The Improvement of Road Performance of Foam Asphalt Cold Recycled Mixture Based on Interface Modification

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

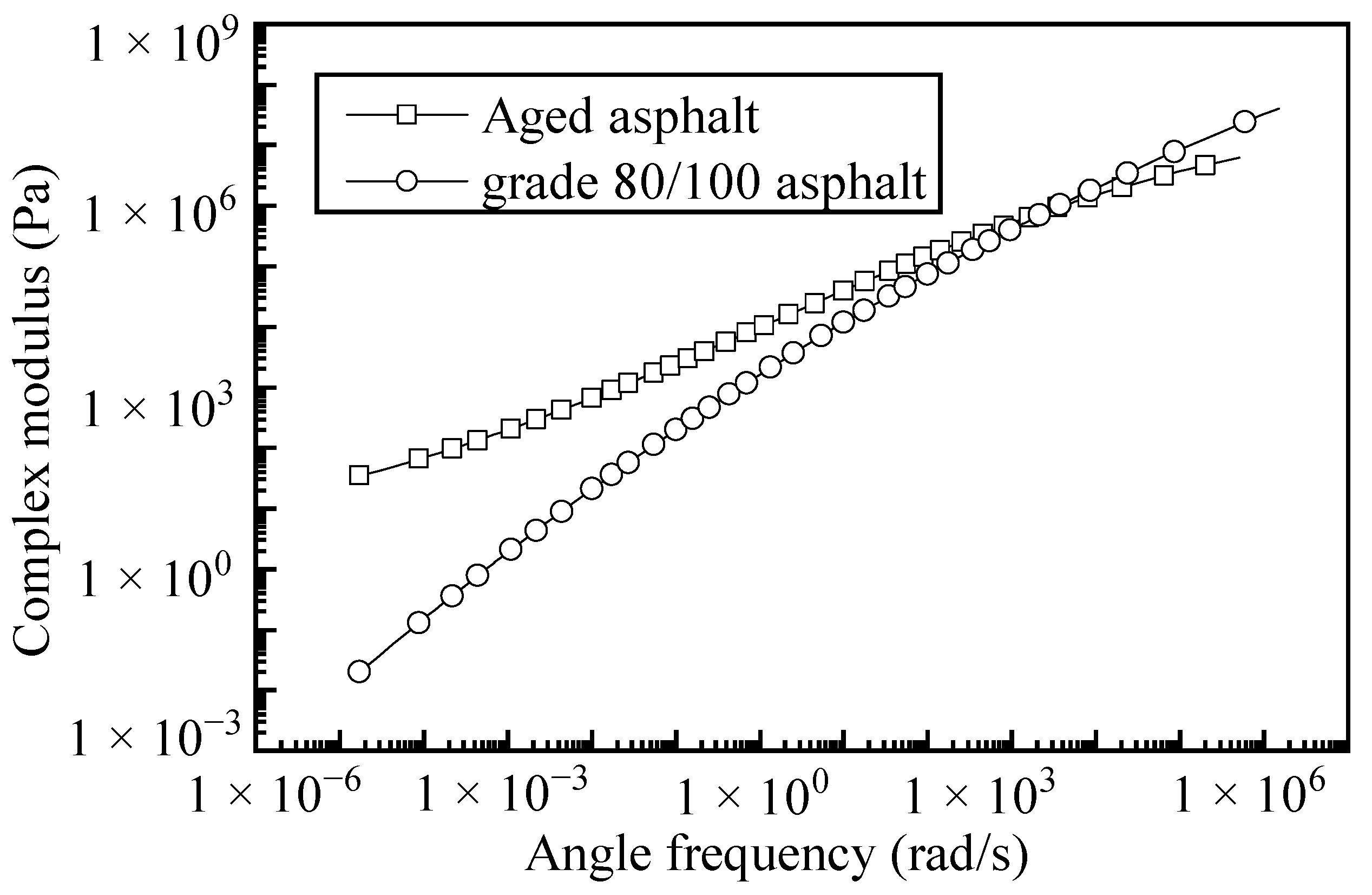

2.1.1. Foam Asphalt

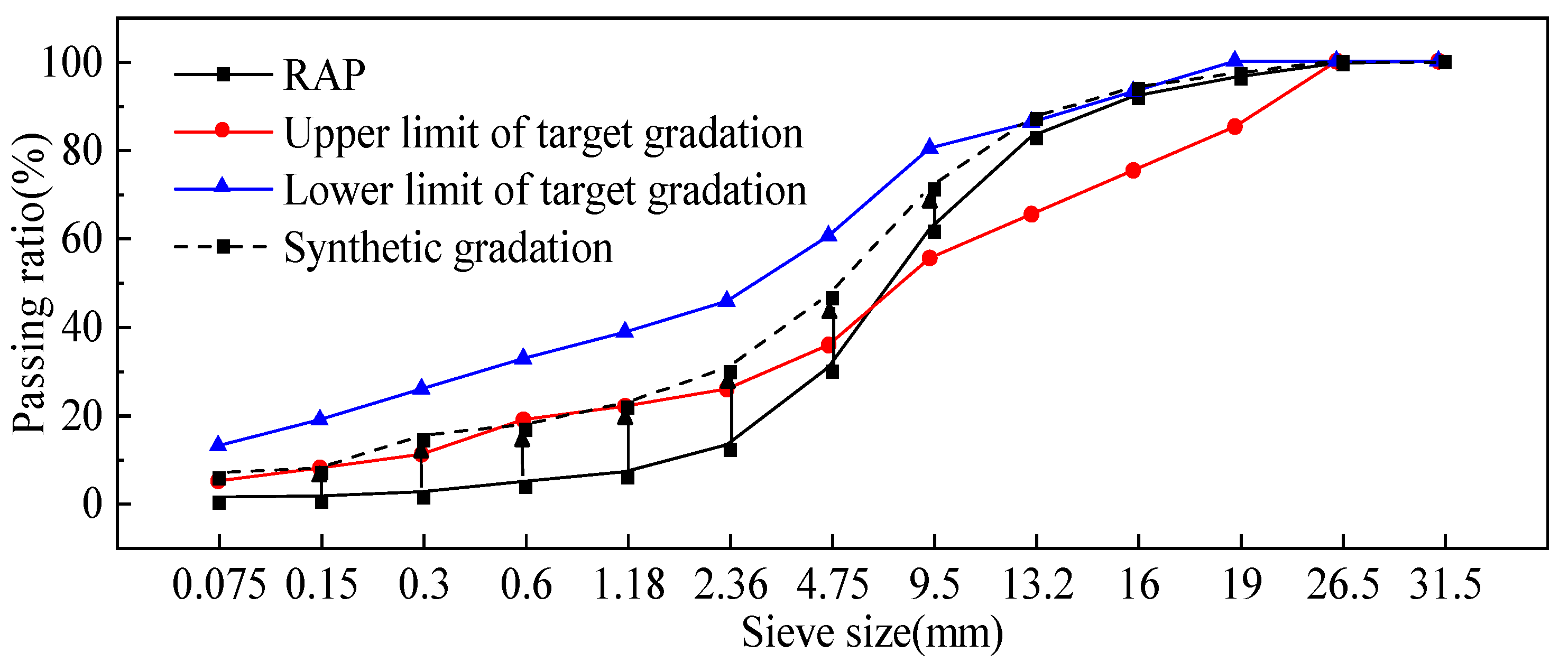

2.1.2. RAP

2.1.3. Modifiers

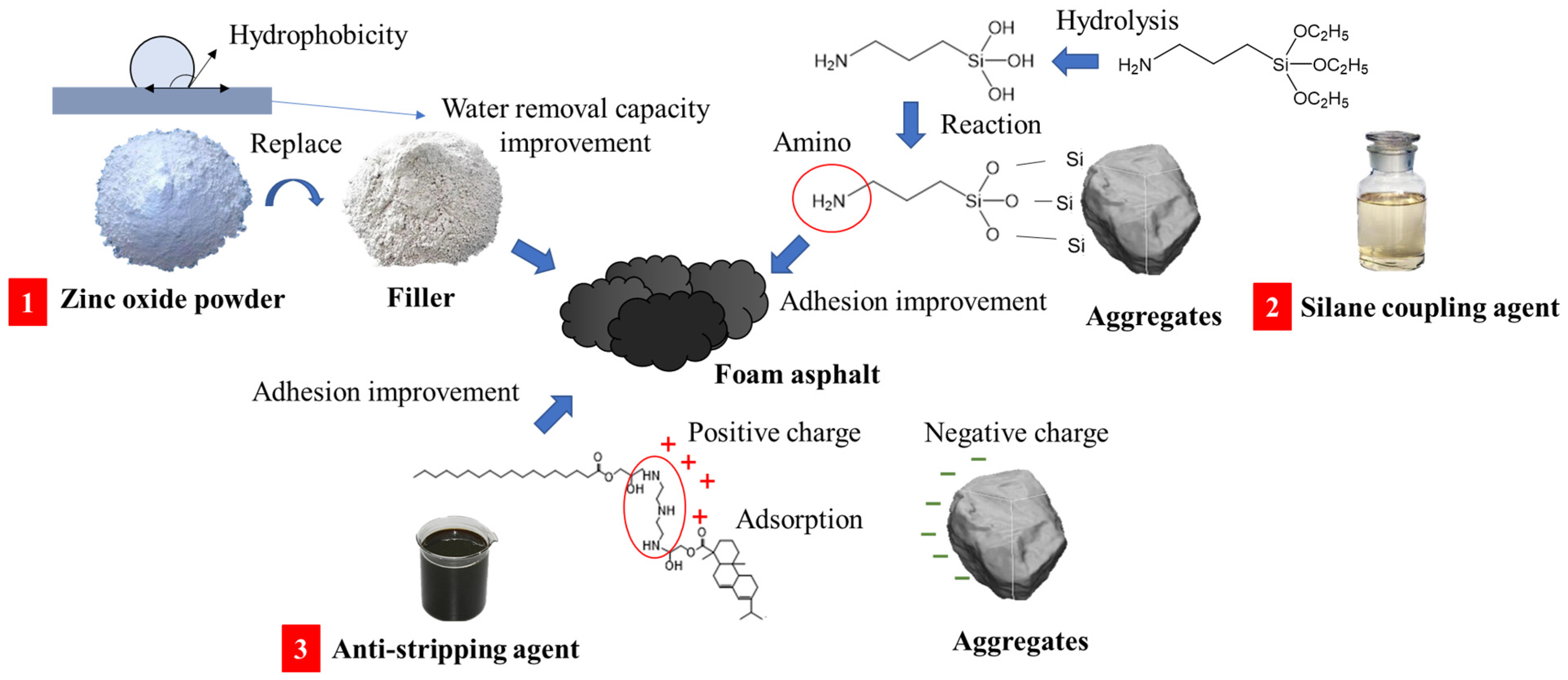

- Filler Replacement: Zinc oxide powder was used as a substitute for the mineral filler in the recycled asphalt mixture, with a replacement dosage of 5%. Replacing part of the mineral powder with zinc oxide powder improves the hydrophobicity of the asphalt mastic, which in turn enhances the water removal capacity of the entire foam asphalt mix [33].

- Surface Modification of RAP Material: A silane coupling agent–ethanol–water solution was applied to modify the surface of the RAP material. The solution dosage was 2% of the total aggregate mass, with a silane coupling agent–ethanol–water ratio of 1:5:10. While the coupling agent reacts chemically with the aggregate, its organic functional groups are very compatible with the asphalt, thus improving the bond strength between the aggregate and the asphalt [34].

- Foam Asphalt Modification: An amine-based anti-stripping agent was incorporated into the foam asphalt with a dosage of 0.3%. Anti-stripping agents contain alkaline groups and are soluble in asphalt. The polar cationic terminals are chemisorbed by ionic bonding with the aggregate surface, thus improving the bonding strength of the aggregate to the asphalt [35].

2.2. Preparation Methods

2.2.1. Mixing Ratio Design

2.2.2. Preparation Method

2.3. Performance Evaluation Methods

2.3.1. Basic Performance

- (1)

- Wet and dry ITS test

- (2)

- Semicircle bending test

- (3)

- Drying shrinkage test

2.3.2. Fatigue Test

- (1)

- Three-Point Bending Fatigue Test

- (2)

- Indirect Tensile Test

2.3.3. Dynamic Modulus Test

2.4. TOPSIS Analysis Method

3. Results and Discussion

3.1. Basic Performance

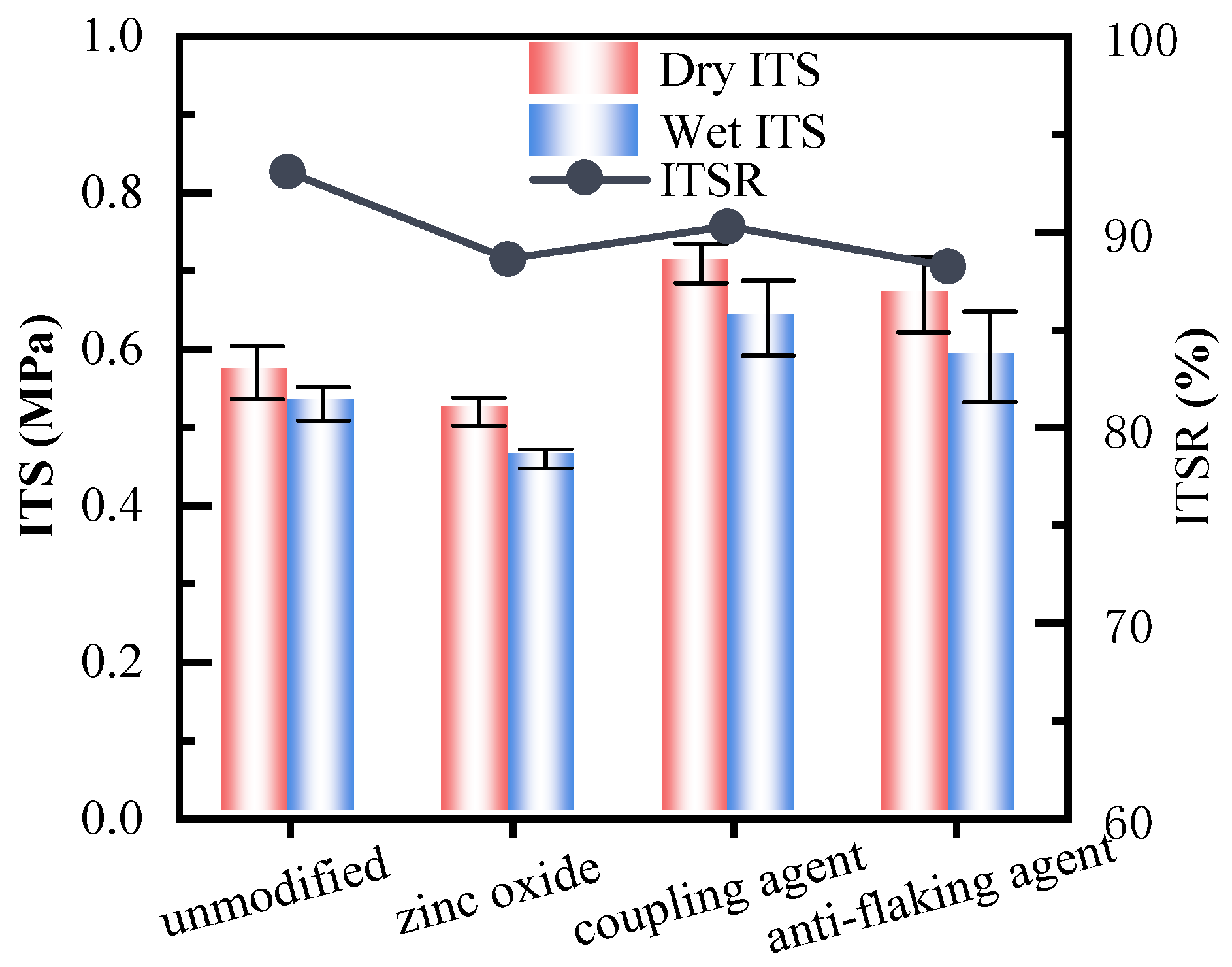

3.1.1. Wet and Dry ITS Test

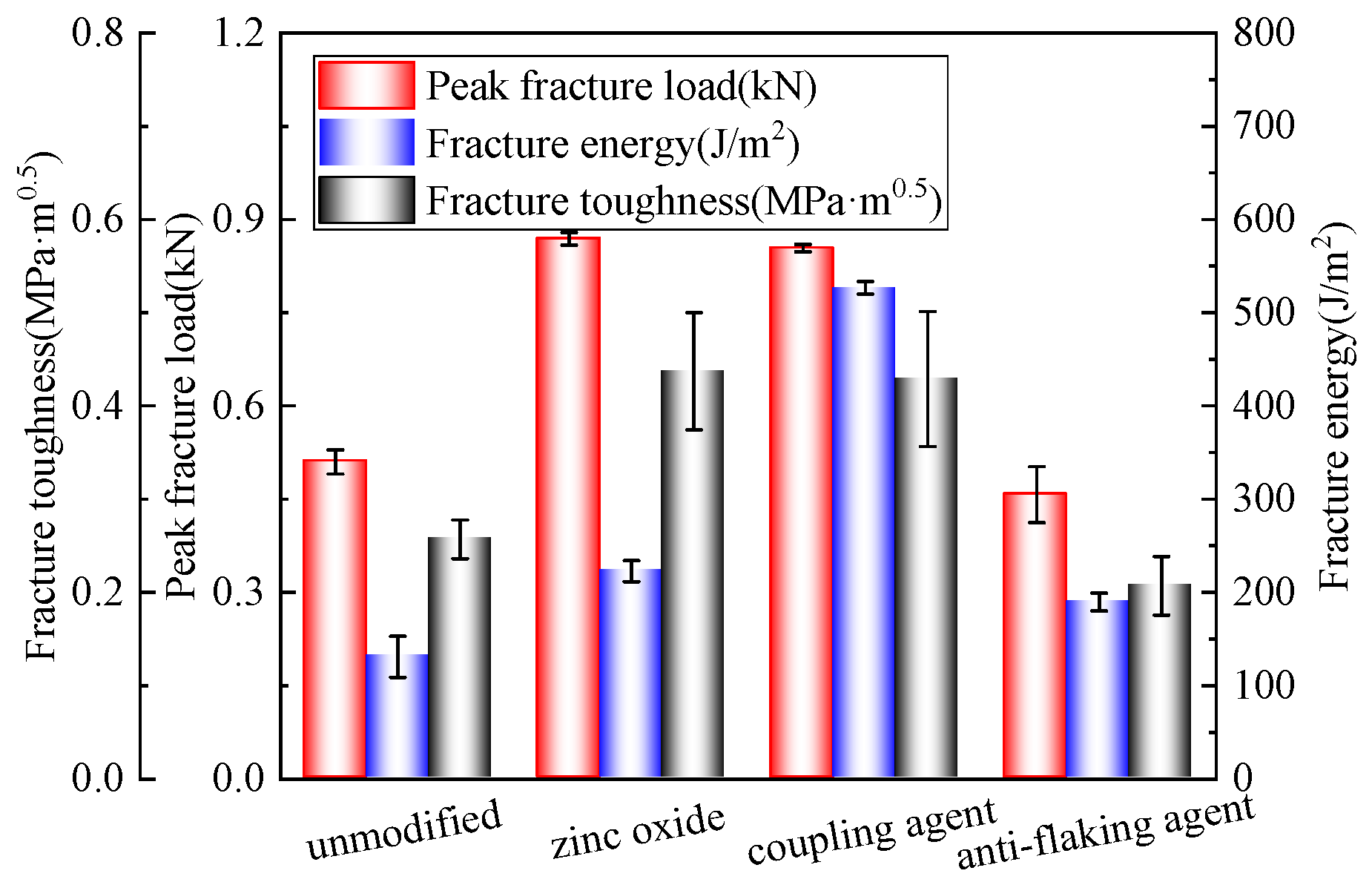

3.1.2. Semicircle Bending Test

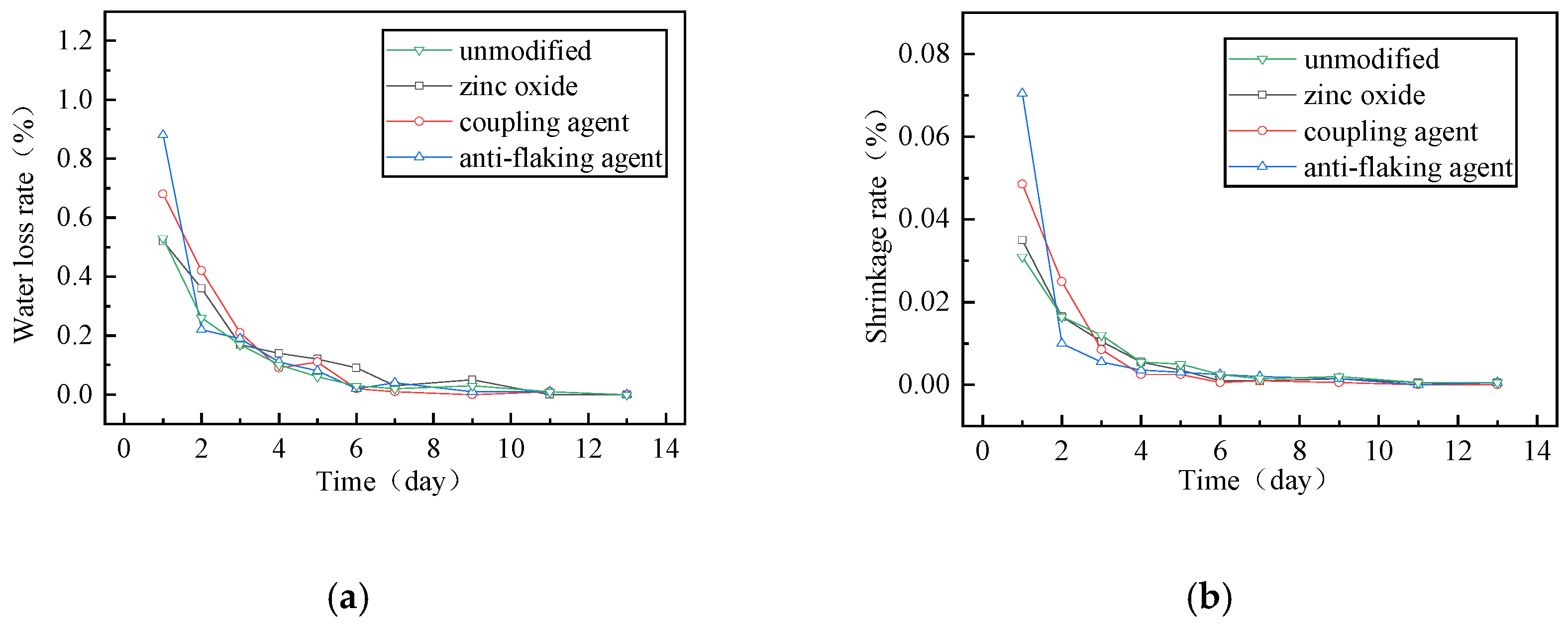

3.1.3. Dying Shrinkage Test

3.2. Fatigue Performance

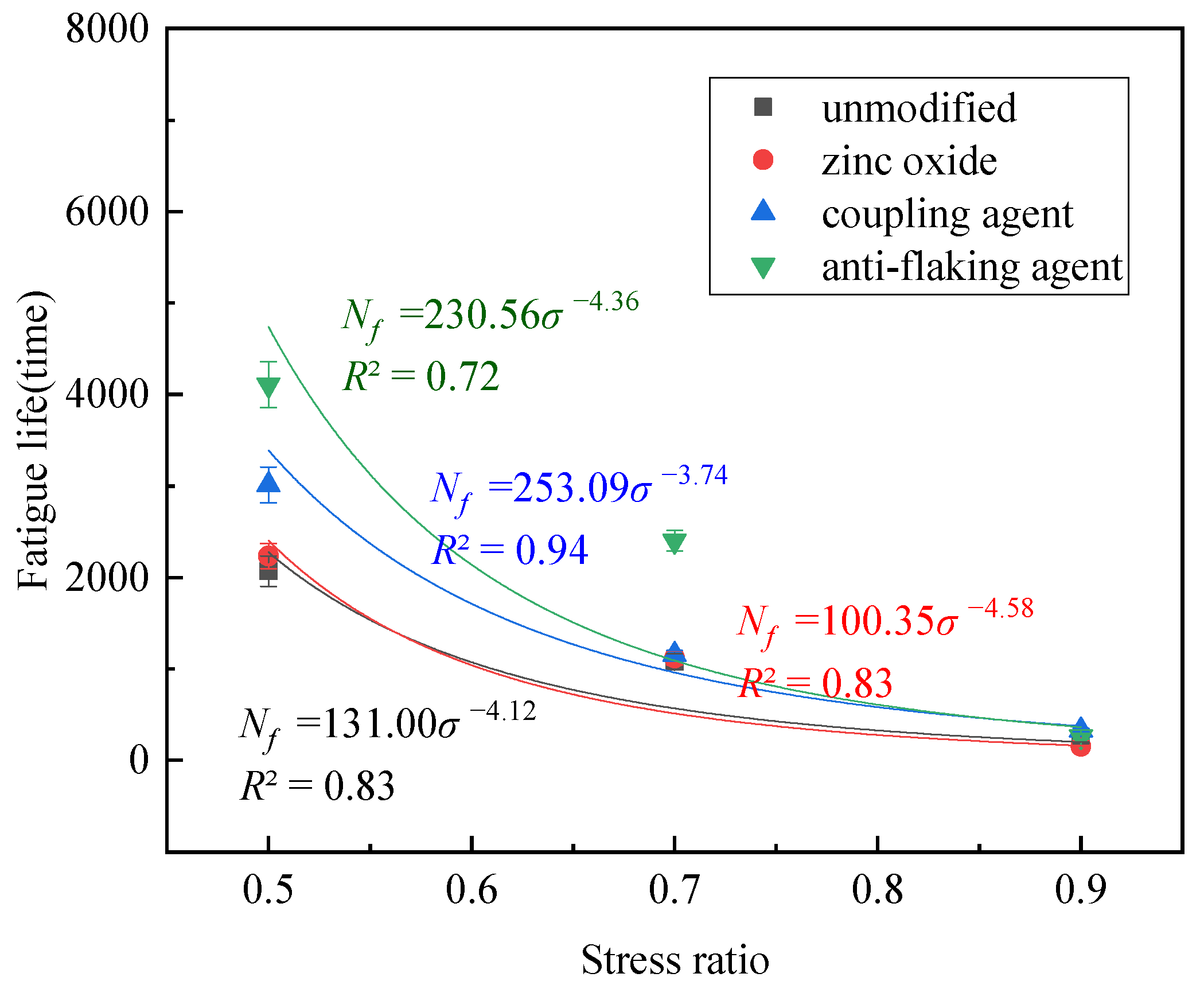

3.2.1. Three-Point Bending Fatigue Test

3.2.2. Indirect Tensile Test

3.3. Dynamic Modulus

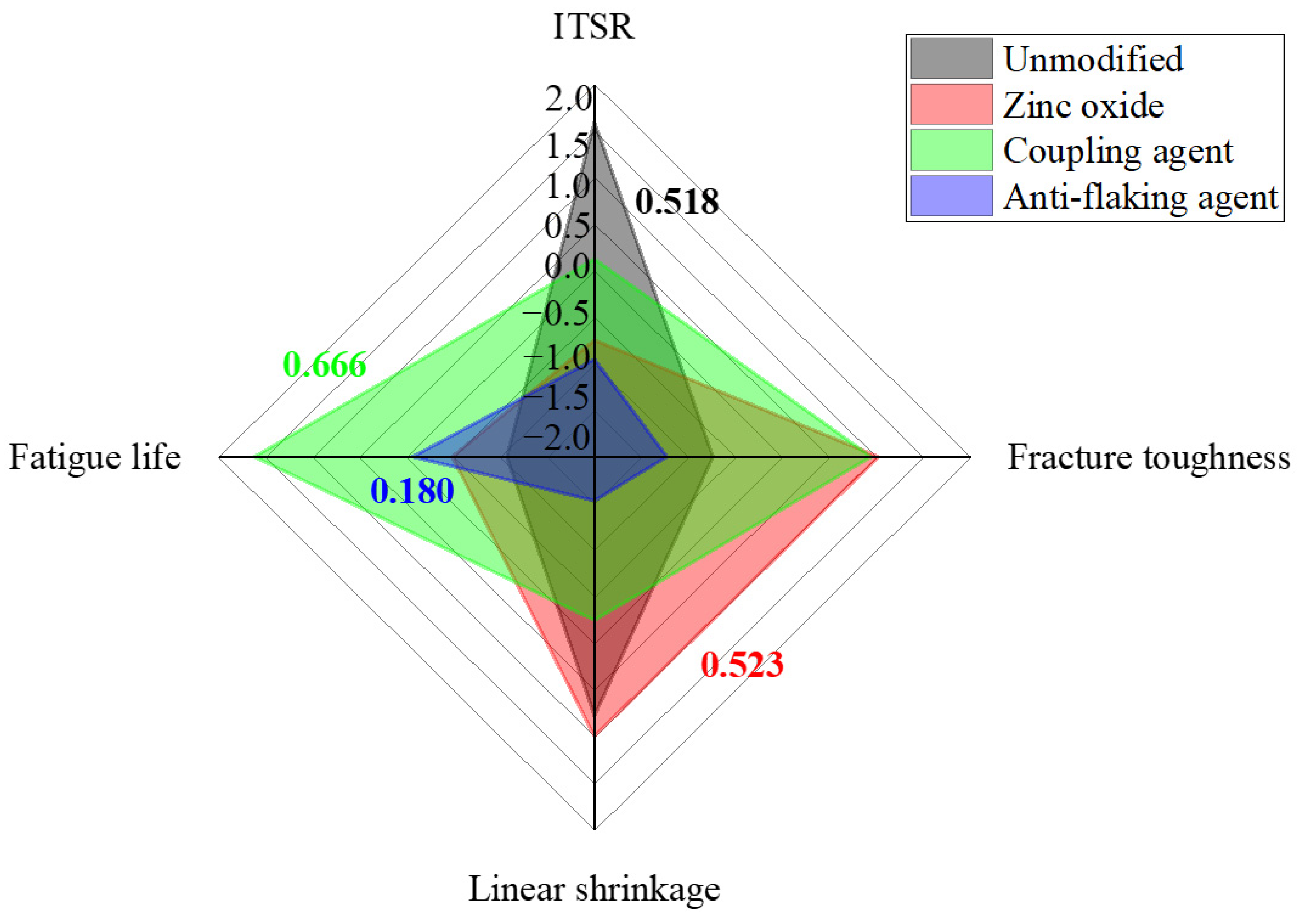

3.4. Determination of the Optimal Modification Method Based on the TOPSIS Approach

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Tarsi, G.; Tataranni, P.; Sangiorgi, C. The challenges of using reclaimed asphalt pavement for new asphalt mixtures: A review. Materials 2020, 13, 4052. [Google Scholar] [CrossRef]

- Xing, C.; Li, M.; Liu, L.; Lu, R.; Liu, N.; Wu, W.; Yuan, D. A comprehensive review on the blending condition between virgin and RAP asphalt binders in hot recycled asphalt mixtures: Mechanisms, evaluation methods, and influencing factors. J. Clean. Prod. 2023, 398, 136515. [Google Scholar] [CrossRef]

- Belousov, A.; Lushpeev, V.; Sokolov, A.; Sultanbekov, R.; Tyan, Y.; Ovchinnikov, E.; Shvets, A.; Bushuev, V.; Islamov, S. Experimental Research of the Possibility of Applying the Hartmann–Sprenger Effect to Regulate the Pressure of Natural Gas in Non-Stationary Conditions. Processes 2025, 13, 1189. [Google Scholar] [CrossRef]

- Yang, B.; Jiang, J.; Leng, Z.; Jiang, X.; Sun, Y.; Yan, C.; Tan, Z.; Li, G. Maintenance mechanisms of rejuvenator-optimized asphalt emulsion in damaged porous asphalt mixture: Morphological, physicochemical, and rheological characterizations. Constr. Build. Mater. 2025, 464, 140185. [Google Scholar] [CrossRef]

- Chen, Z.; Yi, J.; Zhao, H.; Luan, H.; Xu, M.; Zhang, L.; Feng, D. Strength development and deterioration mechanisms of foamed asphalt cold recycled mix-ture based on MD simulation. Constr. Build. Mater. 2021, 269, 121324. [Google Scholar] [CrossRef]

- Tassiri, S.; Kanitpong, K.; Sawangsuriya, A. Effects of additives on the performance properties of warm mix asphalt with reclaimed asphalt pavement. Int. J. Pavement Res. Technol. 2022, 15, 1239–1250. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, J.; Yu, X.; Zhao, X.; Lyu, L.; Wang, Q.; Zhang, M.; Huang, G. Laboratory evaluation of cold recycled mixture with foamed waste oil-activated rubberized asphalt. Transp. Res. Part D Transp. Environ. 2024, 135, 104395. [Google Scholar] [CrossRef]

- He, G.; Cao, C.; Han, H. Analysis of factors affecting the foaming performance of asphalt for cold regeneration of pavement. J. Highw. Transp. Res. Dev. 2004, 10, 9–13. [Google Scholar]

- Little, D.N.; Button, J.W. Structural properties of laboratory mixtures containing foamed asphalt and marginal aggregates. Transp. Res. Rec. 1983, 617, 104–113. [Google Scholar]

- Cao, C.; He, G.; Sun, C. Foam asphalt cold recycling technology. Highway 2003, 11, 99–102. [Google Scholar]

- Tabakovic, A.; Mcnally, C.; Fallon, E. Specification development for cold in-situ recycling of asphalt. Constr. Build. Mater. 2016, 102, 318–328. [Google Scholar] [CrossRef]

- Li, H.; Xing, C.; Zhu, B.; Zhang, X.; Gao, Y.; Tang, S.; Cheng, H. Comparative analysis of four styrene-butadiene-styrene (SBS) structure repair agents in the rejuvenation of aged SBS-modified bitumen. Constr. Build. Mater. 2025, 476, 141232. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, J.; He, Y.; Li, J.; Song, C.; Li, G. Investigation of mechanical properties, stiffness, and flexibility of cold recycled cement-stabilized gravel base milling mixes with foamed asphalt. J. Mater. Civ. Eng. 2023, 35, 04023443. [Google Scholar] [CrossRef]

- Xing, C.; Tang, S.; Chang, Z.; Han, Z.; Li, H.; Zhu, B. A comprehensive review on the plant-mixed cold recycling technology of emulsified asphalt: Raw materials and factors affecting performances. Constr. Build. Mater. 2024, 439, 137344. [Google Scholar] [CrossRef]

- Song, S.; Li, Q.; Wang, J.; Liu, T.; Zhang, S. Development of the asphalt foaming performance evaluation system based on binocular ranging technology. J. Mater. Civ. Eng. 2024, 36, 04024322. [Google Scholar] [CrossRef]

- Ruckel, P.J.; Acott, S.M.; Bowering, R.H. Preparation of design mixes and treatment of test specimens. Sol. Energy Mater. Sol. Cells 1983, 118, 48–53. [Google Scholar]

- Niazi, Y.; Jalili, M. Effect of portland cement and lime additives on properties of cold in-place recycled mixtures with asphalt emulsion. Constr. Build. Mater. 2008, 247, 362–371. [Google Scholar] [CrossRef]

- Graziani, A.; Spadoni, S.; Ingrassia, L.P.; Virgili, A.; Canestrari, F. Composite fatigue failure of cold recycled material mixtures: New insights into the role of bitumen and cement. Mater. Struct. 2024, 57, 10. [Google Scholar] [CrossRef]

- Chen, Q.; Song, L.; Wang, S.; Wen, P. Comprehensive evaluation of road performance of foam asphalt cold recycled mixture. J. Chongqing Jiaotong Univ. (Nat. Sci. Ed.) 2021, 40, 83–88. [Google Scholar]

- Tao, Z.; Shen, S.; Yu, H.; Sun, Y.; Zou, Y. Rejuvenating aged asphalt using surfactant-foaming warm recycling technology. Constr. Build. Mater. 2023, 384, 131297. [Google Scholar] [CrossRef]

- Liang, X.; Yu, X.; Xu, B.; Chen, C.; Ding, G.; Jin, Y.; Huang, J. Storage stability and compatibility in foamed warm-mix asphalt containing recycled asphalt pavement binder. J. Mater. Civ. Eng. 2024, 36, 04024062. [Google Scholar] [CrossRef]

- Guatimosim, F.V.; Vasconcelos, K.L.; Bernucci, L.L.B.; Jenkins, K.J. Laboratory and field evaluation of cold recycling mixture with foamed asphalt. Road Mater. Pavement Des. 2018, 19, 385–399. [Google Scholar] [CrossRef]

- Harvey, J. The effects of asphalt binder and granular material characteristics on foamed asphalt mix strength. Constr. Build. Mater. 2011, 25, 1093–1101. [Google Scholar]

- Zhou, J.; Hu, K.; Gao, J.; Chen, Y.; Yang, Q.; Du, X. Study on the Properties and Mechanism of Recycled Aggregate/Asphalt Interface Modified by Silane Coupling Agent. Appl. Sci. 2023, 13, 10343. [Google Scholar] [CrossRef]

- Yan, X.; Huang, X.; Hu, L.; Liu, Z.; Yang, J.; Chen, J.; Liu, W.; Zheng, X.; Qiu, R.; Wu, S. Microscale interface mechanism of the improved high and low-temperature performance of modified bamboo fibres-reinforced asphalt mixture. Int. J. Pavement Eng. 2024, 25, 2300939. [Google Scholar] [CrossRef]

- Zhang, G.; Qiu, J.; Zhao, J.; Wei, D.; Wang, H. Development of Interfacial Adhesive Property by Novel Anti-Stripping Composite between Acidic Aggregate and Asphalt. Polymers 2020, 12, 473. [Google Scholar] [CrossRef]

- Zhou, W.; Yi, J.; Chen, Z.; Feng, D. Verification of interfacial adhesion enhancement principle and road performance of foam asphalt cold recycled mixtures. Mater. Rep. 2022, 36, 37–45. [Google Scholar]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transportation and Communications: Beijing, China, 2011.

- JTG/T 5521-2019; Technical Specification for Highway Asphalt Pavement Recycling. Ministry of Transportation and Communications: Beijing, China, 2019.

- JTG 3432-2024; Aggregate Test Methods of Aggregates for Highway Engineering. Ministry of Transportation and Communications: Beijing, China, 2024.

- Chen, Y.; Chen, Z.; Xiang, Q.; Qin, W.; Yi, J. Research on the influence of RAP and aged asphalt on the performance of plant-mixed hot recycled asphalt mixture and blended asphalt. Case Stud. Constr. Mater. 2021, 15, e00722. [Google Scholar] [CrossRef]

- Rondon-Quintana, H.A.; Ruge-Cardenas, J.C.; Zafra-Mejia, C.A. The Use of Zinc Oxide in Asphalts: Review. Sustainability 2023, 15, 11070. [Google Scholar] [CrossRef]

- Aziz, T.; Ullah, A.; Fan, H.; Jamil, M.I.; Khan, F.U.; Ullah, R.; Iqbal, M.; Ali, A.; Ullah, B. Recent Progress in Silane Coupling Agent with Its Emerging Applications. J. Polym. Environ. 2021, 29, 3427–3443. [Google Scholar] [CrossRef]

- Shu, S.; Zhuang, C.; Ren, R.; Xing, B.; Chen, K.; Li, G. Effect of Different Anti-Stripping Agents on the Rheological Properties of Asphalt. Coatings 2022, 12, 1895. [Google Scholar] [CrossRef]

- JTG 3441-2024; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. Ministry of Transportation and Communications: Beijing, China, 2024.

- JTG F40-2004; Technical Specification for Construction of Highway Asphalt Pavements. Ministry of Transportation and Communications: Beijing, China, 2023.

- AASHTO T 283-2014; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- AASHTO T 393-2023; Standard Method of Test for Flexibility Index Test (FIT) for Asphalt Mixtures Using the Semi-Circular Bend Geometry. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2023.

- JC/T 603-2004; Standard Test Method for Drying Shrinkage of Mortar. National Development and Reform Commission: Beijing, China, 2023.

- AASHTO T 378-2017; Standard Method of Test for Determining the Dynamic Modulus and Flow Number for Asphalt Mixtures Using the Asphalt Mixture Performance Tester (AMPT). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2017.

- Wang, Y.; Hong, L.; Liu, Z.; Sun, L.; Liu, L. Rheological performance evaluation of activated carbon powder modified asphalt based on TOPSIS method. Case Stud. Constr. Mater. 2024, 20, e02963. [Google Scholar] [CrossRef]

- Yin, A.Y.; Yang, X.H.; Zeng, G.W.; Gao, H. Fracture simulation of pre-cracked heterogeneous asphalt mixture beam with movable three-point bending load. Constr. Build. Mater. 2014, 65, 232–242. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Guo, S.; Zhao, J.; Feng, D.; Yi, J. Research on aging performance of hot mix fully recycled epoxy asphalt mixture with 100% RAP utilization-Take the surface course as the application target. Constr. Build. Mater. 2023, 392, 131430. [Google Scholar] [CrossRef]

| Technical Indicators | Result | Requirements | Test Method |

|---|---|---|---|

| Needle penetration (25 °C)/0.1 mm | 85.2 | 80~100 | T 0604 |

| Softening point/°C | 53 | >45 | T 0606 |

| Elongation (15 °C)/cm | >100 | >100 | T 0605 |

| Amount of Foaming Water (%) | 150 °C | 160 °C | 170 °C | |||

|---|---|---|---|---|---|---|

| Expansion Ratio (Time) | Half-Time (s) | Expansion Ratio (Time) | Half-Time (s) | Expansion Ratio (Time) | Half-Time (s) | |

| 1 | 7 | 30.7 | 6.7 | 38.7 | 6.7 | 27.4 |

| 2 | 10 | 21.7 | 10.7 | 21.3 | 10.7 | 17.3 |

| 3 | 12.6 | 14 | 17.3 | 10.8 | 14.3 | 10 |

| 4 | 17.3 | 8.6 | 22.7 | 8.6 | 17 | 5.6 |

| Materials | Test Item | Result | Requirement |

|---|---|---|---|

| RAP before extraction | Moisture content (%) | 0.17 | ≤3 |

| Maximum particle size (mm) | 26.50 | ≤26.5 | |

| RAP after extraction | Density (g/m3) | 2.74 | ≥2.45 |

| Crushing value (%) | 17.30 | ≤30 | |

| Needle flake content (%) | 8.90 | ≤15 |

| Asphalt Type | Needle Penetration (0.1 mm) | Softening Point (°C) | Elongation (15 °C, mm) | Dynamic Viscosity (60 °C, Pa·s) |

|---|---|---|---|---|

| Aged asphalt | 57.1 | 64.9 | 14.6 | 6014.5 |

| grade 80/100 asphalt | 85.2 | 53 | >100 | 160 |

| Type | Maximum Load (kN) | Strength (MPa) |

|---|---|---|

| Unmodified | 0.6 | 0.51 |

| Zinc oxide | 4.6 | 3.68 |

| Coupling agent | 6.1 | 4.88 |

| Anti-stripping agent | 6.5 | 5.2 |

| Type | Fitting Parameters | |

|---|---|---|

| k | n | |

| Unmodified | 240.28 | 4.73 |

| Zinc oxide | 580.25 | 4.18 |

| Coupling agent | 337.60 | 4.47 |

| Anti-stripping agent | 576.13 | 3.58 |

| Type | Maximum Load (kN) | Strength (MPa) |

|---|---|---|

| Unmodified | 4.9 | 0.48 |

| Zinc oxide | 4.8 | 0.47 |

| Coupling agent | 6.4 | 0.63 |

| Anti-stripping agent | 6.0 | 0.60 |

| Type | Fitting Parameters | |

|---|---|---|

| k | n | |

| Unmodified | 131.00 | 4.12 |

| Zinc oxide | 100.35 | 4.58 |

| Coupling agent | 253.09 | 3.74 |

| Anti-stripping agent | 230.58 | 4.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Chen, Y.; Zhou, W.; Ma, Y.; Chen, Z.; Yi, J. The Improvement of Road Performance of Foam Asphalt Cold Recycled Mixture Based on Interface Modification. Polymers 2025, 17, 1927. https://doi.org/10.3390/polym17141927

Zhao H, Chen Y, Zhou W, Ma Y, Chen Z, Yi J. The Improvement of Road Performance of Foam Asphalt Cold Recycled Mixture Based on Interface Modification. Polymers. 2025; 17(14):1927. https://doi.org/10.3390/polym17141927

Chicago/Turabian StyleZhao, Han, Yuheng Chen, Wenyi Zhou, Yichao Ma, Zhuo Chen, and Junyan Yi. 2025. "The Improvement of Road Performance of Foam Asphalt Cold Recycled Mixture Based on Interface Modification" Polymers 17, no. 14: 1927. https://doi.org/10.3390/polym17141927

APA StyleZhao, H., Chen, Y., Zhou, W., Ma, Y., Chen, Z., & Yi, J. (2025). The Improvement of Road Performance of Foam Asphalt Cold Recycled Mixture Based on Interface Modification. Polymers, 17(14), 1927. https://doi.org/10.3390/polym17141927