The Impact of Elevated Printing Speeds and Filament Color on the Dimensional Precision and Tensile Properties of FDM-Printed PLA Specimens

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

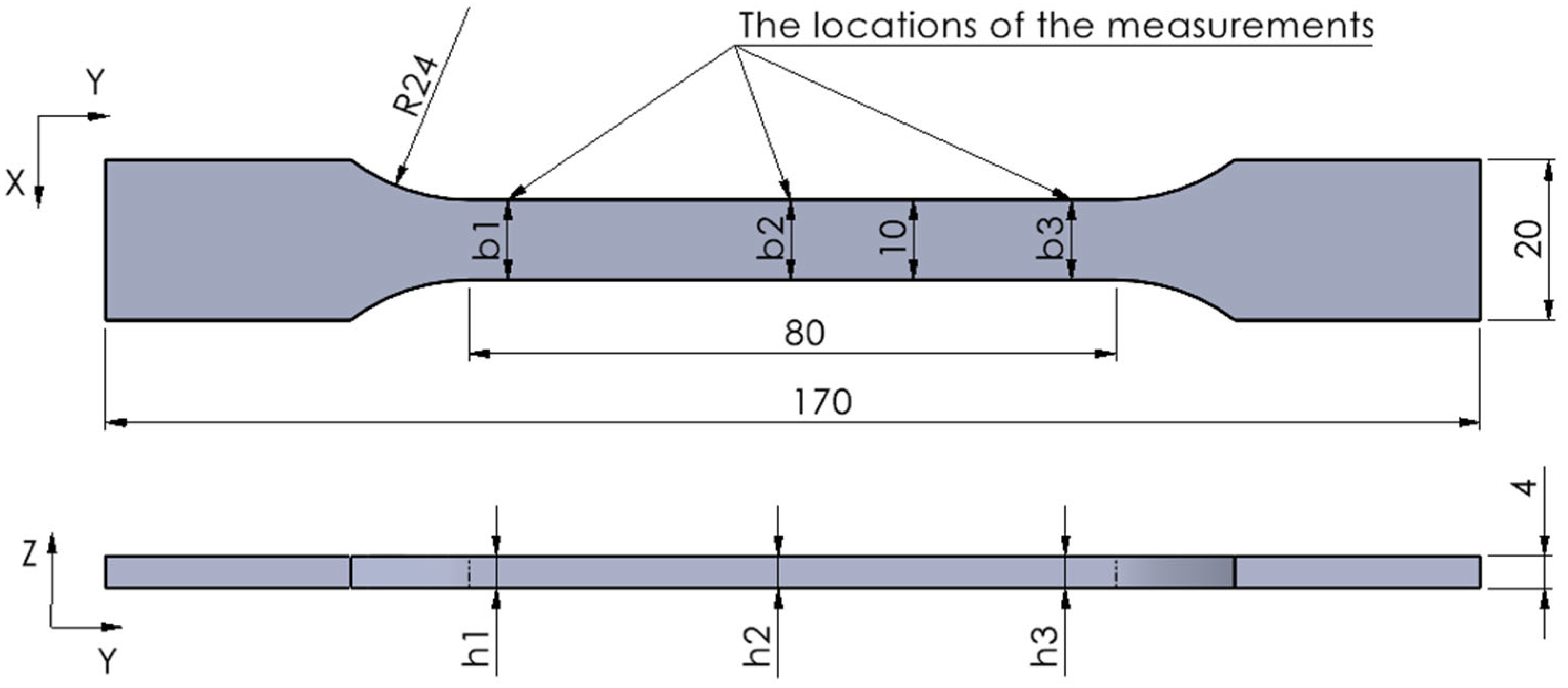

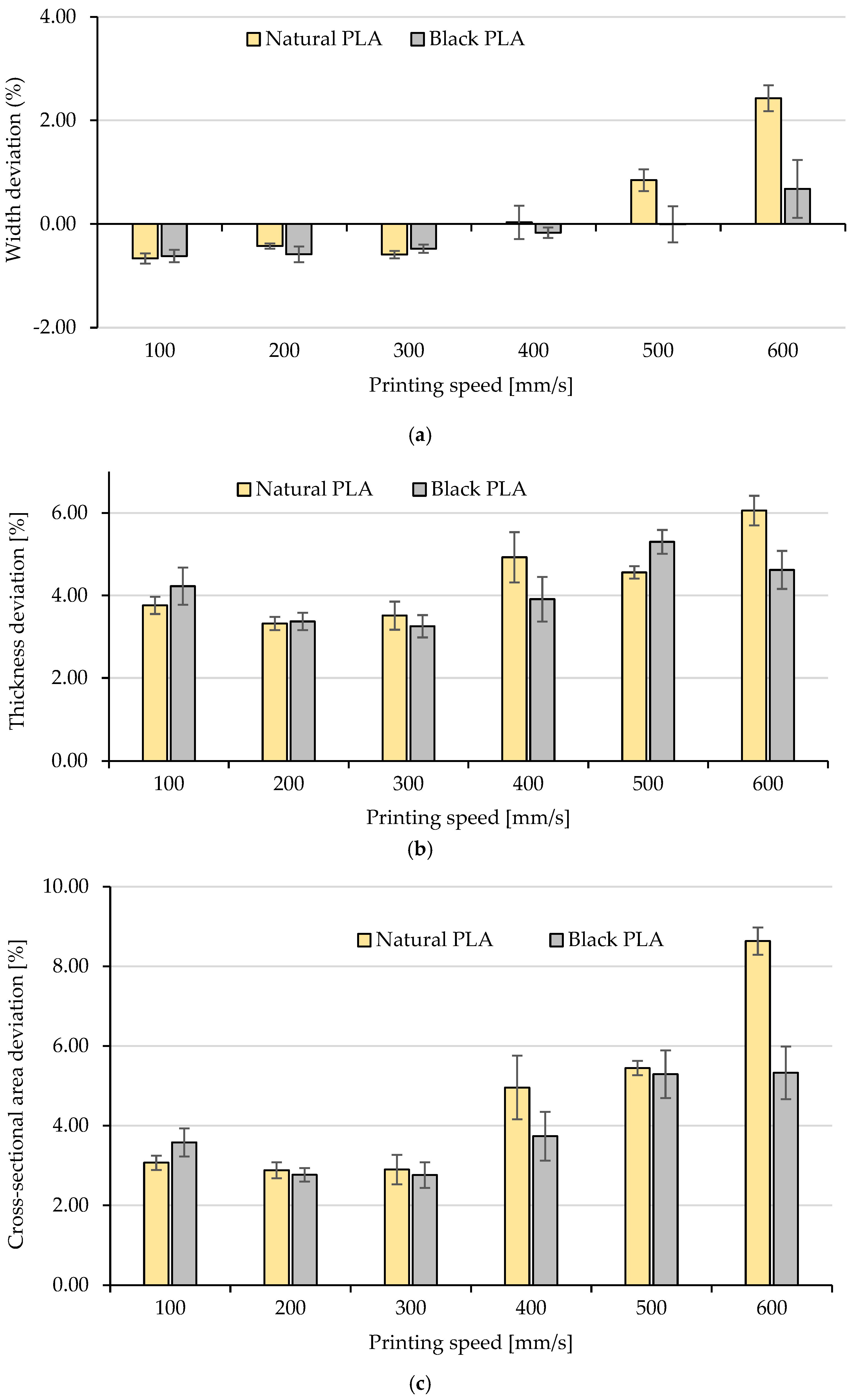

3.1. Dimensional Accuracy

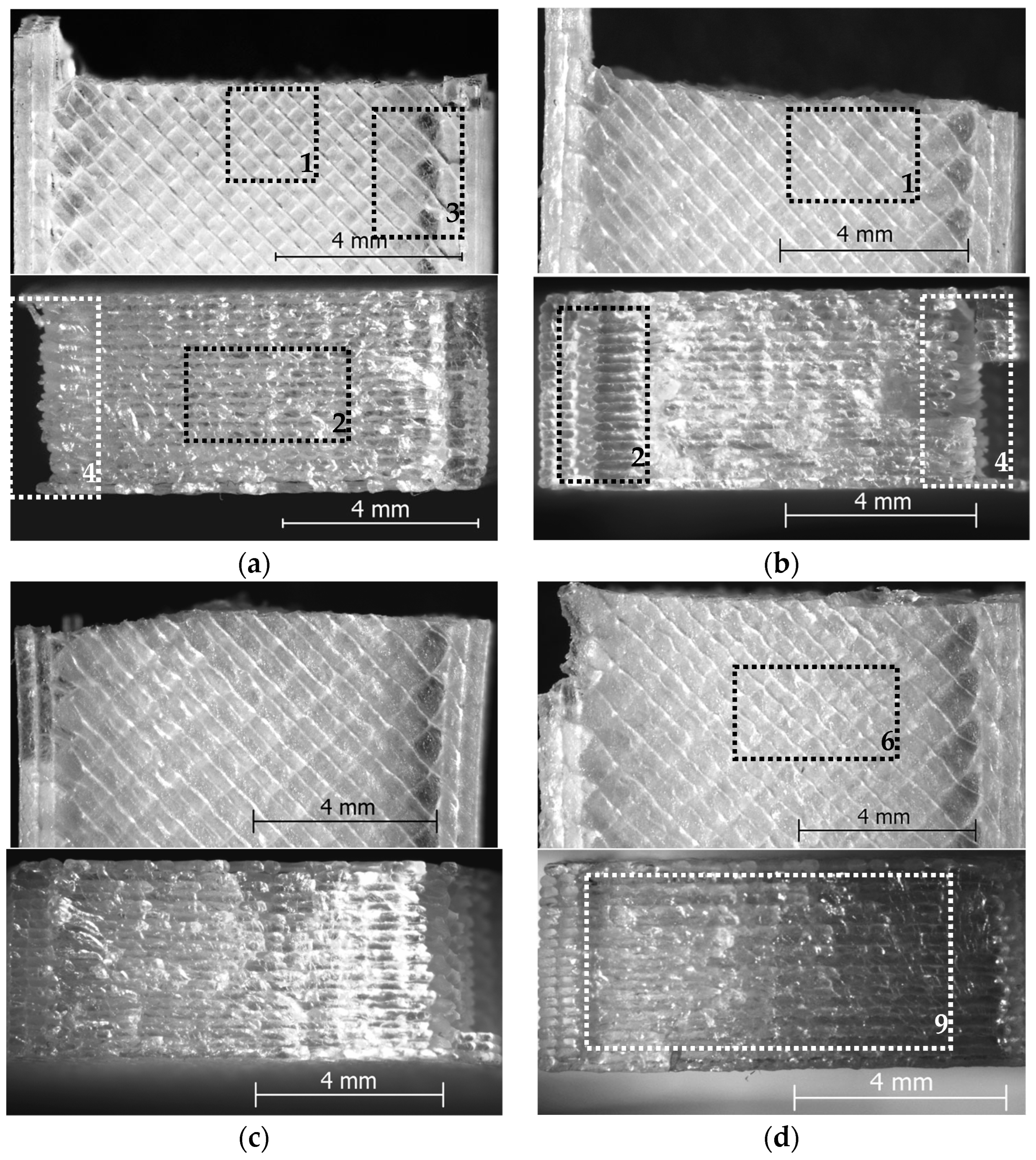

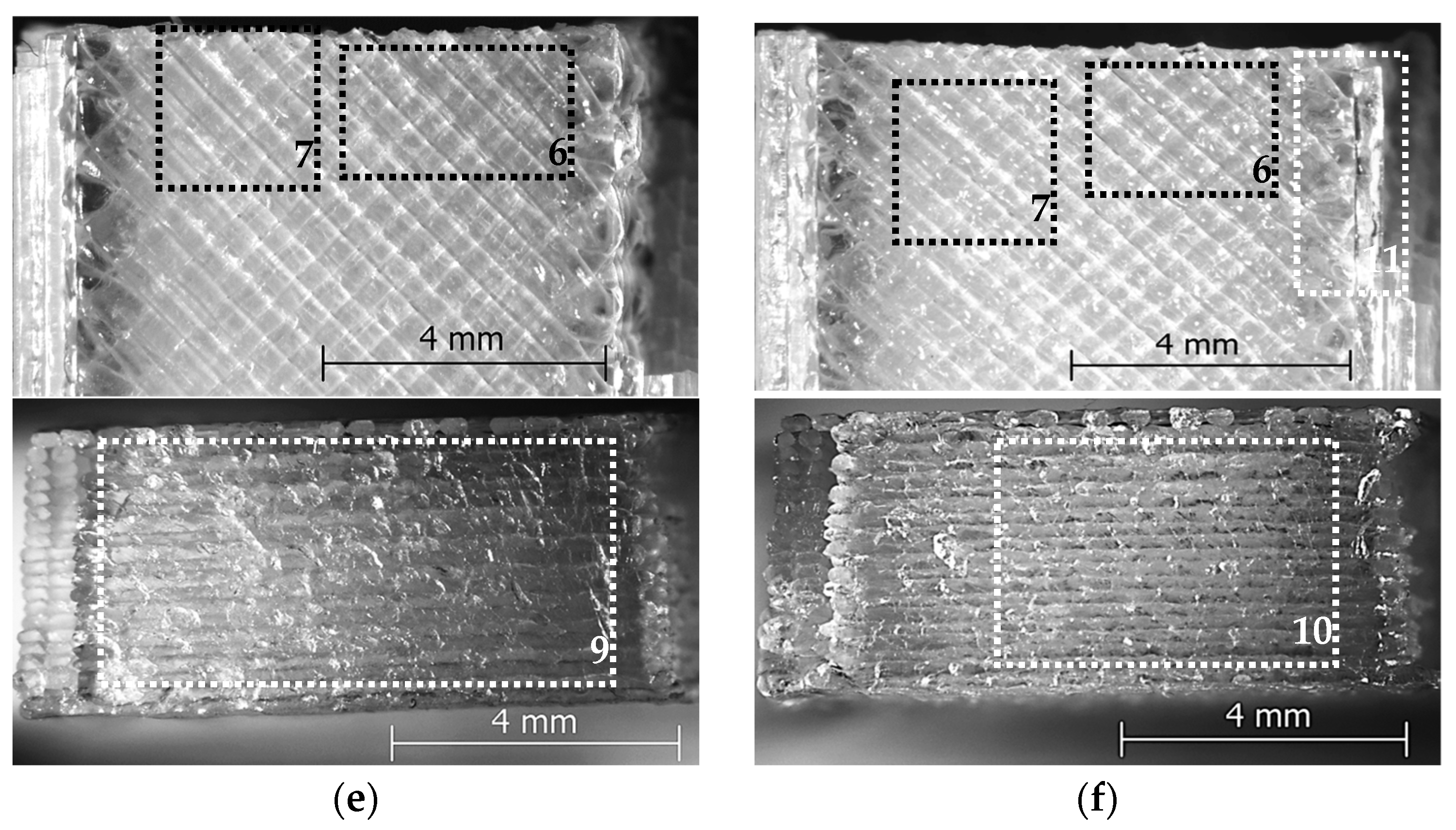

3.2. Tensile Behavior

- -

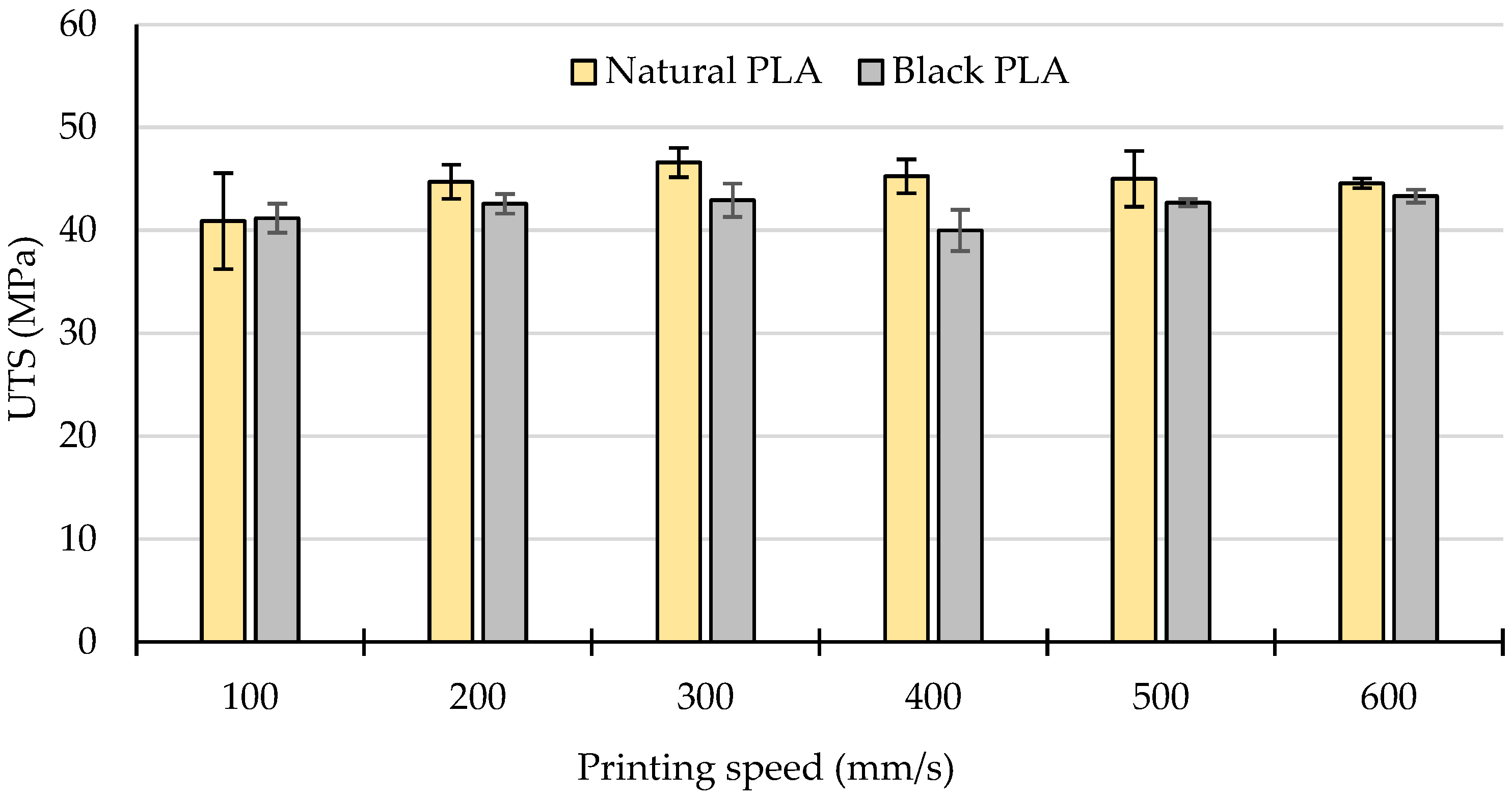

- For natural PLA, the ultimate tensile strength (UTS) exhibited a variation dependent on the printing speed, ranging from 40.90 MPa at 100 mm/s to a maximum of 46.59 MPa at 300 mm/s, corresponding to an increase of approximately 13.90%.

- -

- In the case of black PLA, the lowest UTS was recorded at a printing speed of 400 mm/s (40.00 MPa), while the highest value was observed at 600 mm/s (43.33 MPa), reflecting a difference of 8.32%. It is worth noting that the black PLA samples printed at 300 mm/s also exhibited a relatively high ultimate tensile strength (42.94 MPa), which was close to the maximum observed value.

4. Conclusions

- Dimensional accuracy: The dimensional deviations in both width and thickness remained within acceptable ranges, comparable to those observed at moderate printing speeds, despite the significant increase in print rate. Among the tested speeds, 300 mm/s yielded the lowest deviations in cross-sectional area, indicating optimal dimensional fidelity for both PLA variants. Notably, black PLA exhibited superior dimensional accuracy at high speeds (≥200 mm/s) compared to natural PLA, likely due to differences in thermal conductivity and pigment composition.

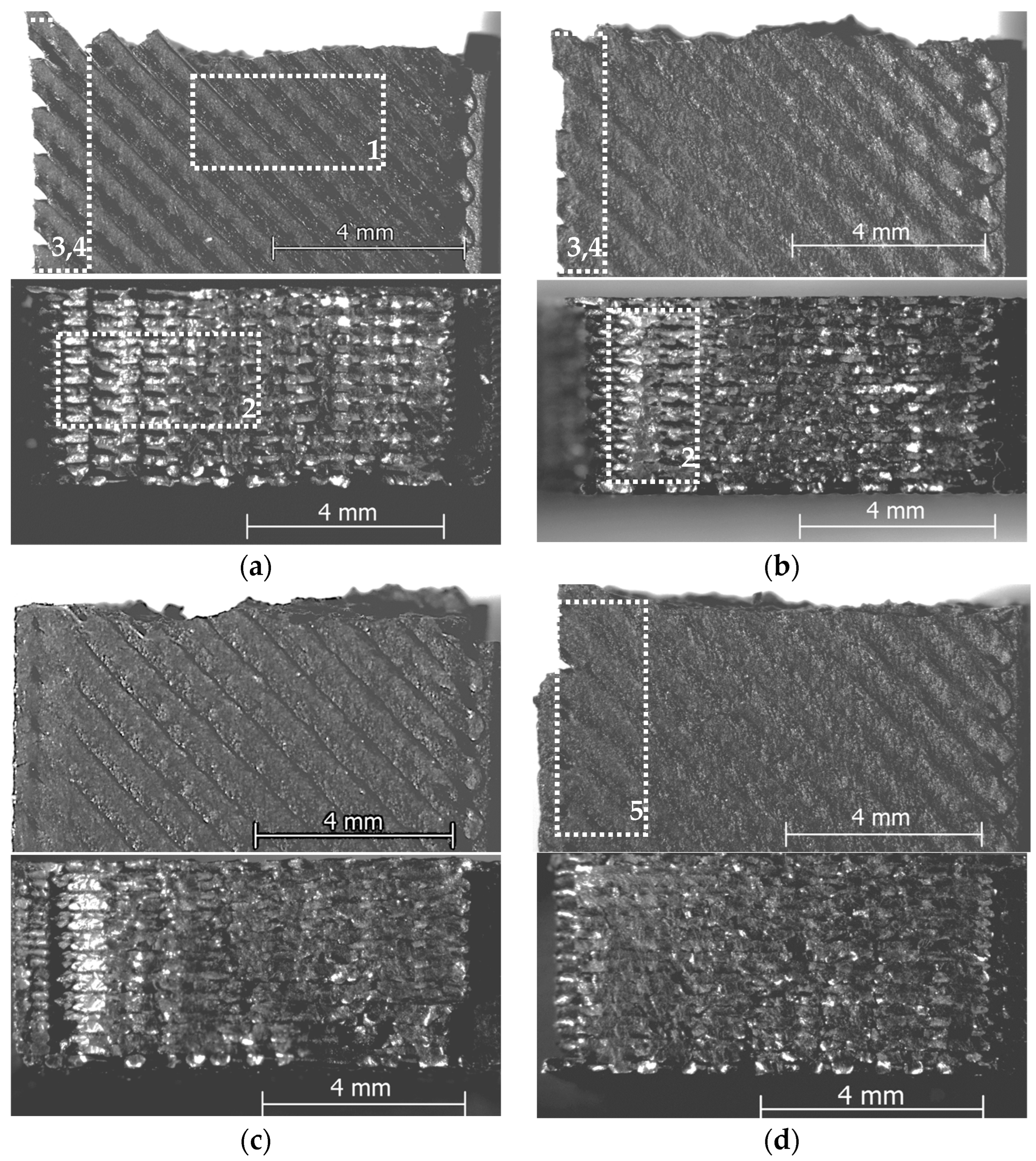

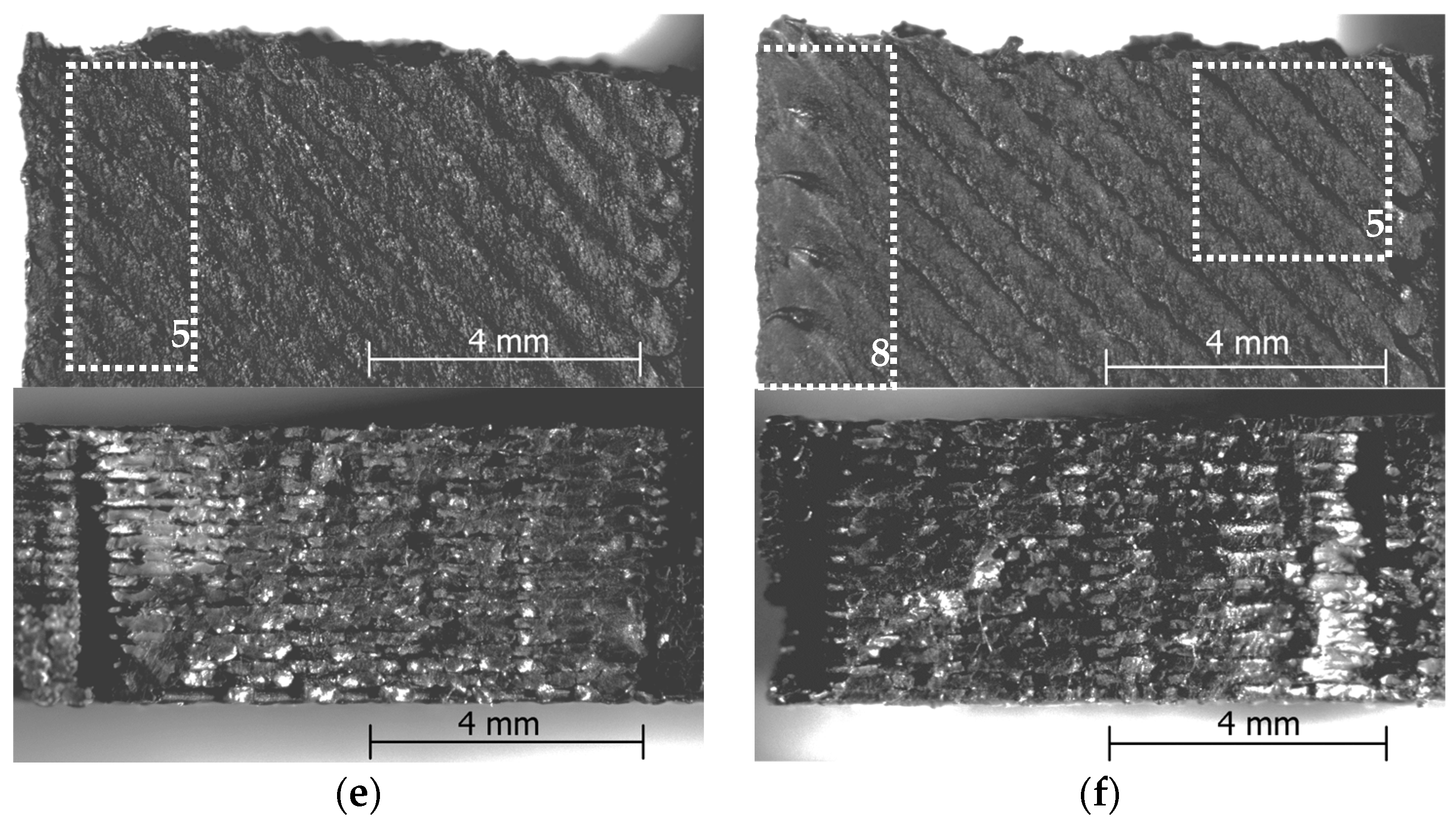

- Tensile strength: The UTS followed a non-linear trend with respect to the printing speed for both materials. It improved as the speed increased from 100 mm/s up to 300 mm/s, reaching a maximum of 46.59 MPa for natural PLA and 42.94 MPa for black PLA. Beyond this point, UTS declined due to over-extrusion effects and interlayer delamination, particularly evident in the surface morphology and fracture structure analyses. Regarding the color influence, black PLA consistently showed, across all speeds, lower tensile strength than natural PLA, with differences reaching up to 13.16%. This reinforces the impact of filament pigmentation on mechanical performance, even under identical printing conditions.

- Structural insights: Microscopic analysis revealed that suboptimal speeds (too low or too high) introduced structural anomalies. Under-extrusion at lower speeds and over-extrusion at higher speeds both degraded print quality and mechanical strength. Optimal interlayer bonding and surface integrity were observed at 300 mm/s.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ponis, S.T.; Koronis, E.; Ntalla, A.C.; Voulgaris, F. Additive Manufacturing as a Disruptive Technology: A Review of Implications for Supply Chains and the Circular Economy. Sustainability 2021, 13, 6007. [Google Scholar] [CrossRef]

- Rouf, S.; Malik, A.; Singh, N.; Raina, A.; Naveed, N.; Siddiqui, M.I.H.; Haq, M.I.U. Additive Manufacturing Technologies: Industrial and Medical Applications. Sustain. Oper. Comput. 2022, 3, 258–274. [Google Scholar] [CrossRef]

- Jung, S.; Kara, L.B.; Nie, Z.; Simpson, T.W.; Whitefoot, K.S. Is Additive Manufacturing an Environmentally and Economically Preferred Alternative for Mass Production? Environ. Sci. Technol. 2023, 57, 6373–6386. [Google Scholar] [CrossRef] [PubMed]

- Schmitt, P.; Zorn, S.; Gericke, K. Additive manufacturing research landscape: A literature review. Proc. Des. Soc. 2021, 1, 333–344. [Google Scholar] [CrossRef]

- Iacob, D.V.; Zisopol, D.G.; Minescu, M. Study on the Optimization of FDM Parameters for the Manufacture of Three-Point Bending Specimens from PETG and Recycled PETG in the Context of the Transition to the Circular Economy. Polymers 2025, 17, 1645. [Google Scholar] [CrossRef]

- Chalgham, A.; Ehrmann, A.; Wickenkamp, I. Mechanical Properties of FDM Printed PLA Parts before and after Thermal Treatment. Polymers 2021, 13, 1239. [Google Scholar] [CrossRef]

- Dey, A.; Yodo, N. A Systematic Survey of FDM Process Parameter Optimization and Their Influence on Part Characteristics. J. Manuf. Mater. Process. 2019, 3, 64. [Google Scholar] [CrossRef]

- Portoacă, A.I.; Ripeanu, R.G.; Diniță, A.; Tănase, M. Optimization of 3D Printing Parameters for Enhanced Surface Quality and Wear Resistance. Polymers 2023, 15, 3419. [Google Scholar] [CrossRef]

- Cojocaru, V.; Frunzaverde, D.; Miclosina, C.-O.; Marginean, G. The influence of the process parameters on the mechanical properties of PLA specimens produced by fused filament fabrication—A review. Polymers 2022, 14, 886. [Google Scholar] [CrossRef]

- Gao, G.; Xu, F.; Xu, J.; Tang, G.; Liu, Z. A Survey of the Influence of Process Parameters on Mechanical Properties of Fused Deposition Modeling Parts. Micromachines 2022, 13, 553. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Cojocaru, V.; Frunzaverde, D.; Miclosina, C.-O. On the Behavior of Honeycomb, Grid and Triangular PLA Structures under Symmetric and Asymmetric Bending. Micromachines 2023, 14, 120. [Google Scholar] [CrossRef]

- Ziadia, A.; Habibi, M.; Kelouwani, S. Machine Learning Study of the Effect of Process Parameters on Tensile Strength of FFF PLA and PLA-CF. Eng 2023, 4, 2741–2763. [Google Scholar] [CrossRef]

- Frunzaverde, D.; Cojocaru, V.; Ciubotariu, C.-R.; Miclosina, C.-O.; Ardeljan, D.D.; Ignat, E.F.; Marginean, G. The Influence of the Printing Temperature and the Filament Color on the Dimensional Accuracy, Tensile Strength, and Friction Performance of FFF-Printed PLA Specimens. Polymers 2022, 14, 1978. [Google Scholar] [CrossRef]

- Ekinci, B.; Ehrmann, A. Influence of Printing Parameters on the Dimensional Accuracy of Concave/Convex Objects in FDM Printing. Eng. Proc. 2023, 31, 40. [Google Scholar] [CrossRef]

- Frunzaverde, D.; Cojocaru, V.; Bacescu, N.; Ciubotariu, C.-R.; Miclosina, C.-O.; Turiac, R.R.; Marginean, G. The Influence of the Layer Height and the Filament Color on the Dimensional Accuracy and the Tensile Strength of FDM-Printed PLA Specimens. Polymers 2023, 15, 2377. [Google Scholar] [CrossRef] [PubMed]

- Hanon, M.M.; Zsidai, L.; Ma, Q. Accuracy investigation of 3D printed PLA with various process parameters and different colors. Mater. Today Proc. 2021, 42, 3089–3096. [Google Scholar] [CrossRef]

- Maalihan, R.D.; Aggari, J.C.V.; Alon, A.S.; Latayan, R.B.; Montalbo, F.J.P.; Javier, A.D. On the optimized fused filament fabrication of polylactic acid using multiresponse central composite design and desirability function algorithm. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024. [Google Scholar] [CrossRef]

- Cojocaru, V.; Turiac, R.R.; Frunzaverde, D.; Trisca, G.; Bacescu, N.; Marginean, G. Effect of the Printing Scenario on the Dimensional Accuracy and the Tensile Strength of Different Colored PLA Specimens Produced by Fused Deposition Modeling. Appl. Sci. 2024, 14, 7642. [Google Scholar] [CrossRef]

- Solouki, A.; Aliha, M.R.M.; Makui, A.; Choupani, N.; Seiti, H. Analyzing the Effects of Printing Parameters to Minimize the Dimensional Deviation of Polylactic Acid Parts by Applying Three Different Decision-Making Approaches. Sci. Rep. 2024, 14, 27674. [Google Scholar] [CrossRef]

- Nurul Najaa, S.; Muhamad, K.F.; Jaapar, M.H. Investigation of the Effect of Print Parameter on Dimensional Accuracy for Fused Deposition Modelling (FDM) 3D Printer. In Proceedings of the 2022 Engineering Technology International Conference (ETIC 2022), Kuantan, Malaysia, 7–8 September 2022; IET Conference Proceedings, Institution of Engineering and Technology: London, UK, 2022; Volume 2022, Issue 22. pp. 142–145. [Google Scholar] [CrossRef]

- Ghaffar, A. Correlating FDM Printing Parameters with Mechanical Properties and Surface Quality of PLA Printouts. Eng. Res. Express 2024, 6, 045538. [Google Scholar] [CrossRef]

- Solouki, A.; Aliha, M.R.M.; Makui, A. A Methodology for Optimizing Impact Strength, Dimensional Accuracy and Costs of Manufacturing with Three-Dimensional Printing of Polylactic Acid. Arab. J. Sci. Eng. 2024, 49, 7545–7569. [Google Scholar] [CrossRef]

- Kartal, F.; Kaptan, A. Response of PLA Material to 3D Printing Speeds: A Comprehensive Examination on Mechanical Properties and Production Quality. Eur. Mech. Sci. 2024, 8, 137–144. [Google Scholar] [CrossRef]

- Singh, M.; Bharti, P.S. Identification of Process Parameter Combination for Maximum Tensile Strength in 3D Printed Polylactic Acid Specimens Using Regression and ANOVA. In Proceedings of the 2nd International Conference on Mechanical and Energy Technologies (ICMET 2021), Greater Noida, India, 28–29 October 2021; Yadav, S., Jain, P.K., Kankar, P.K., Shrivastava, Y., Eds.; Lect. Notes Mech. Eng. 2023. pp. 217–225. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Ezati, N.; Sadeghi, P.; Badrossamay, M.R. Optimization of FDM Process Parameters for Tensile Properties of Polylactic Acid Specimens Using Taguchi Design of Experiment Method. J. Thermoplast. Compos. Mater. 2022, 35, 2435–2452. [Google Scholar] [CrossRef]

- Lorkowski, L.; Wybrzak, K.; Brancewicz-Steinmetz, E.; Świniarski, J.; Sawicki, J. Influence of Print Speed on the Mechanical Performance of 3D-Printed Bio-Polymer Polylactic Acid. Materials 2025, 18, 1765. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.-Y.; Liu, C.-Y. The Influence of Forced-Air Cooling on a 3D Printed PLA Part Manufactured by Fused Filament Fabrication. Addit. Manuf. 2019, 25, 196–203. [Google Scholar] [CrossRef]

- Ambrus, S.; Soporan, R.A.; Kazamer, N.; Pascal, D.T.; Muntean, R.; Dume, A.I.; Marginean, G.M.; Serban, V.A. Characterization and Mechanical Properties of Fused Deposited PLA Material. Mater. Today Proc. 2020, 45, 4356–4363. [Google Scholar] [CrossRef]

- Altan, M.; Eryildiz, M.; Gumus, B.; Kahraman, Y. Effects of process parameters on the quality of PLA products fabricated by fused deposition modeling (FDM): Surface roughness and tensile strength. Mater. Test. 2018, 60, 471–477. [Google Scholar] [CrossRef]

- Megersa, G.K.; Sitek, W.; Nowak, A.J.; Tomašić, N. Investigation of the Influence of Fused Deposition Modeling 3D Printing Process Parameters on Tensile Properties of Polylactic Acid Parts Using the Taguchi Method. Materials 2024, 17, 5951. [Google Scholar] [CrossRef]

- Gao, G.; Xu, F.; Xu, J.; Liu, Z. Study of Material Color Influences on Mechanical Characteristics of Fused Deposition Modeling Parts. Materials 2022, 15, 7039. [Google Scholar] [CrossRef]

- Hanon, M.M.; Zsidai, L. Comprehending the Role of Process Parameters and Filament Color on the Structure and Tribological Performance of 3D Printed PLA. J. Mater. Res. Technol. 2021, 15, 647–660. [Google Scholar] [CrossRef]

- Beniak, J.; Šooš, Ľ.; Križan, P.; Matúš, M.; Ruprich, V. Resistance and Strength of Conductive PLA Processed by FDM Additive Manufacturing. Polymers 2022, 14, 678. [Google Scholar] [CrossRef] [PubMed]

- Soares, J.B.; Finamor, J.; Silva, F.P.; Roldo, L.; Candido, L.H. Analysis of the influence of polylactic acid (PLA) colour on FDM 3D printing temperature and part finishing. Rapid Prototyp. J. 2018, 24, 1305–1316. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S. Characterization of electrical heating of graphene/PLA honeycomb structure composite manufactured by CFDM 3D printer. Fash. Text. 2020, 7, 8. [Google Scholar] [CrossRef]

- Spina, R. Performance analysis of colored PLA products with a fused filament fabrication process. Polymers 2019, 11, 1984. [Google Scholar] [CrossRef]

- Zheng, Y.; Huang, X.; Chen, J.; Wu, K.; Wang, J.; Zhang, X. A Review of Conductive Carbon Materials for 3D Printing: Materials, Technologies, Properties, and Applications. Materials 2021, 14, 3911. [Google Scholar] [CrossRef]

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Molding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- Orca Slicer. Available online: https://orcaslicer.download/ (accessed on 20 January 2025).

- FLSUN T1 Pro 3D Printer. Available online: https://flsun3d.com/pages/t1-pro (accessed on 2 June 2025).

- FLSUN T1 Pro Silent Module. Available online: https://eu.store.flsun3d.com/products/flsun-t1-pro-silent-module (accessed on 2 June 2025).

- Form Futura. EasyFil ePLA. Available online: https://formfutura.com/product/easyfil-epla/ (accessed on 7 October 2024).

- ISO/ASTM 52921:2013; Standard Terminology for Additive Manufacturing—Coordinate Systems and Test Methodologies. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019.

- Aljazara, A.; Abu Tuhaimer, N.; Alawwad, A.; Bani Hani, K.; Qusef, A.D.; Alsalhi, N.R.; Al-Dawoodi, A. Quality of 3D Printed Objects Using Fused Deposition Modeling (FDM) Technology in Terms of Dimensional Accuracy. Int. J. Online Biomed. Eng. 2023, 19, 45–62. [Google Scholar] [CrossRef]

- Sukindar, N.A.; Md Yasir, A.S.H.; Azhar, M.D.; Md Azhar, M.A.; Abd Halim, N.F.H.; Sulaiman, M.H.; Haji Ahmad Sabli, A.S.; Mohd Ariffin, M.K.A. Evaluation of the Surface Roughness and Dimensional Accuracy of Low-Cost 3D-Printed Parts Made of PLA–Aluminum. Heliyon 2024, 10, e25508. [Google Scholar] [CrossRef]

- Tunçel, O. The influence of the raster angle on the dimensional accuracy of FDM-printed PLA, PETG, and ABS tensile specimens. Eur. Mech. Sci. 2024, 8, 11–18. [Google Scholar] [CrossRef]

- Ansari, A.A.; Kamil, M. Effect of Print Speed and Extrusion Temperature on Properties of 3D Printed PLA Using Fused Deposition Modeling Process. Mater. Today Proc. 2021, 45, 5462–5468. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Lin, X.; Huang, W. Modeling of Deposition Morphology and Characteristic Dimensions in Material Extrusion Additive Manufacturing. Addit. Manuf. 2024, 89, 104306. [Google Scholar] [CrossRef]

- Ahmad, N.F.N.; Wong, Y.H.; Ghazali, N.N.N. A systematic review of fused deposition modeling process parameters. Soft Sci. 2022, 2, 11. [Google Scholar] [CrossRef]

- Birosz, M.T.; Andó, M. Effect of infill pattern scaling on mechanical properties of FDM-printed PLA specimens. Prog. Addit. Manuf. 2024, 9, 875–883. [Google Scholar] [CrossRef]

- Jakupi, K.; Dukovski, V.; Hodolli, G. Surface Roughness Modeling of Material Extrusion PLA Flat Surfaces. Int. J. Polym. Sci. 2023, 2023, 8844626. [Google Scholar] [CrossRef]

- Li, H.; Wang, T.; Li, Q.; Yu, Z.; Wang, N. A Quantitative Investigation of Distortion of Polylactic Acid/PLA) Part in FDM from the Point of Interface Residual Stress. Int. J. Adv. Manuf. Technol. 2018, 94, 381–395. [Google Scholar] [CrossRef]

- Dave, H.K.; Prajapati, A.R.; Rajpurohit, S.R.; Patadiya, N.H.; Raval, H.K. Investigation on Tensile Strength and Failure Modes of FDM Printed Part Using In-House Fabricated PLA Filament. Adv. Mater. Process. Technol. 2020, 8, 576–597. [Google Scholar] [CrossRef]

- Taşcıoğlu, E.; Kıtay, Ö.; Keskin, A.Ö.; Kaynak, Y. Effect of Printing Parameters and Post-Process on Surface Roughness and Dimensional Deviation of PLA Parts Fabricated by Extrusion-Based 3D Printing. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 139. [Google Scholar] [CrossRef]

- Deshwal, S.; Kumar, A.; Chhabra, D. Exercising Hybrid Statistical Tools GA-RSM, GA-ANN and GA-ANFIS to Optimize FDM Process Parameters for Tensile Strength Improvement. CIRP J. Manuf. Sci. Technol. 2020, 31, 189–199. [Google Scholar] [CrossRef]

- Muzli, M.; Ismail, K.; Yap, T. Effects of Infill Density and Printing Speed on the Tensile Behaviour of Fused Deposition Modelling 3D Printed PLA Specimens. J. Eng. Technol. Appl. Phys. 2024, 6, 2. [Google Scholar] [CrossRef]

- Bembenek, M.; Kowalski, Ł.; Kosoń-Schab, A. Research on the Influence of Processing Parameters on the Specific Tensile Strength of FDM Additive Manufactured PET-G and PLA Materials. Polymers 2022, 14, 2446. [Google Scholar] [CrossRef]

- Lendvai, L.; Fekete, I.; Rigotti, D.; Pegoretti, A. Experimental Study on the Effect of Filament-Extrusion Rate on the Structural, Mechanical and Thermal Properties of Material Extrusion 3D-Printed Polylactic Acid (PLA) Products. Prog. Addit. Manuf. 2025, 10, 619–629. [Google Scholar] [CrossRef]

| Parameters | Values | |

|---|---|---|

| Invariable parameters | Printing head temperature, TH | 230 °C |

| Build plate temperature, TB | 60 °C | |

| Layer thickness, t | 0.2 mm | |

| Nozzle diameter, dn | 0.40 mm | |

| Filament diameter, df | 1.75 mm | |

| Build orientation | YX | |

| Raster angle, θ | 45°/−45° | |

| Infill density | 100% | |

| Number of wall lines, WL | 2 | |

| Number of simultaneously printed samples | 1 (individually printing) | |

| Fan speed | 100% | |

| Variable parameters | Printing speed, sp | 100 mm/s; 200 mm/s; 300 mm/s; 400 mm/s; 500 mm/s; 600 mm/s |

| Material/Filament color | ePLA Natural; ePLA Traffic Black | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ardeljan, D.D.; Frunzaverde, D.; Cojocaru, V.; Turiac, R.R.; Bacescu, N.; Ciubotariu, C.R.; Marginean, G. The Impact of Elevated Printing Speeds and Filament Color on the Dimensional Precision and Tensile Properties of FDM-Printed PLA Specimens. Polymers 2025, 17, 2090. https://doi.org/10.3390/polym17152090

Ardeljan DD, Frunzaverde D, Cojocaru V, Turiac RR, Bacescu N, Ciubotariu CR, Marginean G. The Impact of Elevated Printing Speeds and Filament Color on the Dimensional Precision and Tensile Properties of FDM-Printed PLA Specimens. Polymers. 2025; 17(15):2090. https://doi.org/10.3390/polym17152090

Chicago/Turabian StyleArdeljan, Deian Dorel, Doina Frunzaverde, Vasile Cojocaru, Raul Rusalin Turiac, Nicoleta Bacescu, Costel Relu Ciubotariu, and Gabriela Marginean. 2025. "The Impact of Elevated Printing Speeds and Filament Color on the Dimensional Precision and Tensile Properties of FDM-Printed PLA Specimens" Polymers 17, no. 15: 2090. https://doi.org/10.3390/polym17152090

APA StyleArdeljan, D. D., Frunzaverde, D., Cojocaru, V., Turiac, R. R., Bacescu, N., Ciubotariu, C. R., & Marginean, G. (2025). The Impact of Elevated Printing Speeds and Filament Color on the Dimensional Precision and Tensile Properties of FDM-Printed PLA Specimens. Polymers, 17(15), 2090. https://doi.org/10.3390/polym17152090