Effect of Addition of Spheroidal Cellulose Powders on Physicochemical and Functional Properties of Cosmetic Emulsions

Abstract

1. Introduction

2. Materials and Methods

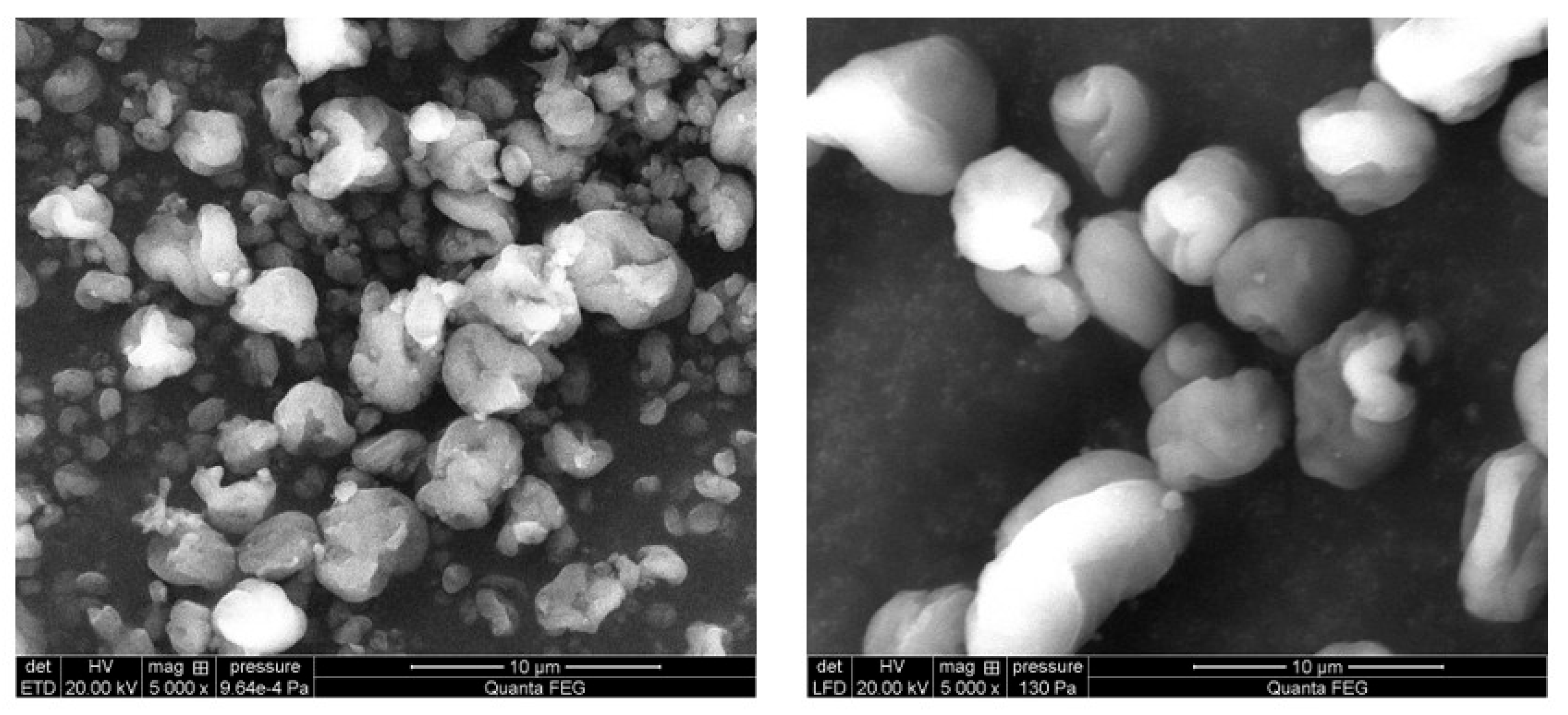

2.1. Materials

2.2. Formulations

2.3. Methods

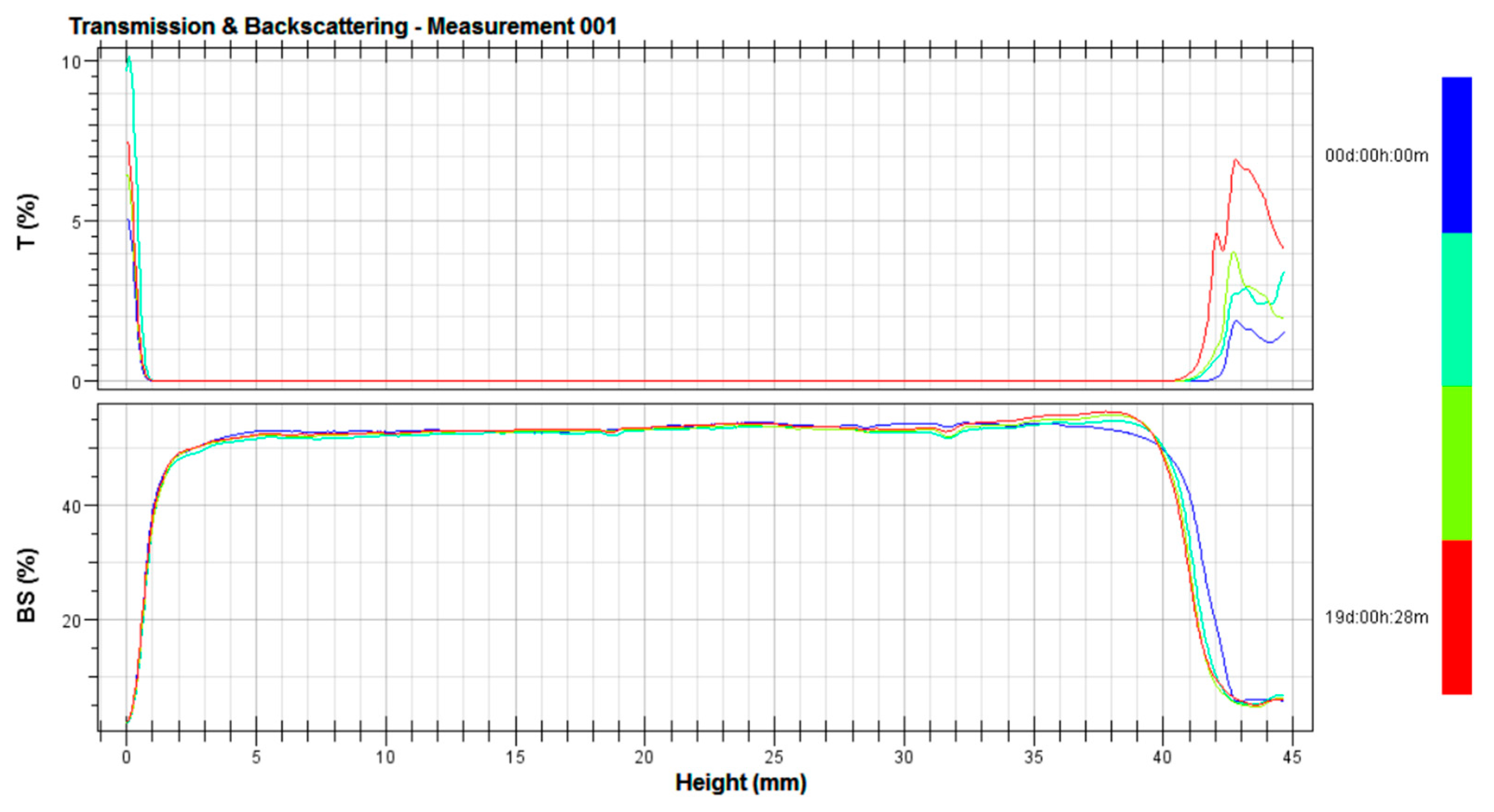

2.3.1. Stability Analysis

2.3.2. Dynamic Viscosity

2.3.3. Texture Analysis

2.3.4. Skin Hydration

2.3.5. Consumer Evaluation of Sensory Appeal

2.3.6. Statistical Analyses

3. Results and Discussion

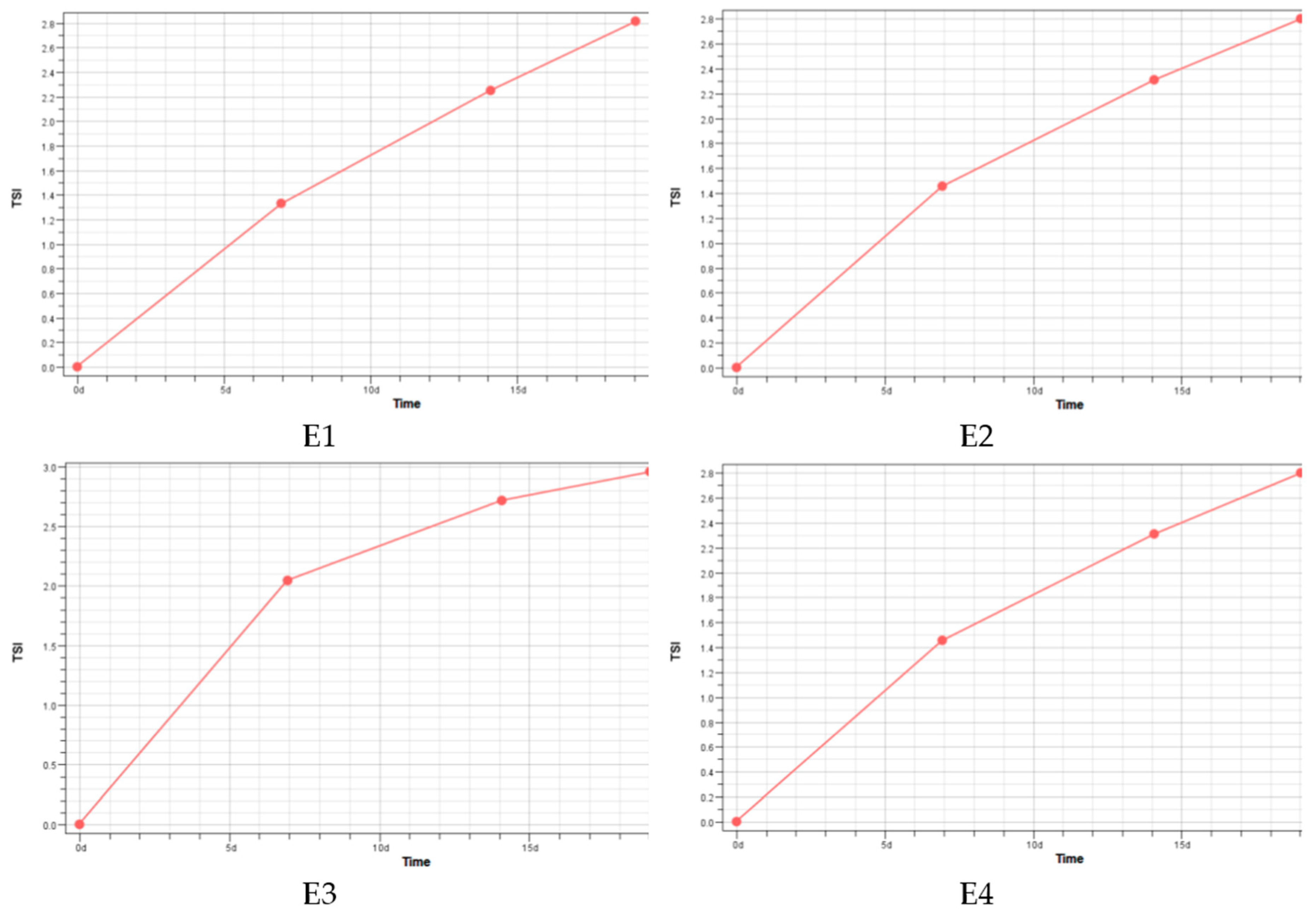

3.1. Stability Analysis

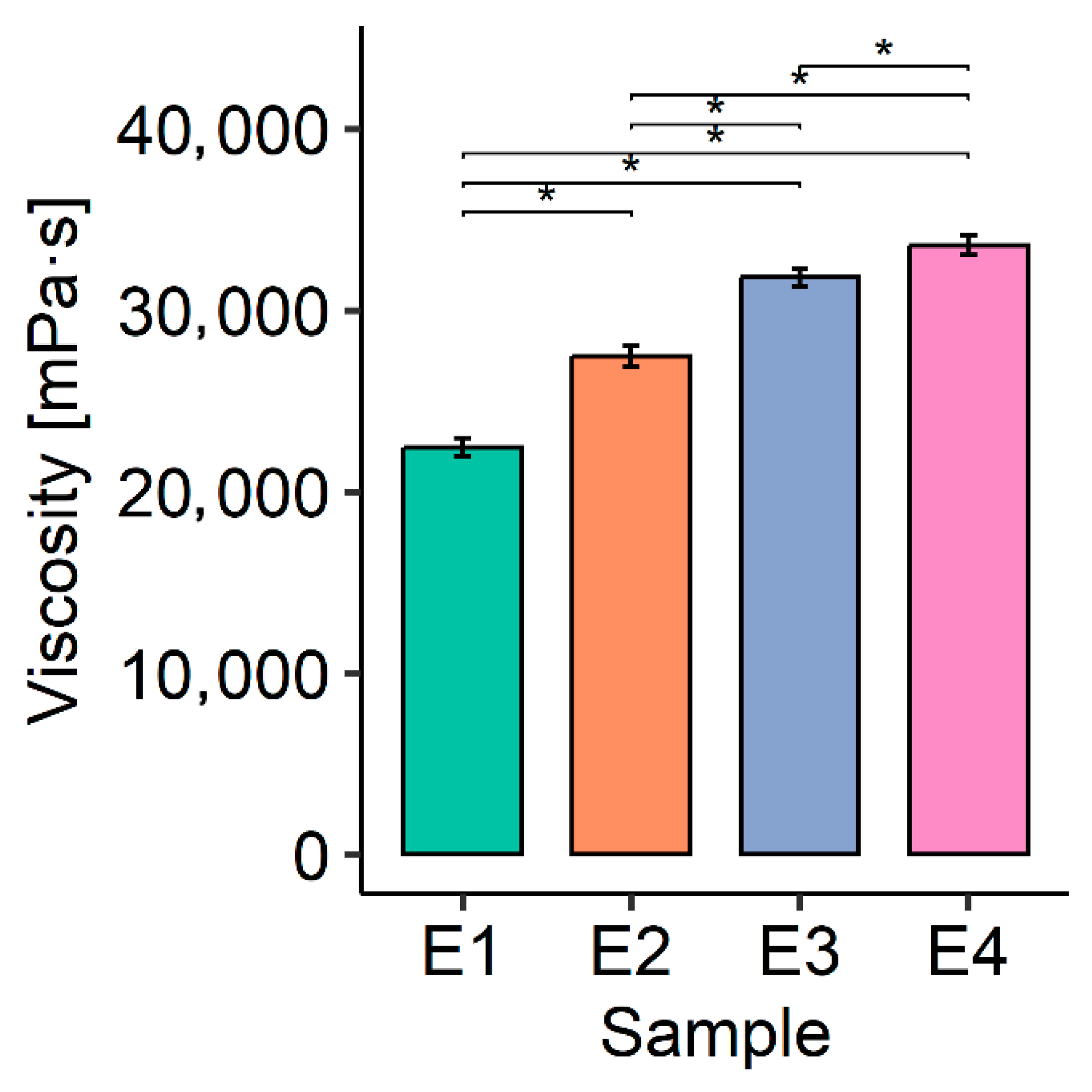

3.2. Dynamic Viscosity

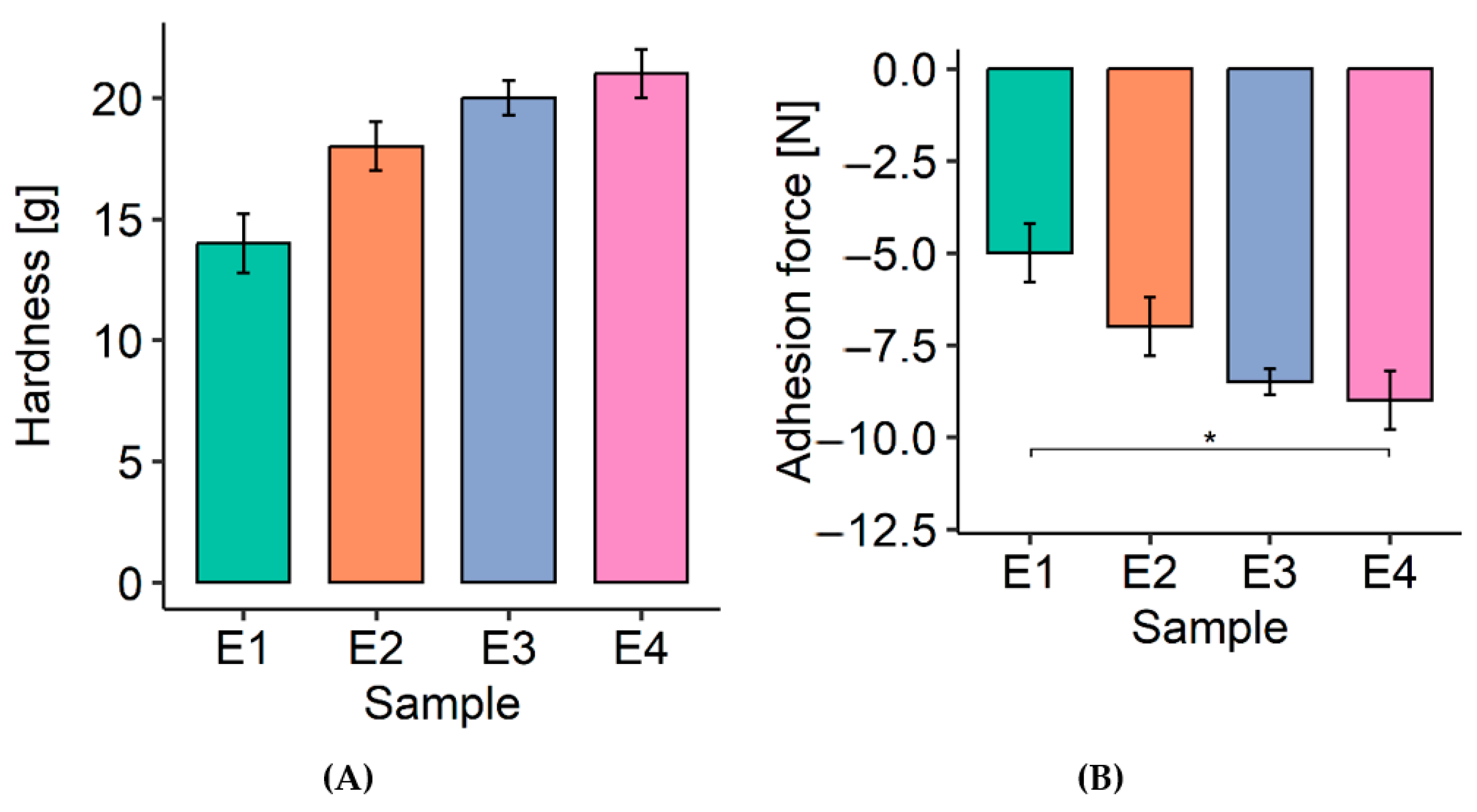

3.3. Texturometric Evaluation

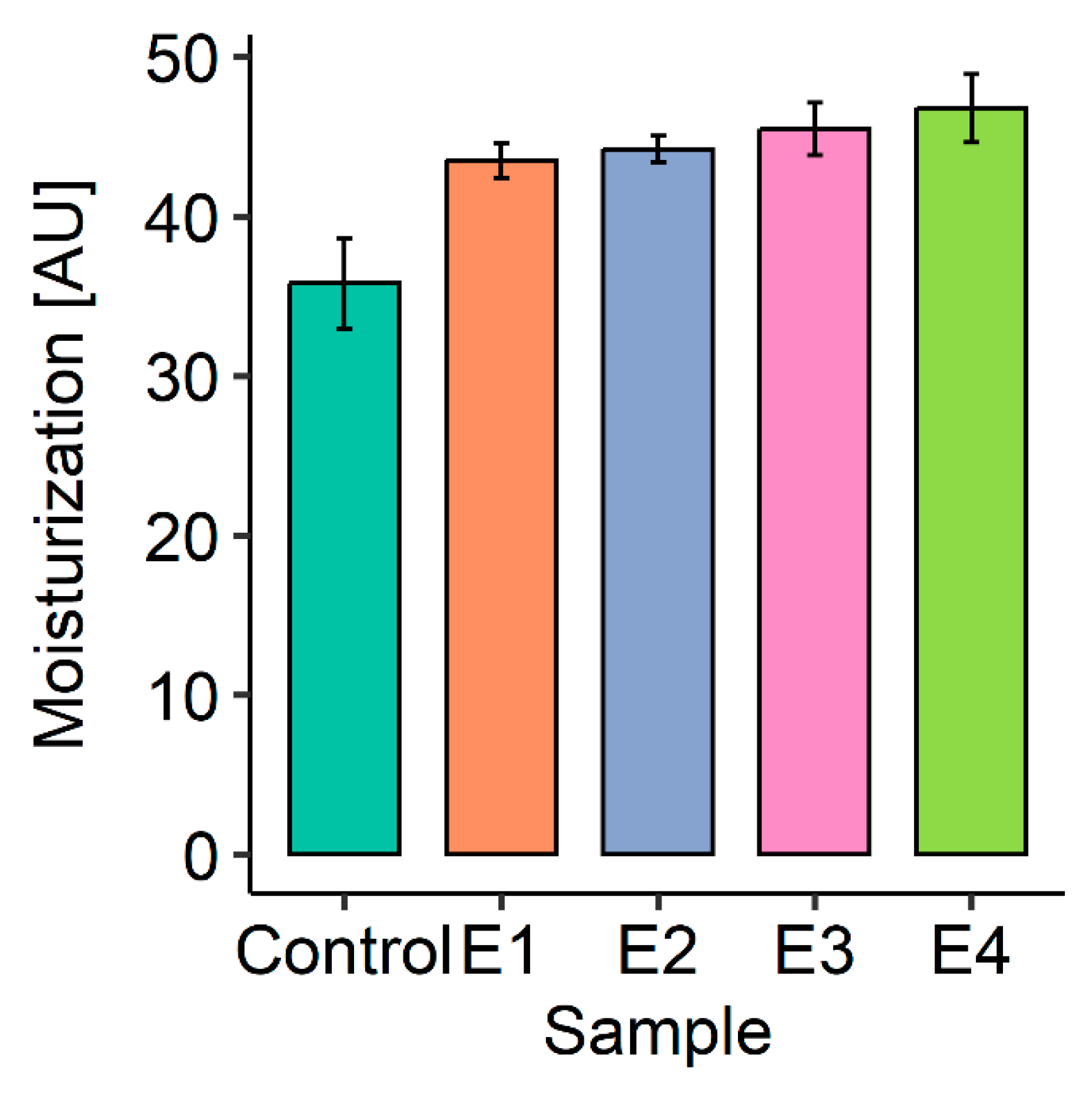

3.4. Degree of Skin Hydration

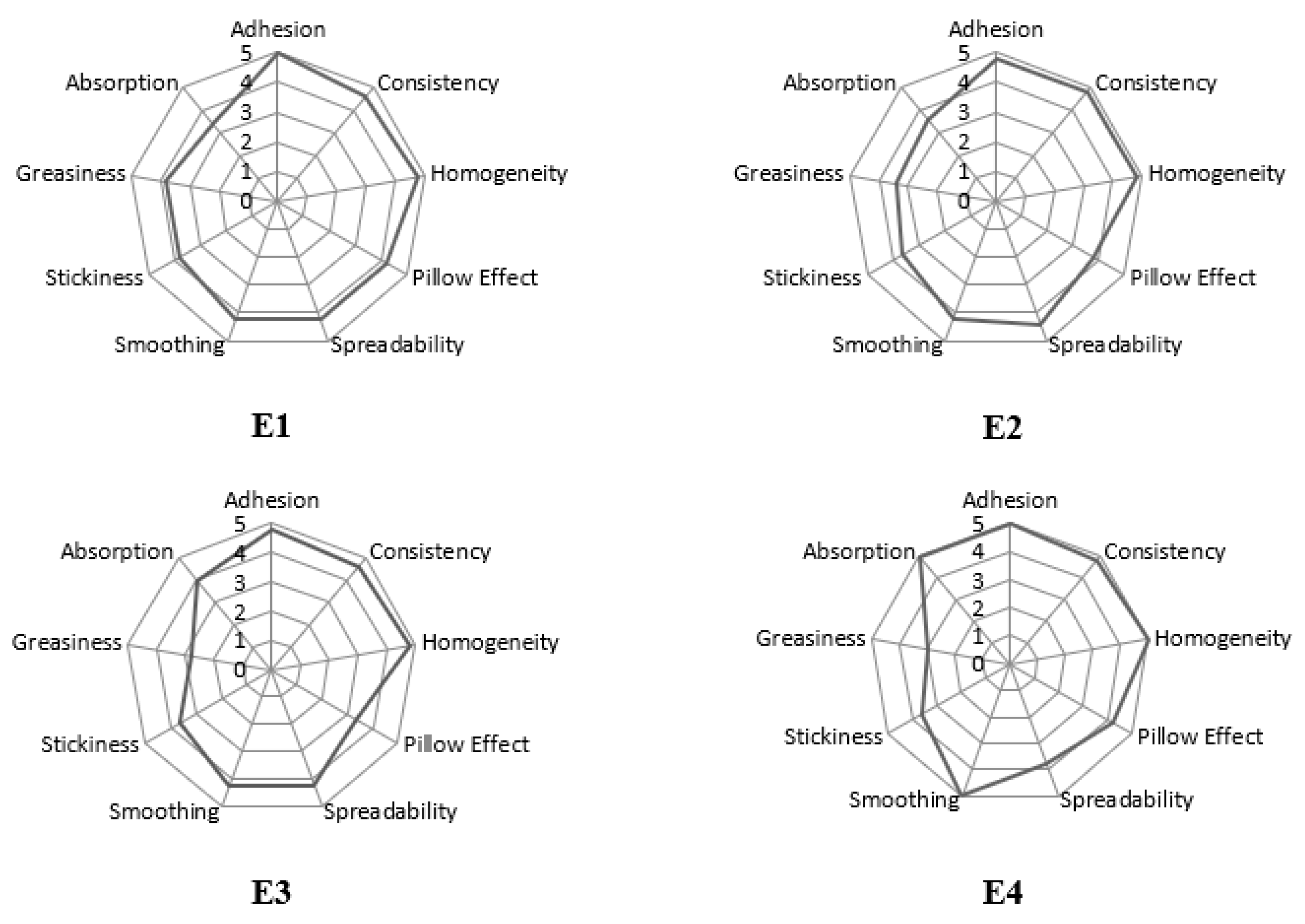

3.5. Consumer Evaluation of Sensory Appeal

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cottom, J.W.; Cook, E.; Velis, C.A. A local-to-global emissions inventory of macroplastic pollution. Nature 2024, 633, 101–108. [Google Scholar] [CrossRef] [PubMed]

- Bhuiyan, M.R.; Islam, M.E.; Syeed, S.; Sayeed, S.; Razzaque, A.S.A.; Rhidoy, M.H.; Mariner, M. Make Your Life Green. Nat. Study 2024, 7, 1. [Google Scholar]

- Stoett, P.; Scrich, V.M.; Elliff, C.I.; Andrade, M.M.; Grilli, N.D.M.; Turra, A. Global plastic pollution, sustainable development, and plastic justice. World Dev. 2024, 184, 106756. [Google Scholar] [CrossRef]

- Gouin, T.; Avalos, J.; Brunning, I.; Brzuska, K.; De Graaf, J.; Kaumanns, J.; Wolf, T. Use of micro-plastic beads in cosmetic products in Europe and their estimated emissions to the North Sea environment. SOFW J. 2015, 141, 40–46. [Google Scholar]

- Patil, P.M.; Mahamuni-Badiger, P.; Ingavale, R.R.; Patel, P.R.; Dhanavade, M.J. Usage of microplastic beads in pharmaceuticals and cosmetics industry: A review. In Microplastic Pollution; Springer: Singapore, 2024; pp. 51–72. [Google Scholar]

- Losetty, V.; Reddy, G.N.; Yadav, C.H.; Sivakumar, K. Study on Microplastic Content in Cosmetic Products and Their Detrimental Effect on Human Health. In Toxic Effects of Micro-and Nanoplastics: Environment, Food Human Health; Wiley: Hoboken, NJ, USA, 2024; pp. 253–264. [Google Scholar]

- Available online: https://www.crodabeauty.com/en-gb/resources/technical-library/resource-finder/resource/23995-chromapur-cv2-and-cv7-data-sheet (accessed on 1 May 2025).

- Chen, W.; Yu, H.; Liu, Y. Preparation of millimeter-long cellulose nanofibers with diameters of 30–80 nm from bamboo fibers. Carbohydr. Polym. 2011, 86, 453–461. [Google Scholar] [CrossRef]

- Yu, L.; Lin, J.; Tian, F.; Li, X.; Bian, F.; Wang, J. Cellulose nanofibers generated from jute fibers with tunable polymorphs and crystallinity. J. Matter. Chem. A 2014, 2, 6402–6411. [Google Scholar] [CrossRef]

- Chen, D.; Lawton, D.; Thompson, M.R.; Liu, Q. Biocomposites reinforced with cellulose nanocrystals derived from potato peel waste. Carbohydr. Polym. 2012, 90, 709–716. [Google Scholar] [CrossRef]

- Ogorzałek, M.; Klimaszewska, E.; Małysa, A.; Czerwonka, D.; Tomasiuk, R. Research on Waterless Cosmetics in the Form of Scrub Bars Based on Natural Exfoliants. Appl. Sci. 2024, 14, 11329. [Google Scholar] [CrossRef]

- Pena, D.W.P.; Tonoli, G.H.D.; de Paula Protásio, T.; de Souza, T.M.; Ferreira, G.C.; do Vale, I.; Bufalino, L. Exfoliating agents for skincare soaps obtained from the crabwood waste bagasse, a natural abrasive from Amazonia. Waste Biomass Valorization 2021, 12, 4441–4461. [Google Scholar] [CrossRef]

- Bikiaris, N.; Nikolaidis, N.F.; Barmpalexis, P. Microplastics (MPs) in Cosmetics: A Review on Their Presence in Personal-Care, Cosmetic, and Cleaning Products (PCCPs) and Sustainable Alternatives from Biobased and Biodegradable Polymers. Cosmetics 2024, 11, 145. [Google Scholar] [CrossRef]

- R DevelopmentCore Team. A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2013. [Google Scholar]

- Navarro-Pérez, Y.M.; Cedeño-Linares, E.; Norman-Montenegro, O.; Ruz-Sanjuan, V.; Mondeja-Rivera, Y.; Hernández-Monzón, A.M.; González-Bedia, M.M. Prediction of the physical stability and quality of O/W cosmetic emulsions using full factorial design. J. Pharm. Pharmacogn. Res. 2021, 9, 98–112. [Google Scholar] [CrossRef]

- Bhikadiya, D.; Bhikadiya, K. Accelerated Stability Testing Using Statistical Modeling and AI-Based Predictions. Int. J. Multidiscip. Sci. Manag. 2025, 2, 43–52. [Google Scholar]

- Zięba, M.; Klimaszewska, E.; Ogorzałek, M.; Ruszkowska, M. The role of burdock and black radish powders obtained by low-temperature drying in emulsion-type hair conditioners. Appl. Sci. 2024, 14, 3390. [Google Scholar] [CrossRef]

- Hyung Guen, A.; Kyung-Sup, Y. Evaluation of physical properties of nanoemulsion ampoule as customized cosmetic bases and evaluation of satisfaction according to skin type. J. Soc. Cosmet. Sci. Korea 2022, 48, 343–355. [Google Scholar]

- Liu, J.; Huang, X.-F.; Lu, L.; Li, M.-X.; Xu, J.-C.; Deng, H.-P. Turbiscan Lab® Expert analysis of the biological demulsification of a water-in-oil emulsion by two bioemulsifiers. J. Hazard. Mater. 2011, 190, 214–221. [Google Scholar] [CrossRef] [PubMed]

- Miastkowska, M.; Kulawik-Pióro, A.; Lasoń, E.; Śliwa, K.; Malinowska, M.A.; Sikora, E.; Nowak, K. Topical formulations based on ursolic acid-loaded nanoemulgel with potential application in psoriasis treatment. Pharmaceutics 2023, 15, 2559. [Google Scholar] [CrossRef]

- Mirzaaghaei, M.; Nasirpour, A.; Keramat, J.; Goli, S.A.H.; Dinari, M.; Desobry, S. Influence of fatty acid-esterified waxy maize starch type and concentration on stability and properties of oil-in-water emulsions. Int. J. Biol. Macromol. 2023, 233, 123526. [Google Scholar] [CrossRef]

- Costa, C.; Medronho, B.; Filipe, A.; Mira, I.; Lindman, B.; Edlund, H.; Norgren, M. Emulsion formation and stabilization by biomolecules: The leading role of cellulose. Polymers 2019, 11, 1570. [Google Scholar] [CrossRef]

- Zhao, G.X.; Zhu, L.J.; Li, H.; Liu, X.Y.; Yang, L.N.; Wang, S.N.; Ma, T. A hierarchical emulsion system stabilized by soya saponin emulsion droplets. Food Funct. 2021, 12, 10571–10580. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, L.; Liu, Y.; Li, J. A mechanistic investigation of the effect of dispersion phase protein type on the physicochemical stability of water–in–oil emulsions. Food Res. Int. 2022, 157, 111293. [Google Scholar] [CrossRef]

- Perrin, L.; Desobry-Banon, S.; Gillet, G.; Desobry, S. Study and optimization of oil-in-water emulsions formulated by low-and high-frequency ultrasounds. Int. J. Cosmet. Sci. 2023, 45, 198–213. [Google Scholar] [CrossRef] [PubMed]

- Calvo, F.; Gómez, J.M.; Alvarez, O.; Ricardez-Sandoval, L. Effect of emulsification parameters on the rheology, texture, and physical stability of cosmetic emulsions: A multiscale approach. Chem. Eng. Res. Des. 2022, 186, 407–415. [Google Scholar] [CrossRef]

- Huynh, A.; Garcia, A.G.; Young, L.K.; Szoboszlai, M.; Liberatore, M.W.; Baki, G. Measurements meet perceptions: Rheology–texture–sensory relations when using green, bio-derived emollients in cosmetic emulsions. Int. J. Cosmet. Sci. 2021, 43, 11–19. [Google Scholar] [CrossRef]

- Kim, J.; Jeong, E.H.; Baik, J.H.; Park, J.D. The role of rheology in cosmetics research: A review. Korea-Aust. Rheol. J. 2024, 36, 271–282. [Google Scholar] [CrossRef]

- Klimaszewska, E.; Zięba, M.; Gregorczyk, K.; Markuszewski, L. Application of blue honeysuckle powder obtained by an innovative method of low-temperature drying in skincare face masks. Molecules 2021, 26, 7184. [Google Scholar] [CrossRef] [PubMed]

- Deuschle, V.C.K.N.; Deuschle, R.A.N.; Bortoluzzi, M.R.; Athayde, M.L. Physical chemistry evaluation of stability, spreadability, in vitro antioxidant, and photo-protective capacities of topical formulations containing Calendula officinalis L. leaf extract. Braz. J. Pharm. Sci. 2015, 51, 63–75. [Google Scholar] [CrossRef]

- Franceschini, M.; Pizzetti, F.; Rossi, F. On the Key Role of Polymeric Rheology Modifiers in Emulsion-Based Cosmetics. Cosmetics 2025, 12, 76. [Google Scholar] [CrossRef]

- Różańska, S.; Różański, J.; Wagner, P.; Warmbier-Wytykowska, E. Rheological Properties of Emulsions Stabilized by Cellulose Derivatives with the Addition of Ethyl Alcohol. Materials 2024, 17, 6090. [Google Scholar] [CrossRef]

- Martins, D.; Rocha, C.; Dourado, F.; Gama, M. Bacterial Cellulose-Carboxymethyl Cellulose (BC: CMC) dry formulation as stabilizer and texturizing agent for surfactant-free cosmetic formulations. Colloids Surf. A Physicochem. Eng. Asp. 2021, 617, 126380. [Google Scholar] [CrossRef]

- Dong, H.; Ding, Q.; Jiang, Y.; Li, X.; Han, W. Pickering emulsions stabilized by spherical cellulose nanocrystals. Carbohydr. Polym. 2021, 265, 118101. [Google Scholar] [CrossRef]

- Busuioc, A.; Antonoaea, P.; Ciurba, A. Practical Contributions to Texture Analysis of Cosmetic Products. Acta Marisiensis Ser. Med. 2024, 70, 111. [Google Scholar]

- Peleg, M. The instrumental texture profile analysis revisited. J. Texture Stud. 2019, 50, 362–368. [Google Scholar] [CrossRef] [PubMed]

- Moldovan, M.; Lahmar, A.; Bogdan, C.; Părăuan, S.; Tomuţă, I.; Crişan, M. Formulation and evaluation of a water-in-oil cream containing herbal active ingredients and ferulic acid. Clujul Med. 2017, 90, 212–219. [Google Scholar] [CrossRef] [PubMed]

- Gilbert, L.; Picard, C.; Savary, G.; Grisel, M. Rheological and textural characterization of cosmetic emulsions containing natural and synthetic polymers: Relationships between both data. Colloids Surf. A Physicochem. Eng. Asp. 2013, 421, 150–163. [Google Scholar] [CrossRef]

- Quan, T. Molecular insights of human skin epidermal and dermal aging. J. Dermatol. Sci. 2023, 112, 48–53. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Lan, S.; Zhao, Y.; Xiong, Y.; Yang, W.; Du, Y. Characterization of Skin Moisture and Evaluation of Cosmetic Moisturizing Properties Using Miniature Near-Infrared Spectrometer. Infrared Phys. Technol. 2023, 132, 104759. [Google Scholar] [CrossRef]

- Rahrovan, S.; Fanian, F.; Mehryan, P.; Humbert, P.; Firooz, A. Male versus female skin: What dermatologists and cosmeticians should know. Int. J. Women’s Dermatol. 2018, 4, 122–130. [Google Scholar] [CrossRef]

- Shi, V.Y.; Leo, M.; Hassoun, L.; Chahal, D.S.; Maibach, H.I.; Sivamani, R.K. Role of sebaceous glands in inflammatory dermatoses. J. Am. Acad. Dermatol. 2015, 73, 856–863. [Google Scholar] [CrossRef]

- Meftahi, A.; Samyn, P.; Geravand, S.A.; Khajavi, R.; Alibkhshi, S.; Bechelany, M.; Barhoum, A. Nanocelluloses as skin biocompatible materials for skincare, cosmetics, and healthcare: Formulations, regulations, and emerging applications. Carbohydr. Polym. 2022, 278, 118956. [Google Scholar] [CrossRef]

- Furtado, I.F.; Sydney, E.B.; Rodrigues, S.A.; Sydney, A.C. Xanthan gum: Applications, challenges, and advantages of this asset of biotechnological origin. Biotechn. Res. Innov. J. 2022, 6, e202204. [Google Scholar] [CrossRef]

- Al-Halaseh, L.K.; Al-Jawabri, N.A.; Tarawneh, S.K.; Al-Qdah, W.K.; Abu-Hajleh, M.N.; Al-Samydai, A.M.; Ahmed, M.A. A review of the cosmetic use and potentially therapeutic importance of hyaluronic acid. J. Appl. Pharm. Sci. 2022, 12, 034–041. [Google Scholar] [CrossRef]

- Losetty, V. Role of Polymers in Cosmetics and Personal Care Harvests: Precarious Impact on Human Health and Environment. In Applications of Polymers in Surgery II; Materials Research Forum LLC: Millersville, PA, USA, 2025; Volume 172. [Google Scholar]

- Danila, A.; Ibanescu, S.A.; Zaharia, C.; Muresan, E.I.; Popescu, A.; Danu, M.; Rotaru, V. Eco-friendly O/W emulsions with potential application in skincare products. Colloids Surf. A Physicochem. Eng. Asp. 2021, 612, 125969. [Google Scholar] [CrossRef]

- Roso, A.; Kern, C.; Cambos, S.; Garcia, C. Diversity Challenge in Skin Care: Adaptations of a Simple Emulsion for Efficient Moisturization across Multiple Geographies. Appl. Sci. 2023, 13, 13175. [Google Scholar] [CrossRef]

- Lotos, E.D.; Danila, A.; Vasiliu, A.L.; Rosca, I.; Stroian, D.V.; Simionescu, B.C.; Mihai, M. The potential emulsions of xanthan gum and Daucus carota macerated oil in functional textiles for skincare applications: Formulation, characterization, and performance evaluation. Colloids Surf. A Physicochem. Eng. Asp. 2024, 682, 132960. [Google Scholar] [CrossRef]

- Lee, H.; Lee, K.; Kim, M.; Kwon, Y.; Yun, J.; Choi, J.H.; Youn, H.J. Synergistic moisturizing effect of a cellulose nanofibril/hyaluronic acid/poly-γ-glutamic acid blend system. Cellulose 2025, 32, 4781–4796. [Google Scholar] [CrossRef]

- Lephart, E.D. Skin aging and oxidative stress: Equol’s anti-aging effects via biochemical and molecular mechanisms. Ageing Res. Rev. 2016, 31, 36–54. [Google Scholar] [CrossRef]

- Leyden, J.J.; Rawlings, A.V. Skin Moisturization, 1st ed.; Marcel Dekker: New York, NY, USA, 2002. [Google Scholar]

- Mérat, E.; Roso, A.; Dumaine, M.; Sigurani, S. Sensory evaluation of cosmetic functional ingredients. In Nonfood Sensory Practices; Woodhead Publishing: Cambridge, UK, 2022; Volume 10, pp. 197–216. [Google Scholar] [CrossRef]

- Böger, B.R.; Lonni, A.A.S.G.; Benassi, M.D.T. Characterization and sensory evaluation of a cosmeceutical formulation for the eye area with roasted coffee oil microcapsules. Cosmetics 2023, 10, 24. [Google Scholar] [CrossRef]

- Akanny, E.; Kohlmann, C. Predicting tactile sensory attributes of personal care emulsions based on instrumental characterizations: A review. Int. J. Cosmet. Sci. 2024, 46, 1035–1063. [Google Scholar] [CrossRef]

- Franzol, A.; Banin, T.M.; Brazil, T.R.; Rezende, M.C. Assessment of kinetic stability of cosmetic emulsions formulated with different emulsifiers using rheological and sensory analyses. J. Sol-Gel Sci. Technol. 2021, 99, 469–481. [Google Scholar] [CrossRef]

- Sikora, E. Cosmetic Emulsions: Monograph; Cracow Polytechnics Publishing: Cracow, Poland, 2019; ISBN 978-83-65991-50-8. [Google Scholar]

- Roso, A.; Aubert, A.; Cambos, S.; Vial, F.; Schäfer, J.; Belin, M.; Bize, C. Contribution of cosmetic ingredients and skin care textures to emotions. Int. J. Cosmet. Sci. 2024, 46, 262–283. [Google Scholar] [CrossRef]

- Meneguello, T.G.; Palma, N.K.; Santos, Y.R.; Carvalho, A.F.; Ladeira, A.D.D.S.; Bonsanto, F.P.; Leite-Silva, V.R. Physicochemical and Sensory Evaluation of Sustainable Plant-Based Homopolymers as an Alternative to Traditional Emollients in Topical Emulsions. Pharmaceutics 2025, 17, 265. [Google Scholar] [CrossRef] [PubMed]

| Particle Characterization | Cellulose 2 µm | Cellulose 7 µm |

|---|---|---|

| Buk density | 0.30 g/cm3 | 0.56 g/cm3 |

| Surface area | 3.5 m2/g | 1.0 m2/g |

| Refractive index | 1.54 | 1.54 |

| Oil up-take | 46.1 g/100 g | 44.6 g/100 g |

| Phase | INCI Name | Concentration [% w/w] | |||

|---|---|---|---|---|---|

| E1 | E2 | E3 | E4 | ||

| I | Hedera Helix (Ivy) Leaf Extract | 3.0 | |||

| Cetearyl Alcohol | 3.0 | ||||

| Cetearyl Olivate and Sorbitan Olivate | 5.0 | ||||

| II | Aqua | to 100 | |||

| Cellulose (CV 2) | - | 5.0 | - | 2.5 | |

| Cellulose (CV 7) | - | - | 5.0 | 2.5 | |

| III | Tocopheryl Acetate | 0.5 | |||

| Sodium Benzoate and Potassium Sorbate | 0.5 | ||||

| Sample | n | Mean ± SD (mPa·s) | Median (mPa·s) |

|---|---|---|---|

| E1 | 5 | 22,440 ± 508 | 22,500 |

| E2 | 5 | 27,470 ± 561 | 27,300 |

| E3 | 5 | 31,807 ± 490 | 31,800 |

| E4 | 5 | 33,575 ± 534 | 33,700 |

| Kruskal–WallisH | 17.86 | p = 4.7 × 10−4 |

| Sample | n | Mean ± SD (g) | Median (g) |

|---|---|---|---|

| E1 | 5 | 14.0 ± 1.22 | 14.0 |

| E2 | 5 | 18.0 ± 1.00 | 18.0 |

| E3 | 5 | 20.0 ± 0.71 | 20.0 |

| E4 | 5 | 21.0 ± 1.00 | 21.0 |

| Kruskal–Wallis H | 16.66 | p = 8.3 × 10−4 |

| Sample | n | Mean ± SD (g) | Median (g) |

|---|---|---|---|

| E1 | 5 | −5.0 ± 0.79 | −5.0 |

| E2 | 5 | −7.0 ± 0.79 | −7.0 |

| E3 | 5 | −8.5 ± 0.35 | −8.5 |

| E4 | 5 | −9.0 ± 0.79 | −9.0 |

| Kruskal–WallisH | 15.98 | p = 1.1 × 10−3 |

| Sample | n | Mean ± SD (AU) | Median (AU) |

|---|---|---|---|

| Control | 5 | 35.8 ± 2.84 | 35.2 |

| E1 | 5 | 43.5 ± 1.07 | 43.9 |

| E2 | 5 | 44.2 ± 0.85 | 44.4 |

| E3 | 5 | 45.5 ± 1.65 | 45.4 |

| E4 | 5 | 46.8 ± 2.14 | 46.6 |

| Kruskal–WallisH | 18.04 | p = 1.2 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klimaszewska, E.; Ogorzałek, M.; Okulska-Bożek, M.; Jabłońska, E.; Wyłup, H.; Nizioł-Łukaszewska, Z.; Tomasiuk, R. Effect of Addition of Spheroidal Cellulose Powders on Physicochemical and Functional Properties of Cosmetic Emulsions. Polymers 2025, 17, 1926. https://doi.org/10.3390/polym17141926

Klimaszewska E, Ogorzałek M, Okulska-Bożek M, Jabłońska E, Wyłup H, Nizioł-Łukaszewska Z, Tomasiuk R. Effect of Addition of Spheroidal Cellulose Powders on Physicochemical and Functional Properties of Cosmetic Emulsions. Polymers. 2025; 17(14):1926. https://doi.org/10.3390/polym17141926

Chicago/Turabian StyleKlimaszewska, Emilia, Marta Ogorzałek, Małgorzata Okulska-Bożek, Ewa Jabłońska, Hanna Wyłup, Zofia Nizioł-Łukaszewska, and Ryszard Tomasiuk. 2025. "Effect of Addition of Spheroidal Cellulose Powders on Physicochemical and Functional Properties of Cosmetic Emulsions" Polymers 17, no. 14: 1926. https://doi.org/10.3390/polym17141926

APA StyleKlimaszewska, E., Ogorzałek, M., Okulska-Bożek, M., Jabłońska, E., Wyłup, H., Nizioł-Łukaszewska, Z., & Tomasiuk, R. (2025). Effect of Addition of Spheroidal Cellulose Powders on Physicochemical and Functional Properties of Cosmetic Emulsions. Polymers, 17(14), 1926. https://doi.org/10.3390/polym17141926