Rate-Dependent Tensile Behavior of Glass Fiber Composites Reinforced with Quadriaxial Fabrics, with or Without Coremat Xi3 Interlayer, for Marine Applications

Abstract

1. Introduction

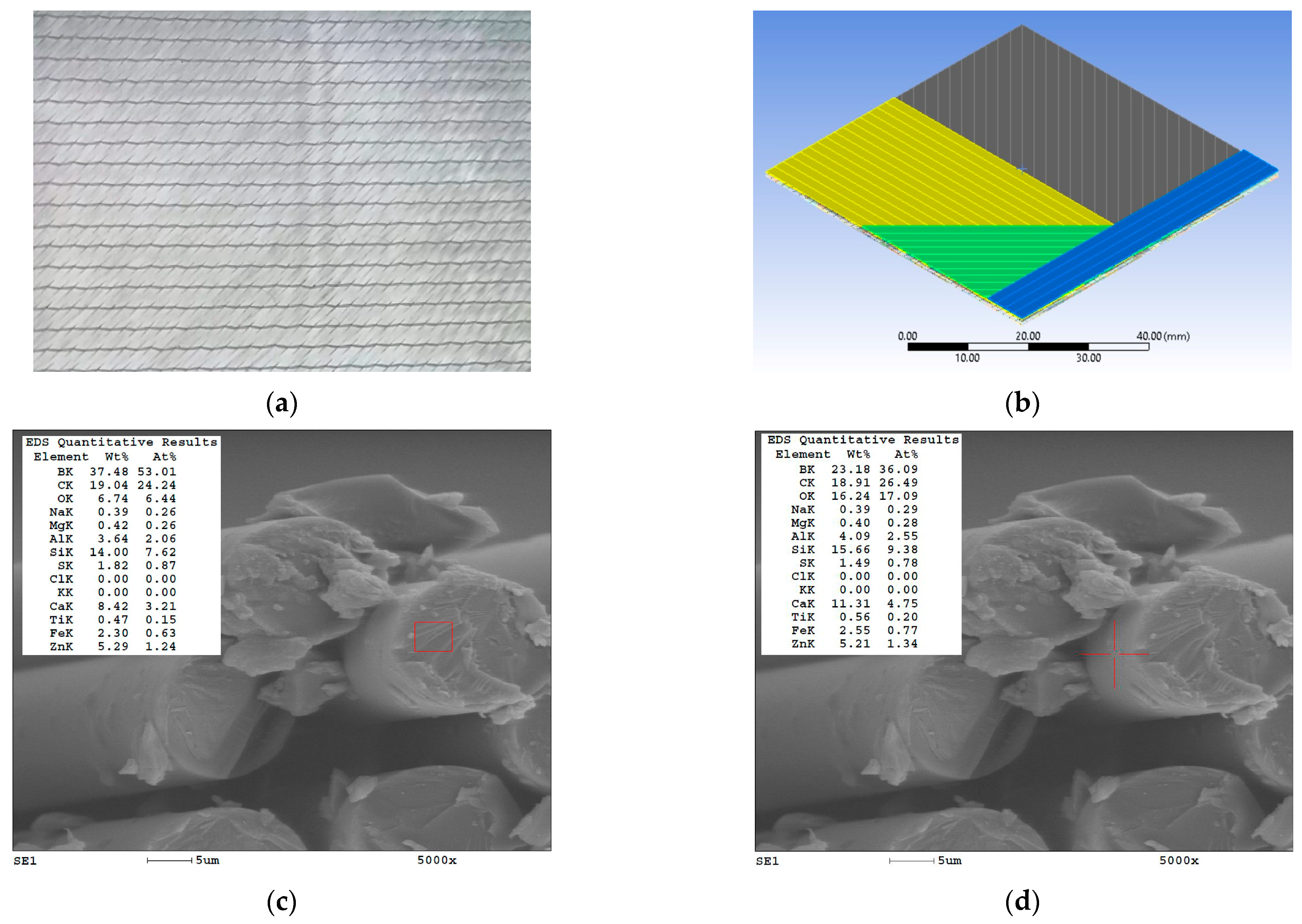

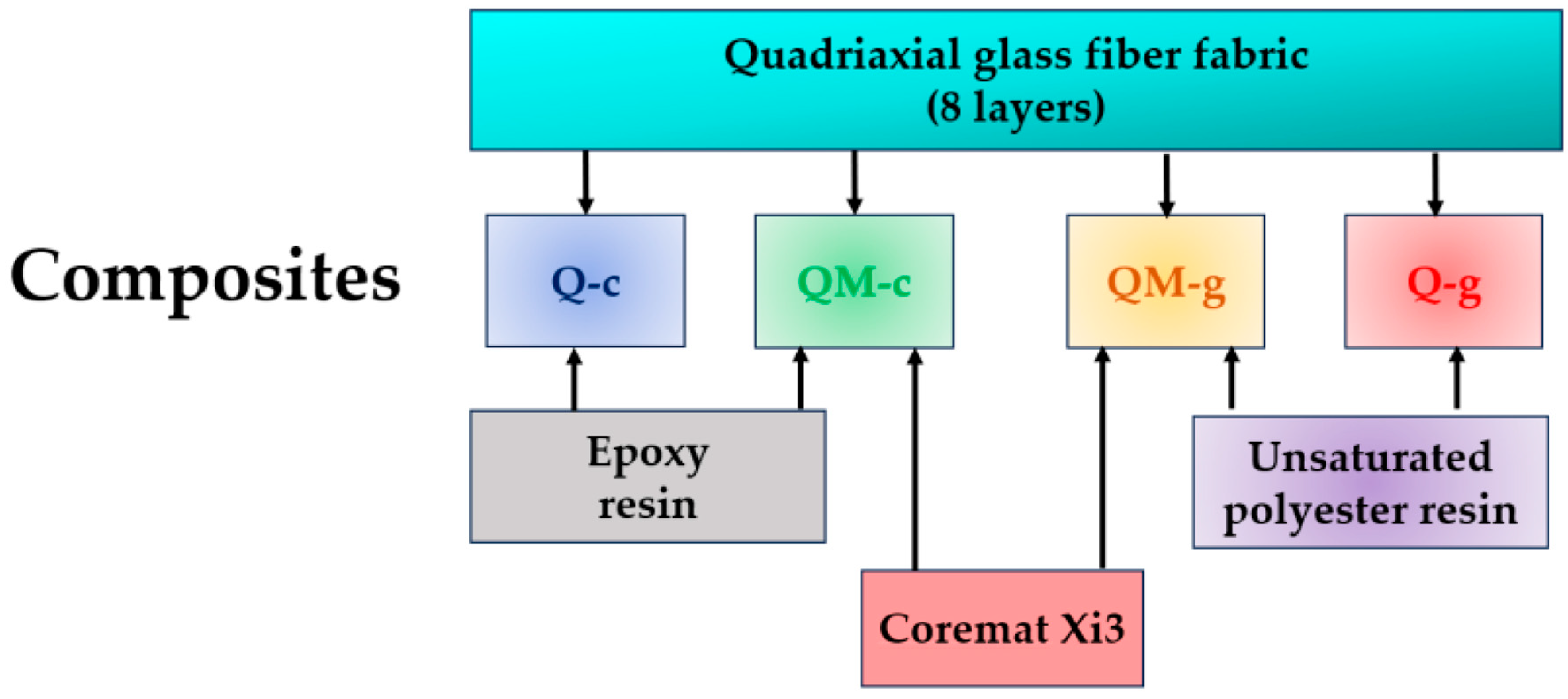

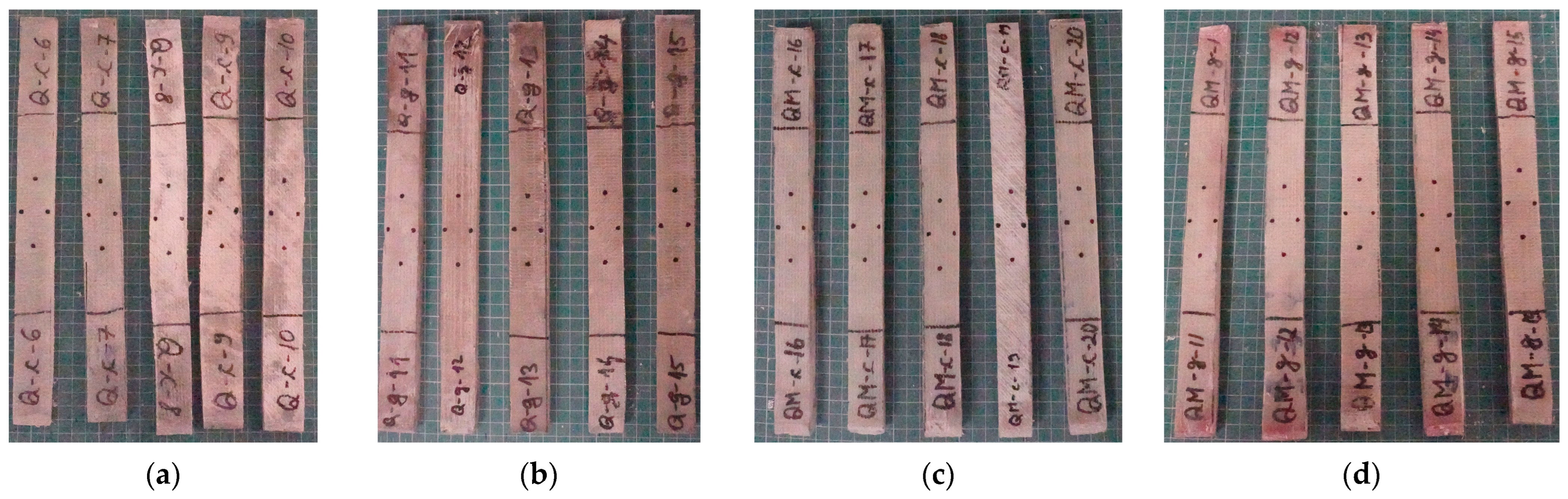

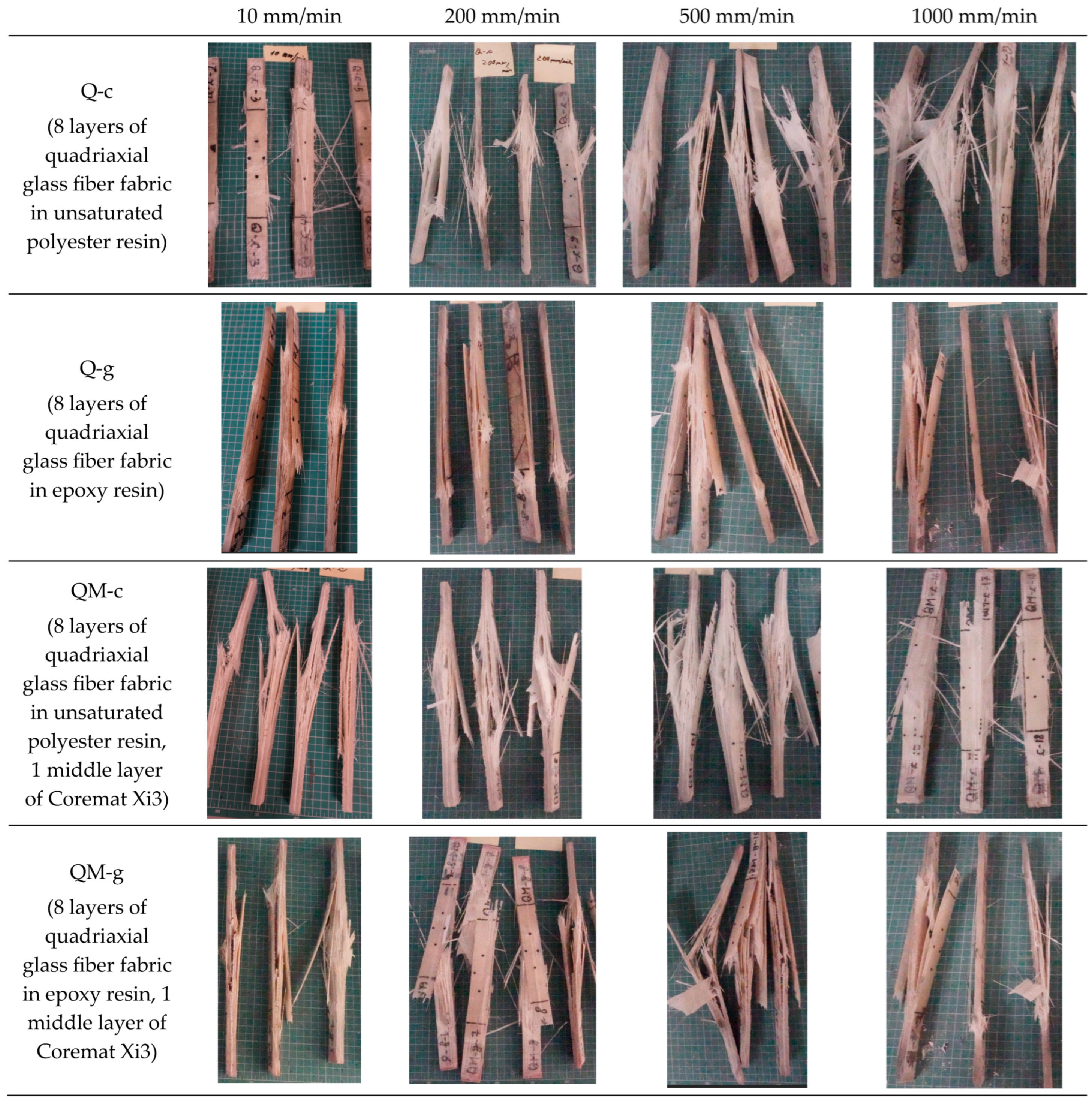

2. Materials and Methods

- -

- Fiber-reinforced thermosetting and thermoplastic composites incorporating non-unidirectional reinforcements such as mats, woven fabrics, woven rovings, chopped strands, combinations of such reinforcements, hybrids, rovings, short or milled fibers, or preimpregnated materials (prepregs);

- -

- Combinations of the above with unidirectional reinforcements and multidirectional reinforced materials constructed from unidirectional layers, provided such laminates are symmetrical;

- -

- Finished products made from materials mentioned above.

- Global structural strain rates remain low, typically < 1 s−1, often 0.1–10 s−1;

- In a ship-side collision simulation, local equivalent plastic strain rates up to ~30 s−1 just before fracture, in a complex model [60];

- Low-velocity wave slamming is similar to quasi-static, with strain rates just a few s−1, often negligible change in response [62];

- Under more violent conditions (high-speed slamming or wave impact), strain rates can rise to tens or hundreds of s−1, though exact values vary with energy and structure;

- In extreme “blast-like” marine events, such as freak waves, strain rates can reach 1 s−1 to 104 s−1, with an average around 10 s−1 near the blast range [63].

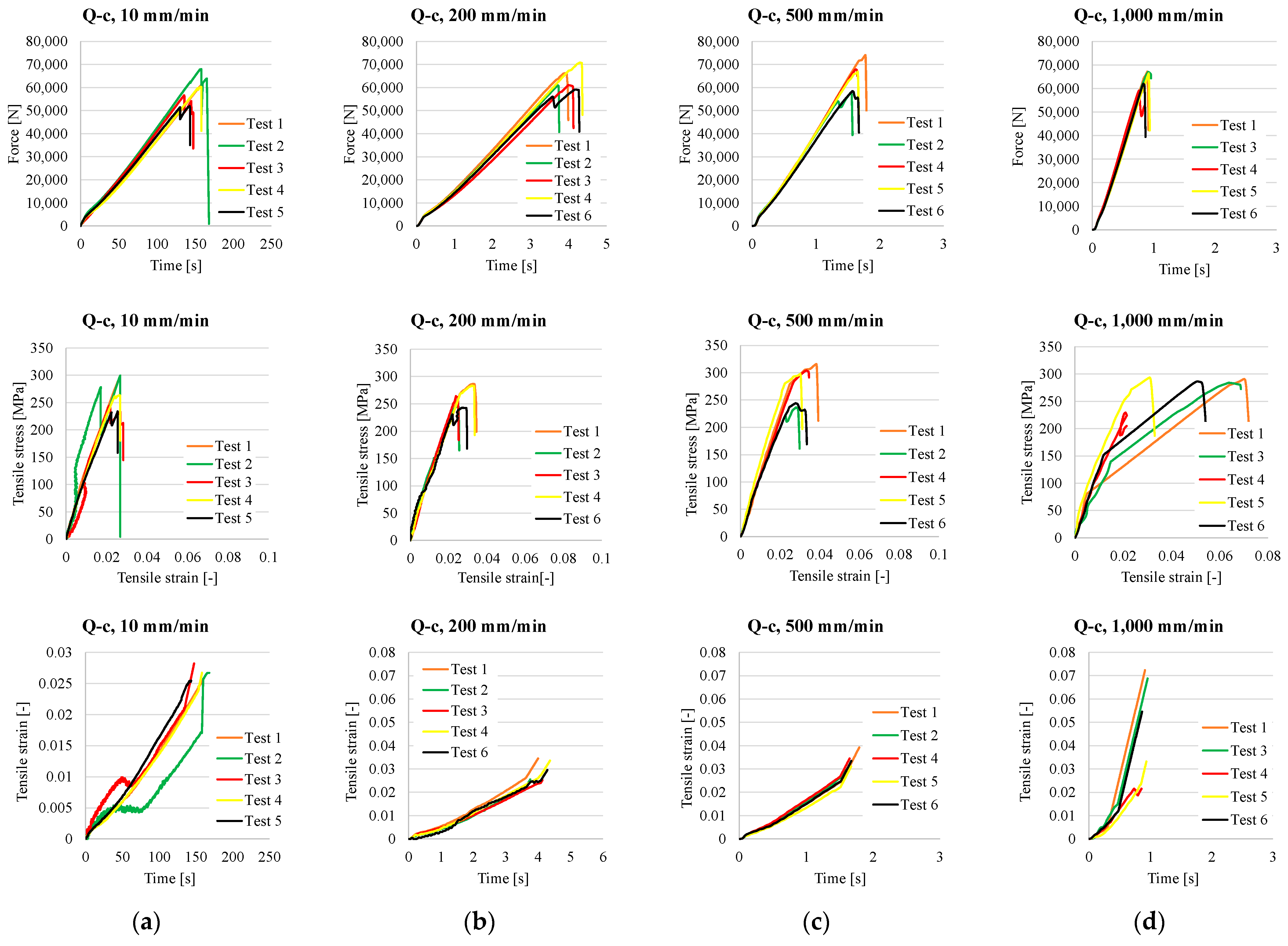

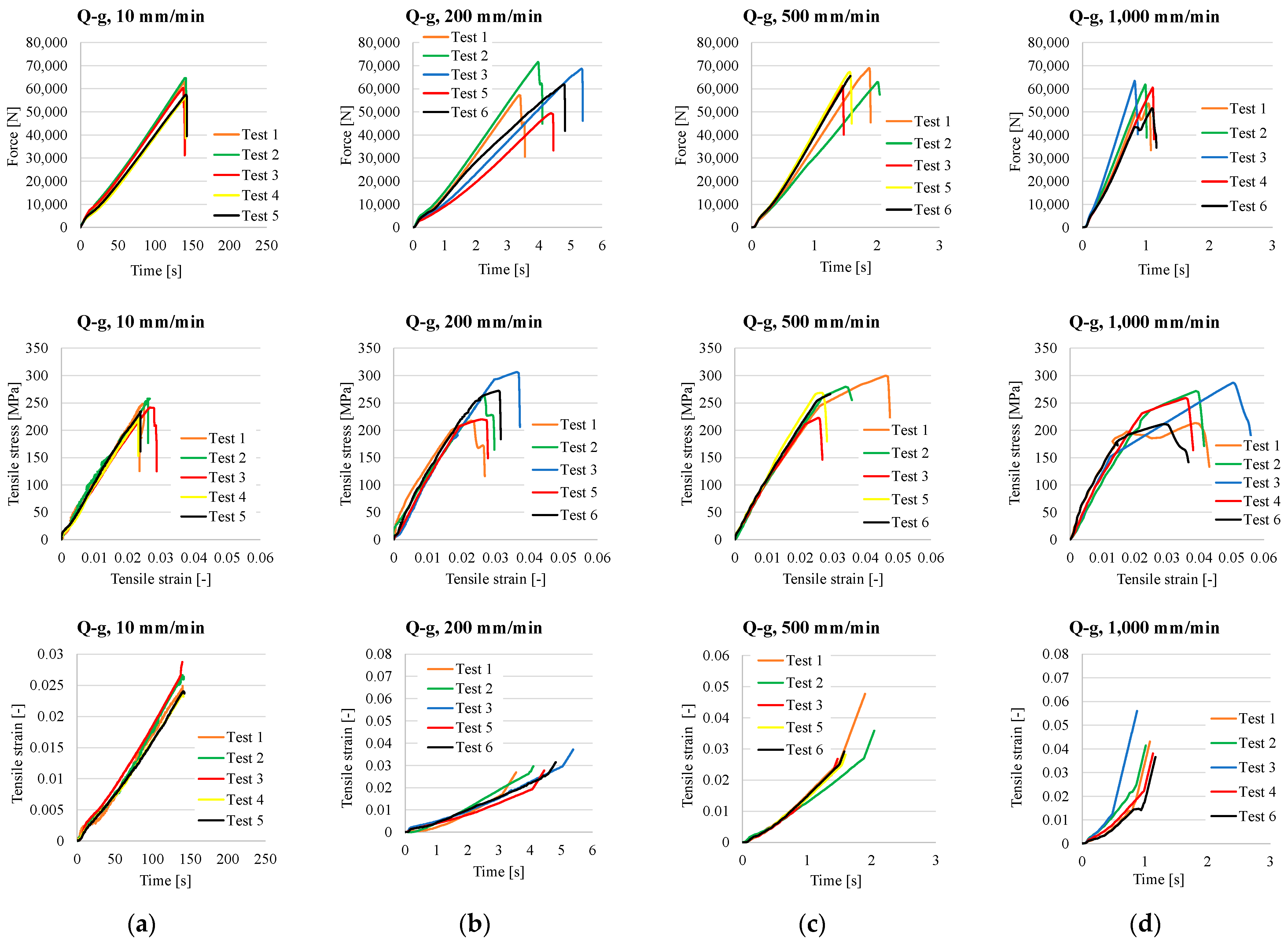

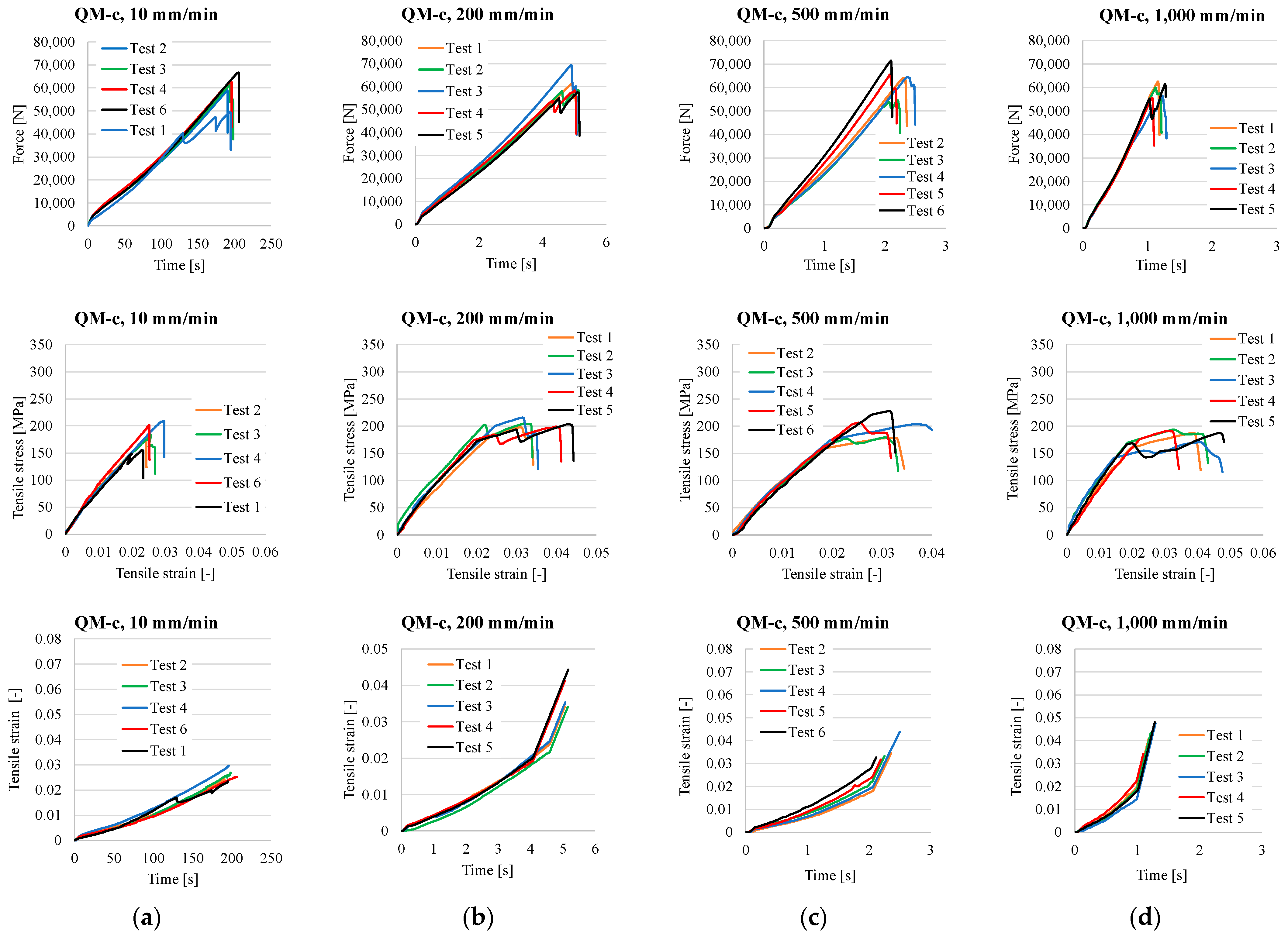

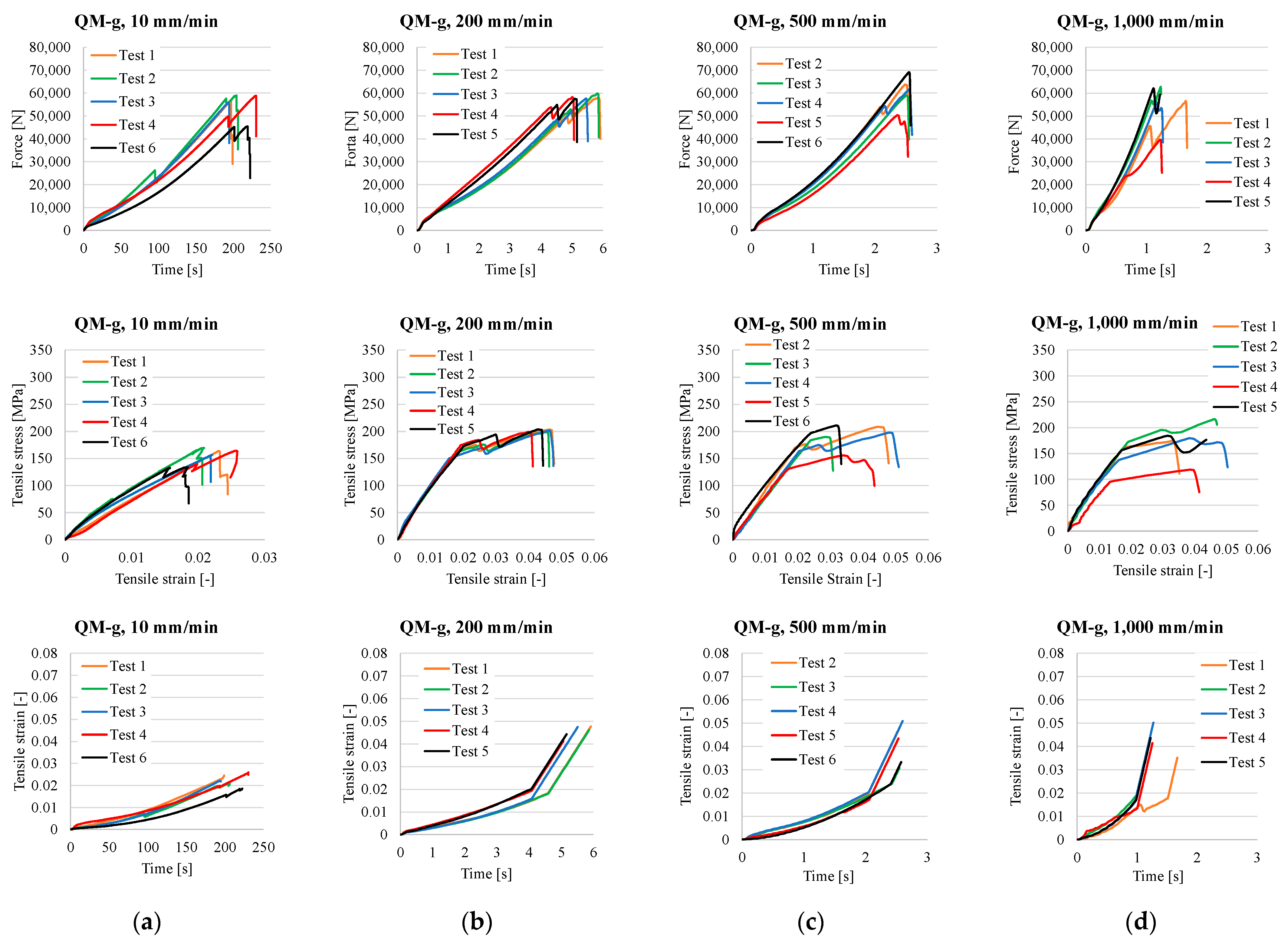

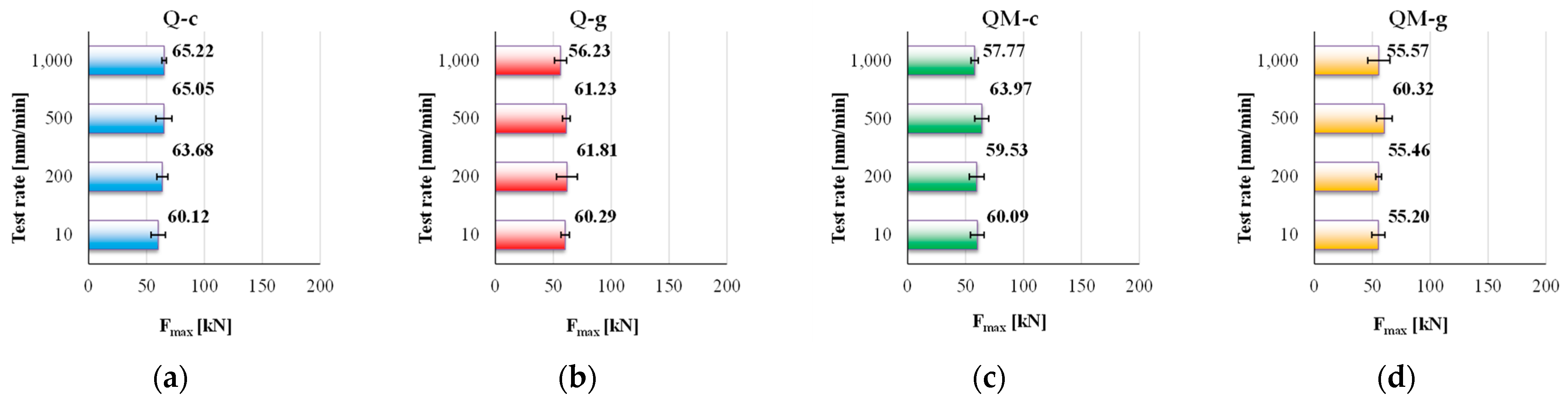

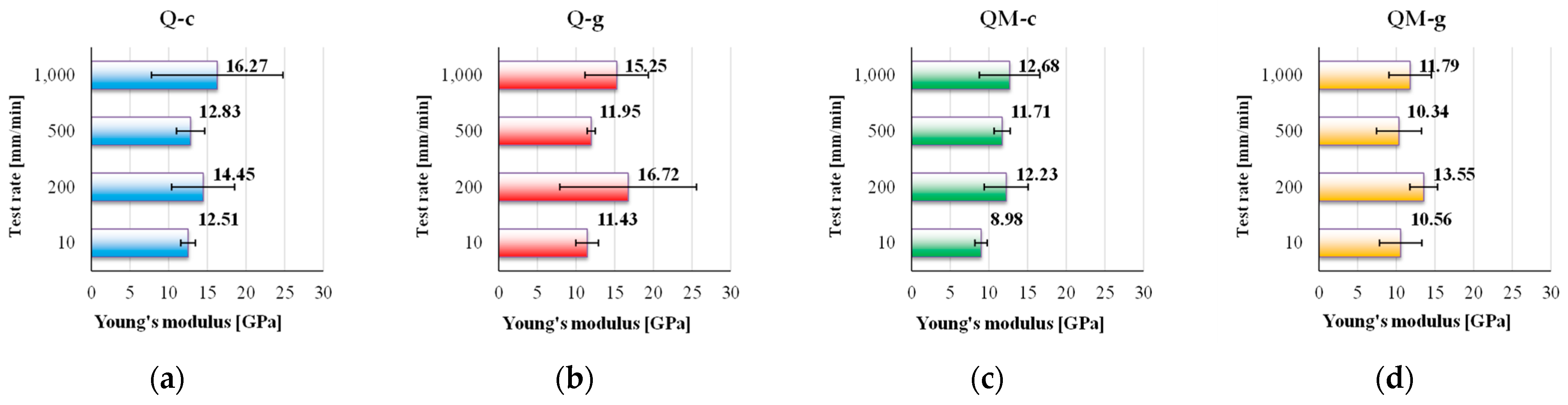

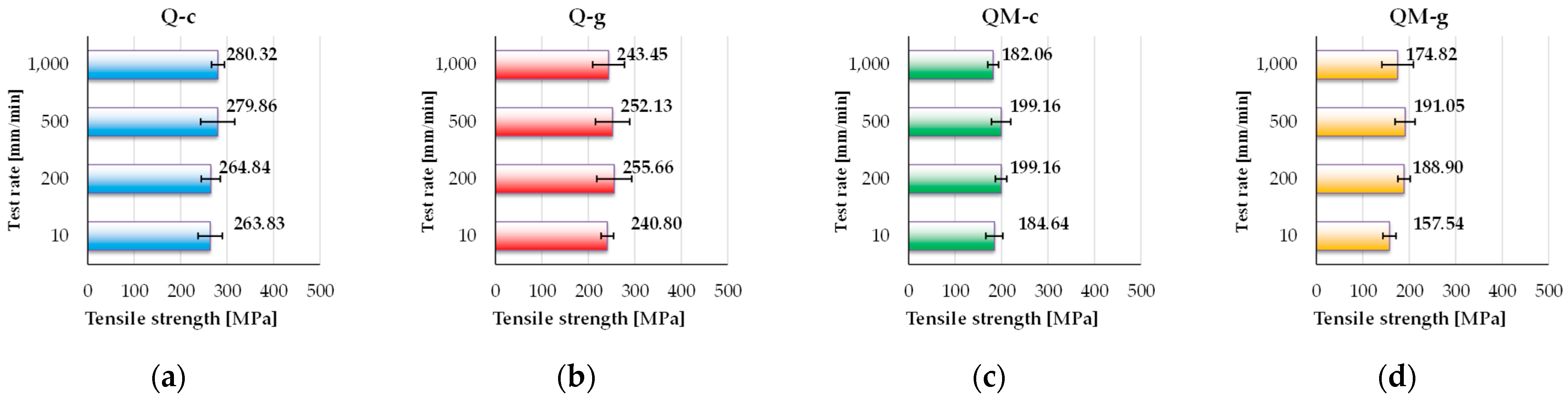

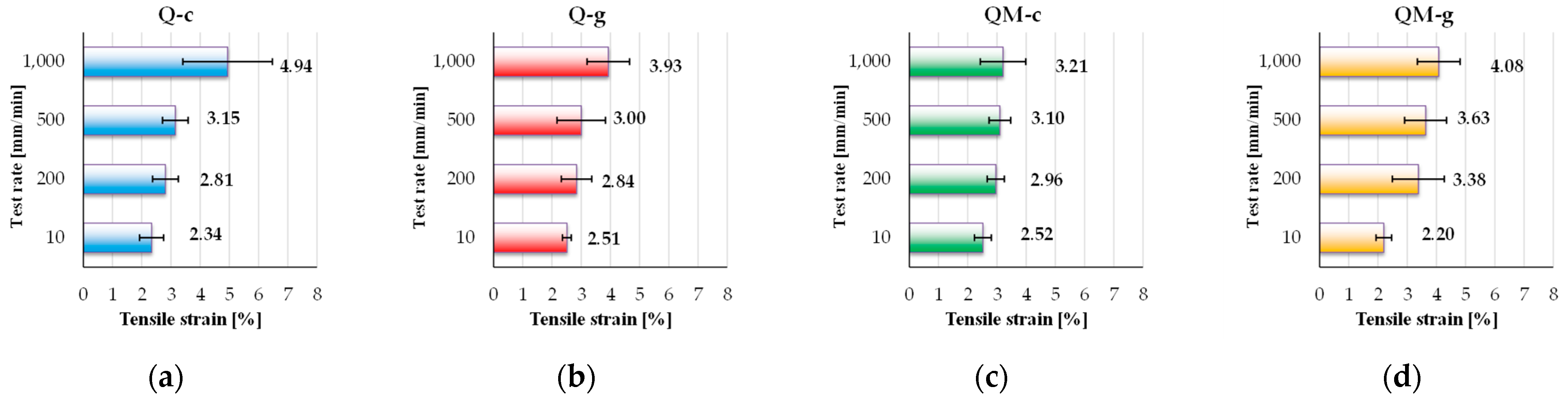

3. Results

- -

- Strain up to the elastic limit, which corresponds to normal operating conditions, where the structure returns to its original shape after the load is removed;

- -

- Strain beyond the elastic limit, but below the strain at break, indicating that the material has entered the (elasto-)plastic deformation range and is experiencing advanced loading.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| 10 mm/min | |||||||||||||||

| Q-c | Q-g | QM-c | QM-g | ||||||||||||

| Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width |

| (mm) | (mm) | (mm) | (mm) | ||||||||||||

| 1 | Q-c_1 | 7.70 | 27.72 | 1 | Q-g_1 | 8.92 | 28.40 | 1 | QM-c_1 | 11.79 | 26.95 | 1 | QM-g_1 | 12.50 | 27.70 |

| 2 | Q-c_2 | 8.36 | 29.21 | 2 | Q-g_2 | 9.11 | 27.53 | 2 | QM-c_2 | 12.34 | 26.54 | 2 | QM-g_2 | 12.44 | 27.98 |

| 3 | Q-c_3 | 8.65 | 26.81 | 3 | Q-g_3 | 9.20 | 27.18 | 3 | QM-c_3 | 12.19 | 27.47 | 3 | QM-g_3 | 12.79 | 27.94 |

| 4 | Q-c_4 | 8.71 | 26.25 | 4 | Q-g_4 | 9.21 | 27.41 | 4 | QM-c_4 | 11.91 | 25.15 | 4 | QM-g_4 | 12.12 | 29.58 |

| 5 | Q-c_5 | 8.64 | 25.69 | 5 | Q-g_5 | 9.12 | 26.81 | 6 | QM-c_21 | 11.82 | 26.20 | 6 | QM-g_21 | 12.37 | 27.52 |

| Average | 8.41 | 27.14 | Average | 9.11 | 27.47 | Average | 12.01 | 26.46 | Average | 12.44 | 28.14 | ||||

| SD | 0.42 | 1.38 | SD | 0.12 | 0.59 | SD | 0.24 | 0.87 | SD | 0.24 | 0.82 | ||||

| SD% | 5.00 | 5.09 | SD% | 1.28 | 2.15 | SD% | 2.02 | 3.30 | SD% | 1.94 | 2.93 | ||||

| 200 mm/min | |||||||||||||||

| Q-c | Q-g | QM-c | QM-g | ||||||||||||

| Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width |

| (mm) | (mm) | (mm) | (mm) | ||||||||||||

| 1 | Q-c_6 | 8.40 | 27.51 | 1 | Q-g_6 | 9.03 | 29.19 | 1 | QM-c_6 | 11.95 | 25.89 | 1 | QM-g_6 | 10.84 | 26.35 |

| 2 | Q-c_7 | 8.88 | 27.83 | 2 | Q-g_7 | 9.32 | 29.33 | 2 | QM-c_7 | 11.40 | 25.13 | 2 | QM-g_7 | 10.79 | 27.89 |

| 3 | Q-c_8 | 8.64 | 26.78 | 3 | Q-g_8 | 8.11 | 27.65 | 3 | QM-c_8 | 11.82 | 27.18 | 3 | QM-g_8 | 10.55 | 27.11 |

| 4 | Q-c_9 | 8.52 | 29.36 | 4 | Q-g_9 | 7.26 | 28.83 | 4 | QM-c_9 | 11.52 | 25.37 | 4 | QM-g_9 | 10.90 | 26.76 |

| 5 | Q-c_10 | 8.45 | 29.01 | 5 | Q-g_10 | 8.21 | 27.33 | 5 | QM-c_10 | 11.41 | 24.76 | 5 | QM-g_10 | 11.34 | 27.00 |

| Average | 8.58 | 28.10 | Average | 8.39 | 28.47 | Average | 11.62 | 25.67 | Average | 10.88 | 27.02 | ||||

| SD | 0.19 | 1.07 | SD | 0.82 | 0.87 | SD | 0.25 | 0.94 | SD | 0.29 | 0.57 | ||||

| SD% | 2.23 | 3.81 | SD% | 9.73 | 3.06 | SD% | 2.16 | 3.66 | SD% | 2.64 | 2.09 | ||||

| 500 mm/min | |||||||||||||||

| Q-c | Q-g | QM-c | QM-g | ||||||||||||

| Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width |

| (mm) | (mm) | (mm) | (mm) | ||||||||||||

| 1 | Q-c_11 | 8.12 | 28.87 | 1 | Q-g_11 | 8.33 | 27.61 | 2 | QM-c_12 | 12.02 | 28.86 | 2 | QM-g_12 | 10.85 | 28.19 |

| 2 | Q-c_12 | 8.73 | 27.99 | 2 | Q-g_12 | 8.31 | 27.12 | 3 | QM-c_13 | 11.68 | 26.03 | 3 | QM-g_13 | 11.05 | 28.14 |

| 4 | Q-c_14 | 8.11 | 25.53 | 3 | Q-g_13 | 9.69 | 28.36 | 4 | QM-c_14 | 11.66 | 27.12 | 4 | QM-g_14 | 10.90 | 28.55 |

| 5 | Q-c_15 | 8.31 | 27.02 | 5 | Q-g_15 | 9.18 | 27.30 | 5 | QM-c_15 | 11.45 | 27.67 | 5 | QM-g_15 | 11.61 | 27.87 |

| 6. | Q-c_22 | 8.80 | 27.21 | 6 | Q-g_22 | 9.23 | 26.73 | 6 | QM-c_23 | 12.01 | 26.12 | 6 | QM-g_23 | 12.14 | 27.01 |

| Average | 8.41 | 27.32 | Average | 8.95 | 27.42 | Average | 11.76 | 27.16 | Average | 11.31 | 27.95 | ||||

| SD | 0.33 | 1.24 | SD | 0.61 | 0.61 | SD | 0.25 | 1.17 | SD | 0.55 | 0.58 | ||||

| SD% | 3.94 | 4.54 | SD% | 6.78 | 2.23 | SD% | 2.09 | 4.32 | SD% | 4.90 | 2.07 | ||||

| 1000 mm/min | |||||||||||||||

| Q-c | Q-g | QM-c | QM-g | ||||||||||||

| Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width | Test no. | Specimen label | Thickness | Width |

| (mm) | (mm) | (mm) | (mm) | ||||||||||||

| 1 | Q-c_16 | 8.47 | 27.21 | 1 | Q-g_16 | 9.08 | 27.67 | 1 | QM-c_16 | 11.86 | 28.09 | 1 | QM-g_16 | 11.04 | 29.44 |

| 3 | Q-c_18 | 8.42 | 28.01 | 2 | Q-g_17 | 8.25 | 27.59 | 2 | QM-c_17 | 11.70 | 26.40 | 2 | QM-g_17 | 10.94 | 26.51 |

| 4 | Q-c_19 | 8.82 | 29.20 | 3 | Q-g_18 | 8.19 | 26.96 | 3 | QM-c_18 | 11.79 | 28.00 | 3 | QM-g_18 | 12.17 | 25.60 |

| 5 | Q-c_20 | 8.43 | 26.81 | 4 | Q-g_19 | 8.33 | 28.03 | 4 | QM-c_19 | 11.81 | 24.60 | 4 | QM-g_19 | 11.86 | 28.23 |

| 6 | Q-c_23 | 8.24 | 26.24 | 6 | Q-g_23 | 8.97 | 27.22 | 5 | QM-c_20 | 11.76 | 27.80 | 5 | QM-g_20 | 12.07 | 27.91 |

| Average | 8.48 | 27.49 | Average | 8.56 | 27.49 | Average | 11.78 | 26.98 | Average | 11.62 | 27.54 | ||||

| SD | 0.21 | 1.15 | SD | 0.43 | 0.41 | SD | 0.06 | 1.50 | SD | 0.58 | 1.50 | ||||

| SD% | 2.50 | 4.19 | SD% | 4.97 | 1.51 | SD% | 0.50 | 5.54 | SD% | 5.02 | 5.46 | ||||

- -

- For composites without Coremat Xi3, the composite mass isVcomposite × ρcomposite = Vf × ρf + mresin

- -

- For composites with Coremat Xi3, the composite mass isVcomposite × ρcomposite = Vf × ρf + mmat + mresin

| Plate | Fabric Mass, mf | Composite Plate Mass | Resin Mass * | Mass Fiber Ratio (mf/mcomposite) | Surface Density (mcomposite/Acomposite **) | Vf/Vcomposite | h1 | h2 | h3 | h4 | haverage |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (g) | (g) | (g) | (kg/m2) | (mm) | (mm) | (mm) | (mm) | (mm) | |||

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Q-c-02 | 855.0 | 1443.7 | 588.672 | 0.592 | 16.041 | 0.416 | 8.75 | 9.10 | 8.90 | 9.20 | 8.988 |

| Q-c-03 | 865.5 | 1461.4 | 595.901 | 0.639 | 14.967 | 0.470 | 8.20 | 7.95 | 7.80 | 8.30 | 8.063 |

| Q-c-04 | 863.0 | 1457.2 | 594.180 | 0.608 | 15.250 | 0.440 | 8.65 | 8.40 | 8.70 | 8.55 | 8.575 |

| Average Q-c | 861.2 | 1454.1 | 592.918 | 0.613 | 15.419 | 0.442 | 8.53 | 8.48 | 8.46 | 8.68 | 8.542 |

| Q-g-07 | 883.0 | 1295.6 | 412.583 | 0.682 | 13.939 | 0.462 | 8.40 | 8.45 | 8.35 | 8.25 | 8.363 |

| Q-g-08 | 850.0 | 1247.2 | 397.164 | 0.625 | 15.017 | 0.431 | 8.65 | 8.70 | 8.60 | 8.55 | 8.625 |

| Q-g-09 | 848.5 | 1245.0 | 396.463 | 0.651 | 14.444 | 0.430 | 8.60 | 8.55 | 8.65 | 8.75 | 8.638 |

| Average Q-g | 860.5 | 1262.6 | 402.070 | 0.653 | 14.467 | 0.441 | 8.55 | 8.56 | 8.53 | 8.51 | 8.542 |

| QM-c-08 | 823.0 | 1518.1 | 687.108 | 0.547 | 17.278 | 0.313 | 11.65 | 11.20 | 11.40 | 11.70 | 11.488 |

| QM-c-09 | 866.6 | 1598.5 | 724.433 | 0.558 | 17.044 | 0.343 | 10.90 | 11.10 | 10.75 | 11.45 | 11.050 |

| QM-c-10 | 852.5 | 1572.5 | 712.024 | 0.552 | 17.144 | 0.333 | 10.90 | 11.45 | 11.25 | 11.25 | 11.213 |

| Average QM-c | 847.4 | 1563.1 | 707.855 | 0.552 | 17.155 | 0.330 | 11.15 | 11.25 | 11.13 | 11.46 | 11.250 |

| QM-g-07 | 850.3 | 1392.6 | 534.309 | 0.617 | 15.122 | 0.339 | 11.25 | 11.55 | 10.35 | 10.80 | 10.988 |

| QM-g-08 | 864.0 | 1415.0 | 542.547 | 0.635 | 15.139 | 0.344 | 11.20 | 10.70 | 11.25 | 10.75 | 10.975 |

| QM-g-09 | 845.5 | 1384.7 | 532.248 | 0.642 | 15.033 | 0.334 | 11.20 | 11.10 | 10.90 | 11.10 | 11.075 |

| Average QM-g | 853.3 | 1397.5 | 536.368 | 0.631 | 15.098 | 0.339 | 11.21 | 11.11 | 10.83 | 10.88 | 11.013 |

References

- Rajendran, S.; Palani, G.; Trilaksana, H.; Marimuthu, U.; Kannan, G.; Yang, Y.-L.; Shanmugam, V. Advancements in natural fibre based polymeric composites: A comprehensive review on mechanical-thermal performance and sustainability aspects. Sustain. Mater. Technol. 2025, 44, 01345. [Google Scholar] [CrossRef]

- Graham-Jones, J.; Summerscales, J. (Eds.) Introduction. In Marine Applications of Advanced Fibre-Reinforced Composites; Woodhead Publishing: Cambridge, UK; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–16. [Google Scholar][Green Version]

- Baley, C.; Davies, P.; Troalen, W.; Chamley, A.; Dinham-Price, I.; Marchandise, A.; Keryvin, V. Sustainable polymer composite marine structures: Developments and challenges. Prog. Mater. Sci. 2024, 145, 101307. [Google Scholar] [CrossRef]

- Penumadu, D. Durability of US Naval Composites and Sandwich Structures: Science Framework Considering Multiscale Response in Harsh Sea Environment. In Durability of Composites in a Marine Environment; Davies, P., Rajapakse, Y.D.S., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 59–74. [Google Scholar][Green Version]

- Tsai-Wu, S.; Melo, H.D. Composites Materials. Design and Testing; Composites Design Group: Ockley, UK, 2015. [Google Scholar][Green Version]

- Hashin, Z. Failure Criteria for Unidirectional Fiber Composites. J. Appl. Mech. 1980, 47, 329–334. [Google Scholar] [CrossRef]

- Hwu, C. Mechanics of Laminated Composite Structures; CRC Press: Boca Raton, FL, USA, 2024. [Google Scholar][Green Version]

- Rosen, B.W. Failure of Fiber Composite Laminates. In Mechanics of Composite Materials: Recent Advances; Hashin, Z., Herakovich, C.T., Eds.; Pergamon: New York, NY, USA, 1983; pp. 105–134. [Google Scholar] [CrossRef]

- Caramatescu, A.; Mocanu, C.I.; Modiga, A. A New Concept of Composite Material for High-Speed Boats. Mater. Plast. 2019, 56, 11–17. [Google Scholar] [CrossRef]

- Caramatescu, A.; Mocanu, C.I. Review of composite materials applications in marine industry. Ann. Dunarea De Jos Univ. Galati. Fascicle XI Shipbuild. 2019, 42, 169–174. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Moustabchir, H.; Pruncu, C.I. Improving the tensile and flexural properties of reinforced epoxy composites by using cobalt filled and carbon/glass fiber. Forces Mech. 2021, 4, 100029. [Google Scholar] [CrossRef]

- Itu, C.; Scutaru, L.M.; Modrea, A.; Mihălcică, M. Traction Characteristics for the componentes of a composite sandwich used to build high-rigidity plates. Procedia Manuf. 2019, 32, 268–277. [Google Scholar] [CrossRef]

- Cao, Y.; Gao, G.; Zhang, P.; Bao, J.; Feng, P.; Li, R.; Wang, W. Improving tensile properties of glass fiber-reinforced epoxy resin composites based on enhanced multiphase structure: The modification of resin systems and glass fibers. Mater. Today Commun. 2024, 40, 110225. [Google Scholar] [CrossRef]

- Golfman, Y. Materials for Turbine Power Blades, Reinforcements, and Resins. In Hybrid Anisotropic Materials for Wind Power Turbine Blades; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Abingdon, UK, 2012; pp. 55–88. [Google Scholar]

- Summerscales, J. Materials selection for marine composites. In Marine Composites: Design and Performance; Pemberton, R., Summerscales, J., Graham-Jones, J., Eds.; Woodhead Publishing: Elsevier, Cambridge, UK, 2019; pp. 3–30. [Google Scholar]

- Zhang, L. The application of composite fiber materials in sports equipment. In Proceedings of the 5th International Conference on Education, Management, Information and Medicine (EMIM 2015), Shenyang, China, 24–26 April 2015. [Google Scholar] [CrossRef]

- Lu, C.Y.; Pilla, S. Design of Automotive Composites; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Linganiso, L.Z.; Anandjiwala, R.D. Fibre-reinforced laminates in aerospace engineering. In Advanced Composite Materials for Aerospace Engineering. Processing, Properties and Applications; Sano, T., Srivatsan, T.S., Eds.; Woodhead Publishing: Amsterdam, The Netherlands, 2016; pp. 101–128. [Google Scholar]

- Shubham; Chandra Ray, B. Fiber Reinforced Polymer (FRP) Composites in Ballistic Protection: Microstructural and Micromechanical Perspectives; Springer: Singapore, 2024; pp. 35–50. [Google Scholar]

- Ou, Y.; Zhu, D. Tensile behavior of glass fiber reinforced composite at different strain rates and temperatures. Constr. Build. Mater. 2015, 96, 648–656. [Google Scholar] [CrossRef]

- Cui, J.; Wang, S.; Wang, S.; Li, G.; Wang, P.; Liang, C. The Effects of Strain Rates on Mechanical Properties and Failure Behavior of Long Glass Fiber Reinforced Thermoplastic Composites. Polymers 2019, 11, 2019. [Google Scholar] [CrossRef]

- Chiracu, I.G.; Ojoc, G.G.; Cristea, G.C.; Boțan, M.; Cantaragiu Ceoromila, A.; Pîrvu, C.; Vasiliu, A.V.; Deleanu, L. Behavior of Composites Made of Quadriaxial Glass Fiber Fabrics and Epoxy Resin under Three-Point Bending. Polymers 2024, 16, 1925. [Google Scholar] [CrossRef]

- Shahzad, A. Comparison of tensile properties and impact damage tolerance of hemp and glass fiber composites. J. Reinf. Plast. Compos. 2011, 30, 1877–1893. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Lv, Y.; Li, J. Quasi-static and dynamic properties of unidirectional glass fiber/epoxy laminate for structural strengthening. Mater. Struct. 2022, 55, 202. [Google Scholar] [CrossRef]

- Mahato, K.K.; Dutta, K.; Ray, B.C. High-temperature tensile behavior at different crosshead speeds during loading of glass fiber-reinforced polymer composites. J. Appl. Polym. Sci. 2017, 134, 44715. [Google Scholar] [CrossRef]

- Bochnia, J.; Blasiak, M.; Kozior, T. Tensile Strength Analysis of Thin-Walled Polymer Glass Fiber Composites Manufactured by Selective Laser Sintering (SLS). Polymers 2020, 12, 2783. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Tensile behavior of glass/epoxy laminates at varying strain rates and temperatures. Compos. B Eng. 2013, 44, 433–439. [Google Scholar] [CrossRef]

- Dong, C.; Davies, I.J. Flexural and tensile strengths of unidirectional hybrid epoxy composites reinforced by S-2 glass and T700S carbon fibres. Mater. Des. (1980–2015) 2014, 54, 955–966. [Google Scholar] [CrossRef]

- Ismail, K.I.; Pang, R.; Ahmed, R.; Yap, T.C. Tensile Properties of In Situ 3D Printed Glass Fiber-Reinforced PLA. Polymers 2023, 15, 3436. [Google Scholar] [CrossRef]

- Stanciu, M.D.; Drăghicescu, H.T.; Roșca, I.C. Mechanical Properties of GFRPs Exposed to Tensile, Compression and Tensile–Tensile Cyclic Tests. Polymers 2021, 13, 898. [Google Scholar] [CrossRef]

- Non-Crimp Fabrics. Saertex. Available online: https://www.saertex.com/en/products/multiaxial-fabrics (accessed on 10 March 2025).

- Multiaxial Reinforcements. Available online: https://www.metyx.com/multiaxial-reinforcements/ (accessed on 12 February 2025).

- Multi-Layer Reinforcement for Superior Strength and Integrity. Available online: https://www.solidian-kelteks.com/en/products/composite/reinforcements/complex-fabrics/combimat-detail (accessed on 10 March 2025).

- Non-Crimp Glass Multiaxials. Castro Composites. Available online: https://www.castrocompositesshop.com/en/80-non-crimp-glass-multiaxials (accessed on 12 February 2025).

- Cristea, G.C.; Deleanu, L.; Chiracu, I.G.; Boțan, M.; Ojoc, G.G.; Vasiliu, A.V.; Cantaragiu Ceoromila, A. Influence of Resin Grade and Mat on Low-Velocity Impact on Composite Applicable in Shipbuilding. Polymers 2025, 17, 355. [Google Scholar] [CrossRef]

- 1200 g/m2 Quadriaxial Stitched Glass Fabric (0°/+45°/90°/−45°), 127 cm Wide. Available online: https://www.castrocompositesshop.com/en/fibre-reinforcements/1204-1200-gm2-quadriaxi-al-stitched-glass-fabric-0%C2%BA45%C2%BA90%C2%BA-45%C2%BA-127-cm-wide.html (accessed on 12 January 2022).

- Ojoc, G.G.; Chiper Titire, L.; Munteniță, C.; Pîrvu, C.; Sandu, S.; Deleanu, L. Ballistic Response of a Glass Fiber Composite for Two Levels of Threat. Polymers 2023, 15, 1039. [Google Scholar] [CrossRef]

- Coremat Xi 3 mm. Available online: https://www.nedform.com/DOC/EN/EN%20-%20Product%20Information%20Coremat%20Xi%203.pdf (accessed on 12 September 2024).

- Lantor 3 mm Xi Coremat (50 mts). Available online: https://grpukltd.com/product/lantor-3mm-xi-coremat-50mts/ (accessed on 3 December 2024).

- Composites. Datasheet Coremat® Xi. Available online: https://grpukltd.com/wp-content/uploads/2016/10/Xi.pdf (accessed on 3 December 2024).

- Lantor Coremat®; The Original Laminatebulker, Creating Cost Effective Stiffness. Lantor Composites. Available online: https://www.lantorcomposites.com/textile-foam-cores/coremat/ (accessed on 3 May 2025).

- Ultimate Glassfiber and Resin Guidebook. Available online: https://fiberglasswarehouse.com/blogs/news/ultimate-fiberglass-and-resin-guidebook-for-beginners (accessed on 3 September 2024).

- Guide to Composites. Available online: https://www.gurit.com/wp-content/uploads/2022/12/guide-to-composites-1.pdf (accessed on 3 December 2024).

- SikaBiresin® CR82 (Composite Resin System for Hand Lay-Up Process with Tg up to 89 °C). Available online: https://industry.sika.com/en/home/advanced-resins/sports-and-leisure/composite-resin-systems/composite-systemsforwetlay-up/sikabiresin-cr82.html (accessed on 1 July 2025).

- Advanced Composites Solutions. High Performance Epoxy and Polyurethane Systems. Available online: https://automotive.sika.com/dam/dms/global-industry/m/advanced-compositessolutions.pdf (accessed on 4 October 2024).

- Enydyne H 68372 TA Rășină Poliesterică Nesaturată. Available online: https://www.rompolimer.ro/fise_tehnice/_TDS_ENYDYNE_H_68372_TA.RO.pdf (accessed on 5 April 2024).

- Gama Completa de Rasini. Available online: https://www.rompolimer.ro/produse/rasini/ (accessed on 5 April 2024).

- TDS METOX-50W.EN. Available online: https://www.grs.ie/wp-content/uploads/2021/02/metox-50we-tds.pdf (accessed on 5 April 2024).

- RomPolimer Composites. Available online: https://www.rompolimer.ro/ (accessed on 9 April 2025).

- Agents de Démoulage Externes Pour L’industrie des Composites. Available online: https://www.airetec.fr/composites-d%C3%A9moulants-externes (accessed on 10 May 2025).

- Demulanti/Agenti de Lustruire. Available online: https://www.rompolimer.ro/produse/demulanti-agenti-lustruire/ (accessed on 4 October 2024).

- 5980 Series Universal Testing System up to 600 kN Force Capacity. Available online: https://www.instron.com/en/products/testing-systems/universal-testing-systems/high-force-universal-testing-systems/5989-floor-model/ (accessed on 22 January 2025).

- Data Acquisition and Analysis. Available online: https://www.instron.com/-/media/literature-library/products/2013/09/ceast-data-acquisition-and-analysis.pdf (accessed on 22 January 2025).

- Mechanical Wedge Action Tensile Grips for Tensile Testing on a Wide Range of Materials and Specimen Types. Available online: https://www.instron.com/en/products/testing-accessories/grips/mechanical-wedge-action-grips/ (accessed on 28 January 2025).

- Instron AVE. Advanced Video Extensometer, Reference Manual—Application Notes, M26-14059-EN Revision A. Available online: https://biomech.unideb.hu/sites/default/files/upload_documents/ave.pdf (accessed on 3 May 2025).

- ISO 527-1:2019; Plastics—Determination of Tensile Properties Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- ISO 527-4:2021; Plastics—Determination of tensile properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites. ISO: Geneva, Switzerland, 2021.

- ISO 527-5:2021; Plastics—Determination of Tensile Properties—Part 5: Test Conditions for Unidirectional Fibre-Reinforced Plastic Composites. ISO: Geneva, Switzerland, 2021.

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Cerik, B.C.; Choung, J. Fracture Estimation in Ship Collision Analysis—Strain Rate and Thermal Softening Effects. Metals 2021, 11, 1402. [Google Scholar] [CrossRef]

- Jacob, C.G.; Starbuck, M.J.; Fellers, J.F.; Simunovic, S.; Boeman, R.G. Strain Rate Effects on the Mechanical Properties of Polymer Composite Materials. J. Appl. Polym. Sci. 2004, 94, 296–301. [Google Scholar] [CrossRef]

- Gao, H.; Li, Y. Dynamic mechanical response evaluation of woven carbon fiber reinforced rubber laminated composites under high strain rates. Sci. Rep. 2025, 15, 16711. [Google Scholar] [CrossRef] [PubMed]

- Sutherland, L.S. A review of impact testing on marine composite materials: Part IV—Scaling, strain rate and marine-type laminates. Compos. Struct. 2018, 200, 929–938. [Google Scholar] [CrossRef]

- Perry, D.; Walley, S.M. Measuring the Effect of Strain Rate on Deformation and Damage in Fibre-Reinforced Composites. J. Dyn. Behav. Mater. 2022, 8, 178–213. [Google Scholar] [CrossRef]

| First Author (Year) | Composite (Glass Fiber Reinforcement, Resin, Additives) | Specimen Dimensions | Test Rate | Ultimate Tensile Strength (MPa) | Young’s Modulus (GPa) | Energy at Break (J) | Strain at Break (%) |

|---|---|---|---|---|---|---|---|

| Ou, Y. (2016) [20] | Unidirectional GFRP, epoxy | ASTM D3039 | 25–200 s−1 | 700–900 | 40–50 | Not reported | 1.5–2.0 |

| Cui, J. (2019) [21] | Thermoplastics matrix with long glass fibers | Not specified | 0.001–400 s−1 | 75.4–146.7 | 5.2–7.3 | Not reported | 2.8–4.6 |

| Chiracu, I.G. (2024) [22] | Composite made of quadriaxial glass fiber fabric, epoxy matrix | 8 layers | 10–1000 mm/min (bending) | 502–562 | 20–23 | Not reported | 3.31–3.61 |

| 16 layers | 484–546 | 17.8–19.2 | 3.5–4.0 | ||||

| Not sensitive to test rate | Not sensitive to test rate | ||||||

| Shahzad, A. (2011) [23] | Chopped strand mat (CSM) GFRP polyester matrix | Not specified | Not specified | 200–250 | 10–15 | Not reported | 1.5–2.0 |

| Zhang, X. (2022) [24] | Unidirectional GFRP, epoxy | ASTM D3039 | 6 × 10−5 to 260 s−1 | 500–800 | 35–45 | Not reported | 1.8–2.5 |

| Mahato, K.K. (2016) [25] | GFRP with epoxy matrix and MWCNTs | Not specified | 1 mm/min | UTS increases with 15.11% adding 0.1% MWCNT | Not specified | Not reported | Not specified |

| Bochnia, J., (2020) [26] | PA 3200 GF (polyamide + 30% glass fibers) | 80 × 10 × 4 mm | Not specified | 48–53 | Not specified | Not specified | Not specified |

| Ramesh, M. (2013) [27] | Glass fibers in epoxy matrix | 250 × 25 × 2.5 mm | 0.0017 s−1 to 160 s−1 | 200–350 | 20–30 | 1.5–2.5 | |

| Dong, C. (2013) [28] | Glass fiber or carbon fibers in epoxy matrix | 250 × 25 × 2 mm | 5 mm/min | 300–600 | 25–60 | 1.2–2.0 | |

| Ismail, K.I. (2023) [29] | PLA reinforced with glass fibers (3D printing) | 165 × 13 × 3.2 mm | Not specified | 45–60 | 2.5–3.0 | 2.5–3.5 | |

| Stanciu, M.D., (2021) [30] | GFRP-RT500 (4 layers 0/90) | 250 × 25 × 2 mm | 1 mm/min | 400–450 | 21–22 | 1.8–2.2 | |

| GFRP-MAT450 (short fibers) | 1 mm/min | 200–250 | 10–11 | 1.0–1.5 | |||

| GFRP-RT500 (4 layers 0/90) | 20 mm/min | 380–430 | 18–19 | 1.6–2.0 | |||

| GFRP-MAT450 (short fibers) | 20 mm/min | 180–230 | 9–10 | 0.9–1.4 | |||

| Crosshead Speed (Test Rate) | = v/L0 | |

|---|---|---|

| (mm/min) | [mm/s) | (s−1) |

| 10 | 0.167 | 0.0033 |

| 200 | 3.33 | 0.0666 |

| 500 | 8.33 | 0.1666 |

| 1000 | 16.67 | 0.3334 |

| Composite (Resin) | Test Rate (mm/min) | Without Coremat Xi3 Layer (Q-g and Q-c) | With Coremat Xi3 Layer (QM-g and QM-c) |

|---|---|---|---|

| Epoxy (coded g) | 10 | Controlled pull-out, good resin quality | Pull-out + bending in Coremat area |

| 200 | Fiber pull-out + reduced delamination | Localized deformation in Coremat layer | |

| 500 | Pull-out + controlled crack propagation | Mixed failure: pull-out + interlaminar cracking | |

| 1000 | Large delaminations among several layers | Larger delaminations among layers; different aspect of the broken samples; visible successive rupture of the layers (see last photo in line for QM-g, Figure 2) | |

| Polyester (coded c) | 10 | Pronounced brittleness, clean cracks | Gradual failure, stress diffusion |

| 200 | Pull-out + interfacial debonding | Ductile failure, controlled delamination | |

| 500 | Massive, uncontrolled delamination | Layered crack propagation | |

| 1000 | Extensive delamination across layers, pronounced fragmentation across several layers, fiber pull-out | Large-scale layer separation, gradual failure, visible fiber bridging |

| Composite | Test Rate | |||

|---|---|---|---|---|

| 10 mm/min | 200 mm/min | 500 mm/min | 1000 mm/min | |

| Q-g (epoxy resin, without Coremat Xi3) | Controlled pull-out, tough resin, smaller areas with delamination | Fiber pull-out, moderate delamination | Extensive matrix cracking, brittle zones appear | Extensive matrix cracks, multiple delaminations, brittle failure with sudden fiber breakage across several layers |

| QM-g (epoxy resin, with Coremat Xi3) | Pull-out + bending in Coremat area | Localized deformation in intermediate layer | Extensive delamination, successive breaks of fibers in different layers, throughout the sample, and in the loading direction | Mixed failure continues, more dispersed damage through Coremat |

| Q-c (polyester resin, without Coremat Xi3) | Brittle fracture, clean cracks | Pull-out + interfacial debonding | Severe fragmentation, high brittleness, abrupt failure | |

| QM-c (polyester resin, with Coremat Xi3) | Gradual failure, efficient energy dissipation | Controlled delamination, partial pull-out | Energy absorption visible, layered cracks with fiber bridging | |

| Characteristic | Enydyne H 68372 TA [66] | SikaBiresin CH80-2 [69] |

|---|---|---|

| Density (at 20 °C), g/cm3 | 1.10 | 1.14 |

| Tensile strength (ISO 527) [51], MPa | 45 | 90 |

| Strain at break, % | 1.5 | 5.6% |

| Flexural strength (ISO 178 [52]), MPa | 65 | 130 |

| Flexural modulus, MPa | 3300 | 3000 |

| Characteristic | Formula | Q-c | Q-g | QM-c | QM-g |

|---|---|---|---|---|---|

| Young’s modulus, E | 30.06 | 33.42 | 41.20 | 11.65 | |

| 8.48 | −6.73 | −3.86 | 0.01 | ||

| Tensile strength, | 6.25 | 1.10 | −1.40 | 10.97 | |

| Strain at break, | 111.11 | 56.57 | 27.38 | 85.45 | |

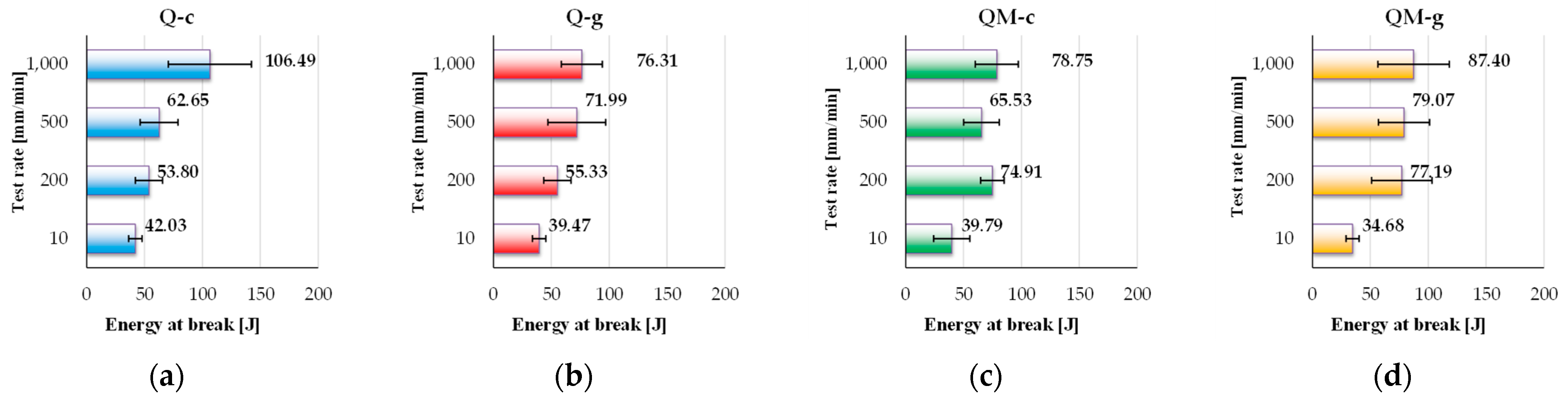

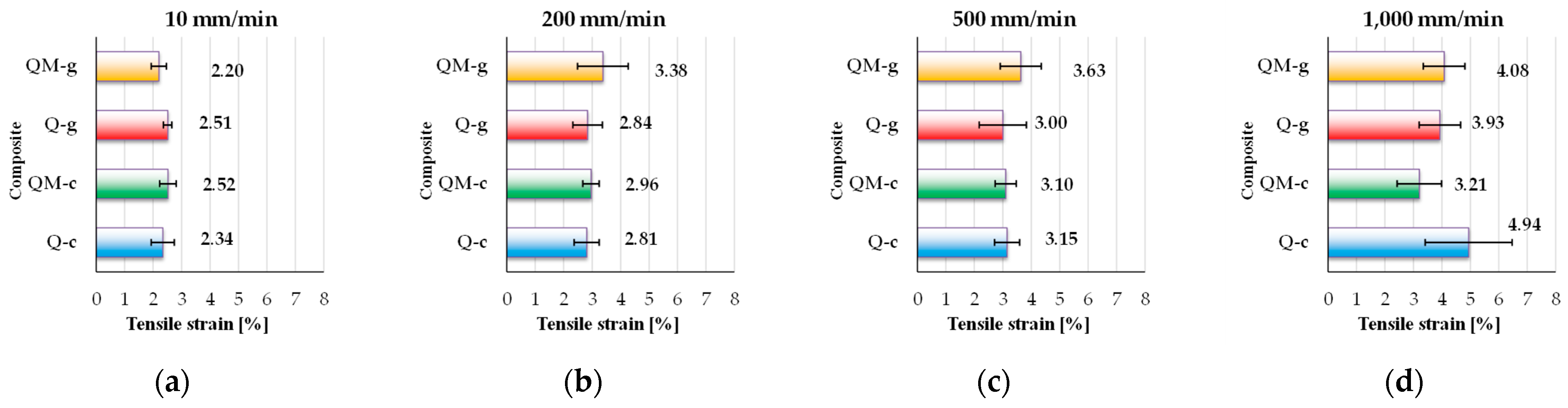

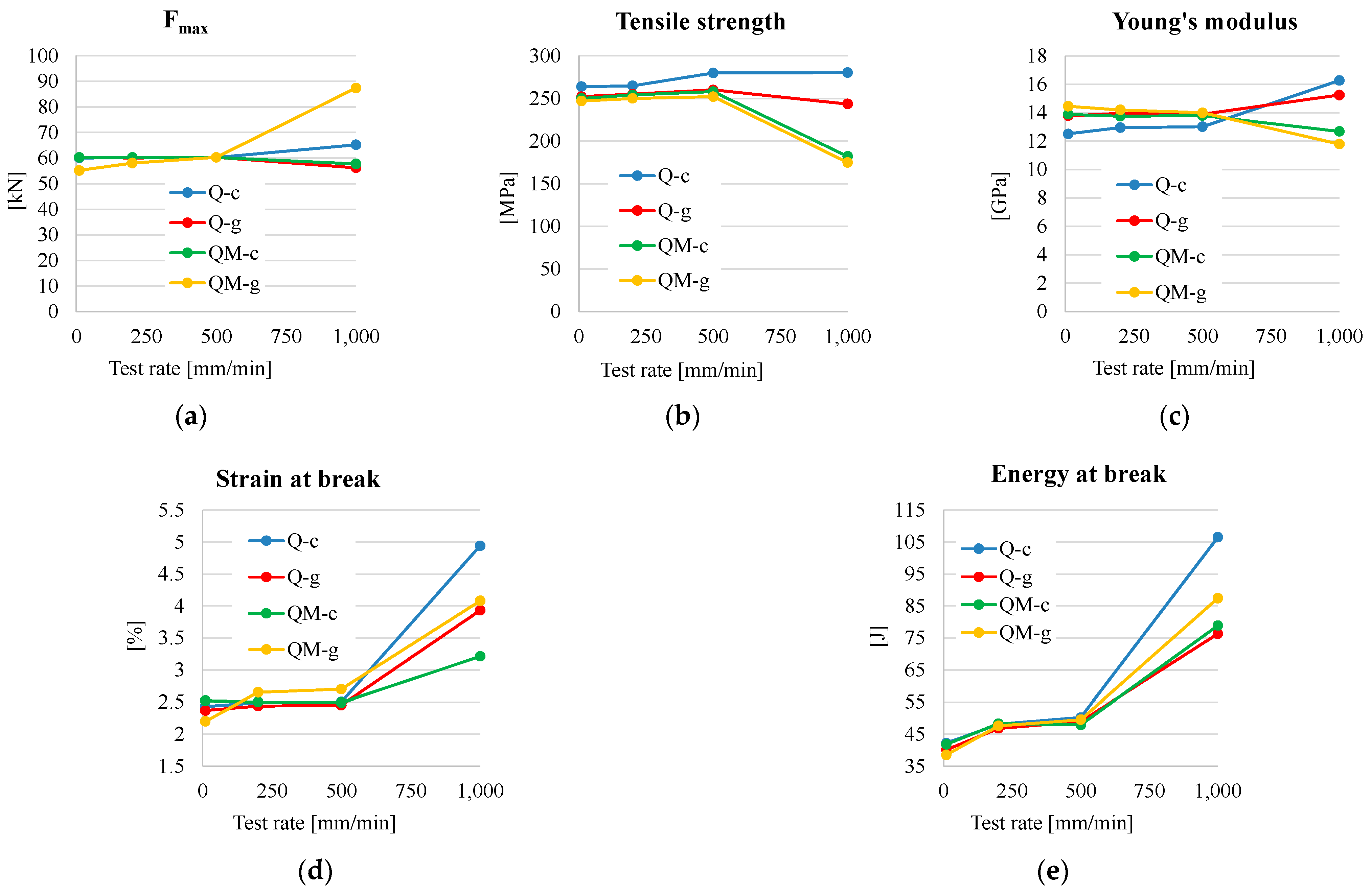

| Energy at break, | 153.37 | 93.34 | 97.91 | 152.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deleanu, L.; Pelin, G.; Chiracu, I.G.; Păduraru, I.; Constandache, M.; Ojoc, G.G.; Vasiliu, A.V. Rate-Dependent Tensile Behavior of Glass Fiber Composites Reinforced with Quadriaxial Fabrics, with or Without Coremat Xi3 Interlayer, for Marine Applications. Polymers 2025, 17, 2074. https://doi.org/10.3390/polym17152074

Deleanu L, Pelin G, Chiracu IG, Păduraru I, Constandache M, Ojoc GG, Vasiliu AV. Rate-Dependent Tensile Behavior of Glass Fiber Composites Reinforced with Quadriaxial Fabrics, with or Without Coremat Xi3 Interlayer, for Marine Applications. Polymers. 2025; 17(15):2074. https://doi.org/10.3390/polym17152074

Chicago/Turabian StyleDeleanu, Lorena, George Pelin, Ioana Gabriela Chiracu, Iulian Păduraru, Mario Constandache, George Ghiocel Ojoc, and Alexandru Viorel Vasiliu. 2025. "Rate-Dependent Tensile Behavior of Glass Fiber Composites Reinforced with Quadriaxial Fabrics, with or Without Coremat Xi3 Interlayer, for Marine Applications" Polymers 17, no. 15: 2074. https://doi.org/10.3390/polym17152074

APA StyleDeleanu, L., Pelin, G., Chiracu, I. G., Păduraru, I., Constandache, M., Ojoc, G. G., & Vasiliu, A. V. (2025). Rate-Dependent Tensile Behavior of Glass Fiber Composites Reinforced with Quadriaxial Fabrics, with or Without Coremat Xi3 Interlayer, for Marine Applications. Polymers, 17(15), 2074. https://doi.org/10.3390/polym17152074