The Influence of the Dispersion and Covalent Functionalization of CNTs on Electrical Conduction Under an Electric Field in LDPE/CNT Composites

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of Composites

2.3. Material Characterization

2.4. Electrical Performance Characterizations

3. Results and Discussion

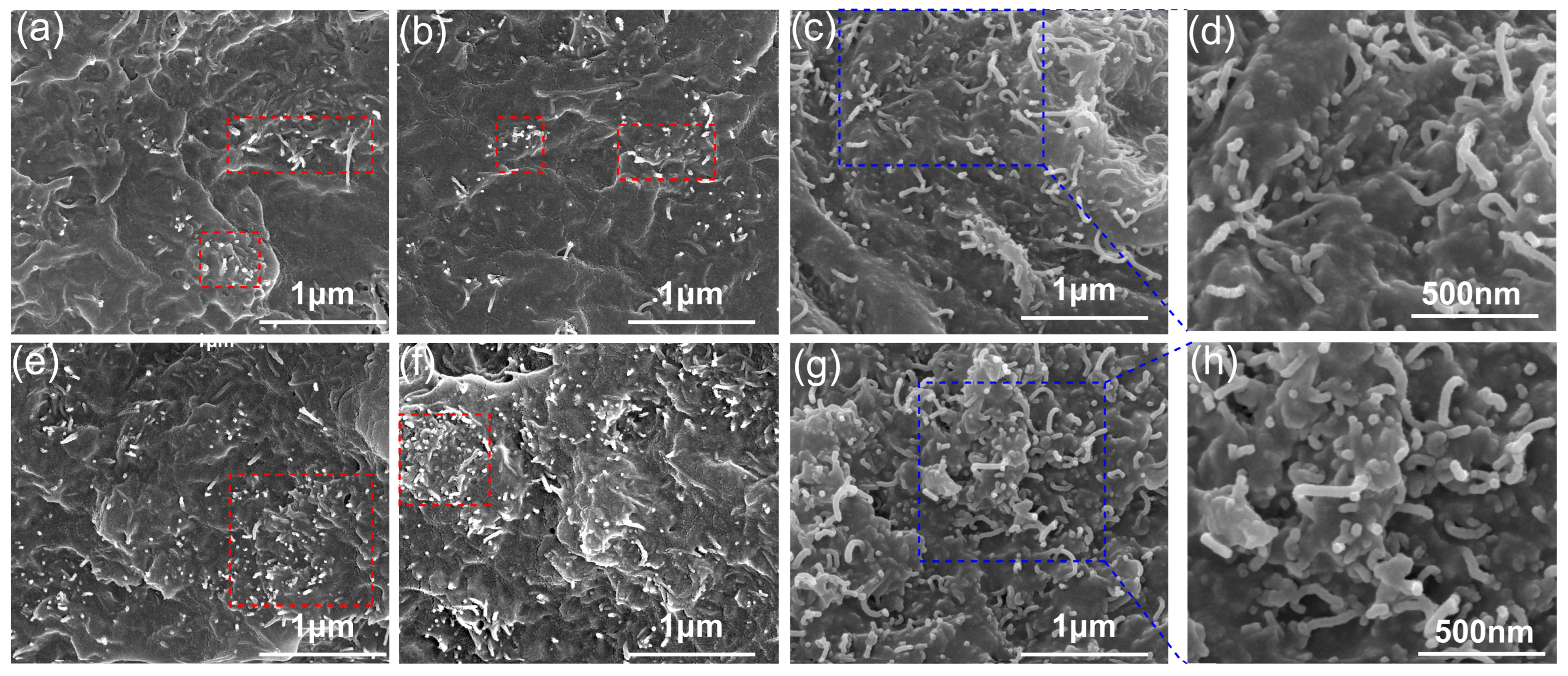

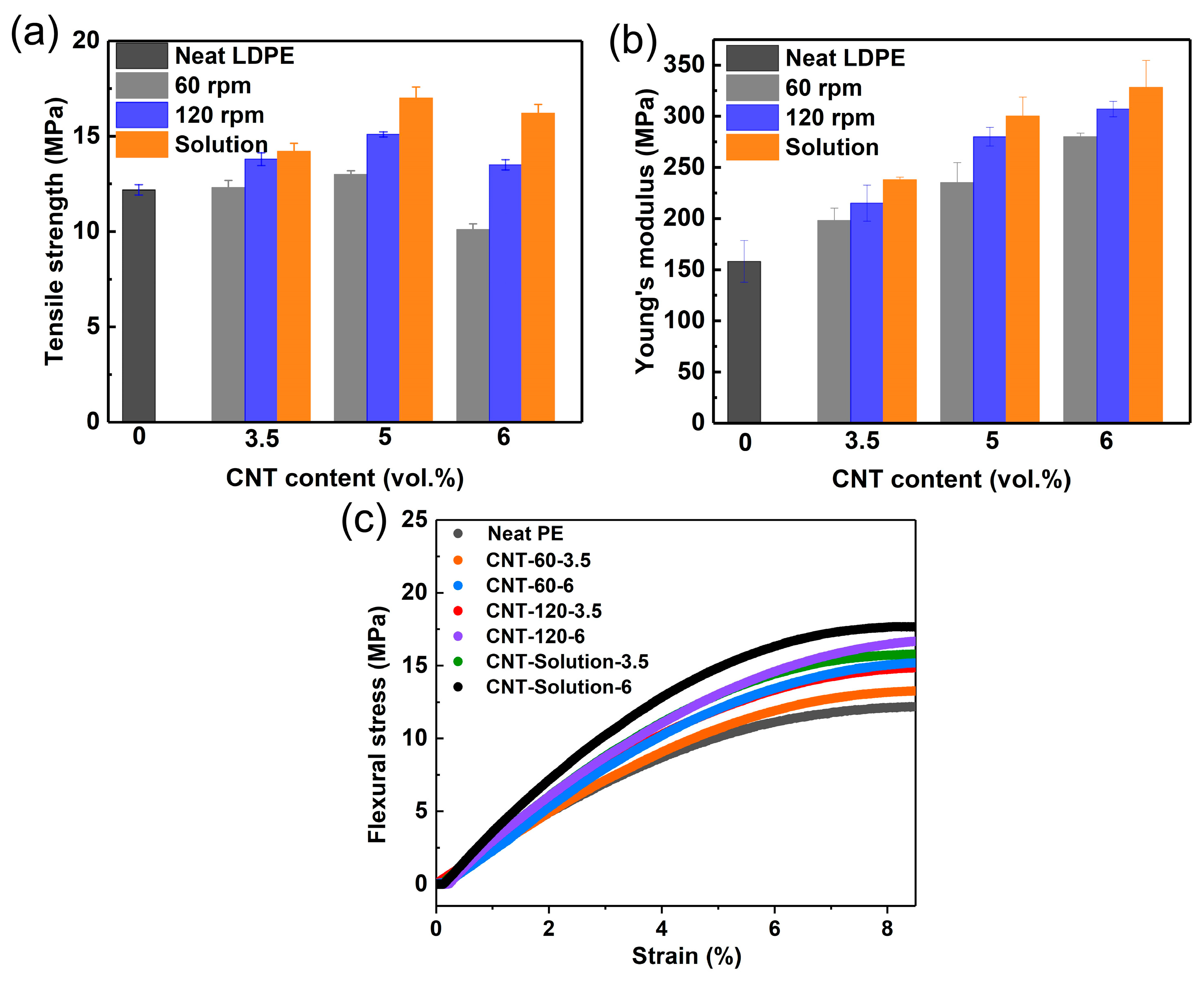

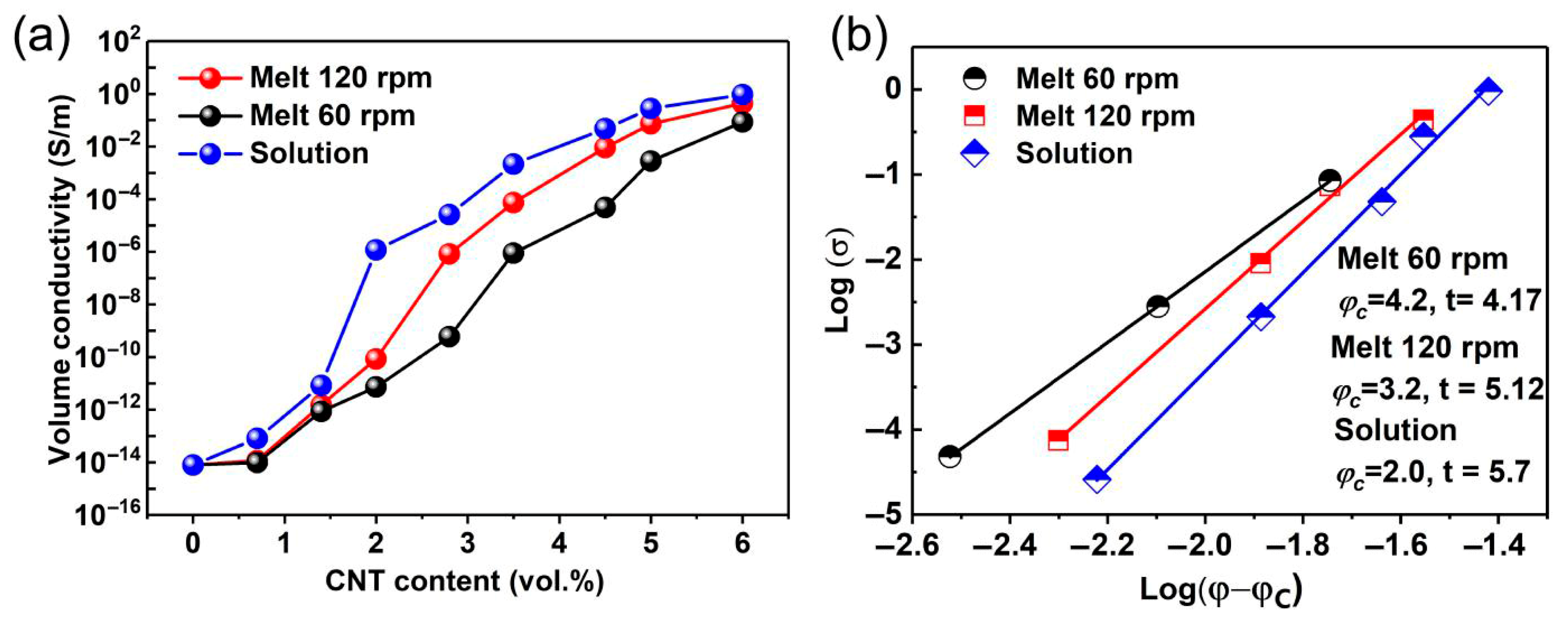

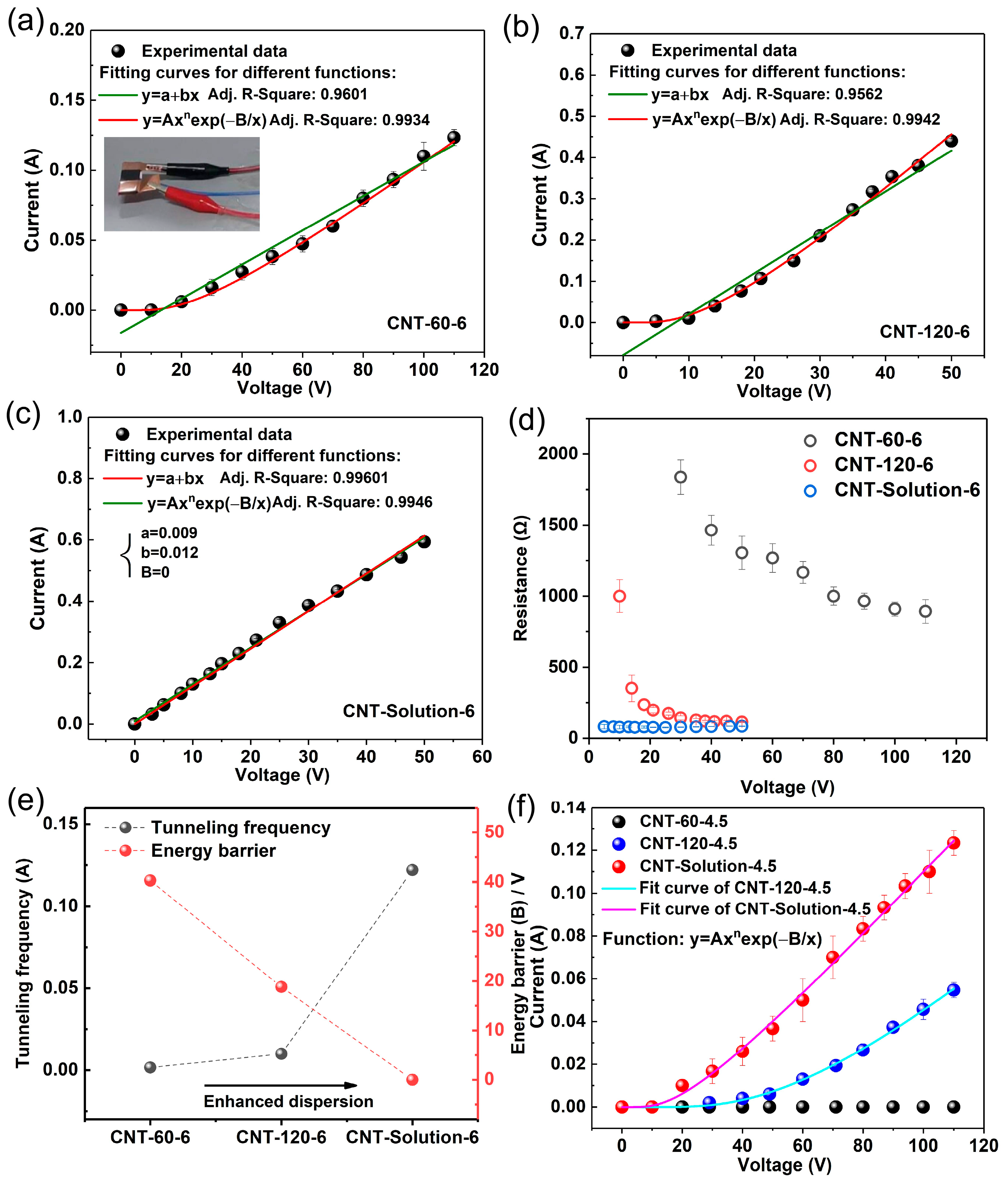

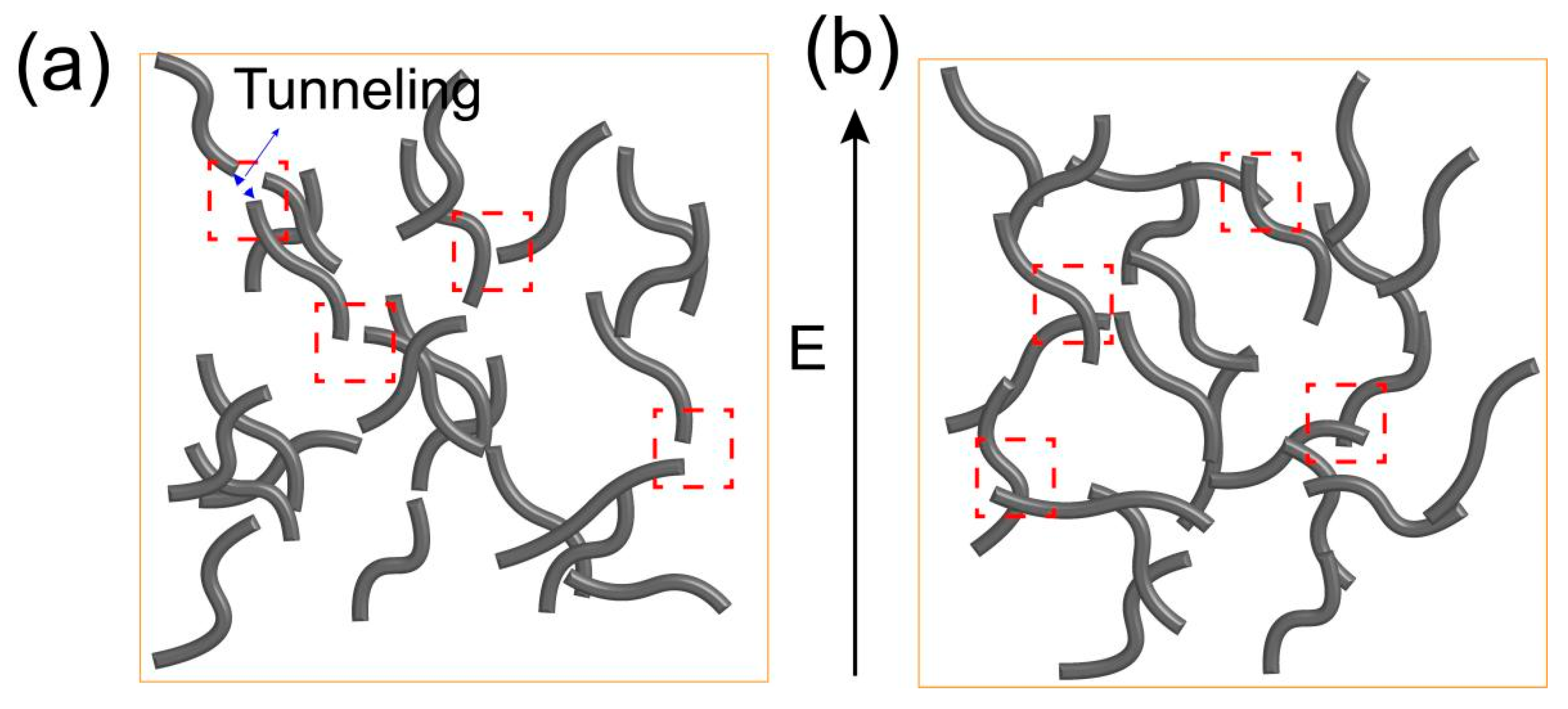

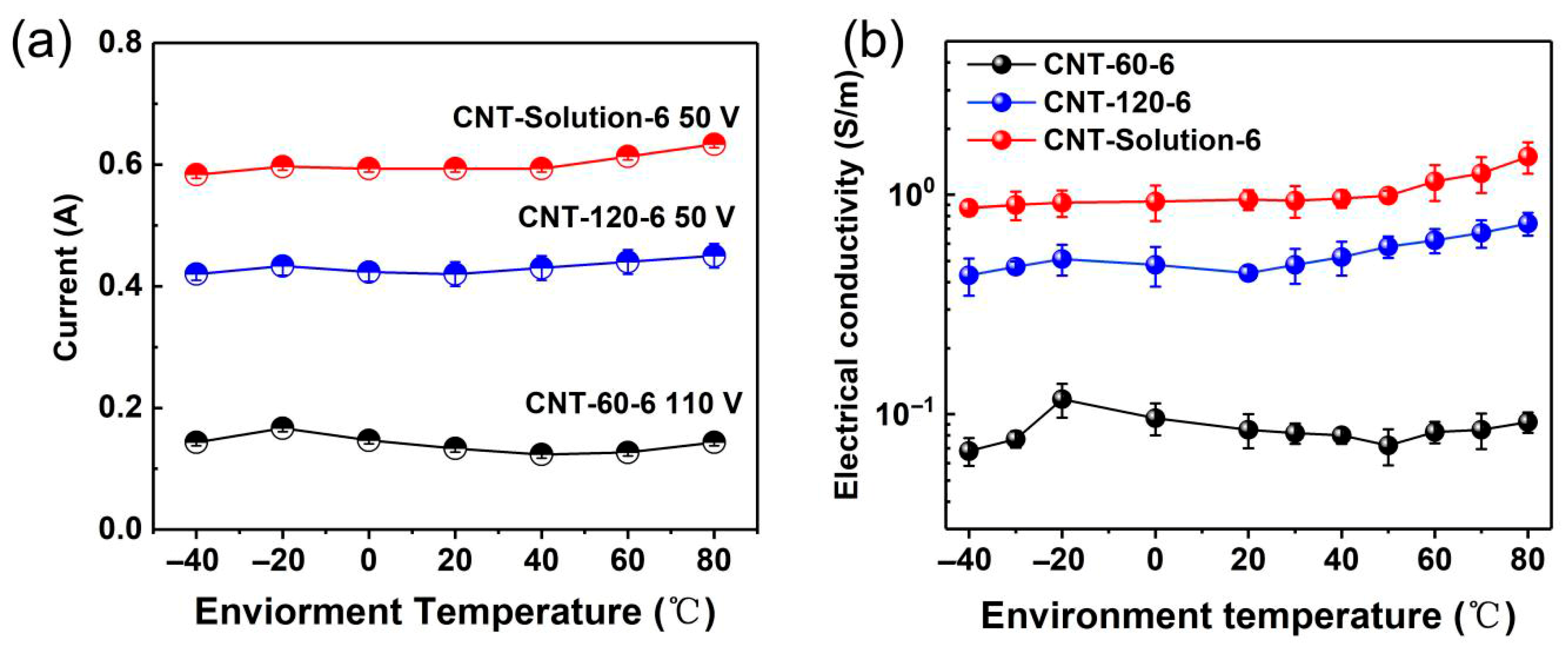

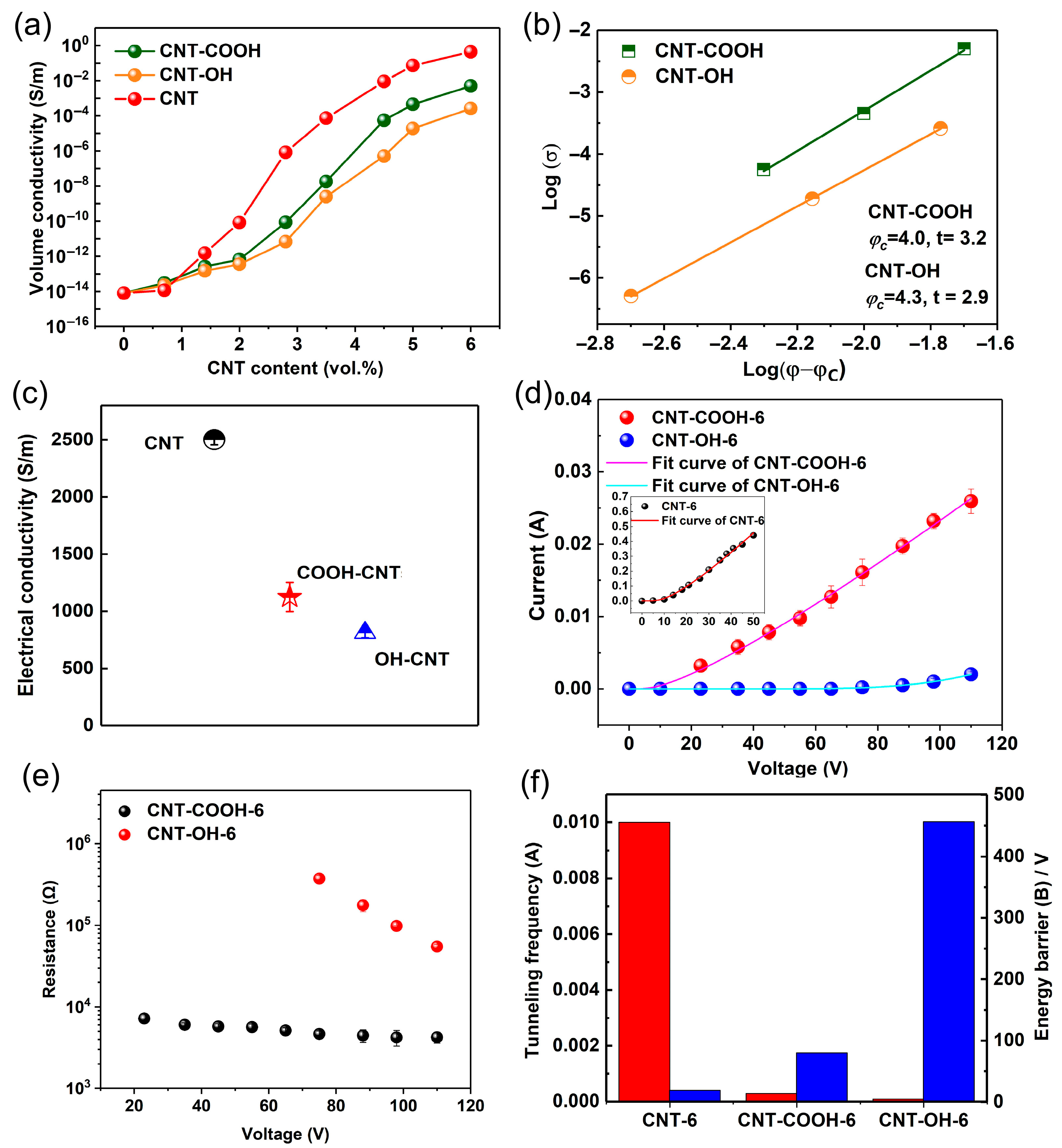

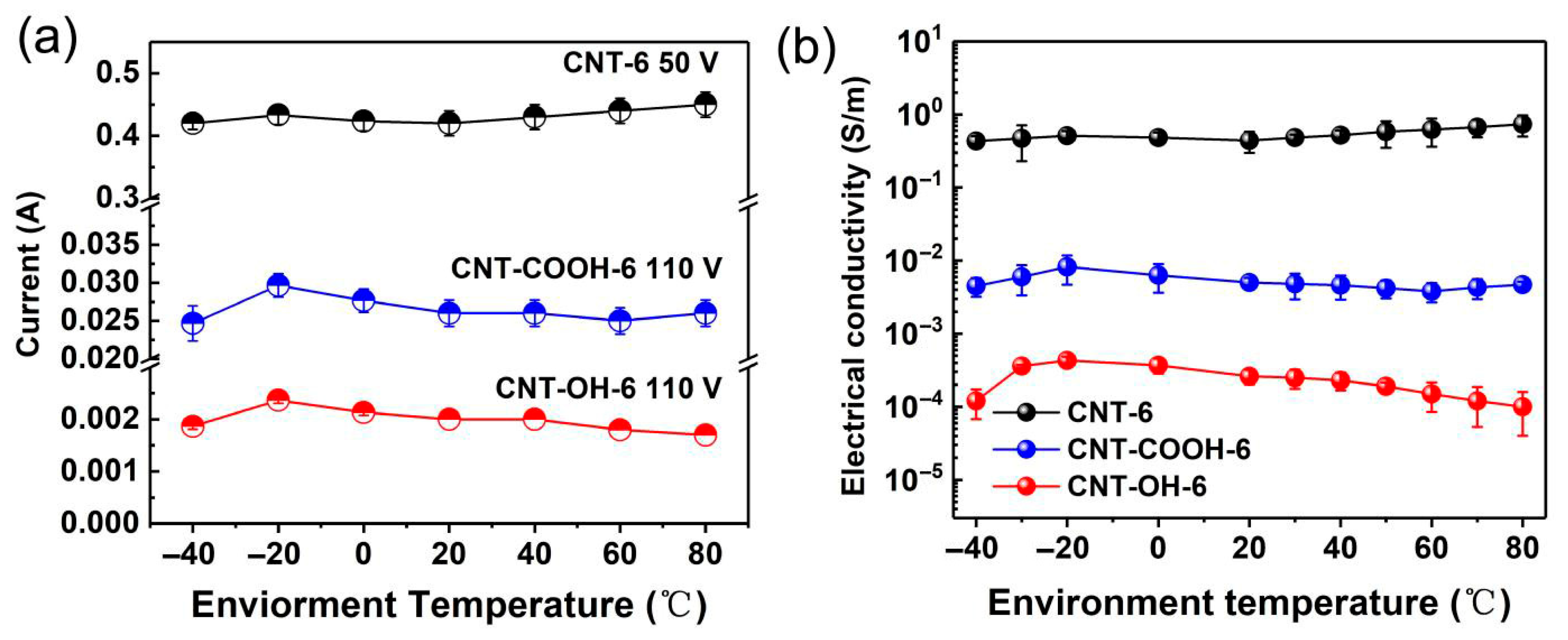

3.1. The Effect of CNT Dispersion on the Electrical Conduction Under an Electric Field for the LDPE/CNT Composites

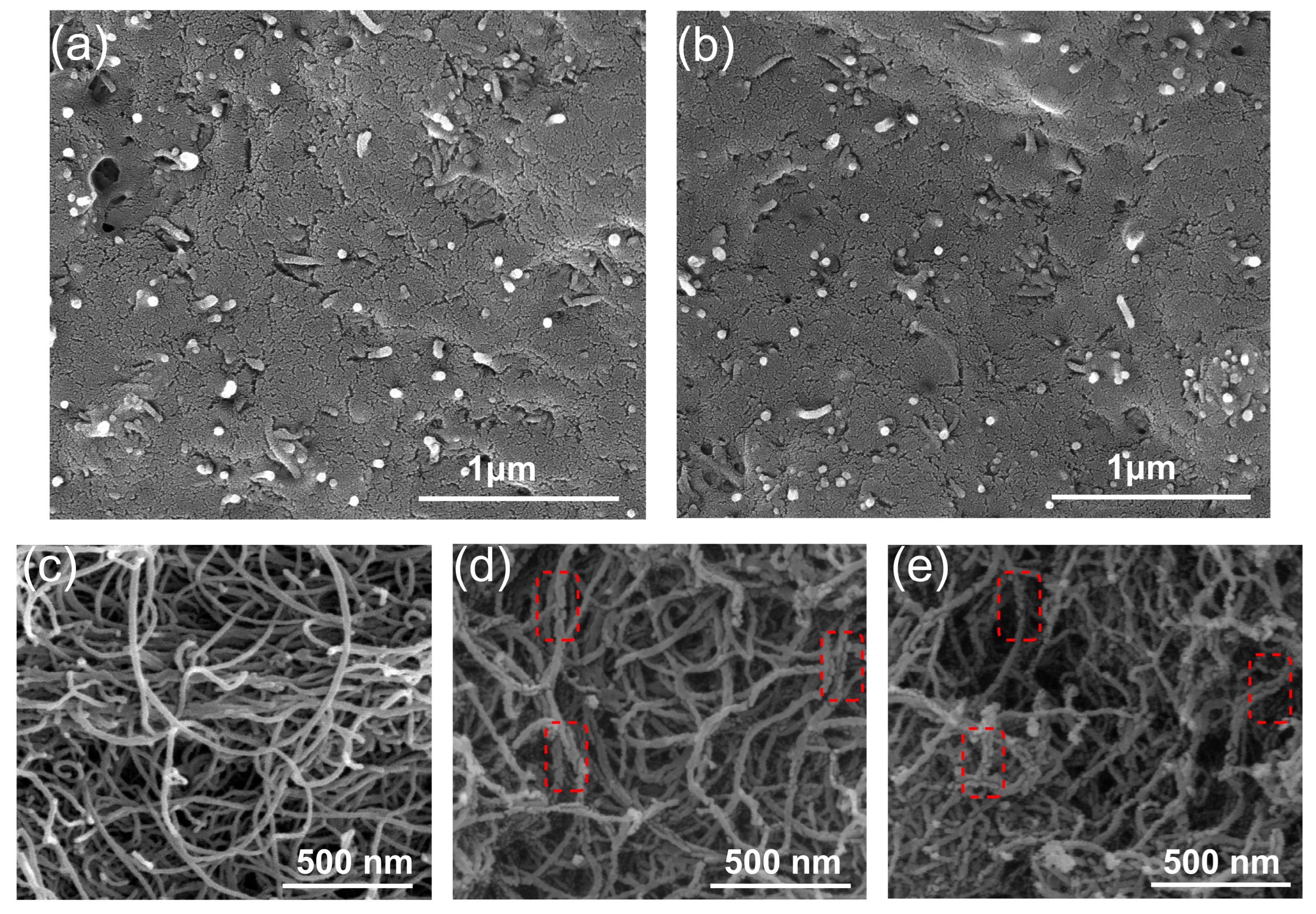

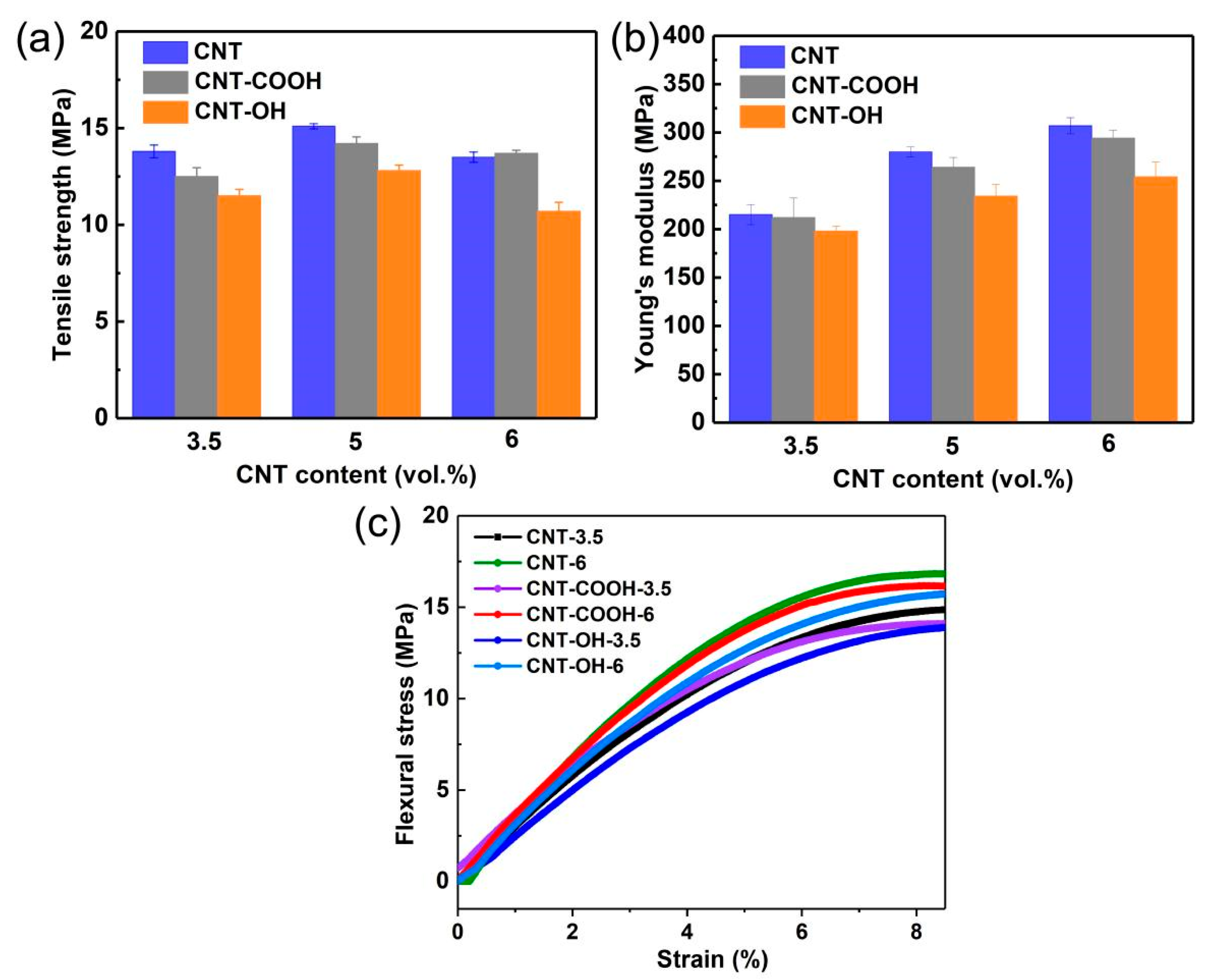

3.2. The Effect of Covalent Functionalization on the Dispersion of CNT and the Electrical Conduction Under an Electric Field for the LDPE/CNT Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Rathinavel, S.; Priyadharshini, K.; Panda, D. A review on carbon nanotube: An overview of synthesis, properties, functionalization, characterization, and the application. Mater. Sci. Eng. B 2021, 268, 115095. [Google Scholar] [CrossRef]

- Bhatia, R.; Kumari, K.; Rani, R.; Suri, A.; Pahuja, U.; Singh, D. A critical review of experimental results on low temperature charge transport in carbon nanotubes based composites. Rev. Phys. 2018, 3, 15–25. [Google Scholar] [CrossRef]

- Khan, T.; Irfan, M.S.; Ali, M.; Dong, Y.; Ramakrishna, S.; Umer, R. Insights to low electrical percolation thresholds of carbon-based polypropylene nanocomposites. Carbon 2021, 176, 602–631. [Google Scholar] [CrossRef]

- Soares, B.G.; Cordeiro, E.; Maia, J.; Pereira, E.; Silva, A. The effect of the noncovalent functionalization of CNT by ionic liquid on electrical conductivity and electromagnetic interference shielding effectiveness of semi-biodegradable polypropylene/poly(lactic acid) composites. Polym. Compos. 2019, 41, 82–93. [Google Scholar] [CrossRef]

- Thi, T.B.N.; Ata, S.; Morimoto, T.; Kato, Y.; Horibe, M.; Yamada, T.; Okazaki, T.; Hata, K. Annealing-induced enhancement of electrical conductivity and electromagnetic interference shielding in injection-molded CNT polymer composites. Polymer 2022, 245, 124680. [Google Scholar] [CrossRef]

- Zheng, B.; Wang, H.; Wu, X.; Yang, K.; Yu, Y.; Cui, H.; Gao, F.; Qian, K.; Yao, H.; Li, J.; et al. Flexible nanocomposite electrothermal films based on carbon nanotubes and waterborne polyurethane with high reliability, stretchability and low-temperature performance for wind turbine blade deicing. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106979. [Google Scholar] [CrossRef]

- Yadav, R.; Tirumali, M.; Wang, X.; Naebe, M.; Kandasubramanian, B. Polymer composite for antistatic application in aerospace. Def. Technol. 2020, 16, 107–118. [Google Scholar] [CrossRef]

- Tian, Y.; Zhong, J.; Hu, L.; Zheng, X.; Cheng, J.; Pu, Z. Preparation of carbon nanotubes/polyethersulfone antistatic composite materials by a mixing process. Polym. Compos. 2019, 41, 556–563. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Siddiqui, N.A.; Li, E.L.; Sham, M.L.; Tang, B.Z.; Munir, A.; Kim, J.K. Tensile strength of glass fibres with carbon nanotube–epoxy nanocomposite coating: Effects of CNT morphology and dispersion state. Compos. Part A Appl. Sci. Manuf. 2010, 41, 539–548. [Google Scholar] [CrossRef]

- Xu, H.; Gong, L.X.; Wang, X.; Zhao, L.; Pei, Y.B.; Wang, G.; Liu, Y.J.; Wu, L.B.; Jiang, J.X.; Tang, L.C. Influence of processing conditions on dispersion, electrical and mechanical properties of graphene-filled-silicone rubber composites. Compos. Part A Appl. Sci. Manuf. 2016, 91, 53–64. [Google Scholar] [CrossRef]

- Pötschke, P.; Villmow, T.; Krause, B. Melt mixed PCL/MWCNT composites prepared at different rotation speeds: Characterization of rheological, thermal, and electrical properties, molecular weight, MWCNT macrodispersion, and MWCNT length distribution. Polymer 2013, 54, 3071–3078. [Google Scholar] [CrossRef]

- Bai, J.B.; Allaoui, A. Effect of the length and the aggregate size of MWNTs on the improvement efficiency of the mechanical and electrical properties of nanocomposites-experimental investigation. Compos. Part A Appl. Sci. Manuf. 2003, 34, 689–694. [Google Scholar] [CrossRef]

- Zhang, W.; Dehghani-Sanij, A.A.; Blackburn, R.S. Carbon based conductive polymer composites. J. Mater. Sci. 2007, 42, 3408–3418. [Google Scholar] [CrossRef]

- Sui, G.; Liu, D.; Liu, Y.; Ji, W.; Zhang, Q.; Fu, Q. The dispersion of CNT in TPU matrix with different preparation methods: Solution mixing vs melt mixing. Polymer 2019, 182, 121838. [Google Scholar] [CrossRef]

- Faraguna, F.; Pötschke, P.; Pionteck, J. Preparation of polystyrene nanocomposites with functionalized carbon nanotubes by melt and solution mixing: Investigation of dispersion, melt rheology, electrical and thermal properties. Polymer 2017, 132, 325–341. [Google Scholar] [CrossRef]

- Liu, C.H.; Fan, S.S. Nonlinear electrical conducting behavior of carbon nanotube networks in silicone elastomer. Appl. Phys. Lett. 2007, 90, 041905. [Google Scholar] [CrossRef]

- Lin, H.; Lu, W.; Chen, G. Nonlinear DC conduction behavior in epoxy resin/graphite nanosheets composites. Phys. Rev. B Condens. 2007, 400, 229–236. [Google Scholar] [CrossRef]

- Bardhan, K.K. Nonlinear conduction in composites above percolation threshold-beyond the backbone. Phys. A Stat. Mech. Its Appl. 1997, 241, 267–277. [Google Scholar] [CrossRef]

- Lu, W.; Wu, D.; Wu, C.; Chen, G. Nonlinear DC response in high-density polyethylene/graphite nanosheets composites. J. Mater. Sci. 2006, 41, 1785–1790. [Google Scholar] [CrossRef]

- Kenkel, S.W.; Straley, J.P. Percolation theory of nonlinear circuit elements. Phys. Rev. Lett. 1982, 49, 767–770. [Google Scholar] [CrossRef]

- Zheng, Q.; Song, Y.; Wu, G.; Yi, X. Reversible Nonlinear Conduction Behavior for High-Density Polyethylene/Graphite Powder Composites near the Percolation Threshold. J. Polym. Sci. Part B 2001, 39, 2833–2842. [Google Scholar] [CrossRef]

- He, L.; Tjiong, S.C. Nonlinear electrical conduction in percolating systems induced by internal field emission. Synth. Met. 2011, 161, 540–543. [Google Scholar] [CrossRef]

- Liu, X.L.; Li, M.; Geng, W.H.; Cao, W.; Tian, Y.H.; Li, T.Y.; Bin, P.S.; Qian, P.F.; Geng, H.Z. Modified carbon nanotubes/polyvinyl alcohol composite electrothermal films. Surf. Interfaces 2023, 36, 102540. [Google Scholar] [CrossRef]

- Yanmaz, E.; Doğan, M.; Turhan, Y. Effect of sodium dodecyl sulfate on thermal properties of polyvinyl alcohol (PVA)/modified single-walled carbon nanotube (SWCNT) nanocomposites. Diam. Relat. Mater. 2021, 115, 108359. [Google Scholar] [CrossRef]

- Barick, A.K.; Tripathy, D.K. Preparation, characterization and properties of acid functionalized multi-walled carbon nanotube reinforced thermoplastic polyurethane nanocomposites. Mater. Sci. Eng. B 2011, 176, 1435–1447. [Google Scholar] [CrossRef]

- Wongtimnoi, K.; Guiffard, B.; Moortèle, A.; Seveyrat, L.; Cavaillé, J.Y. Electrostrictive thermoplastic polyurethane-based nanocomposites filled with carboxyl-functionalized multi-walled carbon nanotubes (MWCNT-COOH): Properties and improvement of electromechanical activity. Compos. Sci. Technol. 2013, 85, 23–28. [Google Scholar] [CrossRef]

- Trinh, P.V.; Anh, N.N.; Tam, N.T.; Hong, N.T.; Hong, P.N.; Minh, P.N.; Thang, B.H. Influence of defects induced by chemical treatment on the electrical and thermal conductivity of nanofluids containing carboxyl-functionalized multi-walled carbon nanotubes. RSC Adv. 2017, 7, 49937–49946. [Google Scholar] [CrossRef]

- Guadagno, L.; De Vivo, B.; Di Bartolomeo, A.; Lamberti, P.; Sorrentino, A.; Tucci, V.; Vertuccio, L.; Vittoria, V. Effect of functionalization on the thermo-mechanical and electrical behavior of multi-wall carbon nanotube/epoxy composites. Carbon 2011, 49, 1919–1930. [Google Scholar] [CrossRef]

- Hay, J.N.; Zhou, X.Q. The effect of mixing on the properties of polyethylene blends. Polymer 1993, 34, 2282–2288. [Google Scholar] [CrossRef]

- Aljoumaa, K.; Ajji, Z. Mechanical and electrical properties of gamma-irradiated silane crosslinked polyethylene (Si-XLPE). J. Radioanal. Nucl. Chem. 2015, 307, 1391–1399. [Google Scholar] [CrossRef]

- Wang, Y.; Weng, G.J.; Meguid, S.A.; Hamouda, A.M. A continuum model with a percolation threshold and tunneling-assisted interfacial conductivity for carbon nanotube-based nanocomposites. J. Appl. Phys 2014, 115, 193706. [Google Scholar] [CrossRef]

- Souri, H.; Yu, J.; Jeon, H.; Kim, J.W.; Yang, C.-M.; You, N.-H.; Yang, B.J. A theoretical study on the piezoresistive response of carbon nanotubes embedded in polymer nanocomposites in an elastic region. Carbon 2017, 120, 427–437. [Google Scholar] [CrossRef]

- Gao, L.; Li, Z. Effective medium approximation for two-component nonlinear composites with shape distribution. J. Phys. Condens. Matter 2003, 15, 4397. [Google Scholar] [CrossRef]

- Hashemi, R.; Weng, G.J. A theoretical treatment of graphene nanocomposites with percolation threshold, tunneling-assisted conductivity and microcapacitor effect in AC and DC electrical settings. Carbon 2016, 96, 474–490. [Google Scholar] [CrossRef]

- Pan, Y.; Weng, G.J.; Meguid, S.A.; Bao, W.S.; Zhu, Z.H.; Hamouda, A.M.S. Percolation threshold and electrical conductivity of a two-phase composite containing randomly oriented ellipsoidal inclusions. J. Appl. Phys. 2011, 110, 123715. [Google Scholar] [CrossRef]

- Li, W.; Liu, Z.Y.; Yang, M.B. Preparation of carbon black/polypropylene nanocomposite with low percolation threshold using mild blending method. J. Appl. Polym. Sci. 2009, 115, 2629–2634. [Google Scholar] [CrossRef]

- Tanabi, H.; Erdal, M. Effect of CNTs dispersion on electrical, mechanical and strain sensing properties of CNT/epoxy nanocomposites. Results Phys. 2019, 12, 486–503. [Google Scholar] [CrossRef]

- Guo, W.; Liu, C.; Sun, X.; Yang, Z.; Kia, H.G.; Peng, H. Aligned carbon nanotube/polymer composite fibers with improved mechanical strength and electrical conductivity. J. Mater. Chem. 2012, 22, 903–908. [Google Scholar] [CrossRef]

- Russ, M.; Rahatekar, S.S.; Koziol, K.; Farmer, B.; Peng, H.X. Length-dependent electrical and thermal properties of carbon nanotube-loaded epoxy nanocomposites. Compos. Sci. Technol. 2013, 81, 42–47. [Google Scholar] [CrossRef]

- Gao, J.F.; Li, Z.M.; Meng, Q.J.; Yang, Q. CNTs/ UHMWPE composites with a two-dimensional conductive network. Mater. Lett. 2008, 62, 3530–3532. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 6, 1486–1498. [Google Scholar] [CrossRef]

- Vionnet-Menot, S.; Grimaldi, C.; Maeder, T.; Strassler, S.; Ryser, P. Tunnelingpercolation origin of nonuniversality: Theory and experiments. Phys. Rev. B (Condens. Matter Mater. Phys.) 2005, 71, 064201. [Google Scholar] [CrossRef]

- Feng, C.P.; Wan, S.S.; Wu, W.C.; Bai, L.; Bao, R.Y.; Liu, Z.Y.; Yang, M.B.; Chen, J.; Yang, W. Electrically insulating, layer structured SiR/GNPs/BN thermal management materials with enhanced thermal conductivity and breakdown voltage. Compos. Sci. Technol. 2018, 167, 456–462. [Google Scholar] [CrossRef]

- Zener, C. A theory of the electrical breakdown of solid dielectrics. Proc. R. Soc. Lond. A 1934, 145, 523–529. [Google Scholar] [CrossRef]

- Franz, W. Handbook der Physik; Springer: Berlin/Heidelberg, Germany, 1956. [Google Scholar]

- Beek, L.K.H.V.; Pu, B.I.C.F.V. Internal field emission in carbon black-loaded natural rubber vulcanizates. Rubber Chem. Technol. 1964, 37, 348–354. [Google Scholar] [CrossRef]

- He, L.; Tjiong, S.C. Electrical behavior and positive temperature coefficient effect of graphene/polyvinylidene fluoride composites containing silver nanowires. Nanoscale Res. Lett. 2014, 9, 375. [Google Scholar] [CrossRef]

- Muchharla, B.; Narayanan, T.N.; Balakrishnan, K.; Ajayan, P.M.; Talapatra, S. Temperature dependent electrical transport of disordered reduced graphene oxide. 2D Mater. 2014, 1, 011008. [Google Scholar] [CrossRef]

- Shen, J.T.; Buschhorn, S.T.; Hosson, J.T.M.D.; Schulte, K.; Fiedler, B. Pressure and temperature induced electrical resistance change in nano-carbon/epoxy composites. Compos. Sci. Technol. 2015, 115, 1–8. [Google Scholar] [CrossRef]

- Trushin, M. Thermally activated conductivity in gapped bilayer graphene. Europhys. Lett. 2012, 98, 47007. [Google Scholar] [CrossRef][Green Version]

- Eda, G.; Mattevi, C.; Yamaguchi, H.; Kim, H.; Chhowalla, M. Insulator to Semimetal Transition in Graphene Oxide. J. Phys. Chem. C 2009, 35, 15768–15771. [Google Scholar] [CrossRef]

- Rajendran, D.; Bautista-Quijano, J.R.; Bouhamed, A.; Kanoun, O. Influence of Carbon nanotubes (CNT) Functionalization on CNT/PDMS Nanocomposite Pressure Sensor. In Proceedings of the 2019 5th International Conference on NanoflM, Sfax, Tunisia, 30–31 October 2019. [Google Scholar] [CrossRef]

- Disfani, M.N.; Jafari, S.H. Assessment of intertube interactions in different functionalized multiwalled carbon nanotubes incorporated in a phenoxy resin. Polym. Eng. Sci. 2013, 53, 168–175. [Google Scholar] [CrossRef]

- Li, Z.I.; Lou, C.W.; Pan, Y.J.; Hsieh, C.T.; Huang, C.L.; Huang, C.H.; Chen, Y.S.; Lin, J.H. The effects of MWCNT length on the mechanical, crystallization and electromagnetic interference shielding effectiveness of PP/MWCNT composites. J. Polym. Res. 2017, 24, 32. [Google Scholar] [CrossRef]

| Specimens | A | B | n | Adj. R-Square |

|---|---|---|---|---|

| CNT-120-4.5 | 0.00141 | 113.86 | 1.05 | 0.9964 |

| CNT-Solution-4.5 | 0.00161 | 31.68 | 1.08 | 0.9977 |

| CNT-60-6 | 0.00158 | 40.33 | 1.06 | 0.9934 |

| CNT-120-6 | 0.010 | 18.79 | 1.09 | 0.9942 |

| CNT-Solution-6 | 0.122 | 0 | — | 0.9946 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Yin, T.; Yang, Y.; Liu, W.; Wang, D.; Wan, L.; Liao, Y. The Influence of the Dispersion and Covalent Functionalization of CNTs on Electrical Conduction Under an Electric Field in LDPE/CNT Composites. Polymers 2025, 17, 1940. https://doi.org/10.3390/polym17141940

Wu X, Yin T, Yang Y, Liu W, Wang D, Wan L, Liao Y. The Influence of the Dispersion and Covalent Functionalization of CNTs on Electrical Conduction Under an Electric Field in LDPE/CNT Composites. Polymers. 2025; 17(14):1940. https://doi.org/10.3390/polym17141940

Chicago/Turabian StyleWu, Xiaoli, Ting Yin, Yi Yang, Wenyan Liu, Danping Wang, Libo Wan, and Yijun Liao. 2025. "The Influence of the Dispersion and Covalent Functionalization of CNTs on Electrical Conduction Under an Electric Field in LDPE/CNT Composites" Polymers 17, no. 14: 1940. https://doi.org/10.3390/polym17141940

APA StyleWu, X., Yin, T., Yang, Y., Liu, W., Wang, D., Wan, L., & Liao, Y. (2025). The Influence of the Dispersion and Covalent Functionalization of CNTs on Electrical Conduction Under an Electric Field in LDPE/CNT Composites. Polymers, 17(14), 1940. https://doi.org/10.3390/polym17141940