The Effect of Bio-Based Polyamide 10.10 and Treated Fly Ash on Glass-Fiber-Reinforced Polyamide 6 Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composites

2.3. Characterization

2.3.1. X-Ray Diffraction

2.3.2. Fourier-Transform Infrared Spectroscopy (FTIR)

2.3.3. Dynamic Light Scattering (DLS)

2.3.4. Thermal Characterization

2.3.5. Dynamic Mechanical Analysis (DMA)

2.3.6. Mechanical Analysis

2.3.7. Scanning Electron Microscopy (SEM)

3. Results and Discussion

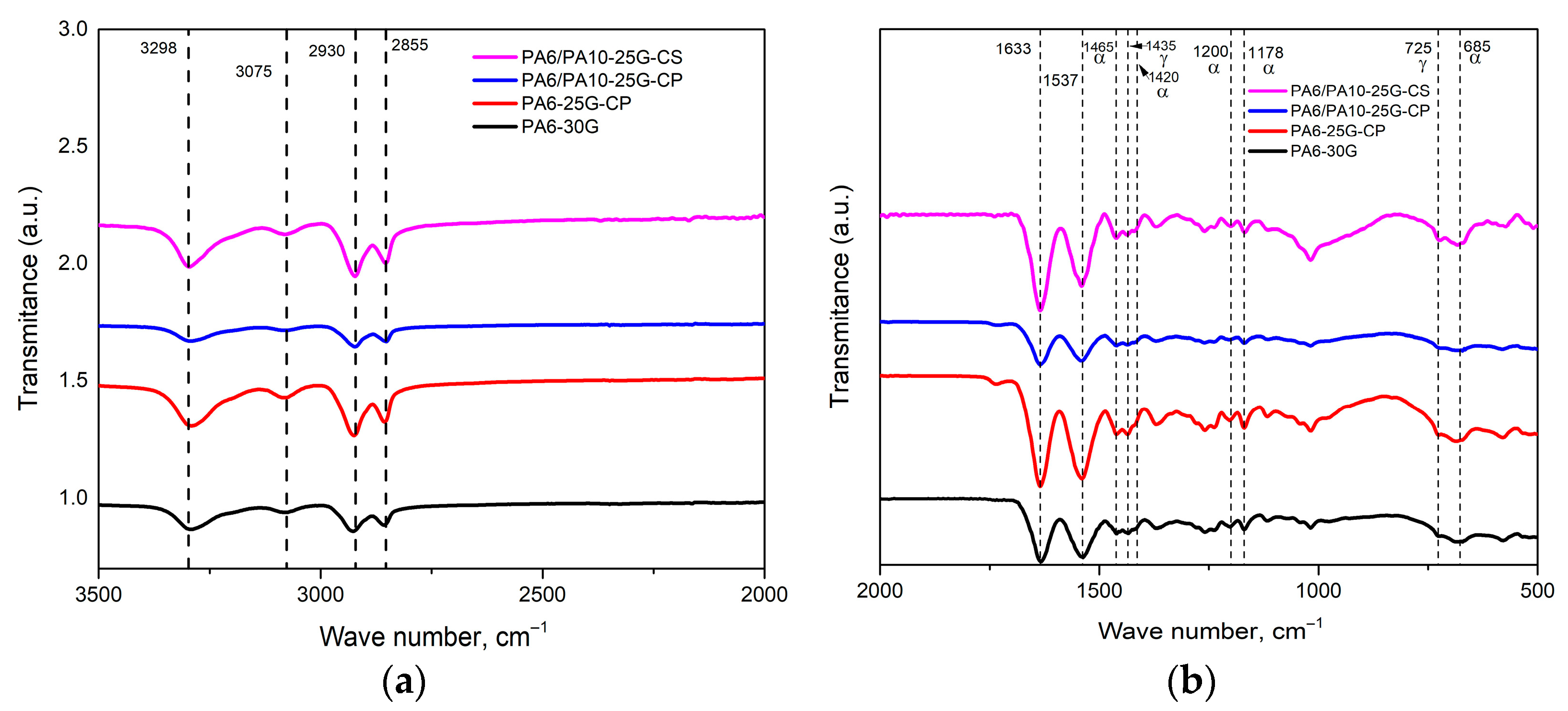

3.1. FTIR and DLS Analysis

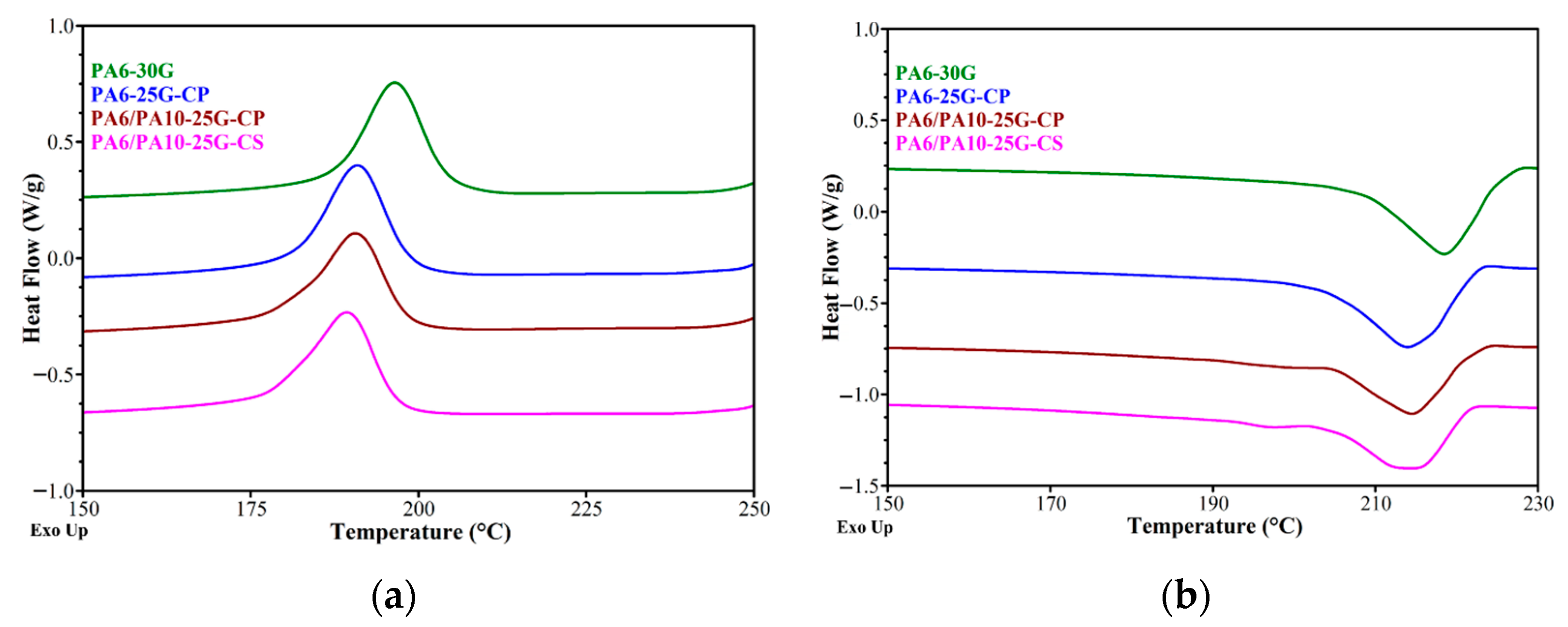

3.2. Differential Scanning Calorimetry Analysis

3.3. X-Ray Diffraction Analysis

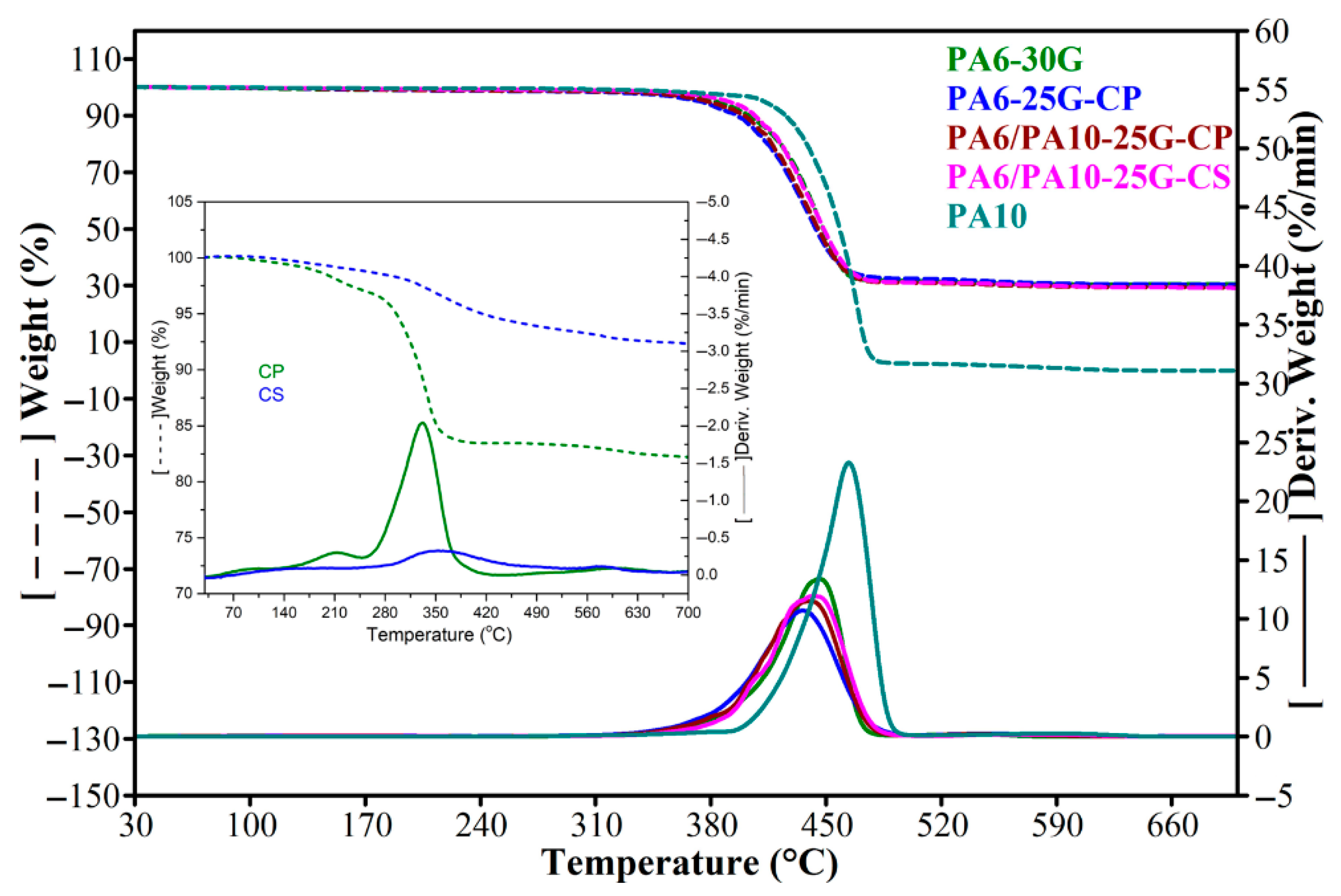

3.4. Thermogravimetric Analysis

3.5. Mechanical and Dynamic Mechanical Analysis

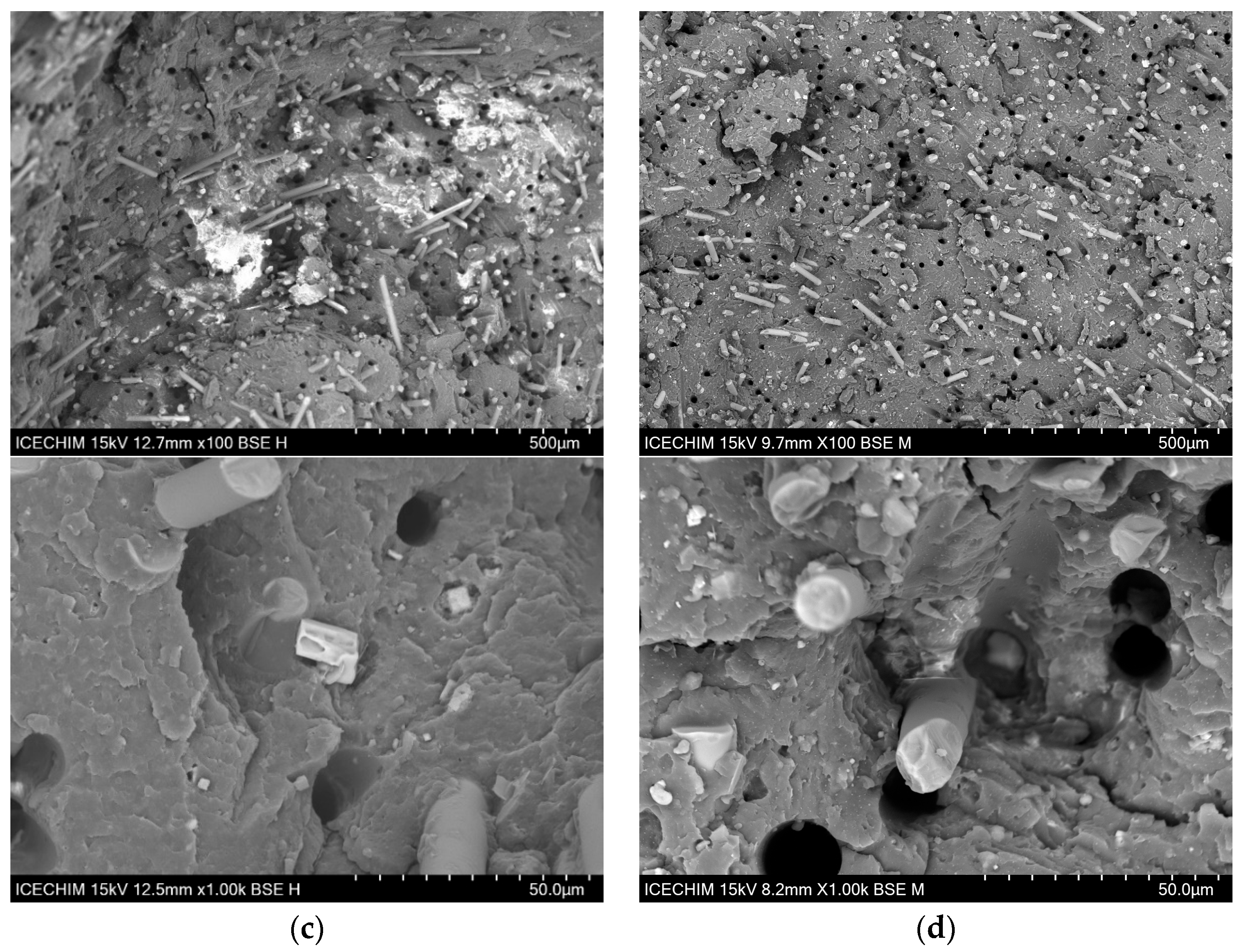

3.6. SEM Analysis

3.7. Aspects Regarding Recyclability and Industrial Feasibility

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Rakib, M.R.; De-la-Torre, G.; Jolly, Y.; Nahian, S.; Khan, N.; Idris, A. First record of plastiglomerate and pyroplastic pollution in the world’s longest natural beach. Sci. Total Environ. 2023, 891, 164369. [Google Scholar] [CrossRef] [PubMed]

- Bostan, N.; Ilyas, N.; Akhtar, N.; Mehmood, S.; Saman, R.U.; Sayyed, R.Z.; Shatid, A.A.; Alfaifi, M.Y.; Elbehairi, S.E.I.; Pandiaraj, S. Toxicity assessment of microplastic (MPs); a threat to the ecosystem. Environ. Res. 2023, 234, 116523. [Google Scholar] [CrossRef] [PubMed]

- Nagalakshmaiah, M.; Kissi, N.; Dufresne, A. Ionic Compatibilization of Cellulose Nanocrystals with Quaternary Ammonium Salt and Their Melt Extrusion with Polypropylene. ACS Appl. Mater. Interfaces 2016, 8, 8755–8764. [Google Scholar] [CrossRef] [PubMed]

- Nagalakshmaiah, M.; Afrin, S.; Malladi, R.P.; Elkoun, S.; Robert, M.; Ansari, M.A.; Svedberg, A.; Karim, Z. Chapter 9—Biocomposites: Present trends and challenges for the future. In Green Composites for Automotive Applications; Koronis, G., Silva, A., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 197–215. [Google Scholar]

- Petraşcu, O.-L.; Pascu, A.-M. Comparative study of polyamide 6 (PA6) and polyamide 6 reinforced with 30% of glass fiber (PA6GF30). Mater. Today Proc. 2023, 93, 625–629. [Google Scholar] [CrossRef]

- Klata, E.; Van de Velde, K.; Krucińska, I. DSC investigations of polyamide 6 in hybrid GF/PA 6 yarns and composites. Polym. Test. 2003, 22, 929–937. [Google Scholar] [CrossRef]

- Hassan, A.; Abd Rahman, N.M.M.; Yahya, R. Moisture Absorption Effect on Thermal, Dynamic Mechanical and Mechanical Properties of Injection-Molded Short Glass-Fiber/Polyamide 6,6 Composites. Fibers Polym. 2012, 13, 899–906. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, C.; Cai, L.; Garcia, A.C.; Shi, S.Q. Development of natural fiber-reinforced composite with comparable mechanical properties and reduced energy consumption and environmental impacts for replacing automotive glass-fiber sheet molding compound. J. Clean. Prod. 2018, 184, 92–100. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Wötzel, K.; Wirth, R.; Flake, M. Life cycle studies on hemp fibre reinforced components and ABS for automotive parts. Die Angewandte Makromol. Chem. 1999, 272, 121–127. [Google Scholar] [CrossRef]

- Schmidt, W.-P.; Beyer, h.-m. Life Cycle Study on a Natural Fibre Reinforced Component. SAE Tech. Pap. 1998, 982195. [Google Scholar] [CrossRef]

- Corbière-Nicollier, T.; Gfeller Laban, B.; Lundquist, L.; Leterrier, Y.; Månson, J.A.E.; Jolliet, O. Life cycle assessment of biofibres replacing glass fibres as reinforcement in plastics. Resour. Conserv. Recycl. 2001, 33, 267–287. [Google Scholar] [CrossRef]

- Teodorescu, G.-M.; Vuluga, Z.; Oancea, F.; Ionita, A.; Paceagiu, J.; Ghiurea, M.; Nicolae, C.-A.; Gabor, A.R.; Raditoiu, V. Properties of Composites Based on Recycled Polypropylene and Silico-Aluminous Industrial Waste. Polymers 2023, 15, 2545. [Google Scholar] [CrossRef] [PubMed]

- Teodorescu, G.M.; Vuluga, Z.; Ion, R.M.; Fistoș, T.; Ioniță, A.; Slămnoiu-Teodorescu, S.; Paceagiu, J.; Nicolae, C.A.; Gabor, A.R.; Ghiurea, M. The Effect of Thermoplastic Elastomer and Fly Ash on the Properties of Polypropylene Composites with Long Glass Fibers. Polymers 2024, 16, 1238. [Google Scholar] [CrossRef] [PubMed]

- Wolff, S.; Rüppel, A.; Rida, H.A.; Heim, H.-P. Emission and Mechanical Properties of Glass and Cellulose Fiber Reinforced Bio-Polyamide Composites. Polymers 2023, 15, 2603. [Google Scholar] [CrossRef] [PubMed]

- Battegazzore, D.; Salvetti, O.; Frache, A.; Peduto, N.; De Sio, A.; Marino, F. Thermo-mechanical properties enhancement of bio-polyamides (PA10.10 and PA6.10) by using rice husk ash and nanoclay. Compos. Part A Appl. Sci. Manuf. 2016, 81, 193–201. [Google Scholar] [CrossRef]

- Oulidi, O.; Elaaraj, I.; Jabri, M.; Nakkabi, A.; Bouymajane, A.; Filali, F.R.; Fahim, M.; El Moualij, N. Enhancing and hindering biodegradation: A comparative study on polyamide 6 reinforced with bio-fillers (peanut shell, olive pomace, and plaster). Sustain. Chem. Environ. 2024, 7, 100116. [Google Scholar] [CrossRef]

- Gülel, Ş.; Güvenilir, Y. Olive stone powder filled bio-based polyamide 5.6 biocomposites: Biodegradation in natural soil and mechanical properties. Polym. Bull. 2024, 81, 14385–14410. [Google Scholar] [CrossRef]

- Hernández-García, E.; Pacheco-Romeralo, M.; Pascual-Ramírez, L.; Vargas, M.; Torres-Giner, S. Synthesis and characterization of polyamide 1010 and evaluation of its cast-extruded films for meat preservation. Food Packag. Shelf Life 2023, 36, 101058. [Google Scholar] [CrossRef]

- Kuciel, S.; Romańska, P.; Jakubowska, P. Properties of composites based on polyamide 10.10 reinforced with carbon fibers. Polimery 2016, 61, 106–112. [Google Scholar] [CrossRef]

- Levinta, N.; Corobea, M.C.; Vuluga, Z.; Nicolae, C.-A.; Gabor, A.R.; Raditoiu, V.; Osiac, M.; Teodorescu, G.-M.; Teodorescu, M. Bio-Based Polyamide 1010 with a Halogen-Free Flame Retardant Based on Melamine–Gallic Acid Complex. Polymers 2020, 12, 1482. [Google Scholar] [CrossRef] [PubMed]

- Hirsch, P.; Theumer, T. Comparative Study on Polyamide 11 and Polyamide 10.10 as Matrix Polymers for Biogenic Wood-Plastic Composites. Macromol. Symp. 2022, 403, 2100492. [Google Scholar] [CrossRef]

- Cogen, J.; Lin, T.; Whaley, P. Material Design for Fire Safety in Wire and Cable Applications. In Fire Retardancy of Polymeric Materials; CRC Press: Boca Raton, FL, USA, 2009; pp. 783–808. Available online: https://www.researchgate.net/publication/345950991_Material_Design_for_Fire_Safety_in_Wire_and_Cable_Applications (accessed on 3 June 2025).

- Zhao, Y.; Liang, H.; Wu, D.; Bian, J.; Hao, Y.; Zhang, G.; Liu, S.; Zhang, H.; Dong, L. Poly(1,2-propylene glycol adipate) as an Environmentally Friendly Plasticizer for Poly(vinyl chloride). Polym. Korea 2015, 39, 247–255. [Google Scholar] [CrossRef][Green Version]

- Bahramnia, H.; Semnani, H.; Habibolahzadeh, A.; Abdoos, H. The Effect of 3-(Glycidoloxy Propyl) Trimethoxy Silane Concentration on Surface Modification of SiO2 Nanoparticles. Silicon 2022, 14, 4969–4977. [Google Scholar] [CrossRef]

- Qin, C.; Lu, W.; He, Z.; Qi, G.; Li, J.; Hu, X. Effect of Silane Treatment on Mechanical Properties of Polyurethane/Mesoscopic Fly Ash Composites. Polymers 2019, 11, 741. [Google Scholar] [CrossRef] [PubMed]

- Klata, E.; Borysiak, S.; Velde, K.; Garbarczyk, J.; Krucińska, I. Crystallinity of polyamide-6 matrix in glass fibre/polyamide-6 composites manufactured from hybrid yarns. Fibres Text. East. Eur. 2004, 12, 64–69. [Google Scholar]

- Penel-Pierron, L.; Depecker, C.; Séguéla, R.; Lefebvre, J.-M. Structural and mechanical behavior of nylon 6 films part I. Identification and stability of the crystalline phases. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 484–495. [Google Scholar] [CrossRef]

- ISO 527-1; Plastics-Determination of Tensile Properties-Part. ISO: Geneva, Switzerland, 1996; p. 1.

- ISO 179; Plastics-Determination of Charpy Impact Properties-Part 1: Non Instrumented Impact Test. ISO: Geneva, Switzerland, 2010; p. 1.

- Tummino, M.L.; Chrimatopoulos, C.; Bertolla, M.; Tonetti, C.; Sakkas, V. Configuration of a Simple Method for Different Polyamides 6.9 Recognition by ATR-FTIR Analysis Coupled with Chemometrics. Polymers 2023, 15, 3166. [Google Scholar] [CrossRef] [PubMed]

- Tao, L.; Liu, K.; Zheng, Y.; Xiao, R. Structure and properties of bio-based polyamide 69 after treated with water under different states. Mater. Res. Express 2019, 6, 115331. [Google Scholar] [CrossRef]

- Ma, N.; Liu, W.; Ma, L.; He, S.; Liu, H.; Zhang, Z.; Sun, A.; Huang, M.; Zhu, C. Crystal transition and thermal behavior of Nylon 12. e-Polymers 2020, 20, 346–352. [Google Scholar] [CrossRef]

- Kang, H.; Wang, Z.; Hao, X.; Liu, R. Thermal induced crystalline transition of bio-based polyamide 56. Polymer 2022, 242, 124540. [Google Scholar] [CrossRef]

- Leszek, A.; Utracki, C.A.W. Polymer Blends Handbook; Springer: Dordrecht, Switzerland, 2002. [Google Scholar]

- Athokpam, B.; Ramesh, S.G.; McKenzie, R.H. Effect of hydrogen bonding on the infrared absorption intensity of OH stretch vibrations. Chem. Phys. 2017, 488–489, 43–54. [Google Scholar] [CrossRef]

- Vikram, K.; Pramanik, S.; Bhaumik, S. Thermal kinetic, mechanical and wear properties of glass fiber reinforced polyamide 6 thermoplastic composites. J. Appl. Polym. Sci. 2024, 141, e56119. [Google Scholar] [CrossRef]

- Kasar, A.; Gupta, N.; Rohatgi, P.; Menezes, P. A Brief Review of Fly Ash as Reinforcement for Composites with Improved Mechanical and Tribological Properties. JOM 2020, 72, 2340–2351. [Google Scholar] [CrossRef]

- Dencheva, N.; Denchev, Z.; Oliveira, M.J.; Funari, S.S. Relationship between crystalline structure and mechanical behavior in isotropic and oriented polyamide 6. J. Appl. Polym. Sci. 2007, 103, 2242–2252. [Google Scholar] [CrossRef]

- González, N.; Fernández-Berridi, M. Fourier transform infrared Spectroscopy in the study of the interaction between PVC and plasticizers: PVC/Plasticizer compatibility. J. Appl. Polym. Sci. 2008, 107, 1294–1300. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Composites Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Hernández-González, A.C.; Téllez-Jurado, L.; Rodríguez-Lorenzob, L.M. Synthesis of in-situ silica-alginate hybrid hydrogels by a sol-gel route. Carbohydr. Polym. 2020, 250, 116877. [Google Scholar] [CrossRef] [PubMed]

- Lazorenko, G.; Kasprzhitskii, A.; Mischinenko, V.; Kruglikov, A. Fabrication and characterization of metakaolin-based geopolymer composites reinforced with cellulose nanofibrils. Mater. Lett. 2022, 308, 131146. [Google Scholar] [CrossRef]

- Liu, Y.; Naidu, R.; Ming, H. Surface electrochemical properties of red mud (bauxite residue): Zeta potential and surface charge density. J. Colloid Interface Sci. 2013, 394, 451–457. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhang, P.; Jiang, X.; Rao, G. Influence of maleic anhydride grafted polypropylene on the miscibility of polypropylene/polyamide-6 blends using ATR-FTIR mapping. Vib. Spectrosc. 2009, 49, 17–21. [Google Scholar] [CrossRef]

- Özdilek, C.; Kazimierczak, K.; van der Beek, D.; Picken, S.J. Preparation and properties of polyamide-6-boehmite nanocomposites. Polymer 2004, 45, 5207–5214. [Google Scholar] [CrossRef]

- Kaßner, L.; Spange, S.; Nagel, K.; Grützner, R.-E.; Korb, M.; Rüffer, T.; Lang, H. Polyamide 6/silica hybrid materials by a coupled polymerization reaction. Polym. Chem. 2015, 6, 6297–6304. [Google Scholar] [CrossRef]

- Dodd, J.W.; Holliday, P.; Parker, B.E. The effect of casting conditions on the crystalline forms of nylon-6 films. Polymer 1968, 9, 54–56. [Google Scholar] [CrossRef]

- Blumstein, R.B. Thermal Characterization of Polymeric Materials. Second Edition Volumes 1 and 2 Edited by Edith A. Turi (Polytechnic University, New York). J. Am. Chem. Soc. 1997, 119, 9589–9590. [Google Scholar] [CrossRef]

- Şanlı, S.; Durmus, A.; Ercan, N. Effect of nucleating agent on the nonisothermal crystallization kinetics of glass fiber- and mineral-filled polyamide-6 composites. J. Appl. Polym. Sci. 2012, 125, E268–E281. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Tjong, S.C. Structural and mechanical properties of polymer nanocomposites. Mater. Sci. Eng. R Rep. 2006, 53, 73–197. [Google Scholar] [CrossRef]

- Khanna, Y.P.; Kuhn, W.P. Measurement of crystalline index in nylons by DSC: Complexities and recommendations. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 2219–2231. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Q. Phase transition in nylon 6/clay nanocomposites on annealing. Polymer 2002, 43, 1933–1936. [Google Scholar] [CrossRef]

- Harrell, T.M.; Le, C.; Shen, V.; Cordier, R.; Li, X. The effect of stretching on polyamide—6: Assessment of crystallinity, mechanical properties, and surface roughness. J. Polym. Res. 2024, 31, 198. [Google Scholar] [CrossRef]

- D’Alò, B.; Coppola, G.; Pallesi, B. Studies of crystalline forms of nylon-6 by X-ray and i.r. spectrophotometry. Polymer 1974, 15, 130–132. [Google Scholar] [CrossRef]

- Kuram, E. Hybridization effect of talc/glass fiber as a filler in polycarbonate/acrylonitrile-butadiene-styrene composites. Compos. Part B Eng. 2019, 173, 106954. [Google Scholar] [CrossRef]

- Omollo, E.; Koech, J.; Kamalha, E.; Adolkar, V. Morphological and Mechanical Analysis of Polyamide-66/Poss Nanocomposite Fiber. Mat. Sci. Ind. J. 2017, 16, 124. [Google Scholar]

- Avbar, M.; Oliveira, G.H.M.d.; Amancio-Filho, S.d.T. Enhancing Mechanical Properties of Polyamide 66 with Carbon-Based Nano-Fillers: A Review. J. Compos. Sci. 2025, 9, 48. [Google Scholar] [CrossRef]

- Dorr, N.; Ribeiro, G.F.; Schmidt, J.; Busch, A.B.; Selvarayan, S.K.; Brandt, R. Residual stresses in intrinsic thermoset-thermoplastic hybrid composites. Adv. Compos. Hybrid Mater. 2025, 8, 171. [Google Scholar] [CrossRef]

- Eijpe, M.P.I.M.; Powell, P.C. Residual stress evaluation in composites using a modified layer removal method. Compos. Struct. 1997, 37, 335–342. [Google Scholar] [CrossRef]

- Sheikh, M.R.; Hassan, A.; Mohamad Salleh, N.; Yahya, R. Fiber length, thermal, mechanical, and dynamic mechanical properties of injection-molded glass-fiber/polyamide 6,6: Plasticization effect. J. Reinf. Plast. Compos. 2011, 30, 488–498. [Google Scholar] [CrossRef]

- Zhu, L.H.; Sheng, J.F.; Guo, Z.F.; Ju, X.S.; Li, S.; Chen, Y.F.; Luo, J. Properties of Polypropylene and Surface Modified Glass-Fibre Composites. Polym. Polym. Compos. 2014, 22, 381–386. [Google Scholar] [CrossRef]

- Khan, F.; Hossain, N.; Mim, J.J.; Rahman, S.M.M.; Iqbal, M.J.; Billah, M.; Chowdhury, M.A. Advances of composite materials in automobile applications—A review. J. Eng. Res. 2025, 13, 1001–1023. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Jan, D.; Khan, M.S.; Ud Din, I.; Khan, K.A.; Shah, S.A.; Jan, A. A review of design, materials, and manufacturing techniques in bumper beam system. Compos. Part C Open Access 2024, 14, 100496. [Google Scholar] [CrossRef]

- Wang, C.; Wang, D.; Zheng, S. Preparation of aluminum silicate/fly ash particles composite and its application in filling polyamide 6. Mater. Lett. 2013, 111, 208–210. [Google Scholar] [CrossRef]

- Pashaei, S.; Siddaramaiah, S.P.; Avval, M.; Syed, A. Thermal degradation kinetics of nylon6/GF/crysnano nanoclay nanocomposites by TGA. Chem. Ind. Chem. Eng. Q. 2011, 17, 141–151. [Google Scholar] [CrossRef]

- López-Manchado, M.A.; Biagiotti, J.; Kenny, J.M. Comparative Study of the Effects of Different Fibers on the Processing and Properties of Polypropylene Matrix Composites. J. Thermoplast. Compos. Mater. 2002, 15, 337–353. [Google Scholar] [CrossRef]

- Hassan, A.; Rahman, N.A.; Yahya, R. Extrusion and injection-molding of glass fiber/MAPP/polypropylene: Effect of coupling agent on DSC, DMA, and mechanical properties. J. Reinf. Plast. Compos. 2011, 30, 1223–1232. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Gimeno, O.; Balart, R.; Torres-Giner, S.; Rallini, M.; Dominici, F.; Torre, L. A comparative study on the reactive compatibilization of melt-processed polyamide 1010/polylactide blends by multi-functionalized additives derived from linseed oil and petroleum. Express Polym. Lett. 2020, 14, 583–604. [Google Scholar] [CrossRef]

- Thomason, J.L.; Nagel, U.; Yang, L.; Bryce, D. A study of the thermal degradation of glass fibre sizings at composite processing temperatures. Compos. Part A Appl. Sci. Manuf. 2019, 121, 56–63. [Google Scholar] [CrossRef]

- Fu, S.Y.; Lauke, B.; Zhang, Y.H.; Mai, Y.W. On the post-mortem fracture surface morphology of short fiber reinforced thermoplastics. Compos. Part A Appl. Sci. Manuf. 2005, 36, 987–994. [Google Scholar] [CrossRef]

- Robeson, L.M. Polymer Blends: A Comprehensive Review; Hanser: Munich, Germany, 2007. [Google Scholar]

- Isayev, A.I. Encyclopedia of Polymer Blends, Volume 1: Fundamentals; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Laoutid, F.; Estrada, E.; Michell, R.M.; Bonnaud, L.; Müller, A.J.; Dubois, P. The influence of nanosilica on the nucleation, crystallization and tensile properties of PP–PC and PP–PA blends. Polymer 2013, 54, 3982–3993. [Google Scholar] [CrossRef]

- Kurkin, E.; Chertykovtseva, V.; Sedelnikov, A.; Minaev, E.; Kurkina, E.; Gavrilov, A. Short-Glass-Fiber Aspect Ratios in Polyamide-6 Composites: Homogenization and Deep Learning-Based Scanning Image-Microscope Segmentation Comparison. Appl. Sci. 2024, 14, 11464. [Google Scholar] [CrossRef]

| Sample | PA6 (wt.%) | GF (wt.%) | PA10 (wt.%) | CP (wt.%) | CS (wt.%) |

|---|---|---|---|---|---|

| PA6-30G | 70 | 30 | - | - | - |

| PA6-25G-CP | 68.5 | 25 | - | 6.5 | - |

| PA6/PA10-25G-CP | 59.8 | 24.5 | 9.2 | 6.5 | - |

| PA6/PA10-25G-CS | 59.85 | 24.6 | 9.8 | - | 5.75 |

| PA6-30G, cm−1 | PA6-25GF-CP, cm−1 | PA6/PA10-25GF-CP, cm−1 | PA6/PA10-25GF-CS, cm−1 | Band Assignment | |

|---|---|---|---|---|---|

| 3298 | 3298 | 3300 | 3300 | N–H stretching vibration | General |

| 3075 | 3075 | 3075 | 3075 | N–H stretch and amide II overtone | General |

| 2922 | 2922 | 2919 | 2919 | CH2 asymmetric stretching | General |

| 2855 | 2855 | 2850 | 2850 | CH2 symmetric stretching | General |

| 1633 | 1633 | 1635 | 1635 | Amide I band (C=O stretching) | General |

| 1537 | 1537 | 1539 | 1539 | Amide II band (N–H in-plane bending coupled with C–N and C–O stretch) | General |

| 1462 | 1462 | 1467 | 1467 | CH2 scissoring not adjacent to the amide group | α-structure |

| 1435 | 1435 | 1435 | 1435 | CH2 scissors vibration | γ-structure |

| 1420 | 1420 | 1420 | 1420 | CH2 scissoring | α-structure |

| 1236 | 1236 | 1237 | 1237 | CH2 twist-wagging | γ-structure |

| 725 | 725 | 726 | 726 | Rocking mode of CH2 | γ-structure |

| Ramp 10 °C/min | Crystallization | Melting 1 (M1) | Melting 2 (M2) | Melting Total (M1 + M2) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Onset | Tc | ΔHc | Xc | Onset | Tm1 | ΔHm1 | Onset | Tm2 | ΔHm2 | ΔHm | Xc | |

| (He, 25 mL/min) | °C | °C | J/(g) | % | °C | °C | J/(g) | °C | °C | J/(g) | J/(g) | % |

| PA6-30G | 205.1 | 196.9 | 41.68 | 25.9 | - | - | - | 207.2 | 217.9 | 48.32 | 48.32 | 30.0 |

| PA6-25G-CP | 199.6 | 191.3 | 41.04 | 26.0 | - | - | - | 200.4 | 214.2 | 45.73 | 45.73 | 29.0 |

| PA6/PA10-25G-CP | 198.2 | 190.5 | 41.32 | 30.0 | 176.1 | 198.6 | 17.46 | 201.3 | 214.2 | 27.80 | 45.26 | 28.5 |

| PA6/PA10-25G-CS | 196.9 | 189.3 | 40.21 | 29.2 | 181.3 | 197.5 | 16.65 | 201.9 | 214.5 | 26.58 | 43.23 | 27.0 |

| αPA6.6/PA10 (200) | αPA6.6/PA10 (002) + (202) | ||

|---|---|---|---|

| PA6-30G CI = 73% | 2θ (°) | 21.04 | 22.94 |

| Height (cps) | 5715 | 8033 | |

| FWHM (°) | 2.84 | 2.53 | |

| PA6-25G-CP CI = 57% | 2θ (°) | 21.22 | 22.62 |

| Height (cps) | 5146 | 7761 | |

| FWHM (°) | 2.49 | 2.48 | |

| PA6/PA10-25G-CP CI = 53% | 2θ (°) | 20.97 | 22.90 |

| Height (cps) | 4971 | 4360 | |

| FWHM (°) | 3.05 | 2.34 | |

| PA6/PA10-25G-CS CI = 67% | 2θ (°) | 20.78 | 22.68 |

| Height (cps) | 6053 | 8393 | |

| FWHM (°) | 2.73 | 2.77 | |

| Sample | RT—230 °C Wt. Loss % | Onset Point Temp °C | Tmax °C | Residue 700 °C | Temp for Wt. Loss 5% °C |

|---|---|---|---|---|---|

| PA10 | 0.39 | 440.8 | 468.0 | 0.20 | 412.0 |

| CP | 3.63 | 299.4 | 336.7 | 74.28 | 267.4 |

| CS | 0.97 | 298.1 | 350.0 | 92.35 | 415.0 |

| PA6-30G | 1.49 | 416.1 | 448.6 | 30.78 | 382.0 |

| PA6-25G-CP | 1.23 | 402.1 | 438.2 | 30.26 | 374.0 |

| PA6/PA10-25G-CP | 1.11 | 403.7 | 441.0 | 29.22 | 378.0 |

| PA6/PA10-25G-CS | 0.71 | 408.9 | 440.0 | 29.15 | 390.6 |

| Sample | Tensile Stress at Tensile Strength (MPa) | Young’s Modulus (MPa) | Tensile Strain at Break (%) | Impact Strength (KJ/m2) |

|---|---|---|---|---|

| PA6-30G | 145.1 ± 1 | 7578 ± 70 | 2.8 ± 0.1 | 6.5 ± 0.3 |

| PA6-25G-CP | 127 ± 0.4 | 6347 ± 91 | 3.2 ± 0.1 | 7.3 ± 0.3 |

| PA6/PA10-25G-CP | 130 ± 0.4 | 6664 ± 78 | 3.5 ± 0.2 | 7.4 ± 0.5 |

| PA6/PA10-25G-CS | 138 ± 0.4 | 6930 ± 37 | 4.3 ± 0.4 | 7.9 ± 0.3 |

| Sample | Storage Modulus, E′ | Loss Modulus, E″ | Loss Factor | |||

|---|---|---|---|---|---|---|

| Temp | E′ | Temp | E″ Peak | Temp | Tan Delta | |

| °C | MPa | °C | MPa | °C | Tan δ Peak | |

| PA6-30G | 30 | 4287 | 70.2 | 258.7 | 75.76 | 0.089 |

| PA6-25GF-CP | 30 | 3518 | 69.5 | 243.6 | 76.23 | 0.110 |

| PA6/PA10-25GF-CP | 30 | 3702 | 60.1 | 262.7 | 67.01 | 0.129 |

| PA6/PA10-25GF-CS | 30 | 3733 | 62.8 | 259.5 | 69.74 | 0.133 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teodorescu, G.-M.; Vuluga, Z.; Fistoș, T.; Slămnoiu-Teodorescu, S.; Paceagiu, J.; Nicolae, C.-A.; Gabor, A.R.; Ghiurea, M.; Gîfu, C.; Ion, R.M. The Effect of Bio-Based Polyamide 10.10 and Treated Fly Ash on Glass-Fiber-Reinforced Polyamide 6 Properties. Polymers 2025, 17, 1950. https://doi.org/10.3390/polym17141950

Teodorescu G-M, Vuluga Z, Fistoș T, Slămnoiu-Teodorescu S, Paceagiu J, Nicolae C-A, Gabor AR, Ghiurea M, Gîfu C, Ion RM. The Effect of Bio-Based Polyamide 10.10 and Treated Fly Ash on Glass-Fiber-Reinforced Polyamide 6 Properties. Polymers. 2025; 17(14):1950. https://doi.org/10.3390/polym17141950

Chicago/Turabian StyleTeodorescu, George-Mihail, Zina Vuluga, Toma Fistoș, Sofia Slămnoiu-Teodorescu, Jenica Paceagiu, Cristian-Andi Nicolae, Augusta Raluca Gabor, Marius Ghiurea, Cătălina Gîfu, and Rodica Mariana Ion. 2025. "The Effect of Bio-Based Polyamide 10.10 and Treated Fly Ash on Glass-Fiber-Reinforced Polyamide 6 Properties" Polymers 17, no. 14: 1950. https://doi.org/10.3390/polym17141950

APA StyleTeodorescu, G.-M., Vuluga, Z., Fistoș, T., Slămnoiu-Teodorescu, S., Paceagiu, J., Nicolae, C.-A., Gabor, A. R., Ghiurea, M., Gîfu, C., & Ion, R. M. (2025). The Effect of Bio-Based Polyamide 10.10 and Treated Fly Ash on Glass-Fiber-Reinforced Polyamide 6 Properties. Polymers, 17(14), 1950. https://doi.org/10.3390/polym17141950