Dependent Tensile Behaviour and Viscoelastic Modelling of Kevlar® 29 Plain-Woven Fabric for Ballistic Applications. Polymers 2025, 17, 2097. https://doi.org/10.3390/polym17152097

Liu K, Feng Y, Kang B, Song J, Li Z, Wu Z, Zhang W. Strain-Rate-Dependent Tensile Behaviour and Viscoelastic Modelling of Kevlar® 29 Plain-Woven Fabric for Ballistic Applications. Polymers. 2025; 17(15):2097. https://doi.org/10.3390/polym17152097

Chicago/Turabian StyleLiu, Kun, Ying Feng, Bao Kang, Jie Song, Zhongxin Li, Zhilin Wu, and Wei Zhang. 2025. "Strain-Rate-Dependent Tensile Behaviour and Viscoelastic Modelling of Kevlar® 29 Plain-Woven Fabric for Ballistic Applications" Polymers 17, no. 15: 2097. https://doi.org/10.3390/polym17152097

APA StyleLiu, K., Feng, Y., Kang, B., Song, J., Li, Z., Wu, Z., & Zhang, W. (2025). Strain-Rate-Dependent Tensile Behaviour and Viscoelastic Modelling of Kevlar® 29 Plain-Woven Fabric for Ballistic Applications. Polymers, 17(15), 2097. https://doi.org/10.3390/polym17152097