Intumescent Coatings and Their Applications in the Oil and Gas Industry: Formulations and Use of Numerical Models

Abstract

1. Introduction

1.1. Background and Significance of Fire Protection in the Oil and Gas Industry

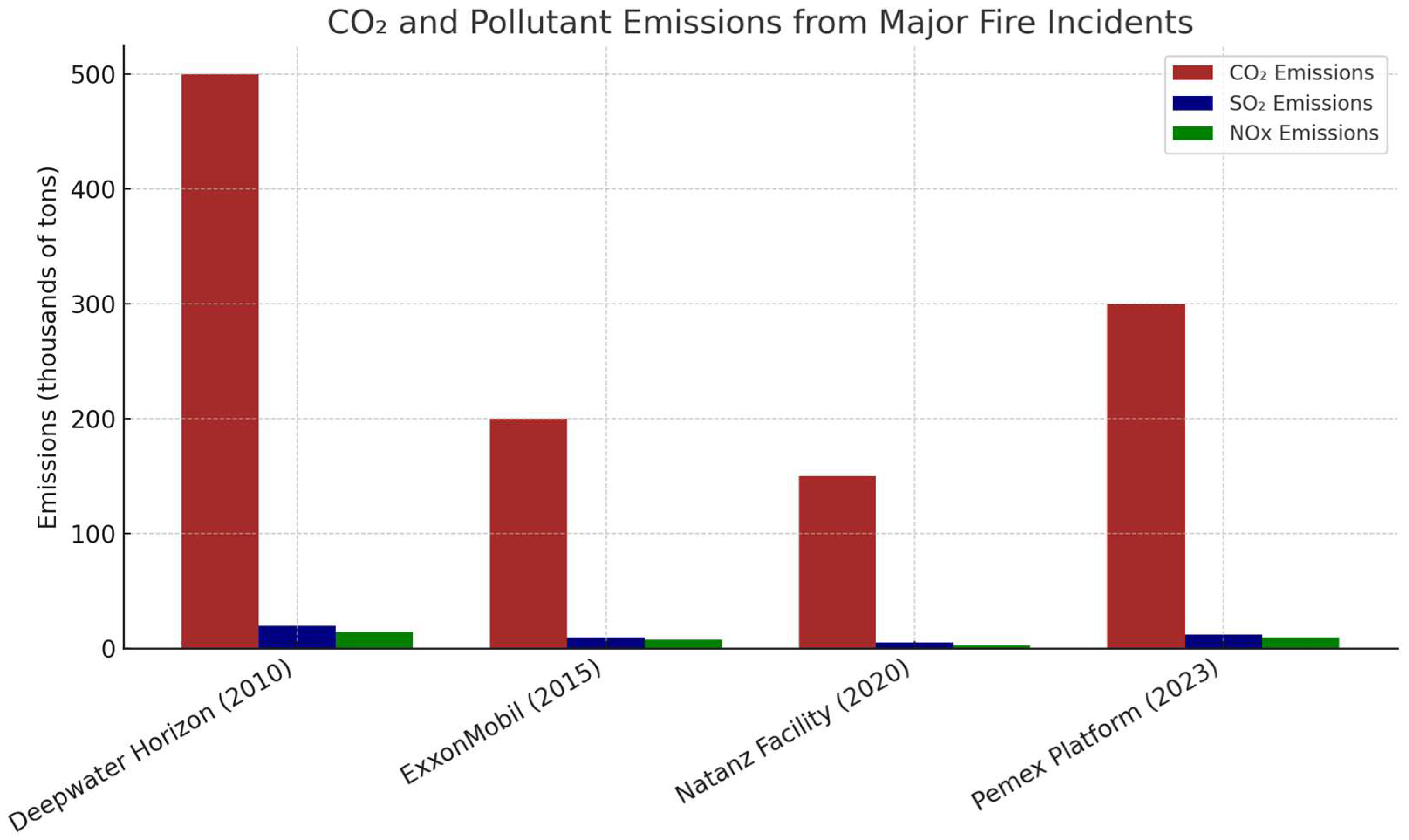

Environmental Impact of Fire Hazards in the Oil and Gas Industry

1.2. Scope of This Article

1.3. Motivations

1.4. Novelty

- Bio-Derived Innovations: This review introduces tannic acid as a dual-function acid source and charring agent in bio-derived ICs, enhancing sustainability—a novel focus not commonly emphasized in other reviews.

- AI-Driven Modeling: This review examines AI-based numerical models for predicting and optimizing thermal insulation under conditions involving hydrocarbon fires. This cutting-edge approach differs from traditional modeling methods.

- Nano-Additive Synergies: Provides the first detailed study on the synergistic effects of graphene and silica nanoparticles, improving the mechanical durability and heat-blocking efficiency of ICs, and setting it apart from general nano-additive discussions.

- Self-Healing Technology: This section explores self-healing ICs with fire-responsive sensors for real-time monitoring, an innovative feature not widely covered in other IC literature.

- Environmental Impact Quantification: This study uniquely quantifies reductions in CO2, SO2, and NOx emissions using optimized IC formulations, addressing environmental concerns more specifically than other studies.

- Hybrid Coating Systems: Proposes a novel hybrid IC–ceramic coating system to enhance durability in offshore conditions, a strategy not commonly discussed in other documents.

- Rheological Insights: This study investigates the rheological modification of IC binders with boric acid and clay, linking viscosity to improved char morphology—a new perspective on formulation optimization.

- Industry-Specific Applications: Uses 3E Plus software (3EPlus version 4.1 (Naima.exe)) to optimize IC thickness for oil and gas infrastructure, a tailored application not typically highlighted in broader IC reviews.

- Regulatory and Economic Focus: Links IC performance to API, ASME, and NFPA standards while analyzing economic impacts, offering a practical framework for industry adoption unique to this review.

- Historical Fire Analysis: This paper integrates a comprehensive review of industrial fire incidents (2010–2025) with IC performance, providing a real-world data correlation not extensively covered in other papers.

2. Importance of PFP Systems in the Oil and Gas Industry

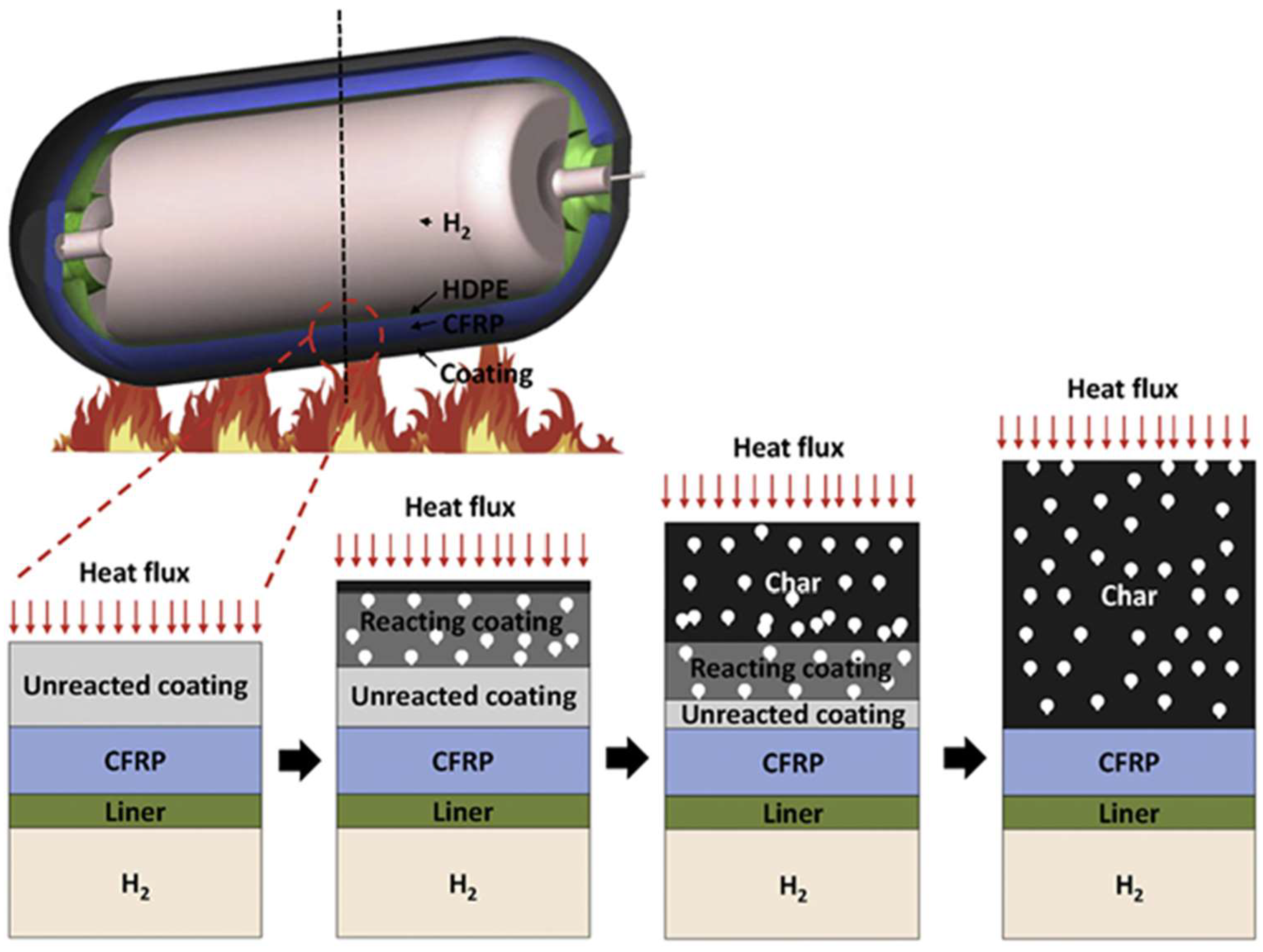

2.1. Role of Intumescent Coatings in Fire Protection

| Study | Findings Related to Flame Retardancy | Emission Impact | Methodology |

| Flame Retardancy Effects on Intumescent Coatings with Vinyl Acetate Copolymers [49] | Reduced peak heat release rate, extended time to peak, low foam content forms ideal char, reduces CO, CO2. | Significant reduction in CO, CO2 emissions. | Fire combustion tests, emission analysis. |

| Flammability properties of intumescent vinyl acetate-ethylene copolymer emulsion [52] | 73% reduction in peak heat release rate with bio-based additives, LOI increased to 31.5. | Reduced CO2 emissions due to char formation. | LOI, UL-94, cone calorimetry tests. |

| Fire retardant mechanism in intumescent ethylene vinyl acetate compositions [50] | MH-APP interaction enhances ammonia evolution and modifies combustion behavior. | Potential increase in NOx due to ammonia. | UL94 test, thermal analysis. |

2.2. Economic Impact of IC in the Oil and Gas Industries

3. Fire Hazards and the Role of Intumescent Coatings

4. Formulation of Intumescent Fire Retardants

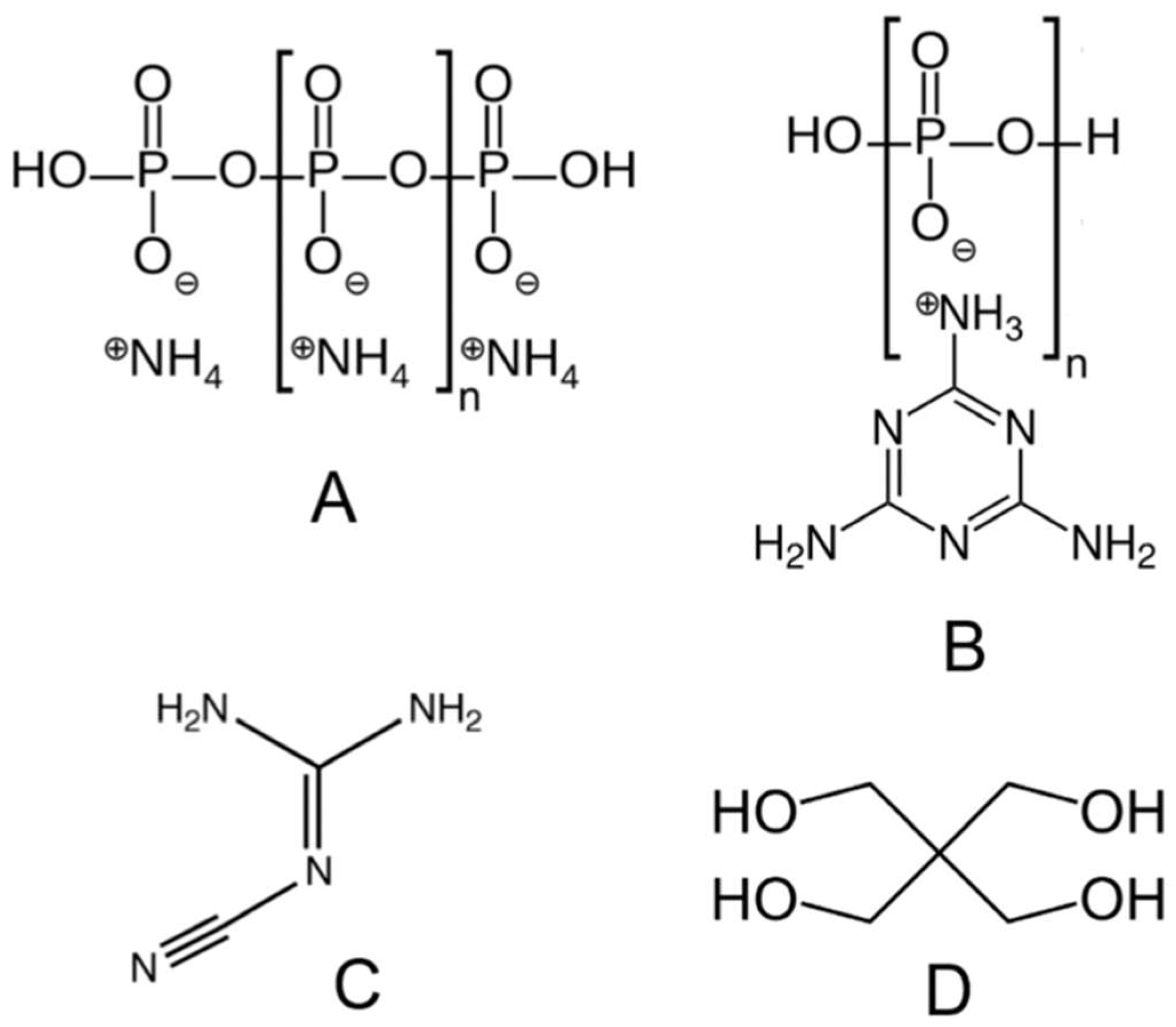

4.1. Acid Sources

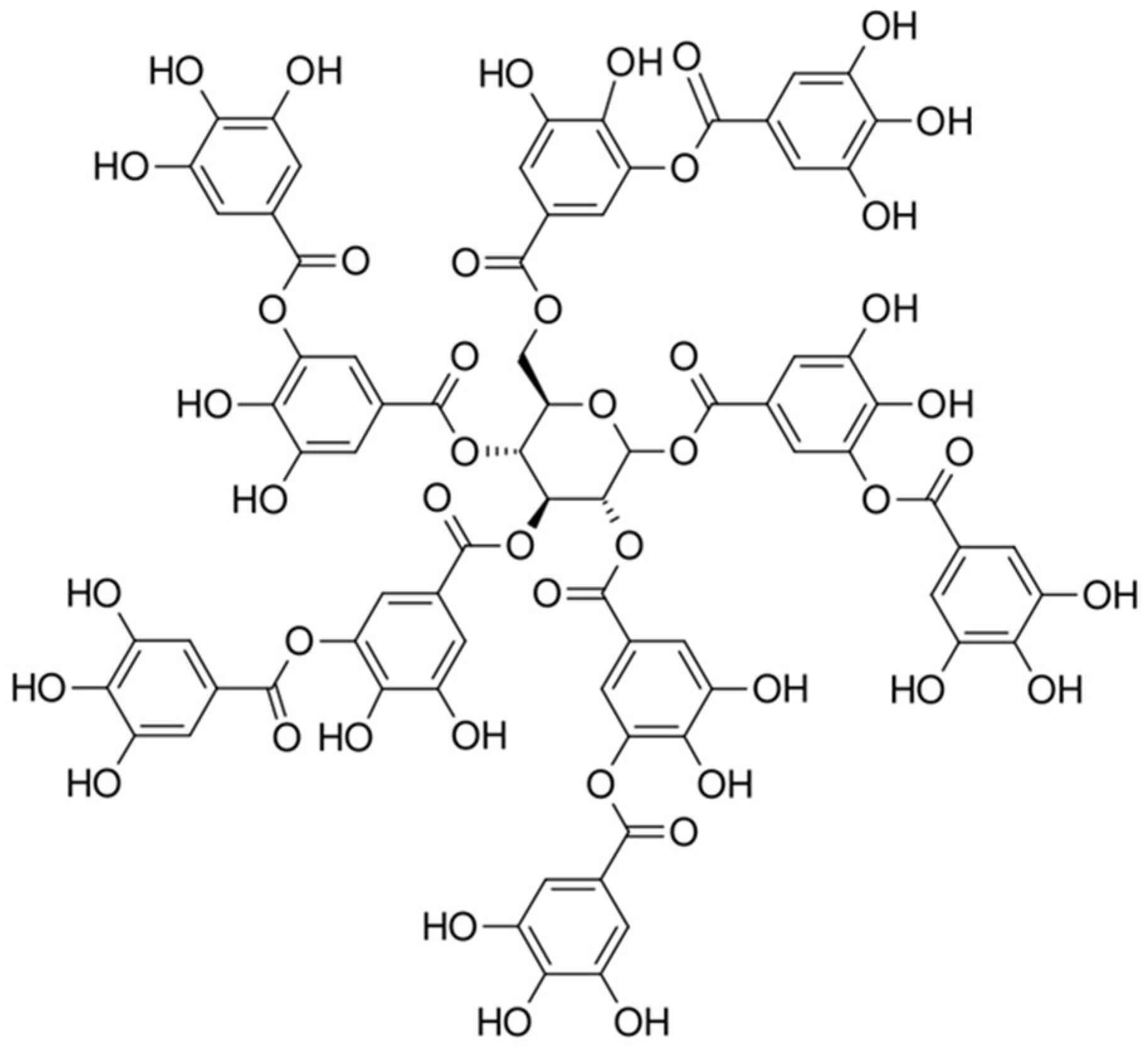

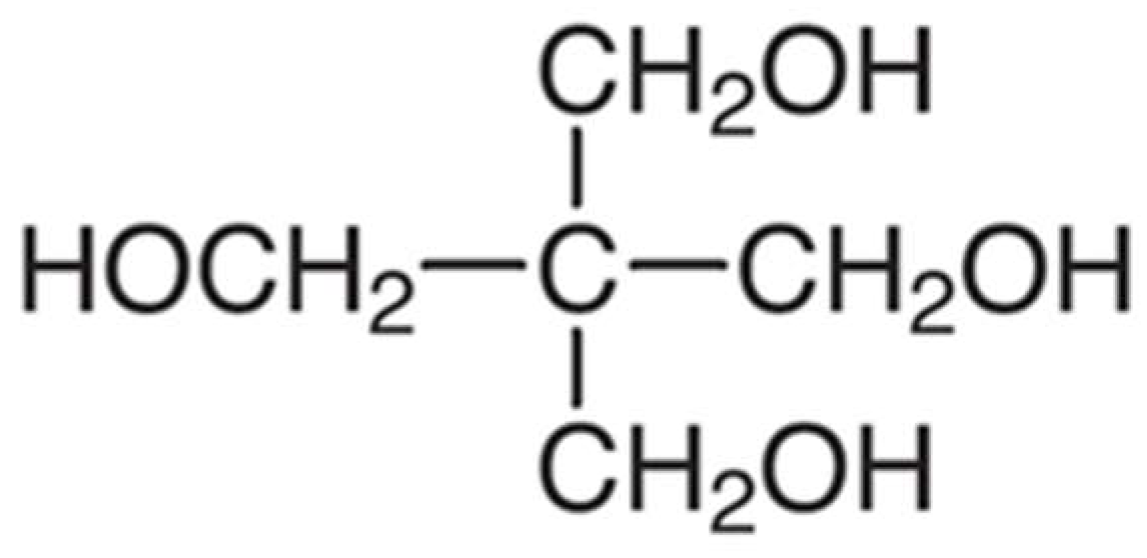

4.2. Char Formers

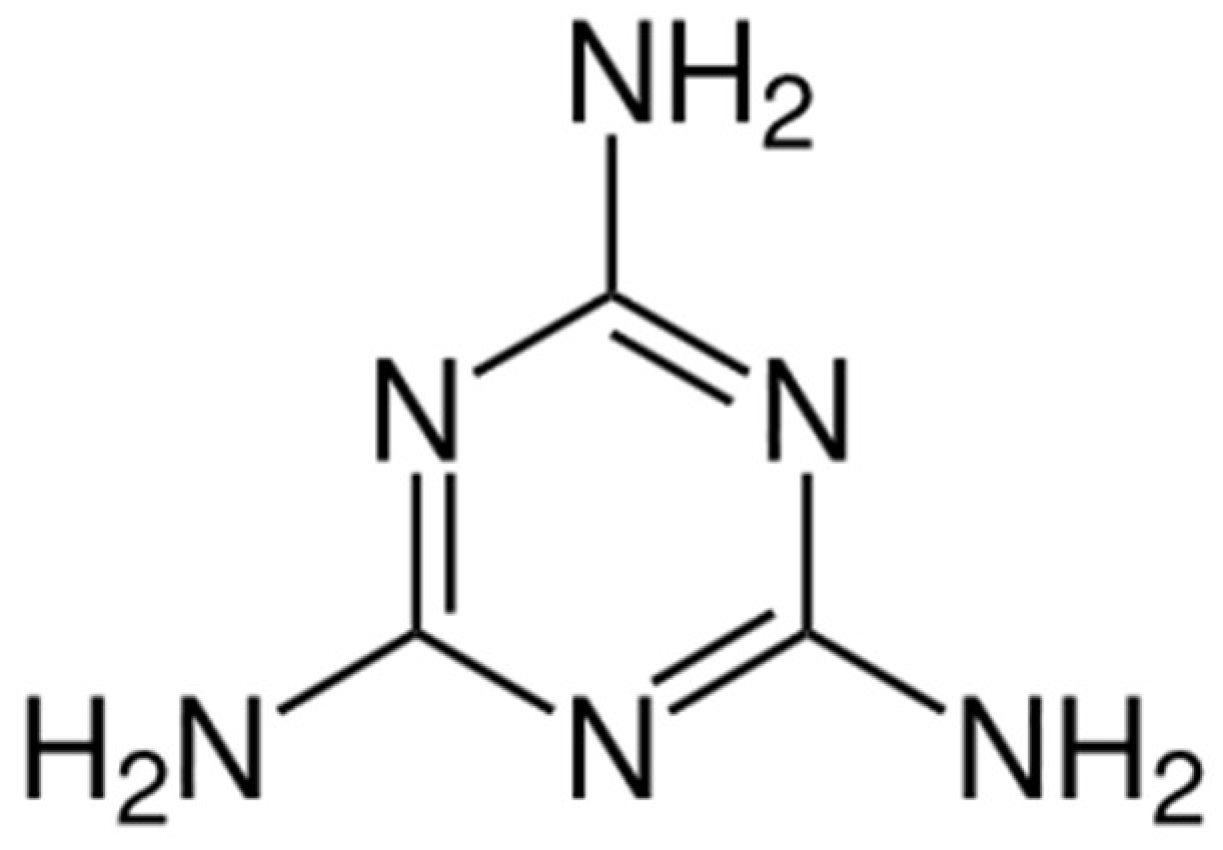

4.3. Blowing Agents

4.4. Binders and Binder Rheology

4.5. Other Additives

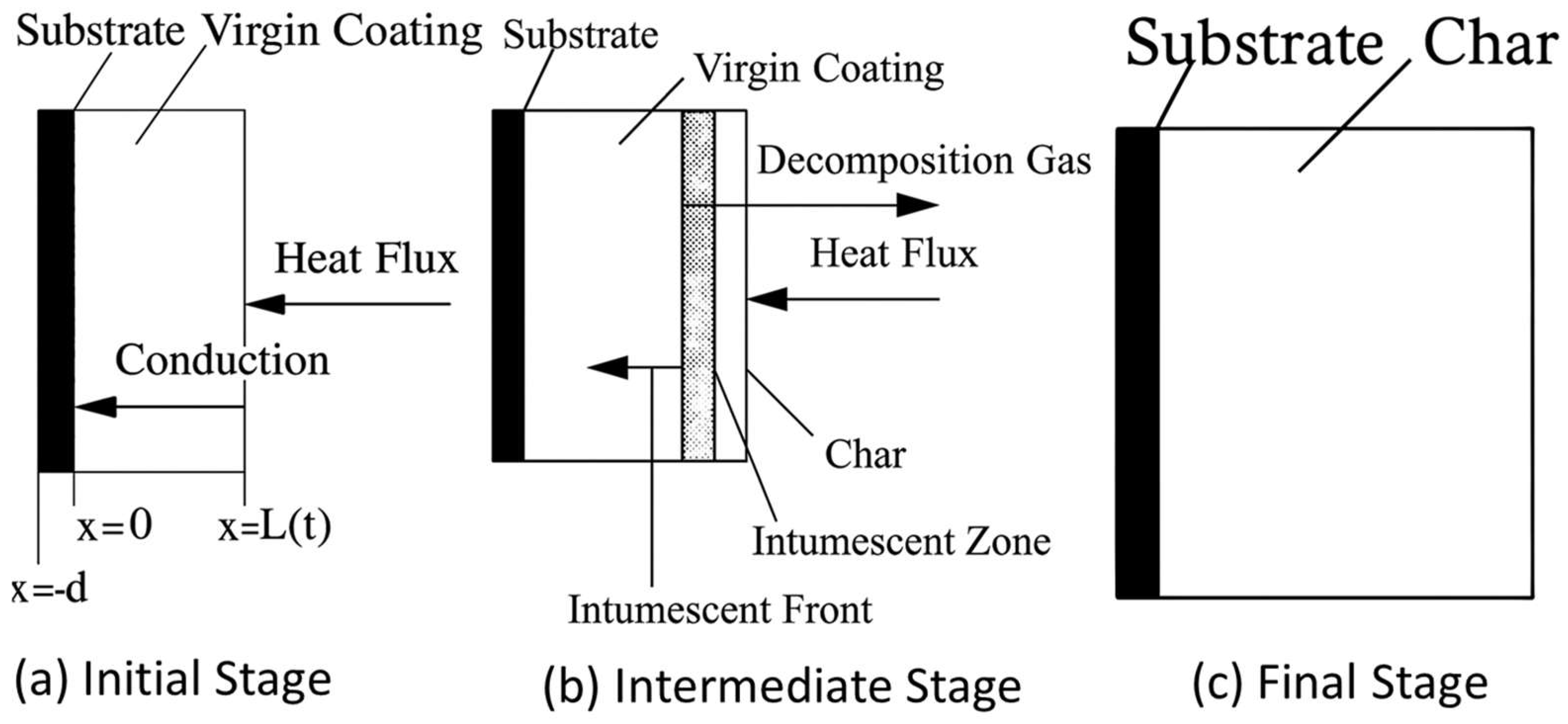

5. The Use of Numerical Models to Study IC Performance

Key Equations Used to Model ICs

6. Industry Perspectives on ICs in the Oil and Gas Sector: Challenges, Opportunities, and Future Directions

Survey-Based Industry Reflections and Adoption Insights

7. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Litvinenko, V. The Role of Hydrocarbons in the Global Energy Agenda: The Focus on Liquefied Natural Gas. Resources 2020, 9, 59. [Google Scholar] [CrossRef]

- Löffler, K.; Krumm, A. The Energy Transition in India: Quantifying Effects of the Low-Carbon Transition on the Indian Energy System. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Ben-Naceur, K. How the Oil and Gas Industry Is Contributing to Sustainability. J. Pet. Technol. 2019, 71, 38–39. [Google Scholar] [CrossRef]

- Solomon, M.B.; Rabha, S.S.; Fimbres-Weihs, G.; Goyal, H.; Taghikhah, F.R.; Varghese, J.J.; Wenger, S.R.; Liang, W.; Kearns, E.R.; Huang, J.; et al. Decarbonization in Australia and India: Bilateral Opportunities and Challenges for the Net Zero Transformation. ACS Eng. Au 2024, 4, 295–311. [Google Scholar] [CrossRef]

- Keerthi Narayanan, D.; Abdur Ravoof, A.; Jayapriya, J.; Revathi, G.; Murugan, M. 4—Hazards in Oil, Gas, and Petrochemical Industries. In Crises in Oil, Gas and Petrochemical Industries; Rahimpour, M.R., Omidvar, B., Shirazi, N.A., Makarem, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 71–99. [Google Scholar] [CrossRef]

- Yazdi, M.; Adesina, K.A.; Korhan, O.; Nikfar, F. Learning from Fire Accident at Bouali Sina Petrochemical Complex Plant. J. Fail. Anal. Prev. 2019, 19, 1517–1536. [Google Scholar] [CrossRef]

- Baerncopf, J.; Hutches, K. A Review of Modern Challenges in Fire Debris Analysis. Forensic Sci. Int. 2014, 244, e12–e20. [Google Scholar] [CrossRef]

- Bassi, I.; Delchiaro, F.; Bandinelli, C.; Mazzocchetti, L.; Salatelli, E.; Sarti, G. A New Perspective on Hydrogen Chloride Scavenging at High Temperatures for Reducing the Smoke Acidity of PVC Cables in Fires, IV: The Impact of Acid Scavengers at High Temperatures on Flame Retardance and Smoke Emission. Fire 2023, 6, 259. [Google Scholar] [CrossRef]

- Gravit, M.V.; Kotlyarskaya, I.L.; Zybina, O.A.; Korolchenko, D.A.; Nuguzhinov, Z.S. Fire Resistance of Building Structures and Fire Protection Materials: Bibliometric Analysis. Fire 2024, 8, 10. [Google Scholar] [CrossRef]

- Soares, I.; Ferreira, J.L.; Silva, H.; Rodrigues, M.P. Fire-Retardant and Fire-Resistant Coatings: From Industry to the Potential Use on Cultural Heritage. J. Cult. Herit. 2024, 68, 316–327. [Google Scholar] [CrossRef]

- Kim, Y.; Makarov, D.; Kashkarov, S.; Joseph, P.; Molkov, V. Modelling Heat Transfer in an Intumescent Paint and Its Effect on Fire Resistance of On-Board Hydrogen Storage. Int. J. Hydrogen Energy 2017, 42, 7297–7303. [Google Scholar] [CrossRef]

- Aydin, N.; Seker, S.; Şen, C. A New Risk Assessment Framework for Safety in Oil and Gas Industry: Application of FMEA and BWM Based Picture Fuzzy MABAC. J. Pet. Sci. Eng. 2022, 219, 111059. [Google Scholar] [CrossRef]

- Cirpici, B.K.; Aydin, I. Investigation of Intumescent Coating on the Fire Endurance of Concrete-Filled Steel Columns with Varied Characteristics. J. Mater. Res. Technol. 2023, 25, 1959–1980. [Google Scholar] [CrossRef]

- Gorlenko, N.V.; Murzin, M.A. Comparative Analysis of Fire Risks in Coal and Oil and Gas Industries. IOP Conf. Ser. Mater. Sci. Eng. 2019, 687, 066009. [Google Scholar] [CrossRef]

- Zang, X.; Liu, W.; Wu, D.; Pan, X.; Zhang, W.; Bian, H.; Shen, R. Contemporary Fire Safety Engineering in Timber Structures: Challenges and Solutions. Fire 2023, 7, 2. [Google Scholar] [CrossRef]

- Siddiqui, N.A.; Tauseef, S.M.; Abbasi, S.A.; Rangwala, A.S. Advances in Fire and Process Safety; Springer Transactions in Civil and Environmental Engineering; Springer: Berlin/Heidelberg, Germany, 2018; pp. 171–181. [Google Scholar]

- Zhu, Y.; Li, X.; Yu, J.; Cheng, Y.; Zhang, F. A Simplified Heat Transfer Model for Intumescent Coatings. J. Therm. Anal. Calorim. 2024, 149, 1343–1350. [Google Scholar] [CrossRef]

- Kuznetsov, G.V.; Zhdanova, A.O.; Volkov, R.S.; Strizhak, P.A. Optimizing Firefighting Agent Consumption and Fire Suppression Time in Buildings by Forming a Fire Feedback Loop. Process Saf. Environ. Prot. 2022, 165, 754–775. [Google Scholar] [CrossRef]

- Chopade, M. Fire Suppression Systems for High Rise Buildings in India. Int. J. Sci. Res. Eng. Dev. 2020, 3, 473–489. [Google Scholar]

- Edwards, A.; Smith, S.; Busch, P.; Winchester, D.; Tan, F.; Pang, V. Critical Learning from Fires: An Investigation of Complexity in IS-Enabled Emergency Management. 2020. Available online: https://web.archive.org/web/20220802072600id_/https://aisel.aisnet.org/cgi/viewcontent.cgi?article=1098&context=pacis2020 (accessed on 15 June 2025).

- Cadena, J.E.; Osorio, A.F.; Torero, J.L.; Reniers, G.; Lange, D. Uncertainty-Based Decision-Making in Fire Safety: Analyzing the Alternatives. J. Loss Prev. Process Ind. 2020, 68, 104288. [Google Scholar] [CrossRef]

- Takahashi, F. Fire Blanket and Intumescent Coating Materials for Failure Resistance. MRS Bull. 2021, 46, 429–434. [Google Scholar] [CrossRef]

- Kang, J.; Takahashi, F.; T’ien, J.S. In Situ Thermal-Conductivity Measurements and Morphological Characterization of Intumescent Coatings for Fire Protection. J. Fire Sci. 2018, 36, 419–437. [Google Scholar] [CrossRef]

- Gomez-Mares, M.; Tugnoli, A.; Landucci, G.; Barontini, F.; Cozzani, V. Behavior of Intumescent Epoxy Resins in Fireproofing Applications. J. Anal. Appl. Pyrolysis 2012, 97, 99–108. [Google Scholar] [CrossRef]

- Gomez-Mares, M.; Tugnoli, A.; Landucci, G.; Cozzani, V. Performance Assessment of Passive Fire Protection Materials. Ind. Eng. Chem. Res. 2012, 51, 7679–7689. [Google Scholar] [CrossRef]

- Brameld, M.; Baensch, T. Development of a Novel Passive Fire Protection System–Humidur Char. APPEA J. 2023, 63, S155–S158. [Google Scholar] [CrossRef]

- M.R.F. Intumescent Coatings Market Size, Share and Forecast Report 2032. Available online: https://www.marketresearchfuture.com/reports/intumescent-coatings-market-10536 (accessed on 19 March 2025).

- Sorathia, U.; Gracik, T.; Ness, J.; Durkin, A.; Williams, F.; Hunstad, M.; Berry, F. Evaluation of Intumescent Coatings for Shipboard Fire Protection. J. Fire Sci. 2003, 21, 423–450. [Google Scholar] [CrossRef]

- Gravit, M.; Korolchenko, D.; Nedviga, E.; Portnov, F.; Diachenko, S. Impact of Jet Fires on Steel Structures: Application of Passive Fire Protection Materials. Fire 2024, 7, 281. [Google Scholar] [CrossRef]

- Mariappan, T. Recent Developments of Intumescent Fire Protection Coatings for Structural Steel: A Review. J. Fire Sci. 2016, 34, 120–163. [Google Scholar] [CrossRef]

- Jagadeesha, T.; Kunar, S. Integrating Metal Forming and Additive Manufacturing for Enhanced Product Quality and Efficiency. In Advances in Additive Manufacturing; John Wiley & Sons: Hoboken, NJ, USA, 2024; pp. 129–143. [Google Scholar] [CrossRef]

- Jagadeesha, T.; Kunar, S. Nano-Additives for Advanced Additive Manufacturing: Enhancing Quality, Sustainability and Performance. In Advances in Additive Manufacturing; John Wiley & Sons: Hoboken, NJ, USA, 2024; pp. 157–164. [Google Scholar]

- Jo, S.; Oterkus, E. Thermal and Structural Behaviour of Offshore Structures with Passive Fire Protection. Sustain. Mar. Struct. 2022, 4, 16–28. [Google Scholar]

- Ngene, S.; Tota-Maharaj, K.; Eke, P.; Hills, C. Environmental Implications of Flaring and Venting in Crude Oil and Natural Gas Production. Energy Res. 2015, 4, 154. [Google Scholar] [CrossRef]

- Otutu, J.O. Environmental Impact of Gas Flaring within Umutu-Ebedei Gas Plant in Delta State, Nigeria. 2011. Available online: https://www.scholarsresearchlibrary.com/articles/environmental-impact-of-gas-flaring-within-umutuebedei-gas-plant-in-delta-state-nigeria.pdf (accessed on 15 June 2025).

- Hunter, E. Wildfire Resilience in Southern Alberta. Available online: https://ucalgary.scholaris.ca/items/e3f17a1b-2101-44bb-bb58-bb449c3d9067 (accessed on 15 June 2025).

- Asad, M.M.; Bin Hassan, R.; Sherwani, F.; Soomro, Q.M.; Sohu, S.; Lakhiar, M.T. Oil and Gas Disasters and Industrial Hazards Associated with Drilling Operation: An Extensive Literature Review. In Proceedings of the 2019 2nd International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 30–31 January 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Zia, A.W.; Hussain, S.A.; Baig, M.M.F.A. Optimizing Diamond-like Carbon Coatings—From Experimental Era to Artificial Intelligence. Ceram. Int. 2022, 48, 36000–36011. [Google Scholar] [CrossRef]

- Al-Hemoud, A.; Al-Dousari, A.; Misak, R.; Al-Sudairawi, M.; Naseeb, A.; Al-Dashti, H.; Al-Dousari, N. Economic Impact and Risk Assessment of Sand and Dust Storms (SDS) on the Oil and Gas Industry in Kuwait. Sustainability 2019, 11, 200. [Google Scholar] [CrossRef]

- Elehinafe, F.B.; Nwizu, C.I.; Odunlami, O.B.; Ibukun, F.D. Natural Gas Flaring in Nigeria, Its Effects and Potential Alternatives—A Review. J. Ecol. Eng. 2022, 23, 141–151. [Google Scholar] [CrossRef]

- Usiabulu, G.I.; Amadi, A.H.; Adebisi, O.; Ifedili, U.D.; Ajayi, K.E.; Moses, P.R. Gas Flaring, and Its Environmental Impact in Ekpan Community, Delta State, Nigeria. Am. J. Sci. Eng. Technol. 2023, 8, 42–53. [Google Scholar]

- Makocha, I.R.; Ete, T.; Saini, G. Deepwater Horizon Oil Spill: A Review. Volume 5. Available online: https://www.researchgate.net/publication/351372279_Deepwater_Horizon_Oil_Spill_A_Review (accessed on 15 June 2025).

- Reuters. Fire on Pemex Offshore Platform in Gulf of Mexico Kills Five. 2021. Available online: https://www.bbc.com/news/world-latin-america-58315356 (accessed on 15 June 2025).

- Kohler, M.D.; Massari, A.; Heaton, T.H.; Kanamori, H.; Hauksson, E.; Guy, R.; Clayton, R.W.; Bunn, J.; Chandy, K.M. Downtown Los Angeles 52-Story High-Rise and Free-Field Response to an Oil Refinery Explosion. Earthq. Spectra 2016, 32, 1793–1820. [Google Scholar] [CrossRef]

- Al Jazeera. Iran’s Natanz Nuclear Facility Hit by “Sabotage”. 2020.

- Gałaj, J.A.; Saleta, D. 5—Toxicity of Toxic Gases Emitted during a Fire and Ventilation. In Advances in the Toxicity of Construction and Building Materials; Pacheco-Torgal, F., Falkinham, J.O., Gałaj, J.A., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Oxford, UK, 2022; pp. 81–115. [Google Scholar] [CrossRef]

- Terrill, J.B.; Montgomery, R.R.; Reinhardt, C.F. Toxic Gases from Fires. Science 1978, 200, 1343–1347. [Google Scholar] [CrossRef]

- Docslib. Chapter 1: Chemistry and Physics of Fire. Available online: https://docslib.org/doc/11675931/chapter-1-chemistry-and-physics-of-fire (accessed on 20 March 2025).

- Chuang, C.-S.; Fan, Y.-J.; Sheen, H.-J. Flame Retardancy Effects on Intumescent Coatings with Vinyl Acetate Copolymers. Int. Polym. Process. 2019, 34, 541–550. [Google Scholar] [CrossRef]

- Riva, A.; Camino, G.; Fomperie, L.; Amigouët, P. Fire Retardant Mechanism in Intumescent Ethylene Vinyl Acetate Compositions. Polym. Degrad. Stab. 2003, 82, 341–346. [Google Scholar] [CrossRef]

- Jimenez, M.; Duquesne, S.; Bourbigot, S. Kinetic Analysis of the Thermal Degradation of an Epoxy-Based Intumescent Coating. Polym. Degrad. Stab. 2009, 94, 404–409. [Google Scholar] [CrossRef]

- Lu, J.; Li, L.; Jiang, P.; Chen, Z.; Fontaine, G.; Zhang, Y.; Yu, G.; Bourbigot, S. Flammability Properties of Intumescent Vinyl Acetate–Ethylene Copolymer Emulsion Including Natural Carbonization Agent. Polymer 2022, 245, 124709. [Google Scholar] [CrossRef]

- Lucherini, A.; Hidalgo, J.P.; Torero, J.L.; Maluk, C. A Novel Approach to Model the Thermal and Physical Behaviour of Swelling Intumescent Coatings Exposed to Fire. In Proceedings of the 11th International Conference on Structures in Fire (SiF2020); The University of Queensland: Brisbane, Australia, 2020. [Google Scholar] [CrossRef]

- Lucherini, A.; Hidalgo, J.P.; Torero, J.L.; Maluk, C. Influence of Heating Conditions and Initial Thickness on the Effectiveness of Thin Intumescent Coatings. Fire Saf. J. 2021, 120, 103078. [Google Scholar] [CrossRef]

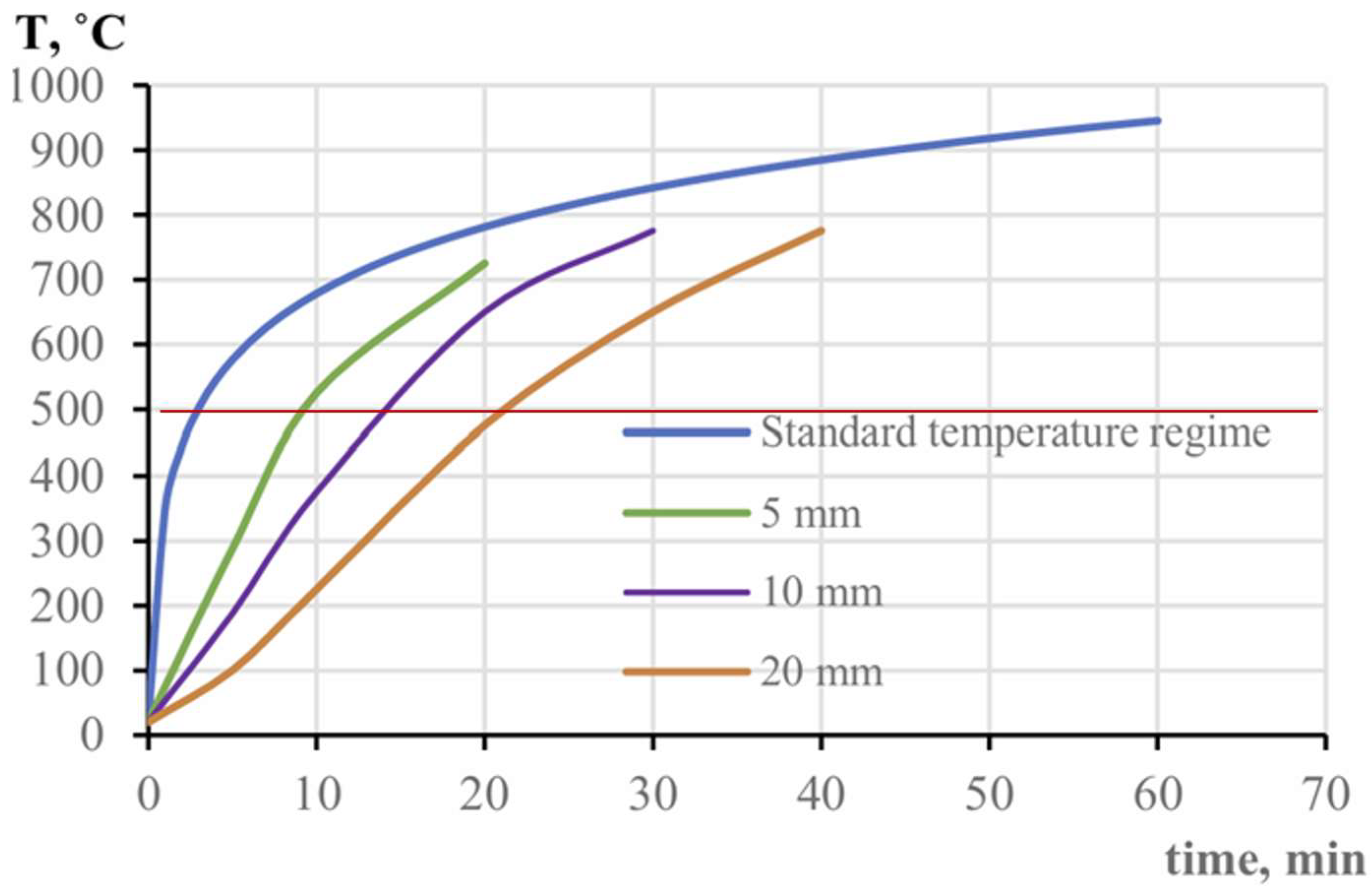

- Kovalov, A.; Otrosh, Y.; Semkiv, O.; Konoval, V.; Chernenko, O. Influence of the Fire Temperature Regime on the Fire-Retardant Ability of Reinforced-Concrete Floors Coating. Mater. Sci. Forum 2020, 1006, 87–92. [Google Scholar] [CrossRef]

- Kovalov, A.I.; Otrosh, Y.A.; Kovalevska, T.M.; Safronov, S.O. Methodology for Assessment of the Fire-Resistant Quality of Reinforced-Concrete Floors Protected by Fire-Retardant Coatings. IOP Conf. Ser. Mater. Sci. Eng. 2019, 708, 012058. [Google Scholar] [CrossRef]

- Qin, D.; Gao, P.; Aslam, F.; Sufian, M.; Alabduljabbar, H. A Comprehensive Review on Fire Damage Assessment of Reinforced Concrete Structures. Case Stud. Constr. Mater. 2022, 16, e00843. [Google Scholar] [CrossRef]

- Amini, R.; Amini, M.; Jafarinia, A.; Kashfi, M. Numerical Investigation on Effects of Using Segmented and Helical Tube Fins on Thermal Performance and Efficiency of a Shell and Tube Heat Exchanger. Appl. Therm. Eng. 2018, 138, 750–760. [Google Scholar] [CrossRef]

- Hafiz, T.; Gassama, E.; Covello, J.; Wnek, G.; Liao, Y.-T.; Melaiye, A.K. Experimental and Numerical Approaches to Optimize Heat Blocking Efficiency in Intumescent Coatings. Eng. Model. Anal. Simul. 2025, 2. [Google Scholar] [CrossRef]

- Natarajan, E.; Freitas, L.I.; Santhosh, M.S.; Markandan, K.; Al-Talib, A.A.M.; Hassan, C.S. Experimental and Numerical Analysis on Suitability of S-Glass-Carbon Fiber Reinforced Polymer Composites for Submarine Hull. Def. Technol. 2023, 19, 1–11. [Google Scholar] [CrossRef]

- Barrera, A. Neil Prophet, Senior Partner. Available online: https://www.iomosaic.com/about/our-teams/neil-prophet (accessed on 15 June 2025).

- Bloor, M.; Boyle, T.; Chintapatla, T. Failures, Repeated—The Tianjin Explosion. Available online: https://www.icheme.org/media/18714/lpb286_pg17.pdf (accessed on 15 June 2025).

- Nolan, D.P. Handbook of Fire and Explosion Protection Engineering Principles for Oil, Gas, Chemical, and Related Facilities; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Fatal Explosion Hits Giant BASF Site. CEN Glob. Enterp. 2016, 94, 13. [CrossRef]

- Fire and Explosions at Philadelphia Energy Solutions Refinery. Available online: https://www.csb.gov/philadelphia-energy-solutions-pes-refinery-fire-and-explosions-/ (accessed on 15 June 2025).

- Iheukwumere, O.E.; Moore, D.; Omotayo, T. Investigating the Challenges of Refinery Construction in Nigeria: A Snapshot across Two-Timeframes over the Past 55 Years. Int. J. Constr. Supply Chain Manag. 2020, 10, 46–72. [Google Scholar]

- Manikumar, D.; Raju, T.B.; Sharma, U. Analysis of Accidents in the Oil and Gas Industry in Kuwait. Int. J. Saf. Secur. Eng. 2024, 14, 893–905. [Google Scholar] [CrossRef]

- Бeздeнeжнaя, E.H.; Дoлгушинa, Л.B. Пoжaрнaя Бeзoпaснoсть Нa Склaдaх Нeфти и Нeфтeпрoдуктoв. Facilities 2023, 10. [Google Scholar]

- Shell Will Sell Its Singapore Cracker. CEN Glob. Enterp. 2024, 102, 12. [CrossRef]

- Seydi, S.T. Assessment of the January 2025 Los Angeles County Wildfires: A Multi-Modal Analysis of Impact, Response, and Population Exposure. arXiv 2025, arXiv:250117880. [Google Scholar]

- Qiu, M.; Chen, D.; Kelp, M.; Li, J.; Huang, G.; Yazdi, M.D. The Rising Threats of Wildland-Urban Interface Fires in the Era of Climate Change: The Los Angeles 2025 Fires. Innovation 2025, 6, 100835. [Google Scholar] [CrossRef] [PubMed]

- Yasir, M.; Ahmad, F.; Yusoff, P.S.M.M.; Ullah, S.; Jimenez, M. Latest Trends for Structural Steel Protection by Using Intumescent Fire Protective Coatings: A Review. Surf. Eng. 2020, 36, 334–363. [Google Scholar] [CrossRef]

- Yasir, M.; Amir, N.; Ahmad, F.; Ullah, S.; Jimenez, M. Synergistic Effect of Basalt Fiber on the Thermal Properties of Intumescent Fire Retardant Coating. Mater. Today Proc. 2019, 16, 2030–2038. [Google Scholar] [CrossRef]

- Tiwari, V.M.; Rao, M.B.S.V.; Mishra, D.C. Density Inhomogeneities beneath Deccan Volcanic Province, India as Derived from Gravity Data. J. Geodyn. 2001, 31, 1–17. [Google Scholar] [CrossRef]

- Tran, H.K.; Johnson, C.E.; Rasky, D.J.; Hui, F.C.L.; Hsu, M.-T.; Chen, T.; Chen, Y.K.; Paragas, D.; Kobayashi, L. Phenolic Impregnated Carbon Ablators (PICA) as Thermal ProtectionSystems for DiseoveN Missions; NASA TM-110440; NASA: Washington, DC, USA, 1997.

- Hao, J.; Chow, W.K.; Chow, W.K. A Brief Review of Intumescent Fire Retardant Coatings. Archit. Sci. Rev. 2003, 46, 89. [Google Scholar] [CrossRef]

- Horacek, H.; Pieh, S. The Importance of Intumescent Systems for Fire Protection of Plastic Materials. Fire Retard. Polym. 2000, 49, 1106–1114. [Google Scholar] [CrossRef]

- Wang, W.; Liu, B.; Kodur, V. Effect of Temperature on Strength and Elastic Modulus of High-Strength Steel. J. Mater. Civ. Eng. 2013, 25, 174–182. [Google Scholar] [CrossRef]

- Kodur, V. Properties of Concrete at Elevated Temperatures. Int. Sch. Res. Not. 2014, 2014, 468510. [Google Scholar] [CrossRef]

- El-Zohairy, A.; Hammontree, H.; Oh, E.; Moler, P. Materials Temperature Effect on the Compressive Behavior and Constitutive Model of Plain Hardened Concrete. Materials 2020, 13, 2801. [Google Scholar] [CrossRef]

- Keltner, N.R.; Alvares, N.J.; Grayson, S.J. (Eds.) Very Large-Scale Fires; STP1336-EB; ASTM International: Conshohocken, PA, USA, 1998. [Google Scholar]

- Alongi, J.; Han, Z.; Bourbigot, S. Intumescence: Tradition versus Novelty. A Comprehensive Review. Prog. Polym. Sci. 2015, 51, 28–73. [Google Scholar] [CrossRef]

- Puri, R.G.; Khanna, A.S. Intumescent Coatings: A Review on Recent Progress. J. Coat. Technol. Res. 2017, 14, 1–20. [Google Scholar] [CrossRef]

- Camino, G.; Costa, L.; Trossarelli, L. Study of the Mechanism of Intumescence in Fire Retardant Polymers: Part l-Thermal Degradation of Ammonium Polyphosphate-Pentaerythritol Mixtures. Polym. Degrad. Stab. 1984, 6, 243–252. [Google Scholar] [CrossRef]

- Pan, Y.; Zhao, H. A Novel Blowing Agent Polyelectrolyte for Fabricating Intumescent Multilayer Coating that Retards Fire on Cotton Fabric. J. Appl. Polym. Sci. 2018, 135, 46583. [Google Scholar] [CrossRef]

- Shih, Y.C.; Cheung, F.B.; Koo, J.H. Theoretical Modeling of Intumescent Fire-Retardant Materials. J. Fire Sci. 1998, 16, 46–71. [Google Scholar] [CrossRef]

- Bugajny, M.; Bras, M.L.; Noeuml, A.; Bourbigot, S. Use of Thermoplastic Polyurethanes as Carbonisation Agents in Intumescent Blends. Part 3: Modification of the Dynamic Properties of Polypropylene/Thermoplastic Polyurethane/Ammonium Polyphosphate Formulations with Heat and Stress. J. Fire Sci. 2000, 18, 104–129. [Google Scholar] [CrossRef]

- Jimenez, M.; Duquesne, S.; Bourbigot, S. Multiscale Experimental Approach for Developing High-Performance Intumescent Coatings. Ind. Eng. Chem. Res. 2006, 45, 4500–4508. [Google Scholar] [CrossRef]

- Duquesne, S.; Bras, M.L.; Bourbigot, S.; Delobel, R.; Camino, G.; Eling, B.; Lindsay, C.; Roels, T.; Vezin, H. Mechanism of Fire Retardancy of Polyurethanes Using Ammonium Polyphosphate. J. Appl. Polym. Sci. 2001, 82, 3262–3274. [Google Scholar] [CrossRef]

- Bugajny, M.; Bras, M.L.; Bourbigot, S. New Approach to the Dynamic Properties of an Intumescent Material. Fire Mater. 1999, 23, 49–51. [Google Scholar] [CrossRef]

- Duquesne, S.; Magnet, S.; Jama, C.; Delobel, R. Thermoplastic Resins for Thin Film Intumescent Coatings—Towards a Better Understanding of Their Effect on Intumescence Efficiency. Polym. Degrad. Stab. 2005, 88, 63–69. [Google Scholar] [CrossRef]

- Bourbigot, S. Chapter 6—Evaluation of Condensed Phase: Char/Residue Analysis. In Analysis of Flame Retardancy in Polymer Science; Vahabi, H., Saeb, M.R., Malucelli, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 191–231. [Google Scholar] [CrossRef]

- Chang, W.-H.; Scriven, R.L.; Ross, R.B. Flame-Retardant Organic Coatings. In Flame-Retardant Polymeric Materials; Lewin, M., Atlas, S.M., Pearce, E.M., Eds.; Springer: Boston, MA, USA, 1975; pp. 399–453. [Google Scholar] [CrossRef]

- Muller, M.; Bourbigot, S.; Duquesne, S.; Klein, R.A.; Giannini, G.; Lindsay, C.I. Measurement and Investigation of Intumescent Char Strength: Application to Polyurethanes. J. Fire Sci. 2013, 31, 293–308. [Google Scholar] [CrossRef]

- Zeng, Y.; Weinell, C.E.; Dam-Johansen, K.; Ring, L.; Kiil, S. Effects of Coating Ingredients on the Thermal Properties and Morphological Structures of Hydrocarbon Intumescent Coating Chars. Prog. Org. Coat. 2020, 143, 105626. [Google Scholar] [CrossRef]

- Rajan, K.P.; Thomas, S.P.; Gopanna, A.; Al-Ghamdi, A.; Chavali, M. Rheology, Mechanical Properties and Thermal Degradation Kinetics of Polypropylene (PP) and Polylactic Acid (PLA) Blends. Mater. Res. Express 2018, 5, 085304. [Google Scholar] [CrossRef]

- Zybina, O.; Gravit, M. Basic Ingredients of Intumescent Compositions. In Intumescent Coatings for Fire Protection of Building Structures and Materials; Zybina, O., Gravit, M., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–51. [Google Scholar] [CrossRef]

- Leca, M.; Cioroianu, L.; Cioroianu, G.; Damian, G. Aqueous Ecological Intumescent Fire Retardant Coatings for Multifunctional Applications. 1. Preparation and Characterization. 2007. Available online: https://revroum.lew.ro/wp-content/uploads/2007/RRCh_8-9_2007/Art_M.Leca.pdf (accessed on 15 June 2025).

- Lu, W.; Jin, Z. Synthesis of Phosphorus/Nitrogen Containing Intumescent Flame Retardants from p-Hydroxybenzaldehyde, Vanillin and Syringaldehyde for Rigid Polyurethane Foams. Polym. Degrad. Stab. 2022, 195, 109768. [Google Scholar] [CrossRef]

- Wang, J.; Li, G.; Yang, S.; Jiang, J. New Intumescent Flame-retardant Agent: Application to Polyurethane Coatings. J. Appl. Polym. Sci. 2004, 91, 1193–1206. [Google Scholar] [CrossRef]

- Zoleta, J.B.; Itao, G.B.; Resabal, V.J.T.; Lubguban, A.A.; Corpuz, R.D.; Ito, M.; Hiroyoshi, N.; Tabelin, C.B. Improved Pyrolysis Behavior of Ammonium Polyphosphate-Melamine-Expandable (APP-MEL-EG) Intumescent Fire Retardant Coating System Using Ceria and Dolomite as Additives for I-Beam Steel Application. Heliyon 2020, 6, e03119. [Google Scholar] [CrossRef]

- Gao, M.; Yang, S. A Novel Intumescent Flame-retardant Epoxy Resins System. J. Appl. Polym. Sci. 2010, 115, 2346–2351. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, J.; Zhang, M.; Du, X.; Ma, S.; Xu, B. Synergistic Flame-Retardant Effect of IFR and PPO in Improving Flame Retardancy of Polystyrene. Adv. Polym. Technol. 2016, 35, 208–214. [Google Scholar] [CrossRef]

- Wladyka-Przybylak, M.; Kozlowski, R. The Thermal Characteristics of Different Intumescent Coatings. Fire Mater. 1999, 23, 33–43. [Google Scholar] [CrossRef]

- Angelova, L.V.; Shugar, A.; Maines, C.A.; Tanimoto, S.; Singer, M.; Dommermuth, J.; Duggan, H.; Duncan, T.T.; Finnefrock, A.C.; Mass, J.L. The Use and Deterioration of Intumescent Fire-Retardant Paint on Louise Nevelson’s Erol Beker Chapel of the Good Shepherd. Heritage 2025, 8, 128. [Google Scholar] [CrossRef]

- Lim, K.-S.; Bee, S.-T.; Sin, L.T.; Tee, T.-T.; Ratnam, C.T.; Hui, D.; Rahmat, A.R. A Review of Application of Ammonium Polyphosphate as Intumescent Flame Retardant in Thermoplastic Composites. Compos. Part B 2015, 84, 155–174. [Google Scholar] [CrossRef]

- Wang, J.S.; Wang, D.Y.; Liu, Y.; Ge, X.G.; Wang, Y.Z. Polyamide-Enhanced Flame Retardancy of Ammonium Polyphosphate on Epoxy Resin. J. Appl. Polym. Sci. 2008, 108, 2644–2653. [Google Scholar] [CrossRef]

- Nagieb, Z.A.; Nassar, M.A.; El-Meligy, M.G. Effect of Addition of Boric Acid and Borax on Fire-Retardant and Mechanical Properties of Urea Formaldehyde Saw Dust Composites. Int. J. Carbohydr. Chem. 2011, 2011, 146763. [Google Scholar] [CrossRef]

- Wang, Q.; Li, J.; Winandy, J.E. Chemical Mechanism of Fire Retardance of Boric Acid on Wood. Wood Sci. Technol. 2004, 38, 375–389. [Google Scholar] [CrossRef]

- Anna, P.; Marosi, G.; Csontos, I.; Bourbigot, S.; Le Bras, M.; Delobel, R. Influence of Modified Rheology on the Efficiency of Intumescent Flame Retardant Systems. Polym. Degrad. Stab. 2001, 74, 423–426. [Google Scholar] [CrossRef]

- Wang, Z.; Han, E.; Ke, W. Effect of Nanoparticles on the Improvement in Fire-Resistant and Anti-Ageing Properties of Flame-Retardant Coating. Surf. Coat. Technol. 2006, 200, 5706–5716. [Google Scholar] [CrossRef]

- Ullah, S.; Ahmad, F.; Yusoff, P.S.M.M. Effect of Boric Acid and Melamine on the Intumescent Fire-Retardant Coating Composition for the Fire Protection of Structural Steel Substrates. J. Appl. Polym. Sci. 2013, 128, 2983–2993. [Google Scholar] [CrossRef]

- Coimbra, A.; Sarazin, J.; Bourbigot, S.; Legros, G.; Consalvi, J.-L. A Semi-Global Reaction Mechanism for the Thermal Decomposition of Low-Density Polyethylene Blended with Ammonium Polyphosphate and Pentaerythritol. Fire Saf. J. 2022, 133, 103649. [Google Scholar] [CrossRef]

- Schinazi, G.; D’almeida, J.J.M.; Pokorski, J.K.; Schiraldi, D.A. Bio-Based Flame Retardation of Acrylonitrile−Butadiene−Styrene. ACS Appl. Polym. Mater. 2020, 2021, 372–388. [Google Scholar] [CrossRef]

- Kulkarni, S.; Xia, Z.; Yu, S.; Kiratitanavit, W.; Morgan, A.B.; Kumar, J.; Mosurkal, R.; Nagarajan, R. Bio-Based Flame-Retardant Coatings Based on the Synergistic Combination of Tannic Acid and Phytic Acid for Nylon-Cotton Blends. ACS Appl. Mater. Interfaces 2021, 13, 61620–61628. [Google Scholar] [CrossRef]

- Villamil Watson, D.A.; Schiraldi, D.A. Biomolecules as Flame Retardant Additives for Polymers: A Review. Polymers 2020, 12, 849. [Google Scholar] [CrossRef] [PubMed]

- Price, E.J.; Covello, J.; Paul, R.; Wnek, G.E. Tannic Acid Based Super-intumescent Coatings for Prolonged Fire Protection of Cardboard and Wood. SPE Polym. 2021, 2, 153–168. [Google Scholar] [CrossRef]

- Xia, Z.; Singh, A.; Kiratitanavit, W.; Mosurkal, R.; Kumar, J.; Nagarajan, R. Unraveling the Mechanism of Thermal and Thermo-Oxidative Degradation of Tannic Acid. Thermochim. Acta 2015, 605, 77–85. [Google Scholar] [CrossRef]

- Basak, S.; Raja, A.S.M.; Saxena, S.; Patil, P.G. Tannin Based Polyphenolic Bio-Macromolecules: Creating a New Era towards Sustainable Flame Retardancy of Polymers. Polym. Degrad. Stab. 2021, 189, 109603. [Google Scholar] [CrossRef]

- Celzard, A.; Fierro, V.; Amaral-Labat, G.; Pizzi, A.; Torero, J. Flammability Assessment of Tannin-Based Cellular Materials. Polym. Degrad. Stab. 2011, 96, 477–482. [Google Scholar] [CrossRef]

- Hobbs, C. Recent Advances in Bio-Based Flame Retardant Additives for Synthetic Polymeric Materials. Polymers 2019, 11, 224. [Google Scholar] [CrossRef]

- Jü, B.; Irran, E.; Senker, J.R.; Kroll, P.; Mü, H.; Schnick, W. Melem (2,5,8-Triamino-Tri-s-Triazine), an Important Intermediate during Condensation of Melamine Rings to Graphitic Carbon Nitride: Synthesis, Structure Determination by X-Ray Powder Diffractometry, Solid-State NMR, and Theoretical Studies. J. Am. Chem. Soc. 2003, 125, 10288–10300. [Google Scholar] [CrossRef]

- Federal Institute for Occupational Safety and Health. CLH Report Proposal for Harmonised Classification and Labelling Based on Regulation (EC) No 1272/2008 (CLP Regulation): Melamine. 2019. Available online: https://www.iaeg.com/binaries/content/assets/iaeg-newsletters/2023/04/eu_clh-report_proposal-for-harmonised-classification-and-labelling.pdf (accessed on 15 June 2025).

- Bodzay, B.; Bocz, K.; Bárkai, Z.; Marosi, G. Influence of Rheological Additives on Char Formation and Fire Resistance of Intumescent Coatings. Polym. Degrad. Stab. 2011, 96, 355–362. [Google Scholar] [CrossRef]

- Zeng, Y.; Weinell, C.E.; Dam-Johansen, K.; Ring, L.; Kiil, S. Exposure of Hydrocarbon Intumescent Coatings to the UL1709 Heating Curve and Furnace Rheology: Effects of Zinc Borate on Char Properties. Prog. Org. Coat. 2019, 135, 321–330. [Google Scholar] [CrossRef]

- Chen, X.; Jiao, C. Flame Retardancy and Thermal Degradation of Intumescent Flame Retardant Polypropylene Material. Polym. Adv. Technol. 2011, 22, 817–821. [Google Scholar] [CrossRef]

- Drabek, J.; Zatloukal, M. Evaluation of Thermally Induced Degradation of Branched Polypropylene by Using Rheology and Different Constitutive Equations. Polymers 2016, 8, 317. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.; Xia, Z.; Li, Q.; Li, Z. Effects of Inorganic Fillers on the Shear Viscosity and Fire Retardant Performance of Waterborne Intumescent Coatings. Prog. Org. Coat. 2013, 76, 844–851. [Google Scholar] [CrossRef]

- Jiao, C.; Chen, X.; Zhang, J. Synergistic Flame-Retardant Effects of Aluminum Oxide with Layered Double Hydroxides in EVA/LDH Composites. J. Thermoplast. Compos. Mater. 2010, 23, 501–512. [Google Scholar] [CrossRef]

- Aziz, H.; Ahmad, F. Effects from Nano-Titanium Oxide on the Thermal Resistance of an Intumescent Fire Retardant Coating for Structural Applications. Prog. Org. Coat. 2016, 101, 431–439. [Google Scholar] [CrossRef]

- Lin, X.-Y.; Yang, Z.-H.; Hsu, S.-Y. The Performance Evaluation of Intumescent Coating in Bench-Scale Tests by Using Experiments and Numerical Models. In Proceedings of the 2018 IEEE International Conference on Applied System Invention (ICASI), Chiba, Japan, 13–17 April 2018; pp. 1192–1195. [Google Scholar] [CrossRef]

- Zhu, A.; Wu, H.; Liu, J. Feasibility Study on Novel Fire-Resistant Coating Materials. J. Mater. Civ. Eng. 2022, 34, 04022080. [Google Scholar] [CrossRef]

- Branca, C.; Di Blasi, C.; Horacek, H. Analysis of the Combustion Kinetics and Thermal Behavior of an Intumescent System. Ind. Eng. Chem. Res. 2002, 41, 2107–2114. [Google Scholar] [CrossRef]

- Hsu, S.-Y. The Thermal Response of Intumescent Coating Under Different Combinations of External Heat Fluxes. J. Heat Transf. 2018, 140, 082001. [Google Scholar] [CrossRef]

- Weisheim, W.; Schaumann, P.; Sander, L.; Zehfuß, J. Numerical Model for the Fire Protection Performance and the Design of Intumescent Coatings on Structural Steel Exposed to Natural Fires. J. Struct. Fire Eng. 2019, 11, 33–50. [Google Scholar] [CrossRef]

- FastEST, Inc. FastWRAP—Mechanical Insulation Estimating Software. Available online: https://fastest-inc.com/FastWRAP (accessed on 20 February 2025).

- Purwanto, R.E.; Fuadi, F. The Method of NAIMA 3E plus Simulation for Selection of Material Insulation in Removable Thermal Insulation Cover. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 732, p. 012095. [Google Scholar]

- Kazmi, B.; Raza, F.; Taqvi, S.A.A.; Ali, S.I.; Suleman, H. Energy, Exergy and Economic (3E) Evaluation of CO2 Capture from Natural Gas Using Pyridinium Functionalized Ionic Liquids: A Simulation Study. J. Nat. Gas Sci. Eng. 2021, 90, 103951. [Google Scholar] [CrossRef]

- King, R.R.L. Insulation Investment= Energy Savings and Exceptional Financial Returns. Strateg. Plan. Energy Environ. 2009, 28, 37–52. [Google Scholar] [CrossRef]

- Griffin, G.J. The Modeling of Heat Transfer across Intumescent Polymer Coatings. J. Fire Sci. 2010, 28, 249–277. [Google Scholar] [CrossRef]

- Lagaros, N.D. Design Optimization of Active and Passive Structural Control Systems; IGI Global: New York, NY, USA, 2012. [Google Scholar]

- Wilson, T.; Grossman, I.; Temple, J. Local Area Population Projections Dataset for Australia. Data Brief 2022, 44, 108559. [Google Scholar] [CrossRef]

- Ogundairo, O. A Comparative Study of Finite Difference and Finite Element Methods for Fractional Diffusion Equations Author Ogundairo Obaloluwa. J. Math. Math. Educ. 2024, 8, 166–186. [Google Scholar]

- Behseresht, S.; Park, Y.H.; Love, A.; Valdez Pastrana, O.A. Application of Numerical Modeling and Finite Element Analysis in Fused Filament Fabrication: A Review. Materials 2024, 17, 4185. [Google Scholar] [CrossRef] [PubMed]

- Roniotis, A.; Marias, K.; Sakkalis, V.; Stamatakos, G.; Zervakis, M. Comparing Finite Elements and Finite Differences for Developing Diffusive Models of Glioma Growth. In Proceedings of the 2010 Annual International Conference of the IEEE Engineering in Medicine and Biology, Buenos Aires, Argentina, 31 August–4 September 2010; pp. 6797–6800. [Google Scholar] [CrossRef]

- Cirpici, B.K.; Wang, Y.C.; Rogers, B.D.; Bourbigot, S. A Theoretical Model for Quantifying Expansion of Intumescent Coating under Different Heating Conditions. Polym. Eng. Sci. 2016, 56, 798–809. [Google Scholar] [CrossRef]

- Tian, N.; Delichatsios, M.A.; Zhang, J.; Fateh, T. A Methodology and a Simple Engineering Fire Performance Model for Intumescent Fire Retardant Coatings. Fire Saf. J. 2018, 98, 120–129. [Google Scholar] [CrossRef]

- Jiang, G.; Xu, X.; Zhang, J.; He, C.; Tao, S.; Wu, Y.; Ding, Y. Pyrolysis Characteristics and Reaction Mechanism of Intumescent Fire-Retardant Coating with Thermogravimetry/Fourier Transform Infrared Analysis. J. Anal. Appl. Pyrolysis 2024, 177, 106306. [Google Scholar] [CrossRef]

- Lucherini, A.; de Silva, D. Modelling Intumescent Coatings for the Fire Protection of Structural Systems: A Review. J. Struct. Fire Eng. 2024, 15, 483–507. [Google Scholar] [CrossRef]

- Di Blasi, C.; Branca, C. Mathematical Model for the Nonsteady Decomposition of Intumescent Coatings. AIChE J. 2001, 47, 2359–2370. [Google Scholar] [CrossRef]

- Hsu, S.-Y. Modeling of Heat Transfer in Intumescent Fire-Retardant Coating Under High Radiant Heat Source and Parametric Study on Coating Thermal Response. J. Heat Transf. 2017, 140, 032701. [Google Scholar] [CrossRef]

- Mesquita, L.M.R.; Piloto, P.A.G.; Vaz, M.A.P.; Vila Real, P.M.M. Experimental and Numerical Research on the Critical Temperature of Laterally Unrestrained Steel I Beams. J. Constr. Steel Res. 2005, 61, 1435–1446. [Google Scholar] [CrossRef]

- Anderson, C.E.; Wauters, D.K. A Thermodynamic Heat Transfer Model for Intumescent Systems. Int. J. Eng. Sci. 1984, 22, 881–889. [Google Scholar] [CrossRef]

- Wang, Y.; Goransson, U.; Holmstedt, G.; Omrane, A. A Model for Prediction of Temperature in Steel Structure Protected by Intumescent Coating, Based on Tests in the Cone Calorimeter. Fire Saf. Sci. 2005, 8, 235–246. [Google Scholar] [CrossRef]

- Xu, W. Modeling Gas Transport in Shale Reservoir—Conservation Laws Revisited. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 25–27 August 2014. [Google Scholar] [CrossRef]

- Di Blasi, C. Modeling the Effects of High Radiative Heat Fluxes on Intumescent Material Decomposition. J. Anal. Appl. Pyrolysis 2004, 71, 721–737. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Y.; Li, M. Combined Heat Transfer Mechanisms in the Porous Char Layer Formed from the Intumescent Coatings under Fire. Coatings 2021, 11, 200. [Google Scholar] [CrossRef]

- Jimenez, M.; Duquesne, S.; Bourbigot, S. Intumescent fire protective coating: Toward a better understanding of their mechanism of action. Thermochim. Acta 2006, 449, 16–26. [Google Scholar] [CrossRef]

- Lucherini, A.; Abusamha, N.; Segall-Brown, J.; Maluk, C. Experimental Study on the Onset of Swelling for Thin Intumescent Coatings. J. Phys. Conf. Ser. 2018, 1107, 032017. [Google Scholar] [CrossRef]

- Li, G.; Li, J.; Lu, X.; Lü, K.; Huang, J.; Huang, Y.; Chen, W.; Deng, L.; Jiang, J.; Dong, S.; et al. Oxidation Behavior and Interface Evolution of Tri-Layer Si/Yb2SiO5/LaMgAl11O19 Thermal and Environmental Barrier Coatings under Isothermal Heat Treatment at 1300 °C. Surf. Coat. Technol. 2023, 464, 129554. [Google Scholar] [CrossRef]

- De Schampheleire, S.; De Kerpel, K.; Ameel, B.; De Jaeger, P.; Bagci, O.; De Paepe, M. A Discussion on the Interpretation of the Darcy Equation in Case of Open-Cell Metal Foam Based on Numerical Simulations. Materials 2016, 9, 409. [Google Scholar] [CrossRef]

- Gong, T.; Xie, Q.; Huang, X. Fire Behaviors of Flame-Retardant Cables Part I: Decomposition, Swelling and Spontaneous Ignition. Fire Saf. J. 2018, 95, 113–121. [Google Scholar] [CrossRef]

- Piperopoulos, E.; Scionti, G.; Atria, M.; Calabrese, L.; Valenza, A.; Proverbio, E. Optimizing Ammonium Polyphosphate–Acrylic Intumescent Coatings with Sustainable Fillers for Naval Fire Safety. Materials 2024, 17, 5222. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhao, X. Thermal Conductivity Analysis of High Porosity Structures with Open and Closed Pores. Int. J. Heat Mass Transf. 2022, 183, 122089. [Google Scholar] [CrossRef]

- Li, P.; Jiang, X.-C.; Song, W.-M.; Zhang, L.-Y.; Xu, Y.-J.; Liu, Y.; Zhu, P. Green Organic-Inorganic Coatings for Flexible Polyurethane Foams: Evaluation of the Effects on Flame Retardancy, Antibacterial Activity, and Ideal Mechanical Properties. J. Clean. Prod. 2023, 411, 137265. [Google Scholar] [CrossRef]

- Kaya, A. Effects of Buoyancy and Conjugate Heat Transfer on Non-Darcy Mixed Convection about a Vertical Slender Hollow Cylinder Embedded in a Porous Medium with High Porosity. Int. J. Heat Mass Transf. 2011, 54, 818–825. [Google Scholar] [CrossRef]

- Yu, X.; Kang, Z.; Li, Y.; Lin, X.; Xie, L.; Li, J. Integration of Geological Model and Numerical Simulation Technique to Characterize the Remaining Oil of Fractured Biogenic Limestone Reservoirs. Arab. J. Sci. Eng. 2024, 50, 5117–5133. [Google Scholar] [CrossRef]

- Hafiz, T.; Covello, J.; Wnek, G.E.; Hostler, S.; Gassama, E.; Wei, Y.; Ji, J. Thermal Insulation Performance of Epoxy-Based Intumescent Coatings: Influence of Temperature-Induced Porosity Evolution on Heat Transfer Resistance. Polymers 2025, 17, 1426. [Google Scholar] [CrossRef]

| Gas | Lethal Concentration | References [46,47,48] |

| CO2 | 1000 ppm exposure is fatal within minutes | |

| SO2 | 500 ppm is fatal within 10 min | |

| NOx | 200 ppm is fatal within 10 min |

| Year of Incident | Location | Cause | Impact (Casualties, Damage) | Fire Protection System Used | Reference Authors and Year |

|---|---|---|---|---|---|

| 2010 | Deepwater Horizon, Gulf of Mexico | Blowout and gas leak | 11 fatalities; estimated economic loss of over $65 billion, including cleanup costs, penalties, and settlements. | Conventional fireproofing | [42] |

| 2011 | Amuay Refinery, Venezuela | Equipment failure | 42 fatalities, extensive infrastructure damage, estimated economic loss of approximately $1.7 billion. | PFP coatings | [5] |

| 2012 | Pemex Gas Plant, Mexico | Gas pipeline explosion | 30 fatalities, plant destruction, and economic loss are estimated at $500 million. | Passive and active fire protection | [61] |

| 2013 | Tianjin Refinery, China | Hydrocarbon leak | 10 fatalities, environmental contamination, and economic loss estimated at $1 billion. | Advanced PFP coatings | [62] |

| 2014 | BP Refinery, Whiting, USA | Chemical process failure | Extensive fire damage; operational disruption; economic loss estimated at $230 million. | Cementitious fireproofing | [63] |

| 2015 | ExxonMobil Refinery, California, USA | Mechanical failure | Structural damage; no fatalities; economic loss estimated at $240 million | Intumescent coatings | [44] |

| 2016 | BASF Chemical Plant, Germany | Hydrocarbon explosion | 4 fatalities; major facility damage; economic loss estimated at $500 million. | Active suppression systems | [64] |

| 2017 | Iran Oil Rig Explosion | Pipeline rupture | 6 fatalities; offshore drilling loss; economic loss estimated at $200 million. | Intumescent and ceramic coatings | [45] |

| 2018 | Philadelphia Energy Solutions Refinery, USA | Equipment failure | No fatalities; economic loss of approximately $750 million; significant environmental impact. | Fire-resistant coatings | [65] |

| 2019 | Dangote Refinery Fire, Nigeria | Electrical fault | Partial damage; no casualties; economic loss estimated at $50 million. | Hybrid (what are the hybrid system?) fire protection | [66] |

| 2020 | Natanz Nuclear Facility, Iran | Sabotage explosion | Severe facility damage; economic loss estimated at $2 billion. | Reinforced PFP barriers | [45] |

| 2021 | Pemex Offshore Platform, Mexico | Gas leak | 5 fatalities; production halt; economic loss estimated at $400 million. | Passive and active PFP | [43] |

| 2022 | Kuwait Oil Field Fire | Drilling malfunction | Large-scale fire; no casualties; economic loss estimated at $600 million. | Intumescent coatings | [67] |

| 2023 | Russian Oil Depot Fire | Drone attack | Major oil loss, infrastructure damage, and economic loss estimated at $300 million. | Fire suppression foams | [68] |

| 2024 | Shell Refinery, Singapore | Tanker explosion | Extensive fire, economic disruption, economic loss estimated at $500 million. | Multi-layered PFP systems | [69] |

| 2025 | California Wildfire | Extreme heat and dry conditions | Large-scale fires, loss of wildlife, and economic damages are estimated at $1.2 billion. | Retardant sprays | [70,71] |

| Reference | Findings | Limitations | Applications | Key Governing Equations | Model Type | Validation | Material Focus | Porosity Consideration | Computational Tool | Future Research Needs |

|---|---|---|---|---|---|---|---|---|---|---|

| [53,159] | Swelling process is critical for insulation; heat flux governs swelling rate. | Thermo-physical properties have secondary effects. | Fire protection for structural steel elements. | ρcp ∂T/∂t = ∇⋅(keff ∇T) + Q (Heat transfer equation). | 1D | Experimental validation with steel plates coated with commercial intumescent paint. | Organic polymer-based coatings. | Empirical correlations for swelled coating thickness. | Finite difference numerical model (Crank–Nicolson method). | Performance-based design for steel structures. |

| [11,160] | Gasification drives expansion, improving insulation. | Simplified reaction representation; assumes independent reactions. | On-board hydrogen storage protection. | dα/dt = Ae^(−Ea/RT) (1 − α)^n (Arrhenius kinetics for decomposition). | 1D | Experimental TGA comparison. | Inorganic & organic intumescent coatings. | Gas-driven expansion included. | MATLAB-based computational approach. | Multi-step kinetic modeling. |

| [161] | Darcy’s law applied to predict permeability in intumescent coatings. | Excludes radiative heat transfer. | Enhancing char stability for jet fire protection. | v = −(K/μ) ∇P (Darcy’s Law). | 2D | Fire test validation. | Inorganic-based coatings. | Includes pore flow dynamics. | Fluent. | Incorporate radiation effects. |

| [150] | 1D transient model captures decomposition of multi-layered coatings. | Limited validation with different heat fluxes. | High-temperature fire protection. | Multi-component degradation model coupling mass and heat transfer. | 1D | Model comparison with real-time thermal data. | Composite polymer-based coatings. | Swelling and bubbling effects included. | Finite element modeling. | Improved swelling kinetics representation. |

| [162] | Swelling rate depends on mass loss; peak insulation at 540 °C. | Neglects multi-layer expansion effects. | Fire-resistant coatings for military applications. | Phase change-based reaction kinetics and heat transfer model. | 2D | Solar furnace experiments. | Multi-layered intumescent materials. | Porosity distribution estimated from empirical tests. | Custom heat transfer solver. | Experimental validation of swelling rate models. |

| [163] | Ammonium polyphosphate-based coatings form thick, stable char. | Limited multi-component thermal degradation data. | Naval fire protection systems. | Empirical correlations for swelling rate and porosity evolution. | 1D | Flame exposure experiments with thermocouple validation. | Inorganic-based intumescent coatings. | Experimental validation of swelling thickness. | Custom finite difference solver. | Advanced swelling prediction models. |

| [164] | Higher porosity reduces keff by 10%, enhancing insulation under 50 kW/m2 heat flux. | Assumes uniform porosity; neglects convection. | Optimizing coating thickness for steel structures. | ρcp ∂T/∂t = ∇⋅(keff ∇T) + Q (Heat transfer equation). | 2D | Cone calorimeter. | Inorganic. | Effective keff. | ANSYS (2023 R2). | Incorporate convection in pores. |

| [148,165] | Gas generation peaks at 600 °C, driving 15× expansion; validated with experimental data. | Limited to inorganic coatings; ignores shrinkage. | Predicting expansion in hydrocarbon fires. | ∂ρg/∂t + ∇⋅(ρg v) = m˙ (Mass conservation). | 3D | Cone calorimeter. | Inorganic. | Gas-driven expansion. | COMSOL (Multiphysics 6.2). | Model post-expansion shrinkage. |

| [166] | Darcy’s law predicts 5% reduced heat transfer resistance in high-porosity chars. | Simplified permeability; excludes radiation in pores. | Enhancing char stability for jet fires. | v = −(K/μ) ∇P (Darcy’s law). | 2D | Fire test. | Organic. | Pore flow. | Fluent (2023 R2). | Include radiative effects in pores. |

| [167,168] | Reaction rate doubles above 500 °C, critical for char timing; 20% efficiency boost with optimized kinetics. | Single-step reaction; lacks multi-component data. | Rapid-response fire protection coatings. | dα/dt = Ae^(−Ea/RT) (1 − α)^n (Arrhenius kinetics). | 1D | TGA. | Organic. | None (reaction focus). | MATLAB (R2023b). | Multi-step reaction modeling. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hafiz, T.; Covello, J.; Wnek, G.E.; Melaiye, A.; Wei, Y.; Ji, J. Intumescent Coatings and Their Applications in the Oil and Gas Industry: Formulations and Use of Numerical Models. Polymers 2025, 17, 1923. https://doi.org/10.3390/polym17141923

Hafiz T, Covello J, Wnek GE, Melaiye A, Wei Y, Ji J. Intumescent Coatings and Their Applications in the Oil and Gas Industry: Formulations and Use of Numerical Models. Polymers. 2025; 17(14):1923. https://doi.org/10.3390/polym17141923

Chicago/Turabian StyleHafiz, Taher, James Covello, Gary E. Wnek, Abdulkareem Melaiye, Yen Wei, and Jiujiang Ji. 2025. "Intumescent Coatings and Their Applications in the Oil and Gas Industry: Formulations and Use of Numerical Models" Polymers 17, no. 14: 1923. https://doi.org/10.3390/polym17141923

APA StyleHafiz, T., Covello, J., Wnek, G. E., Melaiye, A., Wei, Y., & Ji, J. (2025). Intumescent Coatings and Their Applications in the Oil and Gas Industry: Formulations and Use of Numerical Models. Polymers, 17(14), 1923. https://doi.org/10.3390/polym17141923