Analysis of Woven Fabric Mechanical Properties in the Context of Sustainable Clothing Development Process

Abstract

1. Introduction

2. Materials and Methods

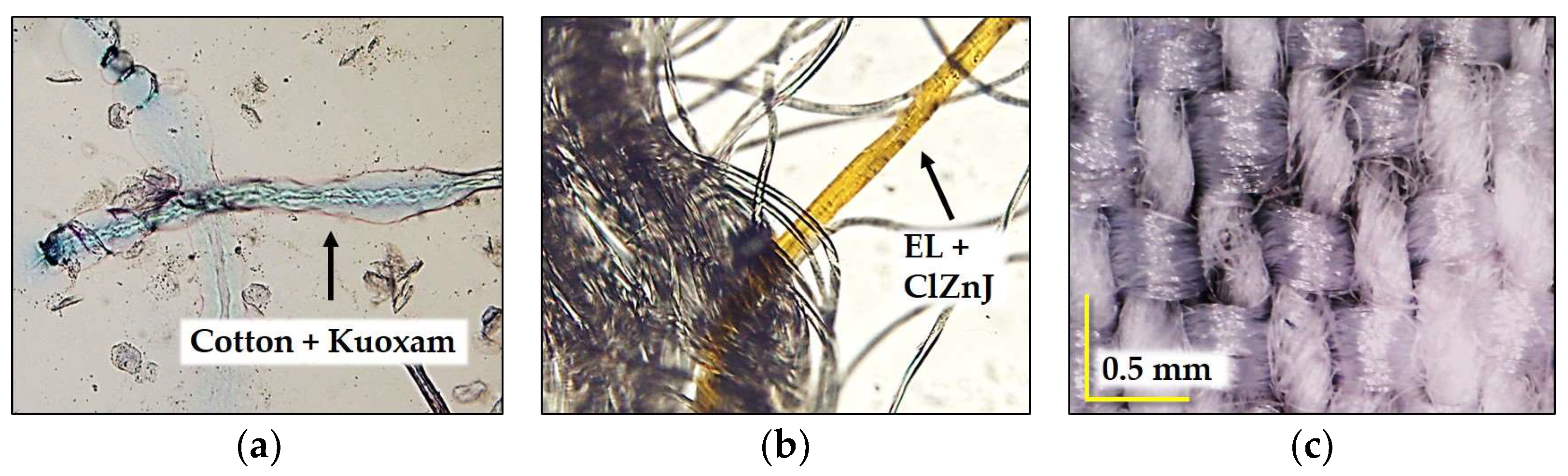

2.1. Analysis of Textile Material Properties for 3D Simulation

2.1.1. Investigation of Fabric Mechanical Parameters Using the KES-FB System

2.1.2. Investigation of Fabric Tensile and Shear Properties Using a Fabric Kit Adapted Method

2.1.3. Digitization of Textile Material Using the SEDDI Textura AI Application

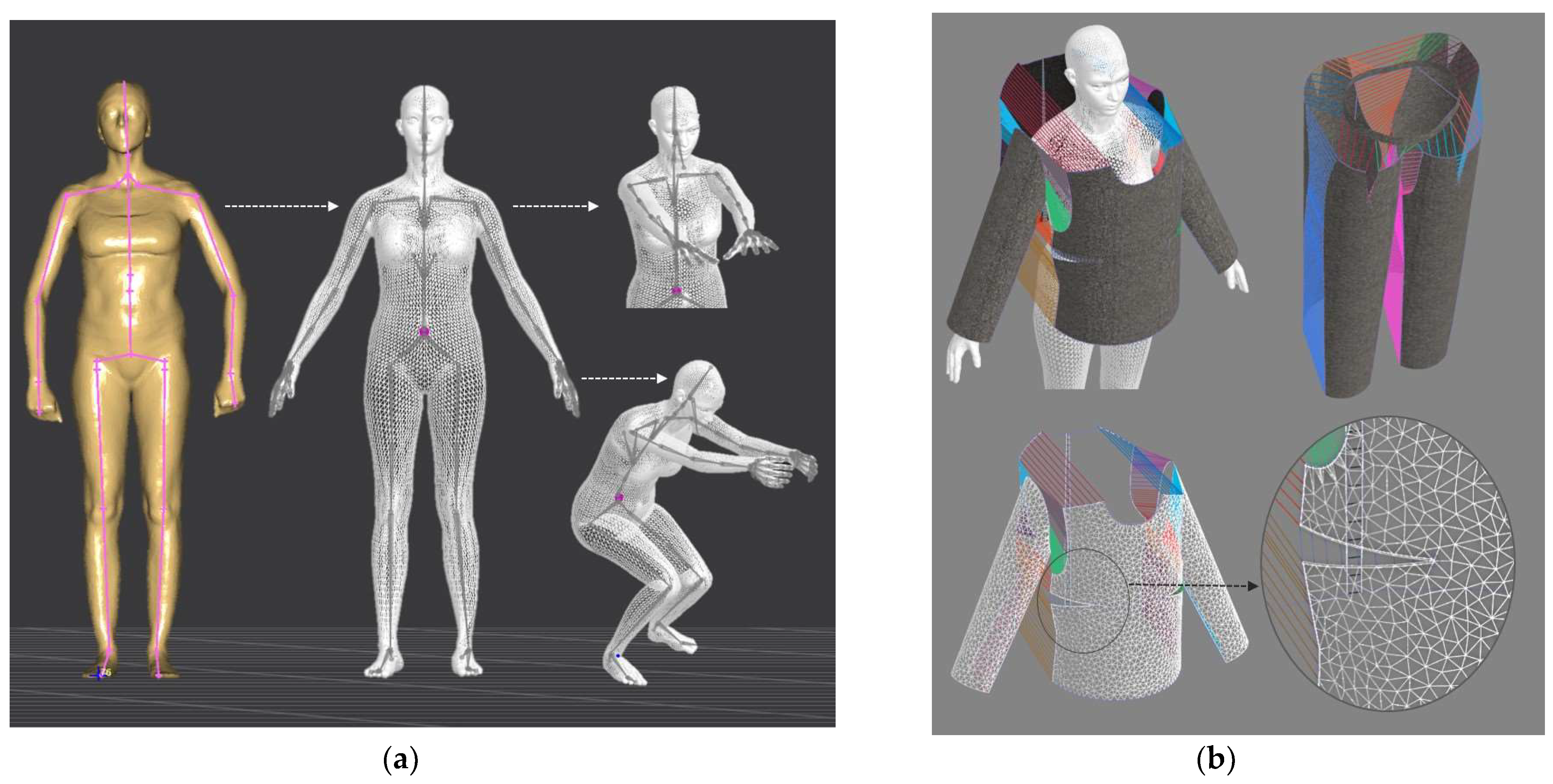

2.2. Development of Digital 3D Prototypes and Static Fit Analysis

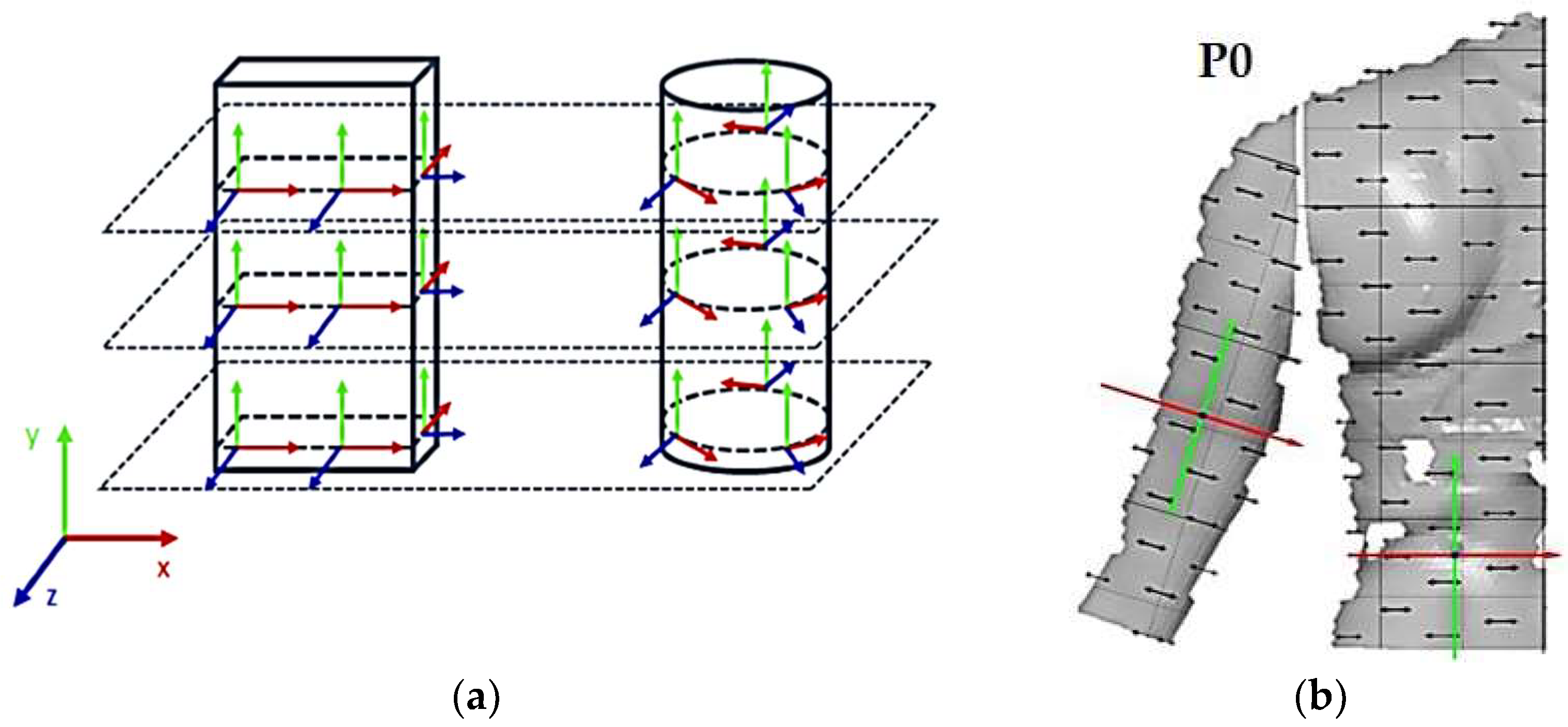

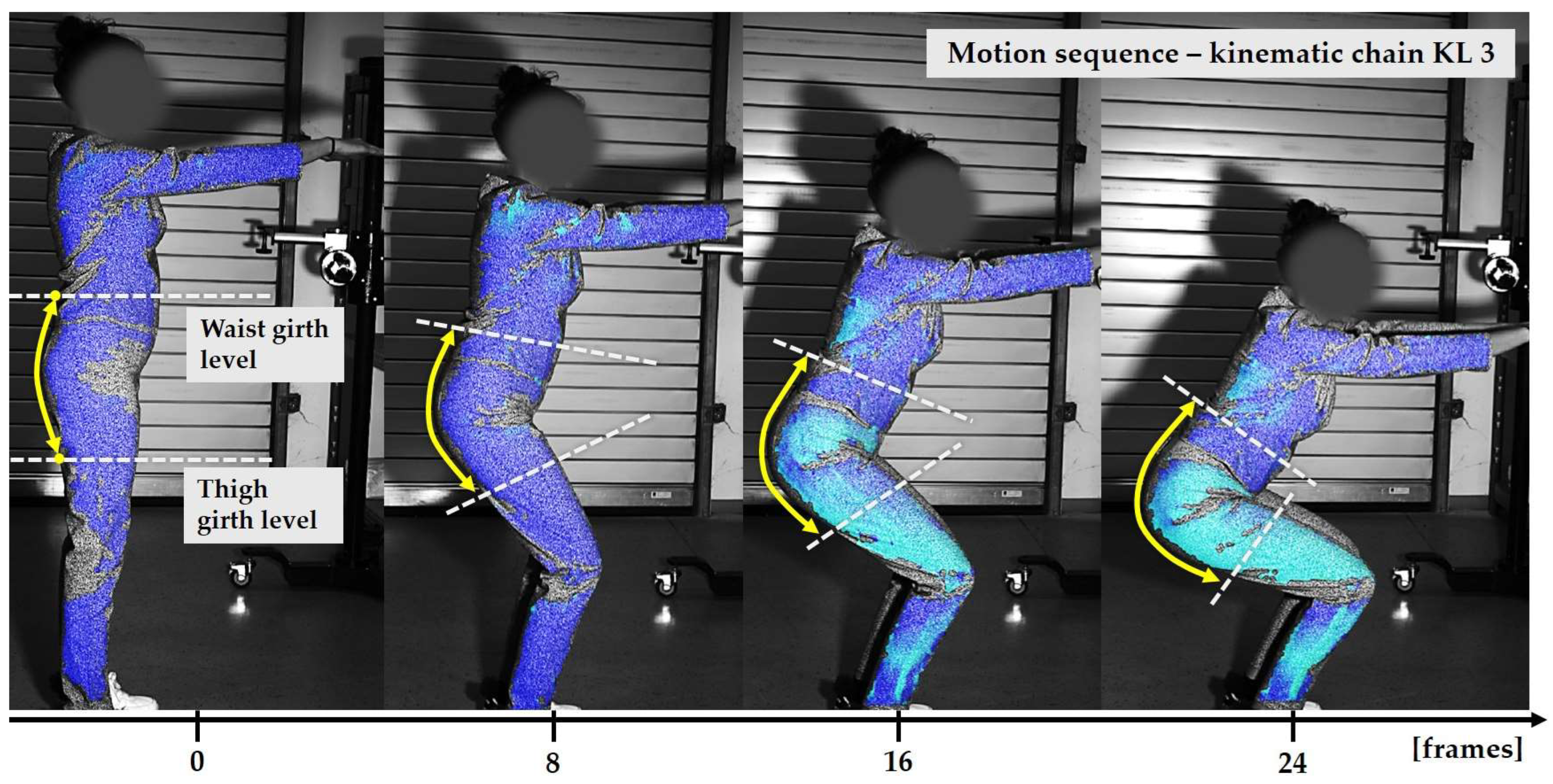

2.3. Surface Deformations Analysis of Digital Prototypes in Dynamic Conditions

2.4. Digital Prototypes Evaluation Based on the Applied Set of Mechanical Parameters

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fan, J.; Yu, W.; Yu, W.W.M.; Hunter, L. Clothing Appearance and Fit: Science and Technology; Woodhead Pub: Cambrige, UK, 2004. [Google Scholar]

- Geršak, J. Complex Fabric Deformations and Clothing Modelling in 3D; LAP Lambert Academic Publishing: Staarbrucken, Germany, 2013. [Google Scholar]

- Glogar, M.; Petrak, S.; Mahnić Naglić, M. Digital Technologies in the Sustainable Design and Development of Textiles and Clothing—A Literature Review. Sustainability 2025, 17, 1371. [Google Scholar] [CrossRef]

- Jhanji, Y. Computer-aided design-garment designing and patternmaking. In Automation in Garment Manufacturing; Nayak, R., Padhye, R., Eds.; Textiles: Cambridge, UK, 2018; pp. 253–290. [Google Scholar]

- Daukantiene, V. Analysis of the sustainability aspects of fashion: A literature review. Text. Res. J. 2023, 93, 991–1002. [Google Scholar] [CrossRef]

- Akhtar, W.H.; Watanabe, C.; Neittaanmäki, P. A new perspective on the textile and apparel industry in the digital transformation era. Textiles 2022, 2, 633–656. [Google Scholar] [CrossRef]

- Faridi, M.S.; Ali, S.; Duan, G.; Wang, G. Blockchain and IoT Based Textile Manufacturing Traceability System in Industry 4.0. In Proceedings of the 13th International Conference Security, Privacy and Autonomy in Computation, Communication and Storage, Nanjing, China, 18–20 December 2020. [Google Scholar]

- Bertola, P.; Teunissen, J. Fashion 4.0. Innovating fashion industry through digital transformation. Res. J. Text. Appar. 2018, 22, 352–369. [Google Scholar] [CrossRef]

- Optitex. Available online: https://optitex.com/ (accessed on 3 March 2025).

- Clo3D. Available online: https://www.clo3d.com/en/ (accessed on 3 March 2025).

- Lectra. Available online: https://www.lectra.com/en (accessed on 3 March 2025).

- Studio Style3D. Available online: https://studio.style3d.com/ (accessed on 3 March 2025).

- Browzwear. Available online: https://browzwear.com/ (accessed on 3 March 2025).

- Pandžić, I.S.; Pejša, T.; Matković, K.; Benko, H.; Čereković, A.; Matijašević, M. Virtualna Okruženja: Interaktivna 3D Grafika i Njene Primjene; Element: Zagreb, Croatia, 2011. [Google Scholar]

- Jevšnik, S.; Fatma, K.; Sena, T.; Jure, P. Review of computer models for fabric simulation. Tekstilec 2014, 57, 300–314. [Google Scholar] [CrossRef]

- House, H.D.; Breen, E.D. Cloth Modeling and Animation; A.K. Peters Natick, Ltd.: Natick, MA, USA, 2000. [Google Scholar]

- Hu, J. Computer Technology for Textiles and Apparel; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2011. [Google Scholar]

- Magnenat-Thalmann, N. Modeling and Simulating Bodies and Garments; Springer: London, UK, 2010. [Google Scholar]

- Volino, P. From early virtual garment simulation to interactive fashion design. Comput.-Aided Des. 2005, 37, 593–608. [Google Scholar] [CrossRef]

- Volino, P.; Magnenat-Thalmann, N. Virtual Clothing: Theory and Practice; Springer: Berlin/Heidelberg, Germany, 2000; pp. 35–60. [Google Scholar]

- Collier, J.R.; Collier, B.J. Drape prediction by means of finite element analysis. J. Text. Inst. 1991, 82, 96–107. [Google Scholar] [CrossRef]

- Jevšnik, S. Predicting mechanical properties of fused panel. Fibres Text. East. Eur. 2000, 8, 54–56. [Google Scholar]

- Hu, J.; Chen, S.F.; Teng, J.G. Numerical drape behaviour of circular fabric sheets over circular pedestal. Text. Res. J. 2000, 70, 593–603. [Google Scholar]

- Li, Y.; Dai, X.Q. Biomechanical Engineering of Texiles and Clothing; Woodhead Publishing with The Textile Institute: Cambridge, UK, 2006. [Google Scholar]

- Behera, B.K. Comfort and Handle Behaviour of Linnen-blended Fabrics. Autex Res. J. 2007, 7, 33–47. [Google Scholar] [CrossRef]

- Chu, C.C.; Cummings, C.L.; Teixeira, N.A. Mechanics of Elastic Performance of Textile Materials: Part V: A Study of the Factors Affecting the Drape of Fabrics—The Development of a Drape Meter. Text. Res. J. 1950, 20, 539–548. [Google Scholar] [CrossRef]

- Luible, C. Study of Mechanical Properties in the Simulation of 3D Garments. Ph.D. Thesis, Université de Genève, Genève, Switzerland, 2008. [Google Scholar]

- Sayem, A.S.M.; Kennon, R.; Clarke, N. 3D CAD systems for the clothing industry. Int. J. Fash. Des. Technol. Educ. 2010, 3, 45–53. [Google Scholar] [CrossRef]

- Kujipers, S.; LuibleBär, C.; Gong, H. The measurement of fabric properties for virtual simulation—A critical review. In IEEE SA Industry Connections; IEEE Standards Association (IEEE SA): Piscataway, NJ, USA, 2020; pp. 8–262020. [Google Scholar]

- Kawabata, S. The Standardization and Analysis of Hand Evaluation; Textile Machinery Society of Japan: Osaka, Japan, 1980. [Google Scholar]

- Petrak, S.; Mahnić Naglić, M.; Glogar, M.; Tomljenović, A. Assessment of Textile Material Properties and the Impact of Digital Ink-Jet Fabric Printing on 3D Simulation as a Sustainable Method for Garment Prototyping. Sustainability 2025, 17, 1388. [Google Scholar] [CrossRef]

- Petrak, S. Digital fashion innovation and sustainability. In Proceedings of the 14th International Scientific Conference on Manufacturing Engineering, Development and Modernization of Manufacturing RIM 2023, Sarajevo, Bosnia and Herzegovina, 20–22 September 2023. [Google Scholar]

- Frontier.Cool. Available online: https://frontier.cool/ai-fabric-digitization-frontier.cool (accessed on 18 February 2025).

- SEDDI Textura. Available online: https://textura.ai/ (accessed on 5 March 2025).

- Lim, H.S. Three Dimensional Virtual Try-On Technologies in the Achievement and Testing of Fit for Mass Customization. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2009. [Google Scholar]

- Wu, Y.Y.; Mok, P.Y.; Kwok, Y.L.; Fan, J.T.; Xin, J.H. An investigation on the validity of 3D clothing simulation for garment fit evaluation. In Proceedings of the IMProVe 2011 International Conference on Innovative Methods in Product Design, Padova, Italy, 15–17 June 2011. [Google Scholar]

- Power, J. Fabric objective measurements for commercial 3D virtual garment simulation. Int. J. Cloth. Sci. Technol. 2013, 25, 423–439. [Google Scholar] [CrossRef]

- Strazdiene, E. Textiles Objective and Sensory Evaluation in Rapid Prototyping. Mater. Sci. (Medžiagotyra) 2011, 17, 407–412. [Google Scholar] [CrossRef][Green Version]

- Petrak, S.; Mahnić Naglić, M.; Rogale, D.; Geršak, J. Analysis of Polygonal Computer Model Parameters and Influence on Fabric Drape Simulation. Materials 2021, 14, 6259. [Google Scholar] [CrossRef] [PubMed]

- Kenkare, N.; Lamar, T.A.; Pandurangan, P.; Eischen, J. Enhancing accuracy of drape simulation, Part I: Investigation of drape variability via 3D scanning. J. Text. Inst. 2008, 99, 211–218. [Google Scholar] [CrossRef]

- Thi, N.; Ngoc, T.; Anh, H. Investigating on Fabric and Skirt Drape. Screen 2010, 2, 2–9. [Google Scholar]

- Buyukaslan, E.; Jevsnik, S.; Kalaoglu, F. Comparative analysis of drape characteristics of actually and virtually draped fabrics. Int. J. Cloth. Sci. Technol. 2018, 30, 286–301. [Google Scholar] [CrossRef]

- Rudolf, A.; Zadravec, M.; Stjepanovič, Z. Investigations Regarding the Effects of Simulating Parameters During 3D Garments’ Drape Simulations. Fib. Text. East. Eur. 2016, 24, 143–150. [Google Scholar] [CrossRef][Green Version]

- Mahnic Naglic, M.; Petrak, S.; Gersak, J.; Rolich, T. Analysis of dynamics and fit of diving suits. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 152007. [Google Scholar]

- Jevšnik, S.; Stjepanovič, Z.; Rudolf, A. 3D Virtual Prototyping of Garments: Approaches, Developments and Challenges. J. Fiber Bioeng. Inform. 2017, 10, 51–63. [Google Scholar] [CrossRef]

- Zangue, F.; Pirch, C.; Klepser, A.; Morlock, S. Virtual Fit vs. Physical Fit—How well does 3D simulation represent the physical reality. In Proceedings of the 3DBODY.TECH 2020 11th Int. Conference and Exhibition on 3D Body Scanning and Processing Technologies, Lugano, Switzerland, 17–18 November 2020. [Google Scholar]

- Kim, S.H.; Kim, S.; Park, C.K. Development of similarity evaluation method between virtual and actual clothing. Int. J. Cloth. Sci. Technol. 2017, 29, 743–750. [Google Scholar] [CrossRef]

- Lapkovska, E.; Dabolina, I. An investigation on the virtual prototyping validity—Simulation of garment drape. In Proceedings of the International Scientific Conference Society Integration Education, Rezekne, Latvia, 23 May 2018. [Google Scholar]

- Klepster, A.; Mahr-Erhardt, A.; Morlock, S. Investigating Fit in Motion with a 4D Photogrammetry Scanner System. In Proceedings of the 3DBODY.TECH 2021 12th Int. Conference and Exhibition on 3D Body Scanning and Processing Technologies, Lugano, Switzerland, 19–20 October 2021. [Google Scholar]

- Zhang, D.; Krzywinski, S.; Kyosev, Y. Possibilities for simulating clothing in motion on person-specific avatars. In Proceedings of the 3DBODY.TECH 2021 12th Int. Conference and Exhibition on 3D Body Scanning and Processing Technologies, Lugano, Switzerland, 19–20 October 2021. [Google Scholar]

- Terrier, J.; Harland, A.R.; Jones, R.; Lucas, T.; Price, D. Using Finite Element Analysis to Perform Garment Simulation of Technical Apparel. Procedia Eng. 2011, 2, 3349–3354. [Google Scholar] [CrossRef]

- ZEISS, GOM Metrology. Available online: https://www.gom.com/en/products/3d-testing/aramis-3d-camera (accessed on 17 April 2025).

- HRN EN ISO 7211-2:2024; Textiles—Methods for Analysis of Woven Fabrics Construction—Part 2: Determination of Number of Threads per Unit Length (ISO 7211-2:2024; EN ISO 7211-2:2024). ISO: Geneva, Switzerland, 2024.

- HRN ISO 3801:2003; Textiles—Woven Fabrics—Determination of Mass per Unit Length and Mass per Unit Area (ISO 3801:1977). ISO: Geneva, Switzerland, 2023.

- HRN ISO 5084:2003; Textiles—Determination of Thickness of Textiles and Textile Products (ISO 5084:1996). ISO: Geneva, Switzerland, 2023.

- Mahnić, M.; Petrak, S. Investigation of the Fit of Computer-based Parametric Garment Prototypes. J. Fiber Bioeng. Inform. 2013, 6, 51–61. [Google Scholar]

- Petrak, S.; Mahnić, M.; Rogale, D. Impact of Male Body Posture and Shape on Design and Garment Fit. Fib. Text. East. Eur. 2015, 23, 150–158. [Google Scholar] [CrossRef]

| Woven Fabric M1 | Fibre Composition | Wave Type | Density | Areal Weight | Thickness |

|---|---|---|---|---|---|

| [Threads per cm] | [g/m2] | [mm] | |||

| Warp | 65% cotton 33% polyester (PES) 2% elastane (EL) | Twill | 40 | 226.58 | 0.52 |

| Weft | 20 |

| Tensile Parameters | Bending Parameters | Shear Parameter | ||

|---|---|---|---|---|

| EMT-1 [%] * | EMT-2 [%] * | B-1 [cNcm] * | B-2 [cNcm] * | G [cN/(cm°)−1] * |

| 1.730 | 11.180 | 0.356 | 0.093 | 0.010 |

| Stretch Warp [g/s2] | Stretch Weft [g/s2] | Bend Warp [gmm2/s2] | Bend Warp [gmm2/s2] | Shear [g/s2] |

| 482,012 | 441,042 | 3560 | 930 | 100,000 |

| Parameter | Warp | Weft | 45° Direction |

|---|---|---|---|

| Extension Interval [mm] | 1 | 10 | 10 |

| Elongation Interval [%] | 0.83 | 8.33 | 8.33 |

| 1 | 3.1 | 3.3 | 2.7 |

| 2 | 8.0 | 10.8 | 5.1 |

| 3 | 17.7 | 47.1 | 9.7 |

| 4 | 29.8 | 139.8 | 20.6 |

| 5 | 45.5 | 214.9 | 45.9 |

| CLO3D convert [g/s2] | 1,000,000 | 590,885 | 436,596 |

| Stretch-Warp | Stretch-Weft | Bend-Warp | Bending-Weft | Shear Rigidity | Areal Weight |

|---|---|---|---|---|---|

| [g/s2] | [g/s2] | [gmm2/s2] | [cNcm] | [g/s2] | [g/m2] |

| 691,472 | 425,985 | 4651 | 2578 | 89,210 | 226 |

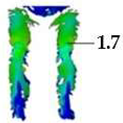

| Transversal (Weft) Elongation [%] | ||

|---|---|---|

| Position | P1 | P2 |

| KES-FB |  |  |

| Fabric Kit |  |  |

| SEDDI |  |  |

| Real prototype |  |  |

| ||

| Transversal (Weft) Elongation [%] | Longitudinal (Warp) Elongation [%] | ||

|---|---|---|---|

| Position | P3—Posterior | P3—Frontal | P3—Sagittal |

| KES-FB |  |  |  |

| Fabric Kit |  |  |  |

| SEDDI |  |  |  |

| Real prototype |  |  |  |

| |||

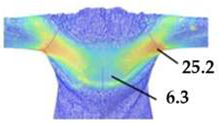

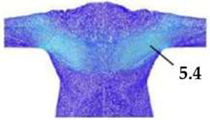

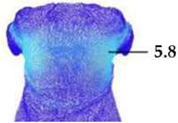

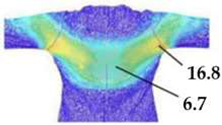

| Movement/Position | Observed Garment Zone | Digital Prototypes | Real Prototype | |||

|---|---|---|---|---|---|---|

| KES-FB | Fabric Kit | SEDDI Textura | Aramis | |||

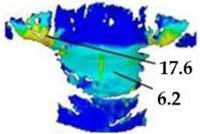

| P1 | Upper back torso (x/weft direction) | Mean strain [%] | 25.22 | 5.43 | 16.79 | 17.62 |

| Standard deviation | 0.91 | 0.43 | 0.42 | 0.25 | ||

| Min. | 24.1 | 4.8 | 16.1 | 17.3 | ||

| Max. | 27.1 | 6.1 | 17.5 | 18.2 | ||

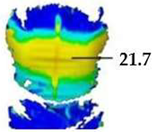

| P2 | Upper back Torso (x/weft direction) | Mean strain [%] | 24.71 | 5.79 | 22.12 | 21.71 |

| Standard deviation | 0.65 | 0.44 | 0.34 | 0.17 | ||

| Min. | 23.5 | 5.1 | 21.6 | 21.4 | ||

| Max. | 25.4 | 6.3 | 22.5 | 22.0 | ||

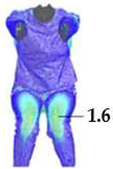

| P3 | Back hips (x/weft direction) | Mean strain [%] | 14.28 | 10.82 | 11.7 | 12.31 |

| Standard deviation | 0.65 | 0.43 | 0.44 | 0.18 | ||

| Min. | 13.5 | 10.1 | 10.9 | 12.0 | ||

| Max. | 15.5 | 11.4 | 12.3 | 12.6 | ||

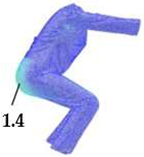

| Front knee (y/warp direction) | Mean strain [%] | 1.81 | 1.41 | 1.62 | 1.69 | |

| Standard deviation | 0.18 | 0.13 | 0.21 | 0.10 | ||

| Min. | 1.5 | 1.2 | 1.3 | 1.5 | ||

| Max. | 2.1 | 1.6 | 1.9 | 1.8 | ||

| Back length, waist to thigh (y/warp direction) | Mean strain [%] | 1.80 | 1.44 | 1.70 | 1.61 | |

| Standard deviation | 0.16 | 0.19 | 0.26 | 0.13 | ||

| Min. | 1.5 | 1.2 | 1.3 | 1.4 | ||

| Max. | 2.1 | 1.8 | 2.1 | 1.8 | ||

| Position | Observed Garment Zone | |||

|---|---|---|---|---|

| KES-FB | Fabric Kit | SEDDI Textura | ||

| P1 | Upper back torso (x/weft direction) | 7.6 | 12.2 | 0.8 |

| P2 | Upper back torso (x/weft direction) | 3.0 | 15.9 | 0.4 |

| P3 | Back hips (x/weft direction) | 2.0 | 1.5 | 0.6 |

| Front knee (y/warp direction) | 0.1 | 0.3 | 0.1 | |

| Back length waist to thigh (y/warp direction) | 0.2 | 0.2 | 0.1 | |

| Mean differences value [%] | 2.58 | 6.02 | 0.40 | |

| Standard deviation | 3.06 | 7.46 | 0.31 | |

| Min. | 0.1 | 0.2 | 0.1 | |

| Max. | 7.6 | 15.9 | 0.8 | |

| Method | Technical Description | Advantages | Limitations | Integration with CLO3D |

| KES-FB | Highly sensitive laboratory system for testing mechanical properties under small loads. |

|

| Low Required conversion |

| FabricKit | Simple measuring system with defined protocol, compatible with Emulator converter for CAD import. |

|

| High Integrated conversion |

| SEDDI Textura | AI tool for prediction of textile mechanical parameters based on 2D image and basic data. |

|

| High Direct data input |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahnić Naglić, M.; Petrak, S.; Tomljenović, A. Analysis of Woven Fabric Mechanical Properties in the Context of Sustainable Clothing Development Process. Polymers 2025, 17, 2013. https://doi.org/10.3390/polym17152013

Mahnić Naglić M, Petrak S, Tomljenović A. Analysis of Woven Fabric Mechanical Properties in the Context of Sustainable Clothing Development Process. Polymers. 2025; 17(15):2013. https://doi.org/10.3390/polym17152013

Chicago/Turabian StyleMahnić Naglić, Maja, Slavenka Petrak, and Antoneta Tomljenović. 2025. "Analysis of Woven Fabric Mechanical Properties in the Context of Sustainable Clothing Development Process" Polymers 17, no. 15: 2013. https://doi.org/10.3390/polym17152013

APA StyleMahnić Naglić, M., Petrak, S., & Tomljenović, A. (2025). Analysis of Woven Fabric Mechanical Properties in the Context of Sustainable Clothing Development Process. Polymers, 17(15), 2013. https://doi.org/10.3390/polym17152013