Lignin-Based Carbon-Fiber-Reinforced LVL Beams for Landscape Timber Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extraction of Lignin

2.2.1. Preparation of Low-Co-Melting Solvents (DES)

2.2.2. Draw

2.3. Preparation of Lignin-Based Carbon Fiber

2.3.1. Preparation of Electrospinning Solution

2.3.2. Preparation of Fiber Membrane by Electrospinning

2.3.3. Pre-Oxidation and Carbonization

2.4. Preparation of LVL Beams for Garden Wooden Structures

2.5. Characterization

2.5.1. Determination of Molecular Weight of Lignin (GPC)

2.5.2. Fourier Transform Infrared Spectroscopy Detection (FT-IR)

2.5.3. Thermogravimetric Analysis (TG)

2.5.4. Scanning Electron Microscopy (SEM)

2.5.5. X-Ray Diffractometer (XRD)

2.5.6. Raman Spectrometer (Raman)

2.5.7. Mechanical Property Testing of Raw Silk and Carbon Fiber

2.5.8. Determination of Moisture Content

2.5.9. Determination of Impregnation Peeling Rate

2.5.10. Determination of Flexural Strength and Elastic Modulus

2.5.11. Determination of Tensile Strength Along the Grain

2.5.12. Determination of Longitudinal Compressive Strength

2.5.13. Determination of Transverse Parallel Compressive Strength

2.5.14. Determination of Parallel Shear Strength Along the Grain

2.5.15. Determination of Mechanical Performance Characteristic Values

3. Results and Discussion

3.1. Extraction and Analysis of Lignin from Corn Stover

3.1.1. Gel Chromatography (GPC)

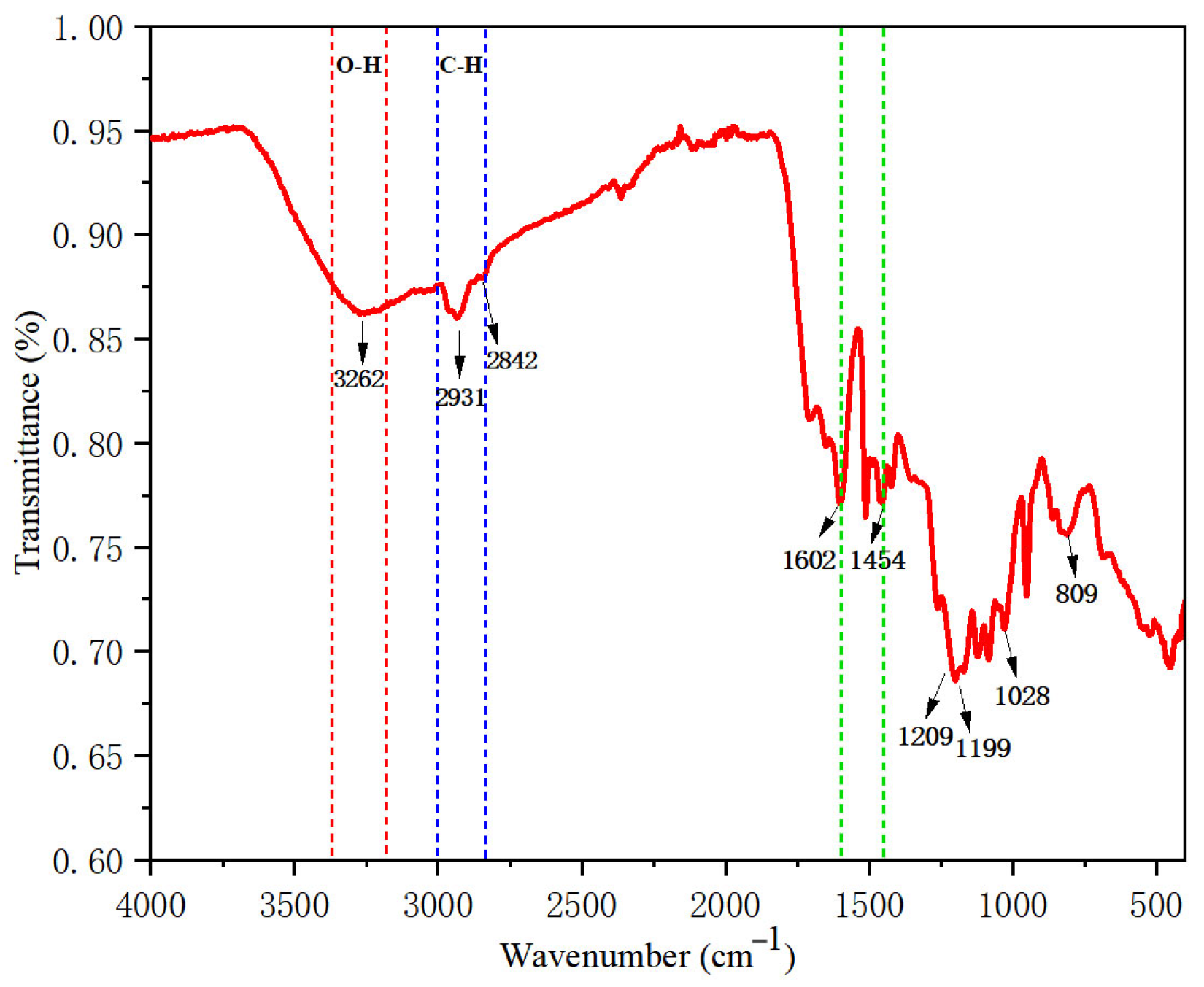

3.1.2. Fourier Transform Infrared Spectroscopy Analysis (FT-IR)

3.1.3. Thermogravimetric Analysis (TG)

3.2. Characterization and Analysis of Lignin-Based Carbon Fiber

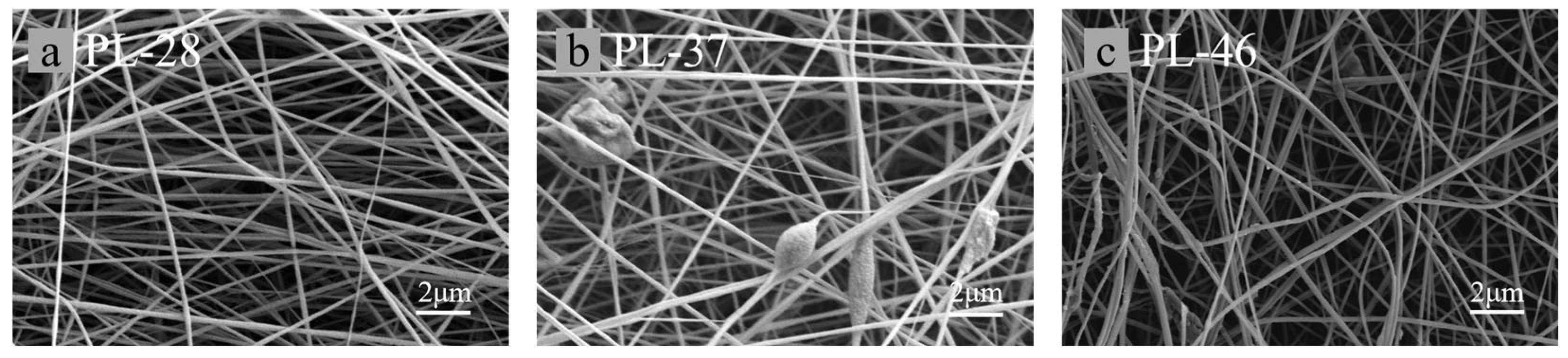

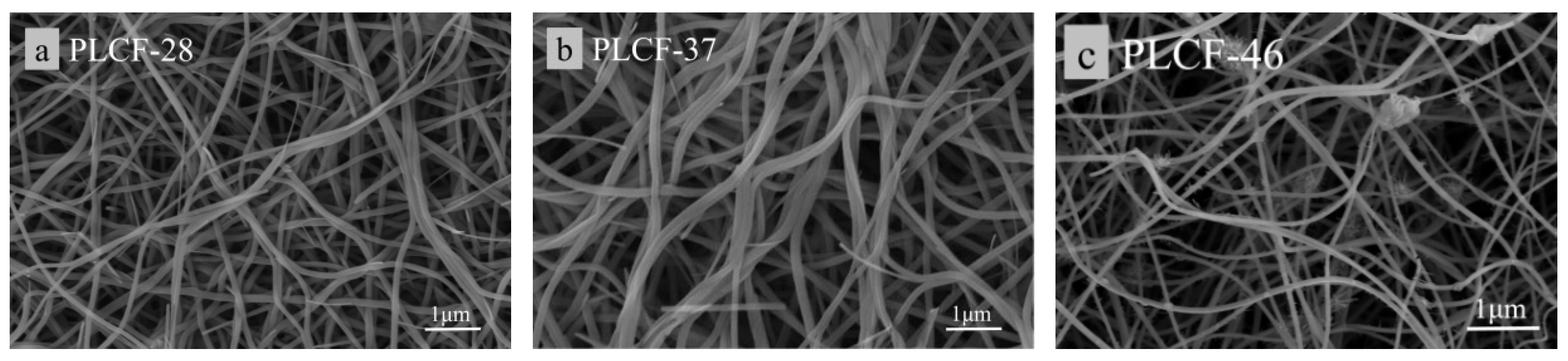

3.2.1. Scanning Electron Microscopy Analysis (SEM)

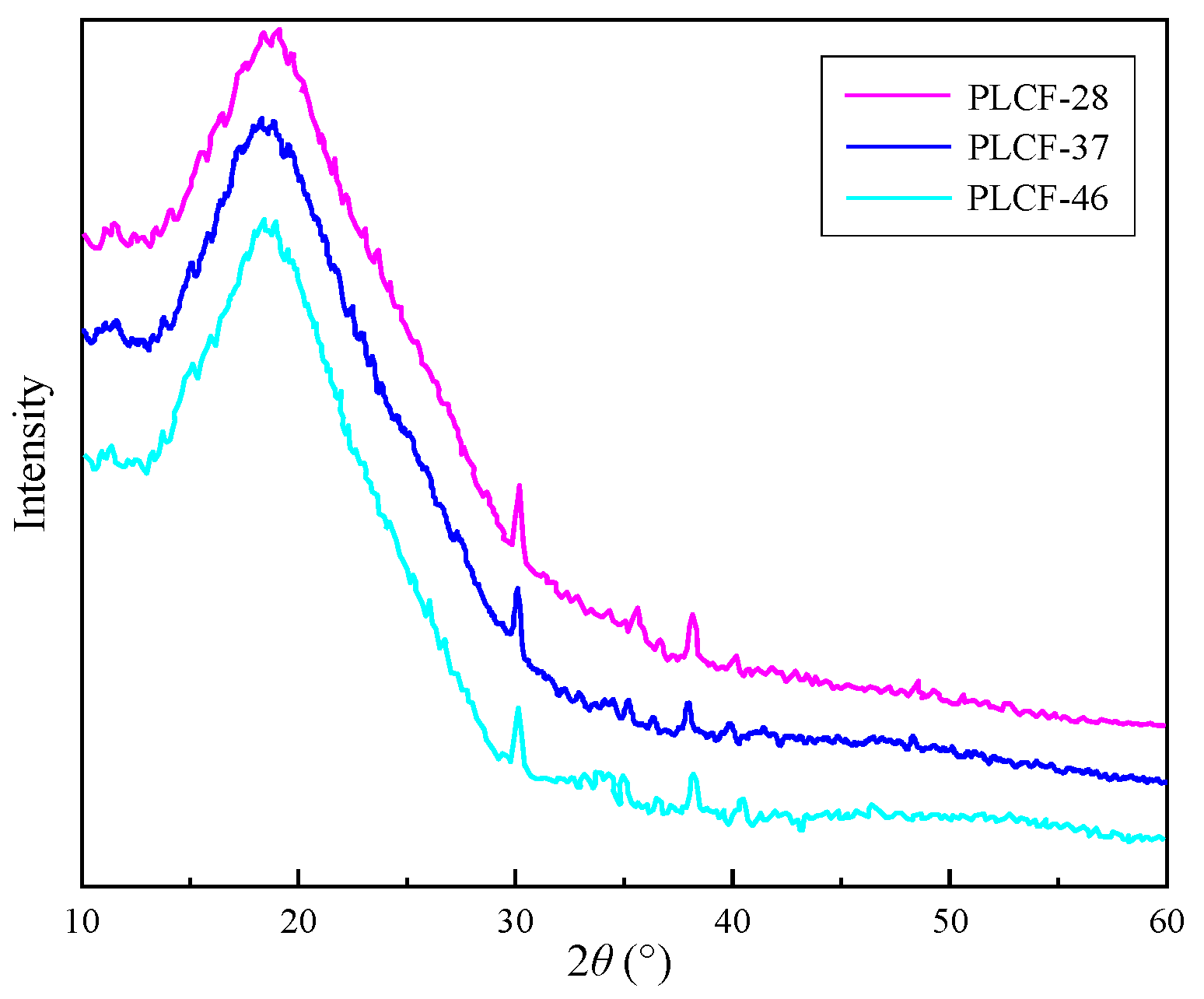

3.2.2. X-Ray Diffraction Analysis (XRD)

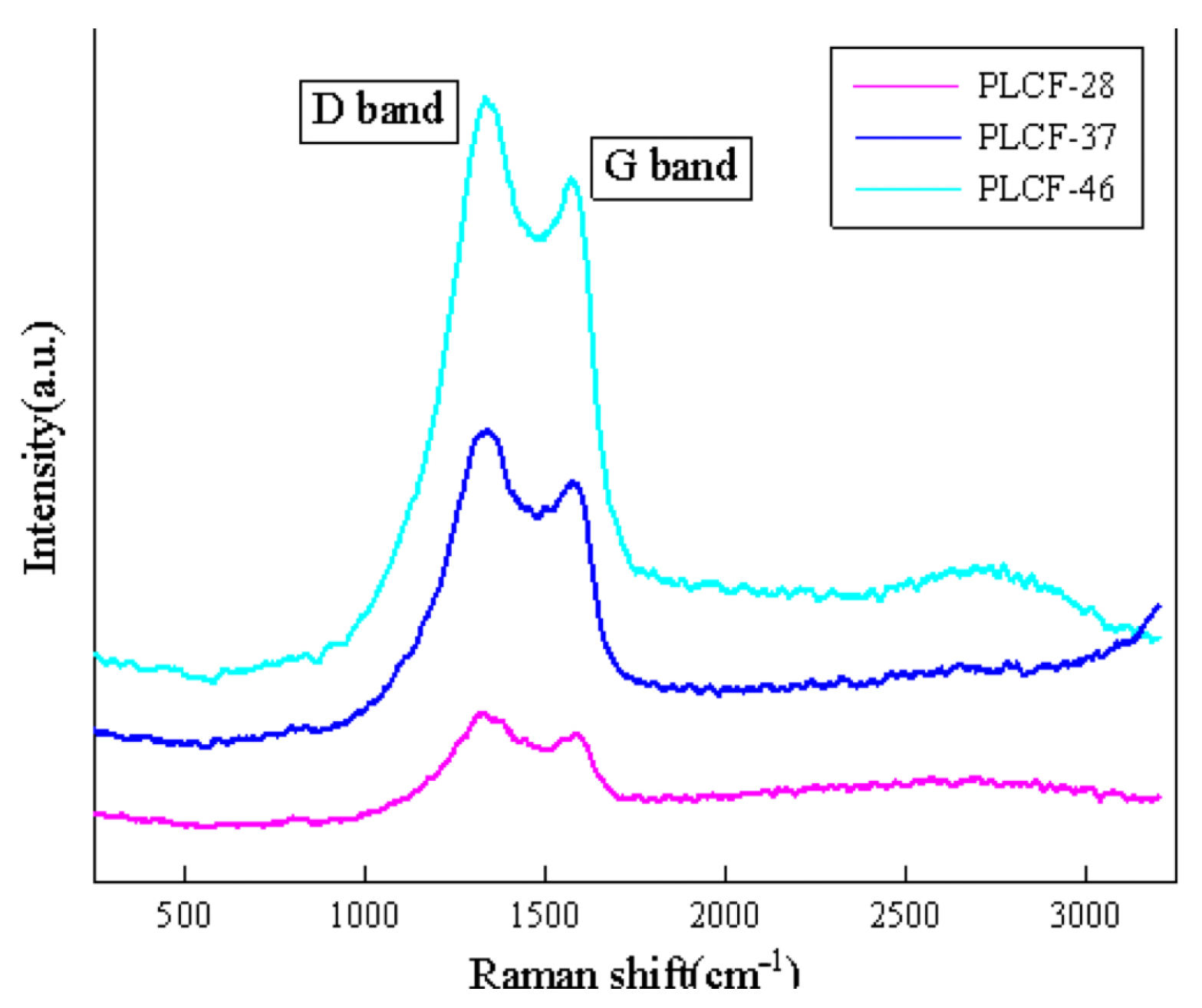

3.2.3. Raman Spectroscopy Analysis (Raman)

3.2.4. Testing and Analysis of Mechanical Properties of Raw Silk and Carbon Fiber

3.3. Testing of LVL Beams in Garden Wooden Structures

3.3.1. Moisture Content Analysis

3.3.2. Analysis of Immersion Peel Strength

3.3.3. Test Results and Analysis of Flexural Strength and Elastic Modulus

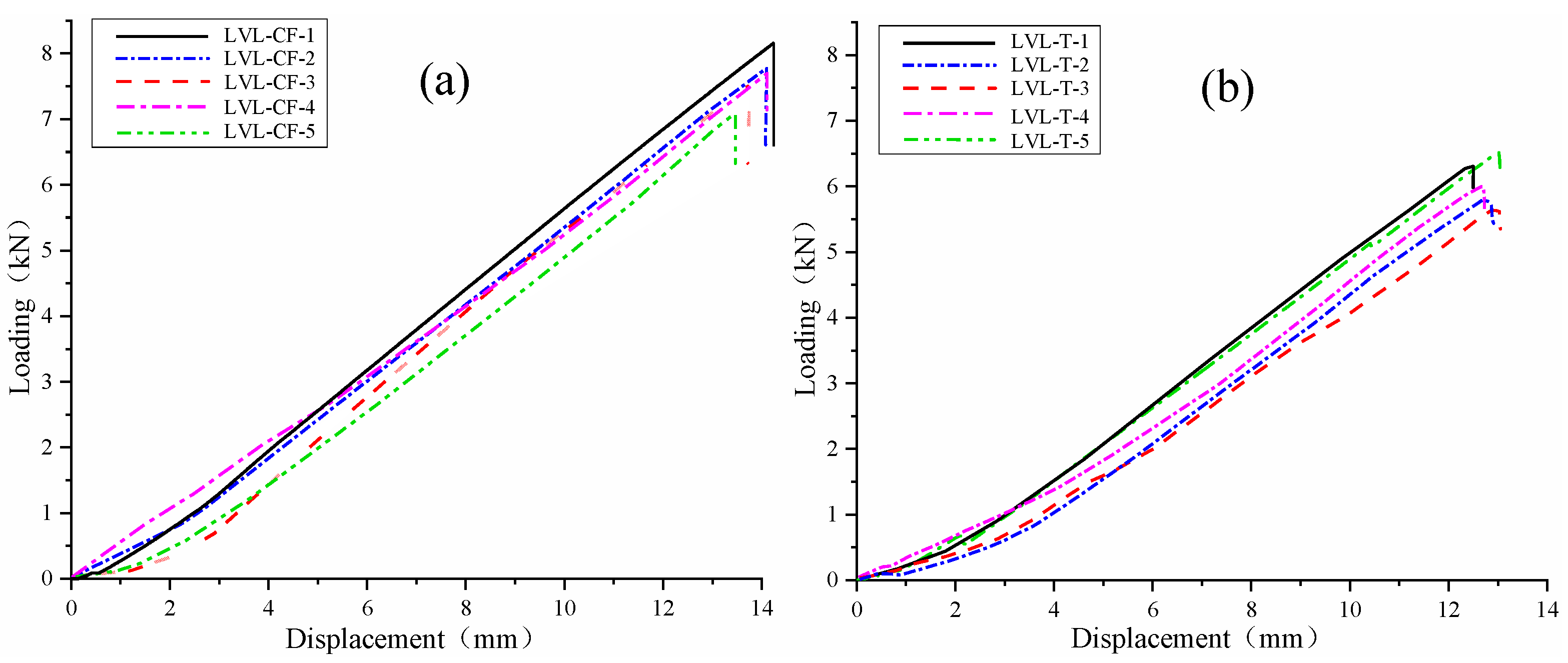

3.3.4. Results and Analysis of Tensile Test Along the Grain

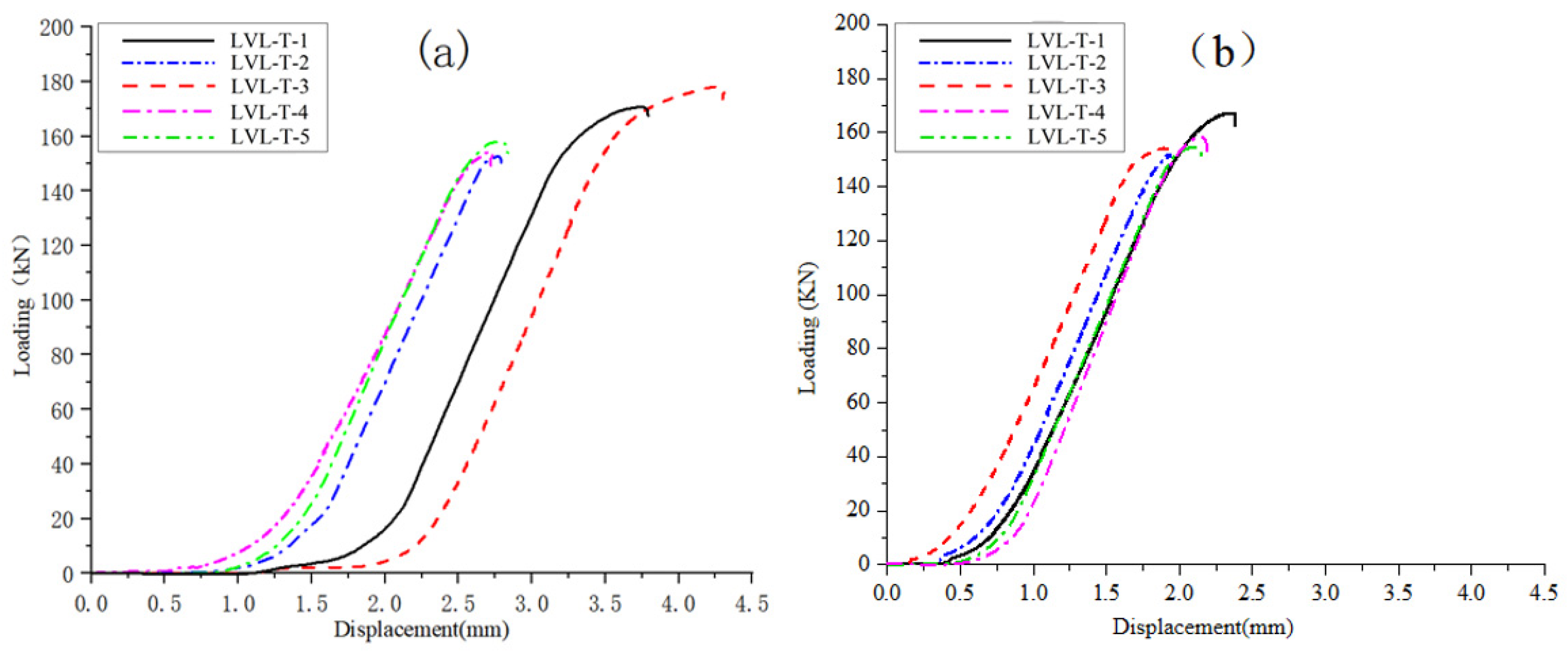

3.3.5. Results and Analysis of Longitudinal Compression Test

3.3.6. Results and Analysis of Transverse Parallel Compression Test

3.3.7. Results and Analysis of Parallel Shear Test Along the Grain

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baker, D.A.; Gallego, N.C.; Baker, F.S. On the characterization and spinning of an organic-purified lignin toward the manufacture of low-cost carbon fiber. J. Appl. Polym. Sci. 2012, 124, 227–234. [Google Scholar] [CrossRef]

- Jayawickramage, R.A.P.; Balkus, K.J.; Ferraris, J.P. Binder free carbon nanofiber electrodes derived from polyacrylonitrile-lignin blends for high performance supercapacitors. Nanotechnology 2019, 30, 355402. [Google Scholar] [CrossRef] [PubMed]

- You, X.; Duan, J.; Koda, K.; Yamada, T.; Uraki, Y. Preparation of electric double layer capacitors (EDLCs) from two types of electrospun lignin fibers. Holzforschung 2016, 70, 661–671. [Google Scholar] [CrossRef]

- Eraghi Kazzaz, A.; Fatehi, P. Fabrication of amphoteric lignin and its hydrophilicity/oleophilicity at oil/water interface. J. Colloid Interface Sci. 2020, 561, 231–243. [Google Scholar] [CrossRef] [PubMed]

- Schlee, P.; Hosseinaei, O.; Baker, D.; Landmér, A.; Tomani, P.; Mostazo-López, M.J.; Cazorla-Amorós, D.; Herou, S.; Titirici, M.M. From Waste to Wealth: From Kraft Lignin to Free-standing Supercapacitors. Carbon 2019, 145, 470–480. [Google Scholar] [CrossRef]

- El Haouzali, H.; Marchal, R.; Bléron, L.; Kifani-Sahban, F.; Butaud, J.C. Mechanical properties of laminated veneer lumber produced from ten cultivars of poplar. Eur. J. Wood Wood Prod. 2020, 78, 715–722. [Google Scholar] [CrossRef]

- Li, M.; He, M.; Li, Z.; Yun, X. Flexural behavior of LVL made from Australian radiata pine. Structures 2024, 61, 106014. [Google Scholar] [CrossRef]

- Romero, A.; Odenbreit, C. Experimental Investigation on Strength and Stiffness Properties of Laminated Veneer Lumber (LVL). Materials 2023, 16, 7194. [Google Scholar] [CrossRef] [PubMed]

- Ido, H.; Nagao, H.; Kato, H.; Miyatake, A.; Hiramatsu, Y. Strength properties of laminated veneer lumber in compression perpendicular to its grain. J. Wood Sci. 2010, 56, 422–428. [Google Scholar] [CrossRef]

- Awaludin, A.; Wusqo, U.; Setiawan, A.F.; Suhendro, B.; Siwosukarto, S.; Basuki, A.; Leijten, A.J.M. Structural Performance of Prefabricated Timber-Concrete Composite Floor Constructed Using Open Web Truss Joist Made of LVL Paraserianthes Falctaria. Open J. Civ. Eng. 2021, 11, 434. [Google Scholar] [CrossRef]

- Bergner, K.; Tosch, M.; Zauer, M.; Spickenheuer, A.; Wagenführ, A.; Heinrich, G. Process development for the manufacture of fiber reinforced wood composites (FRWC). Constr. Build. Mater. 2018, 180, 275–284. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Y. Study on The Preparation and Mechanical Properties of Fiberglass Reinforced Wood-Based Composite. J. Korean Wood Sci. Technol. 2016, 44, 505–514. [Google Scholar] [CrossRef]

- Kim, Y.J.; Harries, K.A. Modeling of timber beams strengthened with various CFRP composites. Eng. Struct. 2010, 32, 3225–3234. [Google Scholar] [CrossRef]

- Nadir, Y.; Nagarajan, P.; Ameen, M. Flexural stiffness and strength enhancement of horizontally glued laminated wood beams with GFRP and CFRP composite sheets. Constr. Build. Mater. 2016, 112, 547–555. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Scialpi, V.; La Tegola, A. Analytical and experimental study on bonded-in CFRP bars in glulam timber. Anal. Exp. Study Bond.-CFRP Bars Glulam Timber 2005, 36, 279–289. [Google Scholar] [CrossRef]

- Rescalvo, F.J.; Duriot, R.; Pot, G.; Gallego, A.; Denaud, L. Enhancement of bending properties of Douglas-fir and poplar laminate veneer lumber (LVL) beams with carbon and basalt fibers reinforcement. Constr. Build. Mater. 2020, 263, 120185. [Google Scholar] [CrossRef]

- Kozinetc, K.G.; Kaarki, T.; Barabanshchikov Yu, G.; Lahtela, V.; Zotov, D.K. Mechanical properties of sustainable wooden structures reinforced with Basalt Fiber Reinforced Polymer. Mag. Civ. Eng. 2020, 8, 10012. [Google Scholar]

- Sokolović, N.M.; Gavrilović-Grmuša, I.; Zdravković, V.; Ivanović-Šekularac, J.; Pavićević, D.; Šekularac, N. Flexural Properties in Edgewise Bending of LVL Reinforced with Woven Carbon Fibers. Materials 2023, 16, 3346. [Google Scholar] [CrossRef] [PubMed]

- Bakalarz, M.M.; Kossakowski, P.G. Numerical, Theoretical, and Experimental Analysis of LVL-CFRP Sandwich Structure. Materials 2023, 17, 61. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Liu, H.; Sun, L. Dynamic Analysis of Carbon Fiber-Reinforced Wood Composites Based on Finite Element Model. BioResources 2015, 11, 545–557. [Google Scholar] [CrossRef]

- Wei, P.; Wang, B.J.; Zhou, D.; Dai, C.; Wang, Q.; Huang, S. Mechanical Properties of Poplar Laminated Veneer Lumber Modified by Carbon Fiber Reinforced Polymer. BioResources 2013, 8, 4883–4898. [Google Scholar] [CrossRef]

- Mascia, N.T.; Mayer, R.M.; Moraes, R.W. Analysis of Wood Laminated Beams Reinforced with Sisal Fibres. Key Eng. Mater. 2014, 600, 97–104. [Google Scholar] [CrossRef]

- Foston, M.; Nunnery, G.A.; Meng, X.; Sun, Q.; Baker, F.S.; Ragauskas, A. NMR a critical tool to study the production of carbon fiber from lignin. Carbon 2013, 52, 65–73. [Google Scholar] [CrossRef]

- Spender, J.; Demers, A.L.; Xie, X.; Cline, A.E.; Earle, M.A.; Ellis, L.D.; Neivandt, D.J. Method for Production of Polymer and Carbon Nanofibers from Water-Soluble Polymers. Nano Lett. 2012, 12, 3857–3860. [Google Scholar] [CrossRef] [PubMed]

- Bowden, M.; Gardiner, D.J.; Southall, J.M.; Gerrard, D.L. Determination of bandshifts as a function of strain in carbon fibres using Raman microline focus spectrometry (MiFS). Carbon 1993, 31, 1057–1060. [Google Scholar] [CrossRef]

- Gupta, V.K.; Agarwal, S.; Saleh, T.A. Chromium removal by combining the magnetic properties of iron oxide with adsorption properties of carbon nanotubes. Water Res. 2011, 45, 2207–2212. [Google Scholar] [CrossRef] [PubMed]

- GB/T 36408-2018[S]; Structural Wood Sub-Technical Committee of the National Technical Committee on Wood Standardization (SAC/TC 41/SC 4). Wood-based Laminated Panels for Timber Structures. China Standards Press: Beijing, China, 2018.

- Jacobsen, R.L.; Tritt, T.M.; Guth, J.R.; Ehrlich, A.C.; Gillespie, D.J. Mechanical properties of vapor-grown carbon fiber. Carbon 1995, 33, 1217–1221. [Google Scholar] [CrossRef]

- Wen, J.L.; Sun, S.L.; Yuan, T.Q.; Sun, R.C. Structural elucidation of whole lignin from Eucalyptus based on preswelling and enzymatic hydrolysis. Green Chem. 2015, 17, 1589–1596. [Google Scholar] [CrossRef]

- Lallave, M.; Bedia, J.; Ruiz-Rosas, R.; Rodriguez-Mirasol, J.; Cordero, T.; Otero, J.C.; Marquez, M.; Barrero, A.; Loscertales, I.G. Filled and Hollow Carbon Nanofibers by Coaxial Electrospinning of Alcell Lignin without Binder Polymers. Adv. Mater. 2007, 19, 4292–4296. [Google Scholar] [CrossRef]

- Wang, S.; Bai, J.; Innocent, M.T.; Wang, Q.; Xiang, H.; Tang, J.; Zhu, M. Lignin-based carbon fibers: Formation, modification and potential applications. Green Energy Environ. 2022, 7, 578–605. [Google Scholar] [CrossRef]

- Dallmeyer, I.; Ko, F.; Kadla, J.F. Electrospinning of Technical Lignins for the Production of Fibrous Networks. J. Wood Chem. Technol. 2010, 30, 315–329. [Google Scholar] [CrossRef]

- GB/T 17657-2013[S]; National Technical Committee for Standardization of Wood-Based Panels (SAC/TC 198). Physical and Chemical Performance Test Methods for Wood-Based Panels and Decorative Wood-Based Panels. China Standards Press: Beijing, China, 2013.

- Ding, R.; Wu, H.; Thunga, M.; Bowler, N.; Kessler, M.R. Processing and characterization of low-cost electrospun carbon fibers from organosolv lignin/polyacrylonitrile blends. Carbon 2016, 100, 126–136. [Google Scholar] [CrossRef]

- Mikkilä, J.; Trogen, M.; Koivu, K.A.; Kontro, J.; Kuuskeri, J.; Maltari, R.; Dekere, Z.; Kemell, M.; Mäkelä, M.R.; Nousiainen, P.A.; et al. Fungal treatment modifies Kraft lignin for lignin-and cellulose-based carbon fiber precursors. ACS Omega 2020, 5, 6130–6140. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; He, J.; Li, H.; Liu, Y.; Pang, J.; Li, C.; Jiang, G. Straw Tar Epoxy Resin for Carbon Fiber-Reinforced Plastic: A Review. Polymers 2024, 16, 2433. [Google Scholar] [CrossRef] [PubMed]

- Lou, C.; Jiang, S.; Yan, A.; Zhou, Y.; Liu, Y.; Zhang, Y.; Kong, X. Self-extracted corn-stalk cellulose/epoxy resin composites. Sci. Rep. 2022, 12, 20968. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Zhang, X.; Ren, H.; Hu, X.; Yang, X.; Liu, H. Fluorine-free and durable hydrophobic coating made with corn straw-derived silane modified epoxy resin. BioResources 2023, 18, 2011. [Google Scholar] [CrossRef]

- Yang, P.J.; Li, T.H.; Li, H.; Dang, A.L. Microstructure, electrical conductivity and mechanical properties of graphitization carbon foam derived from epoxy resin modified with coal tar pitch. Carbon Lett. 2024, 34, 1065–1073. [Google Scholar] [CrossRef]

- Uy Lan, D.N.; Brütting, C.; Bethke, C.; Meuchelböck, J.; Standau, T.; Altstädt, V.; Ruckdäschel, H. Novel expandable epoxy beads and epoxy particle foam. Materials 2022, 15, 4205. [Google Scholar] [CrossRef] [PubMed]

| Sample | MN | MW | PD (MW/MN) |

|---|---|---|---|

| ChCl-EG | 36,837 | 45,156 | 1.2 |

| ChCl-H | 38,229 | 46,294 | 1.2 |

| ZnCl2-EG | 24,019 | 36,029 | 1.5 |

| Alkali Lignin | 791 | 2408 | 3.1 |

| Number | Size (mm × mm × mm) | Initial Mass mw (G) | Drying Quality m0 (G) | Moisture Content W (%) |

|---|---|---|---|---|

| 1 | 50 × 50 × 50 | 102.4 | 91.43 | 12.0 |

| 2 | 50 × 50 × 50 | 103.5 | 92.01 | 12.5 |

| 3 | 50 × 50 × 50 | 101.9 | 91.23 | 11.7 |

| 4 | 50 × 50 × 50 | 103.1 | 91.32 | 12.9 |

| 5 | 50 × 50 × 50 | 102.5 | 91.03 | 12.6 |

| 6 | 50 × 50 × 50 | 103.9 | 92.21 | 12.4 |

| Average | - | 12.3 |

| Number | Layered Length/mm | Size | Layered Length/mm |

|---|---|---|---|

| 1 | 7 | 6 | 9 |

| 2 | 9 | 7 | 13 |

| 3 | 11 | 8 | 8 |

| 4 | 6 | 9 | 12 |

| 5 | 10 | 10 | 10 |

| Number | Failure Load (kN) | Bending Strength (MPa) | Elastic Modulus (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| 1 | 8.16 × 103 | 58.75 | 14,224.0 | - |

| 2 | 7.75 × 103 | 55.80 | 13,805.9 | - |

| 3 | 7.54 × 103 | 54.29 | 13,581.9 | - |

| 4 | 7.62 × 103 | 54.86 | 13,376.7 | - |

| 5 | 7.14 × 103 | 51.41 | 13,137.6 | - |

| Average | - | 55.02 | 13,625.2 | 2.37 |

| Number | Failure Load (kN) | Bending Strength (MPa) | Elastic Modulus (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| 1 | 6.25 × 103 | 45.02 | 12,386.4 | - |

| 2 | 5.77 × 103 | 41.57 | 11,146.1 | - |

| 3 | 5.63 × 103 | 40.55 | 10,679.4 | - |

| 4 | 6.02 × 103 | 43.37 | 11,773.2 | - |

| 5 | 6.52 × 103 | 46.97 | 12,426.7 | - |

| Average | - | 43.50 | 11,682.3 | 2.31 |

| Number | Size (mm × mm × mm) | Failure Load (kN) | Longitudinal Compressive Strength (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| 1 | 2100 × 50 × 50 | 169.10 | 67.64 | - |

| 2 | 2100 × 50 × 50 | 164.05 | 65.62 | - |

| 3 | 2100 × 50 × 50 | 171.33 | 68.53 | - |

| 4 | 2100 × 50 × 50 | 168.84 | 67.54 | - |

| 5 | 2100 × 50 × 50 | 167.91 | 67.16 | - |

| Average | - | 67.30 | 0.95 |

| Number | Size (mm × mm × mm) | Failure Load (kN) | Longitudinal Compressive Strength (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| 1 | 2100 × 50 × 50 | 112.08 | 44.83 | - |

| 2 | 2100 × 50 × 50 | 113.95 | 45.58 | - |

| 3 | 2100 × 50 × 50 | 114.45 | 45.78 | - |

| 4 | 2100 × 50 × 50 | 106.73 | 42.69 | - |

| 5 | 2100 × 50 × 50 | 117.02 | 46.80 | - |

| Average | - | 45.14 | 1.38 |

| Number | Size (mm × mm × mm) | Failure Load (kN) | Longitudinal Compressive Strength (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| 1 | 125 × 50 × 50 | 168.87 | 67.55 | - |

| 2 | 125 × 50 × 50 | 151.54 | 60.62 | - |

| 3 | 125 × 50 × 50 | 178.04 | 71.22 | - |

| 4 | 125 × 50 × 50 | 152.31 | 60.92 | - |

| 5 | 125 × 50 × 50 | 156.25 | 62.50 | - |

| Average | - | 64.56 | 4.15 |

| Number | Size (mm × mm × mm) | Failure Load (kN) | Longitudinal Compressive Strength (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| 1 | 125 × 50 × 50 | 164.81 | 65.92 | - |

| 2 | 125 × 50 × 50 | 150.93 | 60.37 | - |

| 3 | 125 × 50 × 50 | 153.02 | 61.21 | - |

| 4 | 125 × 50 × 50 | 156.87 | 62.75 | - |

| 5 | 125 × 50 × 50 | 152.78 | 61.11 | - |

| Average | - | 62.27 | 1.98 |

| Number | Size (mm × mm × mm) | 1.00 mm Deformation Load (kN) | Transverse Compressive Strength (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| 1 | 150 × 50 × 50 | 26.25 | 10.50 | - |

| 2 | 150 × 50 × 50 | 27.31 | 10.92 | - |

| 3 | 150 × 50 × 50 | 22.51 | 9.01 | - |

| 4 | 150 × 50 × 50 | 24.67 | 9.87 | - |

| 5 | 150 × 50 × 50 | 25.05 | 10.02 | - |

| Average | - | 10.06 | 0.64 |

| Number | Size (mm × mm × mm) | 1.00 mm Deformation Load (kN) | Transverse Compressive Strength (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| 1 | 150 × 50 × 50 | 25.11 | 10.04 | - |

| 2 | 150 × 50 × 50 | 24.02 | 9.61 | - |

| 3 | 150 × 50 × 50 | 25.98 | 10.39 | - |

| 4 | 150 × 50 × 50 | 24.97 | 9.99 | - |

| 5 | 150 × 50 × 50 | 21.87 | 8.75 | - |

| Average | - | 9.76 | 0.56 |

| Number | Size (mm × mm × mm) | Failing Load (kN) | Parallel Shear Strength of Smooth Fiber (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| 1 | 50 × 20 | 4.60 | 7.30 | - |

| 2 | 50 × 20 | 4.58 | 7.10 | - |

| 3 | 50 ×20 | 4.36 | 6.91 | - |

| 4 | 50 × 20 | 4.17 | 6.71 | - |

| 5 | 50 ×20 | 4.29 | 6.89 | - |

| Average | - | 6.98 | 0.20 |

| Number | Size (mm × mm × mm) | Failing Load (kN) | Parallel Shear Strength of Smooth Fiber (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| 1 | 50 × 20 | 3.58 | 6.23 | - |

| 2 | 50 × 20 | 3.79 | 6.31 | - |

| 3 | 50 ×20 | 3.29 | 5.89 | - |

| 4 | 50 × 20 | 3.50 | 6.24 | - |

| 5 | 50 ×20 | 3.42 | 6.19 | - |

| Average | - | 6.17 | 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Niu, Y.; Jiang, Z.; Pang, J.; Niu, X. Lignin-Based Carbon-Fiber-Reinforced LVL Beams for Landscape Timber Structures. Polymers 2025, 17, 2030. https://doi.org/10.3390/polym17152030

Li X, Niu Y, Jiang Z, Pang J, Niu X. Lignin-Based Carbon-Fiber-Reinforced LVL Beams for Landscape Timber Structures. Polymers. 2025; 17(15):2030. https://doi.org/10.3390/polym17152030

Chicago/Turabian StyleLi, Xuebo, Yuan Niu, Zhanpeng Jiang, Jiuyin Pang, and Xiaoyi Niu. 2025. "Lignin-Based Carbon-Fiber-Reinforced LVL Beams for Landscape Timber Structures" Polymers 17, no. 15: 2030. https://doi.org/10.3390/polym17152030

APA StyleLi, X., Niu, Y., Jiang, Z., Pang, J., & Niu, X. (2025). Lignin-Based Carbon-Fiber-Reinforced LVL Beams for Landscape Timber Structures. Polymers, 17(15), 2030. https://doi.org/10.3390/polym17152030