Thermal History-Dependent Deformation of Polycarbonate: Experimental and Modeling Insights

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Specimen Preparation

2.2. Annealing Experiment

2.3. Uniaxial Tension Test

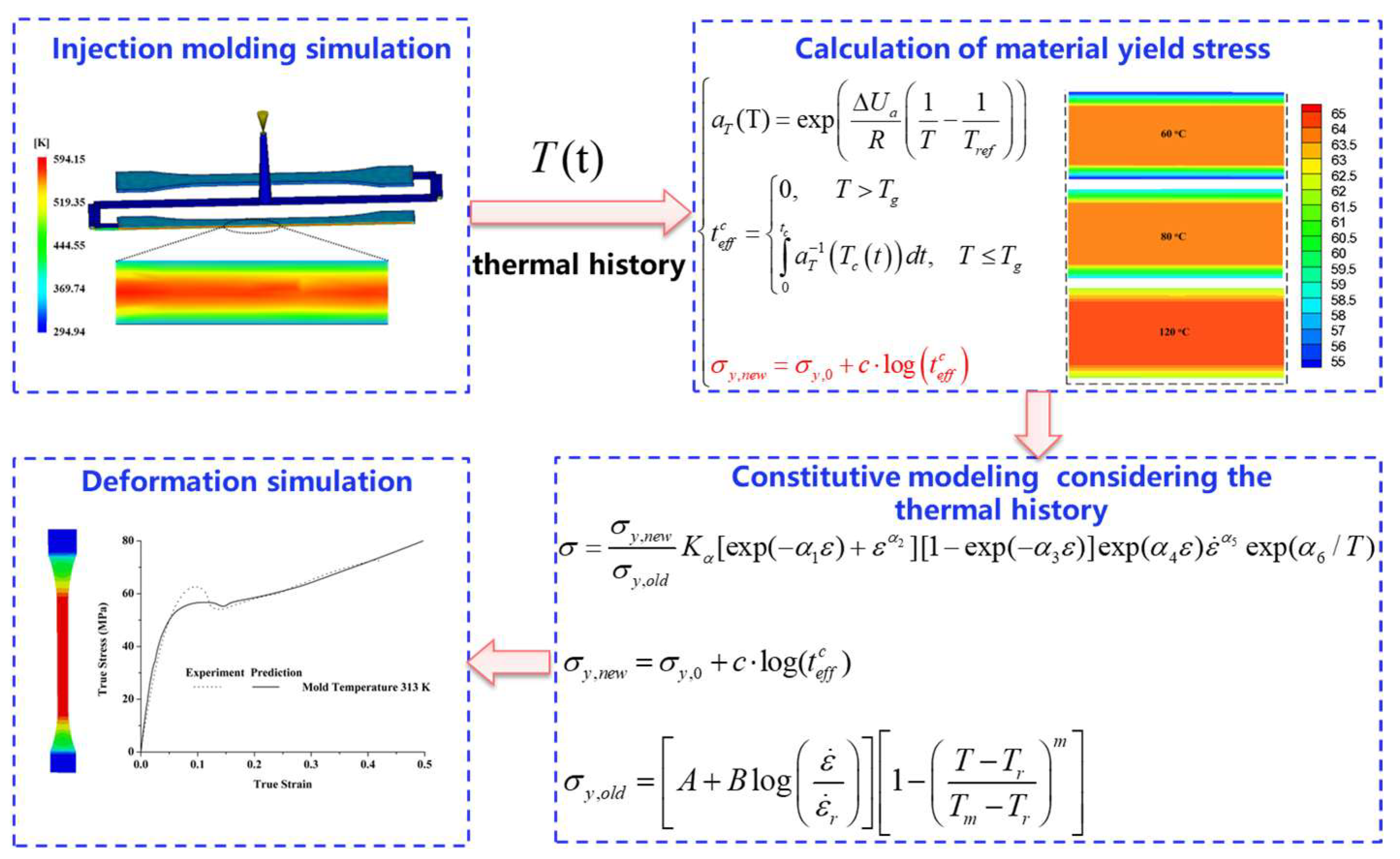

2.4. Constitutive Modeling

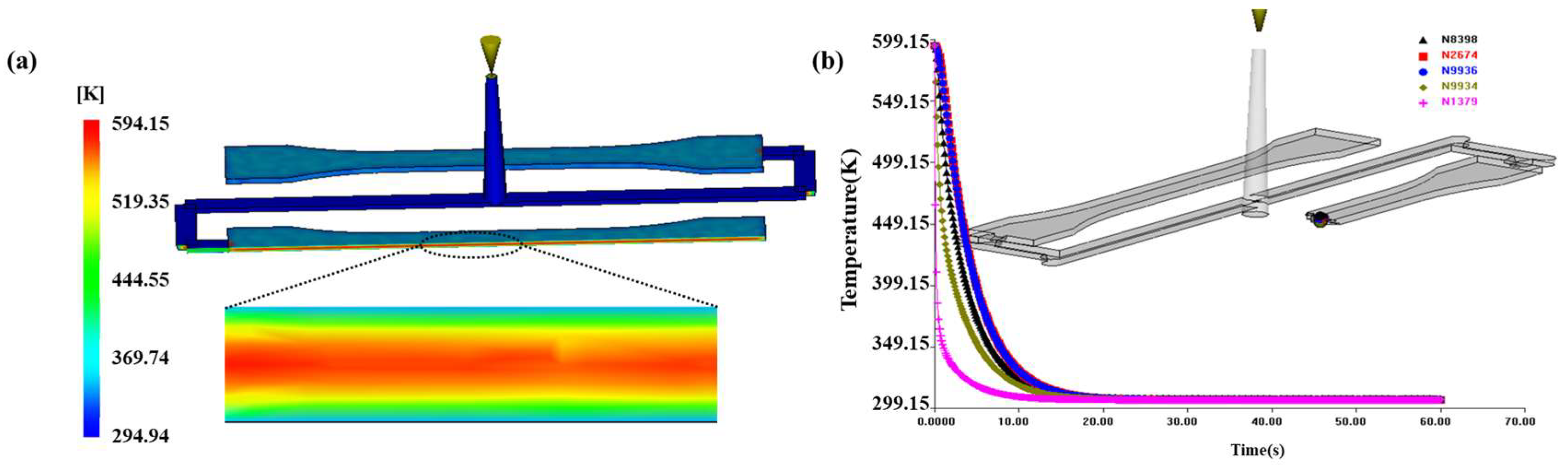

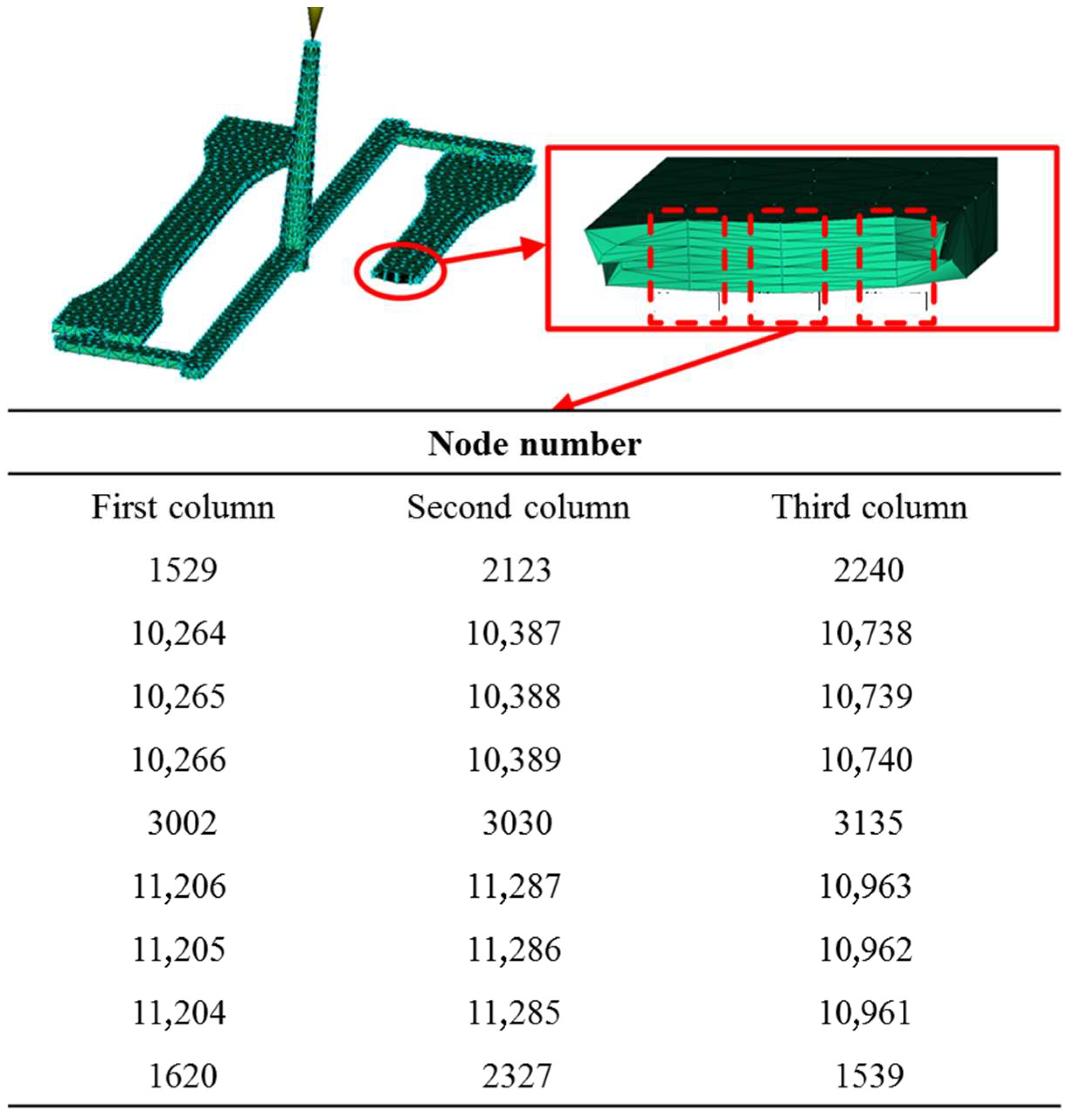

2.5. Finite Element Modeling

3. Results and Discussion

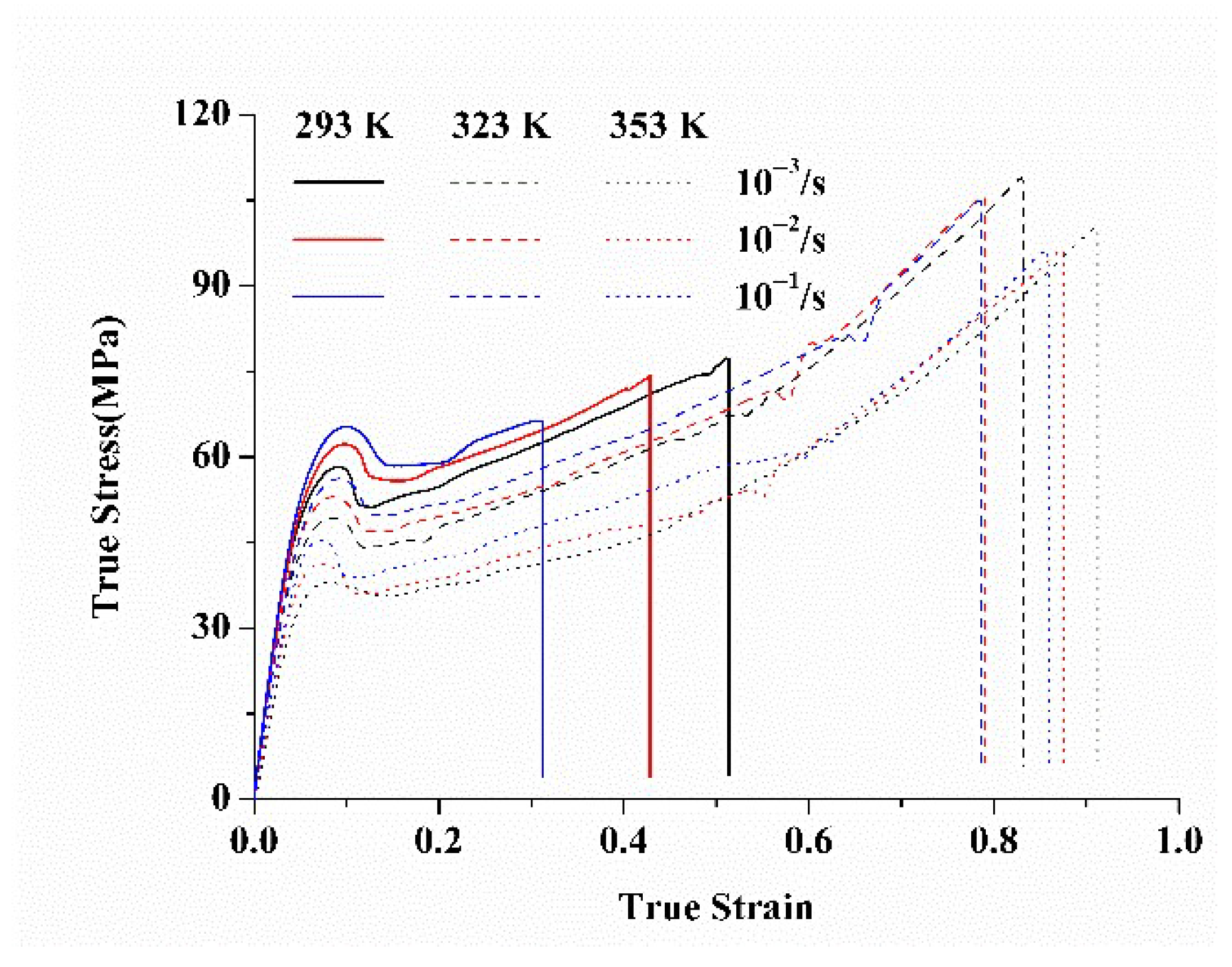

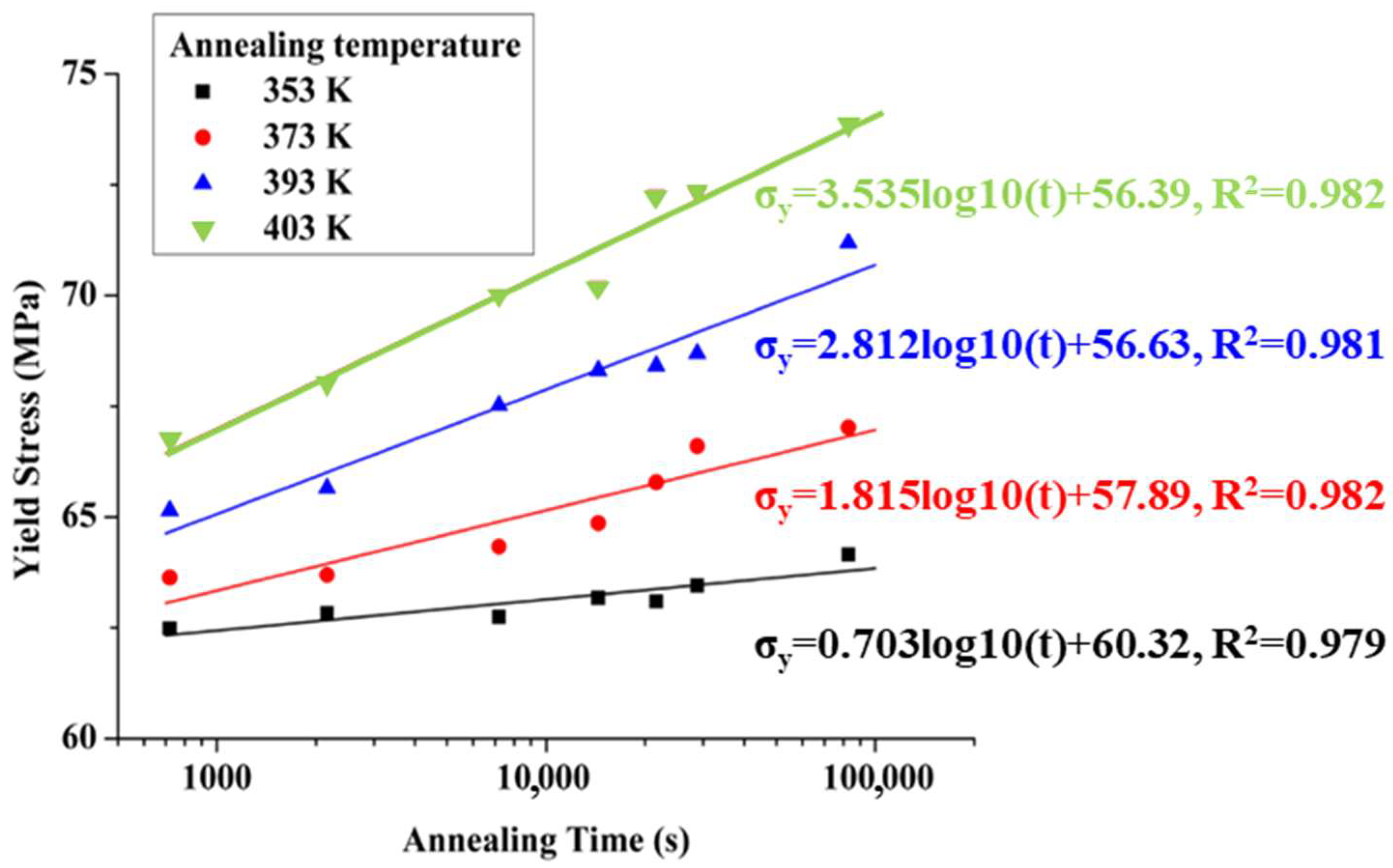

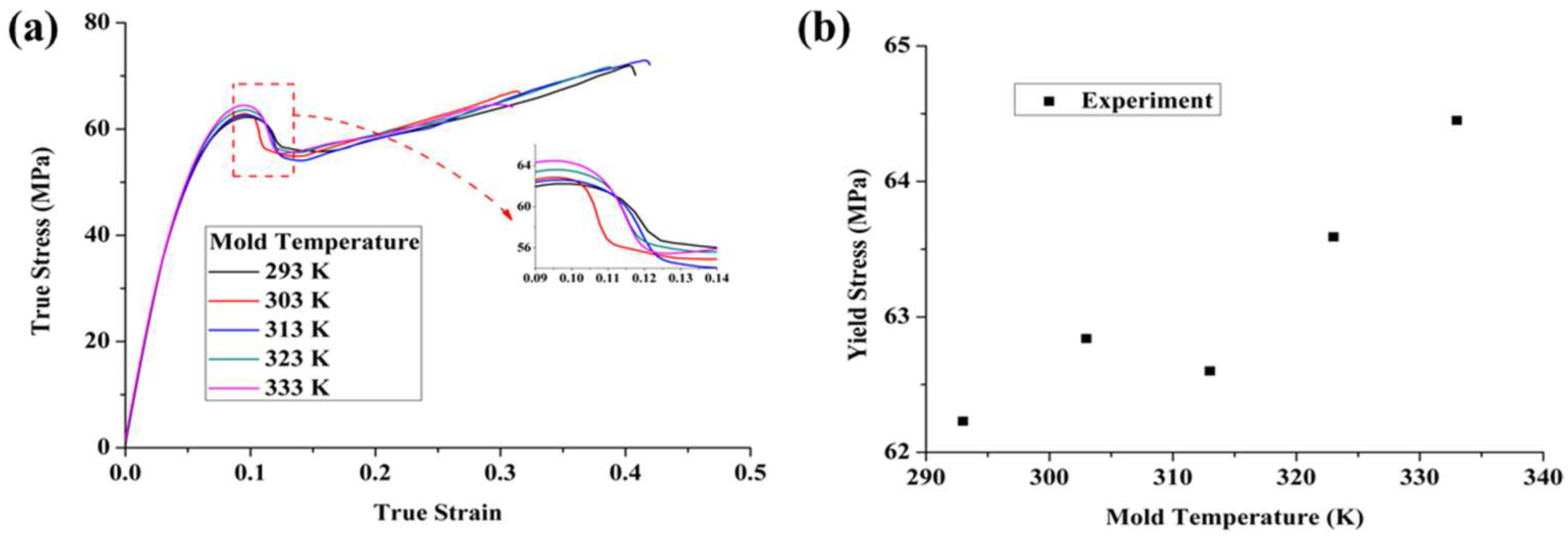

3.1. Experimental Results

3.2. Model Predictions

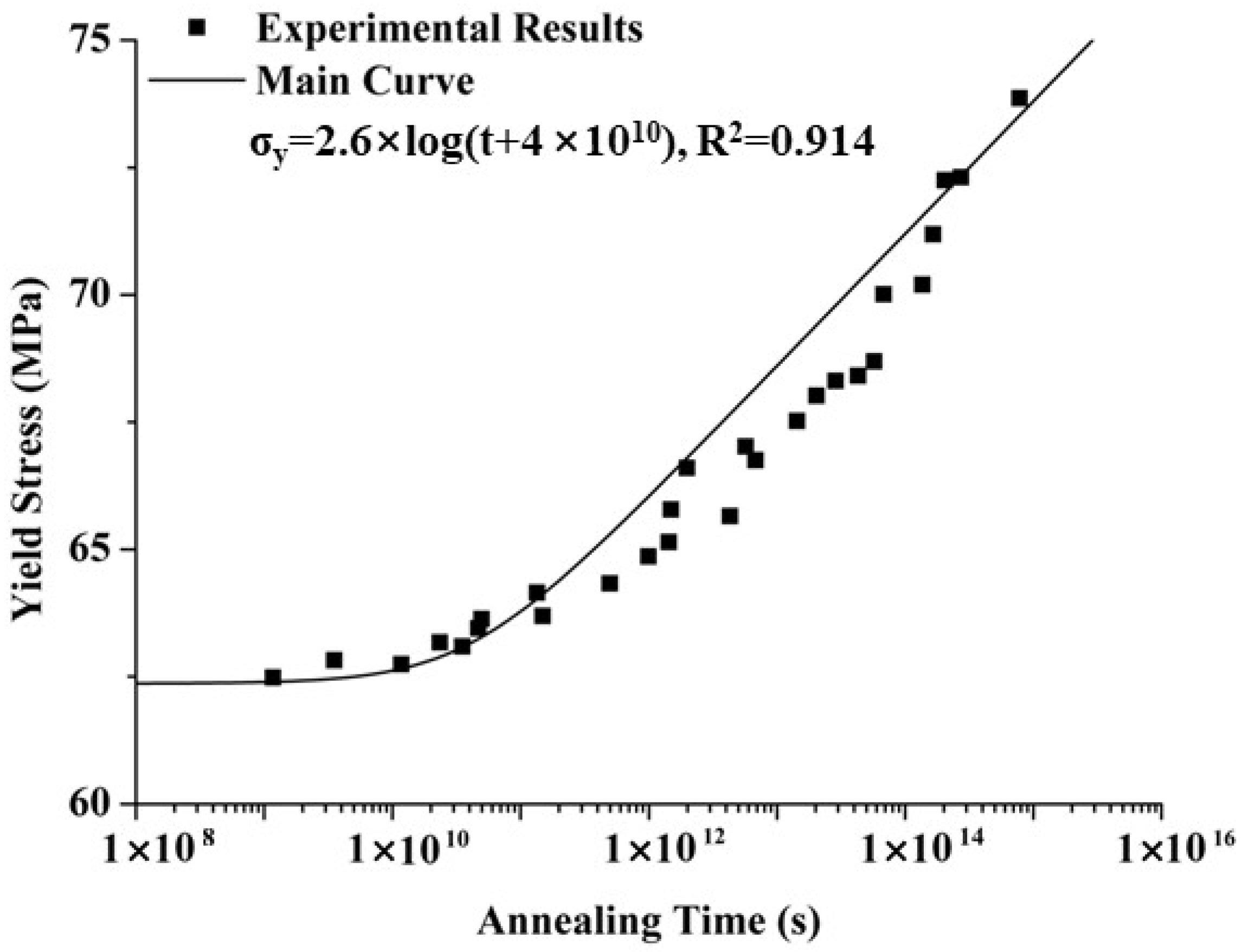

3.2.1. Solution for Model Parameters

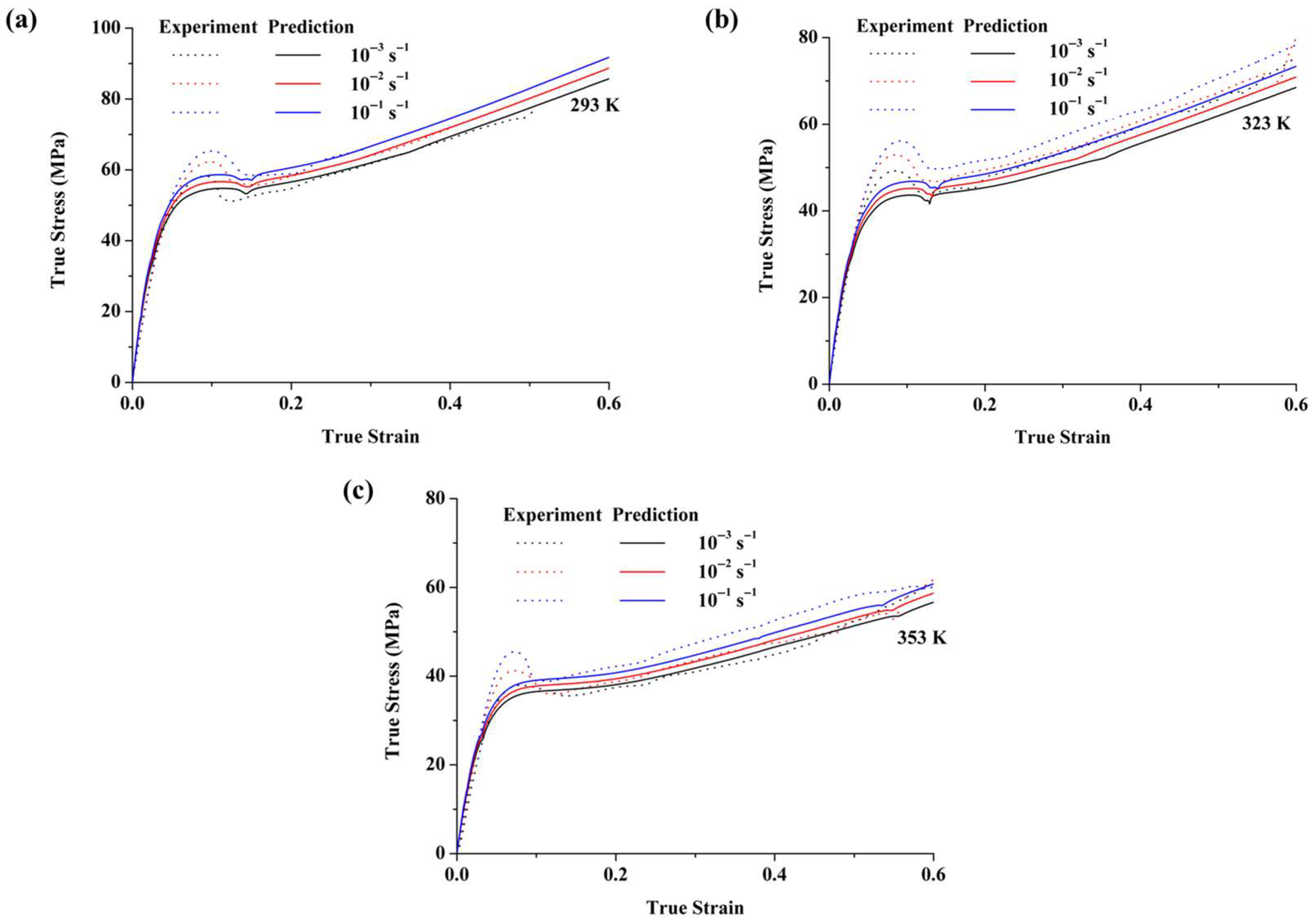

3.2.2. Prediction Results

4. Conclusions

- (1)

- During the injection molding process, a slower cooling rate or higher mold temperature results in higher yield stress, with the core layer exhibiting greater yield stress than the surface layer. During the annealing process, longer annealing times and higher annealing temperatures contribute to higher yield stress. In the service process, higher strain rates and lower temperatures lead to increased yield stress.

- (2)

- A formation thermal history-based constitutive model was developed to study the mechanical behavior of PC. Simulation of the formation process showed that the predicted yield stress of PC specimens at various mold temperatures closely matched experimental values. The absolute value of the error between the simulated value and the experimental value is less than 5%, indicating that the model can accurately simulate the yield stress in the thermal history during formation. In the service process, the new phenomenological model accurately predicted large deformation behavior at different strain rates and temperatures. The formation thermal history constitutive model can precisely capture the large deformation behavior of PC specimens prepared at various mold temperatures, including initial elasticity, strain hardening, yield deformation, and strain softening.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yu, P.; Yao, X.; Han, Q.; Zang, S.; Gu, Y. A visco-elastoplastic constitutive model for large deformation response of polycarbonate over a wide range of strain rates and temperatures. Polymer 2014, 55, 6577–6593. [Google Scholar] [CrossRef]

- Cao, K.; Wang, Y.; Wang, Y. Effects of strain rate and temperature on the tension behavior of polycarbonate. Mater. Des. 2012, 38, 53–58. [Google Scholar] [CrossRef]

- Li, M.; Zhou, H.; Zhang, Y.; Liao, Y.; Zhou, H. Effect of defects on thermal conductivity of graphene/epoxy nanocomposites. Carbon 2018, 130, 295–303. [Google Scholar] [CrossRef]

- Zhou, X.; Zhai, Y.; Ren, K.; Cheng, Z.; Shen, X.; Zhang, T.; Bai, Y.; Jia, Y.; Hong, J.J.R. Life cycle assessment of polycarbonate production: Proposed optimization toward sustainability. Resour. Conserv. Recycl. 2023, 189, 106765. [Google Scholar] [CrossRef]

- Barbagallo, R.; Mirone, G.; Landi, L.; Bua, G. Tensile behavior of polycarbonate: Key aspects for accurate constitutive modelling and simulation. Appl. Eng. Sci. 2024, 18, 100183. [Google Scholar] [CrossRef]

- Olson, G.B. Designing a new material world. Science 2000, 288, 993–998. [Google Scholar] [CrossRef]

- Bian, Y.; Liu, Q.; Feng, Z.; Hua, J.; Xie, H.; Chen, S.; Cai, Y.; Yao, X.; Luo, S. High-speed penetration dynamics of polycarbonate. Int. J. Mech. Sci. 2022, 223, 107250. [Google Scholar] [CrossRef]

- Govaert, L.; Engels, T.; Klompen, E.; Peters, G.; Meijer, H. Processing-induced properties in glassy polymers: Development of the yield stress in PC. Int. Polym. Process. 2005, 20, 170–177. [Google Scholar] [CrossRef]

- Safari, K.H.; Zamani, J.; Ferreira, F.J.; Guedes, R.M. Constitutive modeling of polycarbonate during high strain rate deformation. Polym. Eng. Sci. 2013, 53, 752–761. [Google Scholar] [CrossRef]

- Zheng, B.; Wang, H.; Huang, Z.; Zhang, Y.; Zhou, H.; Li, D. Experimental investigation and constitutive modeling of the deformation behavior of Poly-Ether-Ether-Ketone at elevated temperatures. Polym. Test. 2017, 63, 349–359. [Google Scholar] [CrossRef]

- Ullrich, F.; Singh, S.P.V.; McDonald, S.; Krueger, A.; Vera-Sorroche, J.; Amirkhizi, A.; Masato, D. Effect of strain rate on the mechanical properties of polycarbonate processed by compression and injection molding. Polym. Eng. Sci. 2022, 62, 174–184. [Google Scholar] [CrossRef]

- Engels, T.; Govaert, L.; Meijer, H. Quantitative prediction of mechanical performance of polymer products directly from processing conditions. In Proceedings of the AIP Conference Proceedings, 2008; American Institute of Physics (AIP): College Park, MD, USA, 2008; pp. 1336–1338. [Google Scholar]

- Engels, T.A.; van Breemen, L.C.; Govaert, L.E.; Meijer, H.E. Predicting the Long-Term Mechanical Performance of Polycarbonate from Thermal History during Injection Molding. Macromol. Mater. Eng. 2009, 294, 829–838. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, H.; Gao, T.; Zhang, W. Predicting the low-velocity impact behavior of polycarbonate: Influence of thermal history during injection molding. Int. J. Impact Eng. 2015, 86, 265–273. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, H.; Gao, T.; Zhang, W. Processing-induced inhomogeneity of yield stress in polycarbonate product and its influence on the impact behavior. Polymers 2016, 8, 72. [Google Scholar] [CrossRef]

- Dar, U.A.; Xu, Y.J.; Zakir, S.M.; Saeed, M.U. The effect of injection molding process parameters on mechanical and fracture behavior of polycarbonate polymer. J. Appl. Polym. Sci. 2017, 134, 44474. [Google Scholar] [CrossRef]

- Song, P.; Trivedi, A.R.; Siviour, C.R. Mechanical response of four polycarbonates at a wide range of strain rates and temperatures. Polym. Test. 2023, 121, 107986. [Google Scholar] [CrossRef]

- Song, P.; Chapman, D.; Graham, A.; Trivedi, A.; Siviour, C.R.; Solids, P. Thermomechanical coupling during large strain deformation of polycarbonate: Experimental study. J. Mech. Phys. Solids 2025, 196, 105976. [Google Scholar] [CrossRef]

- Govaert, L.; Timmermans, P.; Brekelmans, W. The influence of intrinsic strain softening on strain localization in polycarbonate: Modeling and experimental validation. J. Eng. Mater. Technol. 2000, 122, 177–185. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, H.; Huang, Z.; Zhang, Y.; Zhao, X. Constitutive modeling of polycarbonate over a wide range of strain rates and temperatures. Mech. Time-Depend. Mater. 2017, 21, 97–117. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Huang, Z.; Gao, H.; Zhang, Y.; Gao, X.; Zhou, H. Experimental and modeling study of the compressive behavior of PC/ABS at low, moderate and high strain rates. Polym. Test. 2016, 56, 115–123. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Huang, Z.; Tang, Z.; Wang, Y.; Zhou, H. Establishment and comparison of four constitutive relationships of PC/ABS from low to high uniaxial strain rates. Mech. Time-Depend. Mater. 2018, 22, 457–481. [Google Scholar] [CrossRef]

- GB/T 1040.2-2006; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. National Standards of the People’s Republic of China: Beijing, China, 2006.

- Johnson, G.R. A constitutive model and data for materials subjected to large strains, high strain rates, and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Mulliken, A.; Boyce, M. Mechanics of the rate-dependent elastic–plastic deformation of glassy polymers from low to high strain rates. Int. J. Solids Struct. 2006, 43, 1331–1356. [Google Scholar] [CrossRef]

- G’sell, C.; Jonas, J. Determination of the plastic behaviour of solid polymers at constant true strain rate. J. Mater. Sci. 1979, 14, 583–591. [Google Scholar] [CrossRef]

- Duan, Y.; Saigal, A.; Greif, R.; Zimmerman, M. A uniform phenomenological constitutive model for glassy and semicrystalline polymers. Polym. Eng. Sci. 2001, 41, 1322–1328. [Google Scholar] [CrossRef]

| Injection Temperature (K) | Volume Flow Rate (cm3/s) | Injection Pressure (MPa) | Hold Pressure (MPa) | Hold Time (s) | Cooling Time (s) | Mold Temperature (K) |

|---|---|---|---|---|---|---|

| 593 | 36.75 | 147 | 117.6 | 8 | 60 | 293, 303, 313, 323, 333 |

| Mold Temperature (K) | Annealing Temperature (K) | Annealing Time (h) |

|---|---|---|

| 293 | 353 | 0.2, 0.6, 2, 4, 6, 8, 23 |

| 373 | 0.2, 0.6, 2, 4, 6, 8, 23 | |

| 393 | 0.2, 0.6, 2, 4, 6, 8, 23 | |

| 403 | 0.2, 0.6, 2, 4, 6, 8, 23 |

| Mold Temperature (K) | Annealing | Strain Rate (s−1) | Temperature (K) |

|---|---|---|---|

| 293 | Yes | 10−2 | 293 |

| 293 | No | 10−3, 10−2, 10−1 | 293, 323, 353 |

| 303, 313, 323, 333 | No | 10−2 | 293 |

| Time (h) | Yield Stress at 353 K (MPa) | Yield Stress at 393 K (MPa) | Yield Stress at 393 K (MPa) | Yield Stress at 403 K (MPa) |

|---|---|---|---|---|

| 0.2 | 62.48 | 63.63 | 65.14 | 66.75 |

| 0.6 | 62.82 | 63.69 | 65.65 | 68.02 |

| 2 | 62.74 | 64.33 | 67.52 | 70.01 |

| 4 | 63.17 | 64.86 | 68.31 | 70.20 |

| 6 | 63.09 | 65.78 | 68.41 | 72.25 |

| 8 | 63.45 | 66.60 | 68.69 | 72.31 |

| 23 | 63.45 | 67.02 | 71.19 | 73.86 |

| Material Coefficient | Value | |

|---|---|---|

| Constitutive model | ||

| 11.91 | ||

| 0.459 | ||

| 19.29 | ||

| 0.209 | ||

| 0.0149 | ||

| 705.8 K | ||

| Yield stress | A | 58.23 MPa |

| B | 3.54 MPa | |

| m | 0.777 | |

| Processing history | 205,000 J/mol | |

| R | 8.314 J/(mol·K) | |

| Tr | 293 K | |

| Tm | 553 K | |

| 34.8 MPa | ||

| c | 2.6 MPa | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Wang, H.; Shen, G.; Huang, T.; Zhang, Y. Thermal History-Dependent Deformation of Polycarbonate: Experimental and Modeling Insights. Polymers 2025, 17, 2096. https://doi.org/10.3390/polym17152096

Li M, Wang H, Shen G, Huang T, Zhang Y. Thermal History-Dependent Deformation of Polycarbonate: Experimental and Modeling Insights. Polymers. 2025; 17(15):2096. https://doi.org/10.3390/polym17152096

Chicago/Turabian StyleLi, Maoyuan, Haitao Wang, Guancheng Shen, Tianlun Huang, and Yun Zhang. 2025. "Thermal History-Dependent Deformation of Polycarbonate: Experimental and Modeling Insights" Polymers 17, no. 15: 2096. https://doi.org/10.3390/polym17152096

APA StyleLi, M., Wang, H., Shen, G., Huang, T., & Zhang, Y. (2025). Thermal History-Dependent Deformation of Polycarbonate: Experimental and Modeling Insights. Polymers, 17(15), 2096. https://doi.org/10.3390/polym17152096